- Maintenance and operation

- Finding a place for a water source

- What materials can be used?

- How to improve well cleaning

- How to build a filter well

- The main types of drainage wells

- Characteristics of manholes

- The purpose of storage structures

- Features of absorption tanks

- How to make a filtration well

- Option number 1 - brick structure

- Option number 2 - construction of concrete rings

- Option number 3 - a well from old tires

- Option number 4 - plastic filter containers

- Recommendations for installing a filtration well

- Basement

- How is the filter well for sewage

- Features and types of bottom filters

- How to make a filtration well

- Option number 1 - brick structure

- Option number 3 - a well from old tires

- Option number 4 - plastic filter containers

Maintenance and operation

Before proceeding with the construction of a filtration system, it is necessary to familiarize yourself with the wastewater treatment technology and operating conditions:

- During operation, at least twice a month, it is necessary to inspect the treatment plant for tightness and silting.

- At least once a month, it is necessary to take samples for analysis of the land downstream of the groundwater from the chamber and to the side. To do this, it is necessary to drill two wells in these places.

- When filling the collector with sewage sewage, it should be pumped out using a sewage machine, and the sump should be cleaned of accumulated sludge.

- If the drainage in the chamber is disturbed, it is necessary to replace or wash the crushed stone filtration layer.

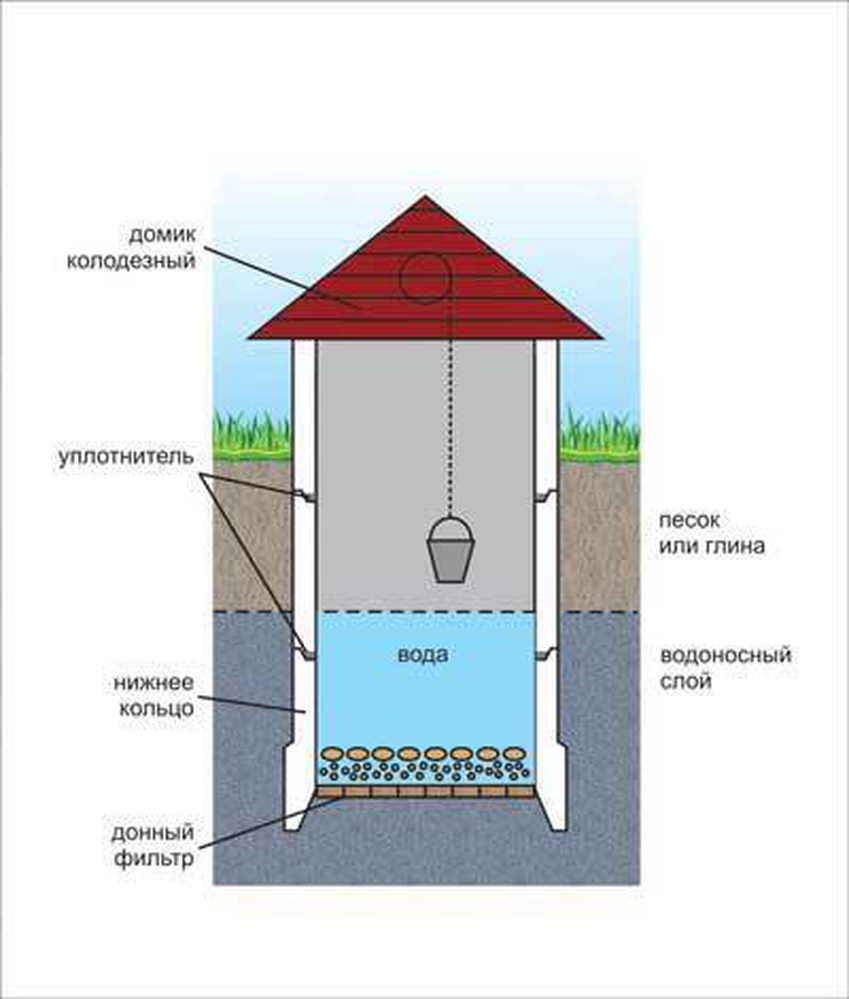

Finding a place for a water source

When building a well, it is important to correctly determine the depth of the horizon of clean drinking water, calculate and purchase the required number of concrete rings, equipment for arranging the hydraulic structure itself and the water distribution system. It is also important to choose the right place and time to dig a well.

Choosing the right place for a well depends on several factors:

- Exploration data. There are many ways to search for water on the site, but nothing more reliable than geological studies of the area has yet been invented.

- Information about nearby sources. It will not be superfluous to ask the nearest neighbors how deep their wells are built, what is the quality of the water.

- Suitability of water for drinking. Be sure to take a water sample for chemical and microbiological analysis at the nearest sanitation station. Specialists will determine the concentration of chemicals and the presence of pathogenic bacteria.

- Soil type. The difficulty of digging wells, the need to use special equipment, etc. depends on this. Ultimately, all this affects the cost of the finished well. The hardest thing is to build a well on rocky soils.

- Terrain relief. The greatest difficulties arise when building a well on a hillside. The ideal option is a flat area.

- Distance from pollution sources. Wells are dug at a considerable distance from cesspools, septic tanks, compost heaps, barns.It is undesirable to place them in a lowland, where rain, melt water flows, as well as water with impurities of agricultural fertilizers.

- Degree of distance from home. The closer the source of water to the house, the more convenient.

We suggest you familiarize yourself with: Thin floor screed on a concrete base

At the same time, the development should be located so that it does not interfere with the passage, does not block access to outbuildings, utility rooms.

During the construction of water supply and sewerage, one should be guided by SNiP 2.04.03-85. This is necessary to prevent contamination of drinking water sources, washing away the foundations of buildings, disruption of systems

What materials can be used?

Let's get acquainted with the materials that can be used in the arrangement of the bottom filter. These include:

- sand;

- jade;

- pebbles;

- shungite;

- crushed stone;

- gravel.

Prohibited Materials

Backfilling of fine fraction is river sand. It is mined, as you probably guessed, in quarries located on the riverbed. There is a lot of quartz in good sand, but there is little silt, clay and other impurities. In order for the material to be such, it must be properly prepared before being filled into the well.

How river sand is mined

Step 1. To begin with, the sand is poured into a large container by about 1/3.

Step 2. Then the sand is poured with a large amount of water.

Sand must be filled with water

Step 3. Sand and water are mixed with a stick until a mass of a homogeneous consistency is obtained. Then you need to wait 30-60 seconds for the impurities to float to the top, and the heavy sand sank to the bottom containers. After that, the water is carefully drained.

Step 3. The procedure must be repeated up to 3 times (the exact amount depends on the condition of the sand).The output is washed and ready-to-use material.

river sand

Pebbles are rounded pebbles that have become such as a result of collision with each other on the shore of a reservoir or at its bottom. The size of the pebble varies between 1-15 cm, and therefore it can be used for both fine and coarse fractions. The material has no problems with the radiation background, and therefore use it without any fear. But before backfilling, the pebbles should be washed in the same way as river sand.

Coarse pebblesMedium river pebbles

As for gravel, it is a sedimentary rock and is used for the middle fraction layer. Gravel is porous and friable, it can absorb various substances, and therefore it is a kind of adsorbent in the filter. But at the same time, this is also a lack of material - the backfill must be periodically changed so that it does not “share” absorbed substances with water.

river gravel

Crushed stone is obtained by crushing rocks and metallurgical waste. The material in the filters is used as coarse-grained backfill (bottom or top). When buying crushed stone, be sure to ask for a certificate that confirms its environmental safety.

Photo of rubble

Shungite is also a rock, but it differs in origin - in the past it was bottom organic sediments. The color of shungite is gray or black, it is an excellent adsorbent. It is used, like gravel, as a backfill of the middle fraction. Purifies water by absorbing harmful substances, and therefore it need to be changed regularly. Shungite must be washed before backfilling or, alternatively, filled up and not used for some time (about 24 hours) in the well so that the shungite dust settles to the bottom.

Shungite

And the last material is jadeite. It is an aluminum-sodium silicate, has a greenish color, like that of jade. It is used in filters for the medium fraction layer. Does not enter into a chemical reaction with water, which is good. As a rule, jadeite is bought for sauna stoves, and therefore it must be sought in the relevant departments of hardware stores.

jadeite stone

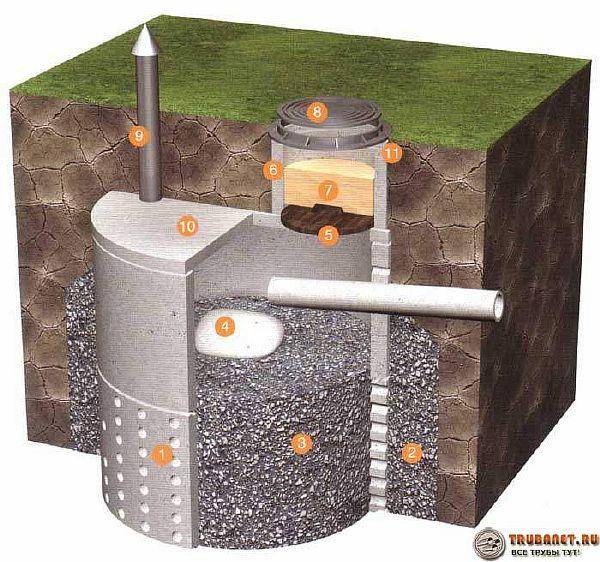

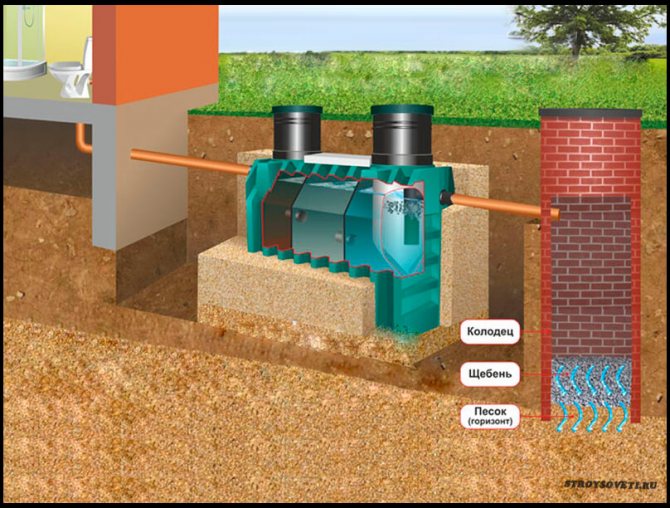

How to improve well cleaning

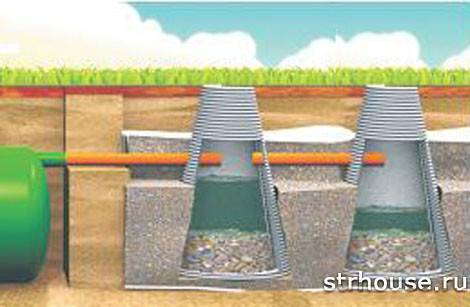

Wastewater treatment can be performed by a septic tank with a drainage system. Unlike the previous purification method, water does not leave the drainage device directly into the ground, but is poured into drains over a larger area.

Post-treatment by this method is almost 98%. The method is environmentally friendly, but requires a large amount of land. The construction of a septic tank is carried out in the following way:

- Sewage sedimentation, their division into fractions takes place in the first chamber.

- Clarification of water is carried out in the second chamber by deposition of mineral sediment on the bottom. The second chamber is cleaner and the upper bridge prevents the foam from getting here, and the lower bridge separates the silt and mineral sediment.

- The clarified water enters the drains, and then is filtered by the soil.

Drains are perforated drainage pipes. They are laid on a layer of gravel 20 cm thick, and then again covered with gravel.

According to SNIP, such wells should be located:

- At least five meters from the house.

- No closer than two meters from the fence.

- There should be at least 50 meters between the well with drinking water and the septic tank.

- At least one meter distance from the bottom of the septic tank and the upper level of groundwater.

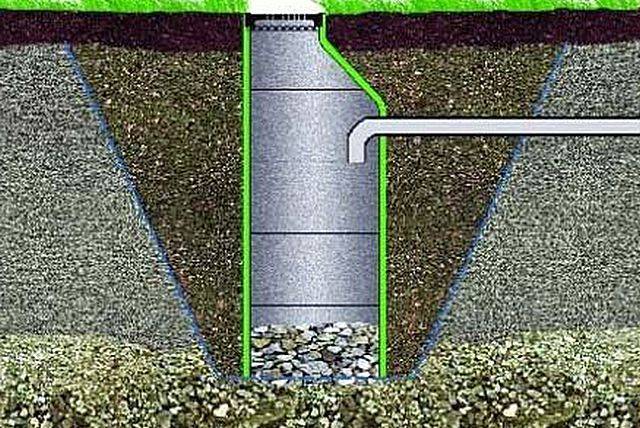

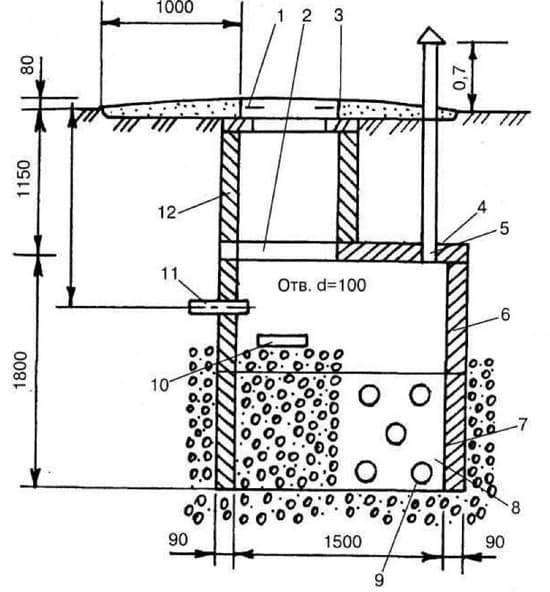

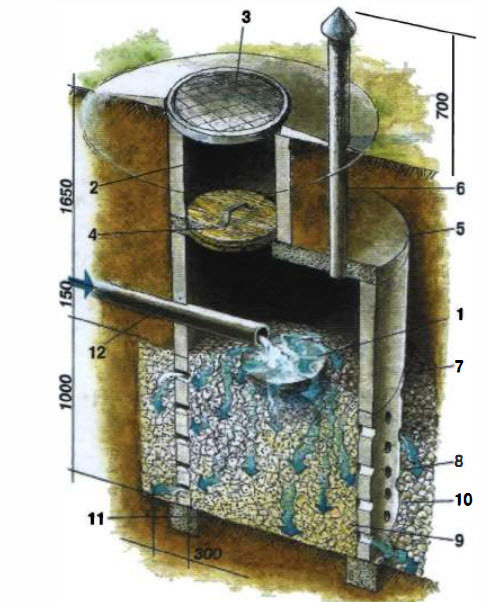

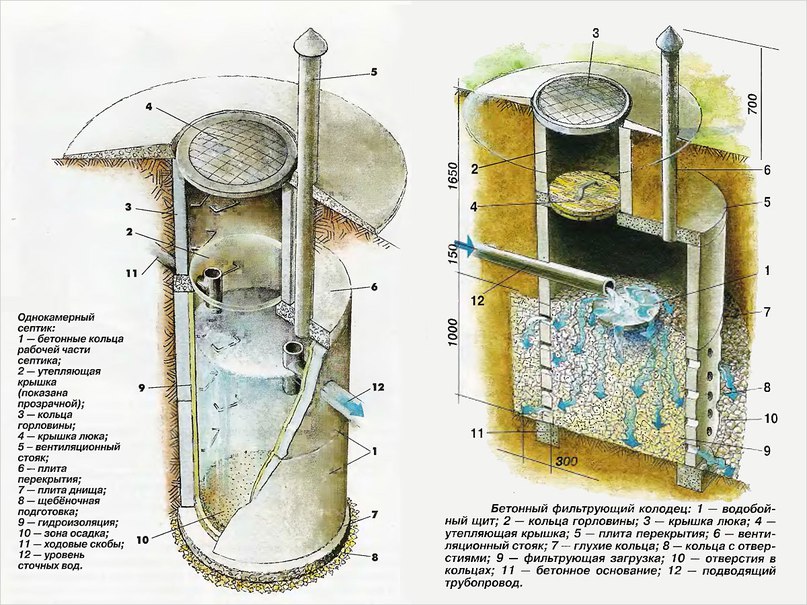

How to build a filter well

When the house is located on sandy or sandy soil, and liquid waste is not produced more than one cubic meter, you can build a filter well. Its purpose will be not only for sewerage, but also for drainage of the site.

In this case, perforated pipes divert excess water into it.

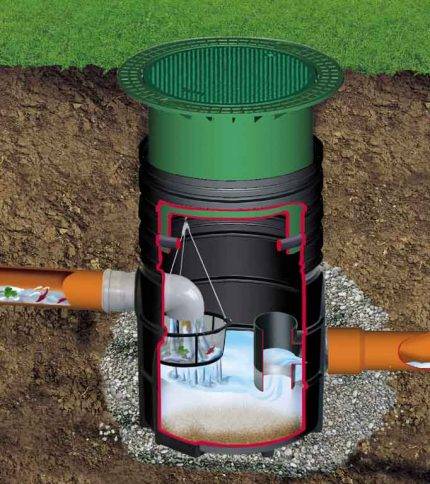

Filter well device

The features of such devices are:

- The material for the manufacture is taken brick, concrete, rubble stone and reinforced concrete rings.

- The size of a rectangular well is 2.8x2, a round one can have diameters from 1.5 to 2 meters.

- The depth in all cases is 2.5 meters.

- The bottom of the well is covered with crushed stone, gravel, boiler slag or other similar material, which serves as a filter for the well. Its height is from 0.5 to one meter.

- The inner surfaces of the walls are covered with cement mortar.

- The base and outer walls of the device are sprinkled with the same material as the filter.

For the construction of a shaft well, other organizations draw up a contract for the construction of a well. This is an employment agreement that specifies the obligations of the parties for the quality performance of all work and timely payment upon completion of construction.

The contract clearly spells out the terms of the operations, their cost, the procedure for calculating. After completion of the work, an act of acceptance of the structure is drawn up.

Details of how we we build a well with our own handsare clearly visible in the video. In this article, we propose to get acquainted with types of wells for sewerage in the suburban area.

The main types of drainage wells

There are several types of wells, which differ from each other in their purpose, material of manufacture and size. The device of drainage wells different species are almost the same.

They are a container with a closed bottom, into the shaft of which drainage sewer pipes are brought. The well is completely submerged in the ground, and its top is closed with a hatch.

The main difference between wells is their purpose. Each type is designed to perform a specific function and is located in a specific place in the drainage system.

Characteristics of manholes

Inspection or otherwise revision drainage wells are designed for:

- conducting scheduled inspections of the sewer system;

- pipeline performance monitoring;

- periodic pipe cleaning and repair work.

Revision wells are installed in places where there is the greatest likelihood of contamination or silting of pipes. Their sizes are selected taking into account the characteristics of the sewer system. In small pipelines, as a rule, manholes are installed diameter from 340 to 460 mm.

It is advisable to equip a large drainage system with large-diameter manholes, equipped with all the necessary devices for scheduled inspections and repair work.

Large drains are equipped with drainage structures with an internal diameter of up to one and a half meters. Some containers are equipped with steps for easy descent. An adult can easily fit into such a well to carry out work on cleaning or repairing the pipeline. The system is cleaned by flushing pressurized water pipes.

A variety of manholes are rotary structures, which are located at the corners of pipes. They do not have to be installed at every turn, they are usually mounted through a corner.

When installing rotary wells, it is necessary to take into account the design of the drainage system and install them so that all the corner and cross sections of the pipeline can be brought to them.

Rotary wells are buried in the corners of the pipeline. They are installed in such a way that, if necessary, it is possible to quickly clean the sewer.

The purpose of storage structures

A collector or otherwise water intake well is used to collect and accumulate water and then pump it into a reservoir or gutter. It is a large container with a diameter of up to one and a half meters, into which all the pipes of the drainage system are discharged.

It is installed in places where it is impossible to put a filter well or drain the water collected by the sewer into the drain. As a rule, they are taken out of the site.

For the removal of accumulated water, in collector submersible drainage pump is installed in wells with a drain pipe that pumps the collected liquid into a natural reservoir

The water intake tank is usually equipped with an electric pump, which pumps the accumulated liquid into a pond or for watering a garden. An automatic system is installed in the storage tanks, which, when the tank is filled to a certain level, pumps out water automatically.

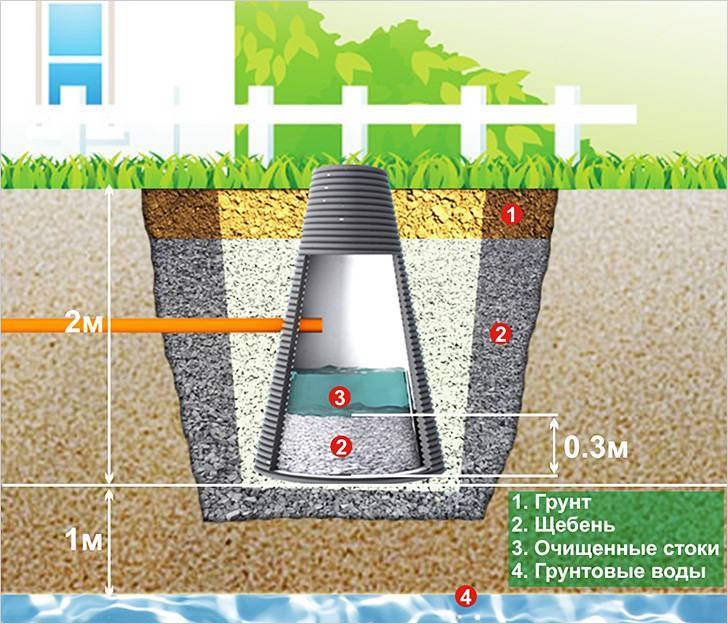

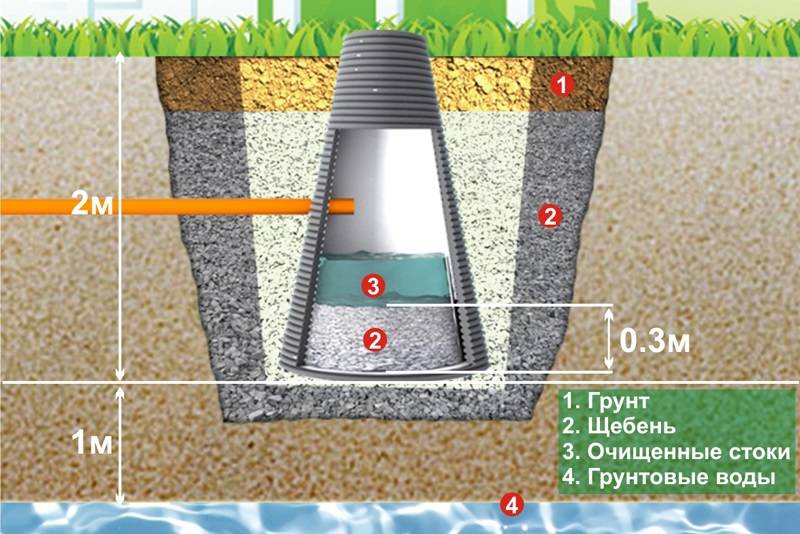

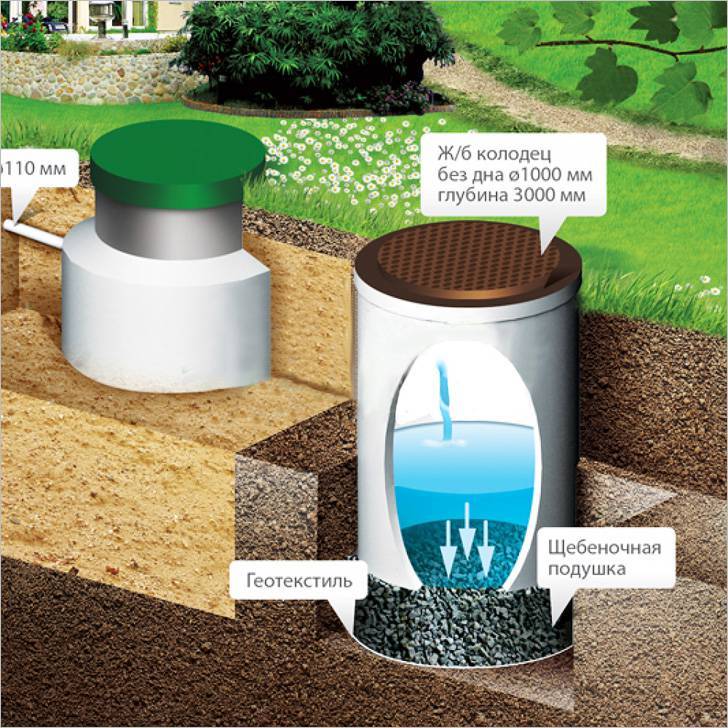

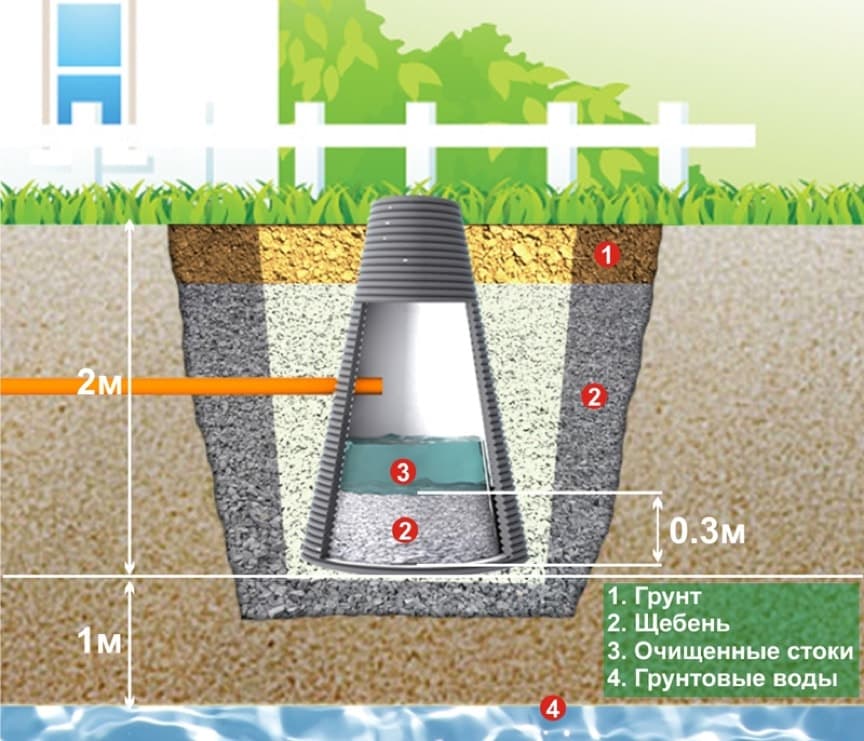

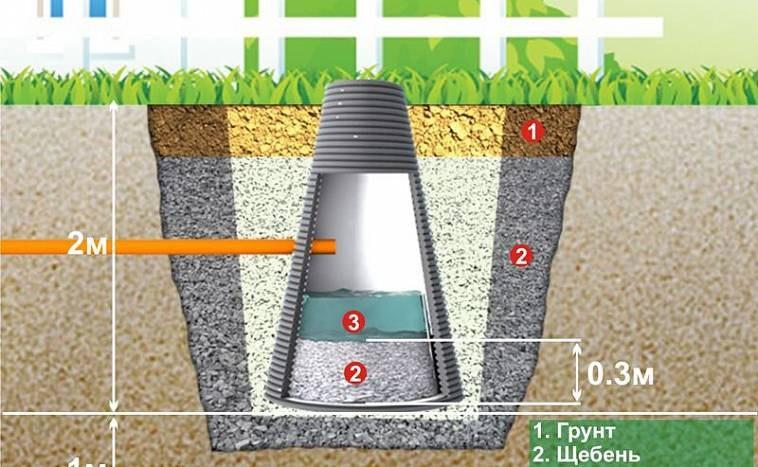

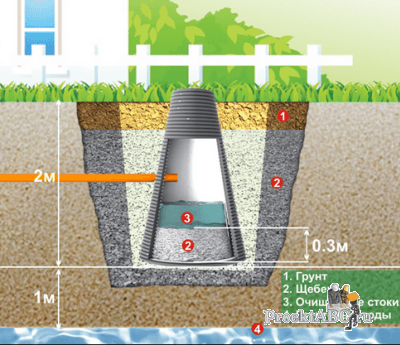

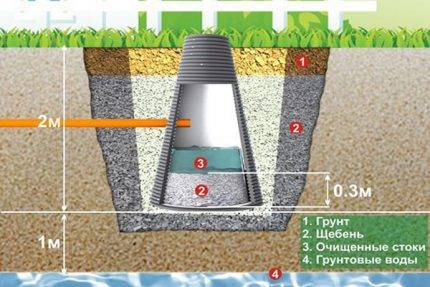

Features of absorption tanks

Filter wells are used in areas with slightly moist soil, located far from natural reservoirs and not equipped with water collection systems. In this case, the amount of water to be pumped out should not exceed 1 cubic meter. m per day.

The shape of the well can be round with a diameter of up to one and a half meters, or rectangular or square with an area of \u200b\u200bnot more than 6 m. Usually concrete rings are used to make a well or plastic containers.

The depth of the absorption well into the ground should be at least two meters, and the thickness of the filter layer is at least 30 cm

The device of the absorption well differs from other types of drainage tanks in that it does not have a sealed bottom. Instead, a filtering system is installed at the bottom of the well, which passes dirty water flows through itself, cleans them of debris and discharges them into the deep layers of the soil.

How to make a filtration well

Absorption wells can be built from baked bricks or rubble, but their construction requires considerable effort. Therefore, more often the walls of the well are made of reinforced concrete rings. Today, plastic structures are also widely used. You can make them yourself from plastic pipes or buy ready-made ones.

Option number 1 - brick structure

The brick structure can be either round or square. Usually round wells are built, which are most convenient to use. The structure for filtering sewage should be deepened into the ground by 2.5 meters, with a diameter of not more than 2 x 2 meters.

The pit is dug in such a way that between the ground and the outer walls of the well there will be a layer of crushed stone, gravel or broken brick up to 40 cm thick. The height of the backfill is one meter. The walls at the level of the filter must be water-permeable.

To do this, at a height of one meter, the masonry is not made solid, but with small holes ranging in size from 2 to 5 cm. They must be staggered.After the construction of the structure, crushed stone or gravel is poured into the crack.

During the construction of the well, it is necessary to make slots in the masonry for the exit of purified water into the ground

During the construction of the well, it is necessary to make slots in the masonry for the exit of purified water into the ground

At the bottom of the structure, the filtering agent is filled crushed stone or gravel to a height of one meter. In this case, large fractions of the material are placed below, small ones - above. The hole for the pipe through which the effluents from the septic tank will flow is made in such a way that water flows in a stream from a height of 40-60 cm.

A plastic sheet must be laid in the place where water flows to prevent the filter from washing out. From above, the structure is closed with a lid or hatch with a diameter of 70 cm. It is also necessary to make a ventilation pipe with a cross section of 10 cm in the well. It should rise 50-70 cm above the ground.

You will find step-by-step instructions for building a brick drain pit in this material.

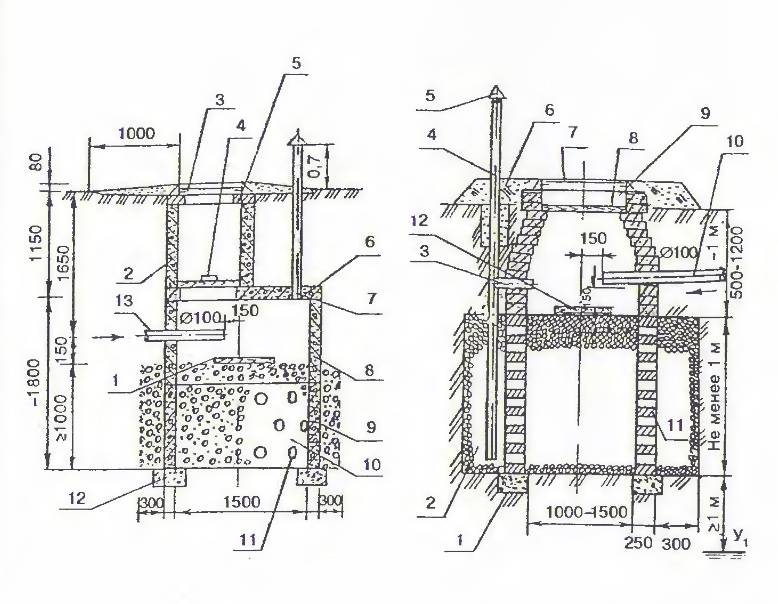

Option number 2 - construction of concrete rings

For the installation of a filtration well, three reinforced concrete rings will be needed. One of them should have holes with a diameter of about 5 cm. You can buy a perforated ring or make holes with a concrete crown. You also need to make a hole for the intake pipe.

The photo shows and describes in detail the process of installing concrete rings for arranging a well

It is necessary to dig a pit, the width of which is 40 cm larger than the diameter of the ring. The perforated ring is installed at the bottom of the structure. You can not dig a hole, but only slightly deepen the site on which it is supposed to make a well.

Put the first ring on the ground and choose the ground from the inside. Gradually it is under the weight of its weight will go down. The two upper rings are installed in the same way.

After that, you need to make a bottom filter from crushed stone or gravel up to one meter high and fill the outer walls of the well with the same material to the level of the filter layer. The hatch and ventilation pipe are installed in the same way as in a brick well.

Another option for arranging a septic tank from concrete rings can be read here.

Option number 3 - a well from old tires

The most inexpensive way to make a filter well is to make one from used tires. This design can filter the sewage of a family of three. Basically, such a well is made in suburban areas, since in winter the rubber freezes and the vital activity of bacteria slows down, and at very low temperatures it stops altogether.

The well is made very simply - the tires are installed one on top of the other and fastened together with plastic clamps. Joints are coated with sealant. All other structural elements are made in the same order as in wells made of other materials.

Scheme of installation of an absorption well from old car tires. The number of tires is calculated based on their size and the required depth of the well

Scheme of installation of an absorption well from old car tires. The number of tires is calculated based on their size and the required depth of the well

Option number 4 - plastic filter containers

For example, the Russian company POLEX-FC, whose products received good consumer ratings. Filter wells are produced in different volumes (from 1200x1500 to 2000x3000 mm), which allows you to choose a product based on the daily water consumption in an individual household.

Tanks are made of corrosion-resistant durable plastic, shaft walls are made of primary polyethylene. The lower compartment of the tank is covered with biofilm and filled with a filter layer of crushed stone, gravel and slag.

A plastic filter well with a three-stage filtration system provides effective water purification from impurities

Recommendations for installing a filtration well

In order for the well to effectively perform its functions, it is better to place it on a site with groundwater, which are located below the well bottom. The bottom of the structure should be higher than groundwater by more than 1.5 m.

If underground water is used as drinking water or on the farm, then the conditions for the installation of the structure must be adjusted by contacting the sanitary and epidermal supervision. The filter well is built on distance from 25 m from sources drinking water - wells and wells.

To protect the load-bearing structures of the house from being washed away and subsequent destruction, the organization of such wells is not allowed. closer than 10 meters from residential and commercial buildings.

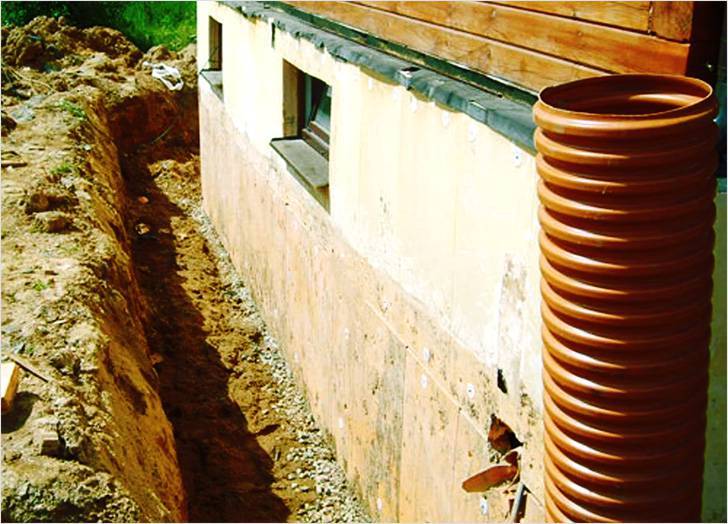

Basement

If your backyard has problematic soil, waterproofing the foundation should be given maximum attention. Basement or semi-basement premises, in addition to well-laid waterproofing layers, require the construction of a pit with a pump and a drainage well.

When the rainy season begins and the soil is oversaturated with moisture, water seeps through small cracks and micropores into the base of the building, entering the room.

You need to make a hole immediately during the concreting of the floor. It's not difficult at all. When installing the reinforcing cage of the floor, a formwork of the required size is additionally installed in the corner. When pouring concrete, you will get a monolithic structure with a recess.

To drain water from the basement, it is necessary to lay a pipeline. It must pass in the basement floor structure itself and in the foundation wall.Further, the pipeline is laid to the place where water is discharged from the system. The walls and bottom of the pit are best laid out with bricks so that they do not collapse from the water.

Install a drainage pump in the pit, equipped with automatic switching on and off. Installation of the pump requires special attention and compliance with certain rules:

- The base of the pit must be level.

- Install protection for the suction device against the ingress of clay particles and sand.

If the pit is not concreted, geotextiles are laid on the bottom and a plank floor is installed. The depth of laying the pipeline in the ground must be at least a meter.

How is the filter well for sewage

Above you learned how a septic tank works, now get acquainted with the device of a filter well - another device for biological treatment household waste water. If the soil conditions (sands and sandy loams) and the groundwater horizon (1 m to the base of the well) allow, then the drains from one house are cleaned by constructing a filter well.

With a total consumption of 0.5 m3 / day. and depending on the quality of the soil, the diameter of the filter well is different - 1000 x 1000 mm (or 1000 mm in diameter) in sand; 1500 X 1500 (or 1500 mm diameter) in sandy loam; with a total consumption of up to 1 m3 / day. - 1500 X 1500 or 2000 X 2000 mm respectively.

Waste water, purified by 90-95%, contains pathogens. It is forbidden to use such water not only as drinking water, but also to dump it into reservoirs from which water is taken for domestic needs. Water becomes suitable for these purposes after disinfection.

The filter well for sewerage is made of burnt brick, buta or reinforced concrete rings. The base is arranged only along the perimeter of the well. Inside, they arrange a bottom filter made of crushed stone, gravel and other material up to 1 m high. Outside, around the well, a backfill is made of the same material as the filter, 40-50 cm high. The walls of the well should have holes arranged in a checkerboard pattern (in their rings drill through 10 cm in length and height; gaps are made in brick and stone walls).

A ventilation drain with a diameter of 100 mm with a wind vane is installed above the above-filter part of the well. It should rise above the ground by 50-70 cm.

The well is covered with a lid, which is insulated at an estimated winter temperature below -25 ° C.

Features and types of bottom filters

Such a filter is, in fact, several layers of materials of natural origin (such as sand, gravel, etc.), which are poured to the bottom of the well

It is important that the particle sizes of each layer differ from the previous one by approximately five times. The liquid is purified due to the fact that various impurities settle in the backfill, and as a result, already filtered water is obtained (the latter is taken by a pump / bucket and used for household needs or drinking)

Table. What are bottom filters?

| Name, photo | Characteristic |

|---|---|

| With direct backfill | It consists of 3 layers with a thickness of about 15 cm each. The layers are arranged according to the size of the fractions - from the largest to the smallest. The liquid passes through these layers and is successively purified from impurities of various sizes. If the water is not very dirty, then one or two layers of backfill can be dispensed with without using fine-grained material. |

| With straight backfill and shield | A variation of the option described above, supplemented by a special shield, which is made of stained wood, oak or aspen. The shield is laid on the very bottom and is intended to protect the filter from immersion / erosion. |

| Backfilled | It differs from the design with direct backfill in the reverse order of the layers - from the fine fraction to the biggest one. |

Shield at the bottom of the well well filter can be made independently using available natural materials

How to make a filtration well

Absorption wells can be built from baked bricks or rubble, but their construction requires considerable effort. Therefore, more often the walls of the well are made of reinforced concrete rings. Today, plastic structures are also widely used. You can make them yourself from plastic pipes or buy ready-made ones.

Option number 1 - brick structure

The brick structure can be either round or square. Usually round wells are built, which are most convenient to use. The structure for filtering sewage should be deepened into the ground by 2.5 meters, with a diameter of not more than 2 x 2 meters.

The pit is dug in such a way that between the ground and the outer walls of the well there will be a layer of crushed stone, gravel or broken brick up to 40 cm thick. The height of the backfill is one meter. The walls at the level of the filter must be water-permeable.

To do this, at a height of one meter, the masonry is not made solid, but with small holes ranging in size from 2 to 5 cm. They must be staggered. After the construction of the structure, crushed stone or gravel is poured into the crack.

During the construction of the well, it is necessary to make slots in the masonry for the exit of purified water into the ground

At the bottom of the structure, a filter layer of crushed stone or gravel is backfilled to a height of one meter. In this case, large fractions of the material are placed below, small ones - above. The hole for the pipe through which the effluents from the septic tank will flow is made in such a way that water flows in a stream from a height of 40-60 cm.

A plastic sheet must be laid in the place where water flows to prevent the filter from washing out. From above, the structure is closed with a lid or hatch with a diameter of 70 cm. It is also necessary to make a ventilation pipe with a cross section of 10 cm in the well. It should rise 50-70 cm above the ground.

You will find step-by-step instructions for building a brick drain pit.

Image gallery

Option number 3 - a well from old tires

The most inexpensive way to make a filter well is to make one from used tires. This design can filter the sewage of a family of three. Basically, such a well is made in suburban areas, since in winter the rubber freezes and the vital activity of bacteria slows down, and at very low temperatures it stops altogether.

The well is made very simply - the tires are installed one on top of the other and fastened together with plastic clamps. Joints are coated with sealant. All other structural elements are made in the same order as in wells made of other materials.

Scheme of installation of an absorption well from old car tires. The number of tires is calculated based on their size and the required depth of the well

Option number 4 - plastic filter containers

Today you can buy ready-made plastic filter wells equipped with everything necessary for effective wastewater treatment. Of course, they cost a lot, but they are reliable, convenient, easy to install and maintain. There are many manufacturers of such equipment on the market.

For example, the Russian company POLEX-FC, whose products received good consumer ratings. Filter wells are produced in different volumes (from 1200x1500 to 2000x3000 mm), which allows you to choose a product based on the daily water consumption in an individual household.

Tanks are made of corrosion-resistant durable plastic, shaft walls are made of primary polyethylene. The lower compartment of the tank is covered with biofilm and filled with a filter layer of crushed stone, gravel and slag.

How to make a well from old tires you will learn from the following video:

Filtering facilities perform a very important function - they provide effective wastewater treatment and do not let dirty untreated water into the ground, which, when it enters the soil, causes significant harm to the environment.

A filtration well is not so difficult to make on your own, but if you do not want to mess with its arrangement and you have the financial ability, you can buy a ready-made plastic well.