- Fitting

- Press fittings for metal-plastic pipes: types, marking, installation features

- Features of installation and selection of fittings

- Conclusions and useful video on the topic

- The structure of the metal-plastic pipe

- Working with the tool

- Crimping instructions

- How to connect and mount metal-plastic pipes

- Types of fittings for metal-plastic pipes

- Preparing for installation

- How is crimping done with a hand tool?

- Characteristics and properties

- Pros and cons

- Processing technology

- Application features

- How threaded fittings for metal-plastic pipes are connected

Fitting

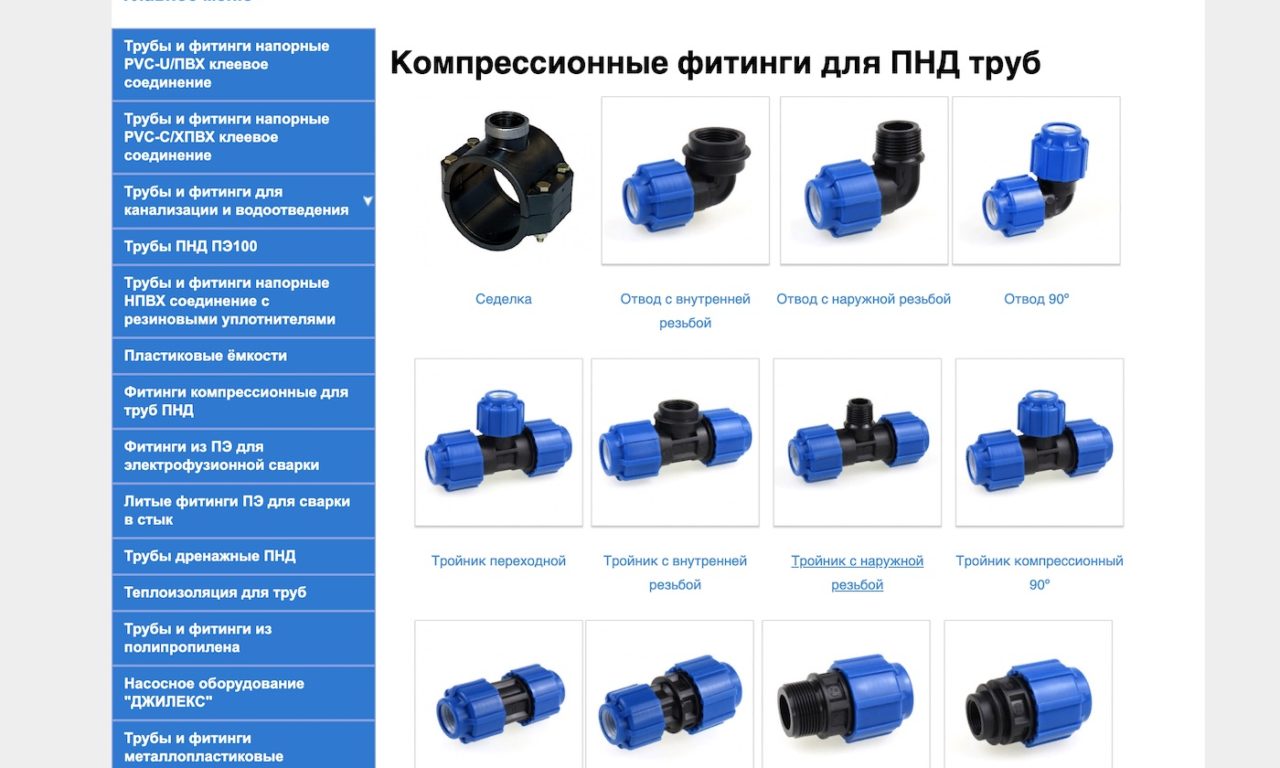

Metal-plastic fittings are the parts necessary for connecting pipes. Such elements differ in the method of installation and the nature of the connection.

Our store has a large selection of connectors:

- • crimp or compression, press fittings, threaded, push-elements, electrofusion;

- • corners, plugs, crosspieces, adapters, unions, couplings, tees.

Popular types of metal-plastic fittings:

- • Crimp - they have a simple installation, a strong connection. Used in low pressure systems.

- • Threaded - strong, durable, pressure resistant.

- • Welded - melt during installation, resistant to corrosion.

- • Press fittings – installed with a press, resistant to temperature changes.

Press fittings for metal-plastic pipes: types, marking, installation features

The connection of pipes made of metal-plastic is made by compression fittings for clamping and their analogues for pressure testing. Installation of pipelines in both cases does not require sophisticated equipment and high qualifications from the master.

The first method is easier to implement, but not as reliable. But press fittings for metal-plastic pipes make it possible to form a durable system with minimal risk of rupture.

Let's figure out what types of connecting elements are on sale, how to choose the right one press fitting and install it.

Features of installation and selection of fittings

Metal-plastic pipes made of cross-linked polyethylene are not originally intended for welding and gluing. The welds on them will still crack and disperse in a couple of months. And glue is not used because of the resistance of this plastic to solvents and its low adhesion. It remains for installation to use only specialized fittings.

All cuts of a metal-plastic pipe must be made exclusively at an angle of 90 degrees, even slight deviations can adversely affect the quality of the connection

When choosing a press fitting, the main attention should be paid to the crimp ring. It must be made of durable metal. And there are no seams on this metal surface, only cast seamless stamping

Any seam is a point for destruction

And there are no seams on this metal surface, only cast seamless stamping. Any seam is a point for destruction.

It is better to immediately reduce or completely eliminate the likelihood of a pipeline rupture with flooding of the house. It's definitely not worth chasing cheapness here.

The dimensions of the press fitting are indicated in the marking both on the ring and on its body. Similar information is contained on the pipe. Everything must match.

The pipe after the fitting has been crimped must not be bent near the latter. This can lead to excess voltage in the connection. It is also unacceptable to apply any lateral force to the press fitting. He himself will not be damaged, but the plastic nearby may collapse.

Additional information about the installation and pressure testing of metal-plastic pipes is given in the articles:

Conclusions and useful video on the topic

Installation of the fittings in question should not cause problems. However, there are still nuances when they connect metal-plastic pipes. And before starting work, we recommend that you watch the video instructions below to avoid beginner mistakes.

Comparison of Compression Compression Fittings and Press Fittings:

Step-by-step instructions for crimping press fittings:

An overview of the pros and cons of compression fittings:

Manufacturers of metal-plastic pipes give a guarantee of up to half a century on their products. However, the pipeline system of them will work all these decades only if the fittings are properly installed. Don't skimp. To assemble a pipeline from metal-plastic, only high-quality connecting parts should be purchased.

The press fittings must be compatible with the pipes to be installed. The best option is when all components are made by one manufacturer. Fortunately, the choice of them now on the market is extensive, there are plenty to choose from.

Have something to add, or have questions about the use of press fittings for metal-plastic pipes? Please leave comments on the post. The contact form is in the bottom block.

The structure of the metal-plastic pipe

As you can see, it consists of three layers: polyethylene-aluminum-polyethylene, between which there are connecting adhesive layers. Therefore, cutting and installation of metal-plastic sewer pipe connections requires precision and accuracy. From the video below you will see how to work with the pipe.

As you can see, there is nothing complicated. A little practice and everything will work out. Do not forget to process the edges of the pipe cut from the outside and from the inside before fitting the fitting.

Otherwise, the rubber seals may be damaged. And in order to give the edge of the pipe a perfectly even round shape and prepare for the connection, be sure to use a calibrator.

The connection is tightened using two wrenches, one holds the fitting, the other tightens the nut.

It is also often necessary to simply bend the pipe, without using a fitting. In this case, a special spring will help you, which will not allow the pipe to simply fold.

Such springs can be both internal and external.

Such bends are used by installers to the maximum, because:

- Fitting savings.

- No risk of leaks as no connection.

If you plan to close the pipe with a box, then use this technique.

Now let's watch a video on how to properly connect metal-plastic pipes and fittings.

It is very convenient to fix the pipe to the wall with the help of special clips.

Fixing the pipe to the wall

Such a clip is attracted to the wall, after which the pipe is simply inserted into it. It's very fast and convenient.These clips are calibrated to the diameter of the pipe and therefore hold very well.

Working with the tool

Precautions when using press equipment

Going to use press tool for metal-plastic pipes, be sure to read the operating instructions. Well, elementarily, do not use the unit in rooms with high humidity and make sure that limbs and clothes do not get inside the working mechanism.

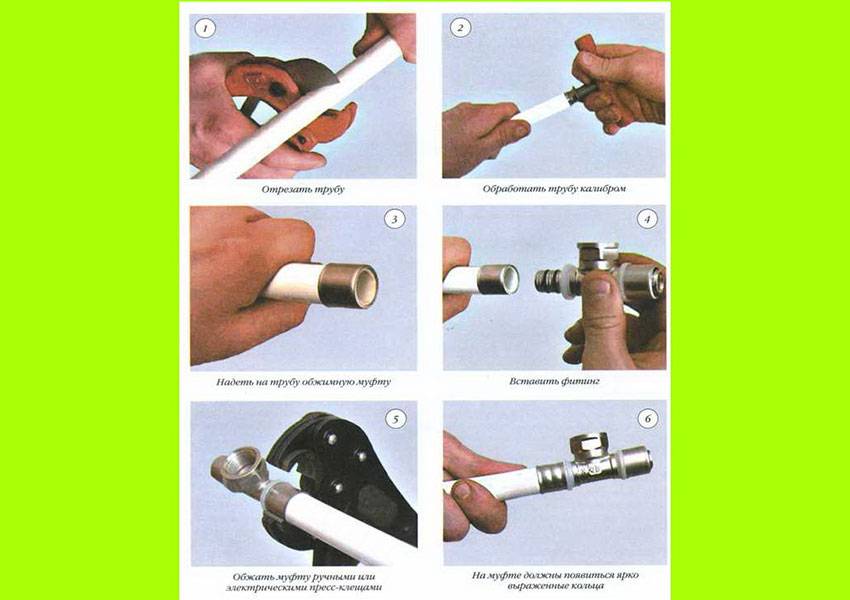

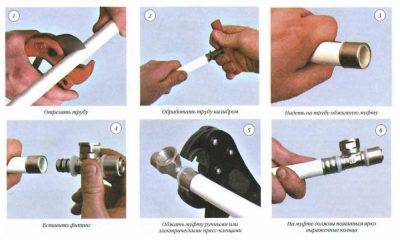

Crimping instructions

In the case when pressure testing of metal-plastic pipes is carried out using press tongs and fittings, the instructions for using the equipment are as follows:

Scheme of the installation process of metal-plastic pipes

- remove the inner chamfer from the end of the pipe; to compensate for the deformation, take a calibrator;

- place a compression sleeve on the pipe to be connected;

- insert the fitting with sealing rubber rings into the end of the pipe; since the fitting is a metal connecting element, use a dielectric gasket in the part where the pipe meets it to prevent electrical corrosion;

- then use an electric press for metal-plastic pipes or any other type of equipment with which the parts of the pipeline are crimped.

The coupling is crimped once, otherwise the reliability of the connection of metal-plastic pipes will be unsatisfactory. The fluid pressure at the connection points must be max. 10 bar.

To check how well the pressure was carried out, inspect the junction - it should be 2 continuous, uniform metal strips.

The second way to check the quality: the tick insert must close completely

The video below will help you get acquainted with the process of using press tongs in more detail.

When installing a metal-plastic pipeline, a more durable method is considered in which the pipes are connected by means of not compression, but press fittings. This method is also suitable when the pipes are subsequently embedded in the floor or walls.

A small-sized press for metal-plastic pipes Valtec will be an excellent solution for a joint purchase

The limiting factor in this case is the need to use a relatively expensive installation tool, which may never be useful later on. However, there are at least two options here:

- rent an electric press;

- to purchase a tool, having formed with several acquaintances who also plan to carry out similar work.

How to connect and mount metal-plastic pipes

Steel pipes are gradually being squeezed out of the market: worthy competitors have appeared that cost less, are easier to install, and serve no less. For example, hot and cold plumbing, a heating system are made of metal-plastic. How to properly install metal-plastic pipes, what fittings to use when, how to use them to connect the segments into a single whole - all this will be discussed.

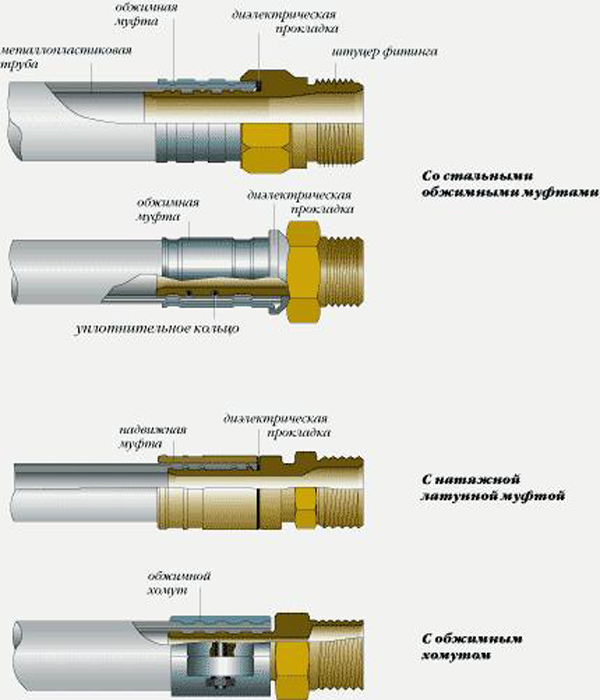

Types of fittings for metal-plastic pipes

The structure of metal-plastic pipes is such that it is impossible to weld or solder them. Therefore, all branches and some bends are made using fittings - special elements of various configurations - tees, adapters, corners, etc. With their help, a system of any configuration is assembled.The disadvantage of this technology is the high cost of fittings and the time that will have to be spent on their installation.

An approximate range of fittings for the installation of metal-plastic pipes with a press

The advantage of metal-plastic pipes is that they bend well. This allows you to use fewer fittings (they are expensive). In general, fittings for metal-plastic pipes are:

Deciding which type of fitting to use is simple. Crimps are used for pipelines to which there is always access - over time, connections need to be tightened. Presses can be walled up. That's the whole choice - you need to know what type of installation of metal-plastic pipes will be in a particular area.

Appearance of some fittings with swivel nuts - screw or compression

A common drawback of metal-plastic pipes is that due to the design of the fittings at each connection, the pipeline section is narrowed. If there are few connections and the route is not long, this cannot have any consequences. Otherwise, either an increase in the cross-section of the pipeline, or a pump with more power is necessary.

Preparing for installation

First of all, it is necessary to draw the entire plumbing or heating system on a piece of paper. At all branch points, draw the fitting to be installed and label it. So it is convenient to count them.

Tools

To work, in addition to the pipe and purchased fittings, you will need:

Pipe cutter. A scissor-like device. Provides the correct location of the cut - strictly perpendicular to the surface of the pipe

It is very important

This tool cuts metal-plastic (and not only) pipes

Calibrator (caliber) for metal-plastic pipes. In the process of cutting, the pipe is slightly flattened, and its edges are slightly bent inward.The calibrator is just needed in order to restore the shape and align the edges. Ideally, the edges are flared outward - this way the connection will be more reliable.

How is crimping done with a hand tool?

The process of crimping a metal-plastic pipe with manual press tongs is not complicated, but it requires attention and accuracy. To work, you need an empty, flat surface that allows you to position the pipe section, connecting fittings and the tool itself.

For correct work with pressing tongs, appropriate conditions are necessary, namely a spacious, even surface and good lighting. At a conveniently equipped place, even a beginner who does not have much repair and installation experience can crimp and correctly install the fitting

When everything you need is prepared, the press tongs are placed on the table and the handles are moved apart by 180 degrees. The upper element of the cage is disconnected from the unit and the upper part of the press insert is inserted into it, corresponding to the size of the section of the pipe that is currently being processed. The lower half is placed in the lower part of the clip, which remains empty, and the tool is snapped into place.

The fitting can only be crimped with press tongs once. The second processing is categorically unacceptable, so each action should be taken responsibly

They make up a joint assembly from the pipe and fitting and insert the structure into the press tongs, carefully making sure that the fitting sleeve is inside the press insert.

It is very important for high-quality crimping to use nozzles that clearly correspond to the diameter of the pipe section. Otherwise, the device will deform the fitting and the part will have to be replaced with a new one. After correctly placing the set of pipes and fittings in the device, the handles are brought together to the stop and crimped

After the operation, two identical arcuate bends and two well-visible annular bands should form on the metal. And the result will be a clearly and firmly installed and fixed fitting, which will be almost impossible to remove with an improvised working tool.

After correctly placing the set of pipe and fitting in the device, the handles are brought together until they stop and crimped. After the operation, two identical arcuate bends and two well-visible annular bands should form on the metal. And the result will be a clearly and firmly installed and fixed fitting, which will be almost impossible to remove with an improvised working tool.

The installation of the fitting must be carried out very carefully, carefully and without haste. Under no circumstances should displacement be allowed to occur. Even 5 millimeters will become critical for the pipeline system and in the future will lead to a violation of the integrity

It is possible to determine incorrectly performed work by a staggering, indistinctly fixed nut, by the presence of an opening more than 1 mm wide visible between the metal-plastic pipe and the nut, and by loose tightening of the nut. If such errors are found, the fitting will have to be cut out of the pipe and re-installed in its place with a new one.

Characteristics and properties

Metal-plastic pipes were originally planned as a universal substitute for metal products. Their technical characteristics in some aspects even exceed the characteristics of metal, and this is with a colossal difference in price.

Metal-plastic pipes consist of three working layers.The inner layer is plastic or, which is much more common, polyethylene. Polyethylene is very durable. Ordinary polyethylene products, afraid of ultraviolet radiation and temperature extremes, are no match for him.

The second layer is aluminum. The last layer is made of the same polymer as the first.

Thus, something like a multilayer pipe with an internal frame made of metal is formed. So it is, by and large, it is.

Exterior finish with plastic improves the technical characteristics of the pipe by increasing its durability. The product has the durability of ordinary plastic, its resistance to corrosion, contact with the external environment, moisture, etc.

Metal-plastic pipes in a section

The inner layer of aluminum, by the way, is very thin, it strengthens the pipe. It levels its coefficient of thermal expansion, makes it more plastic (metal-plastic is bent without fear even by hand) and elastic. You can mount such products, if you wish, with your own hands. It is easy and pleasant to work with them with your own hands.

Pros and cons

Now let's look at the specific advantages and disadvantages that standard metal-polymer pipes have, which are in abundance on the market.

Advantages:

- high strength;

- plastic;

- ease of processing with your own hands;

- low coefficient of thermal expansion;

- a large supply of defrost cycles;

- durability;

- do not give in to corrosion;

- in the presence of a huge range of products for every taste;

- pipes weigh almost nothing, are easily transported and stacked with their own hands.

However, there are such products and their shortcomings, now you will find out which ones.

Main disadvantages:

- increased price;

- do-it-yourself installation is possible with a special tool, otherwise there is a chance of destruction or serious damage to the surface;

- Mounting metal-polymer products is still more difficult than plastic ones.

As you can see, there are not so many shortcomings, but they are. First of all, they relate to what specific tools you use in your work. The tendency to deformation in metal-polymer pipes works in both directions.

On the one hand, they are easy to bend as you wish. On the other hand, excessive flexibility affects the pipe cutting process. When cutting with improvised tools with your own hands, there is a great chance not to cut the pipe, but to bend it.

Processing technology

Consider the installation processes that allow you to mount metal-polymer pipes with your own hands.

To work, we need several tools:

- Scissors for metal-plastic.

- Cleaning knife.

- Calibrator.

- Connecting device or welded mechanism.

- Measuring instruments.

The most important tool is scissors. It is pipe shears with metal cores that are best used in this situation. Scissors are configured to work according to a special pattern. They are able to bite the pipe in one single effort, creating a clear cut point. In this case, the product is not subjected to deformation or destruction.

First, we measure the pipe, find out which specific indicators are better to choose. Then we mark the segments and cut them with scissors.

Radiator connected to metal-polymer pipes

The inside of the product is processed with a calibrator, leveling it and preparing it for further bonding.The deburring knife removes burrs, plastic slivers and protruding parts of the aluminum layer, if any.

Then follows the turn of connecting the individual parts of the metal-plastic pipe. Here you can apply different methods. The most popular are the use of adapters for pipes with threaded connections and diffusion welding.

In the first case, we use fittings specially designed for fastening metal-polymer products. Their edges are threaded, which simplifies the installation and modification of pipelines. However, the thread is not very reliable in terms of tightness, although it gives some room for manipulation.

Another thing is welding. Welding of polymer and metal-polymer products is made easy. In 2 minutes, you can form a finished pipe with excellent joint quality from two separate sections. The only negative is the inability to further disassemble the pipeline, if such a need arises.

Application features

There are many ways to use metal-plastic pipes, namely:

- if it is necessary to transport air under high pressure;

- in a variety of air conditioning and ventilation systems;

- arrangement of an electric line of metal-plastic pipes, often used as a protective element;

- in the agricultural and industrial sphere, which are aimed at transporting liquids and gaseous substances;

- protection and shielding of electrical power and other wires;

- the design is used in the heating system (floor and radiator).

The use of plastic material in the manufacture of metal-plastic pipes does not contain harmful impurities in its structure, which makes the product suitable for drinking water supply systems.

However, there are limitations when using metal-plastic pipes.

In no case should they be used in the case of:

- devices of the central heating system with elevator nodes present in it;

- in a room that was assigned category "G" according to the fire safety standard;

- the proposed fluid supply through the pipes has a pressure in excess of ten bar;

- in a place with sources of thermal radiation with a surface temperature above one hundred and fifty degrees.

But also metal-plastic pipes are used if you are thinking of doing the dismantling yourself. The main rule for dismantling old water pipes is intervention in the interior with minimal damage to the room. Basically, you have to replace the water supply and sewerage, and here metal-plastic pipes come to the rescue. And collet fittings will provide a quality connection.

Installation can be carried out using a pressure connection.

It has the following order:

- using specialized scissors, cut the metal-plastic pipe at an angle of ninety degrees;

- calibration and reaming tools are used when chamfering;

- at one end of the metal-plastic product, a sleeve must be put on, which is made of stainless steel, then we place the shaped part of the connector so that it reaches the end;

- manually or hydraulically pressed, after which the handle of the tool is reduced to the end.

From this we can conclude that metal-plastic pipes are ideal for various means of communication, connecting a riser.

This frequency of use of structures is associated with their low weight. In addition, this device has a working appearance that does not require additional costs for painting. Joints at the junction are hermetically insulated, contributing to a high increase in service life.

The working pressure of such products does not exceed ten atm. As well as low perceptibility of noise in the sewerage system.

You can see about metal-plastic pipes and their assembly instructions in this video.

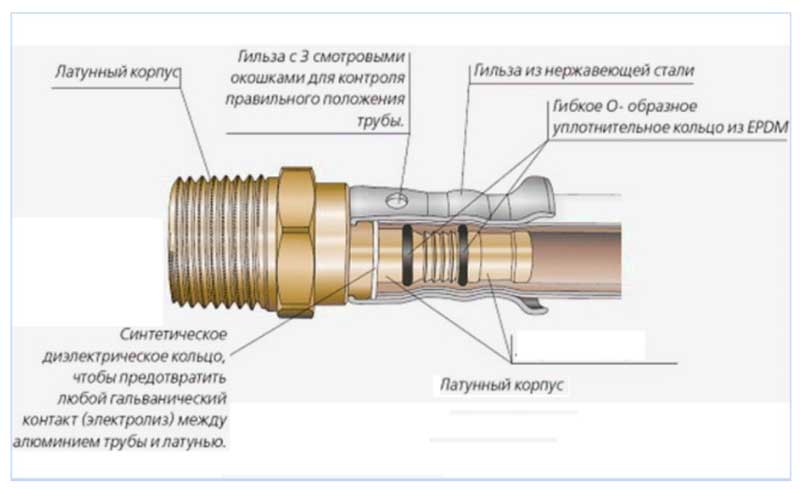

How threaded fittings for metal-plastic pipes are connected

Pipes can be installed with brass compression fittings. Their device includes a fitting, a nut, a split ring. With the use of an open-end wrench and threaded fittings, you can create reliable connections. The procedure is as follows: when tightening the nut, the press sleeve (split ring) is compressed, which forms a hermetic pressing of the fitting to the inner cavity of the pipe.

One of the advantages of compression fittings is that they can be installed without expensive special tools. In addition, the threaded fitting allows quick disassembly of the connections. At the same time, practice shows that reassembling a node with such a fitting may be less airtight, therefore, to repair the network, it is better to cut out the damaged section and install a new pipe section in its place using threaded fittings.To reinstall the used connecting element, it is necessary to replace its sealing elements.

To connect individual pipes, their end must be cut at a right angle. This can be done with a pipe cutter or hacksaw. For bending pipes, it is better to use a spring pipe bender, but you can also perform this operation manually. When bending by hand, the minimum radius is five outer diameters of the tubular product, and when using a pipe bender, three and a half diameters.

You can buy any kind of compression fittings from domestic firms. When choosing such fittings, it is necessary to purchase products in strict accordance with the parameters of metal-plastic pipes (diameter and size of pipe walls). Ideally, it is better to choose pipes and connections from the same brand.

Pipes made of metal-plastic perfectly hold their shape, therefore, when arranging networks, a minimum number of clamps is required. Connection using compression fittings can be made according to the tee (comb) or manifold principle. If the installation is carried out in the form of a comb, then it is necessary to first install the main pipeline, and then cut the fittings into it in the right places (or carry out the installation in a different order).

Example of connecting a compression fitting:

Mark the connection points.

Perform pipe cutting.

Put a corrugation of insulation on the metal-plastic pipe (optional step).

Perform pipe calibration.

Put a nut with a sealing ring on the pipe.

Connect pipe and fitting.

The photo shows the installation of compression fittings of a tee design.In the catalogs you can find many other options for such connections, which makes it possible to assemble pipelines according to any scheme.

The assembly process is carried out in the following sequence:

-

Align the pipe so as to obtain a flat section 100 mm long before the cut and 10 mm after it.

-

In the right place, you need to cut the pipe at a right angle.

-

Finish the face with a reamer with millimetric chamfering. It is necessary to ensure the correct round shape of the end face.

-

A nut with a split ring must be put on the pipe.

-

Wet the fitting.

-

You need to put a fitting on the pipe. In this case, the end of the cut should rest firmly against the edge of the fitting. We screw the fitting nut by hand until it stops. If the nut does not turn well, then the threaded connection may be broken or the nut does not go along the thread, which will reduce the tightness of the connection.

-

You will need two wrenches to tighten the fitting. One needs to fix the fitting, and the other needs to perform up to two turns of the nut so that up to two threads of the threaded connection are visible. Do not use wrenches with reinforced levers, as tightening the nut can lead to loss of tightness of the connection.

To prevent the metal-plastic pipe from fogging during temperature changes of the transported medium, a special insulating casing made of polyethylene foam or other similar materials is put on top of it. Such insulation can also be put on after installation is completed during the operation of the pipeline. To do this, the polyethylene foam sleeve must be cut lengthwise, and after installation, fix it on the pipe with adhesive tape.

Fittings are marked according to two indicators:

-

according to the outer diameter of the pipe;

-

according to the parameters of the threaded connection, with which pipe fittings are mounted.

For example, the presence of symbols 16 × 1/2 for internal thread indicates that the fitting can be connected at one end to a pipe of 16 mm in outer diameter, and the other end to a fitting that has a half-inch threaded connection.

Read the material on the topic: Replacing pipes in an apartment: professional advice