- The ideal place for a pumping station - where is it?

- Equipment maintenance

- What is a pumping station?

- System Components

- The principle of operation and the advantages of the station

- Operating principle

- Self-made ejector

- Choosing a pump and installation location

- The principle of operation of the ejector

- The principle of operation of the ejector

- How the device is arranged and how it works

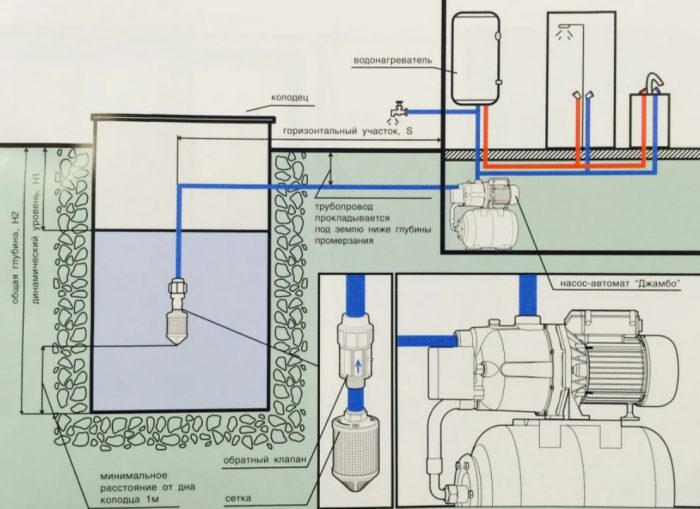

The ideal place for a pumping station - where is it?

Experts recommend installing equipment for water intake in separate from house construction. It is desirable that it be at some distance from the home, since the pump makes quite loud sounds during operation. They can interfere with the sleep of the inhabitants of the house. The installation room must be dry. Remember that the unit is powered by electricity. So, high humidity has a detrimental effect on the pump. Servicing the equipment under such conditions is life threatening.

Pumping station in its designated area

The station should be installed on a special pedestal made of wood blocks or bricks. The unit can also be placed on a solid, well-leveled concrete base. Under the pump, a rubber mat of a suitable size is mandatory.It will protect you from possible electric shocks, as well as dampen vibrations that occur during the start-up and operation of the unit. The station, in addition, must be attached to a concrete (brick, wooden) base. Anchors are used for these purposes. They are installed in the pump legs, which are initially available in the equipment of all manufacturers.

Equipment maintenance

Troubleshooting is a routine part of a preventive inspection. Therefore, you should have an idea about the most common breakdowns, the causes of their occurrence and how to eliminate them. For example, if the equipment simply does not turn on, a broken electrical wiring, low water level, or a blocked check valve may prevent this. If the unit does not turn on, but the emergency indicator is on, it means that the engine is more likely to fail or the protective systems that block the operation of the station are activated with violations. However, problems can arise not only inside the structure. Thus, a pumping station with a submersible pump for a well is especially often faced with the aforementioned damage to the float. Even its accidental clamping in the well can disrupt the operation of the control unit, which will give incorrect commands.

Therefore, it is so important to monitor the work and visually check the condition of submersible pumps.

What is a pumping station?

Before proceeding to the preparatory stage, it does not hurt to consider all the elements of this equipment, to find out how it differs from a conventional unit - a pump. The answer to the last question is a more gentle mode of operation, it guarantees a longer service life.But in order to understand how the equipment functions, it is necessary to consider all the devices of which it consists.

System Components

The structure of any pumping station includes a complex of elements.

- Pump. Its only job is to pump water. More often, surface-type aggregates act as the “protagonist”, less often submersible ones, ideal for wells with a depth of 40-70 m.

- Hydraulic accumulator. This is a tank, but not an easy one. Its inner part is divided into two chambers by an elastic membrane. One of them, the upper one, is intended for liquid, the other for air.

- Control block. Its task is to ensure automatic operation of the pumping station, turn on or turn off the pump when the pressure in the accumulator reaches a certain value.

- Control devices. The main device is a relay with a pressure gauge that determines the pressure level in the pumping station system. It is installed on the hydroblock.

If the farm has a hydraulic accumulator and a pump of sufficient power, then, as a rule, there is no doubt about the expediency of the operation. The remaining elements can be purchased separately, as their price is not so high. The master only needs to know in advance how to assemble the pumping station, what features this work has.

The principle of operation and the advantages of the station

Before assembling a pumping station, it does not hurt to get acquainted with how it functions. Work occurs in cycles, which include two stages.

- The pump turns on, which raises water from a well or a well. The liquid follows into the accumulator, where it is collected until the pressure exceeds the upper threshold. When this happens, the pressure switch stops the water supply, turning off the pump motor. The station goes into standby mode.

- After opening the tap, or the start of household appliances that consume water, the liquid begins to flow from the accumulator. When the pressure in the tank reaches the lower threshold, the relay starts the pump again, which immediately resumes the supply of water from the source.

It seems that a relatively compact system has no drawbacks, and its merits are beyond doubt. These include:

- fully automatic operation, extending the service life of devices;

- maximum efficiency of such a "forced" water supply system;

- the absence of any serious problems - with pressure, with the stability of the water supply;

- increased safety: both pipelines, household appliances, and the equipment itself;

- the ability to always have a certain supply of water, to ensure its supply during a power outage.

If we consider the advantages of self-assembly of such a kit, then one more important plus should be noted. This is a good chance to place the station in a relatively cramped room, since you can place the elements relative to each other at your discretion.

This pumping system is universal. It can be built into the main water supply in the event that the pressure in it leaves much to be desired. Such a problem with a drop in pressure is often found in summer cottages, cottage villages, as well as in rural areas.

Operating principle

Pumping stations operate according to an elementary scheme. The work cycle consists of the following steps:

-

After being connected to the network, the pump begins to pump water into the system, filling the accumulator to a certain level.

-

When the pressure gauge shows the maximum pressure, the pumping station automatically turns off.

-

Water withdrawal lowers the level in the hydraulic accumulator, respectively, the relay gives a command to start the pump.

-

If the tap is constantly open, water is pumped uninterruptedly, when it is closed - until the set level is reached.

In principle, this is an autonomous water supply system that requires only periodic maintenance.

Self-made ejector

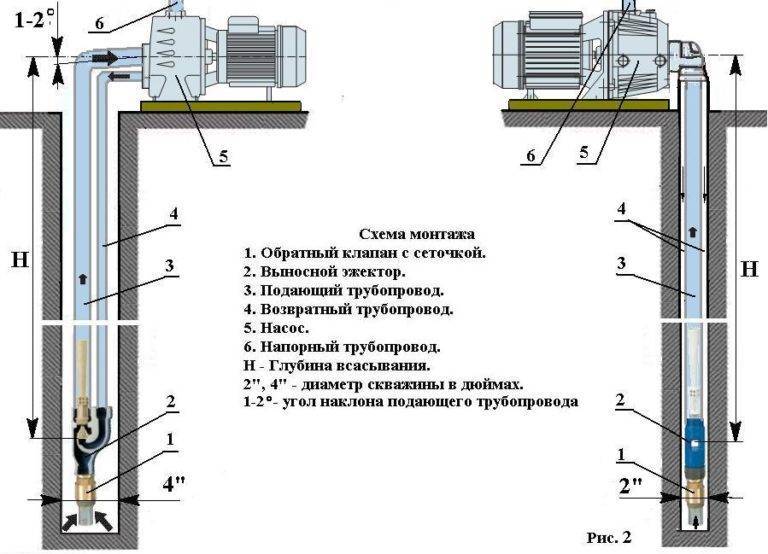

In order to make an air ejector with your own hands, you need to purchase the following set of parts, consisting of fittings and interface elements:

- tee - the basis of the designed air ejector;

- fitting - a conductor of high water pressure in the device;

- couplings and bends - these elements are used for self-assembly of the ejector apparatus.

In order to assemble an ejector for a pumping station from parts with your own hands, you must perform the following steps:

- first, you should take a tee, the ends of which are used for threaded installation. In this case, the thread on its ends must be internal;

- further, a fitting should be installed on the bottom of the tee. In this case, the fitting should be attached to the tee in such a way that the small pipe is inside the pumping unit. In this case, the branch pipe should not appear on the end, which is located on the opposite side of the tee.

In the same way, a short fitting is increased by using a polymer tube. The distance between the ends of the tee and the fitting should be 2-3 mm .;

- then, on top of the tee - above the fitting, an adapter should be installed.Moreover, 1 end of the adapter must be made for external threading (it must be installed on the base of the pumping apparatus), and the second must be installed as a crimp outlet (fitting) for a metal-plastic pipeline through which water flows from the well;

- from the bottom of the tee with the fitting installed, the 2nd crimp outlet is installed, on which it is necessary to put on and fasten the recirculation line pipeline with nuts. In this regard, before installing the device, you must first grind up to 3-4 threads of the thread on the lower part of the fitting;

- upon completion of the assembly of a home-made pumping apparatus, a second corner should be screwed into the branch on the side, at the end of which a collet clamp is installed for installing a water pipe.

The threaded connection is made on seals made of polymers - fluoroplastic sealing material (FUM).

After completing the assembly of a homemade ejector pump, it is connected to the station itself.

If you install a homemade ejector outside the well, then you will end up with a station with a built-in ejection device.

If the ejector device is installed in a shaft in which it is covered with water, then a station with an external ejection device will be obtained.

WATCH VIDEO

When installing such a home-made device, 3 pipes should be connected to the tee at the same time:

- 1st - to the end, which is located on the side of the tee. The pipe is lowered to the bottom, and a filter with a mesh is installed at its end. A small pressure of water begins to flow through such a pipe;

- 2nd - to the end, which is located at the bottom of the tee. It is connected to the pressure line that exits the station. As a result, the water flow rate in the ejector pump begins to increase;

- 3rd - to the end, which is located on top of the tee.It is brought to the surface and connected to a pipe that sucks in water. Through such a pipe, water will flow with even greater pressure.

As a result, the first pipe will be under water, and the second and third - on the surface of the aqueous liquid.

The price of an ejector for a pumping station ranges from 16-18,000 rubles. and depends on its specifications.

Stefan from Bulgaria shared his experience of making a jet ejector with his own hands. This is his first ejector. The jet ejector is designed for gold mining. What you need to have for manufacturing. Well, at least the head and hands. Then comes the material and possibilities. If you have a machine tool and know how to sharpen, then half the work can be said to be done. All that's left is the fight. A beautiful seam may not be needed, but it is desirable. Maybe it's easier to buy from Mikhalych or somewhere else? Maybe it's easier that way. Each decision is made by himself.

And today we will see how Stefan from Bulgaria made his first ejector.

And this is what it looks like broken down into pieces.

Why did he make it that way? Why four cones? Yes, I just didn’t know how it would work and therefore I did it experimentally. At Mikhalych, the production of ejectors has been put on stream because everything has already been tested and the best option has been chosen for a particular diameter of the pipe, pump and sluice. Or vice versa. Here is the first do-it-yourself jet ejector. Sharpened interchangeable cones and change them.

To weld a pipe, in principle, is not difficult for someone who knows how to cook.

And a smaller pipe. We collect. We get the finished ejector.

Choosing a pump and installation location

When choosing a suitable pressure equipment, you need to focus on the following characteristics:

When choosing a suitable pressure equipment, you need to focus on the following characteristics:

Performance.For watering the garden, a pump with an efficiency of about a cube per hour is quite enough, but for the water supply system at home, you will need to make calculations, taking into account the number of people living in it and the number of water intake points

A family of four needs to purchase a pump with a rate of at least three cubes per hour.

Water supply depth

The length of the pipes, their location is taken into account vertically or horizontal, the size of the source of water supply.

The pressure of the water flow at the very last point of the water intake, located as far as possible from the pump. The value must be large enough

The pressure indicator, as a rule, is indicated in the accompanying documentation for the equipment and is measured in atmospheres, bars

You can find the value by summing up all the distance segments that the liquid will pass through. Every 10 m there is a decrease of one atmosphere.

Mains voltage

This indicator is also of no small importance, since it affects the performance of the pumping station. When the voltage drops, the pump simply does not have enough power to provide the entire house with the necessary volume of water. A surface pump, in addition to water supply to the cottage, can also be used to irrigate the garden, or to pump water out of the basement, which is important for areas where spring floods

To equip an autonomous water supply system, you need to purchase a pump with more power than for ordinary greenhouse irrigation

A surface pump, in addition to water supply to a cottage, can also be used to water a vegetable garden, a garden, or to pump water out of a basement, which is important for areas where spring flooding often occurs. To equip an autonomous water supply system, you need to purchase a pump with more power than for ordinary greenhouse irrigation.

Installation of surface pumps is always carried out on land, since moisture is not allowed to enter the device case. Ideally, the electric pump should be located as close as possible to the source of water supply. It is forbidden to install in a room with a high concentration of moisture, low temperature, poor ventilation and open to atmospheric manifestations.

To mount the unit, small buildings are erected next to the well or caissons are equipped in the ground - insulated structures made of concrete, plastic, or metal. The installation of the latter is carried out below the freezing point of the earth.

If a well made of large concrete rings is a water intake point, you can install a pump directly in it. There is no need for earthworks, a strong raft of small size is required, but so that it can withstand the mass of the pump attached to it. The structure is lowered directly onto the water surface. The disadvantage of this method is that the pressure device will have to be periodically removed to adjust the pressure.

This is interesting: How long it is impossible to open windows after wallpapering: we cover the points

The principle of operation of the ejector

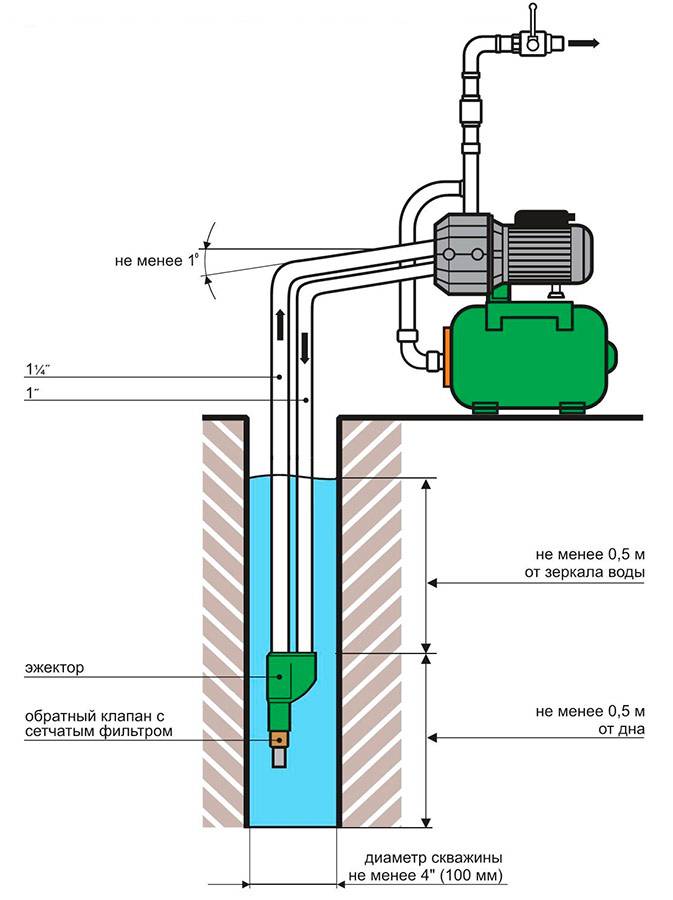

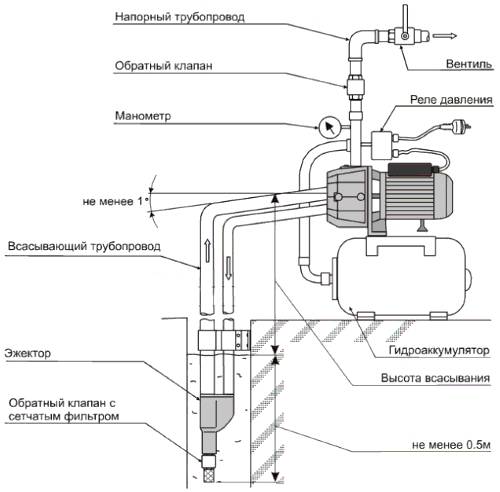

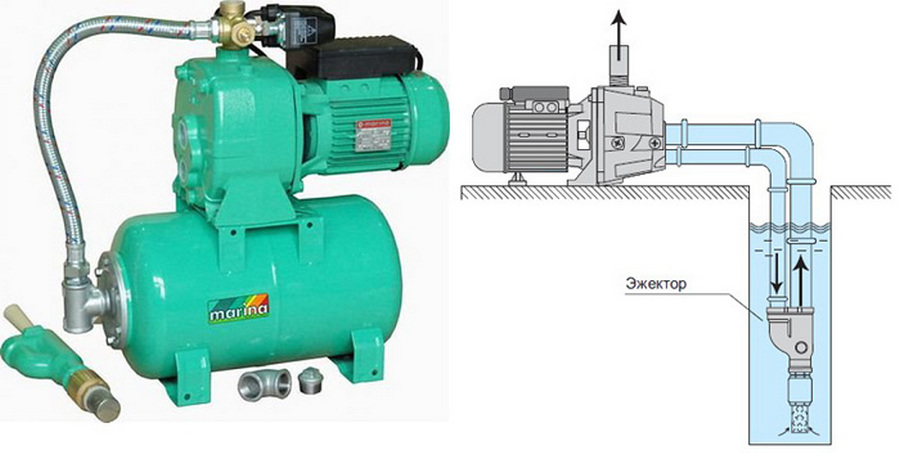

The deeper the water is, the more difficult it is to raise it to the surface. In practice, if the depth of the well is more than seven meters, the surface pump can hardly cope with its tasks.

Of course, for very deep wells, it is more appropriate to purchase a high-performance submersible pump. But with the help of an ejector, it is possible to improve the performance of a surface pump to an acceptable level and at a much lower cost.

The ejector is a small but very effective device. This knot has a relatively simple design, it can even be made independently from improvised materials. The principle of operation is based on giving the flow of water an additional acceleration, which will increase the amount of water coming from the source per unit of time.

Image gallery

Photo from

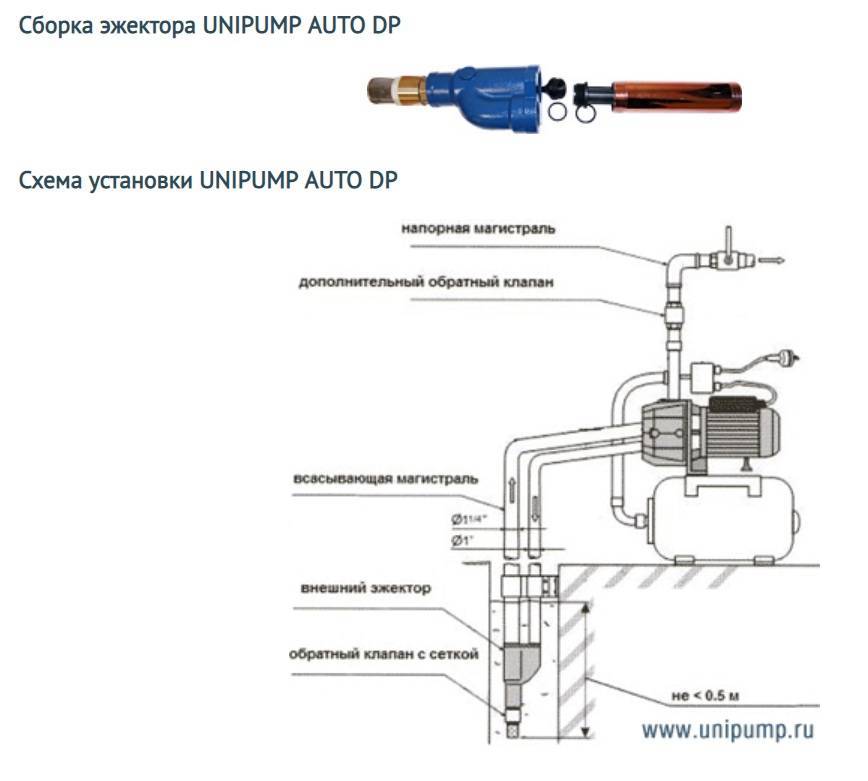

Ejector - a device required to raise water with a surface pump from a depth of more than 7 m. They are used to form pressure in the suction line

Ejectors are divided into built-in and remote varieties. Remote devices are used to lift water from an average depth of 10 to 25 m.

Two pipes of different diameters are connected to the ejector device, due to the pressure difference in adjacent pipes, pressure is created

Factory-made ejectors are supplied to pumping stations and automatic pumps

Devices are used in landscaping schemes requiring pressurized water supply for sprinkler systems, fountains and similar structures.

To install the ejector, the pump unit must have two inlets

Using the schemes and dimensions of factory-made ejectors, you can make a device that is useful in pumping out with your own hands.

A check valve with a strainer is installed on the suction port of a homemade ejector, which ensures normal circulation during the pumping process

This solution is especially convenient for those who are going to install or have already installed a pumping station with a surface pump. The ejector will increase the depth of water intake up to 20-40 meters. It should also be noted that the purchase of more powerful pumping equipment will lead to a noticeable increase in electricity consumption. In this sense, the ejector will bring noticeable benefits.

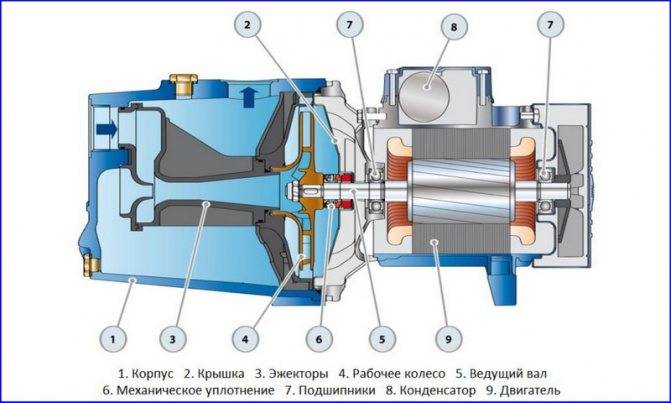

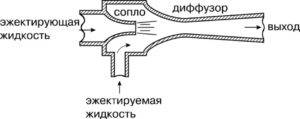

The ejector for a surface pump consists of the following elements:

- suction chamber;

- mixing unit;

- diffuser;

- narrowed nozzle.

The operation of the device is based on the Bernoulli principle. It says that if the speed of the flow increases, an area with low pressure is created around it. In this way, a dilution effect is achieved. Water enters through a nozzle, the diameter of which is smaller than the dimensions of the rest of the structure.

This diagram allows you to get an idea of the device and the principle of operation of the ejector for a pumping station. The accelerated reverse flow creates an area of low pressure and transfers kinetic energy to the main water flow

A slight constriction gives a noticeable acceleration to the flow of water. Water enters the mixer chamber, creating an area with reduced pressure inside it. Under the influence of this process, a stream of water at a higher pressure enters the mixer through the suction chamber.

Water in the ejector does not come from a well, but from a pump. Those. the ejector must be installed in such a way that part of the water raised by the pump returns to the ejector through the nozzle. The kinetic energy of this accelerated flow will be constantly transferred to the mass of water that is sucked from the source.

To create a rarefied pressure area inside the ejector, a special fitting is used, the diameter of which is smaller than the parameters of the suction pipe.

Thus, a constant acceleration of the flow will be ensured. Pumping equipment will need less energy to transport water to the surface. As a result, its efficiency will increase, as will the depth from which water can be taken.

Part of the water extracted in this way is sent back to the ejector through the recirculation pipe, and the rest enters the house's plumbing system. The presence of an ejector has another "plus". It sucks in water on its own, which additionally insures the pump against idling, i.e. from the “dry running” situation, which is dangerous for all surface pumps.

The diagram shows the device of an external ejector: 1- tee; 2 - fitting; 3 - adapter for a water pipe; 4, 5, 6 - corners

To regulate the operation of the ejector, use a conventional valve. It is installed on the recirculation pipe, through which water from the pump is directed to the ejector nozzle. Using a tap, the amount of water entering the ejector can be reduced or increased, thereby reducing or increasing the reverse flow rate.

The principle of operation of the ejector

The deeper the water is, the more difficult it is to raise it to the surface. In practice, if the depth of the well is more than seven meters, the surface pump can hardly cope with its tasks.

Of course, for very deep wells, it is more appropriate to purchase a high-performance submersible pump.But with the help of an ejector, it is possible to improve the performance of a surface pump to an acceptable level and at a much lower cost.

The ejector is a small device, but very effective. This knot has a relatively simple design, it can even be made independently from improvised materials. The principle of operation is based on giving the flow of water an additional acceleration, which will increase the amount of water coming from the source per unit of time.

Image gallery

Photo from

The use of an ejector in pumping out from a depth of more than 7 m

Automatic pump with a structurally built-in ejector

The design of the pressure booster

Model of automatic pump with remote ejector

Application in automatic irrigation system

Option to connect an ejector to a surface pump

Homemade models of ejectors to equip the pump

Check valve on the suction port

This solution is especially convenient for those who are going to install or have already installed a pumping station with a surface pump. The ejector will increase the depth of water intake up to 20-40 meters.

It should also be noted that the purchase of more powerful pumping equipment will lead to a noticeable increase in electricity consumption. In this sense, the ejector will bring noticeable benefits.

The ejector for a surface pump consists of the following elements:

- suction chamber;

- mixing unit;

- diffuser;

- narrowed nozzle.

The operation of the device is based on the Bernoulli principle. It says that if the speed of the flow increases, an area with low pressure is created around it. In this way, a dilution effect is achieved. Water enters through a nozzle, the diameter of which is smaller than the dimensions of the rest of the structure.

This diagram allows you to get an idea of the device and the principle of operation of the ejector for a pumping station. The accelerated reverse flow creates an area of low pressure and transfers kinetic energy to the main water flow

A slight constriction gives a noticeable acceleration to the flow of water. Water enters the mixer chamber, creating an area with reduced pressure inside it. Under the influence of this process, a stream of water at a higher pressure enters the mixer through the suction chamber.

Water in the ejector does not come from a well, but from a pump. Those. the ejector must be installed in such a way that part of the water raised by the pump returns to the ejector through the nozzle. The kinetic energy of this accelerated flow will be constantly transferred to the mass of water that is sucked from the source.

To create a rarefied pressure area inside the ejector, a special fitting is used, the diameter of which is smaller than the parameters of the suction pipe.

Thus, a constant acceleration of the flow will be ensured. Pumping equipment will need less energy to transport water to the surface. As a result, its efficiency will increase, as will the depth from which water can be taken.

Part of the water extracted in this way is sent back to the ejector through the recirculation pipe, and the rest enters the house's plumbing system. The presence of an ejector has another "plus". It sucks in water on its own, which additionally insures the pump against idling, i.e. from the “dry running” situation, which is dangerous for all surface pumps.

The diagram shows the device of an external ejector: 1- tee; 2 - fitting; 3 - adapter for a water pipe; 4, 5, 6 - corners

To regulate the operation of the ejector, use a conventional valve. It is installed on the recirculation pipe, through which water from the pump is directed to the ejector nozzle. Using a tap, the amount of water entering the ejector can be reduced or increased, thereby reducing or increasing the reverse flow rate.

How the device is arranged and how it works

The device uses the Bernoulli principle, from which it follows that an increase in the fluid velocity provokes the formation of a low pressure area in the immediate vicinity of the flow (in other words, a rarefaction effect occurs). The design of the ejector includes:

- suction chamber;

- mixing unit;

- diffuser;

- special nozzle (gradually tapering nozzle).

The liquid medium, moving through the nozzle, picks up a very high speed at the exit from it. The resulting vacuum provokes the flow of water from the suction chamber. The pressure of this portion of the liquid is much greater. Having mixed inside the diffuser, the water begins to move along the pipeline in a general flow. Strictly speaking, the principle of operation of an ejector pump is the exchange of kinetic energy between flows having different speeds (not to be confused with an injector, which acts exactly the opposite).

There are steam and steam jet ejection pumps. Vacuum-type steam apparatus maintains a vacuum by pumping gas out of an enclosed space. Most often, such devices are used to supply water.

Steam jet pumps work by air ejection. Here, the energy of the jet is used, which occurs in the process of pumping out an aqueous, vaporous or gaseous medium. Most often, steam jet pumps are equipped with river and sea vessels.