- How to choose a filter media?

- How to make a filter for a well with your own hands

- gravel

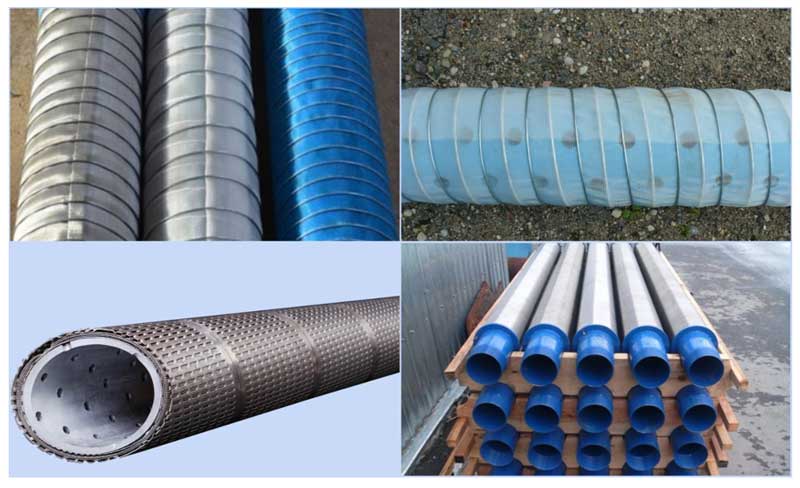

- Perforated perforated well filter

- slotted

- Wire Mesh Filter Systems

- Materials for filtration equipment

- Benefits of using stainless steel

- Features of the use of plastic

- The subtleties of the use of ferrous metals

- Slotted well filter: overview, manufacturing method

- System manufacturers and price

- Enterprise "Geomaster"

- Making a carbon water filter

- Device assembly process

- Making a filter with your own hands

- Cleaning options

- Primary water treatment

- Deep Water Treatment Systems

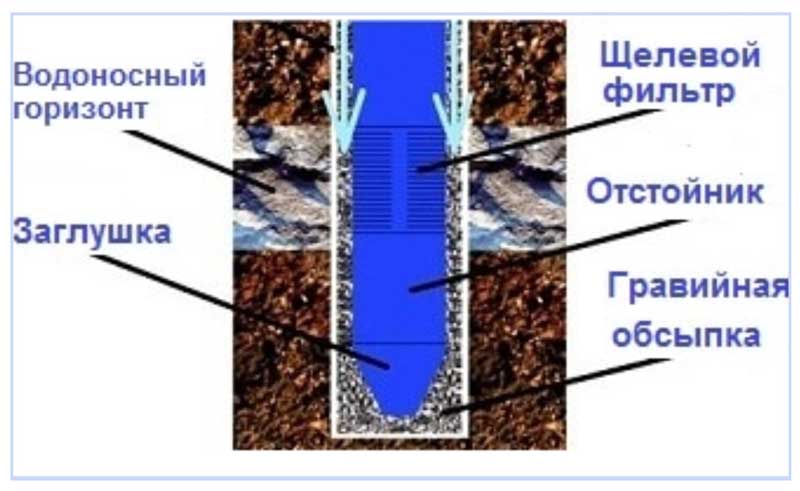

- Why is a well filter necessary?

- How do reverse osmosis filters work?

- Making filters for a well with your own hands

How to choose a filter media?

When choosing a container for a filter, you need to calculate everything properly, because the cleaning properties primarily depend on a properly formed “filling”. The volume of the filter container must be such that it can easily accommodate all components.

As an absorbent, natural materials are widely used, such as quartz river or washed quarry sand, gravel, activated carbon and zeolite. As you know, any filter begins with a primary coarse layer.Often this role is assigned to fabric materials based on cotton.

The water in the filter must go through several stages of purification. The upper layers trap large inclusions and contaminants, the lower ones exclude the penetration of small particles

Natural materials are highly impractical in terms of hygiene. Firstly, in a humid environment, such a filter layer is subject to decay processes, which causes an unpleasant odor. Secondly, the structure of the fabric implies a very rapid contamination of the filter with unwanted particles, which increases the need to change the layer.

Much better performance is observed in synthetic counterparts. More preferable in this regard is lutrasil. The material has moisture-resistant qualities and is more resistant to contamination than cotton or bandage.

Non-woven polypropylene fabric - lutrasil can be used as the bottom layer for final water treatment

A very budget option for a fabric filter can be considered a synthetic layer that is used in making coffee.

Quartz sand does an excellent job of retaining small particles, as well as filtering heavy chemical compounds. While gravel is the opposite, it is better to weed out large inclusions of unwanted materials. A mineral called zeolite has an incommensurable cleansing effect.

Zeolite is widely used in the field of water purification. Extracts from it heavy metals, organic compounds, phenol, nitrates, ammonium nitrogen, etc.

The active effect of the substance with a bang will cope with water pollution with metal and salt suspension, and also neutralize pesticides and other products of processing of the agricultural industry.

How to make a filter for a well with your own hands

Downhole filters are installed on the bottom pipe and lowered into the source along with the casing string, their independent production is pointless if you are not engaged in downhole drilling. The task is relevant for drilling organizations and individual drillers who want to make an inexpensive high-quality filter with high characteristics and parameters that are most suitable for a particular well (depth of occurrence, soil composition).

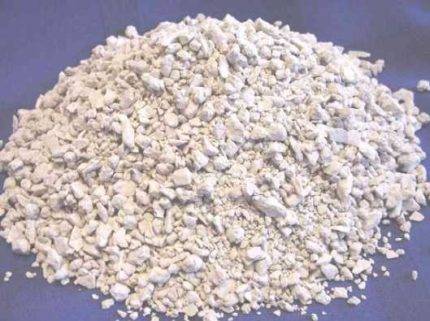

gravel

For a gravel filter device, do it yourself as follows:

- First, the size of the gravel backfill is selected, taking into account the granulometric composition of the water-bearing sand. To do this, contaminated water is extracted to the surface, and after its filtration, the size of the sand particles is determined.

- The gravel pack should have a granule size of approximately 8 times the minimum sand particle diameter or 5 times their maximum diameter. For example, if the dimensional parameters of water-bearing sand are 0.5 - 1 mm, the backfill should have dimensions of 4 - 5 mm, with grains of sand 0.25 - 0.5 mm. gravel sizes are 2 - 2.5 mm.

- The sized gravel fraction is immersed to the well bottom by the method of free fall in the water flow, its minimum thickness is 50 mm.

- Multi-layer filling is allowed, starting with larger fractions and moving to fine particles.

Rice. 11 Backfilling the casing

Perforated perforated well filter

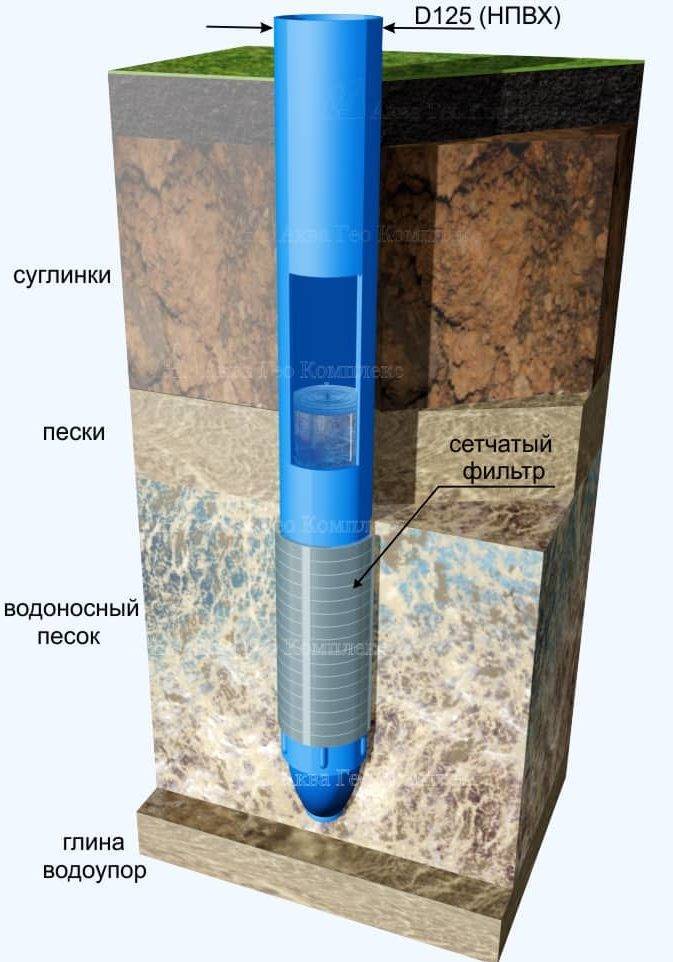

A perforated filter can be made by yourself without much effort with a simple tool (drill with a suitable drill bit). When installing a perforated filter from 125 HDPE casing, proceed as follows:

- The markup is made, marking the distance from the bottom plug to the end of the sump about 50 cm, the length of the filtering part with perforation is 110 cm.

- 4 equidistant lines are drawn along the pipe, 4 rows of holes are drilled with a diameter of 20 - 22 mm. pen drill on wood - they must be performed in a checkerboard pattern. The distance between them should be about 10 cm.

- The burrs formed during the drilling process are cleaned with sandpaper, you can singe them with a gas burner.

If the source is shallow, the number of holes can be increased to 8 rows, and perforated holes can be made for almost the entire length of a 3-meter pipe, their number will be about 20 - 25 pieces in a row.

Rice. 12 Do-it-yourself perforated filter

slotted

The manufacture of a slotted filter is rarely carried out independently - the process is laborious and time-consuming, when it is constructed, the following is done:

- Markings are made along the pipe surface, dividing it into 8 equal-sized sectors, drawing 8 lines and retreating from the ends by 50 cm.

- To cut slots, they take a grinder with a disc for metal or concrete, while it should be borne in mind that the slots from the disc for metal will have a smaller width.

- Cutting is done in 10 mm increments. to the width of the sector between the two lines, alternating free longitudinal sections with cut ones. At the same time, stiffening ribs 20 mm wide are left between the slots. through 10 - 20 lines.

- After cutting out 4 longitudinal segments with slotted areas, their surface is cleaned of burrs with sandpaper.

Rice. 13 Plastic pipe with slots

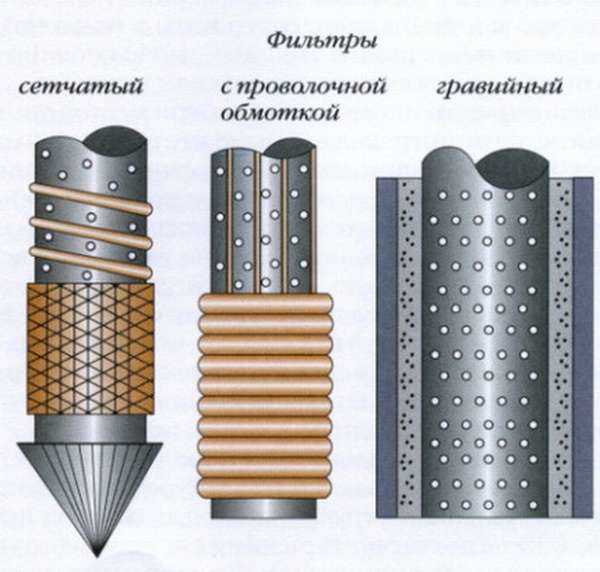

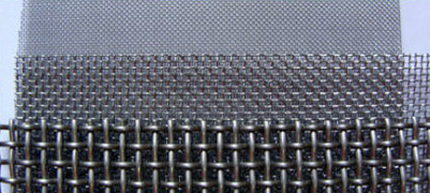

Wire Mesh Filter Systems

Making a wire filter at home is not possible - to ensure a gap between the turns of the V-shaped wire of about 0.5 mm. it needs to be welded onto a rigid frame from the inside at thousands of points.

At home, mesh filters are most often made by doing the following:

- They take as a basis a casing pipe with round holes made according to the technology described above. A nylon cord or stainless steel wire is wound onto its surface with a circumference of about 2 - 5 mm. with a distance between turns of 50 - 100 mm. The ends of the winding are fixed with brackets, screws or screwed with adhesive tape.

- A metal or synthetic mesh is put on top of the winding; a second outer winding with wire or synthetic cord is used to fix it.

Rice. 14 Manufacture of the strainer

Materials for filtration equipment

Stainless steel, plastic and ferrous metals are used as materials. Let us consider in more detail the features and characteristics of each of them.

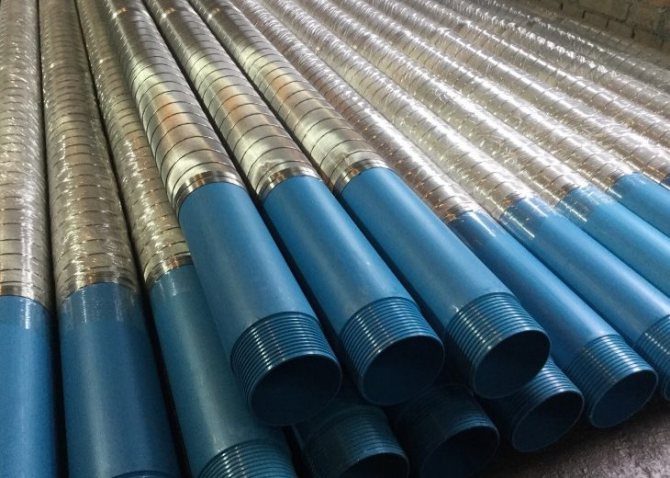

Benefits of using stainless steel

The best material for making well filters is stainless steel. It is able to withstand high crushing and bending forces, and alloying makes it resistant to oxidation.

Stainless steel pipes have a long service life, but their cost is quite high.

All the performance characteristics of stainless steel are also characteristic of the filter mesh made from it and the wire used for winding onto the part.

For the manufacture of a borehole filter, a special mesh made of metal or synthetic threads is used.

Features of the use of plastic

Plastic is another material that is widely used to make filters. Plastic is absolutely inert, therefore it is not subject to oxidation processes. It is very easy to process and has a long service life.

The cost of plastic parts is low, which is very attractive to well owners.

Downhole filters made of plastic pipes are very easy to process and are inexpensive. However, they can only be used at shallow depths, due to a small margin of safety.

The main disadvantage of plastic is its low strength. As a result, it is not able to withstand severe compressive loads that are characteristic of great depths.

The subtleties of the use of ferrous metals

Ferrous metals as filters can only be used for wells that provide water for technical purposes. This is due to the fact that they are oxidized by water, as a result of which iron oxide appears in it. Doctors have not proven that it is harmful to the body.

However, at a concentration of this substance greater than 0.3 mg / l, water will leave unpleasant yellow spots on plumbing, dishes and linens. Galvanized ferrous metals are also subject to oxidation.

Visually, water with a small amount of impurities looks almost transparent. But the plaque that forms on plumbing makes you think about the health hazards when using such water as drinking water.

Visually, water with a small amount of impurities looks almost transparent. But the plaque that forms on plumbing makes you think about the health hazards when using such water as drinking water.

As a result, not only iron oxide appears in the water, but also zinc oxide. The latter irritates the mucous membranes and leads to indigestion.

Thus, experts strongly do not recommend the use of ferrous metals, including galvanized ones, for the manufacture of well filters.

This applies not only to the base, but also to the filter mesh, the lower sections of the casing, as well as the wire that is used in fastening and manufacturing the structure. Otherwise, water obtained from a well with such a filter can only be used for technical purposes.

Thus, for deep wells, it is best to use stainless steel parts, and for shallow depths or in the case of using additional casing, it is optimal to mount plastic components.

Slotted well filter: overview, manufacturing method

Devices of this type are also used by well owners to protect them quite often. Like perforated ones, they are usually made from HDPE pipes.

Slotted filters differ from perforated ones mainly only in the shape of the filtering holes. In this case, they are made not round, but oblong. Slots up to 15 cm long are located across the pipe surface with a small step.

The assembly process of this type of filter itself is no different from mounting a perforated one. In this case, winding from fishing line and mesh is also usually used. One of the ends of the pipe at the final stage is sealed or clogged with a plug.

System manufacturers and price

When choosing equipment for filtration, you should pay attention to trusted organizations with a long service life and a good reputation, including:

- Hydrowell,

- Aquaphor,

- Geyser,

- Ecodar,

- Chemcore,

- Geomaster.

They produce a variety of systems, including for houses with increased or seasonal water consumption.

Product prices:

- Iron removal station. From 35-37 thousand rubles.

- Carbonic. From 25-27 thousand rubles.

- softener. From 30-40 thousand rubles.

Ecodar has been on the market for over 25 years, specializing in the development of filters and water treatment systems for private housing.

Its products are described by the following figures:

- Equipment class Standard. Water softening systems cost from 41 thousand rubles, iron removers - from 30 thousand rubles, an integrated system - from 119 thousand rubles.

- Premium. Softeners will cost from 54 thousand rubles, iron removers - from 56 thousand rubles, an integrated system - from 172 thousand rubles.

- Elite. Silent iron removal - from 117 thousand rubles, reverse osmosis system - from 1 million 106 thousand rubles.

The company offers high-quality downhole filters. Products are certified in Russia, Ukraine and Belarus, meet the requirements of international standards and have the following prices:

- slotted. From 2 thousand rubles.

- With stainless steel wire mesh (for sand). From 4 thousand rubles.

- With a dusting of the filtering layer. From 4.4 thousand rubles.

Enterprise "Geomaster"

The Geomaster organization has been operating since 1990, producing filters, including those according to the customer's project.

Offers the following types of products:

- Filters for wells on a plastic pipe. Depending on the parameters of the pipe and grid: 3.2-4.8 thousand rubles.

- On a metal pipe. From 7.5 thousand rubles.

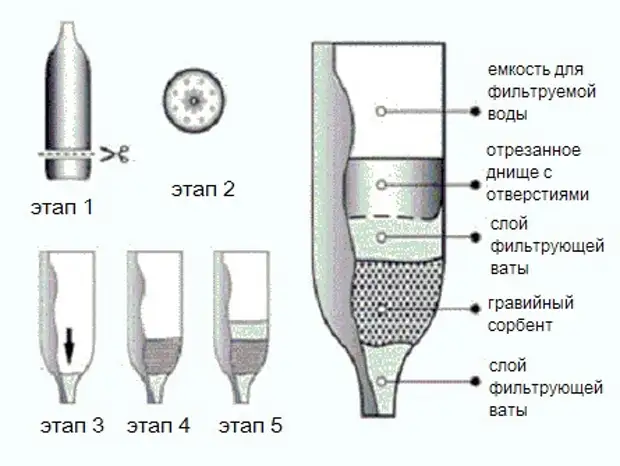

Making a carbon water filter

Before assembling, you need to choose a more optimal version of the case. For this you will need:

- Several plastic containers (bottles or PVC pipe, food containers can be used in some cases. Because of their strength, they will serve well as the basis of the cartridge).

- Tools for plastic processing (various sharp objects: awl, scissors, clerical knife, screwdriver).

- Absorbent material (in this case, activated carbon).

- Additional filter granules (quartz sand, gravel).

- Material for the primary fabric filter (medical bandage, gauze or coffee filter).

- Plastic caps or plugs.

For the tightness of the structure, polymeric substances should be used at the joints of the modules (if the filter is multi-level and consists of several parts). Moisture resistant silicone glue or insulating tape works well.

Device assembly process

To mount the suspended structure, you need to first cut off the bottom from the plastic bottle with a clerical knife. Then make two holes opposite each other for fastening the loops. Now the improvised body can be hung, for example, on a tree branch.

Next, you need to make an outlet valve, from where the filtered liquid will flow. At this stage, the design feature depends on individual preferences. You can organize something according to the principle of a shower - make many small holes in the lid, or you can drill one big one.

The next step will be the actual laying of the components. Having twisted the perforated cover, the body is turned over or hung by the hinges. Then, first of all, a bandage folded several times, or gauze, is laid. The use of a coffee filter is also encouraged.

In some cases, you can find designs where the role of the primary filter material is performed by a fabric cover sewn specifically for the size of the housing. This greatly simplifies the task of changing the absorbent and saves time.

It is worth paying attention to the fact that the laying of absorbent components should be carried out according to the “pyramid” type. This means that the first step is always fine-grained absorbent (coal), then comes a layer of quartz sand, and then comes the turn of river pebbles or gravel.

Each subsequent layer of the filter has a different, often finer structure than the previous one. This contributes to a more thorough cleaning.

Each subsequent layer of the filter has a different, often finer structure than the previous one. This contributes to a more thorough cleaning.

For greater efficiency, it is recommended to alternate several layers of pebbles, however, do not forget that excess material may interfere with the flow of water.

It is better to cover the filler hole with some kind of cloth or lid in order to avoid getting unwanted objects inside the cartridge.

The principle of operation of such a filter is the passive flow of water through all layers. Under the action of the granules, the contaminated liquid is cleared and flows out of the perforated hole. Initially, several liters of water must be passed through the filter. The first filtering procedure will wash the layers and remove contaminants.

The disadvantages of the system include a rather slow cleaning speed and the need to constantly fill in new fluid after the filtration procedure is completed.

The disadvantages of homemade water filters with natural fillers include low speed, the need to frequently change filter layers, and not too high quality cleaning.

Making a filter with your own hands

For this you will need:

- Grid with fine perforation, or special material;

- Thick wire.

"Is that all?" - you ask. “Yes,” I tell you.So, after you have found all the necessary materials, take the pipe, securely fix it on a solid surface so that it does not sway, and perforate the end of the pipe with a drill, at a distance of up to 20 cm of the end. Holes should be made at a close distance from each other, a step of about 0.7-1 cm.

Drill for as long as you can. Remember that the area on which the holes will be located must be completely covered by the filter, so be careful. Once the holes are drilled, wire must be wound around them. Just take a thick aluminum wire, and wind it around the pipe to the end of the holes. This is necessary in order to create a frame on which the filter material will lie. Distance from turn to turn (step) = 2.5 -3 cm.

As for the filter material. There are options here. You can use it as a metal mesh with a very fine mesh, or try to find filter material in specialized stores. It will be a tight fabric or plastic. Perhaps in such stores you will also find reinforcing rings of a suitable diameter for your pipe. When buying a plastic filter, choose a thicker material so that it does not sag and break when put into place.

So, when you have decided on the material, you need to carefully wrap it in one layer around the wire on the pipe and secure it well. It is best to fasten with a welding machine if it is a metal mesh, or with a special, moisture-resistant glue if it is an insulating material. Do not use toxic glue, the water that has passed through this filter is still drinkable.

Reliably "sew" the material and fix it at the end of the pipe - this is a very important point.If this is not done, there is a chance that the filter may slip, which means that either it will not filter at all, or it may block access to water. Believe me, both options are not at all good and the Russian “maybe” will not work here, otherwise, at best, you will have to drink water with sand, and at worst, you will not see it at all.

By the way, I recommend that you prepare the pipe before you start drilling the well. A newly made well tends to quickly drag on, which means that if you do not install a pipe with an attached filter immediately after it has been drilled, you will have to do the work again, because. groundwater will do its job, and the well will fill with water and sand.

And one more piece of advice, keep in mind that there are no eternal things, and filters for a well sometimes fail or simply get clogged, which means that you will sometimes have to get it out and clean it, perhaps change some parts, a grid, for example. Therefore, when installing the pipe, it is not necessary to fill everything around tightly with cement, because over time, you still need to get the pipe out of the ground and carry out preventive work.

I sincerely hope that the above tips will help you when digging a well and installing a filter yourself. Everything that is done by you personally is a guarantee of environmental friendliness and reliability.

Dear readers, comment on the article, ask questions, subscribe to new publications - we are interested in your opinion

Articles that will be of interest to you:

Cleaning options

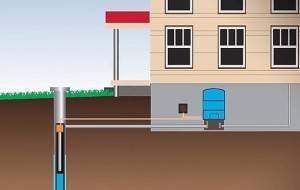

Well water treatment devices depend on which problematic indicators are characteristic of the source. However, there is such a stage of water treatment, which is indispensable even in the cleanest well - mechanical filters. It is with them that we begin the description.

Primary water treatment

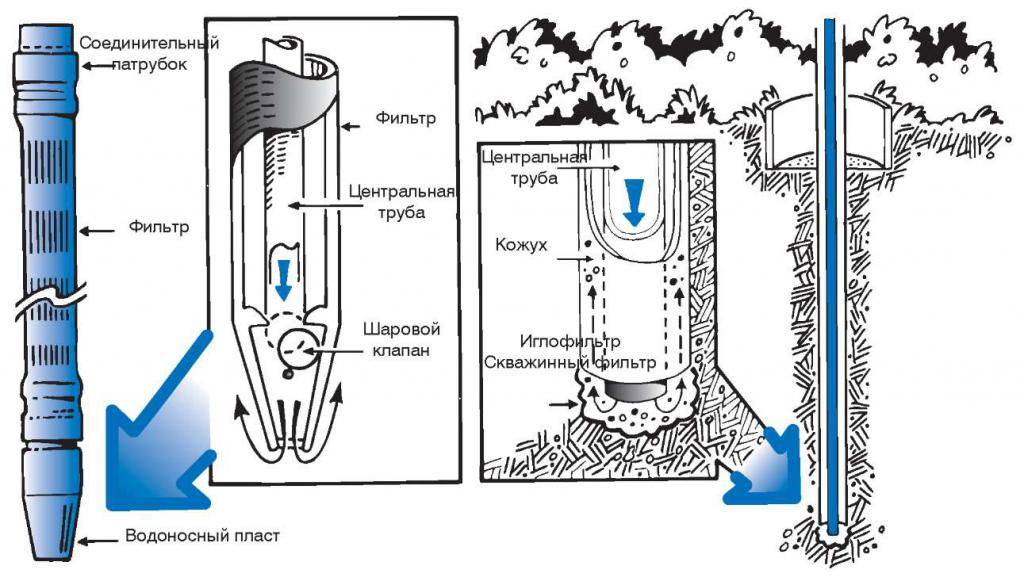

It is important to provide the well with a coarse filter, which will retain particles of sand, silt, clay, etc. It is located at the base of the well string and can be of several types.

First of all, they differ from each other depending on the base on which the filter element is located:

First of all, they differ from each other depending on the base on which the filter element is located:

- perforated is the lower section of the casing pipe, in which rounded holes with a diameter of 10-20 mm are made;

- the slotted base is characterized in that water seeps through cuts, the width of which is also up to 20 mm.

The latter option allows water to pass through better, but withstands soil pressure worse.

Neither slots nor rounded holes have sufficient cleaning capacity, therefore they are equipped with filter elements:

wire wound with a certain pitch;

with a special mesh, which covers the base from above.

Between the filter structure and the base there must be a frame, for example, rods located along the pipe.

A special type of mechanical filter is a gravel filter, which can be made in 2 versions:

- as an additional filter load, poured into the frame of the bottom filter;

- in the form of filling the space around the casing.

If the described options do not completely eliminate suspensions, then an additional mechanical coarse filter is installed as the first stage of water treatment.

Deep Water Treatment Systems

If the water in the well does not meet the standards, after rough cleaning, then additional water treatment is necessary, the composition of which is determined by what indicators do not correspond to the MPC.

-

- Ion-exchange filter - a container, the load in which is an ion-exchange resin. It is saturated with ions, which enter the water during the cleaning process, and pollutants pass into the resin in their place: calcium, manganese, iron, etc. Such filters are most often used to combat hardness. Their disadvantage is the need to regenerate the load or completely replace the cartridge.

- Membrane filters contain several layers of semi-permeable membranes that allow water to pass through but retain contaminants: iron, manganese, organic matter, bacteria, viruses, and more. A variant of such purification is reverse osmosis, during which water molecules under pressure pass through the pores of the membranes, and the remaining components cannot do this. This is a very efficient water treatment method. But it is not suitable for high concentrations of pollutants and leads to excessive desalination of water, which can be hazardous to human health.

- For iron removal and demanganization, filters with a conventional or modified load are more often used. Before filtering, iron or manganese is subjected to oxidation, for which aeration, ozonation, the addition of a chlorine reagent, potassium permanganate can be used. This traditional scheme allows you to get rid of these metals. The negative side is the need for flushing and the formation of wastewater that cannot be discharged to local treatment facilities due to toxicity to activated sludge.

- Sorption filters allow for fine cleaning.Usually they are used as the final step. These are filters with carbon loading, which can trap various contaminants, including organic substances, nitrates, nitrites. The filter material has to be replaced periodically, which requires financial costs.

- If microorganisms were found in the water, then disinfectants cannot be dispensed with. Usually these are ultraviolet installations, which are closed chambers, inside of which there is an emitter that does not come into direct contact with water.

In some cases, a local water treatment station includes several elements, for example, a mechanical filter, an iron removal station, a sorption filter, and a flask with a bactericidal emitter.

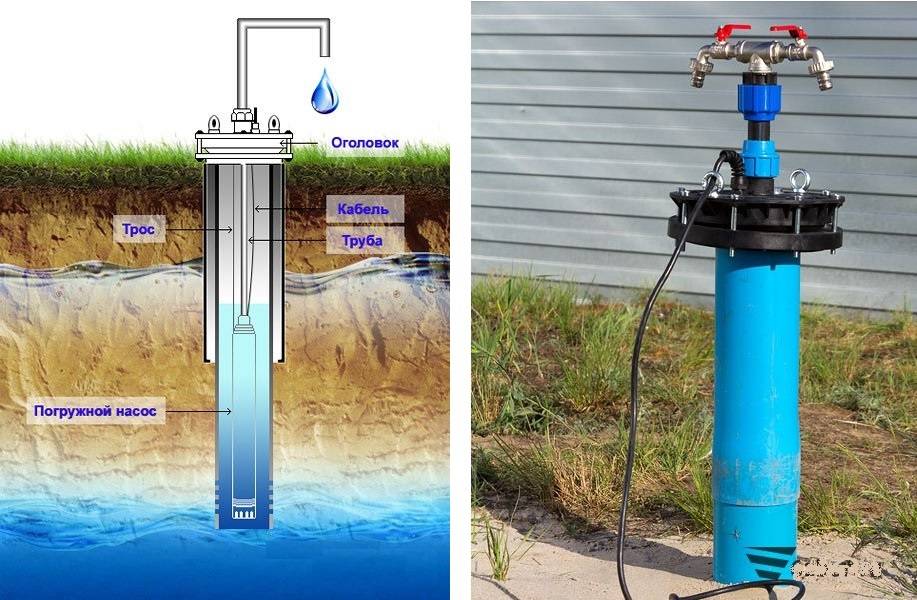

Why is a well filter necessary?

Many people ask this question. Some people use well water without any preparation. However, it is still better to install a water filter and here's why.

First of all, a well filter improves water quality. That is, it removes any impurities

In addition, water is treated against bacteria, which is very important in the case of well water. After all, if in the city this procedure is carried out at water treatment plants, then water from a country well comes to us untreated

Also, the installation of a filter is necessary so that all mechanisms in the well work as long as possible. Indeed, very often, along with water, a lot of debris rises from the depths, which one way or another settles on the mechanisms and prevents their correct, normal operation. Impurities that are usually found in water make it difficult for hydraulic equipment to work on a well.

The range of filters today is very large. And the filter housing can be made from any material. However, when choosing a housing material, you must rely on the quality of the water, as well as the operating conditions of the filter. After all, sometimes the filter has to work in particularly aggressive conditions, and for such conditions a more reliable and durable material may be required.

And now you need to find out what filter options exist for installation on a well. A description of these filters will help you make your final choice.

How do reverse osmosis filters work?

This is the most efficient water filter. Its design implies the presence of several pre-filters for mechanical and organo-lipid water purification, after which water is supplied to a special membrane. The reverse osmosis membrane is a fine sieve. The pores of this sieve allow only water molecules to pass through. Everything else, including microscopic viruses, microorganisms, bacteria, harmful impurities, falls into a special storage tank.

The technology of the reverse osmosis filter is based on the “pushing” of polluted water through a special membrane, the pores of which are so small that only water molecules actually pass through.

Reverse osmosis is ideal for dealing with scale, because it also removes mineral salts dissolved in water. For those who consider demineralized water “dead” and tasteless, the filter can be equipped with a module that artificially adds healthy salts to purified water. A definite disadvantage of reverse osmosis systems is that in order to obtain five liters of clean water, about 40-50 liters must be spilled through the filter.

Another important point is that for the normal operation of such a filter, sufficient water pressure in the water supply system (about 4 atmospheres) is needed. So some residents of the upper floors have to complete the filter with a small pump that increases the pressure. When choosing reverse osmosis, it is worth considering that an integral part of the system is a ten-liter water tank. However, there are filter models with a special 5-liter tank, which at the same time allows you to halve the water consumption during cleaning.

The cost of filters depends on the number of stages of purification and its quality. The first stage of such a filter purifies water only from mechanical impurities (rust and sand), the second stage softens the water, and the third one removes chlorine, phenols, metal salts and organic compounds. In the filter, where cleaning will be distributed over different stages, the quality of water will increase and the life of the cartridges will increase. And when choosing a four-stage system, you will get practically “antiviral” purification from impurities as small as 0.8 microns.

Before going to the tap, the water passes the last filter, it is called a post-filter, and it neutralizes odors. The result is crystal clear water with a very characteristic mild taste.

Making filters for a well with your own hands

The size of the holes depends on the characteristics of the soil.

The most common cleaning device used by summer residents and owners of private houses is a perforated perforated system. By design, it is a pipe with perforations (holes). The device is very simple, but quite effective. For manufacturing as consumables, you will need a metal or plastic pipe with a length of approximately 4.5-5 m.

When using metal pipes, geological or oil country mix can be used. Using drills, perforate a piece of pipe.

Making a perforated filter with your own hands is carried out according to the following technology. The length of the sump is measured, which should be from 1 to 1.5 m. The length will depend on the depth of the well. Markings are applied to the surface of the pipe, taking into account that the perforated section is at least 25% of the length of the entire pipe, and the required length is determined. The length of the pipe also depends on the depth of the well and can be 5 m. Stepping back from the edge of the pipe, holes are drilled. The pitch of the holes is 1-2 cm, the accepted arrangement is in a checkerboard pattern. It is recommended to drill holes not at a right angle, but at an angle of 30-60 degrees from bottom to top. Upon completion of work, the perforated surface of the pipe is cleaned from sharp protrusions. The inside of the pipe is cleaned of chips and closed with a wooden plug. The perforated zone is wrapped with a finely woven mesh made of brass, and preferably stainless steel. The mesh is fastened with rivets. The use of a mesh avoids the rapid clogging of the filter openings.

Types of nets for the filter: a - Galloon weaving; b - Square.

Large throughput is provided by the slotted design of the filters. The area of the filter slit exceeds the area of the hole by about 100 times. There are no so-called dead zones on the filter surface.

To make a do-it-yourself slotted filter instead of a drill, you need a milling tool. Depending on how the holes are made, a cutting torch may be required.The width of the slots is in the range of 2.5-5 mm, and the length is 20-75 mm, the location of the holes is in the belt and checkerboard pattern. A metal mesh is applied over the holes.

The weave of the mesh is chosen galloon, the material is brass. The choice of the size of the mesh holes is carried out empirically by sifting the sand. The most suitable mesh size is the one in which half of the sand is passed during sifting. For especially fine sand, a mesh that passes 70% is a suitable option, for coarse sand - 25%.

The size of sand particles determines its composition:

- coarse sand - particles 0.5-1 mm;

- medium sand - particles 0.25-0.5 mm;

- fine sand - particles 0.1-0.25 mm.

Before applying the mesh to the perforated surface, stainless steel wire is wound with a pitch of 10-25 mm. The wire diameter should be 3 mm. Structural strength is ensured by point soldering of wire sections along the length of the winding, approximately every 0.5 m. After winding the wire, a mesh is applied and pulled together with wire. The wire pitch during tightening is 50-100 mm. The mesh for fixing can be soldered or twisted with steel wire.

The wire cleaning device for the well is distinguished by the complexity of its design. To make such a filter with your own hands, you need to use a wire of a special section shape. The throughput of the system largely depends on the winding pitch of the wire and the shape of its cross section.

The winding technology is as follows. The slot design of the cleaning system is being prepared. The size of the holes depends on the size of the natural particles. Before proceeding with the winding of the wire, 10-12 rods with a diameter of at least 5 mm are superimposed on the frame.

The simplest filter device has a gravel structure. Such a system is built in soils with clay and fine sands. The filter construction process begins with the preparation of the well, the diameter of the well should be with a margin for gravel filling. Gravel is selected with a one-size fraction and is poured from the wellhead into the well. The thickness of the coating must be at least 50 mm. The particle size of the gravel is chosen relative to the particle size of the rock. Gravel particles should be 5-10 times smaller.