- Do-it-yourself procedure for installing a drainage well

- For storm sewers

- For a septic tank

- Water purification septic tank

- Installation of a septic tank

- Filter well

- Types of filtering facilities

- Absorption well in the drainage and storm system

- Filtration structure in the sewer system

- Do-it-yourself installation of a filter well for sewage (video)

- Purpose and features of filtration wells

- Purpose and principle of operation of the filter well

- Installing a filter well

- We make such a well from improvised means: from bricks and tires

- Structural features of the PF

- Typical device diagram

- Design and materials for the manufacture of drainage wells

- Video of installation of a plastic drainage well

- Materials for wells and their features

- Video making a drainage well from bricks with your own hands

Do-it-yourself procedure for installing a drainage well

Regardless of the purpose of the well, the sequence of work on its installation can be considered typical, and yet there are some nuances.

For storm sewers

Since the sequence of installation work is the same for all types of drainage wells, we will consider it using the example of a reinforced concrete well for storm sewers.

For the prompt execution of installation work, it is necessary to prepare in advance:

- reinforced concrete rings;

- a concrete slab for the device of the bottom of the tank or components necessary for the device of a concrete screed;

- bituminous mastic or liquid glass for sealing joints;

- rammer and trowel.

In addition, it is necessary to provide for the possibility of arrival of heavy lifting equipment.

The sequence of operations is as follows:

The marking of the main elements of the system is being carried out and earthworks are being carried out (digging trenches and a foundation pit for a well).

At the bottom of the pit, a sand cushion is arranged, which is carefully rammed. For greater efficiency, sand is spilled with water.

A reinforced concrete slab is laid on the compacted sand layer or a reinforced concrete screed is poured, the thickness of which must be at least 100 mm

In the process of performing these works, it is extremely important to achieve the horizontalness of the concrete base.

Holes for pipes are formed in reinforced concrete rings in pre-marked places. The outer surface of the rings is abundantly covered with bituminous mastic or liquid glass.

Using a hoist, the support ring is slowly raised and lowered onto the concrete base.

If it is necessary to install several rings, cement mortar is applied to the upper end of the previous one and only after that the next ring is installed.

Pipes are installed in pre-prepared holes, and the remaining cracks and gaps are sealed with cement mortar

After the solution has completely dried, the installation sites of the nozzles are treated with bituminous mastic or liquid glass. In addition, the bottom of the mine must also be covered with mastic.

The last ring is covered with a concrete slab with a hole in which the neck of the well is installed.The neck installed in this way is covered with a hatch or a special grate.

The gap between the outer surface of the rings and the ground is half filled with sand and rammed. The rest of the space is covered with earth to the very surface. After the poured soil has finally settled, a blind area of cement mortar is equipped around the perimeter.

Important! Before starting the operation of the drainage well, it is necessary to make sure that it is tight. To do this, the pipes overlap and fill the tank with water.

If the water level does not drop within 3-4 days, the well is ready for operation.

For a septic tank

Grouting drainage wells have some similarities with a conventional cesspool. They also do not have a bottom and, after filtration, allow them to freely go into the soil.

Wells for a septic tank are quite simple, so they can be assembled on their own from improvised materials. The sequence of installation work is as follows.

- Dig a hole, the volume of which exceeds the volume of the future septic tank.

- Install a set of concrete rings, a set of tires or a large plastic barrel without a bottom into the pit, in other words, form the side walls of the well. In addition to the materials listed above, you can use brick, laying it, leaving special drainage windows.

- Cover the bottom of the well with crushed stone or coarse sand.

- To ensure intensive drainage, special drainage holes are made in the side walls of the well at a height of 500 to 800 mm.

- Using sewer pipes, connect the septic tank to the well and connect additional ventilation. Otherwise, "airing" of the system is possible.

- Carefully seal the entrance to the septic tank.

- Cover the space between the outer surface of the tank and the walls of the pit with sand and soil.

At this point, work on the drainage equipment for the septic tank can be considered completed.

Important! Drainage wells should be buried below the level of clay, in addition, the level of groundwater at the site of the well should be at least 2 m.

The construction of drainage wells is not particularly difficult, but requires accurate technical documentation. Properly installed wells significantly increase the efficiency of the drainage system as a whole.

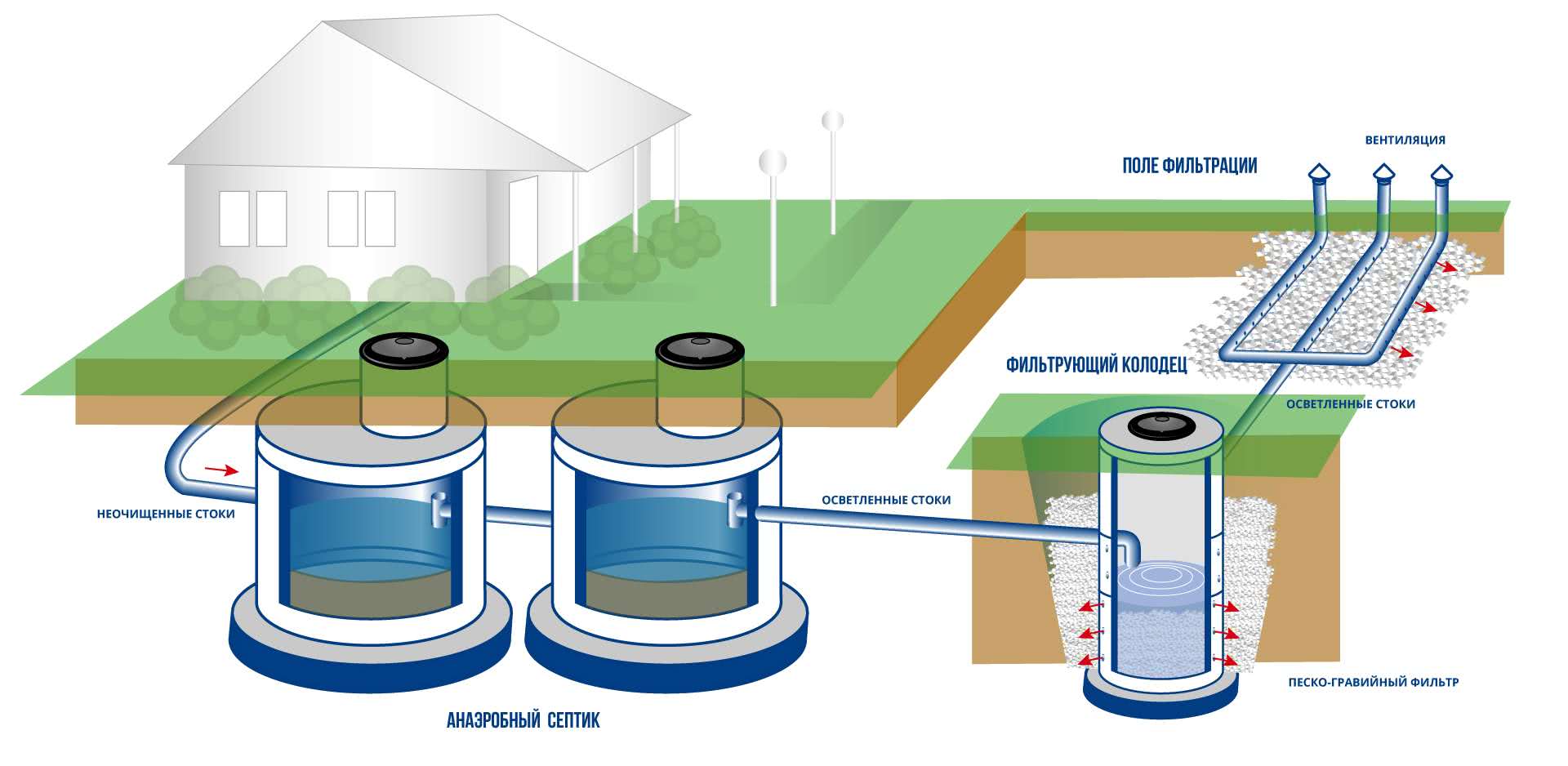

Water purification septic tank

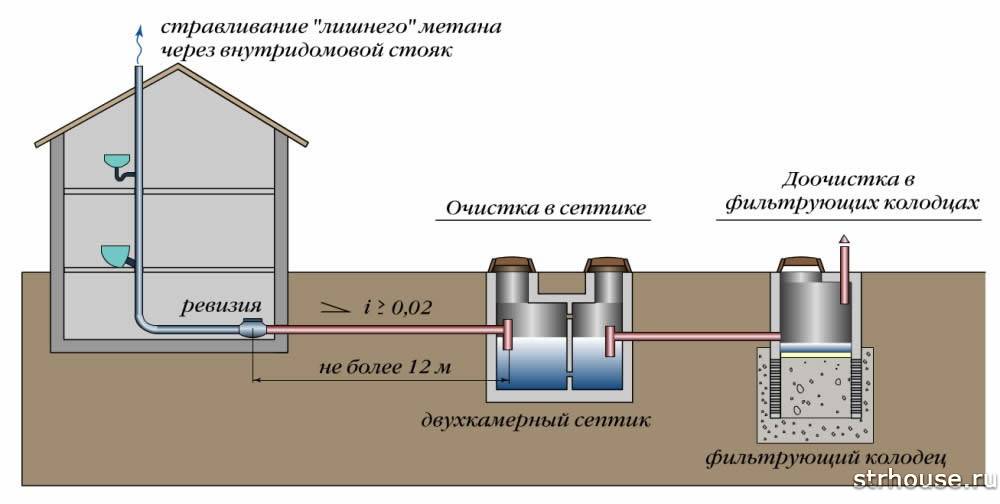

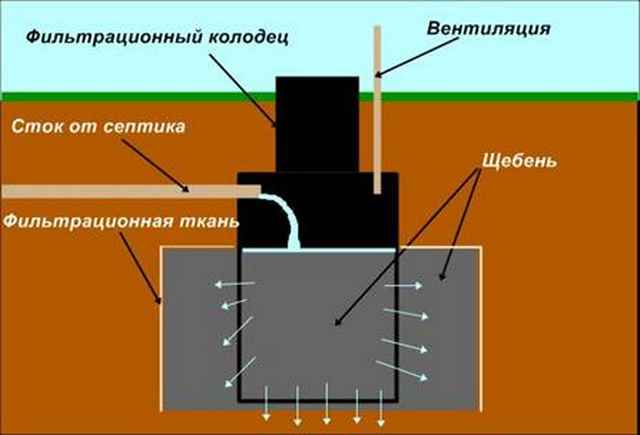

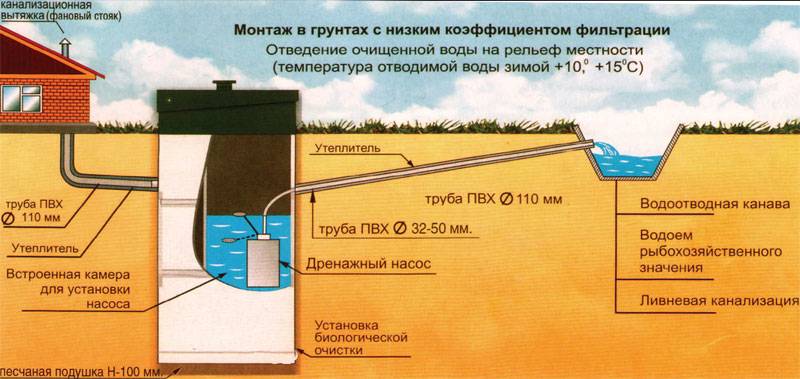

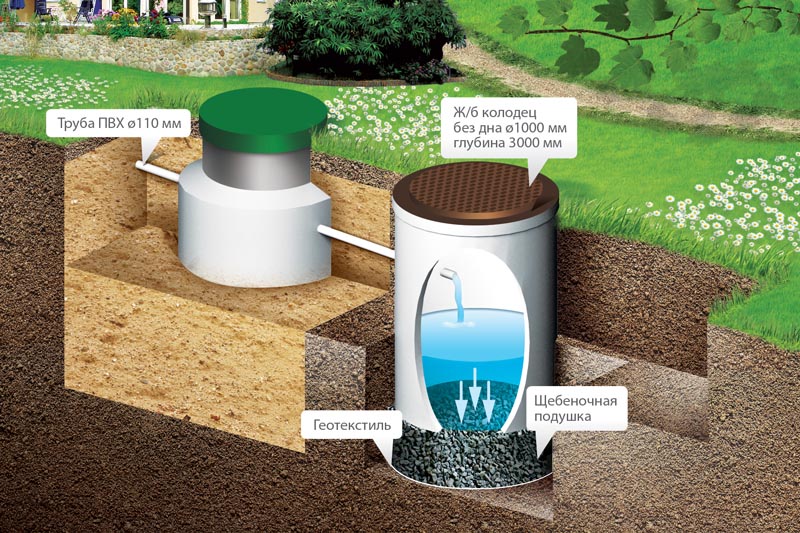

Water purification takes place in two stages. Initially, waste water enters the septic tank. In it, solid particles will precipitate and be processed by aerobic microbes. Then the water ends up in a filtering well, where it is already processed in a purified form by filters and goes into the ground. Pollution of the soil and the environment does not occur during such cleaning.

When installing a treatment system of this type, it is necessary to make internal wiring in the house. To do this, to a common pipe with a diameter of 300 mm, pipes are diverted from all sources of water output:

- bathroom,

- kitchen sink,

- dishwasher.

At the exit of the common pipe from the house, a water seal or a conventional elbow is installed to prevent unpleasant odors from entering the house.

Installation of a septic tank

The next step is to install a septic tank. The place for its location should be no closer than ten meters from all buildings, including outbuildings. In the event that the water consumption is up to 1 m3 / day, then installing a single-chamber septic tank with dimensions of 1x1.5 m and 1.5 m in depth will be enough.

If you plan to use a larger volume of water, then you need a two-chamber septic tank with the first chamber in 75% of the entire treated liquid. It is not difficult to choose a septic tank that is suitable in terms of volume and quality today, since there are a large number of manufacturers with various offers on the market.

For example, under the Topas septic tank or any other, it is necessary to dig a pit 20-30 cm larger than the size of the septic tank itself. A neck must be left above the surface of the pit.

Before digging into the pit, the septic tank is filled with water, otherwise the mixture of earth and sand can press in and deform its walls. After installing the vessel, a pipe outlet is made with a slope of at least 2 cm, connected to the filter well.

Filter well

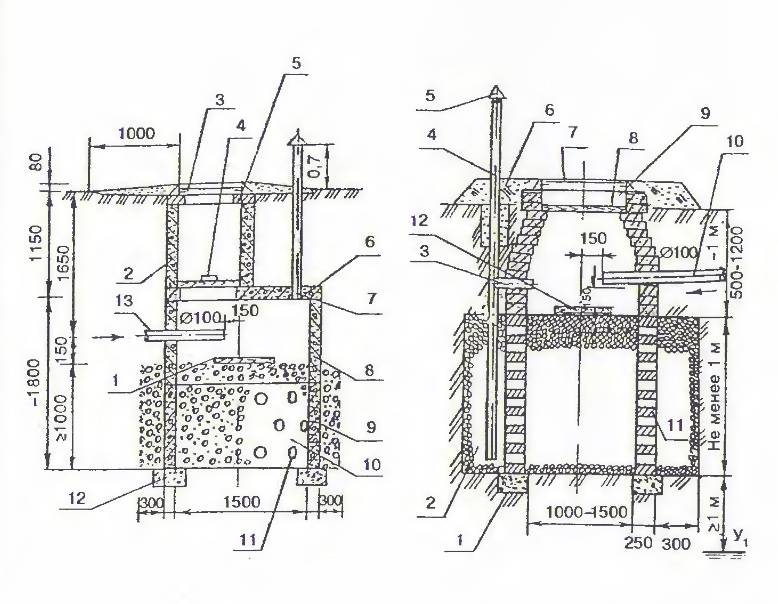

When constructing a filter well, brick, rubble stone or concrete rings are required. The well should be located no closer than 10 m from any buildings, structures, objects in the event that groundwater is located at least 1 m from the bottom of the well.

- With plans for water consumption, not more than 0.5 m3 / day for sandy soils, a well with parameters of 1x1 m is required, for sandy loamy 1.5x1.5 m.

- With a volume of up to 1 m3 / day, then for sandy 1.5x1.5 m, for sandy loam - 2x2 m, respectively.

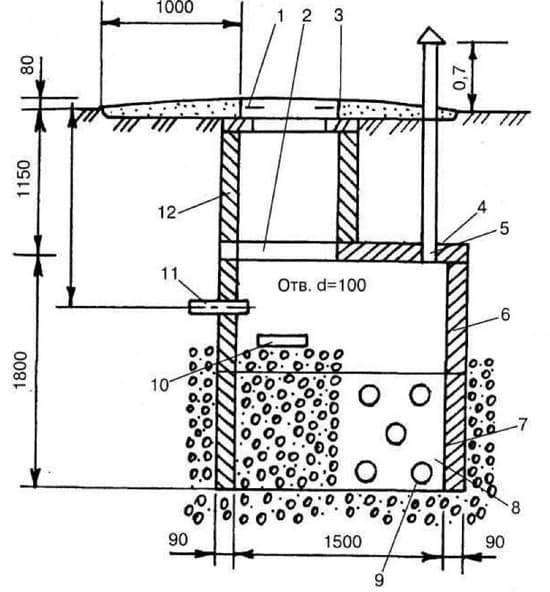

The finished pit is equipped with concrete rings. A filter is laid at its bottom, the material for which can be brick fragments, crushed stone, slag, gravel of various sizes, for example, from 10 to 70 mm. The embankment is formed with a thickness of 400-500 mm. In the same way, with the same material and the same height, the upper part of the well is filled up.

Holes are made in the walls located directly next to the filter.Usually, over that part of the well that is located above the filter, they make an exhaust hood with a ventilation pipe and a wind vane.

Above the ground, it should rise no less than 50-70 cm in height. The well can be covered by a concrete slab with a technological hatch. But it is possible to manufacture floors from wood, only their service life is much less.

Types of filtering facilities

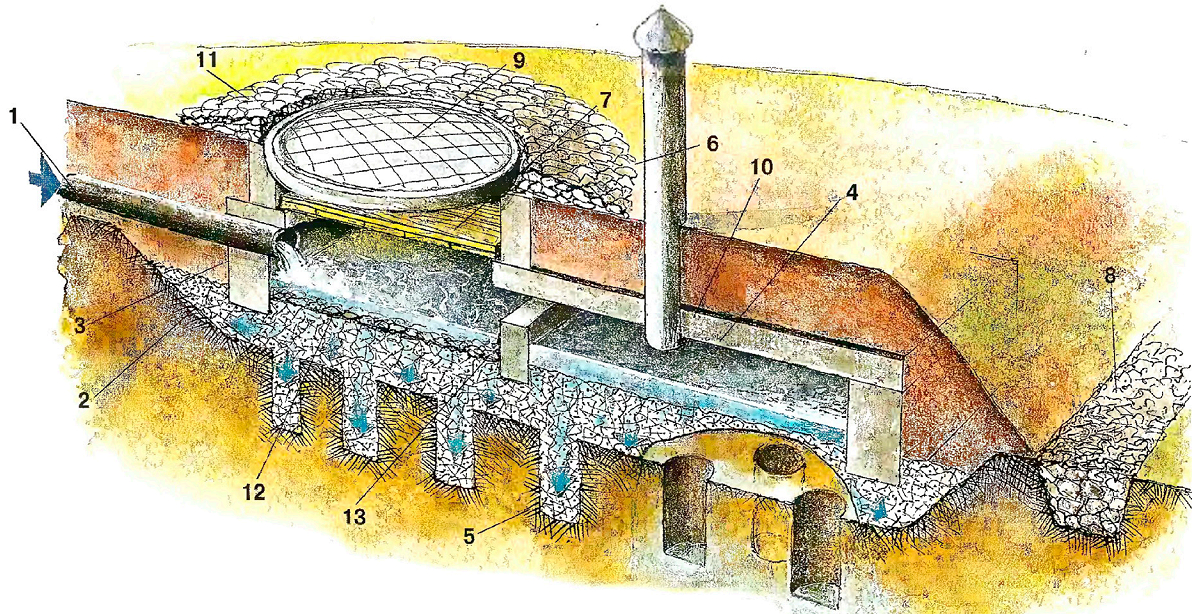

There are two types of filtration well structures that operate on the same principle and are installed in a similar way. Their differences are in the field of application. The former are used in the drainage and storm system, the latter in the sewer.

Absorption well in the drainage and storm system

In this case, drainage absorption wells are the end point of a complex drainage system of the site, where groundwater or rainwater rushes through the pipeline, so that later, after passing through a natural filter, it goes into the ground. Its main purpose is to divert water from the house and clean it from silt and sand.

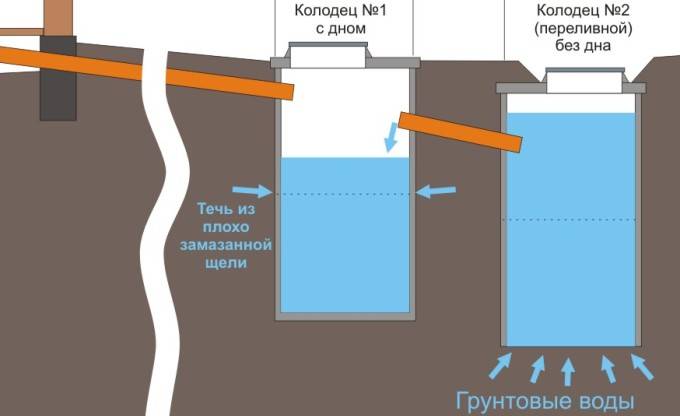

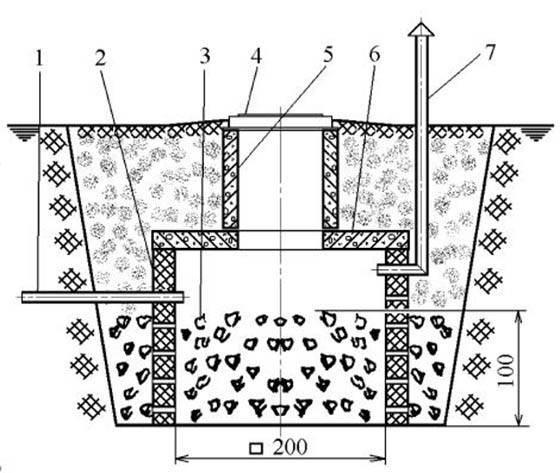

The diagram shows the organization of storm and drainage sewerage of a site with a drive. In soils with a high absorption capacity, instead of a collector, a filtration well is installed

The diameter of such wells, as a rule, is no more than one and a half, and the depth of occurrence is up to two meters. It is allowed to drain both systems into one well. The filter tank is installed at the lowest point of the site so that water flows into it by natural gravity.

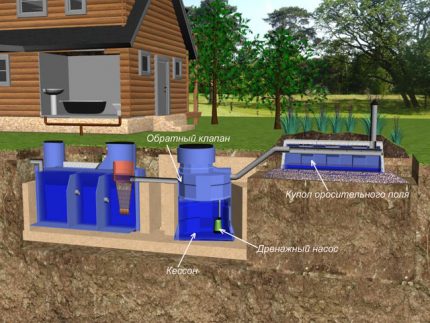

Filtration structure in the sewer system

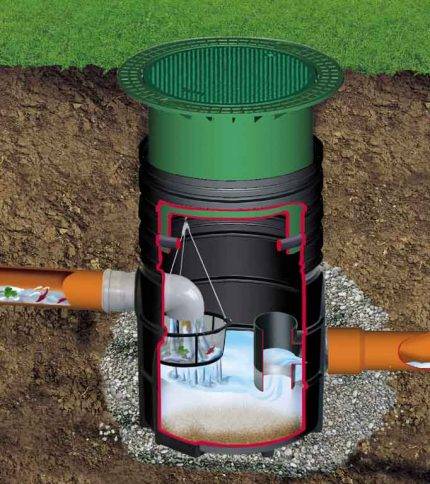

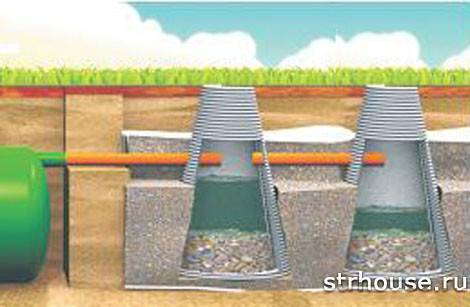

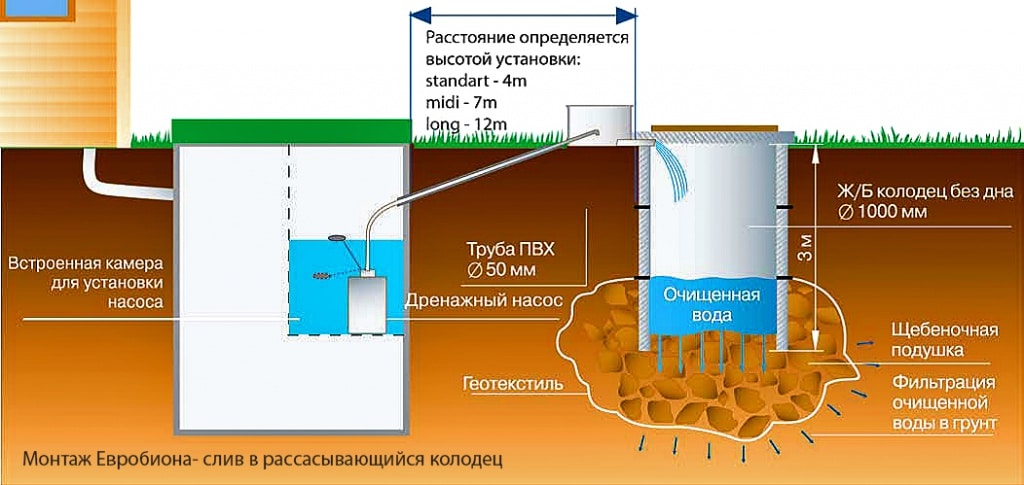

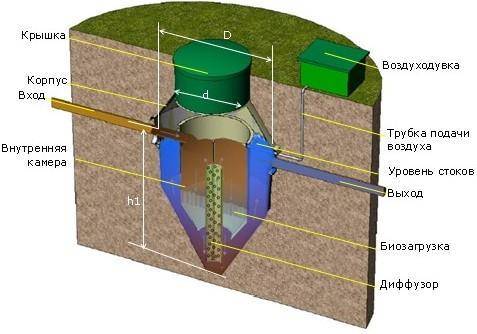

In the sewer system of the site, absorption wells are used for post-treatment of wastewater coming from a hermetically sealed reservoir, in which wastewater undergoes primary biological treatment. The tank is made of concrete rings, brick or rubble stone, or a ready-made septic tank is used.

Scheme of installation of a filtration well with a septic tank, in which sewage flows undergo primary treatment, and then they enter the absorption tank through the pipe and go into the soil through the filter system

The principle of operation of the system is as follows: sewage from the house sewer enters a sealed container, where it is oxidized for two to three days under the influence of anaerobic bacteria living in an airless space. Then the wastewater enters the filtration well, where other bacteria - aerobes - are already present. Their vital activity is activated under the influence of oxygen.

As a result of double purification, the liquid entering the soil from the absorption well is almost completely rid of harmful microorganisms and organic substances.

Wastewater disposal can be organized in two ways:

- Separate. Water from the kitchen, bath, washing machines goes into the septic tank, and sewage with feces goes into the cesspool.

- Joint. All household waste goes to a septic tank or storage tank.

As a rule, in the first case, gray effluents are sent to different sewer facilities. For example, fecal - into a storage well with subsequent pumping and removal, gray domestic wastewater from kitchen sinks, bathtubs, washbasins, etc. devices - in the absorption wells.

In the second case, a septic tank is needed, consisting of two or three chambers, in each of which its own cleaning stage is sequentially carried out. Fecal masses settle in the first chamber, from where they are periodically pumped out by a sewage machine.

A single-chamber septic tank is usually installed in individual farms in which a separate sewerage system is organized

The second chamber receives liquid waste without suspended particles with a minimum amount of impurities, where they undergo further purification. After that, the water passes through the pipes into the filtration well, from where, after passing through a natural filter, it goes into the soil.

The second variant of the joint scheme is the complete pumping and removal of wastewater.

Do-it-yourself installation of a filter well for sewage (video)

- wheelbarrow;

- shovel;

- a hammer;

- construction knife;

- axe;

- hacksaw for wood and metal;

- roulette.

- Organization of the access road. Having chosen a place for such a treatment device, it is necessary to provide an access road to it. Over time, a lot of silt forms at the bottom of its structure, and the filter ceases to cope with its purpose. In this case, you can not do without the help of a sewage machine.

- Digging out a pit. If reinforced concrete rings are used for the shaft walls, then the process involves first installing the first ring. Then you need to dig from the inside of the ring, throwing the earth out. The ring will gradually sink into the ground under the influence of its mass. After the first ring descends underground to its full height, bricks are laid, in which holes are provided in a checkerboard pattern. After that, the next ring is installed and digging of the pit continues.

- Pipe installation. Through it, wastewater leaving the septic tank will flow to the filter. It should be placed 10 cm above the bottom filter under a slope.

- Arrangement of the filter pad. For the bottom filter, the center is filled with: gravel, expanded clay, slag of large fractions, and its smaller particles near the walls. At a level of 15 cm from the bottom filter, a hole is made to the septic tank.

- Overlap installation. It can be used as a plastic cover of a suitable diameter or a home-made wooden round ceiling. If the filtration device is used all year round, then it makes sense to provide for the installation of two covers, between which a gap will be made. In this space, it will be necessary to distribute the insulation in the form of mineral wool or a foam sheet. In order to make it convenient to check the condition if necessary, a closing hatch should be provided inside the filtration device, the diameter of which should be at least 70 cm.

After digging and arranging the mine, it is covered with a large layer of earth. In order not to spoil the landscape view of the site, this place must be decorated in any way you like.

The design of the well can be arbitrary, but one condition must be met - compliance with the task of ensuring water filtration, which can come with varying intensity.

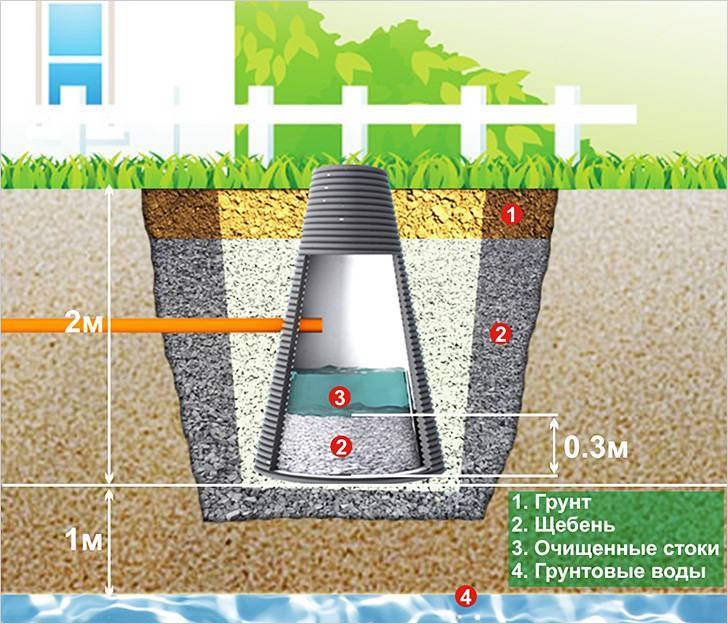

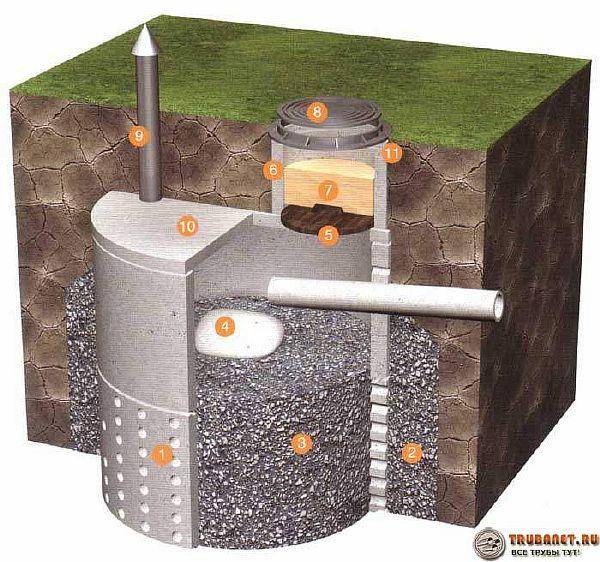

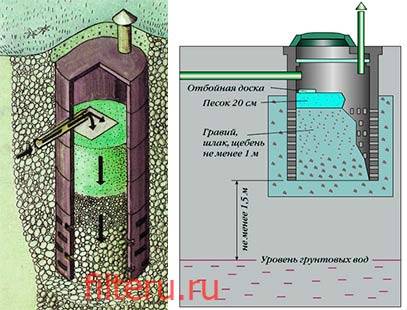

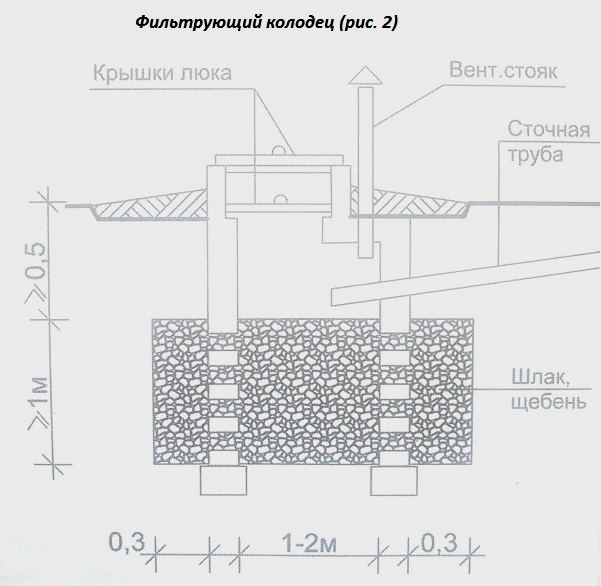

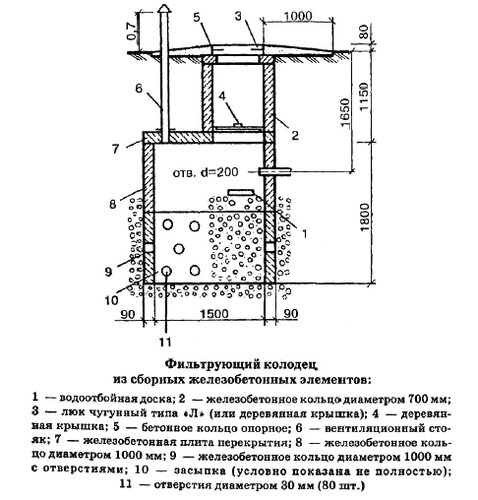

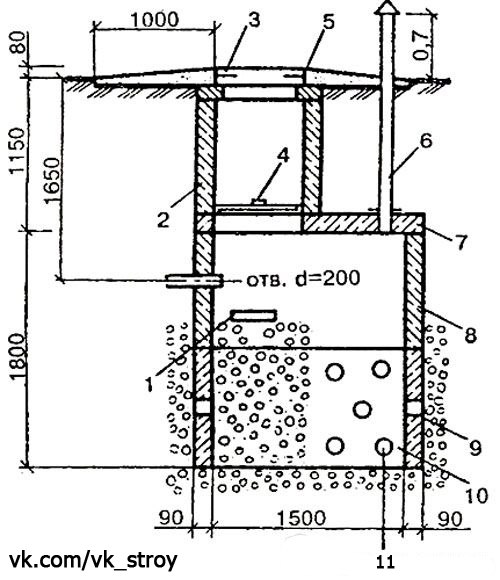

To select the most appropriate type of treatment plant in specific conditions, a number of circumstances should be taken into account, including: the presence of an aquifer, the presence of a conventional well, and the type of soil. PICTURE 1 illustrates the design of the filter well, as well as the standards that should be taken into account when deepening.

In some cases, certain circumstances do not allow equipping a filter well, but if subjective and objective conditions favor the use of this cleaning element, it would be quite logical to ask in which side of the site it is preferable to place it. So, you can easily arrange a filter system with your own hands on soils suitable for filtration, among them: sandy, sandy loam, peat.

Image 1. The design of the filter well.

When trying to build such a filter in clay soil, there is a possibility that the system will not take root there. The filtration area is also important for the filter well, which can be equal to an indicator in the range of 1.5 m², which is true for sandy loam, and 3 m² for sand. The larger the filtering area of the system, the longer its service life will be. IMAGE 2 shows how the walls of the well can be laid using bricks.

In order for the filtering well to be able to fully cope with the assigned tasks, it must be located in a section where it is below the level on which the filtering bottom is located, which is a pillow made of crushed stone. In this case, the distance from the bottom to the water should be at least 0.5 m. The base of the system should be 1 m above the groundwater level. If the territory is characterized by a high groundwater level, in this case it is preferable to refuse to install a filter well.

Purpose and features of filtration wells

The issues of ecology and environmental protection are very acute today.Untreated sewage, if it flows directly into water bodies or soil from domestic sewage, can serve as a source of water and soil contamination.

Therefore, it is strictly forbidden to do so. Before entering open sources or leaving the ground, dirty domestic water must necessarily go through a purification system.

There are various ways to purify wastewater, one of which is an absorption well, which acts as a kind of natural multilayer filter. It retains dirt, debris and other particles, and passes purified water into the soil.

Image gallery

Photo from

An absorption well, also known as a filter well, is an object of the sewer system designed for the disposal of treated wastewater.

In the schemes of an autonomous sewerage device, an absorption well is installed after a septic tank that cleans wastewater by 95%.

The filter well is used in tandem with both industrial and home-made septic tanks that clean gray drains

In fact, an absorption well is a drain pit, equipped with a soil filter with a capacity of 1 m

The device of absorption wells can be carried out only in non-cohesive soils: sands, except for fine and dusty clay, gravel and crushed stone deposits

Treated wastewater that has undergone ground post-treatment in the absorption well should be freely absorbed by the surrounding soils.

In the case of penetration into soils with low filtration qualities, for example, into silty sand or sandy loam, the absorption area is increased by installing perforated brick walls or concrete rings.

Another option for increasing the throughput is to install it inside a perforated pipe, buried 1.5 - 2 m below the conditional bottom of the soil filter

Functional purpose in the sewer

The location of the absorption well after the septic tank

Part of an autonomous purification system

Absorption well prototype

Technical conditions for the construction of a filter well

Filtration qualities of the surrounding soils

Perforated walls of the absorption well

Improved absorber design

A distinctive feature of the filtering structures is the absence of a sealed bottom. At the bottom of the well, a bottom filter made of crushed stone, gravel, broken bricks and other similar building materials is equipped. The total height of the filter bed should be up to one meter.

A filter well, as a rule, is equipped in areas that are not equipped with a drain sewer, as well as in places where there are no natural reservoirs nearby to drain water.

It can be used as an independent structure in the arrangement of a drainage system or storm sewer, or for the post-treatment of wastewater that has undergone preliminary treatment in a septic tank.

The function of the filter well is to pass the liquid flowing through the pipes through the natural filter system and drain the already purified water deep into the ground

This is interesting: Fan pipe - technology fan riser devices

Purpose and principle of operation of the filter well

The filter well is used as a natural wastewater purifier. It is used in the absence of sewerage and the ability to bring domestic water into a reservoir intended for such waste.

The picture explains the operation of such a well

The domestic water treatment system is quite simple.

Water from the house enters the septic tank or sump, where some of the heavy particles settle. Partially purified water is discharged through a pipe into a container.

A filter well for a septic tank is used not only as a place for water drainage, but also as an additional filter, where the last stage of cleaning ends and the liquid is sucked into the ground. If the volume of household waste is not more than 1 cubic meter per day, then a cleaning tank is mounted on the site as an independent structure. Otherwise, it performs the function of water treatment.

The structure is mounted at a distance of 30 meters from the source of drinking water.

Installing a filter well

First of all, it should be noted that the cleaning well is only suitable for certain types of soil.

Sandy soil, peat, loose rock soil, which contain some clay, are an excellent place for the full functioning of the natural filter. A filter well in clay will not fully fulfill its functions, since clay, by its very nature, does not pass water very well. For soils that poorly cleanse and absorb liquid, there are other ways to purify water.

In addition, the soil also affects the area of \u200b\u200bthe structure and its service life. The efficiency of the filter is achieved due to the depth of groundwater, which should be half a meter lower than the well bottom.

Advice. A filter well with a high level of groundwater should not be installed, since the water will not be able to be absorbed into the ground. It is also worth considering the depth of soil freezing in winter.

The filter well consists of:

- overlaps;

- walls (concrete, brick, tires, plastic barrels);

- bottom filter (crushed stone, brick, slag, gravel);

Under the bottom filter is meant a mound at the bottom with a height of about a meter. Large particles are placed in the middle, and small ones along the perimeter.

An example of a stone bottom filter

Waste water is in a septic tank before it enters the treatment tank. Then it moves through the pipe to the well.

The distance between the septic tank and the filter well should be 20 cm.

The walls for the well can be a barrel, brick, stone, standard concrete rings and tires. The main thing is that they have holes with a diameter of up to 10 cm and are staggered.

The filter container must be equipped with a ventilation pipe with a diameter of 10 cm. Above ground level, the pipe must be at a height of about a meter.

The standard dimensions of modern filter tanks are 2 meters in diameter and 3 meters deep. They are built square or round in shape. A few years after the start of operation of the sewage filter and the appearance of the first problems, everyone asks himself the question of how to restore the filtration of the filter well.

And stops letting water into the ground. To slow down this process, experts recommend installing several water septic tanks. And in case of strong silting, call the car a vacuum cleaner.

We make such a well from improvised means: from bricks and tires

To install a filter well, a large pit is dug out of brick. The formwork is installed and lined with bricks. The stone lies at a short distance. A drainage layer is poured at the bottom of the tank. And the top is closed with a wooden or plastic lid.

Example of a well from used tires

A cheap and affordable option is to create a filter well from tires. Most often, automobile and tractor tires are selected for this purpose. Such a structure is not durable, but it can serve for more than 10 years for the benefit of the environment.

The process of arranging the container is quite simple.

At the beginning, a hole is dug along the diameter of the tires and covered with rubble about 30 cm thick. The remains of brick and slag are also suitable. In addition, the space between the tires is filled with rubble. A hole for the pipe is cut in the top tire. To ensure waterproofing from the outside, tires are wrapped in dense polyethylene or roofing material.

The installation of a filter well is a must for any country house where there is no central sewerage system. This will help protect groundwater from contamination by hazardous chemical particles.

The video shows the process of building a filter well. Be sure to check it out.

Structural features of the PF

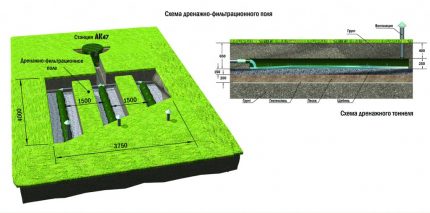

The filtration field is a relatively large piece of land on which the secondary purification of the liquid takes place.

This cleaning method is exclusively biological, natural in nature, and its value is in saving money (no need to buy additional devices or filters).

The dimensions of the PF depend on the area of the free territory and the landscape features of the garden plot. If there is not enough space, instead of PF, an absorbing well is arranged, which also filters the liquid before it enters the ground

The dimensions of the PF depend on the area of the free territory and the landscape features of the garden plot. If there is not enough space, instead of PF, an absorbing well is arranged, which also filters the liquid before it enters the ground

A typical filtration field device is a system of parallel-laid drainage pipes (drains) that extend from the collector and are placed at regular intervals in ditches with a thick sand and gravel layer.

Previously, asbestos-cement pipes were used, now there is a more reliable and economical option - plastic drains. A prerequisite is the presence of ventilation (vertically installed risers that provide oxygen access to the pipes).

The design of the system is aimed at ensuring that the liquid is evenly distributed over the allocated area and has the maximum degree of purification, so there are several important points:

- distance between drains - 1.5 m;

- length of drainage pipes - no more than 20 m;

- pipe diameter - 0.11 m;

- intervals between ventilation risers - no more than 4 m;

- the height of the risers above ground level is not less than 0.5 m.

In order for the natural movement of the liquid to take place, the pipes have a slope of 2 cm / m. Each drain is surrounded by a filtering "cushion" of sand and pebbles (crushed stone, gravel), and is also protected from the ground by a geotextile.

One of the complex options for the device: after cleaning at the filtration field, water enters the storage well, from where it is pumped out using a pump. Its further path is to a pond or ditch, as well as to the surface - for irrigation and technical needs.

One of the complex options for the device: after cleaning at the filtration field, water enters the storage well, from where it is pumped out using a pump. Its further path is to a pond or ditch, as well as to the surface - for irrigation and technical needs.

There is one condition, without which the installation of a septic tank with a filtration field is impractical. Special permeability properties of the soil are required, that is, on loose coarse and fine clastic soils that do not have a connection between particles, it is possible to build a post-treatment system, and dense clay soils, the particles of which are connected in a consolidated manner, are not suitable for this.

Typical device diagram

Whatever the general dimensions of the filtration field, its design consists of the following parts:

- collector (control well, distribution well);

- networks of plastic drains (drainage pipes with holes);

- ventilation risers;

- filter pad.

Traditionally, the drainage layer is poured from sand and gravel (crushed stone, pebbles). Geotextiles are used to protect drains. The sewer system with PF looks like this:

Pay attention to the thickness of the drainage pad. The minimum indicator is considered to be a total thickness of 1 m, in this diagram it is more: crushed stone - 0.3-0.4 m, sand - 0.8-1 m. When building a filtration field with your own hands, it is not necessary to build a collector yourself - on sale you can find plastic sewer containers of the right volume

When building a filtration field with your own hands, it is not necessary to build a collector yourself - on sale you can find plastic sewer containers of the required volume.

Often they do without a distribution well, directly connecting the septic tank and the pipe system - but this is convenient for small PFs.

Diagram of a filtration field with an area of 4 m x 3.75 m. The distance between the drains is 1.5 m, each drainage pipe is equipped with a ventilation riser. As an underground filter - a "cushion" of sand and gravel with a layer of geotextile

Diagram of a filtration field with an area of 4 m x 3.75 m. The distance between the drains is 1.5 m, each drainage pipe is equipped with a ventilation riser. As an underground filter - a "cushion" of sand and gravel with a layer of geotextile

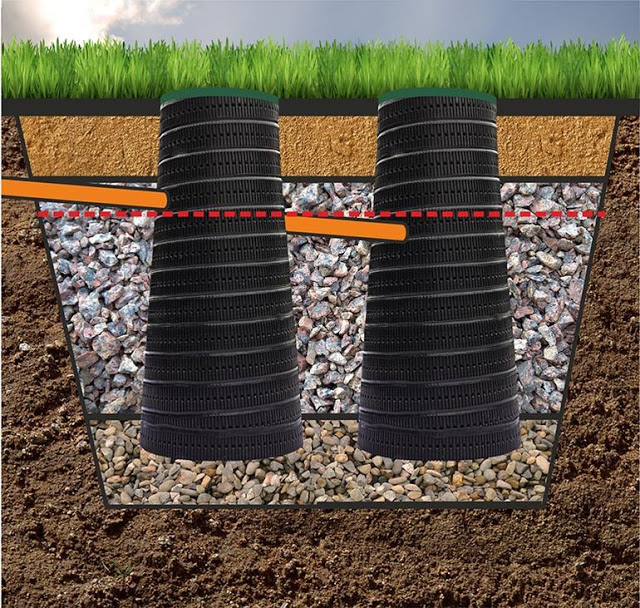

Sometimes, instead of PF, ready-made plastic devices - infiltrators - are used. They help out when there is a shortage of free space, and the soil does not have layers of loam with sandy loam and has sufficient throughput properties.

If desired, you can install several infiltrators connected by pipes in series.

Scheme of a local sewer system with an infiltrator.It is not recommended to break flower beds on filtration fields, as the root system can damage the pipes. For the infiltrator, on the contrary, flower decor is the most acceptable option.

Scheme of a local sewer system with an infiltrator.It is not recommended to break flower beds on filtration fields, as the root system can damage the pipes. For the infiltrator, on the contrary, flower decor is the most acceptable option.

Next, consider how to properly design and install the PF.

Design and materials for the manufacture of drainage wells

Why a drainage well is needed is understandable, now let's deal with the design features. The system consists of the following parts:

- The tray (kinet) can be a through passage, located perpendicular to the corrugated pipe or a tee;

- A shaft, the role of which is played by a corrugated pipe with a socket or a smooth-walled piece of pipe without a socket. The length is at least 2 m. The neck is connected to the storm water inlet by means of an elastic rubber coupling.

In order for the system to work smoothly in spring and autumn, it is necessary to clean the pipes from silt with a long stick, a watering hose, or simply by hand, if possible.

It is important to have a cover that closes the drainage well, this protects against excess pollution.

Video of installation of a plastic drainage well

The purpose of the wells is different:

- Inspection, revision tanks, designed not for the accumulation of water, but for cleaning, monitoring the operation of the system. Settled in the upper sections, representing a pipe with a pair of nozzles. They are quickly cleaned under the pressure of water and can play the role of a rotary element in the well.

- Variable. To smooth out large drops in the system, there are overflow wells with nozzles located at different heights. Shown for arrangement in areas with an unstable level of relief.

- Absorption / filtering.Serve for accumulation of volumes of water and are shown for arrangement on sandy soils. Large dimensions (2-5 m. Depth and 1.5 m or more in diameter), the absence of a bottom with a filter layer of gravel, crushed stone or stone, allow you to quickly build a well of this type on the site yourself.

- Storage wells are installed at the lowest point of the drainage system. It is imperative to have a pumping pump, through which excess water is removed if there is no possibility of discharging moisture into a ditch, river.

Materials for wells and their features

It is worth considering some of the most popular materials used for manufacturing:

- Concrete reinforced wells. These are standard reinforced concrete rings manufactured industrially. Such a drainage well is installed using heavy equipment, which is inconvenient. In addition, the system is financially expensive, prone to destruction;

- plastic structures. Polyethylene, PVC, polypropylene are used for production. Differ in tightness, are equipped with branches for pipes, cuffs. Additional strength is given by the use of a corrugated surface in a special way, which allows the pipes to withstand the pressure of the ground perfectly.

- Brick drainage wells. Very comfortable durable structures, but requiring special skills and knowledge in the arrangement. Because of what the price of the system is extremely high.

- A drainage well from improvised means is the most popular type, well known to summer residents. Low cost is a plus, but low reliability and a short period of use are a minus of the design.

Among all the proposed types, consumers most often purchase plastic systems. Positive product characteristics:

- Extremely light weight;

- Ease of installation;

- Very affordable price;

- High rigidity of rings;

- Impeccable corrosion resistance to external influences;

- Frost resistance;

- Impact resistance.

Video making a drainage well from bricks with your own hands

To equip drainage wells on the site or not is up to the owner to decide. If the dacha serves as a place of rest, and there is no need for planting, then there seems to be no need for a drainage system, especially when the ground aquifer is low. In all other cases, it is worth thinking about improving the outflow of excess moisture. Moreover, it is not difficult to create your own drainage system in the presence of plastic lightweight structures.