- No. 2. Why is the main filter better than others?

- Pros and cons

- Device and design

- Briefly about fine filters

- The main condition for high-quality cleaning filter filler

- We make a water filter with our own hands to clean well and borehole water

- Why filter well water?

- Overview of filtration materials

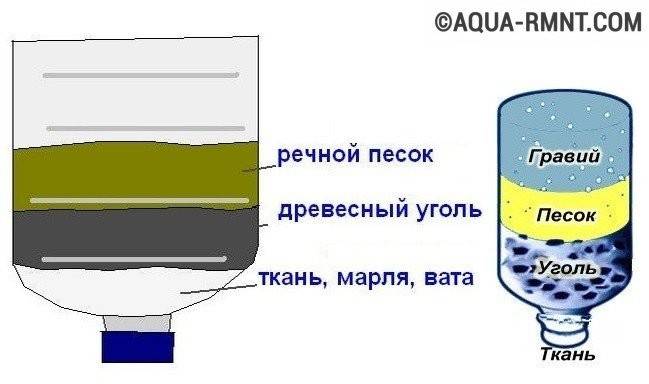

- The simplest plastic bottle filter

- Three-flask design for a full plumbing

- Principle of operation

- How to make a filter for a well with your own hands

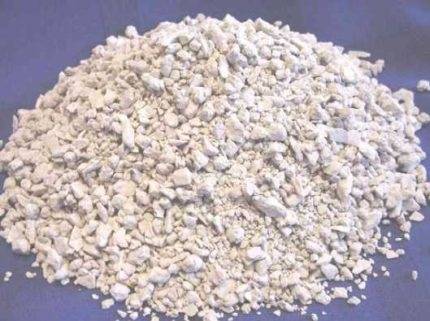

- gravel

- Perforated perforated well filter

- slotted

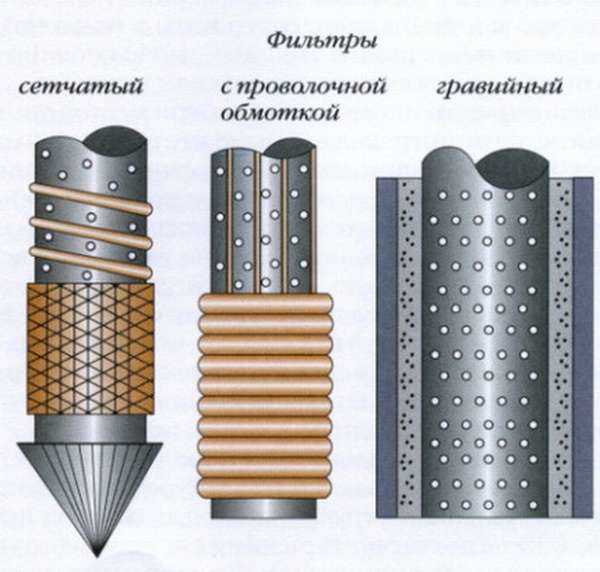

- Wire Mesh Filter Systems

- Well filter. What is it and what are the types?

- Making a filtration well system with your own hands

- Making a filter for a well with your own hands

- How to make a slotted filter for a well

- Perforated perforated filters

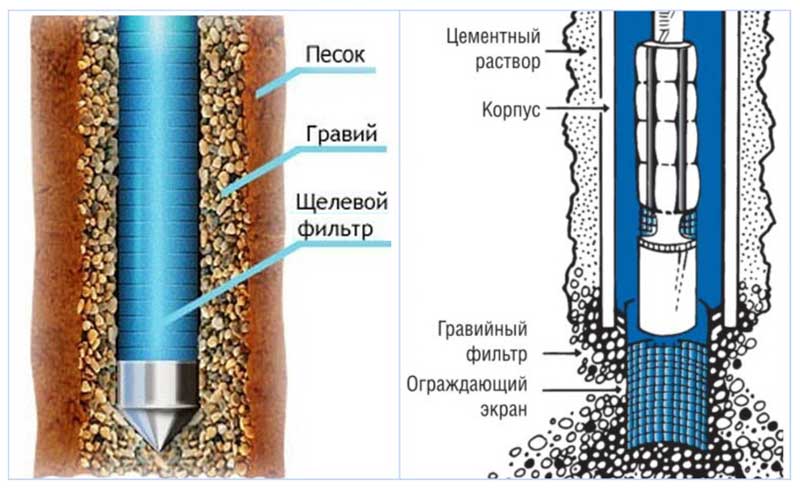

- Gravel filter - how it's done

No. 2. Why is the main filter better than others?

The problem of polluted water is so massive that mankind has come up with a lot of different devices for cleaning it. We will not go into details, but among the most popular filtration systems today they use the following:

- pitcher-type filters and dispensaries do not belong to flow filters - a certain amount of water is poured into them, which after a while is cleaned by built-in cartridges. This solution is only suitable for water purification for drinking and cooking, since the volume of vessels, as a rule, does not exceed 3-4 liters;

- the filter nozzle on the tap allows you to purify water from large mechanical impurities, improve its organoleptic qualities. The filter is suitable if the water quality is satisfactory, meets the standards, but you just want to improve it a little. Such a filter is easy to install, you can even take it with you on trips, but it will not cope with serious pollution, has low performance and requires frequent replacement of cartridges;

- the “next to the sink” filter is also easy to install, connects to the water supply using a special adapter and provides an average level of purification, ridding the water of large contaminants and unpleasant odors;

- stationary filter "under the sink" is installed under the sink, allows you to purify water from mechanical impurities, chlorine, heavy metals, eliminate odors and tastes. This is a very popular system, it is easy to maintain, requires replacement of cartridges every 5-6 months, but the cost of its arrangement is higher than the previously listed options. This solution also has some drawbacks. The filter will not cope with the most serious contaminants, it has limitations in terms of performance and cannot be installed on pipes with hot water.

If any of the listed filters allows you to purify water to an acceptable quality, you are very lucky.But if you are not lucky, then you should not be upset, because there are flow-through main filters, which are actually a miniature water treatment station.

The main filter is built into the water supply system of an apartment or house, crashes into the water main and creates a serious barrier to the water entering the apartment, which, passing through the filter system, is cleaned of mechanical impurities, harmful elements and compounds. The filter can be put on hot and cold water, and since it will stand at the inlet, purified water will flow from all taps.

A flow-through main water filter is usually used in houses that have their own source of water supply (a well or a well), but recently a similar system has often been installed in apartment buildings where the water pipes are very worn out. Such filters allow you to solve several problems at once:

- water purification from harmful impurities, chlorine and microorganisms;

- improving the taste of water and getting rid of metallic and other tastes;

- softening, because hard water negatively affects the skin and hair, leads to the rapid wear of some household appliances;

- keeping plumbing fixtures in good condition. Conventional (non-main) filters purify water only at one point of consumption, and it runs through the rest of the pipes in the apartment silted and contaminated with particles of rust and other debris, which gradually leads to blockages and breakdowns. With the main filter, this problem disappears.

The main advantages of main filters include:

- high cleaning efficiency;

- high performance (the filter cleans 20-50 liters of water per minute);

- variability.Depending on what it is necessary to purify water from, various cartridges can be used;

- the ability to purify water for all water intake points with one filter;

- durability with proper use.

Among the shortcomings, we note only the complexity of installation - you will need the help of specialists. You can service the main filter yourself, but if a blockage occurs, you can hardly do without a professional. The cost of trunk systems, of course, is higher than that of simpler filters, but it is not sky-high.

Pros and cons

Drilling with a small-sized installation Like any source, the structures under consideration have their positive and negative sides.

The advantages include:

- short term of drilling operations (one-two days in the absence of difficulties);

- penetration is carried out by a small-sized installation, which is convenient when working in hard-to-reach places or in a limited area;

- does not require obtaining permits and licensing;

- long service life with proper operation;

- easy access to equipment located in the well, which allows you to quickly remove the pump for maintenance or repair;

- the total cost of work is much lower than when drilling artesian sources.

Among the shortcomings, experts distinguish the following:

- low predictability of aquifer formation;

- the aquifer is located close to the surface, which affects the quality of the water into which chemicals and organics enter from the surface;

- the volume depends on the level of precipitation;

- risk of silting;

- low flow rate;

- requires regular cleaning of the well.

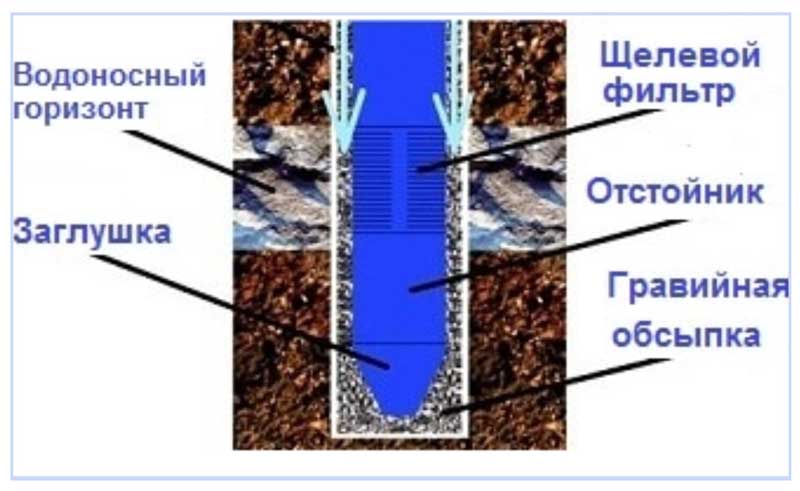

Device and design

Structurally, wells, equipped on sandy horizons, are complex hydraulic structures.

Scheme of arranging a well for sand

- After drilling, a casing string with a diameter of 100 to 150 mm is installed in the wellbore.

- The lower part of the casing pipe is equipped with a mesh or slotted filter tip. The diameter of the holes is selected taking into account the grain size of the sand in the aquifer. This approach avoids clogging and improves water quality.

- In order to protect the source from the effects of precipitation and other atmospheric phenomena, a caisson is installed.

- In some cases, an insulated pavilion is installed above the mouth of the hydraulic structure.

- For sealing the well and fixing the pumping equipment, the mouth of the pipe is equipped with a head of the appropriate diameter.

- The rise of water is carried out by means of a submersible or surface pump.

- The hydraulic accumulator and automation will ensure constant pressure in the system and protect the pump from premature failure.

Briefly about fine filters

If the owners of a country cottage put only a coarse mechanical filter, they did not protect themselves from the impurities contained in the well water. Such an installation is capable of retaining only particles of a large fraction, but water also contains impurities that easily pass through the cells of the coarse cleaning device. Salts of iron, magnesium, calcium, silicon, hydrogen sulfide, nitrates and other contaminants are dangerous for humans if their content in water exceeds the permissible concentration.

Thorough cleaning is required not only for water from a well or for a shallow Abyssinian well.Even fluid coming from artesian aquifers may need additional filtration.

Modern fine cleaning plants are suitable for both city water supply and summer cottages. They cope with any pollution and make the water drinkable. The filtering elements in such installations are ion-exchange resins, sorption materials, chemical reagents, reverse osmosis membranes. The regularity of their replacement depends on the volume of fluid passing through them and the service life of a particular material.

The choice of a fine purification unit must be made after a chemical analysis of the liquid carried out in the laboratory. It will show what impurities are contained in the well water, determine their amount and allow you to choose a water treatment system that will rid the liquid of the identified contaminants and make the water safe and pleasant to the taste.

The main condition for high-quality cleaning filter filler

The working container is selected in such a way that all the necessary filling fits into it. For absorption, a variety of components are used: artificial and natural. The latter have a higher filtration capacity. These include:

- sand from a river or quarry;

- gravel;

- zeolite;

- Activated carbon.

For primary rough cleaning, cloth cotton materials or even paper are usually used. According to hygienic requirements, they are very impractical: they constantly stay in a humid environment, rot, and an unpleasant odor appears. The very structure of such filters contributes to almost instantaneous pollution, which requires frequent replacement.

The best material for filtration is activated carbon

Artificial materials in this respect have the best performance. One of the most preferred is lutrasil. He is not afraid of moisture, dirt accumulates to a lesser extent than on cotton. Of the other fabric filters, they use synthetic, used in coffee machines - the cheapest.

Zeolite also belongs to minerals, but it has a disproportionately large filtration effect. It cuts off metal and salt impurities - everything that comes into the water from the agricultural industry: pesticides, herbicides, mineral fertilizers.

Zeolite used in homemade structures

In homemade devices, activated charcoal is most widely used. It equally qualitatively retains mineral formations and toxic substances. Another advantage is that the water after passing through it becomes transparent, unpleasant odors and microorganisms are eliminated.

Self-cooking coal is not particularly difficult. Wood of any breed, except coniferous, is used. Birch has the best qualities. Firewood is loaded into a metal container, which is placed on fire, ideally in a stove. When they are red hot, stop heating and let cool. If overexposed, valuable filtration properties are lost.

We make a water filter with our own hands to clean well and borehole water

The problem of drinking water purification is becoming relevant not only for citizens, but also for rural residents. To make water from a well or well drinkable, you can make a water filter with your own hands.

Why filter well water?

It would seem that what could be cleaner than well water, sung in ancient Russian epics? Alas, modern reality is not at all like a fairy tale. Water in private wells can be contaminated with a variety of substances, such as:

- nitrates;

- bacteria and pathogens;

- impurities that impair the taste and quality of drinking water.

For an excess of nitrates in drinking water, i.e., salts of nitric acid, one should “thank” the farmers who widely use fertilizers and pesticides in the cultivation of agricultural products. Some of these substances inevitably seep into the aquifer of the soil.

The simplest filter can be made from a plastic bottle with filler

Poor quality and damage to equipment lead to the fact that an admixture of rust, sand, etc. appears in the water. Drinking such water is simply unpleasant. Therefore, for giving it is recommended to buy or make at least a simple water filter.

Overview of filtration materials

The principle of operation of the filter is simple and familiar to everyone. It is necessary to pass water through a layer of filter material. The filler may be different:

- the cloth;

- cotton wool;

- paper napkins;

- gauze;

- sand;

- grass;

- coal;

- lutraxil.

You can buy charcoal at the store or make your own.

For regular use, other materials are used, mainly charcoal. It is laid in layers, alternating with sand, gravel, grass, etc. Lutraxil is a synthetic material made from polypropylene fibers.

The simplest plastic bottle filter

The use of conventional household filters for a small dacha is rarely convenient.Such devices require water to flow from the water supply under a certain pressure, and not every country house has a water supply with suitable characteristics. Pitcher filters purify water too slowly.

In addition, you will have to constantly change cartridges. Therefore, a homemade water filter made from a plastic bottle and a bucket with a plastic lid may be the most viable option.

Homemade water filter can be made from an ordinary plastic bottle

This filter uses charcoal and ordinary cloth as a filler.

The simplest filter for giving is made in this way:

1. Cut off the bottom of a plastic bottle.

2. Cut a suitable hole in the plastic lid of the bucket.

3. Insert the bottle into the hole with the neck down.

4. Fill the filter with media.

On top of the receiving container, you need to install a plastic bottle with a volume of 10 liters, in the bottom of which a filling hole has been made. For the manufacture of the filter, you can use a piece of 40 mm polypropylene pipe. The top and bottom of the pipe are covered with pieces of perforated plastic, which is recommended to be fixed with hot glue. The pipe is filled with charcoal.

Such a homemade filter should fit tightly into the neck of a standard ten-liter bottle. It remains to connect the receiving tank with the filter and the bottle. A full bucket of well water can be immediately poured into the installation, which will be filtered after a few hours. Thus, the house will always have a supply of clean drinking water.

Three-flask design for a full plumbing

Happy owners of a full-fledged water supply in a private house can make a three-flask home-made filter for water purification. For this you need:

- Buy three identical flasks.

- Connect the flasks in series with two quarter-inch nipples. In this case, it is necessary to strictly adhere to the in / out designations in order to observe the direction of water movement. The threads of the nipples should be sealed with FUM tape.

- The end holes of the flasks are connected to the quarter-inch tube with straight adapters.

- Connect the filtration system to the water supply with a tee that is cut into the water supply using a 1/2” connector.

- At the outlet, a standard tap for drinking water is connected to the filter system.

- Fill the flasks with filter material. You can use a polypropylene cartridge, a carbon filter and an anti-scale filler.

This is interesting: Walls in the corridor - finishing options

Principle of operation

Slotted filter for a well - a pipe made of stainless steel or polypropylene with longitudinal slots. It has a housing with inlet and outlet pipes and a lamellar filter element.

In the simplest models of such a filter, a metal mesh is used as a plate element. The top and bottom slotted filters as well as the water pipe together constitute the distribution system of the filter device.

Special holes with a width of 15-25 mm do not allow the smallest particles to leave the filter, supplying clean water without impurities.

Reference. The slotted filter is installed in wells where rocks prone to collapse are noticed, as well as on stony soils.

How to make a filter for a well with your own hands

Downhole filters are installed on the bottom pipe and lowered into the source along with the casing string, their independent production is pointless if you are not engaged in downhole drilling. The task is relevant for drilling organizations and individual drillers who want to make an inexpensive high-quality filter with high characteristics and parameters that are most suitable for a particular well (depth of occurrence, soil composition).

gravel

For a gravel filter device, do it yourself as follows:

- First, the size of the gravel backfill is selected, taking into account the granulometric composition of the water-bearing sand. To do this, contaminated water is extracted to the surface, and after its filtration, the size of the sand particles is determined.

- The gravel pack should have a granule size of approximately 8 times the minimum sand particle diameter or 5 times their maximum diameter. For example, if the dimensional parameters of water-bearing sand are 0.5 - 1 mm, the backfill should have dimensions of 4 - 5 mm, with grains of sand 0.25 - 0.5 mm. gravel sizes are 2 - 2.5 mm.

- The sized gravel fraction is immersed to the well bottom by the method of free fall in the water flow, its minimum thickness is 50 mm.

- Multi-layer filling is allowed, starting with larger fractions and moving to fine particles.

Rice. 11 Backfilling the casing

Perforated perforated well filter

A perforated filter can be made by yourself without much effort with a simple tool (drill with a suitable drill bit). When installing a perforated filter from 125 HDPE casing, proceed as follows:

- The markup is made, marking the distance from the bottom plug to the end of the sump about 50 cm, the length of the filtering part with perforation is 110 cm.

- 4 equidistant lines are drawn along the pipe, 4 rows of holes are drilled with a diameter of 20 - 22 mm. pen drill on wood - they must be performed in a checkerboard pattern. The distance between them should be about 10 cm.

- The burrs formed during the drilling process are cleaned with sandpaper, you can singe them with a gas burner.

If the source is shallow, the number of holes can be increased to 8 rows, and perforated holes can be made for almost the entire length of a 3-meter pipe, their number will be about 20 - 25 pieces in a row.

Rice. 12 Do-it-yourself perforated filter

slotted

The manufacture of a slotted filter is rarely carried out independently - the process is laborious and time-consuming, when it is constructed, the following is done:

- Markings are made along the pipe surface, dividing it into 8 equal-sized sectors, drawing 8 lines and retreating from the ends by 50 cm.

- To cut slots, they take a grinder with a disc for metal or concrete, while it should be borne in mind that the slots from the disc for metal will have a smaller width.

- Cutting is done in 10 mm increments. to the width of the sector between the two lines, alternating free longitudinal sections with cut ones. At the same time, stiffening ribs 20 mm wide are left between the slots. through 10 - 20 lines.

- After cutting out 4 longitudinal segments with slotted areas, their surface is cleaned of burrs with sandpaper.

Rice. 13 Plastic pipe with slots

Wire Mesh Filter Systems

Making a wire filter at home is not possible - to ensure a gap between the turns of the V-shaped wire of about 0.5 mm. it needs to be welded onto a rigid frame from the inside at thousands of points.

At home, mesh filters are most often made by doing the following:

- They take as a basis a casing pipe with round holes made according to the technology described above. A nylon cord or stainless steel wire is wound onto its surface with a circumference of about 2 - 5 mm. with a distance between turns of 50 - 100 mm. The ends of the winding are fixed with brackets, screws or screwed with adhesive tape.

- A metal or synthetic mesh is put on top of the winding; a second outer winding with wire or synthetic cord is used to fix it.

Rice. 14 Manufacture of the strainer

Well filter. What is it and what are the types?

Example of a plastic slotted filter

Example of a plastic slotted filter

The well filter is an element located at the very bottom of the casing string. In some cases, it is called the work area. It performs an important function of preventing soil particles from entering the structure through which clean water flows to the surface. In addition, it serves as additional protection against collapse. Filters are made in several ways. In this article, we will take a look at the following filters that everyone can do:

- perforated filters,

- slot filters,

- gravel filtration plant.

Making a filtration well system with your own hands

It is not difficult to make a borehole slotted filter on your own.First you need to decide on the material for the pipe - the basis of the filter. It can be stainless steel or polypropylene.

Today, preference is given to polypropylene, as it lasts longer than stainless steel, without changing the physical and chemical composition of water.

Required materials for filter assembly:

Required materials for filter assembly:

- Chalk or pencil for marking;

- Pipe made of plastic or stainless steel (diameter must be less than the diameter of the well, length - no more than 5 m);

- Tool for cutting slots (hacksaw or grinder);

- Grid (brass or stainless steel).

DIY step-by-step instructions:

- First you need to mark with chalk (pencil) on the pipe the places where the slots will be located. They can be placed one above the other or staggered.

- Slit cutting. The width will directly depend on the cutting tool. The length of the slots is approximately 2.5 - 7.5 cm. The cut sections must be cleaned.

- The stage of fixing the protective grid. The first thing to do is wrap the pipe with 3 mm wide stainless steel wire. The coils should be applied in a spiral every 20 cm from each other, and every 50 cm they should be spot-soldered. Then wind the mesh and secure it with wire.

- Pull all the turns with pliers and solder.

Attention. In order for the filter to be durable, you should leave sections without slots on it. Installers of such systems say that a brass net is more practical and stronger.

And doctors tend to favor food-grade stainless steel, because it makes water safe for health.

Installers of such systems say that a brass net is more practical and durable. And doctors tend to favor food-grade stainless steel, because it makes water safe for health.

You can clearly see the manufacturing process of the slotted filter in the video.

Making a filter for a well with your own hands

The filter manufacturing process depends on the intended type of construction of a given casing element. Therefore, further in the text, we will consider the manufacturing technologies for each typical type of filter sections of the casing frame.

How to make a slotted filter for a well

Such a filter is made from an ordinary casing pipe, the body of which is cut with a grinder or a hacksaw. Moreover, the first 10 centimeters from the lower end must be left untouched - this will be the sump (sand trap) of the filter.

Slotted well filter

Next, you need to mark (with chalk) the position of the slots, placing them either on top of each other or in a checkerboard pattern. Moreover, untouched areas must be left on the body of the pipe - the basis for the reinforcing belt. Without these elements, the cut pipe will lose its ring stiffness.

It is necessary to cut the filter channels on the pipe body only after careful fixation of the measuring segment consumed under the filter. You can fix the pipe with clamps, which is very convenient, since in this case the pipe rotates very easily around its axis, opening up access to areas that have not yet been cut. To do this, you just need to loosen the tension in the clamps.

The width and length of the notch are arbitrarily defined. Moreover, the thickness of the cutting tool (abrasive wheel or hacksaw blade) affects the width rather than any calculations. But the length of the cut is determined based on the need to equip the reinforcing belt. Therefore, the length of the incisions in most cases varies between 2.5 and 7.5 centimeters.

At the final stage, the body of the pipe is packed in a mesh stocking of galloon or cellular weaving. And before that, it is worth checking the filter for the well for sand - sifting it through such a "sieve".

And the best material for the mesh is stainless steel or brass. But there are complaints about the latter from sanitary doctors, since modern brass is “boiled” from copper with a low degree of purification.

Perforated perforated filters

To make such a filter, we will have to use not a “grinder” (angle grinder) or a hacksaw, but an ordinary drill. Moreover, the manufacturing technology remains unchanged - holes are drilled in the body of the pipe, arranged in a checkerboard or linear order.

perforated filter

Of course, this filter manufacturing method is more labor intensive than the above procedure. But, unlike the slotted counterpart, the perforated filter practically does not reduce the ring stiffness of the pipe. Therefore, this option can be used even at great depths, with a high probability of soil movements.

Gravel filter - how it's done

gravel filter

A gravel filter is the simplest type of filter element for a well. Indeed, in fact, this is the most common bedding, which is “shipped” into the bottom expansion of the source shaft.

As a result, if you use a special nozzle with a separating plow and specially selected gravel (the stones must correspond to a certain “caliber”), then the process of arranging a gravel pack will look like this:

- At the end of the well construction, when the drill enters the aquifers, you need to activate a special nozzle with a folding plow. With this plow, a cone-shaped expansion can be cut in the bottom of the well.

- Next, you need to sew a bag of geotextile, ¼ high from the depth of the well, and, throwing several large fragments onto its bottom, lower it to the bottom layer on ropes.

- After that, all the previously selected soil is poured into the bag. And at the end, the ropes are simply torn off. Moreover, the backfill can be rammed both during the arrangement and after it.

As a result, an embankment of gravel or crushed stone is formed at the bottom of the well, on which silt or sand, washed out from the aquifer of the soil, settles.

Published: 16.09.2014