- What to consider when choosing

- Self-assembly of an electric heat generator

- Unit # 1 - electric heat gun

- Materials and tools

- Assembly process

- Advantages

- What to use instead of homemade

- Unit # 2 - diesel fuel heat gun

- How does such a design work?

- Assembly process

- electric gun

- Conclusions and useful video on the topic

What to consider when choosing

A correctly selected parameter will not only help to optimally heat the room, while rationally using electrical energy, but will also keep the gun working for a long time.

Calculation of thermal electric guns can be made according to the formula:

Р=VхТхК, kW

where V is the volume of the room; T - temperature difference outside and inside the room; K is the coefficient of thermal insulation of the walls.

- K=3…4 - walls made of boards or steel corrugated boards;

- K \u003d 2 ... 2.9 - brick walls in one layer, a roof without insulation, simple windows;

- K = 1 ... 1.9 - standard wall, roof and insulated windows;

- K = 0.6 ... 0.9 - walls made of two layers of bricks, there is additional thermal insulation, high-quality plastic windows, additional thermal insulation of the roof.

The final result calculated by this formula is measured in kcal / hour.

To convert to watts, you need to multiply the resulting number by 1.16.

For rooms with an area of 5-6 m², 0.5 kW of the device is suitable.

For every 2 additional m², add 0.25 kW to 0.5.

In this way, the required power of the heat gun is determined.

If you intend to use the device constantly in the same room, for example, to give, then you can purchase a stationary gun.

If it is planned to use it as an additional source of heat or the frequency of use is not too high, then it is wiser to take a mobile variety.

Pay attention to the device of the heating element. In rooms where people are often enough, you should choose models with a closed thermocouple. In rooms where people are often enough, you should choose models with a closed thermocouple

In rooms where people are often enough, you should choose models with a closed thermocouple.

Otherwise, the products of combustion of garbage particles that fall on the heating element can adversely affect human health.

A wide range of products allows you to choose the version of the case that best fits into the situation.

You should also pay attention to the material from which it is made - choose the most resistant to thermal effects.

The noise level produced by the gun is of no small importance when it is installed in rooms with people. To avoid discomfort, models with a noise level not exceeding 40 dB are recommended. To avoid discomfort, we recommend models with a noise level not exceeding 40 dB

To avoid discomfort, models with a noise level not exceeding 40 dB are recommended.

If the determining factor is the power of the device, for example, installed on a construction site, then in this case efficiency will be much more important than sound influence.

And, of course, an important factor is the cost of an electric heat gun.

It would be irrational to buy an expensive powerful device for a ten-meter room.

And for large areas, such as construction sites, warehouses, industrial premises, powerful industrial thermal electric guns are needed, the cost of which can be 30-40 thousand rubles.

Taking into account the combination of all these factors, you can choose the most optimal option for an electric heat gun.

Self-assembly of an electric heat generator

Assembling an electric heat gun with your own hands begins with drawing up a sketch of the device, selecting the necessary parts and tools. In addition, it is very good to replenish your knowledge base with the basics of electrical engineering, strength of materials, and physics. This knowledge will not be superfluous when assembling a heat gun on your own.

Materials that will be needed to create an electric heat generator:

- A sheet of galvanized metal, 0.7-1 mm thick or a pipe made of a similar material, with a diameter of approximately 25 cm. The pipe will be the body of the heat gun, so its diameter is selected based on the size of the impeller and the size of the heating element.

- Electric motor with impeller. You can purchase any duct-type supply fan at the nearest specialized store, or you can successfully use impeller motors from an old vacuum cleaner.

- Heating element.A simpler and safer option would be to use ready-made tubular heating elements from an old electric furnace with a power of 1.5 - 2 kW. This heating element has been shaped into a coil at the factory, which makes the job a lot easier.

- 2 mm2 copper wire, ceramic insulator, switch, cable with power plug, 25 A fuse for heating element.

Tools for assembling an electric heat gun with your own hands:

- Rivet machine.

- Drill with drills.

- Pliers.

- Screwdrivers.

- Insulating tape.

- Soldering iron.

Let's start assembling. Bend the pipe from the galvanized sheet and fix its position with rivets. This will be the body of the heat gun. Install the heating element on the ceramic insulator and mount it inside the case from one end. On the other side of the case, install the fan using standard fasteners. Then, with the help of wires, connect the heating element and the fan to the mains wire, switch, providing for a fuse in the circuit.

Such a heat gun will have enough power to heat a small room up to 20 m2.

Unit # 1 - electric heat gun

An electric heat gun is perhaps the simplest and safest heater option. If there is access to electricity on the site, just such a unit should be made. It will come in handy both during construction work and later, for various household needs both in the house and on the site.

Materials and tools

To make an electric heat gun you will need:

- the frame on which the structure will rest;

- metal case;

- heating element (TEN);

- fan with electric motor;

- switch or control panel;

- cable for connecting the device to the mains.

The body of the heat gun can be made from a suitable piece of pipe or from a sheet of galvanized iron. To work, you will need a tool for metal and, possibly, a welding machine. The name “cannon” was given to this device because of the similarity of its cylindrical body with an ancient gun. However, the heater body may also have a square or rectangular section if it is easier to manufacture.

Please note that the body of the product may become quite hot during operation. You should choose a heat-resistant or sufficiently thick metal for the case. In addition, it makes sense to apply a heat-insulating coating to its metal parts.

In addition, it makes sense to apply a heat-insulating coating to its metal parts.

When choosing a suitable heating element and fan, it should be remembered that the heating temperature depends on the power and number of heating elements. The fan speed does not affect the amount of heat, but the higher it is, the more evenly the received heat will spread throughout the room. Thus, the heating element is responsible for the heating temperature, and the fan speed is responsible for the quality.

To reduce costs, the heating element can be removed from an old iron or other household appliance. Sometimes it makes sense to shorten the heating element in order to increase the heating temperature. A suitable impeller motor can be found in older vacuum cleaners.

Assembly process

To assemble an electric heat gun correctly, it is recommended that you first draw up a diagram of the electrical circuit of the device.You can use a ready-made scheme, one of the options is presented below:

For the correct installation of an electric heat gun, before starting work, it is recommended to draw up an electrical circuit, reflecting on it the connection of all elements to the mains

Assemble the electric heat gun in the following order:

- Prepare the body and support.

- Install the heating element (or several heating elements) in the center of the body.

- Connect the power cable to the heaters.

- Install the fan and supply power to it

- Bring the power wire, wiring from the heating elements and the fan to the control panel.

- Put a protective grille on the front and back of the case.

During assembly, carefully insulate all electrical connections. At the end of the assembly, a test run of the device is made. If it works without failures, you can use the gun for its intended purpose.

Advantages

The greatest advantage over liquid or gas-fired heaters, such models of mobile heaters, of course, will be the safety of use. There is no open flame here, there is no combustion process itself, and this makes all such units much safer in terms of fire.

The second factor, which can be quite significant in value, is that during the operation of such devices no unpleasant odors are emitted and there are no exhaust gases.

The second factor, which can be quite significant in value, is that during the operation of such devices no unpleasant odors are emitted and there are no exhaust gases.

This allows the use of heaters powered by the mains, even in small enclosed spaces.

Another important feature of such units is their small size. Such guns can be easily carried and transported in a car.

Such guns can be easily carried and transported in a car.

To heat a small trading pavilion, you do not need very significant heating and power, which can be produced by a gas or diesel heater. A small installation that is connected to the network is enough here.

When using such a heater, there is no need to mess around with fuel for refueling, the appearance of unpleasant odors during the operation of the unit is excluded, which means there is no risk of exhaust poisoning from burnt fuel.

What to use instead of homemade

If you doubt your technical skills, consider purchasing a ready-made diesel generator model. Despite the rather high cost of such a unit, such a purchase is quite profitable: subject to the required operating rules, diesel heat guns can operate for ten or more years. Below are the leading manufacturers of such equipment.

Biemmedue: quality + Italian design

The Italian company, founded in 1979, specializes in the production of heaters, generators, dehumidifiers and other heating equipment. Products, in the assortment of which both household and industrial models are presented, are distinguished by durability, reliability and excellent quality.

The manufacturer pays attention not only to technical characteristics, but also to design. All lines developed by Biemmedue specialists are distinguished by their compact size, mobility, and aesthetic appearance.

Master: a company with vast experience

An American company that has been manufacturing portable heating systems for more than half a century, including various types of heat guns.For the manufacture and design of the units, only high-quality material is used, due to which the company's products are distinguished by high technical characteristics.

Diesel heat gun Master BV 110 has excellent characteristics (power 33 kW, 65-liter fuel tank, fuel consumption 2.71 per hour). Within an hour, the unit can heat 460-1000 cubic meters of air

Thanks to the innovative technologies that are used in the production of models, the heat guns have many useful additional options, for example, a flame control function or an emergency automatic shutdown in case of an unusual situation.

Kroll: innovative technologies

Heating equipment manufactured by the well-known German company Kroll is distinguished by a high level of assembly and the use of high-quality materials, primarily stainless steel. In the production of products, including thermal diesel guns, the latest engineering and scientific developments are widely used.

Products of other companies (Vitals, Ballu) are also popular. Products manufactured on the production lines of these multinational companies are distinguished by their reliability and long service life.

Every year, interesting new products can be seen in the product range: for example, for the latest models of the company's heat guns, a heat heating function is provided, thanks to which the devices can work successfully even at low temperatures.

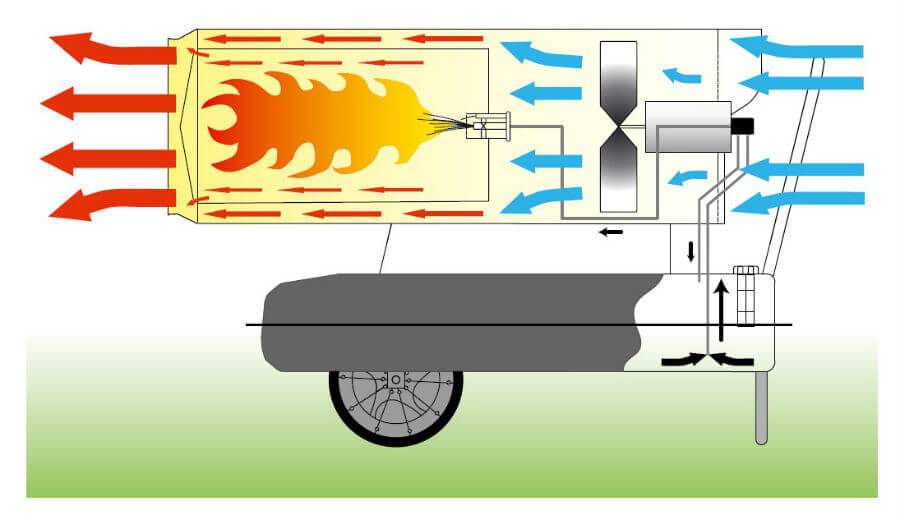

Unit # 2 - diesel fuel heat gun

Where access to electricity is limited or impossible, diesel-fueled heaters are often used. It is somewhat more difficult to make such a heat gun on your own than an electric model.You will need to make two cases and work with a welding machine.

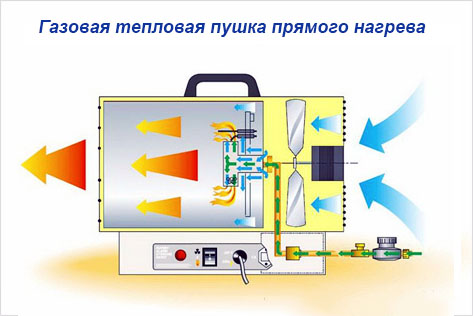

How does such a design work?

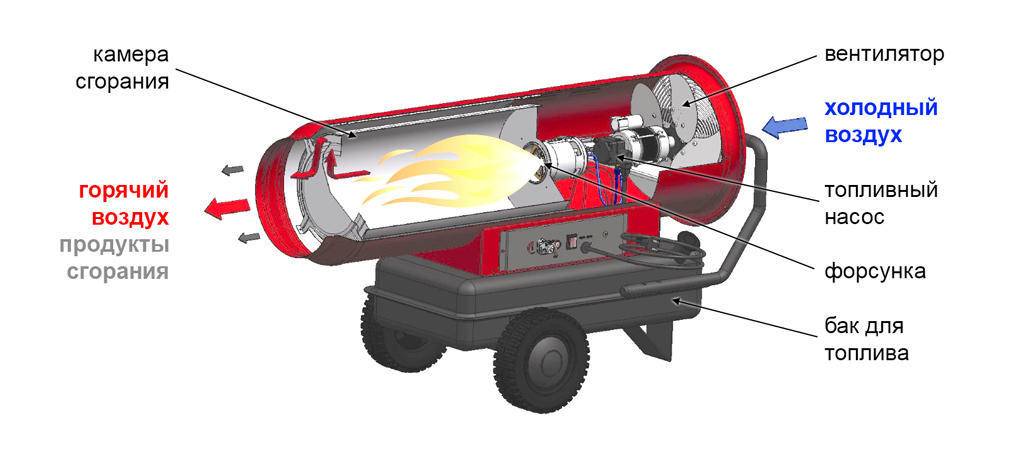

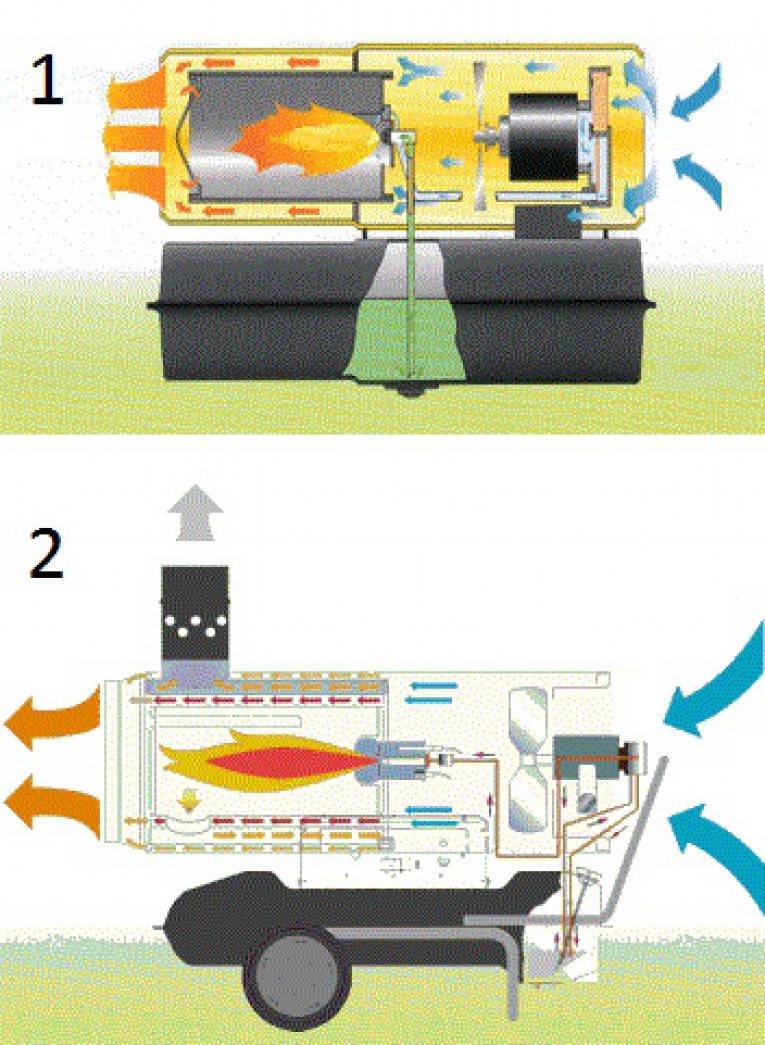

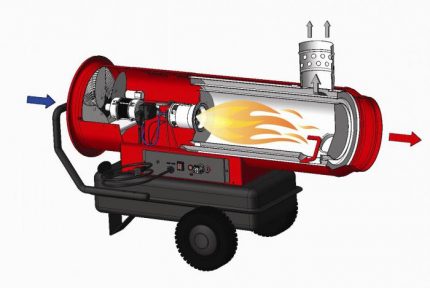

The bottom of the diesel heat gun is the fuel tank. The device itself is placed on top, in which the combustion chamber and the fan are connected. Fuel is supplied to the combustion chamber, and the fan blows hot air into the room. For transporting and igniting fuel, you will need a connecting tube, a fuel pump, a filter and a nozzle. An electric motor is attached to the fan.

The combustion chamber is mounted in the center of the upper body of the heat gun. It is a metal cylinder, the diameter of which should be approximately two times smaller than the diameter of the body. Diesel fuel combustion products are removed from the chamber through a vertical pipe. For heating a room of about 600 sq. m may need up to 10 liters of fuel.

Assembly process

The bottom case must be at least 15 cm from the top. To prevent the fuel tank from overheating, it should be made of a material with low thermal conductivity. You can also use an ordinary metal tank, which will have to be covered with a layer of heat-insulating material.

The diagram clearly shows the device of a heat gun operating on diesel fuel. The device must be mounted on a solid, stable frame.

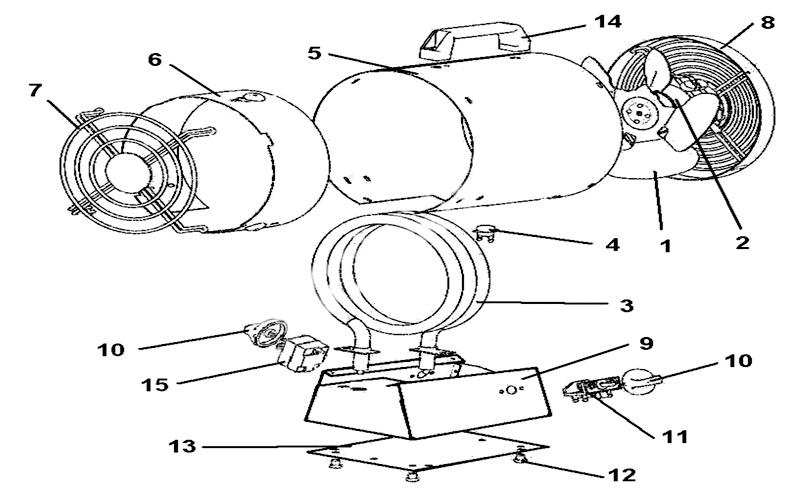

The upper body must be made of thick metal, it can be a suitable piece of a wide steel pipe. It is necessary to fix in the case:

- combustion chamber with vertical outlet;

- fuel pump with nozzle;

- fan with electric motor.

Then a fuel pump is installed, and a metal pipe is removed from the tank, through which fuel is supplied first to the fuel filter, and then to the nozzle in the combustion chamber. From the ends, the upper body is covered with protective nets. The power supply for the fan will have to be taken care of separately. If there is no access to the electrical network, a battery should be used.

When using a diesel heat gun, it is important to adhere to safety regulations. Even at a distance of a meter from the case, the directed flow of hot air can reach 300 degrees. It is not recommended to use this device indoors, as diesel fuel combustion products may be hazardous to human health.

It is not recommended to use this device indoors, as combustion products from diesel fuel may be hazardous to human health.

In addition to the unit running on diesel fuel, other types of liquid combustible materials are also used for heat guns, for example, used engine oil. An interesting version of such a device for “working out” is presented in the following video:

electric gun

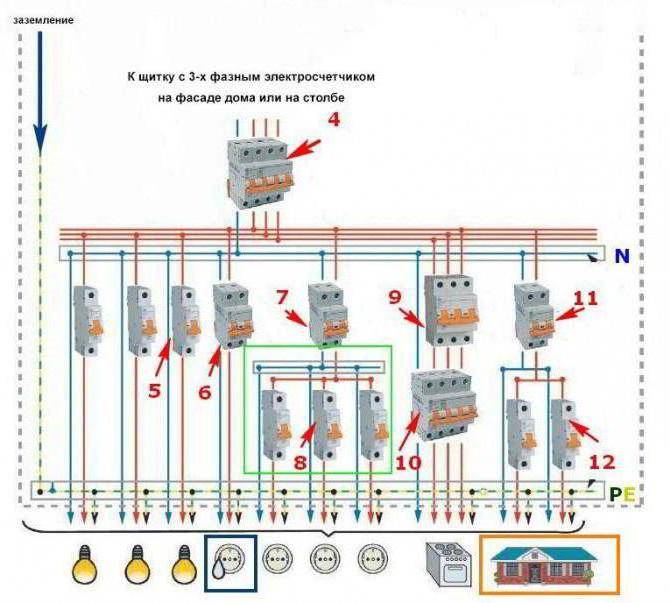

Before proceeding with manufacturing, a detailed electrical circuit of the device is made, all components are assembled.

Diagram of an electric gun

To make a heat gun with your own hands, you will need the following materials:

- Asbestos - zinc pipe of large diameter, so that the fan enters. Some people prefer to make a case of galvanized metal with a thickness of at least 1 m, and the entire home-made device is more mobile.

- An electric motor and an impeller for assembling a fan - can be purchased at stores or assembled from improvised material, for example, use an old fan and a motor from a vacuum cleaner.

- Heating elements can be made from a special wire by winding it around the electrode. You will get a spiral, as for an electric stove, you just need to make preliminary calculations, otherwise such a gun can cut out the light in the entire area.

- Purchase or pick up ceramic insulators, copper wire with a cross section of at least 2 mm, 24 A fuses, a connection wire with a plug, and other little things.

Only after that we begin to assemble the electrical part according to the previously drawn up scheme. The electric heat gun is assembled as follows:

- we prepare the body and support with an insulating lining;

- we stretch the spiral in the form of a star and fix it inside the case, or we install heating elements in the center of the pipe;

- connect the power wires to the terminals;

- we fix the fan, we bring the wiring;

- install protective grilles on both sides of the case;

- we mount the control unit and connect all the wiring to it;

- install the wire connecting the device to the network.

When assembling the heat gun, we carefully isolate all the connections of the electrical circuit - everything is done by hand, so we pay special attention to the little things. After the work is completed, we do a test run: the system is working normally, which means that the product can be operated without fear

Conclusions and useful video on the topic

Detailed video instruction for choosing a heat generator. Features of the operation of different types of guns, comparison of the main technical parameters:

The primary criterion for choosing a heat gun is the type of energy carrier.The power of the device and the specifics of its application depend on the method of heating.

In everyday life it is better to use safe electric models, for production purposes - diesel, gas and multi-fuel units. Water guns can act as a secondary source of heat.

Share with readers your experience of using heat guns. Tell us what the choice of the unit was based on, and whether you are satisfied with the purchase. Please leave comments on the article, ask questions and participate in discussions. The contact form is located below.