- The design of the electric furnace for baths and saunas

- Types of electric furnaces for baths and saunas

- Choosing an electric sauna heater

- Electric heater with a steam generator for a sauna - will we get a Russian bath or not?

- Installation Requirements

- Recommendations for selection

- Room volume

- Controls

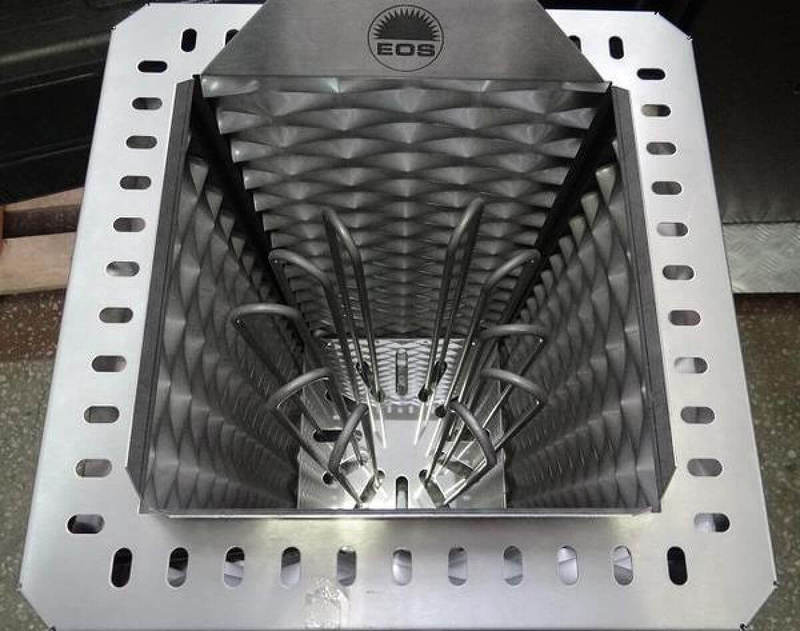

- Heater type

- Stove exterior

- Manufacturing instructions

- Manufacturing instructions

- The best cast iron sauna stoves

- GEFEST PB-04 MS - a model with an excellent design

- VESUVIUS Legend Standard 16 - an oven with a well-thought-out design

- NARVI Oy Kota Inari – a powerful stove for a large room

- TMF Cast iron Cast Vitra - with an enlarged combustion chamber

- KASTOR Karhu-16 JK - compact and lightweight

- Brief overview of popular manufacturers

- Wood burning sauna heater

- Conclusion

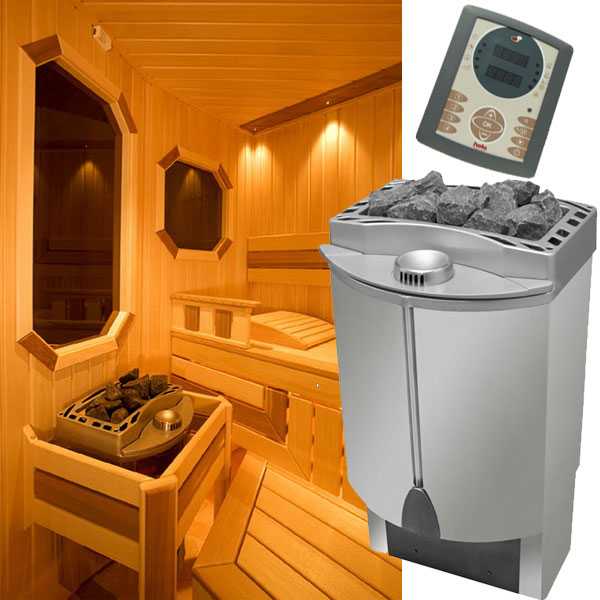

The design of the electric furnace for baths and saunas

The main advantages of electric heaters are their high reliability and safety. This allows you to install even in steam rooms, which are arranged by city residents in their apartments.

The main advantages of electric heaters are their high reliability and safety. This allows you to install even in steam rooms, which are arranged by city residents in their apartments.

They do not pose a health hazard due to carbon monoxide, and due to their small size they can be easily installed even in a small room. An electric oven, which is capable of heating bath rooms no less efficiently than a brick one, has a fairly simple device.

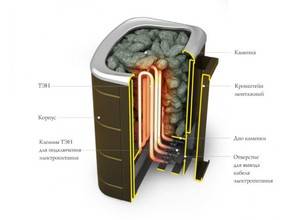

In its design, the following main elements can be distinguished:

- double metal case;

- electric heaters;

- thermal insulation elements.

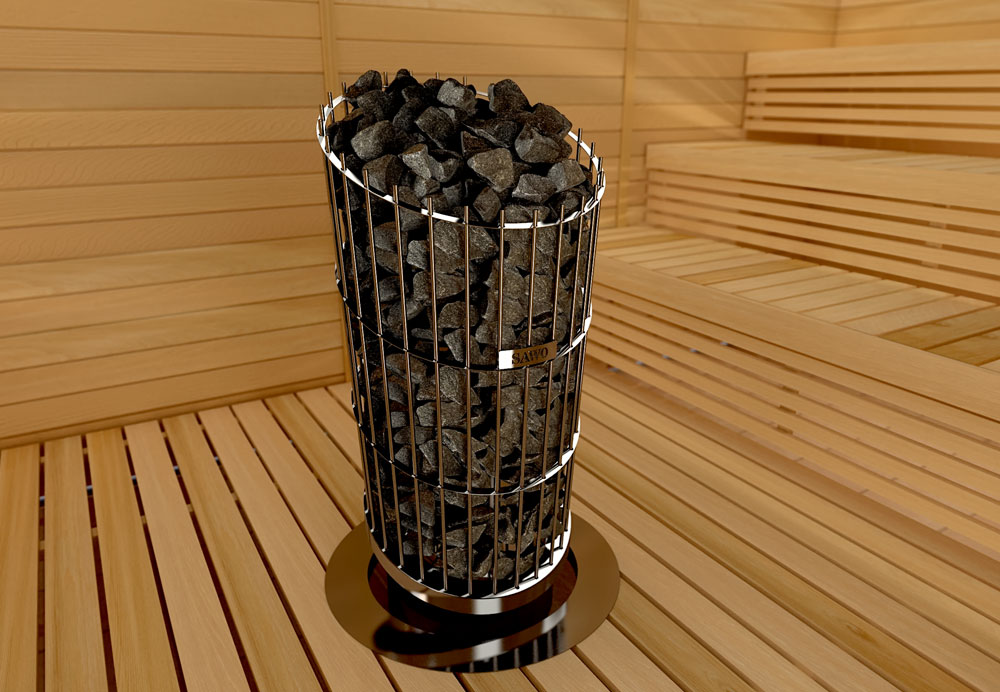

In the case there are heating elements or tape heaters, on which a cage is installed for filling with stones

It is very important to choose the right cobblestones, taking into account their size and weight. It depends on how quickly the room warms up. Therefore, if you want to quickly create a comfortable temperature in the bath, then it is advisable to take weighty and large stones for it.

Therefore, if you want to quickly create a comfortable temperature in the bath, then it is advisable to take weighty and large stones for it.

The outer part of the body is made of metal plates up to 4 mm thick. Ventilation channels appear between them and the walls of the heater, which help to cool the inside of the casing.

The role of heat-insulating elements is performed by steel screens installed one after another. Such an insulation option well protects the wooden surfaces of the bath from the heat emanating from the surface of the stove.

In the bath, you can install an open or closed oven. The final choice is determined by the personal preferences of the owner and the installation features of the heating device. However, it can be said that most often the owners choose open-design stoves.

Such models not only perfectly warm the steam room, but also create good moist steam in it. In furnaces of this type, nichrome wire is necessarily used, which is inserted into a ceramic stand, which turns it into a heating stand.

As for closed sauna stoves, they are presented for sale in the form of horizontal or vertical structures with the following components - a heater, a conductive bus and a heat shield.

Types of electric furnaces for baths and saunas

Modern electric furnaces differ from each other in various characteristics, including the type of heater. Most often, models use tape or tubular electric heaters.

Modern electric furnaces differ from each other in various characteristics, including the type of heater. Most often, models use tape or tubular electric heaters.

The most popular devices that use the second type of heating device. But, despite its low price, such an element of an electric furnace does not last long.

The heating elements used in electric fireplaces are necessary to transfer heat to the stones during the heating process. But if you have not yet prepared the stones for the furnace and you have it empty, then you should not turn it on ahead of time.

Recently, heating elements have a worthy alternative - tape heaters. They are made in the form of a low-temperature metal tape, which differs from its competitor in a larger heat exchange area and high electrical resistance.

And although this type of heater consumes less electricity during operation, furnaces equipped with a similar electric heating element are much more expensive. It should also be taken into account that during prolonged operation, these devices take less oxygen from the air, since the heating temperature of these elements does not exceed 400 ° C.

How to calculate the power of an electric sauna heater? To determine the optimal power of the stove for an electric sauna, it is first necessary to take into account the volume of the steam room.

The device, which is equipped with a heating element with a power of 1 kW, should be enough to maintain a comfortable temperature on an area of one m3. A model equipped with a band heater with the same power rating will easily heat an area of 1.5 m3.

Choosing an electric sauna heater

The main criterion is the required power of the electric furnace. You can calculate on an enlarged basis, according to the established dependence on the volume of the steam room.For one cubic meter of steam room volume, there is a consumption of 1 kW, excluding heat loss through building envelopes and window and door openings. At least 0.5 kW must be added to the losses. A steam room with a size of 2.5 * 2.8 m2 and a height of 2.75 m, for example, will need an electric stove with a capacity of 28.9 kW.

Another important selection parameter is the number of stones in the heater, or its volume. When heated, it is stones that emit heat into the air, and steam as well, so a proportion is necessary. A small sauna is served by a heater with about 2.2-2.5 kg of stones, if the room is large, at least 6.5 kg of stones are needed.

It is also possible to choose according to the design of the stove - it can be open and closed. If dry steam is required in larger quantities, then an open-type heater is needed. The distribution of stones in a container with heating elements is also of considerable importance: stones of large dimensions should be laid at the bottom. Smaller and larger stones are placed between the cobblestones, in an artistic "mess", but by fractions.

According to the type of installation, an electric sauna heater can be floor and mounted. In any case, the unit must meet all the requirements for the operation of modern Finnish baths. Mounted stoves are produced in small capacities and are used for small saunas. The model range of floor ovens is wider, there are both compact devices of small power, and powerful ones that require 380V power supply.

According to the type of heating elements, electric furnaces can be with tubular heating elements and with tape devices, as well as combined ones. Heating of tubular heating elements is limited to 750-800⁰С.The material of the heating elements affects the cost of stoves - stainless steel is considered the best option, but also the most expensive. The advantage of tape heating elements is faster heating of the stove and sauna, but the maximum temperature to which they can heat the stones is only +650⁰С. But on the other hand, during the heating process, air oxygen is not so efficiently consumed, in addition, tape heaters last much longer than tubular ones. The best option is the combined design of heaters, tubular and tape. The result of this combination is high-speed heating to the maximum temperature, but the cost of combined electric furnaces significantly exceeds the prices of devices with heating elements.

The popularity of electric stoves for Finnish baths is due to their compactness and ease of installation. The stoves are not capricious, they can be installed in the center of the sauna, in any of the corners or against the walls, at any convenient distance from doors and shelves. A basic requirement for safe operation is the correct electrical connection. published

If you have any questions on this topic, ask them to specialists and readers of our project here.

Electric heater with a steam generator for a sauna - will we get a Russian bath or not?

To begin with, we will have to turn to those conditions that are commonly called the classic Russian bath. This will help determine which stoves are suitable for a Russian bath. If we talk purely about physical parameters, then the temperature in such a bath should not be higher than 65 degrees, and the humidity is good in the region of 55%.

But the Russian bath has specific requirements for the quality of steam and heat.Steam is needed exceptionally light, invisible to the eye, which is obtained only if the water is heated above the boiling point. And it turns out either by heating the stones to 400 degrees and above, or by heating with electricity.

Note! The steam generator is really able to create light steam, and literally in a matter of minutes.

As for heat, soft IR radiation (IR - infrared) will be optimal in a Russian bath. And it is obtained as a result of the slow heating of the brick or stone surrounding the firebox.

Electric sauna heater with steam generator Harvia

Electric stoves of this kind are found on sale, they are lined with stone in the same way as wood-burning counterparts, but in most cases there are either models with a metal convection case or with a mesh casing that is filled with stones. This is also a kind of convection case - the air actively moves between the heated stones in the casing, its temperature rises and it rises.

It is clear that the metal case (about metal stoves here) does not contribute to the production of soft IR radiation, although the greatest heat will still come from the stones in the open heater, because it is between them that there are heating elements or tape heaters. This is because electric furnaces usually have strong convection, they actively suck in cold air from below, heat it up and release it into space. That is why the air in the steam room heats up so quickly (about steam room stoves in a separate article).

But the Russian banya requires fully regulated convection, which means it stops at the right moment, when the so-called “steam cake” forms under the ceiling.This is where the main contradiction lies: electric stoves were created for saunas, where convection is an integral part of creating the right conditions for a Finnish bath. In the vast majority of cases, the ovens you can buy will not have convection controls.

CONCLUSION! In other words, the stove can be set to the desired temperature, you can turn on the steam generator, but you can’t take a steam bath as it should be with a “steam cake” unless you have a “thermos” stove or something like that.

Where are all these numerous stoves with steam generators used, which can be found in the model ranges of almost all large companies involved in the production of bath stoves? The answer is simple: between the classic Russian and Finnish baths, there are many intermediate states that do not quite correspond to the reference conditions, but may well suit bathers.

On a note! The main thing is that when designing ventilation in a bath / sauna, the possibility of adjusting air exchange is laid - for this you need only doors, dampers or gates that close at will. Only in this case you can really vary the modes of the Russian and Finnish baths.

In connection with all of the above, we would not like to be unfounded, so we asked what they say about electric sauna heaters with steam generators for saunas on the sauna forums (the reviews look less suspicious there).

Installation Requirements

The safest place to place an electric oven is the corner closest to the front door. You can also install in the center, but be sure to comply with the following requirements:

- the presence of a gap between the hot planes of the furnace and the walls of the steam room;

- flammable surfaces are protected with a special screen;

- protective fences are installed with a gap between them and the oven measuring 7 cm or more, which will help to avoid severe burns on the skin in case of accidental contact;

- there should be an inlet of the ventilation system at the back of the oven. It should be through and located at a height of 7 - 10 cm from the floor level. The size of the hole depends on the power of the furnace, on average its diameter is 15 - 25 cm;

- a massive support for such a heater is not needed, however, several layers of fireclay bricks must still be put under the installation of the product. For these purposes, a thick sheet of metal with a substrate of heat-insulating material, such as extruded polystyrene foam boards or fiberglass wool, is also suitable;

- under an electric furnace of small sizes, it is enough to put an asbestos-cement slab or ceramic products on the floor.

Recommendations for selection

There are quite a few different models of electric ovens on the market. To make the right choice, you need to consider several factors:

- sauna dimensions;

- estimated number of people and frequency of use;

- features of the electrical network;

- the intended location in the room;

- etc.

It is also important to check the documentation when buying. It must contain a product passport, an installation guide and two certificates: for the appliance itself and for its fire safety.

Room volume

The required power of the stove depends on the size of the room. To heat 1 cubic meter of a steam room, if it is properly insulated, 1 kW is enough. If the insulation is not enough, a more powerful device will be required.

The power of the stove must be selected exactly depending on the characteristics of the room, and not “with a margin”. An oven that is too powerful will quickly dry out the air and consume more electricity than necessary. And the lack of this characteristic will not allow you to reach the desired temperature (or the sauna will heat up for too long).

Controls

The remote control is more convenient because it allows you to turn on and adjust the stove without even going into the steam room. That is, it will warm up during the preparation for bath procedures. On the other hand, with built-in management, it is easier to change something in the process. Duplicated systems have the advantages of both.

Photo 2. Remote control panel for an electric sauna heater from the manufacturer Harvia.

Remote controls have different complexity. But the more features it has, the more expensive the device is. As a result, in some cases, the cost of the remote control itself will be higher than the cost of the furnace. Therefore, when choosing, it is recommended to decide which functions will be used frequently, and which ones can be dispensed with.

Heater type

Two types of heating elements are used in electric furnaces: tubular and tape. Heating elements are tubes made of carbon or corrosion-resistant steel. They are heated to a fairly high temperature, 700-800°C. But tubular electric heating elements are more fragile. That is why they break more often.

LANs are made of stainless steel, but in the form of ribbons wound on a ceramic frame. They warm up to lower rates, about 400-500°C. But this is enough to heat the steam room.

LANs are more durable than heating elements and create a more comfortable environment in the sauna. The room heats up faster. But tape heaters do not allow contact with water.Because of this, as well as the lower temperature, tubular systems are used for steam generation.

Important! Direct contact of the heating element with water is still undesirable, especially with cold water. Therefore, the pipes are closed with stones, and the liquid is poured onto them. Therefore, those who like to take a steam bath are more suitable for stoves based on heating elements.

There are two types of heaters available. They combine the advantages of both, but are also more expensive.

Therefore, those who like to take a steam bath in the bath are more suitable for stoves based on heating elements. There are two types of heaters available. They combine the advantages of both, but are also more expensive.

Stove exterior

Electric heaters are produced in various forms, which depend on the location in the sauna.

Rectangular, cylindrical and even round stoves are placed in the center of the room or against the wall. Triangular are designed for installation in a corner. This saves space.

Another way to save space is to place the stove on the wall. Such models have special fastenings. They are regular (rectangular) and angular.

Manufacturing instructions

Making an electric furnace for a closed-type sauna with your own hands consists of the following steps:

- Development of a detailed drawing on paper with the determination of the optimal dimensions required for heating the power, the location of the future device. Usually the body of the electric furnace is made small in volume, the main space in their design is occupied by a basket for stone backfill. The shape of the body can be any, but a rectangular oven will be more convenient during operation. It is more stable, able to maintain its shape for a long period of time.Due to the fact that its corner zones almost never become hot, the balance of heat flows and the uniformity of heating of the room are maintained.

- Calculation of the number of heating elements for the furnace, based on the power of one element.

- Marking on a steel sheet of body parts and cutting off the necessary parts.

- Connections of heating elements in one design using metal strips.

- Fixing heating elements on one side. They are mounted to one of the sides of the furnace - side or bottom, using bolts or welding. The distance from the heating elements to the metal walls of the housing must be such that an asbestos sheet can fit into this gap. Its heat transfer coefficient is minimal, therefore, no heating of the body directly by heating elements will occur.

- Furnace body assembly. Sheet steel parts are fastened by welding or bolted.

- Welding of legs made of fittings from the bottom of the furnace body for installation on the floor.

- Laying stones in dense layers, without gaps and large cracks. Larger stones are placed below, and then smaller fractions. There should be a small gap between the heating elements and the filler for air convection, its last row should completely cover the heating element, but not be higher than 8 cm. When laying stones, the heating elements must be held.

- Production of a protective casing of the furnace from sheet steel or fireclay bricks.

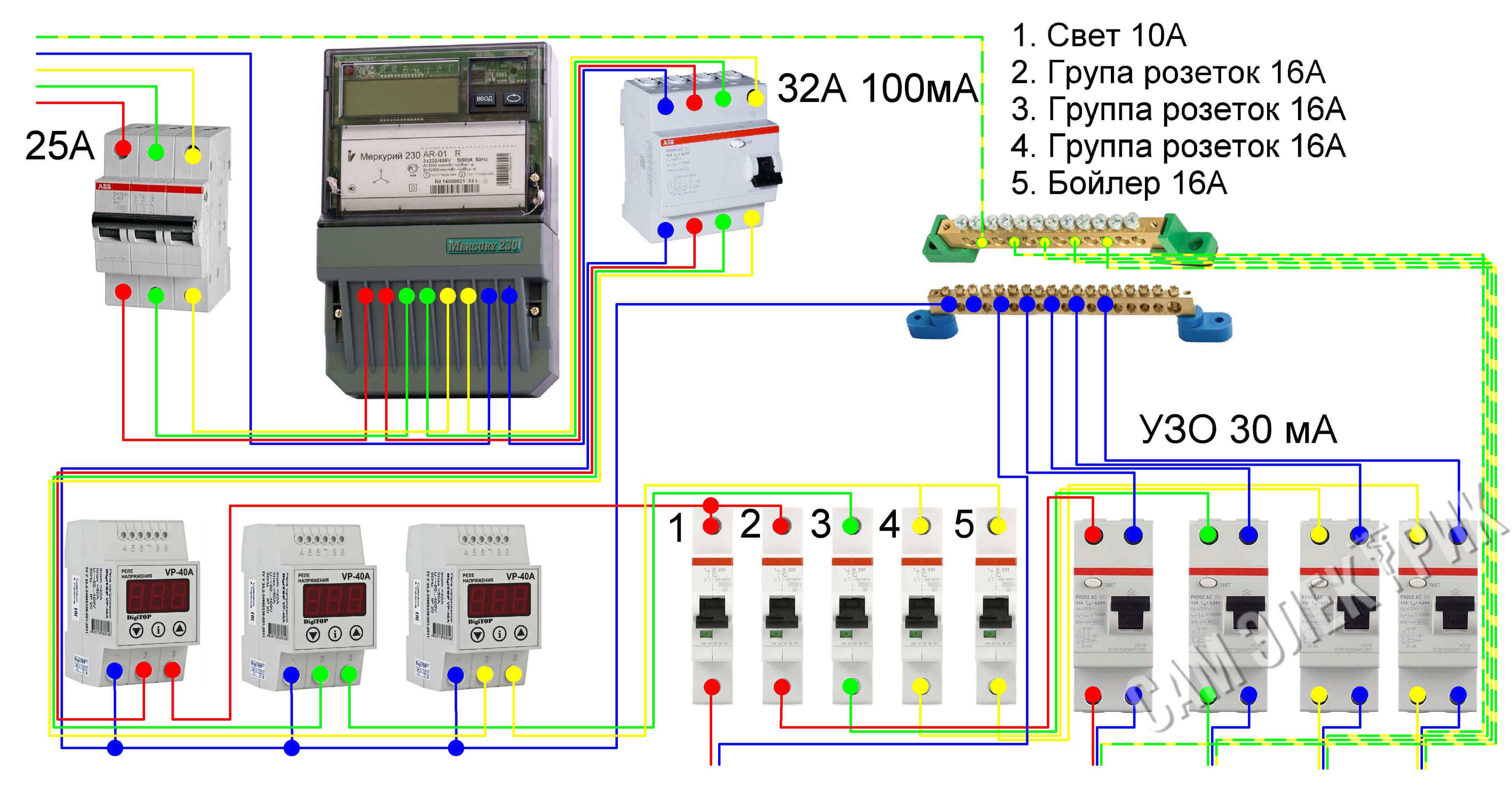

- Installation of power tools in the furnace. For this furnace, a simple circuit diagram is taken as a basis: the voltage from the network is supplied to the terminals of the controller of the remote control, and the wires coming from the heater are connected to the output terminals.

- Installation of the furnace control panel.The steam room maintains a high level of temperature and humidity, so the remote control must be installed on the wall in another room where the temperature is not higher than 25 - 28 degrees. The wires from the remote control must be connected to a separate circuit breaker in the electrical panel and laid in protective corrugated sleeves. Previously, special strobes are punched under the wiring in the walls, which, after the installation of the wires, are sealed with non-combustible building materials, for example, a cement-sand mixture.

- Installation of temperature and humidity control sensors for an electric furnace. For their connection, heat-resistant cables are used, solid in length, without connections. Usually they are mounted on top of the unit, above the shelves or above the front door to the steam room.

- Ground loop devices. The electric oven must be connected to its own grounding loop, which is recommended to be laid in the ground at the construction stage of the sauna. It is brought to the furnace using protective cable channels. If at one time they didn’t worry about grounding, then the grounding cable of the furnace must be connected to the zero terminal of the electrical panel.

- Installation of a thermostat. It is installed inside the structure and is used to measure and adjust the heating temperature of the stones.

- Refinement of the appearance of the furnace. The body parts are cleaned with sandpaper, degreased with gasoline or acetone, primed and painted with two layers of heat-resistant paint;

- Checking the operation of the furnace, the safety of installation and connection.

Manufacturing instructions

Making an electric furnace for a closed-type sauna with your own hands consists of the following steps:

-

Development of a detailed drawing on paper with the determination of the optimal dimensions required for heating the power, the location of the future device. Usually the body of the electric furnace is made small in volume, the main space in their design is occupied by a basket for stone backfill. The shape of the body can be any, but a rectangular oven will be more convenient during operation. It is more stable, able to maintain its shape for a long period of time. Due to the fact that its corner zones almost never become hot, the balance of heat flows and the uniformity of heating of the room are maintained.

-

Calculation of the number of heating elements for the furnace, based on the power of one element.

-

Marking on a steel sheet of body parts and cutting off the necessary parts.

-

Connections of heating elements in one design using metal strips.

-

Fixing heating elements on one side. They are mounted to one of the sides of the furnace - side or bottom, using bolts or welding. The distance from the heating elements to the metal walls of the housing must be such that an asbestos sheet can fit into this gap. Its heat transfer coefficient is minimal, therefore, no heating of the body directly by heating elements will occur.

-

Furnace body assembly. Sheet steel parts are fastened by welding or bolted.

-

Welding of legs made of fittings from the bottom of the furnace body for installation on the floor.

-

Laying stones in dense layers, without gaps and large cracks. Larger stones are placed below, and then smaller fractions. There should be a small gap between the heating elements and the filler for air convection, its last row should completely cover the heating element, but not be higher than 8 cm. When laying stones, the heating elements must be held.

-

Production of a protective casing of the furnace from sheet steel or fireclay bricks.

-

Installation of power tools in the furnace. For this furnace, a simple circuit diagram is taken as a basis: the voltage from the network is supplied to the terminals of the controller of the remote control, and the wires coming from the heater are connected to the output terminals.

-

Installation of the furnace control panel. The steam room maintains a high level of temperature and humidity, so the remote control must be installed on the wall in another room where the temperature is not higher than 25 - 28 degrees. The wires from the remote control must be connected to a separate circuit breaker in the electrical panel and laid in protective corrugated sleeves. Previously, special strobes are punched under the wiring in the walls, which, after the installation of the wires, are sealed with non-combustible building materials, for example, a cement-sand mixture.

-

Installation of temperature and humidity control sensors for an electric furnace. For their connection, heat-resistant cables are used, solid in length, without connections. Usually they are mounted on top of the unit, above the shelves or above the front door to the steam room.

-

Ground loop devices. The electric oven must be connected to its own grounding loop, which is recommended to be laid in the ground at the construction stage of the sauna. It is brought to the furnace using protective cable channels. If at one time they didn’t worry about grounding, then the grounding cable of the furnace must be connected to the zero terminal of the electrical panel.

-

Installation of a thermostat. It is installed inside the structure and is used to measure and adjust the heating temperature of the stones.

-

Refinement of the appearance of the furnace.The body parts are cleaned with sandpaper, degreased with gasoline or acetone, primed and painted with two layers of heat-resistant paint;

-

Checking the operation of the furnace, the safety of installation and connection.

The best cast iron sauna stoves

Cast iron models are characterized by high heat capacity and good corrosion resistance. The main disadvantages of such furnaces are their large mass and relatively low resistance to mechanical damage.

GEFEST PB-04 MS - a model with an excellent design

5.0

★★★★★

editorial score

100%

buyers recommend this product

See review

An open-type wall-mounted wood-burning stove with a top connection to the chimney is designed to work in fairly spacious steam rooms. Its main feature is the impressive efficiency provided by the system of secondary afterburning of pyrolysis gases.

The glass door does not interfere with the control of combustion in the combustion chamber. The average cost of this model is 40 thousand rubles.

Advantages:

- High efficiency;

- Beautiful design;

- Compact dimensions;

- The combustion chamber and the body are made of thick-walled cast iron.

- Ash box.

Flaws:

- Heats up for a long time;

- Big weight.

An excellent sauna stove for a private house and cottage.

VESUVIUS Legend Standard 16 - an oven with a well-thought-out design

4.9

★★★★★

editorial score

97%

buyers recommend this product

See review

A powerful wood-burning wall-mounted sauna stove is designed to work in steam rooms up to 18 squares.

Its feature is the presence of a steel restrictive grid, which prevents accidental contact with the hot surface of the housing.

The furnace and the furnace itself are made of thick-walled cast iron, which has a high heat capacity.The chamber is closed by a transparent glass door. The price of this model is about 22.5 thousand.

Advantages:

- Reliability;

- Good power;

- Nice design.

Flaws:

Impressive dimensions and weight of the device.

This model is an excellent option for organizing a Russian bath on your site.

NARVI Oy Kota Inari – a powerful stove for a large room

4.8

★★★★★

editorial score

89%

buyers recommend this product

Another worthy model of an open-type outdoor wood-burning stove. The main features of this unit are high efficiency, the possibility of top and rear connection of the chimney.

Material of a fire chamber and the case – thick-walled cast iron. The door is made of tempered safety glass. As a bonus, the manufacturer provided for the presence of an ash box. The cost of the furnace is a little more than 30-31 thousand.

Advantages:

- Reliable design;

- Equipment with secondary afterburning;

- Adjustable legs.

Flaws:

A small amount of stones.

An excellent option for use in the country and in a private home, if the volume of the steam room is small.

TMF Cast iron Cast Vitra - with an enlarged combustion chamber

4.8

★★★★★

editorial score

86%

buyers recommend this product

See review

This wood-burning stove is suitable for working in spacious rooms, as it has an increased volume of the combustion chamber and does not require frequent loading of fuel. Material of a fire chamber and the case – refractory cast iron. The door is made of heat-resistant thick-walled glass. The price of the furnace does not exceed 29 thousand rubles.

Advantages:

- Excellent design;

- Large firebox;

- Impressive heated volume;

- Double "shirt" providing protection against burns.

Flaws:

There could have been more stones.

This model is perfect for organizing a bath and sauna in a separate room with a large steam room.

KASTOR Karhu-16 JK - compact and lightweight

4.7

★★★★★

editorial score

80%

buyers recommend this product

A small but powerful closed type wood burning stove with a top flue connection from a well-known Finnish manufacturer. Due to the unique design of the combustion chamber, it is able to quickly heat a steam room up to 16 cubic meters.

A thick-walled steel combustion chamber with a stainless chipper will definitely not burn out even during long-term operation. And the outer casing-convector is completely made of cast iron.

The door is made of heat-resistant glass, which makes it possible to observe the process of fuel combustion. The cost of the model is a little more than 40 thousand.

Advantages:

- High efficiency;

- Light weight;

- Excellent appearance;

- Large heated volume;

- Long service life.

Flaws:

- Small weight of stones;

- High price.

This model will be an excellent solution for capital saunas and steam rooms up to 8 sq.m.

Brief overview of popular manufacturers

Having familiarized yourself with the main parameters, you can proceed to the choice of one or another manufacturer. Below are the most popular brands, for the convenience of visitors, the information is presented in the form of a table.

Table. Popular manufacturers of electric heaters

| Name | Brief Scripture | Average market value of products |

|---|---|---|

| Tylo, Sweden | The company has established itself as a manufacturer of expensive exclusive products. The latest technologies are used in production, furnace bodies are finished with expensive materials. | From 28,111 to 139,795 rubles, depending on the specific modification. |

| Helo, Finland | It produces high-quality and functional ovens that can operate in one of three modes: — Russian bath mode; - sauna mode; - Standby mode.They are distinguished by a high heating rate - after 20-30 minutes the temperature can reach 70 ° C. | From 28,400 to 185,588 rubles. |

| Harvia, Finland | The company produces several models of electric heaters. So, the Fuga model is characterized by slow distribution of thermal energy and high steam humidity; Compact - a small device designed for two or three people; Delta is a small triangular model that saves space. The Topclass Combi heater is equipped with special bowls for liquid fragrances. | From 11,300 to 140,044 rubles. |

| Termofor, Russia | The company that for the first time produced a stove with a panoramic fuel channel extended from the firebox and allowing the flame to be observed from different focuses. The electric model (and it is only one - "Primavolta") is made of fire-resistant high-alloyed "stainless steel" and is capable of heating steam rooms up to 8 m³. | 11 999 rubles. |

| "Ermak" "Inzhkomtsentr VVD", Russia | Domestic companies that have established themselves as manufacturers of high-quality electric heat generators for baths. All stoves are finished with natural stone, they are reliable and can regulate convection temperature fluctuations. Power ranges from 8 to 24 kW. | From 19,250 to 58,740 |

As you can see, most of the electric heaters are made in Finland, but still there are worthy models among domestic products. Moreover, ovens made in Russia are much cheaper.

Wood burning sauna heater

Wooden saunas and baths are the best baths in the world. Block and log walls have a wonderful property to let air and steam through, keep heat well, while creating a unique and inimitable aroma of wood. Inside such baths and saunas it is very warm and dry.Even without special ventilation, they always keep a pleasant atmosphere. But how can there be a sauna without a stove? The stove in the bath or sauna is really their “heart”. And from that, a cast-iron stove or some other will be installed in the bath, and it will hang warmth and comfort in the steam room and in the rest room.

The smell of smoke and the quiet crackling of the fire in the stove for most lovers and connoisseurs of baths and saunas are a mandatory attribute of the steam room. That is why electric sauna stoves, which are very easy to operate, will never force wood-burning stoves out of the market.

Conclusion

Electric heaters cannot be called a full-fledged replacement for a wood-burning stove in a Russian bath or sauna, however, in the conditions of a steam room in an apartment building, such devices are indispensable. The main thing is to do all the work according to the rules and in accordance with the manufacturer's recommendations. Only in this case, the operation of the unit will be safe, which will allow you to fully enjoy the heat, relax and relieve fatigue after a hard day's work.

A properly executed sauna will allow you to fully enjoy the heat

A properly executed sauna will allow you to fully enjoy the heat

We hope that the information presented in today's article was interesting, and most importantly, useful to those who are thinking about arranging a sauna or steam room at home. If you have questions about the topic, ask them in the discussions. The editors will be happy to answer them as detailed and quickly as possible. If you have already equipped a steam room at home, please share your impressions and experience with those who are just planning such work. And finally, we bring to your attention a short video on today's topic, which will no doubt be very interesting for you.

Watch this video on YouTube

Watch this video on YouTube

Previous SaunaPrivate sauna from sawn pine timber - easy and affordable

Next Bath To the envy of Diogenes: do-it-yourself barrel-bath, design features