- Composition selection

- Suite

- STACRIL ECOLOR

- PlastAll Classic

- How to choose a bath enamel composition

- How to restore a bath

- Acrylic liner "bath in the bath"

- How to repair chips or small restoration of damage to the bath

- Video - repair of chips and even through holes in a metal bath

- Spray enamel bath

- Preparatory work

- Enameled composition: from selection to application

- Reasons for restoration

- Features of acrylic coating and its care

- Enamel restoration instructions

- Preparation for work

- How to restore the surface with enamel?

- How to update a bathtub with liquid acrylic?

- Pros and cons of the method

- How to restore a bathtub with enamel

- Material Features

- Debunking myths about the bulk method

Composition selection

Restoration of bathtubs with bulk acrylic own hands has a number of nuances. The main thing is the quality of the selected material. To understand which acrylic is best for restoration, consider the most popular positions.

Suite

Development of the scientific and production company "EcoVanna" (Russia). Produces acrylic bath covers. Takes first place in the ranking of manufacturers of materials for the restoration of old bathtubs using acrylic. It is produced on the basis of raw materials of partners from Germany. The price is in the range of 1600 - 1900 rubles. Advantages:

- no solvent,

- packaging is designed for processing containers of 1.2 - 1.7 meters,

- the formula gives a high plasticity of the structure,

- the color scheme of the color scheme (LUX) has 8 shades,

- covering index - 100%,

- freezing time - days,

- high level of adhesion,

- operating period - 15 years.

STACRIL ECOLOR

Stacril Ecolor (Germany) - a combination of acrylate with epoxy resin. Difficult to use on its own. Another minus - stakril has a sharp unpleasant odor. Surface renewal with STACRIL ECOLOR acrylic during restoration is recommended to be carried out in a ventilated room. It also dries twice as long. Proponents of glass claim that:

- the resulting layer is twice as strong as the analogue,

- service life - at least 20 years,

- The paint adheres better to the old surface.

PlastAll Classic

PlastAll Classic - acrylic coating for baths. The two-component composition is the result of cooperation between the Russian association from the city of Togliatti "Plastol" and the Slovenian factory "Pabrek". Recommended for bathtub restoration with liquid acrylic with your own hands. Advantages:

- white color is guaranteed for 8 years,

- adhesion index - 100% to cast iron, steel, plastic surfaces,

- UV-resistance for at least 15 years,

- temperature stability: +120ºC,

- service life - 20 years,

- recommended for independent use,

- the formula does not contain toxic substances,

- high structural density allows covering even multi-coloured surfaces.

How to choose a bath enamel composition

When performing work on the restoration of the bath, you must first select the enamel, focusing on indicators such as:

When performing work on the restoration of the bath, you must first select the enamel, focusing on indicators such as:

- quality;

- price;

- color.

It is worth choosing from more expensive materials. They have many advantages.One of them is good drying speed. In addition, they remain fluid for a long time. Another plus is high adhesive qualities. They adhere well to the primary layer, forming a rubber coating.

The price of the composition deserves special attention when choosing enamel. It is optimal if it is the same as that of the old coating. If it was not possible to find an identical one, then you can use a material that differs from the main coating by no more than 1 tone. If covering new enamel bath, you will find peeking yellowish spots, then you can eliminate them by applying another coating on top of a new layer of enamel.

From the usual staining with paint, the work of applying enamel has certain differences. You should be aware that the mixtures used during operation are two-component. When added to the compound hardener, they lose fluidity. They cease to be liquid already 45 minutes after adding the hardener. After this time, working with this material is more like plastering. Using such a non-flowing composition, it is extremely difficult to obtain a perfectly flat surface.

Therefore, if this is your first time doing work on creating a bathtub cover by pouring, then it will be useful to read the instruction manual before starting it. Before starting work, it is worth practicing on a small object in order to gain the necessary experience in performing work. Another important point that should not be forgotten is that it is necessary to prepare the material immediately before enameling the product. After the preparatory work is completed, you need to engage in its preparation.

Most often to create a new do-it-yourself covers a composition comprising two components is used. In addition to it, the product can be enameled with liquid acrylic, which is less toxic and has the ability to remain fluid for a long time. In terms of cost, such a composition is more expensive. However, working with it is easier and safer. But, even using liquid acrylic, respirators should not be abandoned. In addition, before starting work, it is necessary to ensure the maximum flow of fresh air into the room.

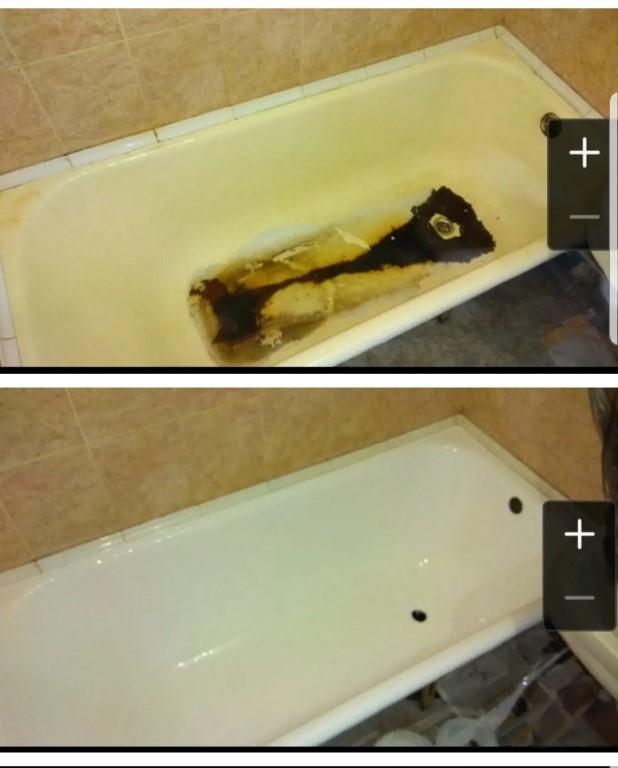

How to restore a bath

A new bathtub is not cheap. The cost of acrylic models starts from five thousand rubles, cast-iron ones - from eight, and the upper price bar goes to infinity. Do not forget to add the replacement costs: dismantling the old bath; payment of movers to take it out of the house; delivery and installation of a new bath; re-tiling of the side tile.

Renovating an old bath will cost an average of 2,000 to 5,000 rubles, depending on the size of the bath, the type of restoration and material, so this method is chosen by many. During the last repair, I myself did the restoration, and not the replacement. My choice fell on bulk acrylic, but we will consider other methods, because they all have their pros and cons.

Acrylic liner "bath in the bath"

Instead of working on the old coating, a new plastic trough is simply inserted into the bath, repeating its shape. It is attached to a special foam, and looks like a new bath. However, there are many "buts" here:

Firstly, this method is not suitable for steel baths and thin cast iron baths, because they bend.Although this movement may be imperceptible to the eyes, it will greatly reduce the life of the liner: it moves away or microcracks are formed into which water enters, stagnates there and begins to smell unpleasant.

Secondly, if you have an old Soviet bath, it is most likely uneven and of a non-standard size, so the liner may simply not fit. Or there will be the same problem as in the paragraph above.

Thirdly, another element comes into play in this case: the sticky foam that holds the liner inside. If its quality is low or there are other unfavorable factors, the bath will simply stick out.

The liner is glued and adjusted for about 2 hours, and then the bathtub is filled with water for a day. You can use it after a day. Acrylic should not be rubbed with abrasives. It is better not to turn on the hot water abruptly, but to let the bath warm up gradually.

Pros:

- no smell during restoration;

- perfect restoration of cracks, chips and any other visual imperfections - this is literally a new bathtub;

- shock-resistant and warm to the touch material;

- does not turn yellow over time.

Minuses:

- design unreliability;

- the indicated service life of about 15 years is rarely realistic;

- high price;

- the need for additional payments for the dismantling / installation of the siphon;

- if the bathtub is built into the tile, it is necessary to dismantle the tile;

- thickness of 7-8 mm "eats" the volume of the bath.

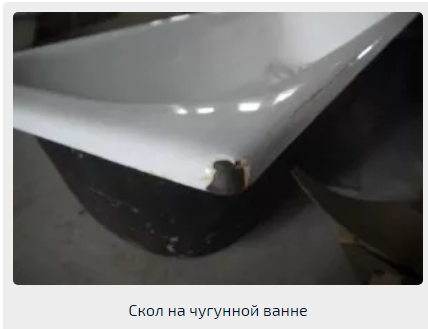

How to repair chips or small restoration of damage to the bath

While epoxy was previously applied and then powdered with porcelain, there are now more effective methods for repairing chipped enamel. Toothpaste is no longer mixed with glue, as this is a solution for a couple of weeks.

Professionals use the following step-by-step instructions:

- Remove corrosion with a special tool.

- Thoroughly wash and dry the work area.

- The site is degreased with acetone, alcohol or a solvent.

- Apply automotive putty, level with a spatula.

- Sand the area to make the surface smooth.

- Paint over the problem area with auto enamel or special paint.

Special repair kits are also sold, which include everything you need, including instructions. However, such a set costs from 800 to 1300 rubles.

Video - repair of chips and even through holes in a metal bath

This video instruction is for those who decide to repair the coating with their own hands. The master will show what needs to be done at all stages, from preparatory measures to the application of a waterproof paint material. If you save a link to this page, you can always review the master class again. And if you ever drop something heavy and damage the enamel, you can fix the situation at any time. And even if the hole is through, act as the master advises, and you will not have to buy a new bathroom.

HelpfulUseless

Spray enamel bath

Refurbished bath

Spraying is another method of applying enamel in restorations. For this, spray bottles are used.

There is an opinion that this method is more reliable, which is not always true. Professionals say that the composition used should include two components: a base and a hardener.

In the case of a spray bottle, there is no hardener, and its non-professional use can lead to the appearance of the streaks and bubbles mentioned above, causing further peeling of the enamel.

The best atomization is achieved by using a powerful compressor instead of a conventional atomizer.

The compressor allows you to more evenly distribute the enamel over the entire inner surface of the restored bath at the same time.

Self-enamelling of the bath is performed as follows:

- The cement mortar is removed from the inner surface by grinding, sandblasting or hydrochloric acid diluted with water in a ratio of 1:4;

- The surface is washed with water and left to dry;

- After complete drying, before performing work, mix the paint;

- The paint is applied to the surface of the bath in 2-4 layers using a roller or brush.

Preparatory work

Recently, many experienced craftsmen recommend not buying new plumbing equipment, but using bulk bathtubs with liquid acrylic, because they can restore cast iron and steel products, the damage of which is superficial, but not through. In order for the restoration result to be durable and stable, it is necessary to carefully prepare the restored bathtub for work using the following technology:

-

First of all, the surface of the bath is cleaned with a strong alkaline detergent, and then rinsed thoroughly with warm water.

- Rust should be carefully removed from the enamel. If household detergents do not cope with it, you can use a rust converter.

-

Then it is necessary to sand cracks, chips and irregularities with sandpaper "null" or grinding disc "grinder". If the enamel of the sanitary ware is severely damaged, then the entire top layer is removed.

-

The inner surface is degreased with oxalic acid, alcohol or white spirit. After processing, the degreaser is thoroughly washed off.

- Then the bath is heated. To do this, they collect a full bowl of water of maximum temperature and leave it for half an hour. Then the water is drained, the bath is quickly wiped dry with a dry, non-fluffy cloth.

- Lastly, before applying the acrylic coating for the bath with your own hands, the drain is dismantled, and a plastic container is placed under it.

Enameled composition: from selection to application

The most budget option for the restoration of a cast-iron bath is applying liquid enamel to the surface. A mixture in a liter iron can costs about a thousand rubles. This amount is quite enough to treat the surface, remove cracks, rust.

Experienced craftsmen recommend special equipment from the manufacturers Svyatozar, Reoflex, Aqua-Color.

You can restore the bathtub with enamel if there are no large chips or cracks on the product. Otherwise, this method will be ineffective.

Restoration of the layer on the cast iron bath by enameling is carried out if small scratches, cracks, rust, darkening have formed on the surface. If chips, depressions, deep scratches have formed, then the enamel will not help. Irregularities will be visible through it.

After the application of the product, the restored surface requires special care:

- nothing can be dropped inside, especially heavy and sharp objects;

- it is forbidden to wash with abrasive sponges, powders, caustic household chemicals;

- a sharp temperature drop is also prohibited - the enamel can move away.

If you still decide to use just such a method, then to restore the bathroom you will need:

- the remedy itself. After opening the can, it is ready for use;

- brush. Choose one that is made from combined fibers;

- sandpaper;

- cleaning powder.

Take care of your own safety at work. The enamel solution is a caustic and strong-smelling special agent. If it comes into contact with the skin, it can cause a chemical burn, it also corrodes mucous membranes when inhaled. To prevent health problems, use protective gloves, goggles and a respirator. You can apply the solution yourself, you do not need to involve professionals.

When restoring the bath with enamel, wear a respirator on your face. The substance emits caustic fumes which may cause poisoning

How to renovate a bathtub with enamel:

- prepare the container for applying the repair agent. To do this, the bath must be dried during the day. The water should evaporate completely. Take powder and sandpaper and clean the surface of dirt. Powder residue must not be washed off with water! They are swept away with a brush and removed with a shovel. Some craftsmen recommend sanding the surface with a grinder or a grinder drill. However, if you are not knowledgeable in this matter, use the manual preparation method. So it will be more reliable.

- Make sure the bath is dry. It will not be superfluous to pick up an ordinary hair dryer and “walk” it around the bathroom to remove any liquid.

Important: there should be no water on the surface at all. If even a small drop gets under the enamel, the coating will swell, you will have to redo the work.

- Remove the siphon.

- Vacuum the inside of the bathroom so that there is not the slightest speck of dust left on it.

- Open an iron can with enamel and pour exactly half of the special agent into a plastic container. Use the first part for the first layer, the second, respectively, for the second;

- Take a brush, lower it into the solution and treat the entire surface of the bathtub. Start from top to bottom from the edges to the central part of the structure. The first layer seals pores and cracks.

- After the first, the second layer is applied immediately, it is not necessary to wait for drying. Now work with the brush from bottom to top, from the center to the sides. So all the bumps will be smoothed out, the layer will lie flat.

- Wait 20 minutes.

- Proceed to leveling the smudges, the layer should be uniform.

- The setting of the enamel occurs after 2-3 days. Before that, it is considered unstable. But already 20 minutes after applying the second layer, it will no longer be possible to level the surface.

- After a day, the siphon can be put in place.

- The use of the bath is possible after a minimum of three days.

Important: experts assure: such a restoration of the bathtub enamel with your own hands is a rather temporary measure. It is not recommended to use it on an ongoing basis.

After a year, the coating will begin to turn yellow, small cracks appear, which gradually grow. But it's cheap - no other bathroom reconstruction can boast of such a price.

Enamel is considered the cheapest way to restore a bath, however, the service life of the coating is short - no more than 5 years

Recommendations for restoring the coating of the bath using enamel in the following video:

Watch this video on YouTube

Reasons for restoration

All household items have their own lifespan. There is also sanitary ware. The price of acrylic baths is relatively low. Buying new inexpensive plumbing is a simple decision. Cast iron products have a safety margin of 10-15 years. Updates require only a yellowed tank. But dismantling old equipment is a complicated process. The problem is the multi-stage dismantling work. Would need:

- turn off hot and cold water supply,

- disassemble knots,

- dismantle the frame structure,

- remove part of the tile

- remove decorative screen

- assemble and install the frame.

This is a waste of time and money. In addition, dirt and dust are provided for at least a day. Restoration of bathtubs with acrylic is devoid of these shortcomings.

Features of acrylic coating and its care

The technologies are different, but the result - a poured acrylic bath - is the same: a bath with a coating that has such physical properties as

- wear resistance (up to 15-20 years),

- low thermal conductivity (and this means a more comfortable preservation of water temperature),

- spectacular and dazzling surface smoothness, pleasing to the eye and skin, and associated with it, ease of care.

Peculiarities acrylic care bathroom

Peculiarities acrylic care bathroom

Acrylic fears:

- falling onto heavy objects

- hit with pointed objects

- warp deformations

- abrasive cleaning powders

- aggressive chemicals

- colored or colored detergents (such as sea bath salts)

However, care is also simple: to remove dirt from the bulk bath, it is enough to use a soft fabric texture with any light gel-like or creamy detergent.

Another important advantage of acrylic is a rich color palette that can be selected, ranging from a variety of colors to their subtlest shades, because the color is obtained by adding color to liquid enamel. Liquid acrylic for old bathtubs can give not only a new surface, but also a new color, which is convenient when renovating an entire bathroom.

Enamel restoration instructions

In order for the bath to last as long as possible after repair, it is necessary to properly prepare its inside and observe the modes of application and drying of the coloring composition.

Preparation for work

Before you start painting old sanitary equipment, you need to properly prepare both the room and the coating inside the bowl. Since you will need to clean off the destroyed layer of paint, you can not do without dust. Therefore, small-sized furniture and household appliances are removed from the bathroom. If this is not possible, protect the items from dust with plastic wrap.

The surface to be painted is prepared as follows:

Manually with a coarse-grained sandpaper or using an angle grinder, the surface is cleaned. It is good if you can completely remove the damaged layer of paint before the primer

In this case, it is important to ensure that the metal becomes absolutely smooth.

Rusty smudges are treated with a rust converter. You can also use oxalic acid by mixing it with water until a thick slurry is obtained.

The cleaning agent is applied to the place of contamination, and after 20 minutes, together with the remnants of the old paint, it is washed off with water.

For degreasing use gasoline or acetone.

Pour hot water into the bowl and leave to warm up for 15-20 minutes.

Carefully wipe the inner surface of the product with a cotton rag. It is important that the coating is completely dry and free of sticky threads or lint.

To dry at this stage, you can use a hair dryer or fan.

How to restore the surface with enamel?

To make the new bathtub coating as smooth as possible, it is necessary to treat the surface with a primer before painting. You can do without this procedure, but then the new coating will turn out to be not too even and will not last so long.

The work is carried out in several stages:

- With a rubber spatula, a layer of soil is applied to the cast-iron surface and left to dry completely, after which it is cleaned with fine sandpaper.

- Three or four coats of paint are alternately applied with a roller or brush. Before applying a new layer, be sure to wait for the previous one to dry. Drying time depends on the material used for painting, and is indicated by the manufacturer in the instructions.

- At the end of the work, the completely dried surface is wiped with a solvent, which will give the product a glossy sheen.

To fix the result, after 3-4 days, you can treat the coating with any polishing agent.

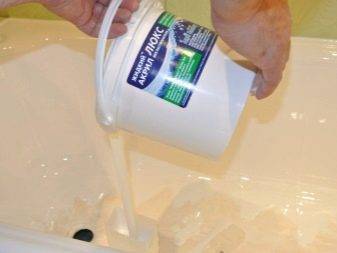

How to update a bathtub with liquid acrylic?

Liquid acrylic (stacryl) consists of acrylic and a hardener. When applied to a cast iron surface, this substance forms a strong film 6 mm thick. The viscous fluid mixture has the property of delayed polymerization, so you can carry out work without hurrying and without fear of a quick solidification of acrylic.

Glass restoration involves the following steps:

- After the cleaning of the inner surface of the sanitary ware is completed, it is necessary to remove the siphon and place a container under the bottom to collect the flowing paint.

- The acrylic mixture is prepared according to the manufacturer's instructions.

- Liquid acrylic is poured from the farthest corner, moving evenly in a circle. Do not smooth out the sagging and remove the bubbles - they will disappear on their own during drying.

- Acrylic, accumulated at the bottom, can be carefully leveled with a spatula.

The acrylic mixture is polymerized from 1 to 4 days. The longer the polymerization time, the stronger and more durable the coating.

If the work on the restoration of the sanitary ware is carried out carefully and fully complies with the instructions, the service life of the new bathtub will be at least 20 years.

Pros and cons of the method

The bulk layer of acrylic dries for at least three days

The bulk layer of acrylic dries for at least three days

If you decide to restore the bath yourself, you can see photos and videos that tell in detail about the restoration procedure. However, before deciding on this process, you need to weigh the pros and cons, evaluating all pros and cons of bulk baths.

Advantages of the method:

- coating durability (up to ten years of operation);

- bulk acrylic has practically no unpleasant odor;

- the coating becomes glossy and smooth;

- restoring a bathtub with acrylic takes only a couple of hours;

- retains heat well;

- bathroom renovation with bulk acrylic does not require preliminary preparation;

Cons of a bulk bath:

- bulk acrylic bathtub dries for at least three days;

- the cost of acrylic is higher in comparison with other materials for the restoration of coatings;

- bulk glass for the restoration of bathtubs requires special care, conventional aggressive sanitary ware cleaners can damage the surface of the bathtub;

How to restore a bathtub with enamel

This method is chosen most often. To achieve the ideal result of the work, the following sequential actions are implemented:

the enamel itself is selected, and high-quality material should be purchased, so you should not save on this element, and the most optimal are Finnish enamels, which are distinguished by excellent parameters;

two sets of enamel are purchased at once, since one will not be enough to completely cover the product;

if, simultaneously with the restoration, the appearance of the bath and the entire room is changed, then a color scheme is purchased that provides the enamel with a certain unique shade;

before applying the material, all surfaces of the bath are degreased, for which suitable means are used;

the walls are processed with a grinder, abrasive or sandpaper, which ensures the formation of a rough surface that provides excellent adhesion of the new coating to the base;

if there are cracks or crevices, they expand slightly with the same tools, after which a cord brush is passed over all surfaces;

another degreasing process is performed;

the bath is completely and thoroughly washed;

work continues only after the structure has completely dried, and this process can occur naturally or be accelerated by a building hair dryer;

various additional fasteners and elements, such as drains or gaskets, are dismantled from the bath;

dust generated during operation is removed with a vacuum cleaner;

rags or sheets of paper are placed under the bath so that excess enamel does not drip onto the floor;

enamel is diluted in a prepared container;

the solution is applied in a thin layer with a brush on the product from its edges to the bottom, and it is constantly leveled by alternating movements horizontally and vertically;

subsequent layers are applied before the previous ones dry;

it is important to achieve uniform coverage, so the same amount of attention is paid to all elements and details of the structure;

at the end of the work, streaks are removed.

You will be able to use the renovated bathroom after 4 days. Thus, updating the coating of a sanitary ware using enamel is a fairly simple and quick process that can be easily implemented by anyone. It does not require significant expenses and excessive physical effort, therefore it is considered an economical and convenient way to upgrade.

Material Features

To solve the problem of restoring the worn or damaged surface of cast iron and metal baths, the so-called liquid acrylic is used - a polymer material made from acrylic and methacrylic acids with the addition of certain polymer components to their composition. Polymethylacrylates have been produced by the chemical industry for more than half a century, and they were originally created as the main composition for the production of organic glass. Today, various components are added to this composition, thanks to which the production of acrylic sanitary ware and facing material has become possible. Acrylic materials today have firmly won their niche in the sales market and have gained increased popularity due to the fact that products made from them are very lightweight, durable in use and easy to process.

Restoration of the inner surface of an old bathtub can be done in various ways, for example, using special paint and varnish coatings, but the service life of such a restoration is not long. The most stable results during operation can be obtained if the old font is repaired with liquid acrylic: this material has an increased adhesive ability to metal surfaces and cast-iron bases, and also creates a durable working layer when applied, which has a thickness of 2 to 8 millimeters.

Using an acrylic composition, restoration work to restore the surface of the bath can be carried out without fear of damaging the bathroom tile. In the process of work, acrylic does not emit harmful components with a pungent odor into the atmosphere, it quickly polymerizes under the influence of air, and special devices and additional components are not required when working with this material. The finished acrylic composition contains a base and curing agents. After treatment with liquid acrylic, the surface of the bath becomes resistant to mechanical and chemical influences, and most importantly, it has an anti-slip effect, which is its feature and distinguishing feature compared to other materials.

Debunking myths about the bulk method

The main myths about bulk bathroom restoration

The main myths about bulk bathroom restoration

- Poor interaction with the surface of the bath, liquid acrylic is removed from plumbing, like skin, literally within one year.

If the product was well cleaned and degreased before applying the material, acrylic will perfectly adhere to the surface of the bath. If the coating begins to move away from the walls and base, it means that you have performed the preparatory work poorly.

- Bulk acrylic for the bathroom is not as reliable as the acrylic insert in the bathroom.

When properly installed, the liner will last a maximum of fifteen years, after which it is subject to peremptory disposal. Installation of such equipment involves the removal of decorative tiles at the junction bathroom with walls. And the internal volume of the sanitary ware is significantly reduced. Liquid acrylic, after the expiration of its service life, can be reapplied to the bathroom, which does not require capital financial investments.

- Purchasing new plumbing will cost less compared to restoration.

Yes, liquid acrylic costs money, but for processing plumbing does not require the dismantling of the old equipment and installation of new. After that, it will also be necessary to make repairs in the bathroom. The costs in this case are simply incomparable.