- When should you choose a sanding device?

- Step #1: Preparing the Sand

- Features and purpose

- Nuances of operation and maintenance

- Procedure #1 - Flushing the Filler

- Procedure #2 - Replacing the sand in the filter

- Do-it-yourself sand filter manufacturing and assembly steps

- The nuances of operating a sand filter

- Device care

- Pump selection

- Pool filters: types and design features

- sand pumping

- Diatoms (earth)

- Cartridge disposable

- What to focus on?

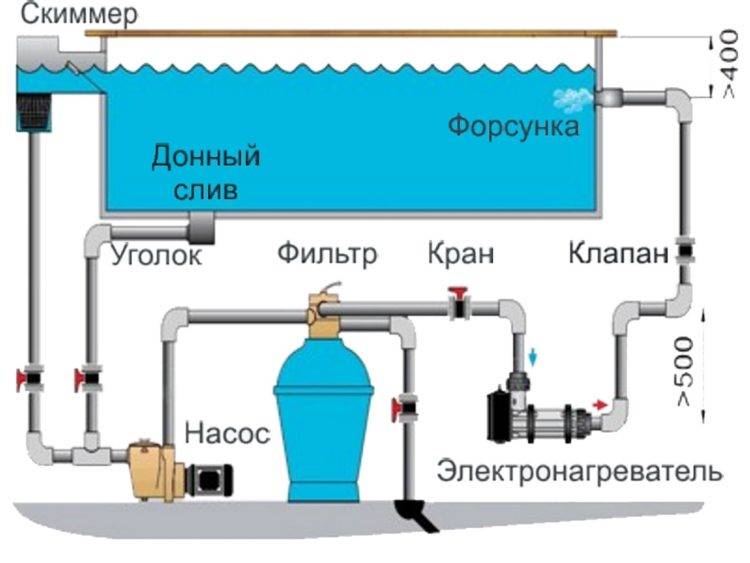

- How to connect correctly?

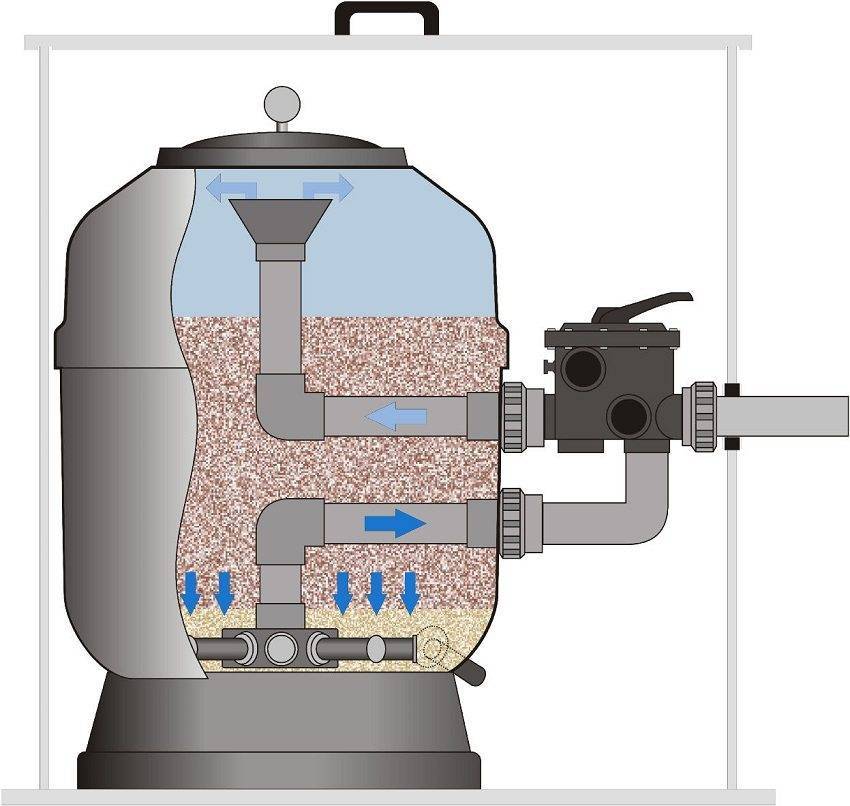

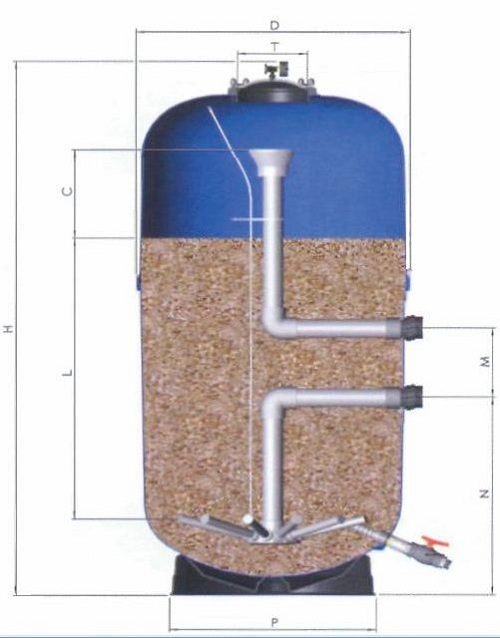

- Drawing and scheme of work

- Tools

- How to choose?

- Rules for operation and maintenance

- Maintenance and care

- Connection and maintenance of filter pumps

- How Filters Work

- Device and connection rules

- Proper care of filters

- How to choose?

- Equipment performance

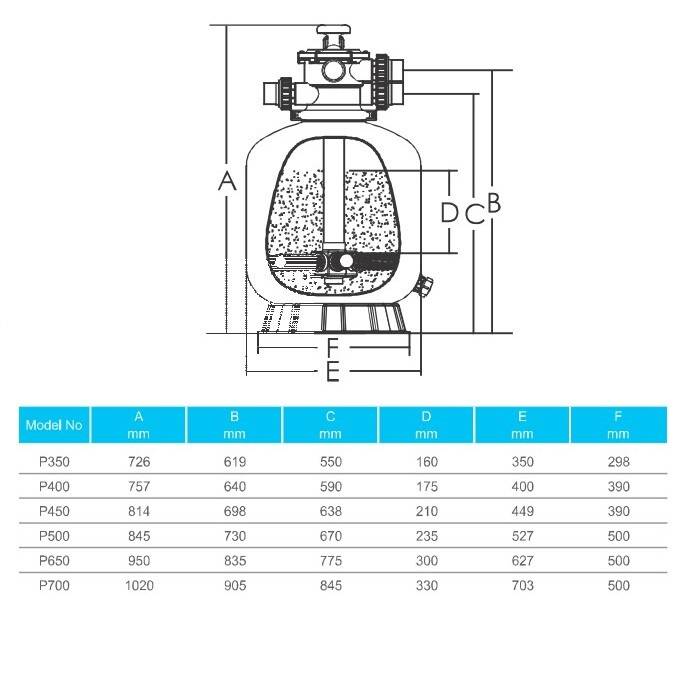

- Dimensions

- Mounting dimensions

- Possibility of chemical cleaning

- Frame pool manufacturers

- bestway

- Intex

- Jilong

- Conclusions and useful video on the topic

When should you choose a sanding device?

Owners of pools with a volume of more than 15 m3 definitely need to opt for the purchase of sand-based filtration equipment.

Owners of pools with a volume of more than 15 m3 definitely need to opt for the purchase of sand-based filtration equipment.

But it is also worth taking into account the fact that the size of the bowl is directly related to the power of the pump - with a larger volume, more powerful pumping equipment will be needed. When installing a filter for a pool with a large depth, it is better to purchase a sand device, in which the valve will be located on top

For a shallower bowl, side connection of filtration equipment is suitable

When installing a filter for a pool with a large depth, it is better to purchase a sand device, in which the valve will be located on top. For a smaller bowl, a side connection of filtration equipment is suitable.

Step #1: Preparing the Sand

The effectiveness of the future filter will directly depend on the quality of the sand used, so the first important step is to choose the right filler. Quartz sand is considered the best option in terms of the ratio of durability and availability. Its angular grains with a polished surface are not prone to sticking, therefore guaranteeing thorough filtration. The working diameter of quartz grains is 0.5-1.5 mm. Before use, the quartz filler must go through several stages of processing:

- Screening. It is necessary to remove grains that do not fit in size from the total mass of sand. This applies mainly to small filters - it is not recommended to use a filler with a diameter of more than 1 mm in them.

- Cleaning. It is necessary to rinse the filler several times with warm water until the liquid with sand is clear.

- Elimination of bacterial contamination. Boil the sand for an hour to kill all bacteria.You can also use special chemicals, but in this case, after completing the processing, the filler will have to be washed several more times.

Features and purpose

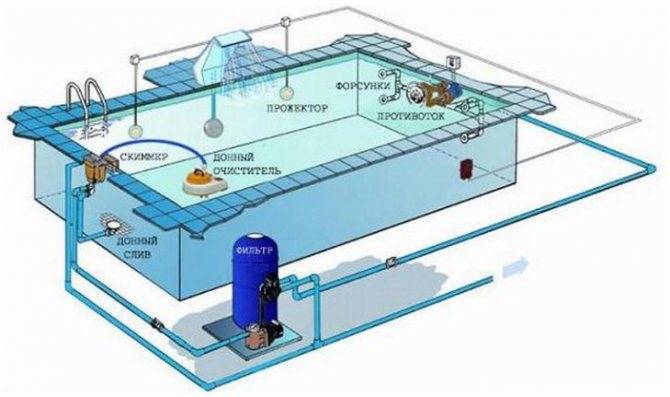

The purpose of a filter for artificial tanks is to combat water pollution - it is more efficient than using nets or garbage overflow devices. Filtering devices purify water from various types of natural and mechanical impurities. They also cope with the unpleasant odor that appears in the pool due to the active reproduction of bacteria due to the heating of water under the influence of the sun and atmospheric phenomena.

The installation of a filter for treating pool water is also necessary to maintain the sanitary and hygienic condition of the bowl. Such equipment provides users with comfortable conditions when taking water procedures, preventing infection of the body with stagnation products. These are modern devices that are designed to improve water quality, they do not allow the development of infectious and skin diseases.

As a rule, pool cleaning equipment is more often produced as an independent unit. It consists of a special water intake chamber and a filter unit. Due to this arrangement, it is possible to maintain the required level of water purification all the time the filter is in operation. At the same time, the dimensions of the device are selected strictly taking into account the type and size of the pool.

Each such cleaner has its own characteristics and principle of operation.

The principle of operation of a standard device is simple: dirty or stagnant water is pumped into the intake chamber by means of a special pump. In it, it undergoes primary cleaning due to chemical reagents.After that, the collected volume of water is passed through the filter system, carrying out mechanical purification. Water is purified from solid impurities and microorganisms and only then flows back into the pool.

Disinfection of water is provided by circulation and purification systems. It is especially true during periods of stagnation. However, the cleaning efficiency is subject to the type of built-in filter, as well as the speed of the cleaning process. According to generally accepted sanitary standards, its frequency should be 2-3 times a day, and the frequency of taking water procedures does not matter.

Mixes. Different raw materials are used as a filter filler: from natural to synthetic. In this case, the filler can be not only single-component, but also combined. For example, one type of mixture is diatomaceous earth, including diatomaceous earth, rock flour, diatomaceous earth. This is a loose sedimentary rock that looks like cement powder. The composition differs in that after purification, the water is enriched with silicon.

Unlike this mixture, when performing chemical purification, water can pass through several filters. The schemes are different and in some cases make it possible to achieve enriched water with oxygen.

Reagents kill germs and bacteria. Chlorine, bromine and iodine stand out among such materials. However, the use of chlorine is associated with the appearance of an unpleasant odor. The skin after chlorinated water will be tight and dry.

In addition, the use of chemicals can create toxic compounds, which include, for example, chloramine. To remove it during water filtration, an integrated purification system is used.

Boron is inferior to chlorine only in cost.It destroys the fungus, swamp smell, viruses, while not affecting the hardness of the water. However, for proper cleansing, its dosage should not be exceeded.

Flocculants are used in pool cleaning. These drugs deliberately increase the size of the boron particles so that they can precipitate. Such reagents cope with the turbidity of the liquid inside the tank.

The use of ozone, ultraviolet radiation, silver and copper also has its own characteristics. For example, overdose of ozone in a purification system can harm the health of bathers. Lamp installation is an alternative to chemical mixtures. However, it works well only in clean water. Copper and silver ions work at the expense of the electrodes and prevent the pool from turning into a swampy lake with algae.

Copper, like flocculants, performs the function of coagulants. However, such systems do not allow to refuse chlorination.

Nuances of operation and maintenance

Those wishing to build their own pool in the country should think in advance and provide for ways to maintain it. Water should be filtered constantly, especially if it is initially dirty (for example, rusty) or has managed to turn green after a forced downtime.

If the water is clean, then in order to save electricity, you can turn it on twice a day for 5-6 hours or once for 10-12 hours. During this time, the entire volume of water in an average reservoir of 15-20 cubic meters. m will change twice.

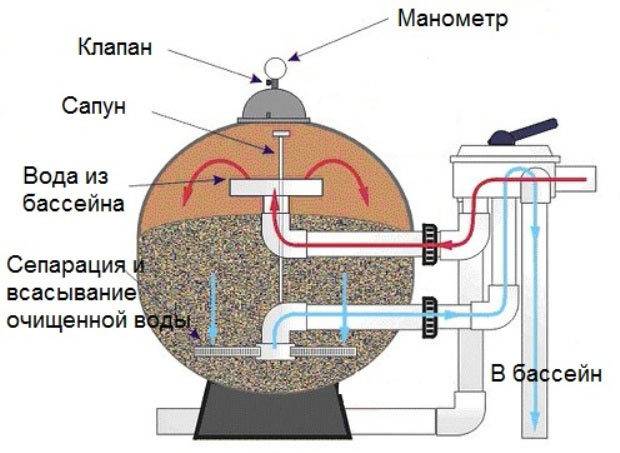

During operation, the filter element is covered with a layer of contaminants, which interferes with the further operation of the unit. Therefore, the sand should be washed.

A film is formed on the surface of the filter element - caked dirt.This layer prevents the passage of water and increases the pressure in the system.

Procedure #1 - Flushing the Filler

The frequency of cleaning sand from pollution depends on the intensity of use of the pool, the degree of contamination of the contents, the composition and amount of chemicals used. You can use the recommendation to rinse the filler every 7-10 days. However, for a pressure-type filtration system, the readings of the pressure gauge should be monitored.

The normal pressure in the system is 0.8 bar. If the indicator has reached 1.3 bar, then the sand needs to be washed.

For the cleaning process, it is necessary to ensure the flow of water under pressure into the lower chamber of the filter - into the intake device. To do this, they arrange the appropriate wiring in advance, so that you can change the direction of the flow by simply switching the taps.

Regardless of the method of connecting the system, the filter needs periodic cleaning of the filler from a dense contaminating layer. To do this, ensure the flow of clean water from the bottom up and the output of dirty water to the sewer or a separate tank

Please note that in this scheme the outlet valve to the pool is closed

If the wiring is not mounted, then you can rearrange the hoses. For the injection system, the hose is removed from the upper fitting and attached to the lower one (to the fitting connected to the water intake). If the pump is on suction, then throw the hoses from the pump.

The suction is disconnected from the fitting of the intake device and connected to a source of clean water or lowered into the pool. Pressure - connected to the outlet of the water intake. A hose is attached to the upper fitting to drain the flushing liquid into the sewer or into a separate container.

The pump is turned on, and the water under pressure loosens and washes away the accumulated layer of dirt. Rinse the sand until the drained washing liquid becomes clear.

Procedure #2 - Replacing the sand in the filter

Gradually, the filter element is heavily clogged with fatty and organic substances, skin particles and hair. Such sand is no longer able to provide proper water purification. Therefore, it needs to be completely replaced.

The filler is replaced as follows:

Close the tap on the water supply.

The remaining water is pumped as far as possible - if the pump is on supply, then a lot of liquid will remain in the filter.

Turn off the power to the pump.

Scoop out all the filler

Contaminated sand is simply teeming with bacteria, so this should be done carefully and with gloves, avoiding contact with mucous membranes and eyes.

Pour some water into the filter tank - about 1/3. The liquid will soften the mechanical impact of falling sand on structural elements.

Add the required amount of filter element.

Open the water supply.

Perform a backwash

If the hose for purified water is simply thrown over the side of the pool, then you can skip this step and drain some of the liquid into the ground when the system is started up.

Enable filtering mode.

When using quartz sand as a filler, its complete replacement will be required every three years.

To increase maximum efficiency, the filtration system is installed in the immediate vicinity of the pool.At the same time, for ease of maintenance, access to the unit must be free.

Do-it-yourself sand filter manufacturing and assembly steps

-

In a barrel (metal or plastic), we need to make two holes with a diameter that will correspond to the drives. If the barrel is metal, then the holes can be made with a special tool or an 80 watt soldering iron. We coat the inserted sleds with insulating sealant. Since a collection of purified water will be located at the bottom, the spacing of the surges is not important. From the container with the filter, water will go up through the installed hose, and through the second run it will pour back into the pool.

Plastic barrel with holes and sealed gussets

-

If there is no water intake, then instead of it we can take an ordinary round plastic bowl, make small holes in it, wrap it in two or three layers with nylon tights. The mesh should be much finer than the sand fraction.

Coarse filter in a can

- We fill the can with sand and close it.

-

We take the purchased pump and connect everything into a common system: from the reservoir, the hose will go to the filter, and then to the pump. After that, he falls into a can of clean sand and back into the pool.

We connect the pump with hoses to the system

-

Before installing the filter, it is necessary to collect all the sediment from the bottom of the pool using a pump and a hose, on which you need to put on a regular brush from a household vacuum cleaner.

Filter system connection

-

Attach a manometer. If the pressure level in the system increases by 30% more than what was shown at start-up, then this means that it is necessary to clean the sand using the backwash method.

Sand filter pressure gauge

-

We put the hoses on hot glue.We install a mesh for injection inside the barrel, which will have to break a large jet, so that water will evenly fall on the sand.

Complete sand filter

- To wash the sand, we just need to swap the hoses. Thus, water from the pump will go to the “outlet” of the filter, and all contamination will be removed through the “inlet”.

-

If the lid on the barrel is loose, then it can simply be torn off under great pressure. In order to prevent this from happening, it is necessary to strengthen the factory fastening of the lid, as well as rearrange the hoses so that the pump does not pump water into the barrel, but, on the contrary, removes it.

DIY sand filter

The nuances of operating a sand filter

After we have assembled a reliable filter, it is necessary to install it correctly and start operating it.

- The most important thing is to ensure good water circulation in the pool. If there are a large number of “dead zones” in the reservoir, then a large amount of dirt and microorganisms will accumulate there. Then all filter work will be simply inefficient.

- The filter should take water to a greater extent from the very top of the water in the pool, since it is on it that a lot of dirt, microorganisms and large debris accumulate. We can place the drainage system anywhere in the reservoir and at any depth.

- A person must have free access to the cleaning filter, not blocked by other devices, otherwise we will not be able to timely replace the sand.

Device care

To flush the sand filter, turn the valve to the back pressure position and turn on the pool pump. After the installation has been cleaned, the sand compaction mode is activated, a lot of pressure is created for a minute, after which the pump turns off and turns on automatically for normal operation. In order for the pond not to become cloudy, it is necessary that all the liquid passes through the filter at least 2-3 times a day.

When using a sand filter, the following rules must be observed:

- never switch the valve when the filter is under pressure;

- when switching the valve, make sure that it is firmly in its position in the grooves, otherwise the valve may break under pressure;

- you can switch the mode only when the filter pump for the pool is turned off;

- the pump needs air, so do not cover it with any objects;

- it is recommended to install the pump no closer than 1 meter from the reservoir itself.

Pump selection

The filtering system is necessarily equipped with a pump that provides forced supply of contaminated water to the filter and reverse flow of purified water to the pool. The device is purchased depending on the operating mode of the artificial reservoir and the nature of possible pollution. With intensive use of the pool, it is recommended to purchase a powerful filter pump capable of separating large particles. In the future, with its help, water is supplied to the purification system, where smaller inclusions are neutralized.

It is possible to ensure economical operation of a high-performance pump by applying different modes. During the absence of bathers, the system is transferred to a passive state, operating at low power. During intensive use of the pool, the cleaning pump turns on at maximum values.

The range offered by manufacturers of pumping equipment includes heating or heat pumps.

It is important to know that they are not intended to be used during a hot period of time. But for the cool season, such equipment can be a real gift. Each pump model has its own service life

So that it does not turn out to be shorter than the period indicated by the manufacturer, the installation must be hidden for the winter. But at the same time, one should not forget that the unit must first be washed and freed from water. Pump parts are lubricated if this stage is prescribed in the operating instructions. It is recommended that you familiarize yourself with all the requirements and nuances even before buying a pump.

Each pump model has its own service life. So that it does not turn out to be shorter than the period indicated by the manufacturer, the installation must be hidden for the winter. But at the same time, one should not forget that the unit must first be washed and freed from water. Pump parts are lubricated if this stage is prescribed in the operating instructions. It is recommended that you familiarize yourself with all the requirements and nuances even before buying a pump.

Pool filters: types and design features

All filter models have a single purpose - water purification and blocking of microparticles to avoid contamination. The difference in characteristics is the presence of additional modes of operation and design features.

sand pumping

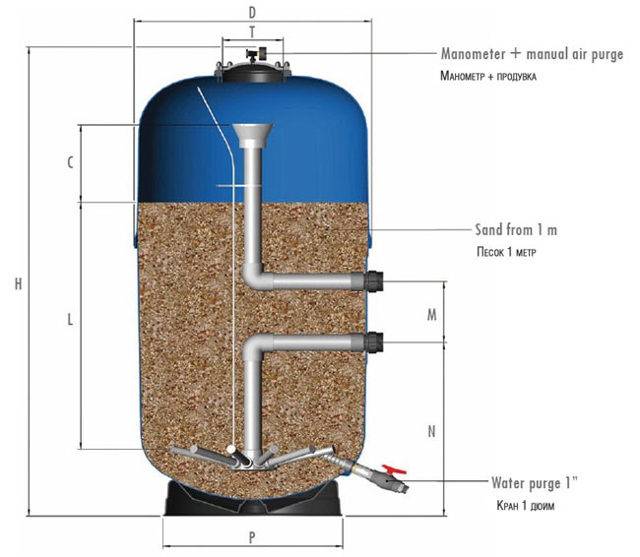

Sand filters are the most budgetary cleaning systems. The design consists of a sealed plastic container, which has two holes used for the supply and output of liquid.

The container is filled with quartz sand, and it plays the role of a filter.Heavy metal salts and organic suspensions remain in the quartz layer. The same applies to chemical compounds formed as a result of pool disinfection.

The disadvantage of this equipment is the inability to filter particles smaller than 20 microns. The period of operation is 3 years.

Even better is to use a combined placeholder. It contains sand, gravel and gravel in layers.

The sand system is easy to operate, cleaning is carried out by flushing during the back pumping process. Lime deposits are removed with special compounds that are introduced into the system for a certain time with the pump turned off. After that, you need to perform a standard cleaning process.

The inexpensive cost and ease of maintenance of this pool filter made the equipment versatile and popular, but there are certain nuances: the large size and weight of the cleaning device.

Diatoms (earth)

Diatom equipment is the most expensive among all mechanical cleaning devices. As a filter composition, diatomite powder is laid - a special rock, which consists of decay products of algae and hollow shells of microorganisms.

Before use, diatomite powder undergoes heat treatment: it is calcined in a special oven with a temperature of 1200C for at least a day. This helps to get rid of organic impurities and make a homogeneous fine filter fraction.

Filters are manufactured in several versions:

- The design of the filter resembles sand equipment. The difference is that diatomite powder is used instead of sand.

- The filter is a construction of cartridges installed in series in the housing, and water passes through them. This makes it possible to produce maximum cleaning, removing impurities up to 2 microns.

Attention! Due to the ability of diatomaceous earth to saturate water with silicon, its use helps to reduce the use of chemically aggressive cleaning compounds by 85%. It's no secret that silica water has rejuvenating and healing properties.

It is for this reason that such expensive pool filters based on diatomaceous earth successfully compete with budget sand filter devices.

It is no secret that silica water has rejuvenating and healing properties. It is for this reason that such expensive diatomaceous powder pool filters successfully compete with budget sand filter devices.

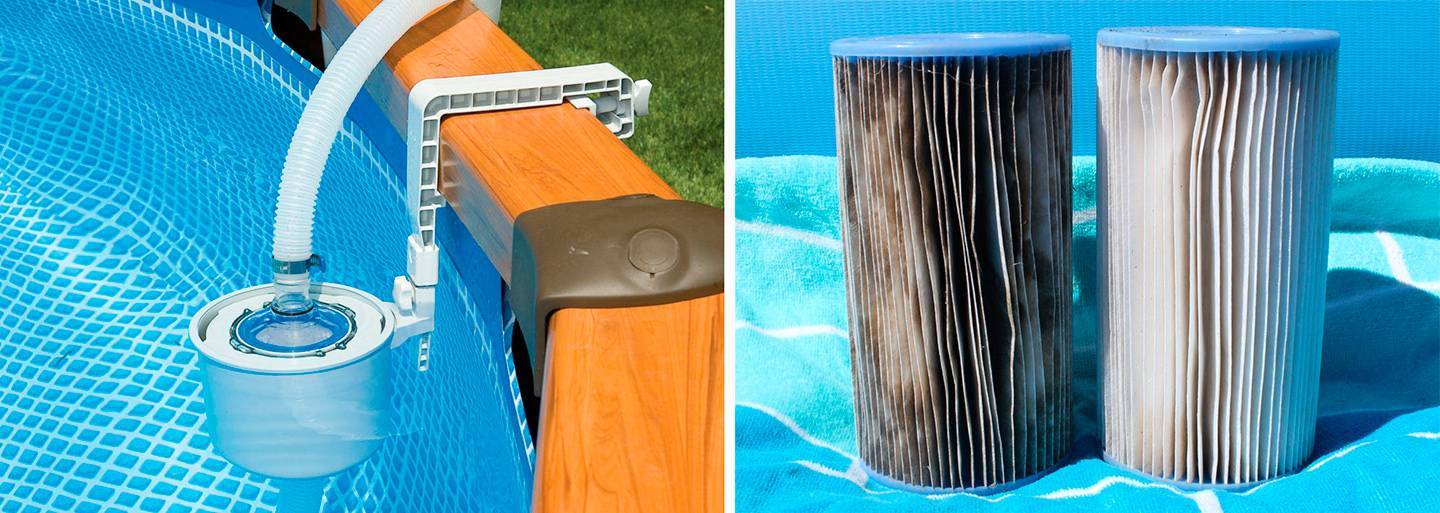

Cartridge disposable

As a working element of the filtering unit, membranes made of propylene plates are used. They do not let organic particles larger than 10 microns in size and heavy metal salts pass through. The effectiveness of cartridge filters for the pool is almost twice as high, unlike sand filter devices.

The design consists of a box with a removable lid, where the cartridge is located inside. Also here is a plastic bag, which is designed for the collected garbage.

Advantages of cartridge filtering equipment:

- effective cleansing;

- small sizes;

- backwash is not required;

- long period of work.

Taking into account contamination, the cartridge is taken out of the box and washed. The time of its operation will depend on the volume of the pool, and is up to 1 year.For trouble-free operation of the filtering equipment, it is recommended to have spare cartridges.

Often, modern models of cartridge systems are installed in a common housing of portable cleaning equipment, which is where another name for the device came from - filter pumps.

Despite effective cleaning and ease of maintenance, cartridge filter systems are not as common as sand filters, this is due to their high cost.

What to focus on?

When buying a filter and a pump, you need to clearly know for what purposes the pool is intended and its immediate volume. These parameters will allow you to accurately determine the amount of time required for the complete passage of water through the cleaning filter.

The time period varies depending on the purpose of the pool:

- Installed on an open suburban area - 4 hours.

- Placed indoors in the country house - 6 hours.

- Sports - 8 hours.

- Wellness - 6 hours.

- Children's training (age category 7 - 10 years) - 2 hours.

You also need to pay attention to the filter itself:

- the area and height of the filter element loading;

- granulometry (the composition of the granulate in the filter itself) - the density of the load and the number of components;

- nozzle or manifold inlet to the filter itself.

A careful study of these aspects will determine the optimal hydraulic resistance of the sand filter.

Compliance with SanPin standards in terms of cleaning intensity is possible only with a properly selected pair of filter and pump.

How to connect correctly?

The pump provides pumping water through the filter, so the first step is to check the readiness of the filter (presence of a cartridge, backfill filter material).

Further instructions on how to install the pump:

- Installation next to the pool (for ground pumps).

- Mounting on a bracket on the inner wall of the pool (for mounted and submersible filter pumps).

- Connecting the filter to the pump using hoses (in filter-pump systems, this is not necessary, the filter and pump are structurally combined).

- Inclusion of the filtering system in the electrical network.

Depending on the type of filter, it can be connected before the pump or after. The connection order is indicated in the technical description of the product.

Drawing and scheme of work

To assemble the filter with your own hands, you need to make your own drawing with the correct calculations or use ready-made diagrams presented on the Internet. We offer two do-it-yourself sand filter assembly drawings from improvised materials.

Drawing No. 1

Sectional Sand Filter

Drawing No. 2

Schematic representation of a sand filter

Tools

For a simple sand filter design, we need:

- Container with a wide "throat" (plastic or milk can);

- Quartz or glass special sand;

- Rotary valve pump with switching modes;

- Thick corrugated hoses;

- Shackles with rubber or plastic gaskets;

- Metal or plastic clamps;

- Coarse filter;

- Fixing pressure gauge;

- Water intake with the smallest mesh.

The power of the pump must match the volume of the pool. The water in it must pass through the filter at least 3 times in 24 hours. So, for example, for a reservoir of 8 cubic meters. (24 cubic meters per day) you will need a pump with a capacity of 40 l / min. Also, the device must have an additional power reserve.

Sand filter assembly pump

How to choose?

When choosing a filter system for your own pool, you should take into account its throughput. This indicator is measured in liters or m3 of liquid, which it can clean in 60 minutes of operation.

Using modern filters, it is possible to weed out not only large contaminants, but also those that have microscopic dimensions.

Do not ignore the degree of purification of the device, which can be determined by the speed of filtration, as well as the type of filter used. The lower the cleaning speed, the better the result of the procedure

When choosing a pump, it is worth taking into account the dimensions of the pool, as well as the thickness of its walls. At the same time, it is worth remembering that due to an increase in the speed of the unit, the quality of water treatment may decrease.

Currently, the owner of an artificial reservoir can purchase filters and a purification plant as a set. For this reason, the consumer does not have to select the filter container separately.

To determine the performance of the filter, it is worth multiplying the volume of liquid in the pool by 2.5 and dividing by 10. It is worth choosing a filtration unit for the pool on your territory, taking into account the calculated power.

Rules for operation and maintenance

In order for the cleaning system to work efficiently and for a long time, use the rules of operation and maintenance:

- The use of the device is carried out only by adults, for children it is unacceptable.

- Dry running is prohibited, the pool must be filled.

- Periodic cleaning of the contents or complete replacement of the filter component (sand, cartridge, diatomaceous earth) is required.

- If the operating mode is switched, the machine is disconnected from the power supply.

- At sub-zero ambient temperatures, the operation of the device is prohibited.

- The device is placed only on a flat surface, avoiding accidental falls.

With proper operation, the service life is at least 5 years.

Maintenance and care

In order for the treatment system to work effectively, it is important to pay attention to the following points:

- Install the device correctly. It should provide water circulation. If there are "blind" zones where water does not enter the intake pipe, pollutants and bacteria will accumulate there.

- Water must be taken from the upper layers of the pool - this is where a large amount of pollutants collect. The drain can be installed at any depth of the bowl.

- Access to the filtration system should not be blocked for the convenience of changing the sandy filtrate.

- Sand is replaced when the filter fails, the pressure drops below the threshold value (0.8 kg / cubic meter).

- If the system has ceased to cope with water purification, it is necessary to replace the filtrate or the entire treatment plant.

All the most important and useful information about sand filters for swimming pools is in this section.

Connection and maintenance of filter pumps

The filtration system is connected in stages:

- Pre-installation of cartridge, sand, diatomaceous sorbent element.

- The location of the filter on the ground or inside the pool, according to the instructions and purpose.

- Connecting a hose from which water flows from the pool to the filter.

- Connecting the hose from the filter back to the pool.

- Connection to the power supply network.

- Setting the operating mode before switching on.

Filter maintenance rules:

- replacement of sand, cartridge, diatom sorbent, depending on the degree of contamination;

- cartridge filters with a small degree of contamination can not be changed, but cleaned;

- a ban on using the system without immersing the hose in water;

- It is not recommended to use the device at sub-zero temperatures.

If all conditions are met, the filter will last a long time, will not break.

How Filters Work

Relatively young way to purify water in the pool. And they work according to the following principles:

Principle of ozonation. This principle of operation of electrophysical filters is the most progressive and environmentally friendly. O3 is a powerful oxidizing agent, so its passage through the water column in the pool destroys all bacteria without changing the composition of the water. Among the advantages of ozonation, one can single out the elimination of all bacteria and unpleasant odors, as well as the enrichment of water with oxygen. Among the minuses, the obvious high cost of such an installation stands out.

When considering this treatment option, please note that in some countries water ozonation is not allowed (its effect on humans is not fully understood).

The principle of ultraviolet radiation

If you are against chemistry, then this method is for you! The most efficient UV lamp works in conjunction with a mechanical filter

It is important to note that the effect of UV cleansing is short-lived.

The principle of ionization with silver and copper. Today it is the most advanced cleaning method.

It prevents the growth of bacteria and algae. How does this happen? Particles of copper and silver, split off under the influence of a small current, purify water from impurities.Obvious advantages of equipping the pool with an electrophysical filter with copper and silver ionization: in comparison with a UV lamp, copper and silver ions continue to work for a long time; if you decide to use an ionizer and an ozonizer in the same pool, then you can safely refuse chlorine; ionization of water in the pool purifies it to drinking standards; does not cause allergies and does not emit an unpleasant specific odor, like chlorine, for example. Among the shortcomings can be identified: if you apply the principle of ionization in a pool with a large volume of water, then you still will not be able to refuse chlorine; In our time, the influence of chemical compounds of metals on humans is poorly understood.

Combined. Each of the above types of filters is effective only in its narrow area, but more is needed to completely purify water. The combined system of purification and filters involves the installation of a mini-plant for water purification. The basic principle that you should consider when installing combined systems is the interaction of different types of cleaning systems with each other. This is necessary in order not to reduce the efficiency of one filter by another, but rather to increase it. Installation of a combined filter system in a swimming pool consists of the following steps: pump selection, installation of two types of filters and a heat exchanger, selection of a room where the filter unit will be located, complete equipment and assembly of the entire system.

pool water filter

pool water filter

Device and connection rules

The appliance itself is a plastic flask with a motor inside and a case with a paper cartridge. On some models, the filter elements are located separately, the same applies to sand and combined systems.The chlorinator is connected separately. The skimmer is a device that takes the top layer of water in the pool.

Its functions:

- Prevents water from overflowing.

- It is used for bookmarking a disinfectant composition.

Water enters the skimmer, passes through the filter and is fed back into the pool.

Pump connection principles:

- Water supply and intake must be connected at opposite ends of the pool bowl, otherwise the cleaning efficiency will be low.

- Be sure to install a large mesh on the skimmer so that debris cannot enter the system.

- It is recommended to additionally connect a water heater - then bathing will be comfortable. In warm water, disinfectants will work better.

Expert opinion

Kulikov Vladimir Sergeevich

Every day you should purify the water 3-4 times.

Proper care of filters

Any type of filter lacks periodic cleaning of contaminants. It needs to be backwashed every ten days. Also, the sand filter is additionally cleaned of accumulated lime. They do it like this:

- before backwashing, a pound of a special substance that dissolves lime is poured into the drain channel of the skimmer;

- briefly open the water so that the substance gets into the sand;

- sand with the substance is left for a couple of hours to dissolve the lime;

- at the end, a long backwash is done until the chemistry is completely washed out.

Because filtration is a very important part of the pool system, ultimately responsible for the safety and health of those who use it, its choice must be approached very carefully.

How to choose?

When choosing a specific model of the filter pump, pay attention to several parameters

Equipment performance

Sellers in the main characteristics provide data on the volume of the pool that the equipment can serve.

Therefore, it is enough to look at this characteristic to understand to what extent the filter pump is suitable for this pool.

For some models, only the filter performance is indicated. That is, the number of cube. m of water, which is able to process the device within 1 hour. In this case, you have to do a little calculation.

SanPiN 2.1.2.1188-03 of 2003 establishes that in small pools (up to 100 sq. M) the renewal time of all water should not exceed 8 hours. Given this figure, knowing the volume of the pool, it is easy to determine the minimum allowable performance of the equipment.

Example: for a pool with a bowl volume of 20,000 liters (20 cubic meters), at least 20,000/8=2,500 liters must be cleaned in 1 hour. Those. when choosing a filter, you have to focus on devices that pump at least 2,500 liters or 2.5 cubic meters. m for 1 hour.

Dimensions

Some devices, such as sand type, are equipped with an impressive tank. The filter element - sand - is poured into it.

The equipment should be located in close proximity to the pool, so when choosing a filtering system, it is worth considering its dimensions and design features, whether there is enough space for it on the site.

Mounting dimensions

The connecting dimensions of the filter system hoses must match the dimensions of the inlet/outlet pipes of the pump and the pool. Otherwise, you will have to purchase adapters.

Possibility of chemical cleaning

Usually, mechanical cleaning of impurities is assigned to the filter system. To combat biological pollution, air conditioners are used, which are added to the pool water.

Filters are produced, combined not only with a pump, but also with a chlorine generator. Such a filtering system performs mechanical cleaning and complete disinfection of the pumped water flow.

When independently connecting the chlorine generator to the cleaning circuit, pay attention to its performance. The technical data for the product indicates the performance of the filter pump that the chlorine generator can work with.

Frame pool manufacturers

bestway

A large manufacturer of inflatable products for outdoor activities (swimming, tourism, diving). Offers a wide range of products for every taste and compares favorably with extraordinary rich colors.

Each product is subjected to rigorous inspection for quality and safety of use.

Intex

A world-famous company, a market leader in inflatable products for home and outdoor recreation. All products undergo increased quality control, durability, service and environmental friendliness. A collection of new products is presented annually.

Jilong

The company is a manufacturer of plastic leisure products. Exporter to more than 50 countries worldwide. Various technical specifications of each new product are tested by an in-house laboratory.

The company is known for the ratio of high quality goods at a relatively low price, which is optimal for the buyer.

Conclusions and useful video on the topic

Overview of sand pump modes:

Equipping the pool with a counterflow pump:

The principle of operation and use of the heat pump:

Choosing a pump for servicing an artificial reservoir can be a very simple matter: just buy an all-in-one unit.

On the other hand, a huge selection of pumping equipment makes it possible to realize any fantasy from a heated indoor pool to attractions and sports countercurrents.

Are you looking for a pool pump and can't decide which one to choose? Or maybe you have experience of using such equipment and would like to share it with our readers? Please leave your questions and valuable advice in the box below.