- Kinds

- Multilayer fabric

- fine-meshed

- Elements with polymer filler

- Filter blocks with mineral fillers

- active carbons

- Ion exchange resin systems

- Reverse osmosis systems

- Ease of use and maintenance

- Types of pre-filters

- Filling materials for cartridges

- How to choose

- Types of filters

- Flanged and coupling

- Straight and oblique

- Mud collectors with a flushing system

- Cartridge and cartridge

- 2 Types of coarse filters

- Installation of coarse mechanical cleaning systems

- Main filters

- Attachment on the crane

- Under sink plumbing filter

- Reverse osmosis

- Cartridges

- Coarse filters

- The design and principle of operation of the coarse filter-sump

- Methods and methods

Kinds

Fine or deep cleaning is understood as a set of processes, for each of which there is a separate type of filter elements.

Multilayer fabric

These blocks are made in the form of a cylinder with a continuous circular winding of textile strips, bundles. Multilayer fabric filters can purify both cold and hot water.

The fabric layer does not provide very deep cleaning, the water thus obtained can be supplied to sanitary equipment.

fine-meshed

An alternative to filtering on several layers of fabric is water purification on metal meshes with a large number of small cells.

There are modifications of mesh filters with a silver-plated surface. They can not only retain debris, but also have a bactericidal effect on water.

Reference! Metal meshes are convenient because they can be easily and reliably washed from adhering dirt.

Elements with polymer filler

Polypropylene cords or granules are most often used as a filter element. The technology for the production of a polymer with a large number of cells and pores has been developed.

Polypropylene actively retains impurities. Possibilities of fillers can be restored by washing.

Filter blocks with mineral fillers

Have good filtering ability

- clay,

- silica,

- silica gels.

Minerals are carefully cleaned, calcined to increase porosity, washed and used for purification. The nature of the filler significantly affects the sorption capacity.

Interesting! So natural alumina absorbs mainly organohalides, arsenic derivatives.

Shungite purifies water from a large number of impurities. Zeolite exhibits not only filtering, but also ion-exchange properties, removes many substances from water, including hardness salts.

active carbons

Coals in the activated state are characterized by sorption capacity in relation to a large number of impurities.

The following is used as a source for obtaining sorbents:

- wood,

- shell nuts;

- fruit bones,

- coconut shavings,

- stone coals,

- peat.

The disadvantage of active carbons is the need for frequent replacement. Several times it can be restored by washing.The number of regenerations should not exceed four times, after which the coal must be disposed of or thrown away.

Ion exchange resin systems

An example of a natural ion exchange material is zeolite. In practice, specific polymers are often used to fill ion-exchange columns. Charged ions are movably attached to them.

During the passage of the water flow, the cations of hardness salts are exchanged for sodium cations. As a result, the water softens. Ion exchange resins can be regenerated by aging in a common salt solution. Fillers are inexpensive, successfully cope with part of the pollution.

Reverse osmosis systems

Reverse osmosis is the process by which a pure liquid, such as water, passes through a membrane. On the other side of the membrane, all the dirt remains, the liquid concentrate with impurities enters the drain.

Only previously purified water can be supplied to the membrane element.

Therefore, several blocks are installed in the system:

- rough cleaning;

- sorption;

- ion exchange;

- reverse osmosis.

In some units, at the final stage, the water is subjected to mineralization.

Ease of use and maintenance

All filters are made of a solid housing (plastic, metal), which contains a filter element that needs to be replaced or cleaned in time. For convenience, there are filters with a transparent housing, which allows you to determine the degree of contamination in a timely manner and make an inspection or replacement in time. Consider also the installation location in terms of access to the filter for maintenance.

Filter elements are replaceable (those that, after being clogged, change to a new one), with automatic flushing (these are those that are washed with running water by opening a special valve in the filter sump) and serviced (those that can be cleaned on their own with a brush, pressure water, a special solution, air, after removing them from the housing).

Types of pre-filters

Representatives of the first group are equipped with a special mesh with small cells, where large fractions and harmful impurities are retained. The second type is equipped with a multi-layer cartridge that retains tiny contaminants.

Stainless steel mesh filters purify water using a metal mesh with a fine mesh structure. The sizes of these holes vary from 50 to 400 microns, which ensures the retention of most solid impurities. Rust and sand from the pipes remain on the filter devices without disturbing the performance of plumbing and other equipment in the house.

On sale are affordable self-cleaning mesh filters that are capable of self-cleaning without human assistance. The rest of the models need to dismantle the dirty mesh for washing.

Filter manufacturers also offer systems with a magnetic trap that attracts ferrous compounds, rust and other iron hydroxides found in water.

Cartridge pre-filters for hot and cold water are fixed on the surface, as they are large and take up a lot of space. Advanced designs are equipped with a transparent body, which allows users to follow the cleaning process and see how many different particles are in the pipeline fluid.

Inside the system there is a replaceable cartridge made of coal or pressed fiber, polypropylene thread or polyester. Depending on the elements used, the cleaning efficiency is determined. The throughput is 20-30 microns, which allows you to get rid of tiny particles.

Due to the limited filtration rate, cartridge devices are not suitable for high pressure areas. After the expiration of the service life, the cartridge must be disposed of, and a new part must be placed in the flask. The body is equipped with a sump and 2 branch pipes: the first passes tap water, and the second receives the purified composition.

In addition to the listed types, high-speed pressure pre-filters are offered on the market, which have improved performance and throughput.

Filters come with the following placement of the housing:

- With a straight line - they are installed perpendicular to the pipes and differ in large dimensions.

- With oblique - occupy a large space and are placed at an angle to the main pipe.

Also, filter systems may differ in the way they are installed. Depending on the installation method, the following categories of devices are distinguished:

- Flanged pre-filters. They are located at interchanges and main pipelines in the basements of multi-storey buildings. Mounted on pipes with a diameter of 2 inches (5.08 cm). The place of installation is selected after drawing up the design.

- Sleeve filters. Designed for urban apartments and mounted on pipes with a diameter of up to 2 inches (5.08 cm).

Filling materials for cartridges

For the manufacture of the cartridge, polypropylene fiber, woven polypropylene rope (cord), cellulose impregnated with polyester, nylon cord are used. But it is propylene that has gained the greatest popularity due to the fact that it has a low cost, is not exposed to chemicals, and is not destroyed by biological organisms.

Polypropylene cord filters use a special winding method that allows larger particles to settle on the outside of the cartridge, while fine particles remain inside the skein. They do not clog very quickly, but the more they exhaust their resource, the more pollution they let through.

For plumbing, this is just a positive feature, because a dirty filter does not reduce the pressure in the system. Polypropylene fiber has a foamed structure that contains small bubbles that accumulate pollution. The disadvantages of the material are manifested in cheap low-quality models.

During water purification, an external filtration ball is clogged in them, while the inner layer can remain clean, that is, not participate in the filtration process. But high-quality cartridges work with the entire surface.

A significant drawback of polypropylene fiber is that if it is heavily polluted, it ceases to pass water and significantly reduces the pressure of water. This can adversely affect the operation of pumping equipment.

The temperature of use of polypropylene products is 1 - 52 °C. They can be used for cold and warm water. For the treatment of hot water, it is necessary to use cartridges made of cotton fibers impregnated with a special substance.They endure high temperatures (up to +93 °C), exposure to microorganisms and various substances.

How to choose

When choosing a cleaning device, one should proceed from the purpose of each particular apparatus. The coarse filter for individual use has smaller volume indicators, and its installation and cleaning is easier. Devices for apartment buildings and industrial purposes are chosen by specialists.

Design flaws are a relative concept. Who is warned is armed. Therefore, in each case, before buying, you should read the instructions for using the model, make inquiries from the seller.

Disadvantages are revealed, unfortunately, only during operation, but this does not affect the quality of the filter, it only complicates maintenance and operation.

Before purchasing, you must make sure that the complete set of the model fully complies with the declared list in the instruction manual. Warranties are required. When installing the filter yourself, do not use incomplete parts and tools if special fittings and keys are included in the purchase.

Types of filters

Although coarse water filters work on the same principle, they can have a different shape. This can affect the way they are inserted into the system, as well as the type of filter elements used. Water filters may also differ in the cleaning method, as well as other characteristics.

Although coarse water filters work on the same principle, they can have a different shape. This can affect the way they are inserted into the system, as well as the type of filter elements used. Water filters may also differ in the cleaning method, as well as other characteristics.

Mesh filters. Already by the name of these devices it is clear that the mesh is designed to trap foreign particles here. Most often, it is made of stainless steel and has a structure with cells ranging in size from 50 to 400 microns.

It is mesh filters for coarse water purification that are most often installed in kitchens.Consumers are attracted to them by high durability, which is why you can not change filter elements for months.

Mesh water treatment devices may differ in the method of inserting into the network. They can also provide for a different layout, as well as the principle of cleaning and operation.

Flanged and coupling

These filters for water supply differ from each other only in the way they are connected to the pipe. For a system where the pipe has a section of at least 2 inches, flanged filters for rough water treatment should be used.

These filters for water supply differ from each other only in the way they are connected to the pipe. For a system where the pipe has a section of at least 2 inches, flanged filters for rough water treatment should be used.

For the most part, such flow filters are installed in the main water supply system or the decoupling of the basements of high-rise buildings.

They use a bolted or stud connection of flanges, which allows the user to change the filter with their own hands without completely dismantling the entire structure.

If we talk about sleeve filters, then they should be chosen for plumbing systems, in which the pipes have a rather small cross section. They have also become widespread in household networks.

These filtering devices differ in the type of construction, which determines the method of their installation: by screwing the filter onto the pipe or connecting it with quick-release union nuts.

Straight and oblique

Such filters are equipped with an inlet and outlet pipe, they also have a tank for water filtration. The type of device, which can be straight or oblique, depends on the placement of this tank.

Such filters are equipped with an inlet and outlet pipe, they also have a tank for water filtration. The type of device, which can be straight or oblique, depends on the placement of this tank.

Regarding direct filters, it can be noted that their reservoir is located at a right angle to the ceiling and directed downwards. Usually the tank is quite voluminous, which is only beneficial, as the quality of cleaning is improved.

It should be taken into account that during the filtration process, the speed of water passage to the points of consumption decreases. As a result, large particles settle to the bottom. And as the water passes through the mesh, it traps smaller particles.

About oblique filters, it must be said that they have a slightly different appearance. They have a tank installed at an angle towards the flow of water. Most often they are chosen for those plumbing systems where space is limited and there are no conditions for installing a direct filter.

Mud collectors with a flushing system

Depending on the cleaning method, there are several types of filtration systems for filters:

- non-flushing;

- mud system;

- equipped cleaning system.

It is customary to include all types of oblique and certain types of direct filters equipped with a removable cover to the class of mud collectors. Cleaning such filtering devices is quite simple - you just need to unwind them.

Straight filters with a flushing system are equipped with a special drain cock that can be used to remove the sediment that has accumulated in its tank. At the same time, they allow you to clean the filter with a direct and reverse flow of water.

Cartridge and cartridge

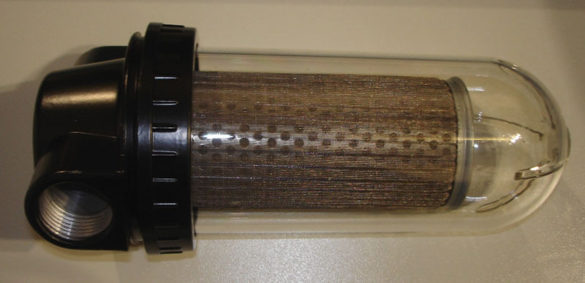

In domestic conditions, filters equipped with cartridges are often used. They look like wall-mounted designs. They provide a rather massive flask, most often made of transparent materials.

In domestic conditions, filters equipped with cartridges are often used. They look like wall-mounted designs. They provide a rather massive flask, most often made of transparent materials.

The flask itself contains a replaceable cartridge that performs the function of rough water purification.Typically, these models use replaceable elements made of polypropylene pressed fibers or twisted threads.

However, sometimes they can be made of polyester. Filters of this type may differ in their filtering capacity. Devices designed for coarse mechanical water purification are equipped with cartridges having from 20 to 30 microns. It will not be possible to return them to working condition using ordinary flushing - they only need to be changed to new ones.

But at the same time, situations are common when devices of this type are used in conjunction with coarse water filters, acting as an additional stage of mechanical filtration.

2 Types of coarse filters

The filter device itself is extremely simple: in fact, it is a metal mesh that traps impurities from the water. It consists in a body (usually metal), which has an inlet and outlet pipe.

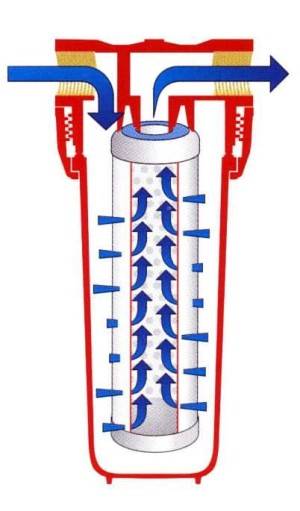

Below the nozzles is a part called a sump - a department where, in fact, filtration takes place. First, the speed of the water decreases in this part - which allows impurities to settle to the bottom of the hull, and not be carried away further. Then - the liquid passes through the mesh, which retains the dirt.

Structurally, the design of the coarse filter may differ in a number of parameters that should be considered separately.

First of all, the material from which the mesh is made should be mentioned. Most often - it is steel, less often - bronze or brass. These strong connections are resistant to mechanical damage and withstand pressure drops.

The difference is in the connection method - the filter can be mounted in the system by means of a coupling or flange connection.This difference is predetermined by the size of the pipe - with a diameter of 2 inches or more, a flange is used, if less, a coupling.

In these ways, an industrial version is usually mounted, in other cases, threaded filters are used. Such household models are relevant for pipelines that run inside apartments and residential cottages. In this case, the installation can be carried out both directly with the pipe, and through the "American".

Pore size is, in fact, a key quality parameter that affects how well the filter can purify water. The smaller the size of the mesh cells, the more dirt it can hold. For a coarse filter, this parameter varies from 50 to 400 microns.

According to the location of the sump, the products can also be divided into two categories:

- Straight.

- oblique.

In the first case, the sump is located perpendicular to the water flow, forming a T-shaped body with inlet and outlet nozzles. Thanks to this solution, this department can be quite large. Therefore, a direct sump will be able to better clean the water passing through it.

The oblique design of the body is easy to determine visually - in this case, the sump is installed at an angle to the water flow. This reduces efficiency compared to a direct filter. Not much, of course - household filters of this type will also successfully cope with the task.

However, they are best used where the installation of a direct model is simply impossible - due to lack of free space (for example - when the pipeline runs too close to the floor or to another pipe).

One of the relatively new and very useful nuances is also the way to clean the filter itself - after all, sooner or later the sump will overflow with accumulated dirt, which will need to be removed from there. In this regard, products are divided into two categories:

- Sump.

- Filter with flushing system.

The first option is non-flushing. This category includes oblique devices and some straight ones. In this case, the sump is closed with a removable cover - through which you can clean the device from dirt.

Its disadvantage is that cleaning in this case requires disassembling the device - the cover will have to be unscrewed first, and then installed back.

The second option is more convenient - in this case, the body is equipped with a crane. Cleaning is extremely simple: the tap opens, and the sludge is drained into a substituted container.

On sale you can find an even more perfect option - a self-cleaning coarse filter. Such a device is equipped with two sensors - one is installed at the inlet, the second - at the outlet. By measuring the pressure, the sensors record its difference - if it decreases at the outlet (after cleaning), it means that the self-cleaning filter is dirty.

It is cleaned through a valve that opens and releases sediment. A self-cleaning filter is good because you do not have to monitor the state of the node - it will automatically determine the need for cleaning and perform it.

The most famous representative producing such models is Honeywell. Honeywell filters are used most often in industry, however, for domestic tasks, the company also produces a number of models suitable for water supply.

Of course, Honeywell devices cost an order of magnitude more expensive than simpler options - this, in fact, is their only drawback.

Installation of coarse mechanical cleaning systems

Installation features are determined by the design.

The general rules boil down to a few key points:

- Before starting installation of any model, turn off the water supply.

- The filter must be placed immediately after the stopcock, in front of the meter.

- After the filter, it is also desirable to install a shut-off valve to simplify maintenance.

- If there is no meter in the apartment, the installation is done in front of household technical equipment.

- Mounting is carried out in accordance with the direction of the arrow on the housing. It indicates the course of the flow.

- The sump in all models must be directed downwards.

- It is easier to install non-flushing devices.

- When installing flushing models, a bypass water supply is made, as indicated in the instructions.

- Installation of self-cleaning structures is the lot of specialists who can competently connect an automation unit, flushing and drain hoses to the network. To supply water to the sump, a separate outlet is made. The drain connects to the sewer.

- Depending on the type of device, it is fixed with couplings or flanges.

- The joints are sealed with fum tapes.

- The pipeline is additionally fixed to the wall with clamps.

Upon completion of installation, start the system, partially reducing the water pressure, carefully check the joints. If there are no leaks anywhere, you can open the shut-off valve completely.

Main filters

The most complete mechanical water purification, comfortable for use, is currently provided by main filters.

Among the filters that allow you to use existing taps in the usual way, there are several options:

- attachment on the crane,

- sink filter,

- reverse osmosis.

Attachment on the crane

A faucet nozzle is the most budgetary and compact option for purifying running water. Purified water comes straight from the tap. The filter cartridge is built into the nozzle itself, however, the cartridge needs to be replaced frequently and this quick cleaning will be less effective than is possible with other options available today. However, such filters may be the only way out if it is not possible to connect to the water supply.

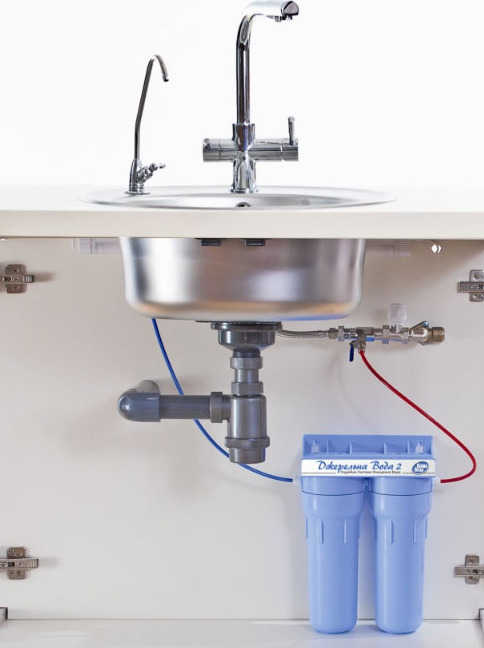

Under sink plumbing filter

The filter is connected to the water supply, has several degrees of purification, the effectiveness of which depends on the cartridges that need to be changed. The sink filter is a purification system equipped with a separate tap, from which you can get high-quality purified water.

Purified water can be obtained in parallel with technical water, thus saving a replaceable cartridge.

The cartridge removes mechanical particles, softens water, removes iron and cleans chlorine. Most of these filters are unable to protect against biocontaminants.

However, there is a group of filters with an ultra-ultrafiltration membrane - with a special deep water purification with the removal of bacteria. They purify better, but do not guarantee complete purification of water from bacteria.

Reverse osmosis

Reverse osmosis is a technology that guarantees 99.9% water purification. Such a filter consists of a block of pre-filters, a membrane, a storage tank for collecting water, a mineralizing filter and a clean water tap.

Cartridges in such a filter are changed every six months, and the membrane is replaced every two years.Thus, by installing such a filter, you can forget about constant maintenance and calmly use clean tap water.

The disadvantages of this solution are the cost of equipment and slow water purification, so for complete comfort of use, you should choose filters with a large tank.

An important requirement for installing a filter reverse osmosis is sufficient pressure in the line - from 2.5 atmospheres.

For an overview of reverse osmosis filters, see the video:

Cartridges

The quality of filtration directly depends on the quality and timely replacement of cartridges. For different types of filters, there are cartridges of different prices and efficiency.

You can learn about filter cartridges by watching the video:

Coarse filters

CSF trap only large particles of impurities in the fuel. They are usually made in the form of a metal (brass) mesh that can be removed, washed and returned to its place.

In carburetor systems, several coarse meshes with cells of different sizes are used.

- A grid with large cells is installed on the neck of the gas tank.

- A grid with smaller cells is installed on the fuel intake.

- The mesh with the smallest cells is equipped with an inlet fitting.

Coarse filters are brass mesh

In the case of an injection engine, the CSF with a grid is built into the fuel pump of the gas tank.

Diesel units are usually equipped with a sump filter. This, however, does not preclude the use of grids.

The diesel fuel coarse filter has a number of advantages over grids, reliably protecting the engine from condensate drops entering it.

Diesel CSF is not disposable. It can be washed and reinstalled.

The design and principle of operation of the coarse filter-sump

The sediment filter consists of the following elements:

- case with cover;

- a filter element made of aluminum plates 0.15 mm thick with protrusions of 0.05 mm - located on the sleeve in a glass attached to the body;

- threaded sleeve screwed into the body;

- distributor pressed by the sleeve;

- sealing paronite gasket between the glass and the body;

- damper located in the lower part of the body.

Diesel engines are usually equipped with a sump filter

The sump filter works as follows:

- Through the holes in the distributor, diesel fuel enters the filter.

- The fuel moves lower into the damper - large particles of mechanical impurities and condensate remain here.

- Then the fuel goes up to the mesh of the filtering part, on which small particles of impurities remain.

- Fuel enters the engine through the fuel line.

Methods and methods

Depending on the implemented filtering method, there are:

- Mechanical filtration systems, represented by coarse mesh or disc filters or winding cartridges made of foamed polymers.

- Sorbent filters that purify water and improve its taste when passing through cartridges with activated carbon (wood or coconut) or aluminosilicate granules.

- Reagent filtration systems that remove dissolved and undissolved particles of heavy metals and hydrogen sulfide from water when passing through interlayers with glauconite sand and similar oxidizing agents.

- Membrane filtration systems, recognized as the most effective in the field of fine water purification.

Read more about filtering methods here.