- Overview of the futorka radiator connection kit

- Features of choice: futorka for a cast-iron radiator

- What are there?

- How to choose the right

- The most common thread options and their sizes

- Types of fittings

- Types of threaded connections

- Using Compression Fittings

- Selection of heating pipes

- Metal-plastic pipes

- Polypropylene pipes

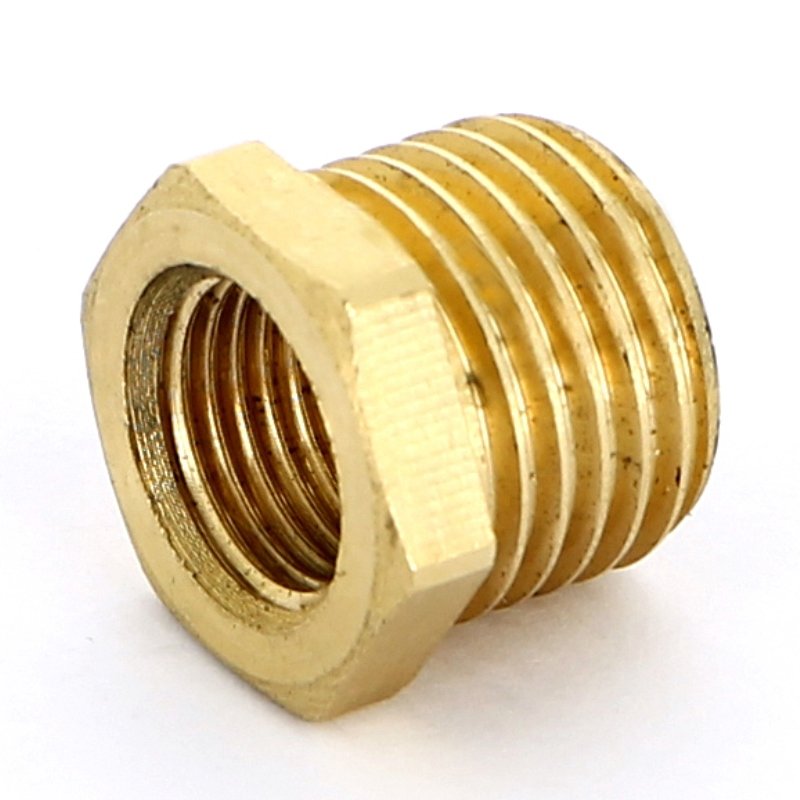

- What is a futorka

- What data is entered on the drawing

- Peculiarities

- Types of seals

Overview of the futorka radiator connection kit

Good afternoon, dear readers. Today we will look at a fairly easy, but no less important topic: "Aluminum radiator connection kit (futorka) overview"

I won’t write anything in the introduction, and it’s better to get straight to the point.

Before us is almost a complete connection (except for taps).

- fixing radiators with dowels

- 4 futorok connection kit, air vent (Maevsky tap), plug, key for air vent

Radiator fixing with dowel.

The metal mount is covered with white paint, which will allow you not to stand out against the background of the radiator. First, we drill a hole in the wall, hammer in the dowel, twist the mount into the dowel. A radiator is placed in the mounting recess. To mount the radiator for better fixation, you will need 4 pcs. mounts.

Futorka (right)

The set comes with 2 pcs. linings with gaskets. They are also painted white so as not to stand out.They screw onto the radiator without much difficulty. If you look closely, you can see the letter “D” on the futorka - this means from which side the futorka is screwed. in this case "to the right".

Futorka (left)

Everything is the same with coating and application as the previous one, only here the letter “S” is already there and, accordingly, the connection is “on the left”.

Stub

The plug is screwed into the futorka just to shut it off if there is no connection on this side. The plug is screwed into absolutely all futorka, whether it is left or right futorka. Cap color is white, complete with gasket.

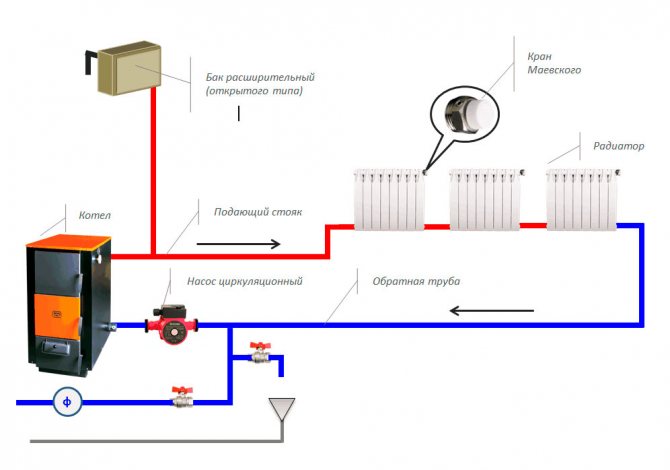

Air vent or Mayevsky crane

The function of the air vent is to remove the air that has formed in the heating system, or rather in the radiator. The air vent is mounted so that the drain (small thin hole) is down. When all the air is bled from the radiator, you need to drain a couple more liters of water and, accordingly, so that the water does not splash in all directions, but strictly down, the direction should be down

Pay attention to this mounting trifle, like the direction of the air hole. Air vent color white, gasket included

Key for ventilator

You can open the air vent with a special key for this. If there is no key or you have lost it, you can use an ordinary flat screwdriver, just do not go specifically for it to construction markets. There were such cases when this key was sold)))

Futorka with plug assembly (left), futorka with vent assembly (right)

This is how the assembled futorka looks like, whether it is a plug or an air vent, or there is a continuation of the pipe suitable for the radiator.

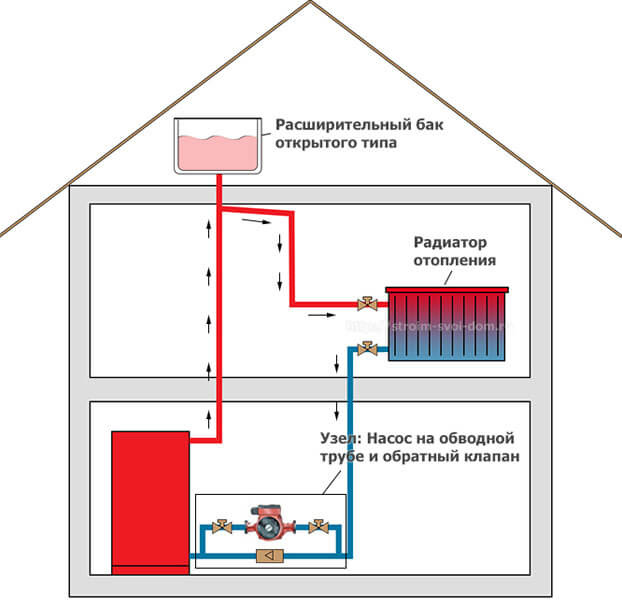

Connection of an aluminum or bimetallic radiator.

Here is a schematic diagram of how the radiator (battery) is connected. I think it's too much to explain. Everything is beautifully shown. We connect either a ball valve with a continuation with a pipe, or a plug, or an air vent to the futor. But in any case, we will have a supply pipe to the radiator, a return pipe from the radiator, an air vent (always placed in the upper part of the radiator, a plug.

Upper part of aluminum radiator in section with futorka

This is how the screwed futorka into the radiator looks like. As you can see, the futorka is screwed into the radiator quite well and deeply, which is quite reliable.

Futorka is screwed into the radiator (connection from below)

Here we have screwed a futorka ("D" - right) into a solid aluminum radiator. to show how it looks from this side.

Futorki at first glance are very simple and insignificant, but choose even these parts wisely. And remember, it is always better to entrust the matter to professionals, both in terms of sales and installation.

Thank you for your attention, we will soon prepare more necessary and interesting articles for you

Features of choice: futorka for a cast-iron radiator

The radiator threaded fitting is ideal for cast-iron batteries and will also find its application in plumbing, this is a kind of flange that will exclude any shifts. Such an application can bring any plumbing installations into perfect condition, as evidenced by the photo.

First you need to consider the criteria that you should pay attention to when buying a set of futorka. These criteria apply not only to fittings, but also to other necessary elements. Here are some of the criteria:

Here are some of the criteria:

Does the size match.As already mentioned, if you do not know the parameters of your equipment, then you will not be able to buy the right components, it is better to take documents for radiators with you so that the consultant can select the necessary part.

Make a plan for the heating system. This detail is much more important than it seems at first glance. The most important thing is to clearly define where the nodes of the system are located. Such a calculation will make it possible to purchase the exact number of components.

Material quality. For an aluminum or bimetallic radiator, you can choose a white product, since installations are most often painted in this color.

But pay attention to how smooth and well-treated the surfaces are.

The material from which the futorka is made. For cast iron radiators, the fittings must be made of the same material as the main part. Also, the best solution would be to purchase a futorka made of galvanized steel.

They are durable and reliable. The price for all these qualities is acceptable.

Take some time to check. As mentioned above, you can check by screwing the element onto the thread. In the event that you purchase a large amount of material, try to check at least a few futons. Winding should be easy and you should not use much force. If you notice interference, it means that the thread has been damaged.

Also, the best solution would be to purchase a galvanized steel futorka. They are durable and reliable. The price for all these qualities is acceptable.

Take some time to check. As mentioned above, you can check by screwing the element onto the thread.In the event that you purchase a large amount of material, try to check at least a few futons. Winding should be easy and you should not use much force. If you notice interference, it means that the thread has been damaged.

Experts recommend purchasing a complete set of the same company. It is best to buy everything in one store, in which case the consultants will advise you to purchase the entire kit, which will save you time, in addition, everyone will be able to explain everything to you on the spot and you will not have to figure it out yourself.

What are there?

Futorki may differ from each other in size - primarily in the value of the diameter. It can be different: M6, M8, M12, M10. Standard sizes for such products can be: M10x1, M14x1.5, M16x1.5, M18x1.5.

Futorki also differ depending on the design features. Several varieties can be distinguished.

Universal wire inserts. This option is considered the most popular. It has the appearance of a thin retainer in the form of an elastic spiral. In the inner side, the coils form a rhombic-type profile. Products are equipped with special driving tongues designed to be screwed into the old thread. After installation, the old element can be easily detached. These models can be used for almost any thread.

Today in specialized stores you can find whole sets with such inserts of different sizes. In such kits, you can find parts to replace any thread.

How to choose the right

The main task in the selection is to accurately determine the dimensions of the external and internal threads (fitting and nuts, in the language of specialists). In addition, it is necessary to determine what type of thread is needed - metric, inch or pipe.

The most common thread options and their sizes

Plumbing is divided into two broad groups. The first of them is designed for installation in cast iron sanitary ware or pipelines, heating radiators, etc. Their advantages:

- relatively low cost;

- ability to withstand pressure up to 25 bar and temperature up to 300 °C;

- the ability to use in difficult conditions, in contact with hot water, steam, oil, etc.;

- the presence of fittings with right and left threads.

The second group is used on aluminum or bimetallic products. As a rule, the material is galvanized steel, resistant to corrosion and other loads. The composition of the linings of the second group has the following characteristics:

- maximum pressure - 16 bar;

- maximum temperature - 110 ° C;

- installation with a special tool that does not destroy pipelines or radiators;

- use of a special coating of powder enamel.

A special table will help determine the necessary parameters.

The diameter of the thread depends on its pitch and the number of threads per inch.

Products for cast iron elements of the system have greater strength and are capable of experiencing high loads. The elements of the second group are designed for milder conditions, which must be taken into account when choosing a suitable fitting.

When buying, you should carefully inspect the products, trying not to miss mechanical damage, cracks or other surface flaws.The best option would be testing - a trial connection to elements with a suitable thread. It should be done easily, without tension and over the entire length of the thread. Otherwise, a different sample or type of fitting should be used.

The use of this fastener allows you to solve many problems without the use of welding or complex technical devices. Acquisition and installation are quite accessible even to an unprepared person, the main condition is the correct selection of the element by thread and size. If no mistakes are made, the installed fitting is able to serve for many years without causing any trouble to the owner.

(1 vote, average: 5 out of 5)

Types of fittings

The need to replace or repair pipes sooner or later arises in any home, plumbing also wears out. Replacing old pipes with more modern ones is a painstaking and complicated process, because it is not always possible to completely change pipes in a water supply or sewerage system. The durability of the repaired communications largely depends on the quality of the pipe connection. A perfect connection can only be achieved with the right fitting. Depending on the purpose, they are divided into the following types.

- Adapter. This is a special quick connect adapter designed to quickly adapt existing piping systems to new thread standards. Adapters do not require the use of complex tools and fixtures, save installation time, simplify the installation and dismantling of pipe connections. Adapters can be reused.

- A barrel is a fitting that has a thread on the outside.

- A water outlet is one of the parts of a water supply system designed for an external outlet of a tap or mixer.Such plumbing fittings are often installed at the construction stage and immured into the wall. Dismantling and installation of fittings of this type require time.

- The sleeve fitting is used for connecting steel and polyethylene pipes, as well as for connecting to control or shut-off valves.

- Knee. Used for horizontal or vertical drainage of sewage.

- Cork or plug. Allows you to completely close one of the ends of the water supply. Indispensable during repair work for sealing the end of the pipe.

- Collector. It is necessary for a uniform supply of water from the main water supply to plumbing fixtures.

- Compensator. It is a piece of polypropylene pipe, bent in the form of a loop. It is used in any systems of water supply. Protects the pipeline, absorbing strong water pressure and sudden temperature changes. Does not require additional seals.

- Cross. This fitting provides a branch in four directions, used for four pipes located at an angle of 90 degrees to each other.

- Coupling. The simplest type of connection. In terms of material and design, fittings-couplings correspond to the pipes that are connected. Does not change the direction of the pipes.

- Withdrawal. Allows you to change the direction of the pipeline. Fittings-bends differ in the degree of slope. For difficult situations, there are non-standard types of taps.

- Pipe branch. It is used to connect the end of a pipe to a stop valve.

- Adapter. Connects different pipes in different ways.

- Revision. The fitting has a cover allowing access to the pipe. Designed for access to the sewer system in order to eliminate blockages.

- The RVD fitting is a connecting piece for a pipeline.It is installed in places of transitions, branches, turns and connections of pipes with different diameters. Another name is high pressure hose fittings.

- Connecting press. With press fittings it is possible to connect pipes with a threaded connection.

- Detachable connection. Used for joining different types of pipes.

- Sgon. It is intended for installation of pipes, for connection of sanitary devices and fittings.

- Siphon. A special fitting that connects plumbing fixtures to sewer outlets.

- Tee. A fitting that connects three pipes together.

- Tee-adapter. Required in case of triple branching and docking with pipes made of other materials or other diameters.

- Corner. Used to change the angle of a pipe.

- Extension. It is intended for installation of pipes, for connection of sanitary devices and fittings.

- Flange. Fittings that connect parts of the pipeline and join a variety of structures.

- Futorka. Type of threaded fitting with external and internal threads.

Information service plot.kz

Types of threaded connections

And now consider the types of metal threaded parts in plumbing. As a rule, they are made of cast iron, steel, brass or bronze and they have pipe threads.

The thread requires sealing with investment material, with rare exceptions: if, for example, a union nut with a gasket is installed on the external thread (see above) -

additional sealing is not required.

Futorka - This is a part with an external thread of a larger diameter and an internal thread of a smaller diameter. By and large, a futorka is a nut, on

the outer side of which is also threaded.There are parts with a hexagonal outer edge for a mounting key or with a solid external thread, but with a hexagon

structure inside.

Radiator futorki differ in direction external thread - left or right. Internal thread normal, right hand.

Nipple or barrel - a short piece, at both ends of which there is an external thread. Usually the length of the nipple is only enough to connect two parts with an internal

threaded among themselves. The diameter of the thread at the ends may vary - then the barrel is considered transitional. In most cases, in the middle of the part there is an outer

hexagonal structure, although in some cases there is only a thread on the outside, and recesses for a hex or hex wrench are inside.

Sgon is a piece of pipe with external threads at both ends. In fact, this is the same nipple, only longer. Sgon does not have a hexagonal structure on the outside and

usually mounted with a gas wrench.

A half-gon is a part in which the external thread is located on only one side. On the opposite side, at the half-way or there is no fastening at all,

or there is a cone for an American (or a union nut).

Coupling - a part with an internal thread at both ends. If the diameter of the thread at the ends is different, then the coupling is called transitional. Sometimes the clutch is completed

a lock nut that protects it from loosening and untwisting. A lock nut is required when the mounted unit has a margin of outer space on both sides.

threads and therefore there is a risk of twisting as a result of mechanical influences.

A coupling is used to connect two parts with an external thread.In other words, when an internal thread is required for the installation of any part, and we have an external one.

Eccentric - a part with any thread on two ends (internal or external, of different diameters), with misalignment of these ends. In other words, the center of one side

intentionally does not coincide with the center of the other.

It is used in those cases when during the installation process it is not possible to position the pipe outlets exactly according to the specified dimensions or the specified size may have

error. An example of use - connecting a wall mixer, allows you to correct the installation of water outlets or change the position of the mixer within a small range.

Union - a part, at one end of which there is a union nut, and on the opposite side there is an external thread. As you can see, this definition also includes

polusgon, so you can use one of these names. In general, a fitting in the broadest sense is a branch pipe for connecting something, so the term can

used in other details.

An example of use is a water meter fitting, also known as a half-drive. Can be equipped with an internal check valve.

Adapter - a detail that allows you to change the mounting diameter from one size to another. Many of the above parts can be adapters. However, the term

usually used when there is no more appropriate definition. For example: a futor can be called an adapter, but the term "futor" more accurately reflects the type of part.

I didn’t describe tees, crosses and elbows here, because I don’t see the point, everything is clear there.

Using Compression Fittings

These products are similar to crimps used in plastic pipelines.They are used in the arrangement of collapsible connections of a section of the highway, which has an outer diameter of less than 60 mm.

Install the product in the following order:

The beginning of installation is the disassembly of the fitting. The clamping nut is unscrewed, after which the clamping ring located in the housing is taken out. Also take out the seal and washer.

The pipe is measured and then cut at a 90° angle. It is necessary to remove the chamfer from the end.

Then the seal is installed in the body of the product. Clamp nut, ring and washer put on a pipe.

One precise movement is enough to press the pipe into the fitting. The pipe must pass through the seal pressed by the nut.

The collet ring is moved to the fixation point, and then the entire system is firmly and securely fixed with a clamping nut. The tightness of the connection is ensured by the fact that the nut presses on the ring.

The use of compression fittings for pipeline installation is the easiest and fastest option. But no one will give you a guarantee that such a connection has high strength. An excellent solution in arranging communications is the use of steel pipes. Their popularity has recently increased. Now managed to save them from some shortcomings.

Modern products provide protection against corrosive processes. In addition, a variety of fittings are now used to connect them, which makes installation easier and faster. Now you know that the use of steel products facilitates the construction of a reliable and durable pipeline that has been functioning without problems for many years.

Selection of heating pipes

Having orientated which heating boiler will heat the water in your house, you can choose pipes for heating radiators and the system as a whole.Traditional materials for heating pipes:

- steel;

- copper;

- plastic.

Quite expensive and requiring the invitation of professionals for welding steel or copper pipes are increasingly being replaced in practice with metal-plastic or polypropylene pipes.

Metal-plastic pipes

Connection and installation of metal-plastic pipes can be done with compression and press fittings.

To make a connection using compression fittings and the subsequent connection of heating pipes, you will need:

- spanners;

- expander;

- springs for bending pipes.

The main disadvantages of connections on compression fittings are:

- their relatively high cost;

- fragility of rubber gaskets under the influence of high temperatures;

- periodic "simple" heating pipes in the summer, which also does not have a very favorable effect on the durability of rubber parts.

As a result, the need for preventive work to tighten the connections may occur every five years or more often.

Rules for connecting metal-plastic pipes using a press fitting

Reliable non-separable connection on press fittings allows installation of heating with plastic pipes, hiding them directly in the walls. These pipes will last without replacement for many years if the temperature of the heating water flowing through them does not exceed 80°C.

The disadvantage of using this type of connection can only be called the need to purchase special equipment for installation

Polypropylene pipes

Recently, a leading place among suitable water and heat supply equipment has been occupied by a pipe for a heating boiler made of polypropylene.The use of polypropylene is due to the fact that it is very durable, is not afraid of defrosting the system, and has a very affordable price.

Polypropylene pipes can be bent quite evenly (unlike metal-plastic). They will last a long time if all the rules of operation are observed.

Their only drawback is the need to use a special tool for welding.

There are the following features of the connection of pipes made of polypropylene by welding:

- It is more convenient to weld polypropylene pipes together with a partner. The main condition for the high-quality connection of plastic pipes is the choice of the correct heating time so as not to overheat them, and precise fixation, which does not allow shifts and displacements along the axis for the first few seconds after connecting the heated parts.

- Welding and installation of heating pipes is carried out at positive ambient temperatures - above +5 °C. When working in winter, it is necessary to create a "heat zone" where polypropylene pipes are welded.

For high-quality work on soldering polypropylene pipes, it is necessary to comply with all the requirements of the instructions attached to the device.

It would be a good idea to do a few trial welds on individual short lengths of pipe using inexpensive couplings to get at least some initial skill in handling the welding set.

What is a futorka

Futorka is a specially designed adapter, which is characterized by both external and internal threads.

Futorka is a specially designed adapter, which is characterized by both external and internal threads.

Very often their diameter is significantly different. In the language of plumbers, they have their own "names".

So, it is customary to call an internal thread a nut, but an external one is referred to as a fitting.There are also pipe and metric threads.

Each product can have its own thread diameter. This indicator is measured in inches or millimeters. A tool with which you can make such calculations is a caliper or ruler.

The accuracy of measurements in this case is quite important. A mismatch of the threaded connection, even one inch, can cause a malfunction of the heating or plumbing system.

Based on the purpose and fittings used, the futorka is divided into two groups: those used for cast iron products and for adapters of bimetallic and aluminum objects.

First class features include:

First class features include:

- Products designed to connect cast iron batteries to pipelines and valves. The guiding factor is the design of the heating system itself.

- Cast iron parts. Despite the low cost and lack of external coating, they have earned their place due to the high level of reliability.

- brass elements. Due to its ability to stick tightly to a cast iron product, it does not have such great popularity among consumers. This kind of products has a slightly higher price and inability to be reused.

- thread direction. The radiator can be connected from different sides - right or left. The direction of twisting at the futorka will also change.

- Possibility for better clamping when using various fixtures. Often used tools are open-end wrenches, plumbing and box wrenches.

- Products are characterized by a certain number of characteristics, namely the maximum pressure, temperature, type of working medium. The adapter can be used with steam, air, oil, gas and water. The pressure can reach a value of 25 bar, the maximum temperature will be 300 degrees. Based on these indicators, not every material is able to cope with its work in such conditions.

Note of the master: it is not recommended to use FUM tape to seal the threads of the radiator tube. This is justified by the fact that it does not tolerate high temperatures. The best option would be the classic type with linen.

The second group of products, namely adapters for aluminum and bimetal, include the following characteristics:

The second group of products, namely adapters for aluminum and bimetal, include the following characteristics:

- Such parts are often made of high strength galvanized steel. This material provides a high level of reliability as well as resistance to corrosive processes.

- Coating of the element with epoxy powder enamel. It gives the product strength, resistance to deformation, as well as attractiveness.

- There is also left hand and right hand thread.

- In order not to violate the integrity of the components, a special key is used during the installation process to tighten them. It will help to secure the connections well when assembling the system, and also not to damage the pipe surface itself.

- Operating pressure. The maximum value of this indicator in the system is 16 bar, and the temperature coolant is 110 degrees.

- Paronite or silicone rings are best suited for sealing joints. Their effectiveness is due to good resistance to high temperatures, as well as the ability to be elastic for a long time.

- To ensure the comfort of customers, manufacturers produce ready-made kits, which include 4 fittings and gaskets, one plug and tap, and another key.

There can still be adapters with a flange, which, in essence, are also a futorka. The internal thread of such conductors is always larger than the external one.

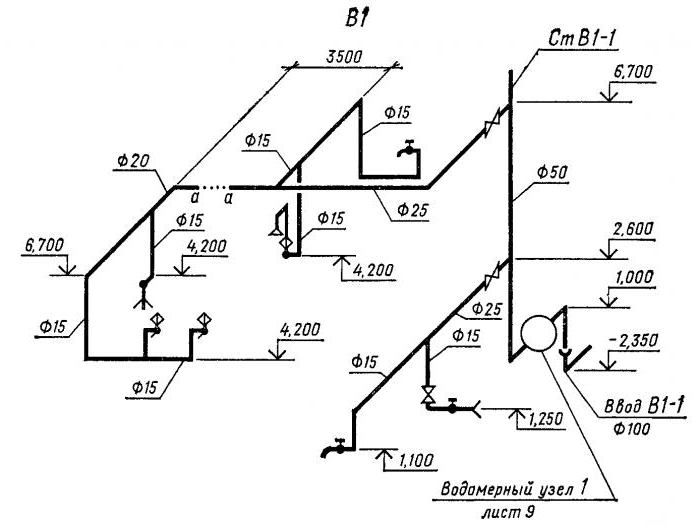

What data is entered on the drawing

The introduction of the following indicators describing the water supply system is mandatory when constructing an axonometric diagram. Such information includes:

- The designation of the risers (usually the area of the leader line).

- The floor level of each of the floors of the room, the boundary of the horizontal branch (at the axes of the pipeline), the height of the points of water intake (marks along the risers).

- Diameters of system elements.

- Slope angles of pipelines (indicating the slope index).

- Dimensions (length) of each of the independent sections of the pipeline, which include risers and horizontal branches in millimeters.

- Coordinating dimensions (minor information).

- Designation of nodes in order to detail the drawing.

In addition to a number of basic data, accompanying documentation is attached to the diagrams, including a specification for materials and equipment.

Peculiarities

Plumbing pipes belong to a fairly wide range of products, which differ according to various parameters, for example, according to the material from which they are made, or dimensions, as well as additional elements used to fasten such connections.

The variety of plumbing pipes is due to the various functions that such pipeline elements must perform, because pipes for cold or hot water will differ in their characteristics from sewer counterparts.

For example, completely different requirements are put forward for communications for hot water than for pipelines of cold water supply. For example, the material used for this type of plumbing must be able to withstand prolonged exposure to high temperatures.

But on this version of the products, plaque forms on the inside to a lesser extent compared to the pipeline for cold water supply.

Types of seals

Previously, there was no such variety of seals as today. Some plumbers use the full range of materials in their work, and there are conservatives who still recognize only linen. Are they right? Let's figure it out. How to seal the thread on the heating pipe:

- fum tape;

- flax with paste;

- anaerobic adhesive sealant;

- sealing thread.

Flax dries in systems with a hot coolant, and rots in cold water. In the first and second cases, the result of the process will be the appearance of a leak. Thanks to the paste, the fitting can be released a little after twisting, making a turn back no more than 45 degrees. Universal material, suitable for connecting metal heating pipes, as well as for polymers.

Flax is suitable for all types of threads on heating pipes, regardless of diameter. It is the cheapest of seals.

It is important to wind it correctly:

- with the help of a cloth for metal or a file, notches are made on the thread;

- a strand of flax is rolled into something like a thread;

- winding is carried out in the course of fitting tightening (usually clockwise);

- protective paste is evenly applied.

Linen seal

When winding flax, it is important not to overdo it. First you need to make the first turn, which will secure the seal on the thread. It leaves a tail

On the second turn, the remaining tail is picked up and wound together with a common fiber. Make sure there are no twists. It is necessary to distribute the material along the thread evenly from the end to the body of the fitting. When working with flax, when connecting heating pipes, you need to watch your hands, as they are constantly smeared with paste. If you take hold of a polypropylene pipe with such hands, an imprint will remain

This leaves a tail. On the second turn, the remaining tail is picked up and wound together with a common fiber. Make sure there are no twists. It is necessary to distribute the material along the thread evenly from the end to the body of the fitting. When working with flax, when connecting heating pipes, you need to watch your hands, as they are constantly smeared with paste. If you take hold of a polypropylene pipe with such hands, an imprint will remain.

Fum tape is used for thin-walled fittings and connectors with fine threads. It is easy to work with the material, hands are always clean. At the same time, fum tape is quite expensive and is mainly used for small diameters. A significant drawback of this seal is the impossibility of adjustment. That is, if the joint of the heating pipes is twisted and needs to be released a little to center it, then the connection loses its tightness.

The sealing thread, like the fum tape, does not need lubrication and the use of a special paste. It can be wound on dirty or wet threads, suitable for plastic.

Sealants are applied to clean and degreased threads (usually new). They are:

- dismantled;

- difficult to dismantle.

And in fact they are not dismantled.Before connecting the heating pipes using a sealant, you must be prepared for the fact that the connection can be disassembled only after heating. And only then, perhaps, it will be possible to unscrew it. But during installation, the joints do not even need to be tightened with keys.