- Types by type of smoke removal and which is better?

- Lemax PRIME-V20 20 kW double-circuit

- Advantages:

- Equipment Features

- Criteria for evaluation

- Analysis of the most reliable equipment

- Device and principle of operation

- Our editorial advice on choosing a household gas boiler for heating a private house

- Main performance characteristics

- Additional features and capabilities

- Equipment

- Floor single-circuit gas boilers and their features

- Kinds

- The choice between atmospheric and turbocharged boiler

- Classification by installation site

- Floor type boilers

- Features of wall equipment

- The nuances of parapet devices

- Pros and cons of non-volatile gas boilers

Types by type of smoke removal and which is better?

There are two types of smoke extraction systems:

- Open (atmospheric). It works on the principle of stove draft, smoke is removed through a common house or its own vertical chimney.

- Closed (turbocharged). The smoke is expelled by the turbo blower.

Natural traction is unstable, depends on many external factors. Sometimes there is a reverse draft, which, instead of removing the smoke, begins to drag it into the premises.

Turbocharged boilers are completely devoid of such problems and demonstrate a stable smoke removal mode in any conditions.This makes the choice of atmospheric installations less attractive, however, all non-volatile boilers work on this principle.

In order to get rid of possible problems, external additional devices are used - turbo nozzles.

They contribute to the stabilization and equalization of the smoke removal mode, although they can only work if there is a power supply.

Lemax PRIME-V20 20 kW double-circuit

Lemax PRIME-V20 is equipped with a built-in 6-liter expansion tank, an enlarged combustion chamber, an ignition transformer, a composite hydraulic group, and a reed flow sensor. Electronic control is convenient and intuitive. The efficiency of the device is 92.5%, solid for convection boilers.

Gas boiler Lemax PRIME-V20 20 kW double-circuit

Advantages:

- work on heating and hot water

- effective security automation

- two-level protection of the control board

- improved heat and sound insulation properties

- water pressure indication on the display

Equipment Features

A gas boiler is a heating device in which the thermal energy released during the combustion of natural gas is used to heat the coolant circulating in the heat exchanger circuit. One of the directions in their design is wall-mounted design, characterized by low weight and small dimensions. This solution allows you to economically spend the usable area of the room.

Depending on the design features, such installations have different technical characteristics and efficiency. The classification of boilers is carried out according to the following indicators:

- The number of independent circuits in the heat exchanger. There are 2 types - single-circuit and double-circuit units.In the first case, the coolant circulates through one circuit, providing only the heating system. The double-circuit boiler has 2 independent circuits for the movement of liquid - they can be distributed to the water supply and heating system. With sufficient power of the installation, a single-circuit boiler can have a tap for connecting a boiler, i.e. hot water tank.

- Combustion chamber design. There are boilers with open and closed chambers. Open fireboxes require a natural system chimney. In the closed version, all gases are forcibly removed through a coaxial type chimney.

- Type of burner - atmospheric and modulating. In the second design, the power is controlled by the boiler automatically.

In addition, it is important to take into account the presence in the design of devices with power supply (pump, fan, etc.). In their presence, the boiler depends on the electrical network (volatile installation)

If there are no electrical devices, then we are talking about non-volatile boilers.

Criteria for evaluation

When choosing the right equipment, special attention should be paid to the following characteristics of the wall-mounted boiler:

- Power. This is a fundamental criterion that determines the capabilities of the heating system in terms of the area of \u200b\u200bthe heated room. It is customary to proceed from such a calculation - 1 kW of power for every 10 sq.m of area with a standard ceiling height. It is recommended to make a margin of 15-30 percent, taking into account the climatic factor, the reliability of the thermal insulation of the house and the height of the room more than 3 m. If an additional boiler is connected to a single-circuit boiler, then the calculated power increases by 20-30%.

- Boiler volume, hot water capacity. This parameter is important for providing hot water.

- Ignition mechanism. It defines serviceability. The burner can be ignited manually, using a piezoelectric element or an electrical device.

- Regulation of water temperature and stability of its maintenance. Modulating burners make it possible to automatically maintain the temperature, regardless of the pressure change. Mechanical adjustment requires setting the mode depending on the pressure. When it changes, you need to switch the controller.

The most important selection criterion is the safety of the equipment. Consideration should be given to the design and efficiency of the chimney. Reliable removal of products of combustion is provided by the built-in fans. It is necessary to have protective devices, systems for shutting down the boiler in automatic mode, incl. when the gas supply is interrupted, the flame is extinguished, etc., control of overheating and hypothermia.

Ease of use depends on the way the boiler is controlled. Mechanical control has shown its reliability, but modern designs use more convenient electronic systems. They make it possible to set time limits for modes, provide remote control, and display information.

Analysis of the most reliable equipment

Numerous consumer reviews and expert opinions of specialists allow us to rank the best models of wall-mounted gas boilers for 2019. When developing it, the performance of equipment in various conditions, adaptation of devices to Russian specifics, ease of use, safety and other criteria are taken into account. The proposed TOP quality products should not be regarded as advertising.It is designed to enable a person to navigate the "sea of proposals".

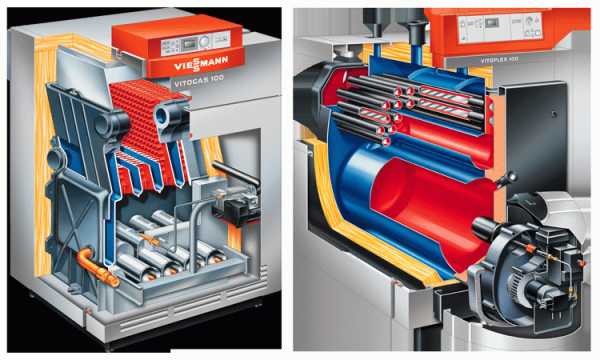

Device and principle of operation

Simple non-volatile gas boilers have an easy control function, although inflexible. All required protective functions are based on the mechanical principle of operation. In modern such modifications, full functionality is implemented, similar to volatile devices.

The functioning of the automation of gas double-circuit floor units, for example, Viessmannwolf and Lemax, is supported by the use of thermal energy: gas fuel burns, the heat generated feeds the thermocouple, which converts heat into electricity, which is quite sufficient for the operation of automation systems.

However, this amount of energy is not enough to power the coolant circulation pump, therefore, such boilers can only be operated in systems with natural movement of heating water.

Non-volatile boilers are produced both in single-circuit and double-circuit versions, with an additional load on hot water supply. In most cases, these models are floor standing.

The principle of operation of double-circuit floor non-volatile heaters:

- The combustion of gas is realized by an igniter, after ignition of the basic burner device.

- The igniter is started by holding the operating button, then the main burner is turned on, which provides gas combustion and hot water heating in the heat exchanger.

- When the temperature in the heating circuit, set by a mechanical thermostat, is reached, the fuel supply to the burner stops, the base burner turns off, and the igniter burns continuously.

- After the temperature drops below the set value, the current generated by the thermocouple enters the electromagnet, which holds the gas supply and gives a signal to open the gas, after which the boiler continues to heat the room.

- When the mixer is opened for hot water, the ball valve redirects the coolant flow to the DHW circuit, after closing the valve, the heating water returns to the heating circuit.

Our editorial advice on choosing a household gas boiler for heating a private house

Before deciding on the choice, purchase and installation of a boiler in your own home, you must formulate your requirements:

- what area should the boiler heat;

- should only heat the house or even supply the owners with hot water for domestic needs;

- be non-volatile or connected to the electrical network;

- placed on the floor or fixed to the wall.

Main performance characteristics

The boiler power is selected from the condition - 1 kW for heating 10 m2 of living space. If the boiler is intended only for heating, then it is enough to install a single-circuit one. If it must work both in the heating system and in the DHW system, then a double-circuit boiler is needed. Or with the possibility of connecting an external boiler.

Non-volatile boilers are chosen where there are problems with power supply. They are put into operation manually, and the gas torch is ignited by a piezo ignition. Volatile ones are equipped with electronic ignition, start up automatically, are equipped with electronic automation and security systems. It is essential that their igniter does not burn constantly, these boilers are more economical.

Wall-mounted boilers are more compact than floor-standing ones, they take up less space, but at the same time they have less power.The floor ones have more weight due to the heavy steel or cast iron heat exchanger. Wall mounted are recommended for houses with an area of up to 240 m2, floor - for houses from 250 m2 or more.

Additional features and capabilities

Additional features include the performance of DHW functions and automatic security control.

The boiler is recommended to be installed not in a residential building, but in a separate room. In this case, thermal insulation of pipes with heat carrier should be performed.

Equipment

A feature of non-volatile devices is the complete absence of the need for electricity. The gas apparatus operates in conditions of complete de-energization.

With an independent heating system, hot water is provided from the domestic domestic circuit, no connection to a single line is required.

The range of wall-mounted models is gradually expanding, but a more traditional one that has proven energy efficiency is a floor-standing unit.

The floor model requires the installation of a heat generator at the lowest point of the system to implement a gravity heating system. Energy independence refers to the way the burner is started, it assumes the absence of a mains-operated circulation pump.

The boiler is placed in the basement on the floor prepared in advance.

By design, non-volatile products do not differ from models powered by electricity. A significant difference in the burner is that piezo ignition is used.

Floor single-circuit gas boilers and their features

The design of floor single-circuit gas boilers is economical and simple.

They are able to perform the only basic function - they heat the coolant for the heating system. These units do not perform any additional tasks, so the set of units and parts of the unit is limited - only the most necessary elements are involved in the work.

In addition, the floor mounting method allows the use of durable and powerful units with increased weight and capabilities.

This makes the design more powerful, capable of developing high performance.

Most models are equipped with massive heat exchangers that have a high heat transfer capacity and accommodate an increased volume of liquid. There are no restrictions on weight or dimensions for floor-standing boilers, so the power can be 100 kW or more.

Many units can be connected in a cascade (usually up to 4 units), creating a high-capacity thermal plant.

Another feature of single-circuit floor boilers is the ability to connect an external storage boiler.

Such a bundle allows you to get not only heating the house, but also a stable supply of hot water.

Most experts consider this option to be more preferable than using a double-circuit boiler, since the mode of supply of hot water from the boiler is even, without temperature fluctuations or pauses.

Kinds

There are several designs that have certain features.

According to the installation method:

- wall. Mounted on load-bearing walls. They are made from lighter parts and assemblies, so their power is limited;

- floor. More powerful and heavier boilers capable of heating larger rooms.

Combustion chamber type:

- atmospheric (open). They work on the principle of a gas stove.Air enters directly from the premises, and the smoke goes into a traditional stove-type chimney under the influence of natural draft;

- turbocharged. Air is supplied by a special turbocharger fan. An excess of pressure arises inside, displacing smoke through a special horizontal chimney.

According to the material of the heat exchanger:

- steel. The most common type of construction for budget models. Usually they have a tubular design, less often they are created in the form of a water jacket;

- copper. Installed in the form of a coil in more expensive models;

- cast iron. They are used only for floor models, as they have a large weight and size. Demonstrate high performance and stability.

Heat transfer method:

- convection. The heating of the coolant depends on the mode of operation of the gas burner;

- condensation. A two-stage method of liquid preparation is used - first, it is partially heated in a condensation chamber, after which it is finally brought to the desired temperature in the usual way. For primary heating, the thermal energy released during the condensation of the exhaust smoke is used.

NOTE!

The operation of condensation models is possible only if the difference between the external and internal temperatures is not more than 20 °. This practically excludes the possibility of using such structures in Russian conditions.

The choice between atmospheric and turbocharged boiler

When choosing a floor heating device, many are interested in the question of which unit is better to choose - atmospheric or turbocharged.

It depends on the conditions of use. A gas boiler with an atmospheric burner is suitable in case of:

- the need for heating a large area;

- in conditions of work on several types of fuel;

- with frequent power problems.

A turbocharged unit is chosen when:

- the inability to allocate a separate furnace;

- small heating area;

- heating device for an apartment building.

Another positive aspect of atmospheric units is their lower cost compared to turbocharged ones. If you choose a model with a minimum configuration, then it will be inexpensive.

Note! Atmospheric boilers are forbidden to be installed in an apartment of a multi-storey building

Classification by installation site

According to the installation principle, boilers serving two communication circuits are floor, wall and parapet. Each option has its own special characteristics.

Focusing on them, the client can choose the most suitable installation method for himself, in which the equipment will be located conveniently, will not “eat up” the usable area and will not cause problems during operation.

Floor type boilers

Floor-standing units are high-power devices capable of heating and providing hot water not only to a standard apartment or residential building, but also to a large industrial premises, public building or structure.

If a double-circuit boiler is planned to be used not only for heating and supplying domestic hot water, but also for feeding warm water floors, the base unit is equipped with an additional circuit

Due to their large size and solid weight (up to 100 kg for some models), floor-standing gas boilers are not placed in the kitchen, but are placed in a separate room directly on the foundation or on the floor.

Features of wall equipment

The hinged appliance is a progressive type of household heating equipment. Due to its compact size, the installation of a geyser can be done in the kitchen or in other small spaces. It is combined with the interior solution of any type and organically fits into the overall design.

A double-circuit mounted boiler can be placed not only in the kitchen, but also in the pantry. It will take up a minimum of space and will not interfere with furniture or other household appliances.

Despite its small size, the wall-mounted boiler has the same functionality as the floor-standing device, but has less power. It consists of a burner, an expansion tank, a pump for the forced movement of the coolant, a pressure gauge and automatic sensors that make it possible to use the fuel resource with maximum efficiency.

All communication elements are "hidden" under a beautiful, modern body and do not spoil the appearance of the product.

The flow of gas to the burner is controlled by a built-in security system. In the event of an unexpected cessation of the resource supply, the unit will completely stop functioning. When the fuel begins to flow again, the automation automatically activates the equipment and the boiler continues to operate in standard mode.

The automatic control unit allows you to set the device to any operating parameters that are most suitable for the user. It is possible to set your own temperature regime for different times of the day, thus ensuring economical consumption of the fuel resource.

The nuances of parapet devices

The parapet boiler is a cross between a floor and wall unit. It has a closed combustion chamber and does not create harmful emissions.Does not require the arrangement of an additional chimney. The removal of combustion products is carried out through a coaxial chimney laid in the outer wall.

A parapet-type boiler is the best option for heating equipment for small rooms with a weak ventilation system. The device is designed in such a way that during operation it does not emit combustion products into the atmosphere of the room in which it is installed.

The device is mainly used to provide hot water and full heating for small houses and apartments in high-rise buildings, where it is not possible to mount a classic vertical chimney. The base power ranges from 7 to 15 kW, but despite such low performance, the unit successfully copes with the tasks.

The main advantage of parapet equipment is the ability to connect heating and water supply communications to the central gas system and pipelines from any side convenient for the user.

Pros and cons of non-volatile gas boilers

Pros:

- The undoubted and main advantage of such boilers is precisely their undemanding to the presence of an outlet with electricity.

- Also, their advantages include their simplicity and safety - in fact, this is the simplest boiler, but it does not work on solid or liquid fuel, but on gas.

- Another plus is the absence of electric pumps, and therefore a lower noise level during operation.

- Non-volatile boilers have been produced for a very long time, so their scheme and design have long been worked out in practice.

But there is also a negative side of the coin, the disadvantages of these boilers are as follows:

- First of all, the presence of a non-volatile boiler does not always give full confidence in the good operation of the heating system as a whole.The fact is that sometimes, for a number of reasons, such a boiler is not able to provide full circulation of water throughout the entire circuit of the system. Often this is due to incorrect initial planning of the system, up to the thickness of the pipes, or the choice of the boiler itself. It should be noted that with a natural heating system, as a rule, pipes of increased diameter are required, installed in a certain way with the desired slope.

- Again, for the good operation of this type of equipment, a chimney with good draft is required, which is also sometimes difficult to implement in practice.

- When taking into account these shortcomings, it already becomes very problematic, and sometimes impossible, to implement the installation and operation of a non-volatile boiler in a two- or more-story building.

Result: if the boiler cannot push through the system, the rooms will not warm up evenly (the batteries will not heat up completely), if there is no good draft in the chimney, the backdraft valve will constantly operate and extinguish the boiler. In addition, sometimes it is inconvenient that the boiler is somewhere downstairs, in the basement, and not hanging on the wall in the kitchen room.

Further: in a scheme with natural circulation, an open expansion tank is required in the system and its periodic (though very rare) replenishment. The fact of feeding the system sometimes adversely affects the condition and service life of the heat exchanger: on it, and on all pipes, there are excess sediments and deposits from poorly treated water.