- Model Rating

- Existing types of cleaners

- Basic product requirements

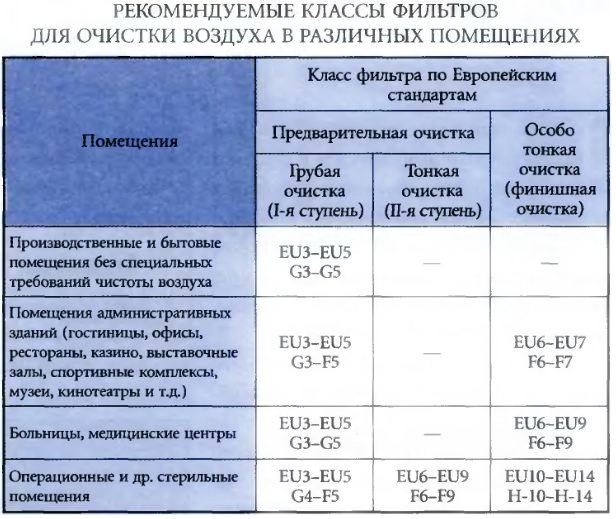

- Filter classes

- What it is?

- Why air filters are important

- Classification according to the degree of purification

- 2 Three cleaning classes

- Filter media in ventilation filters

- Metal Mesh Filters

- Water filters

- Carbon filters

- Synthetic filter mats

- Fiberglass filter mats

- Varieties of ventilation filters by cleaning class

- Cooker hood control

- Features and subtleties of using ventilation filters

- The principle of operation of the hood

- Oil-inertial air filters

- How to choose the most suitable range hood

- Filter designs and their applications

- Grates with filter

- Cassette and panel type devices

- ducted

- Performance and noise of the kitchen hood

- Mounting Features

- Filter media for filters

- Should not emit dust, fibers and harmful substances

- Cleaning methods

- Rating of the best manufacturers

- Budget models

- Middle price segment

- Premium Models

Model Rating

Currently, the market offers a wide variety of cooker hoods from well-known world manufacturers, which guarantee their quality.

Some of the most popular kitchen hood manufacturers today are:

- HOTPOINT ARISTON, whose products have proven themselves for their quality and reliability;

- the GATA brand, whose hoods are renowned for their flawless performance and durability;

- the well-known German company BOSH, whose hoods are presented in a huge assortment and have proven themselves on the market for a very long time on the positive side;

- the company VENTOLUX, which is famous for the use of the latest technologies in the manufacture of its products;

- ELEKTROLUX, whose hoods are diversity, individuality, beauty and quality.

All kitchen hoods are powered by a household network. They are low power devices. Typically, at the highest load, no more than 500 watts are consumed.

Hoods of these global manufacturers have been taking first place in various ratings both in the CIS and abroad for several years in a row.

Existing types of cleaners

The division into types is considered conditional, although it covers all kinds of filter features. This is necessary so that consumers, manufacturers, sellers can better navigate the design features, a variety of materials.

Filter devices are divided into types, taking into account the following features:

- by design;

- purpose, effectiveness;

- working principle.

All design features of air filters are standardized, so several types are distinguished. One and the same products may include products of different efficiency.

The classification of cleaners makes it easy to choose models of the desired designs. For example, pocket filters used for ventilation of various rooms are coarse and ultra-efficient.

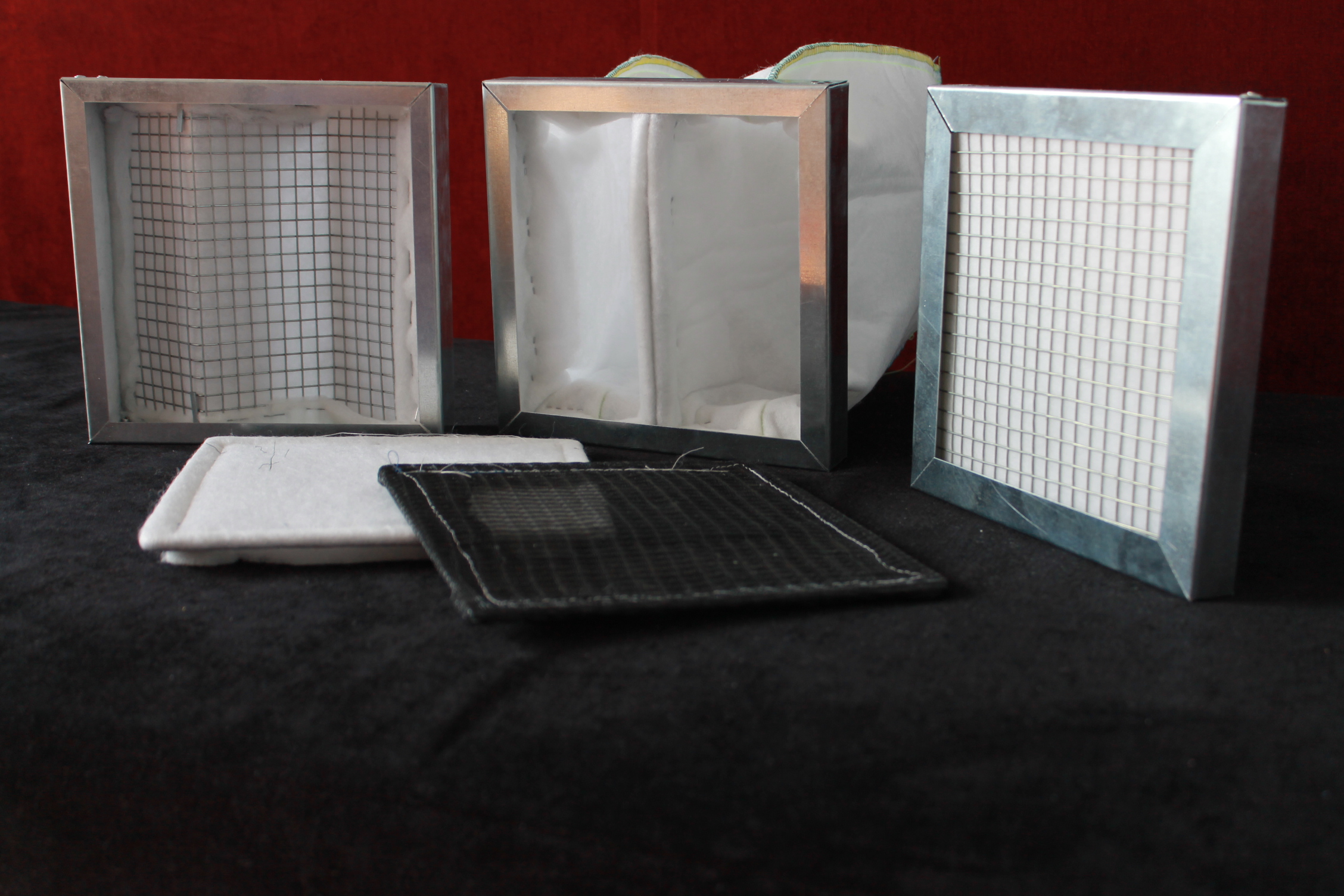

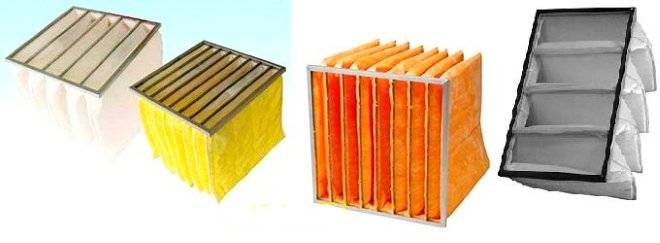

Types of filter products by design type:

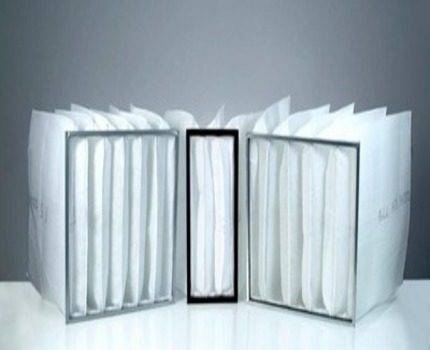

- Pocket;

- cassette;

- panel;

- filter bags.

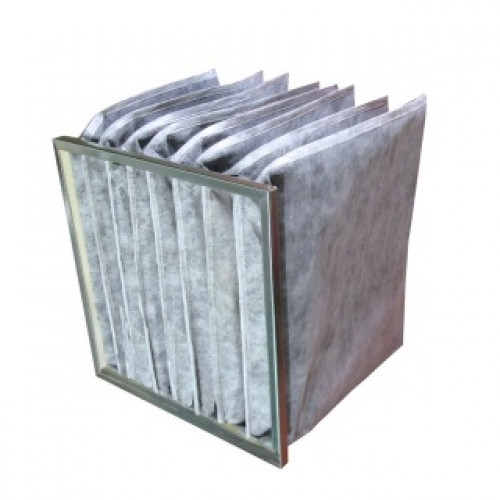

Pocket filters are characterized by low resistance, durability, safety, high dust capacity. They are distinguished by simplicity of design, application, disposal, and also have high fire safety.

Pocket filters are structurally simple, reliable and safe, therefore they are one of the most popular types.

They can be used in various fields (in production, in hospitals, residential premises). Durable synthetic fibers are used as the material of manufacture. They are sewn, soldered structures, similar to pockets, which are attached to a rigid frame.

Cassette filters are used in various fields (in production, in public catering, pharmaceuticals, households), they are distinguished by their strength and durability. The advantages include low initial resistance, significant dust capacity.

The rigid design allows to cope with any loadings. The filter material is made from modern polyester fibers.

Cassette filters have a rigid design, so they can withstand significant loads

Cassette filters have a rigid design, so they can withstand significant loads

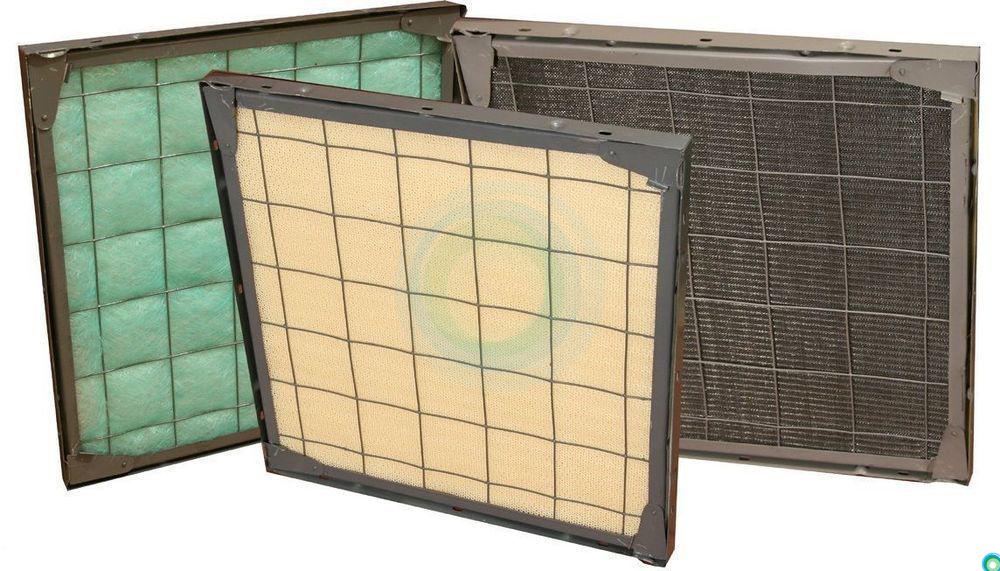

Panel filters are products for which various raw materials can be used as filter materials, including metal mesh, polyurethane foam, but modern polyester fibers are most often used.

Such devices can be part of various air purification systems at work, at home. They are distinguished by practicality, high performance, impressive ability to retain dust.

Filter bags are the most productive filters, therefore they are used mainly in production, including chemical plants, tobacco factories, thermal power plants.Such products can also be used to capture various gases, for example, in the production of aluminum.

Sleeves are the most common filter elements in production, moreover, their use is traditionally considered the most economically viable. And all because these filters are able to perform high-quality cleaning from a variety of gases, dust. They can be changed without stopping the process.

Panel filters. They are easy to distinguish, since the frame of such products is always equipped with power elements in the form of a grid.

Panel filters. They are easy to distinguish, since the frame of such products is always equipped with power elements in the form of a grid.

In addition, the sleeves are durable, little susceptible to operating conditions - they can work at an impressive 280°C and significant frost.

The filter material in this case is modern polyester fibers, which are often covered with additional layers, for example, membranes to improve the quality of air treatment.

Basic product requirements

Filtration elements must ensure complete tightness of the system, but they must be replaced regularly. Based on this, there are some requirements for the product.

Ease of installation, the possibility of repair and tightness of systems in apartments with panel units. The risks of leaks and ruptures must be completely eliminated.

The filter element must be sufficiently reliable against mechanical stresses that may form in the system.

An important characteristic of any filter is its initial and final aerodynamic resistance. Therefore, in the production of such devices, strict standards are imposed, since if the filter fails, the entire ventilation system will fail;

The material of manufacture must withstand normal atmospheric conditions and sufficiently large aerodynamic forces.

When capturing solid particles, filters should not let dust and soot through, which adversely affect technological processes.

Therefore, for the production of filter elements, non-woven materials are used that can provide high reliability in capturing pollutants.

Filter classes

Ventilation filters not only purify the air from various mechanical impurities, but also increase the service life of ventilation equipment, which can become clogged during operation. Therefore, cleaning devices are necessarily laid in ventilation systems, moreover, even at the design stage.

The choice of filtering equipment primarily depends on the following factors:

- Air exchange system configurations;

- environmental conditions.

To make it easier to choose the right device, all filters for ventilation systems differ in the degree of purification into the following classes:

| First grade | Able to clean the air from the smallest particles, up to 0.1 microns in size. |

| Second class | They purify the air from large and medium particles (up to 1 micron). |

| Third class | These devices carry out rough cleaning, removing particles from the air with a size not exceeding 10 microns. |

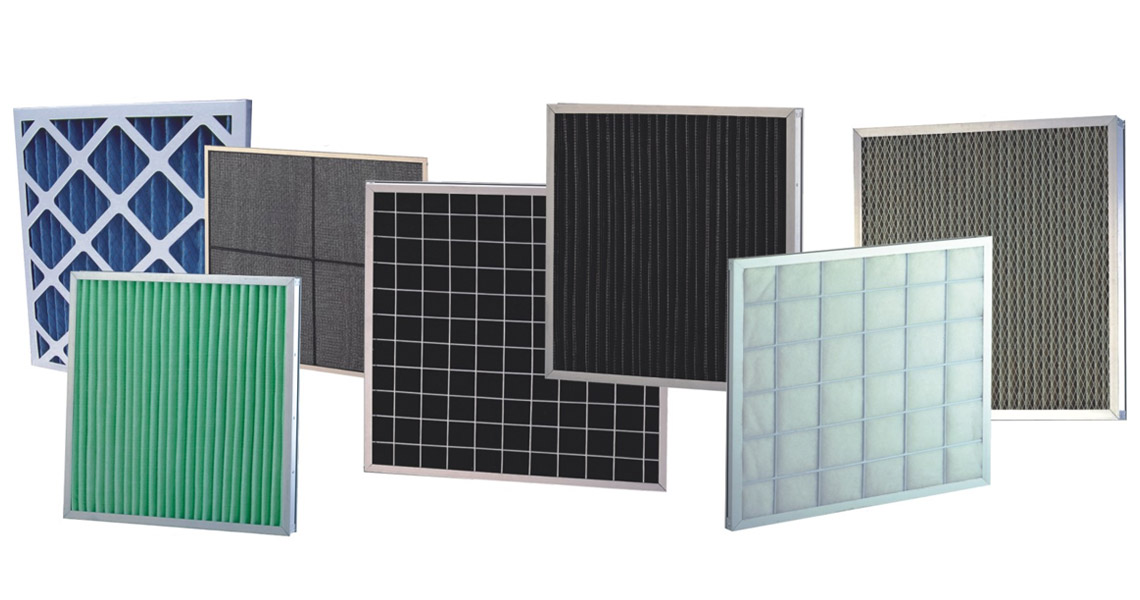

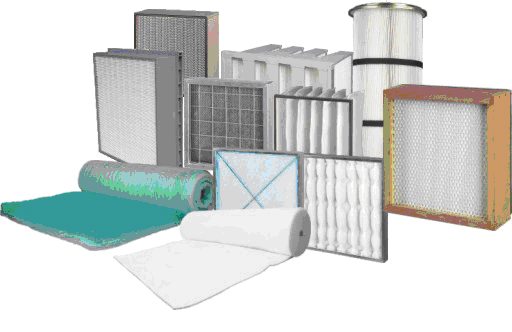

Various types of ventilation filters

More precise characteristics can be found in the product labeling. Depending on the class, it may be as follows:

| G3 | Capable of retaining large impurities in the air masses. |

| G4 | They can retain dust and partially pollen from plants. |

| F5 | They trap smoke, spores and even some chemical compounds. |

| F6-F7 | The device is a bactericidal filter for ventilation, which also completely cleans the air from dust and tobacco smoke. |

| F8 | Provide air purification from dust, most chemical compounds, tobacco smoke, etc. |

| F9 | They clean the air as much as possible from spores of fungi, odors, some bacteria, various impurities, etc. |

As a rule, during the design process, several filters of different purification levels are included in the system, which allows distributing the load between them. If you use one device, for example, first class, especially in polluted conditions, then it will quickly become clogged and fail.

Thus, installing an additional third-class purifier will save on consumables. Considering that the price of quality consumables can be quite high, this solution is economically very profitable.

cell filters

What it is?

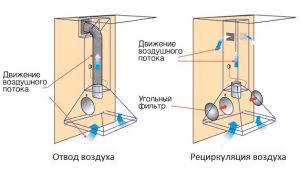

Not all kitchen rooms are connected to the general house ventilation system. There may be various reasons, from clogged channels to their complete absence (for example, this is found in private homes). Sometimes, to normalize the kitchen atmosphere, it is not so much a replacement that is required, but air purification from unwanted components.

For example, in kitchens with electric stoves, you can not make a closing door. And many users completely remove the wall between the living room and the kitchen, thereby expanding the space of both rooms. In such conditions, ventilation is quite sufficient, but another problem arises - the spread of odors, humidity, particles of fat or soot throughout the apartment.

To solve the problem, special devices are used. They are habitually called hoods, although, strictly speaking, they are not.It is more correct to call them filters, or recirculation units that clean and constantly circulate the air in the room.

Outwardly, they look like hoods connected to ventilation. They have an umbrella that extracts air from the cooking surfaces. Getting into the housing, the air is passed through a carbon or other filter, after which it is thrown back into the room. This method does not create a vacuum, does not cause flow into the kitchen from other rooms (which is not always acceptable).

Outwardly, they look like hoods connected to ventilation. They have an umbrella that extracts air from the cooking surfaces. Getting into the housing, the air is passed through a carbon or other filter, after which it is thrown back into the room. This method does not create a vacuum, does not cause flow into the kitchen from other rooms (which is not always acceptable).

The beneficial effect of such devices directly depends on the design and quality of the filters. If they are filled with the simplest materials (activated carbon or other traditional types), then the quality of air purification will be average or frankly low.

Since there is no inflow of fresh air, odors will still be present in the room, and humidity will spread. In addition, stand-alone installations are not able to remove excess heat, which creates the need for frequent ventilation or the use of additional ventilation.

Why air filters are important

If a person has installed a ventilation system in his home, office, at work, then he expects to receive an influx of fresh, clean air, and this is impossible without an effective filtration system. Therefore, in the absence of high-quality purification of air masses, the meaning of installing expensive equipment is lost.

Even if the owner does not see the need for this procedure, it will still need to be done to protect the mechanical parts of the system itself.

Third-party particles, including small fragments of branches, insects, grains of sand and dust raised by the wind, can lead to premature wear and damage to expensive equipment, and repairs will be more expensive than a package of high-quality filters.

In addition, maintenance will be much more expensive. For example, you will have to regularly reconfigure the system. And since only specialists can perform this operation, each such adjustment will be expensive.

Polyester fiber filters are the most popular today. And also in the photo you can see that the filter material is corrugated - this increases the cleaning efficiency

And this is not the whole list of additional work that has to be done in the absence of an effective filtration system.

Classification according to the degree of purification

Filter fabrics are necessary in order to trap and trap dust particles of various sizes. Depending on the density and number of layers of the filter material, the filter for air ventilation systems provides a certain degree of purification. There are 3 in total:

- rough

- Thin

- Extra thin

Coarse filters (indicated by the letters G 1-4) trap large contaminants such as sand, wool, dust, etc., from 10 microns in size. Often used as the first stage of air purification. Protects the ventilation system from dust accumulation and prevents clogging of ventilation equipment.

When choosing a filter, pay attention to the class of filter material

Fine cleaning (F 5-9) captures particles larger than 1 micron. They are installed in rooms with increased requirements for air quality and its cleanliness. It is combined with the previous type of filters to provide better air purification.

Extra fine cleaning (EU 10-14) removes microparticles from 0.1 µm from the air stream. For a three-stage air purification system, all three types of filters are combined, this allows you to extend the life of finer filters, because. large particles are retained at the first stage, then the second type follows - to eliminate smaller particles, and the filter of the supply ventilation system of ultra-fine cleaning completes everything. Such a system is also installed in rooms where air purity is regulated, for example, in some production shops, operating rooms, laboratories, medical institutions.

2 Three cleaning classes

The production of filters is put on stream and companies produce various cleaning products. The choice in favor of one or another design is based on the desired level of purification, the degree of oxygen pollution. In order for the equipment to function properly and not clog, it is supplemented with ventilation filters.

According to the degree of purification, 3 classes of products are distinguished, providing:

- absolute purification - the filter material prevents the penetration of particles up to 0.1 micron in size. The main area of their application is operating rooms, production complexes specializing in the production of high-precision equipment, a military complex;

- fine cleaning - solutions that capture microparticles from 1 to 10 microns. Filter mechanisms provide efficiency up to 94%. They are found in the food industry, pharmacology, laboratories;

- rough cleaning - particles larger than 10 microns do not penetrate into the room. These products capture up to 90% of contaminants. The main area of application is air pre-treatment systems at sites with high dust concentrations.

If it is necessary to provide pure oxygen in the room through fine purification, it is much cheaper to pre-treat the air masses with solutions of a lower class. Cassette filters do not have to be changed as often and can save a decent amount on consumables.

Filter media in ventilation filters

The class of air purification in the ventilation system depends on the characteristics of the filter material. Often, to obtain the best effect, several filter modules of different classes are combined with each other.

Separation of large suspensions occurs with the help of:

- metal mesh;

- non-woven materials (synthetic winterizer, felt);

- fabrics (cotton, flannel, linen, wool);

- paper;

- fiberglass.

Metal Mesh Filters

Able to retain impurities with a particle size of at least 5 microns. That is, metal filters provide preliminary coarse cleaning. In order for the mesh to “collect” dirt better, its surface is sometimes covered with a layer of machine oil. Filters can be cleaned independently: the tape is passed through a container with oil, where the dirt is washed off.

Water filters

There are water filters that are installed in restaurants over sources of open fire (for example, barbecues).

The water filter precipitates impurities and cools the exhaust air to 38 - 40 degrees before it is released into the atmosphere.

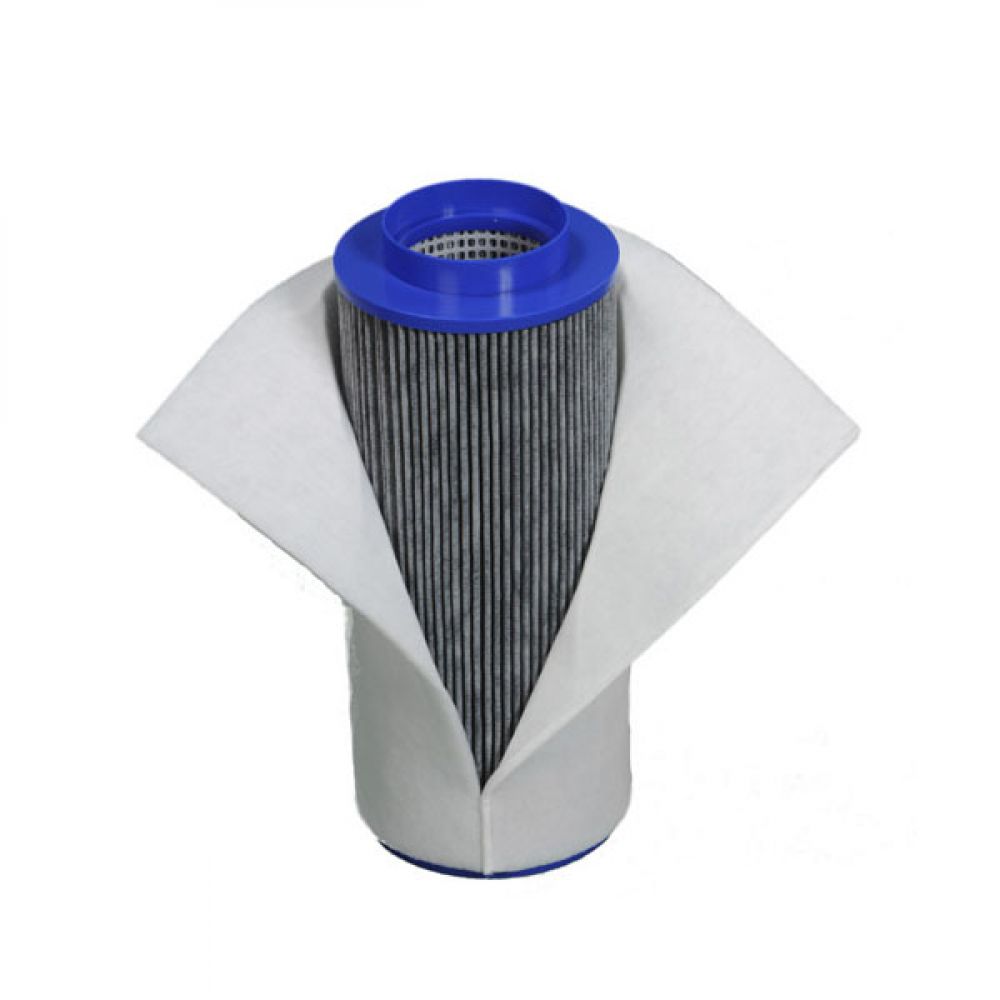

Carbon filters

This material is more effective than others in capturing volatile as well as semi-volatile organic compounds. Therefore, channel carbon ventilation filters are used to absorb relatively "heavy" molecules. This property of coal is given by microscopic pores, and the degree of air purification depends on their number. The more pores, the cleaner the air will come out after the filter.

Another important indicator of channel carbon ventilation filters is the size of the granules. Large granules resist airflow less than small ones.

Charcoal filters are rarely used for pre-cleaning in supply ventilation systems, because they quickly become clogged and fail.

Synthetic filter mats

The basis for the production of filter mats is a synthetic fiber similar to synthetic winterizer. Ventilation filters are equipped with mats of different thicknesses and with different degrees of purification: from EU2 to EU6.

Ventilation filters made of padding polyester can withstand temperatures up to +80 degrees, are not affected by moisture.

Sintepon filters are intended for ventilation of rooms with a high dust load and for the first stage of filtration in painting and varnishing installations.

They are made in the form of ventilation grilles with a synthetic winterizer filter or in the form of a sleeve.

Fiberglass filter mats

Any glass fiber filters have EU2-EU4 cleaning classes. Depending on the variety are used:

- in painting or varnishing installations;

- in furniture production;

- in the automotive industry.

Bactericidal ventilation filters are made from fiberglass. The antibacterial effect is achieved by additional coating of the surface of the fiberglass material with special compounds that repel dust and destroy microbes. Bactericidal fiberglass ventilation filters are usually made in yellow.

They withstand up to 200 degrees Celsius, are not affected by moisture.

Filter mats are sold in rolls. And fiberglass can be ordered according to the required size.The filter material for ventilation is framed with a metal corner and reinforced with a cloth.

Brief video review of HEPA filters for fine air filtration:

Varieties of ventilation filters by cleaning class

For a long and trouble-free service, climate equipment requires reliable cleaning solutions, because without them it quickly becomes clogged with dust and breaks more often. You can get rid of the hassle with the help of ventilation filters and periodic maintenance of air ducts. This is the best way to provide housing with an influx of fresh oxygen, and level the financial costs of buying consumables.

Experts distinguish 3 classes of solutions that differ in the degree of air purification.

Absolute cleaning (first class) - dense material captures the smallest particles up to 0.1 microns in size.

The fabric retains from 96 to 99% of contaminants. They are used mainly in medical institutions, laboratories, scientific complexes, where the requirements for sterility of premises are very high. The main material is glued and submicron fibers.

The effectiveness of these solutions varies from 60 to 95%, depending on the manufacturer and the fabric used. Scope - hospital wards, educational institutions, museums - all those objects that require pure oxygen. To increase efficiency, they are supplemented with coarse cleaning mechanisms.

Coarse ventilation filters (third class) - eliminate microparticles from 10 microns.

They are mainly used in rooms with a high concentration of dust, where there are no special requirements for the degree of oxygen purification.

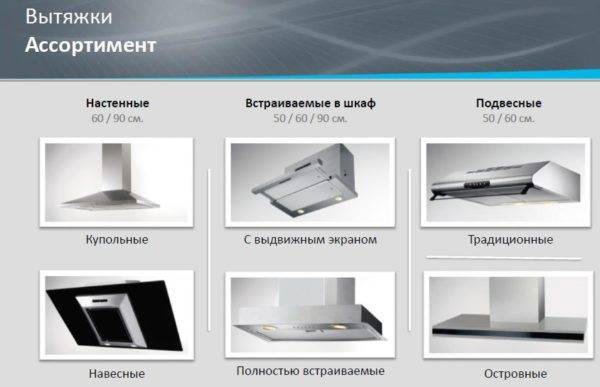

Cooker hood control

The control of the hood, like most kitchen appliances, is mechanical and electronic.In the first case, sliders and various switches make it difficult to wash the unit, but such devices are easy to operate and cheaper.

Fully built-in hood Whirlpool AKR 773/NB with mechanical control

Electronic panels are found in more "fancy" appliances, which are equipped with a number of additional functions (more on them below) and automatic programs - such hoods are more expensive, but also more convenient to use.

Hansa UniQ OKC900UWH sensor hood

For these models, using the control panel, you can select modes, set the timer and power: all values \u200b\u200bare usually displayed on the display.

Features and subtleties of using ventilation filters

Specialized cleaning systems have been created for supply ventilation units, through which street air passes before being supplied to the living space. In cities, the atmosphere is full of dust, plant pollen, exhaust gases. Therefore, air filters for ventilation are an integral part of a comfortable life.

Carbon filters for ventilation

Carbon filters for supply-type ventilation are not effective here. At enterprises, clean air is obtained through the use of complex solutions with a variety of fillers, the use of several products of different purification classes.

The presence of ventilation filters for industrial enterprises is a matter of environmental safety for the cities where these production facilities are located. Most technological processes take place with the parallel formation of stench, harmful toxins, dust with metal and wood fractions. To prevent all this from getting into the lungs of urban residents, filter systems and installations are installed near the sources of pollution.

The principle of operation of the hood

A kitchen hood (kitchen umbrella) is designed to effectively remove and clean polluted air that appears during cooking. In addition, all modern models perfectly cope with local lighting of the working area, and in addition to their main functions, they are one of the most important interior items of the kitchen space.

A kitchen hood (kitchen umbrella) is designed to effectively remove and clean polluted air that appears during cooking. In addition, all modern models perfectly cope with local lighting of the working area, and in addition to their main functions, they are one of the most important interior items of the kitchen space.

A classic kitchen umbrella is a structure inside which a fan is installed that sucks air from the cooking zone into the device. Then the polluted air passes through a system of filters, in which fat, soot, combustion products, fumes and odors settle.

Oil-inertial air filters

All the disadvantages of inertial filters were too obvious, which was a prerequisite for an intensive search for more rational solutions for air purification and led to the creation of inertial oil filters. They significantly exceeded inertial ones in efficiency due to one significant design difference. Engine oil was poured into the bottom of the body of the inertial oil autofilter, which caught and retained polluting particles. Filtering equipment of this type is also reusable. It needs to be cleaned and oil changed regularly. On some types of agricultural machinery, they are still used.

The result of technological research was the appearance in 1953 of a revolutionary new system for filtering the air entering the engine, the basis of which was a paper filter. The new equipment significantly outperformed inertial oil filters in terms of efficiency and service life.

How to choose the most suitable range hood

First of all, you need to calculate what performance of the device will be optimal for you. This is done by multiplying the height of the room by its area. The result obtained must be multiplied by 12 again. The resulting value will be the desired performance of the hood.

The next criterion will be the size of the hood and stove.

Please note that the hood with a filter without a drain makes noise depending on its power. The more power, the louder the device works. Thus, when choosing, consider the size of the entire kitchen. If the area of the room is small, then a powerful hood will make too much noise. The orientation should be an indicator of 40 dB. Such an indicator of the emitted noise is optimal.

When choosing, give preference to models with a large number of adjustment programs. This will allow you to adjust the operation of the hood without an air duct to the amount of pollution.

As you can see, this type of home appliance can be a great solution for cleaning the air in any room. Having studied all the above facts, you can decide whether or not to purchase a hood without connecting to ventilation.

Filter designs and their applications

In addition to the cleaning method, the devices differ in the type of design, which determines the scope of their application. Next, we will get acquainted with their most common types and areas of application.

The pocket filter for ventilation allows you to remove contaminants from the supply and recirculation air masses. Filter materials can be used differently depending on the purpose of the device. Therefore, the degree of purification can be from G3-G4 to F8-F9.

The design of such cleaners is quite simple:

- Metal or plastic frame.

- The filtering module, made in the form of a pocket, which is attached to the frame.

This equipment has a large dust capacity and excellent ability to trap various types of pollution.

Therefore, it is most often used for the following purposes:

- For ventilation systems of food industry enterprises;

- in public buildings;

- in catering establishments;

- In supermarkets, etc.

Since the production of pocket-type ventilation filters is not difficult, their cost is usually quite affordable.

Grille with filter element and fan

Grates with filter

The ventilation grille with filter is very popular in domestic systems. The device is installed in the ventilation hole, the degree of its cleaning depends on the purpose (exhaust or supply).

I must say that there are similar grilles for forced ventilation systems that are equipped with a fan. Installing such a grate with your own hands is quite simple, the main thing is to choose the appropriate diameter of the pipe so that it fits in the vent.

Cassette filter

Cassette and panel type devices

Cassette and panel filters are most often used in kitchen ventilation, both domestic and industrial. There are models in which the cassette is allowed to be washed and reused. As a rule, several layers of galvanized fine-mesh steel mesh are used as their filler.

Some models are disposable, so attempts to clean them will not give a positive result.

In the photo - channel coal cleaner

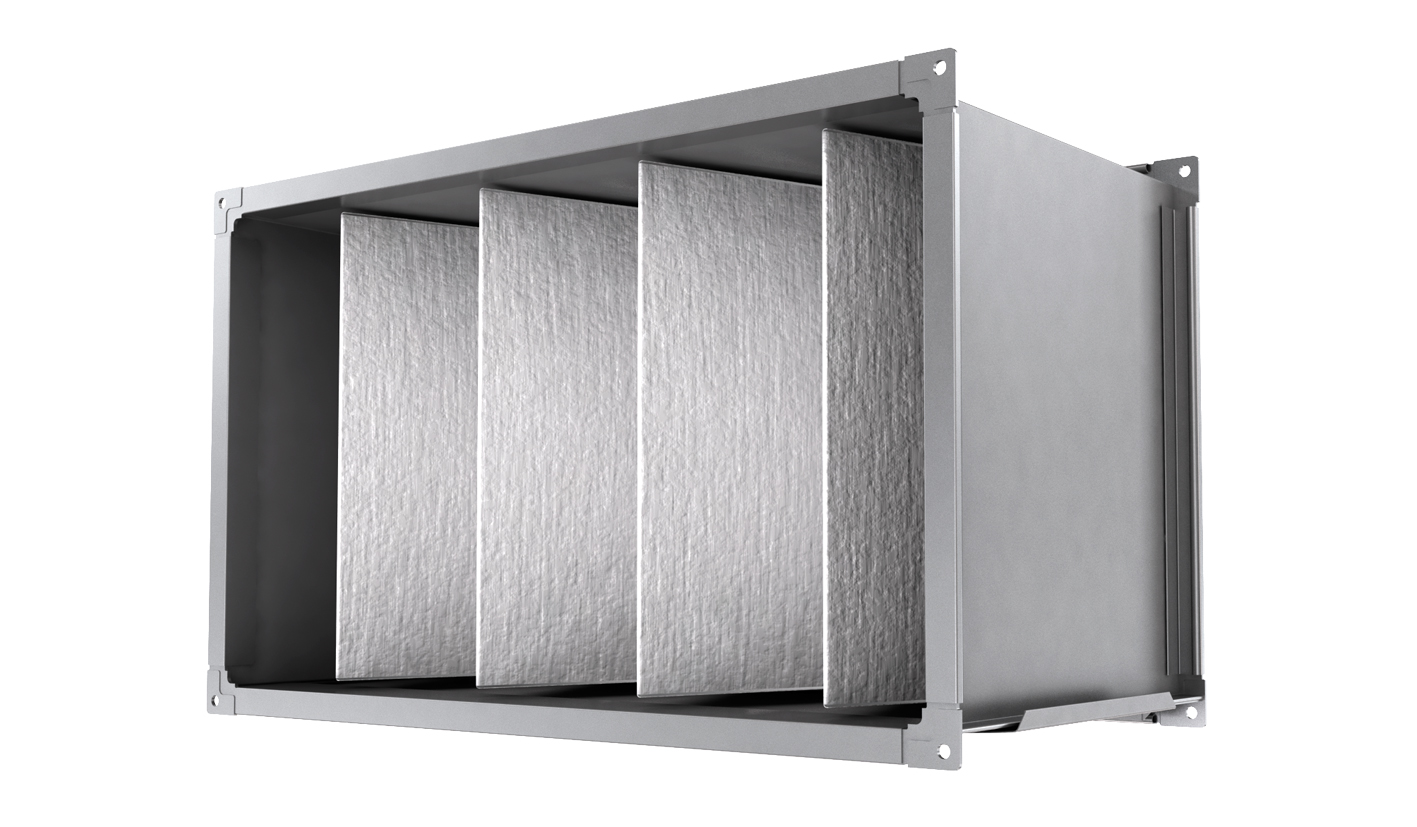

ducted

As the name suggests, duct filters are installed in ventilation ducts.

They come in different sizes and different section shapes, however, their design is always the same and contains only two elements:

- Galvanized body with a quick-release cover, which is attached to the body with latches;

- Filter material located inside the housing.

The most commonly used filter materials are metal mesh or activated carbon. The level of cleaning may vary. For example, a channel carbon filter for ventilation is able to purify the air not only from various mechanical impurities, but also from all kinds of gases and aerosols.

Such cleaners can be used in both industrial and domestic ventilation systems. Standard sizes their standard sizes coincide with standard sizes of other ventilating equipment. Here, perhaps, are all the most common types of filtering devices that are used to purify air in ventilation systems.

Performance and noise of the kitchen hood

We recommend choosing an extractor hood mainly according to its power. This parameter represents the amount of air that the device can clean per unit of time. The larger the kitchen, the higher the performance should be. Best of all - not less than 350 m3 / h. Also, do not forget that with high power, the air will be cleaned faster, but power consumption will also increase.

Suspended hood Bosch Serie | 2 DWP96BC60 with capacity up to 600 m3/h

To select the hood for performance, you will need to multiply the length, width and height of the kitchen room and multiply this figure by 12 (exactly 12 times per hour the air in the room should be updated).If the hood is flowing, then you need to multiply the resulting value by another 1.3. Then the number is rounded up and the closest value is selected performance.

Chimney hood Candy CCE 16 X with a noise level of 50 dB

As for the noise level, it is better that it does not exceed 50 dB. And make sure that the hood is not too powerful for a particular kitchen - otherwise, during its operation, it will seem that you are on the runway.

Mounting Features

The installation procedure for any hood is described in detail in the instructions.

As a rule, installation takes place in 3 stages:

- umbrella installation;

- duct laying, connection to the outlet;

Does your kitchen have a range hood?

Of course! No, but it will be!

Most users install the hoods themselves. However, if there are no suitable tools or self-confidence, specialists are invited. They will quickly, efficiently perform the installation, which will cost a certain amount.

Sometimes you can’t do without the participation of invited masters if you need to perform a hidden installation of an air duct, or the configuration of the kitchen is too complicated.

Sometimes you can’t do without the participation of invited masters if you need to perform a hidden installation of an air duct, or the configuration of the kitchen is too complicated.

Filter media for filters

The main element of the filter is the filter element, which is made of special materials that can withstand normal atmospheric conditions and high aerodynamic loads.

Below are photos of various filter materials for fine air filters (F-class filtration).

Photo of filter material for class F5 filter

Photo of filter material for class F7 filter

Photo of filter material for class F8 filter

Photo of filter material for class F15 filter

Photo of filter material for class F20 filter

Should not emit dust, fibers and harmful substances

The general requirement for all materials used is that when the air flow passes through them, they must not emit dust, fibers or any other substances that have a harmful effect both on humans and on technological processes and equipment in the premises into which air.

Therefore, non-woven filter materials are most often used, for example, polyester fiber, which provides a high level of reliability and air purification, while not having a high cost.

The cost of the filter is largely determined by the cost of the filter material: the higher its filtration capabilities, the more expensive the material and, accordingly, the filter itself. But since filters can also perform special functions (for example, such as eliminating odor, etc.), it is not always possible to save significant money when creating them, since it is these special properties of materials that ultimately determine the final cost of the filter.

Cleaning methods

All types of filtering equipment can be divided into three categories according to the cleaning method:

- Sorption - PVC, rubber crumb, fine gravel or activated carbon are used as a filler.

- Porous (cellular) - they are synthetic or metal meshes, various perforated tapes, woolen fabric, etc. A cellular filter for ventilation can be either impregnated with oil or without it.

- Electrostatic - cleaning of passing air flows is carried out using an electrostatic charge.

Each type of cleaner is good for a particular type of cleaning. Sometimes they are combined to achieve the best result.

Pocket Cleaners

Rating of the best manufacturers

Before making a purchase of a kitchen air purifier, experts recommend that you familiarize yourself in detail with the rating of the most popular models in the price segment that suits you.

Most of our compatriots prefer such brands as Siemens, Bosch, Kronasteel, Hansa, Gorenje, Elikor, Samsung. They successfully combine high quality, reliability, affordable cost and attractive appearance of the products.

Budget models

| Gorenje DU5345W This model is recognized as one of the best hanging air cleaners that will look great in a small kitchen. Productivity — 300 m3/h. Two-stage filtration system, three modes of operation of the axial fan, bright halogen lighting. It is completed with aluminum fatty and coal filters. Control type - push-button. Advantages:

Flaws: High noise level. |

| Elikor Integra 60 Elikor Integra 60 is considered one of the most inexpensive built-in models. The device perfectly copes with the tasks in the kitchens of medium size. A feature of this device is the ability to work in circulation (without connection to ventilation) and in flow modes (with a vent to the ventilation system). Productivity — 400 m3/h. Two speeds, grease filter. Illumination with incandescent lamps. Control type - push-button. Advantages:

Flaws: Weak functionality. |

Middle price segment

| Candy CBT 6130 X Despite the relatively low cost, this built-in model is one of the most inexpensive in the middle price segment. Productivity - 200 m3 / h makes it easy to cope with air purification in a small kitchen. Features: two engines; the ability to work in two modes, a two-stage filtration system, three speeds of rotation of the fan blades. Illumination is halogen. Button control type. Comes with grease and charcoal filter. Advantages:

Flaws:

|

| Zigmund Stein K 003.51 The Zigmund Shtain K 003.51 hood is characterized by a high performance level of 1000 m3/h. The width of 50 cm makes it easy to place the appliance in small kitchens. Features: possibility of work in two modes (removal/recirculation); 3 speeds, grease filter, incandescent lighting. Push-button control makes this model as simple as possible in everyday use. Advantages:

Flaws: Single stage filtration system. |

Premium Models

| Hansa OKC 6726 IH Hansa OKC 6726 IH is a modern dome-type air purifier that will fit into any kitchen design thanks to its striking design. Width - 60 cm. Productivity - 62 m3 / h. Features and functionality: two operating modes (ventilation/absorber); 3 speeds, off timer. Illumination with 2 incandescent lamps. Advantages:

Flaws: Only one grease filter is supplied with the kit. | |

| Bosch DFS 067K50 The products of this brand have earned a reputation as a reliable manufacturer of high-quality household appliances. According to reviews, the Bosch DFS 067K50 built-in kitchen air cleaner has the best value for money today. The device is equipped with a steel body 60 cm wide. Productivity is 700 m3/h. Three operating modes (removal/circulation/intensive); 4 speeds; touch control. Cleaning system: grease filter with contamination indicator and the possibility of installing an active filter element. The device is equipped with a timer and LED backlight. Advantages:

The disadvantage is the high cost. |