- Ground gas tank features

- Model range of Antonio Merloni gas tanks

- Type #1 - vertical single

- Type #2 - vertical doubles

- Type #3 - horizontal

- How to choose a gas tank Antonio Merloni

- Advantages of a vertical gas tank

- Gas tank Antonio Merloni: main advantages

- Installation work and connection

- Conclusions and useful video on the topic

Ground gas tank features

To install a ground gas tank, it will not be necessary to carry out earthworks. The installation of such a tank does not take much time, and also does not violate the harmony of the space on the site. The installation of a ground tank allows autonomous gasification even in a place where it is forbidden to carry out earthworks of any kind.

An important disadvantage of a ground reservoir is a rather strong dependence on the temperature regime - in winter, at too low a temperature, the gas does not evaporate as it should. This drawback can be eliminated by using special pumps and evaporators. Above-ground devices are often used in Europe, in countries with a predominance of a southern climate.

Ground gas tank features:

- Differ in high durability.

- Able to function without failures in temperature conditions from 40 minutes to plus forty degrees Celsius.

- Resistant to external influences.

- The protective material does not allow corrosion to destroy the tank.

- Differ in long service life.

- Safe to use.

The installation of a ground gas tank will allow you to provide yourself and your family with a supply of gas for a summer residence. When the gas in the gas tank runs out, it is replenished by special vehicles, which guarantees the uninterrupted operation of the device. With the help of a gas tank, an efficient heating system can be implemented.

Model range of Antonio Merloni gas tanks

Market analysis revealed models that are in the greatest demand. Now there are 8 of them: 7 are vertical and 1 is horizontal.

Models of the same type differ in volume, which is selected individually for each particular house. If the volume of one gas tank is not enough, then several tanks are combined in a cascade way.

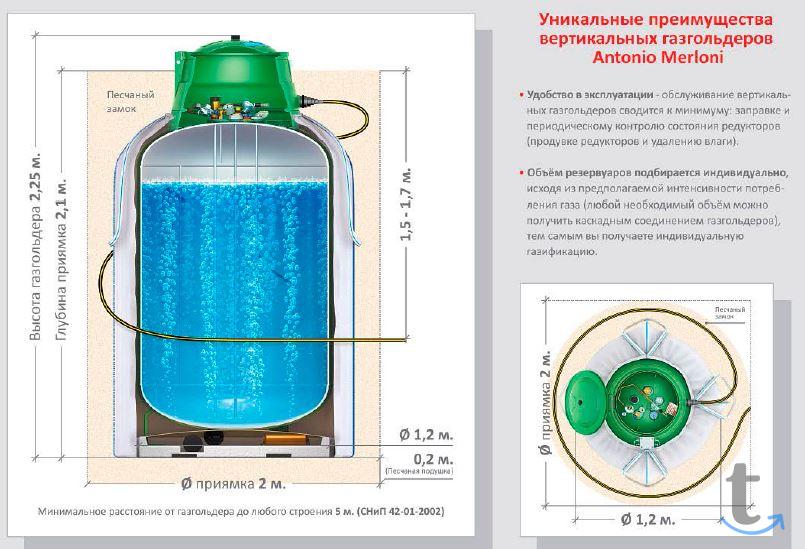

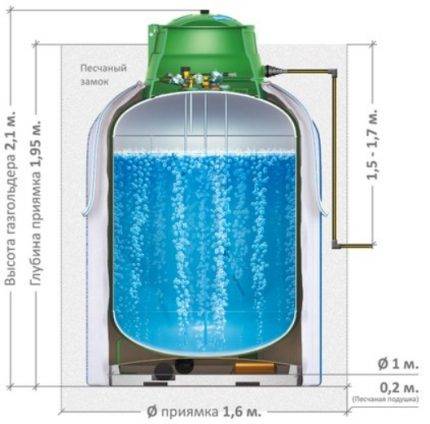

Type #1 - vertical single

The four vertical models differ in tank volume as well as size and performance.

The company's engineers calculated the approximate area of the house for this or that model:

- 1000 l - for a house of 100 m²;

- 1650 l - 170 m²;

- 2250 l - 250 m²;

- 5000 l - 500 m².

We will analyze the main characteristics using the example of the smallest gas tank. It is designed for 1000 liters of LPG / GPL / LPG gas, has a height of 2.1 and a diameter of 1 m. The installation pit is larger in diameter - 1.6 m, but less in depth - 1.95 m, since after installation and backfilling the neck with the lid remains above the ground.

The weight of the empty tank is 560 kg, the wall thickness of the body is half a centimeter. An important indicator is the evaporation of gas: when operating the equipment up to 2 hours - 8.1 kg / h, up to 8 hours - 4 kg / h (+)

The weight of the empty tank is 560 kg, the wall thickness of the body is half a centimeter. An important indicator is the evaporation of gas: when operating the equipment up to 2 hours - 8.1 kg / h, up to 8 hours - 4 kg / h (+)

A manhole with a HDPE cover required for maintenance is hermetically sealed to the neck.In addition to the case, the kit comes with a Marsupio bag and a concrete-alkaline slab, the thickness of which for the 1000 l model is 0.15 m.

There is also a thermal lock, a 2-stage reducing head (for high and low pressure), an equalizer, valves for filling, protection, liquid fraction and ventilation, a pressure gauge and a padlock.

One of the safety steps is a safety valve rated at 17.65 bar. When an emergency occurs (sudden heating), it automatically works and releases the tank (+)

One of the safety steps is a safety valve rated at 17.65 bar. When an emergency occurs (sudden heating), it automatically works and releases the tank (+)

Other models differ in dimensions, weight, pit dimensions, body wall thickness, and performance. Suppose the most voluminous 5000 l gas tank weighs 2450 kg, has a height of 3.08 m, a wall thickness of 10 mm, a gas evaporation rate of 40 l/h (in operation up to 2 h) and 15 l/h (up to 8 h).

The cost of a gas tank with a minimum volume is 3100 €, with a maximum one – 7900 €.

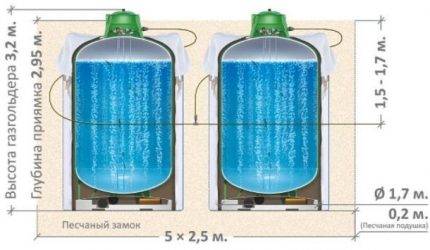

Type #2 - vertical doubles

If a larger volume of tanks is needed, then a set of 2 gas tanks is installed. Moreover, their volume can be the same (2500 l + 2500 l) and different (2250 l + 5000 l). The installation of 2 models is called double redundancy, and their connection is called cascade.

Calculation by building area:

- 4500 l - for a house of 500 m²;

- 7250 l - 750 m²;

- 10000 l - 1000 m².

Suppose, to provide gas to a house of 750 m², a tank of 7200-7500 liters is needed. There is no such thing, and therefore a pair is mounted - for 5000 liters and for 2250 liters. The width of the pit increases (the dimensions of both tanks are added), and the depth is determined by a larger gas tank.

The main indicator - evaporability - does not add up and depends on which of the reservoirs is active.For the model with a volume of 7250 l, the values of single gas tanks are saved: 40/11 (up to 2 hours) and 15/5.3 (up to 8 hours) (+)

The main indicator - evaporability - does not add up and depends on which of the reservoirs is active.For the model with a volume of 7250 l, the values of single gas tanks are saved: 40/11 (up to 2 hours) and 15/5.3 (up to 8 hours) (+)

For mounting an additional gas tank more space is required. But this should not worry the owners of the site, since all design and installation work is carried out by the company's specialists. Installation of the second (and each subsequent) tank costs about 100€.

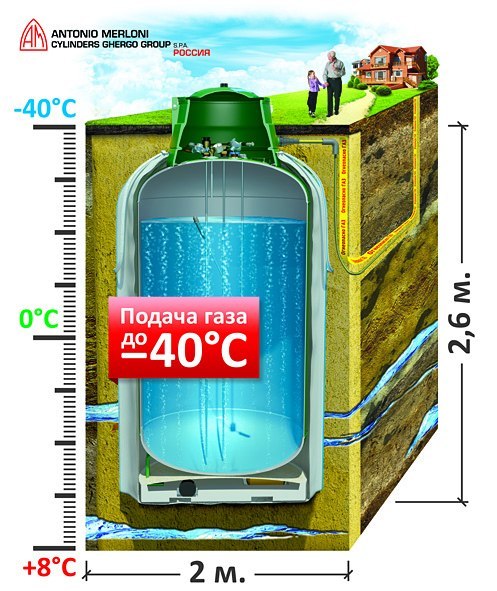

Type #3 - horizontal

Among the 8 popular models, only one is horizontal, and this is a well-thought-out marketing policy of the company. It is believed that the functioning of the horizontal model is not so effective. Evaporation occurs at temperatures of -20ºС and above, while vertical gas holders work fine down to -40 ºС.

Horizontal models are not suitable for use in the northern regions, since at temperatures below -20 ° C, the gas simply cannot go from liquid to gaseous state

It is also estimated that the intensity of the work of vertical models is much higher. They are approximately 2.2 times more productive than horizontal counterparts and do not require the installation of expensive evaporators, as they work using geothermal technology.

The downside of horizontal models is also considered to be a more voluminous pit, which requires additional free territory.

The line of underground and surface horizontal gas holders includes tanks from 1000 l to 5000 l. Unlike vertical ones, which are always in stock, horizontal ones must be ordered in advance. The cost of a model with a volume of 5000 l is 6500 €. In the same way, ground vertical gas holders with a volume of 500 l and 1000 l are delivered to order.

How to choose a gas tank Antonio Merloni

When choosing the design and volume of the tank (one or more), they are guided by the number of consumers and the intensity of use.

It is estimated that the volume of the gas tank is directly related to the area of the house, therefore, they start from this indicator. For example, for a house of 170 m², a tank with a volume of 1650 liters is recommended.

The performance of the equipment is also taken into account, which in gas tanks is associated with the amount of gas being evaporated. The higher the temperature, the greater the performance

With an independent choice, you can encounter difficulties, so manufacturers recommend consulting a specialist with a site visit. The engineer analyzes the individual technical features of the building and selects the best option, taking into account all the operational nuances and reducing the client's financial investments.

Advantages of a vertical gas tank

It is necessary to choose the type of gas tank taking into account the area intended for the tank. Those whose area does not allow to place a large device often opt for a vertical gas tank. Due to the compactness of the vertical gas tank, fuel is consumed evenly and economically.

Modern vertical gas holders have high strength and increased reliability. The three-layer epoxy material that covers the body protects the gas tank from external influences and various kinds of damage. If the tank is installed correctly, it can last for many years without breakdowns and failures.

Advantages of a vertical gas holder:

- Durability. With proper installation and use, they have a long service life.

- Ease of installation. Gas holders with a unique polymer bag are characterized by increased strength, they can be safely installed in the ground.

- Quality. Often depends on the price, but it should not be a decisive factor.

- Convenience.Vertical gas holders do not require specific care and maintenance.

- Protection. A high-quality tank is made according to modern technology, which involves the use of a flask in a flask. The technology allows to provide the maximum external and internal protection of the device from corrosion.

Installing a vertical gas tank is a modern gasification solution. A high-quality tank will be of interest to those who want to provide a summer residence with fuel. The vertical gas tank perfectly copes with its task of storing gas, which allows you not to limit yourself in using gas for various household needs.

Gas tank Antonio Merloni: main advantages

A rational and affordable alternative to main gasification is the installation of an autonomous gas tank. Installing and using a gas storage tank results in significant cost savings. Using the gas tank is very convenient and safe.

The individual gas supply system is very economical, since gas prices are usually lower than other fuels. The leader in terms of technical and operational indicators is Antonio Merloni. The company produces high-quality, durable, convenient and profitable tanks for storing liquefied gas.

Advantages of Italian gas tanks:

- They have a three-layer epoxy coating, which is an excellent protection against external influences on the tank.

- The anode-cathode counteraction system protects the gas holders from the effects of underground currents.

- The equipment has a bag that prevents the possibility of incorrect installation, and also protects the tank from the effects of stray current.

When purchasing equipment for autonomous gasification, it is necessary to make sure that the product is certified, technically of high quality, complies with the regulations and is allowed to be put into operation. A distinctive feature of gas tanks from Italy is their high quality and ability to work properly even in the coldest frosts, unlike Russian-made gas tanks. The company "Merloni" is engaged not only in the production of tanks, but also supplies and installs them.

Installation work and connection

The installation and connection of the gas tank should be carried out only by qualified representatives of the company who know everything to the smallest detail standards and nuances of installation. When constructing a pit, PB 12-609-03 and SNiP 42.01.2002 are guided.

Work order:

- The preparatory stage is the digging of a pit and a trench for laying a gas pipeline.

- Installation of the base concrete slab.

- Transportation of a gas tank (one or more) to the facility.

- Lowering the tank into the pit, fixing it on a concrete slab.

- Equipped with anode-cathode protection.

- Installation and connection of the gas pipeline.

- Arrangement of the basement entrance to the house.

- Internal installation work.

- Pressing and testing.

- Backfilling the pit and trenches with sand.

- Gas filling and commissioning.

- Commissioning and connection to consumers.

Each item is worked out by specialists, so the installation of equipment is carried out within one day. It is forbidden to independently arrange a pit, install a gas tank or install a gas pipeline.

Recommendations for the main stages of installation:

Image gallery

Photo from

The pit is dug strictly according to the design dimensions at a distance of at least 5 m from the house (1 m from the septic tank, 2 m from the fence). Depth of the trench for the gas pipeline - from 1.5 m to 1.7 m (below the GTU), width - 0.6 m

For delivery, special equipment with a manipulator is used. When loading / unloading, the gas tank is hung on specially designed belts that are equipped with the Marsupio bag

The supporting concrete-alkaline slab, which is included in the kit and has fasteners for installation, performs two functions: it plays the role of an "anchor" for the tank and compensates for possible soil movements. The total depth of the pit is from 2.1 m to 3 m

The basement input provides for the arrangement of the transition from HDPE pipes to a steel pipe, which is brought out of the building to the outside. This is a welded joint made in accordance with GOST 9.015-74

Commissioning works are carried out using the proven method and are regulated by SNiP 2.04.08-87. Equipment and fittings are manufactured in the factory and assembled on site

To connect the tank and transport gas to the consumer, HDPE pipes are used. Together with the pipes, equipment that regulates the pressure in the tank and a safety valve are mounted.

Installation of a shut-off valve, gas leakage sensors, internal gas equipment, as well as connection to consumers (boilers, boilers, stoves, heating systems, gas generators, etc.)

A bright yellow warning tape is laid in the trench over the pipe. The trench and pit are backfilled with sand

Stage 1 - earthworks

Stage 2 - transportation of the gas tank

Stage 3 - installation of a gas tank on a concrete slab

Stage 4 - preparation for the basement

Stage 5 - installation of the basement entry into the house

Stage 6 - connecting the gas pipeline

Stage 7 - installation and diagnostics of valves

Step 8 - backfill with sand

Sand backfill ("castle") is given special attention. They use river sand, and not ordinary soil, because it prevents the spread of flame, performs the function of drainage, conducts the heat of the earth perfectly, protects the tank from deformation in case of possible soil movements

Conclusions and useful video on the topic

You can learn about the features of Antonio Merloni's equipment and the secrets of installing a gas tank from useful videos.

About the advantages of autonomous gasification and installation of a gas tank:

Details about the technical nuances of the equipment:

Feedback on products and installation quality:

Antonio Merloni's gas tanks have proven themselves as reliable, efficient, durable equipment for arranging autonomous suburban gas supply. By choosing a tank of the optimal volume, you can forget about problems with heating, air conditioning and water supply.

Do you have experience using an Italian manufacturer's gas tank? Please tell us what technical parameters you took into account when choosing a tank, are you satisfied with the work of autonomous gasification? Comment on the post and participate in discussions. The feedback block is located below.