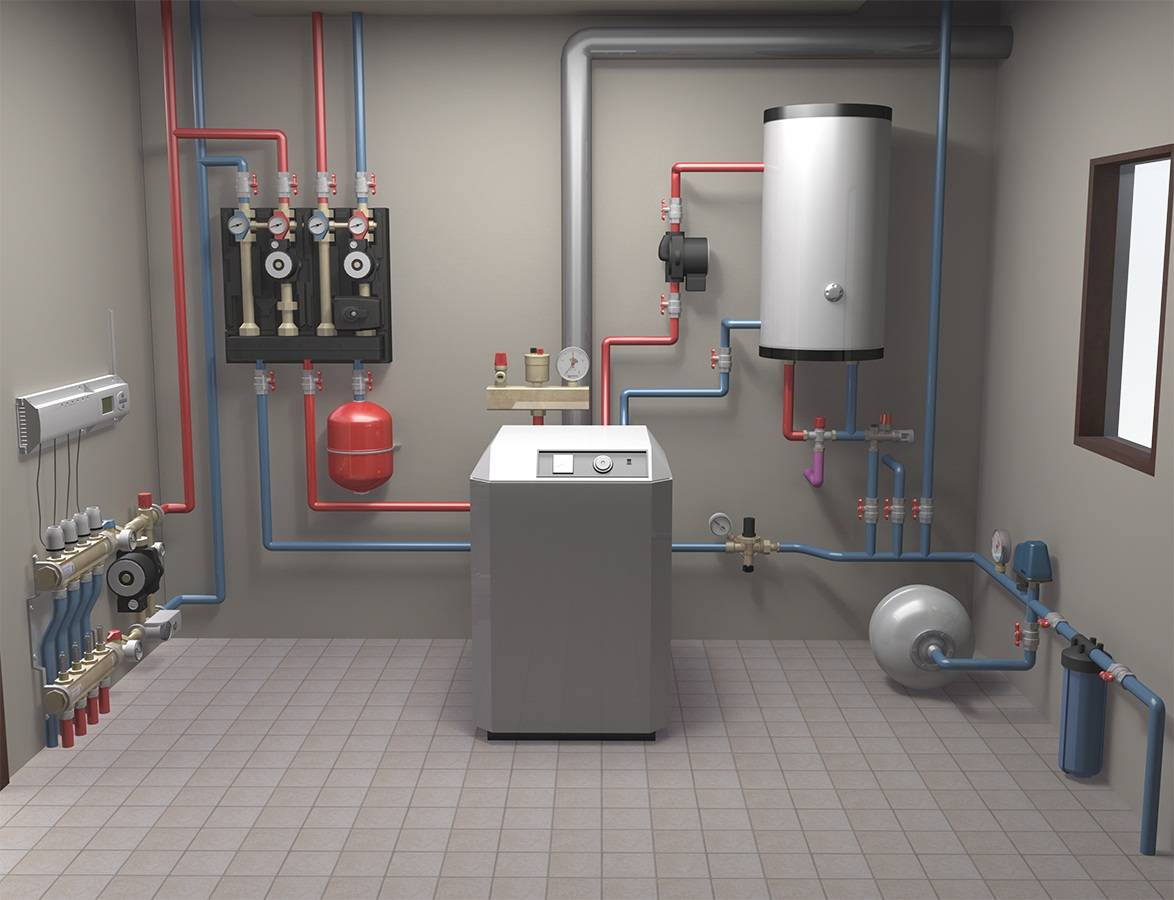

- Models of electric boilers

- Tenovy electric boiler

- Electrode Electric Boiler

- Electric induction boiler

- Electrode electric boiler for a private house

- Principle of operation

- Feature of operation

- The layout of the electrode heating boiler

- Choosing an electric boiler

- Boiler device

- The main criteria for choosing boilers

- Solid fuel boilers

- Pros and cons

- Long burning boilers

- How to choose the power of a gas boiler

- Calculation of a single-circuit heating boiler

- How to calculate the power of a double-circuit boiler

- Calculation of the power of an indirect heating boiler and a single-circuit boiler

- What power reserve should a gas boiler have

- Calculation of gas demand based on boiler power

- Which electric boiler is better to buy for home

- Single-phase and three-phase electric boilers

- Single phase electric boiler

- Three phase electric boiler

- Infrared heaters

- Video description

- Convectors

- Video description

- As a result - how to optimize electric heating

Models of electric boilers

The principle of any electric boiler is the conversion of electricity into heat. Electric units are not the most cost-effective, but the efficiency of their use is 95-99%, which is good enough for such units. Such boilers are divided into three types according to the type of coolant. Let's talk about each of them in more detail.

Tenovy electric boiler

Electric heating boilers equipped with heating elements work on the principle of an electric kettle. Water passes through tubular heating elements - heating elements. Acting as a heat carrier, it passes through the entire heating system, circulating with a pump.

One of the advantages can be called its compactness, neat appearance and the ability to mount on the wall. The installation process will not cause any particular difficulties, and the operation is comfortable and simple, thanks to the sensors and thermostats. Automation allows you to maintain the desired heating, focusing on data from sensors that measure the ambient air temperature.

The coolant can be not only water, but also a non-freezing liquid, due to which scale will not form on the heating elements, which cannot be avoided using water.

Attention. Scale formed on heating elements impairs heat transfer and energy-saving properties of an electric heating boiler. This option for heating a house is also good because it has a low cost.

For the convenience of adjusting the consumption of electricity, it is equipped with several heating elements that can be turned on separately

This option for home heating is also good because it has a low cost. For the convenience of adjusting the consumption of electricity, it is equipped with several heating elements that can be turned on separately.

Electrode Electric Boiler

The principle of operation of an electrode electric boiler for heating a house is completely different from the previous model. The liquid is heated not by a heating element.The electrode, installed in the housing, gives the liquid an electric charge, under the influence of which the molecules are split into negatively and positively charged ions. The coolant has its own resistance, which provides intense heating. Either water or a special composition (similar to antifreeze) is poured into the system.

This type of electric unit for heating the house is completely safe, if a liquid leak occurs, it will simply turn off. Electrode models are very compact (looks like a small cylinder with nozzles), equipped with sensors for measuring ambient temperature, controlled by automation.

The maintenance of this model comes down to replacing the electrode, as they gradually dissolve as they work, which worsens the heating of the house. It is also necessary to monitor the proper operation of the circulation pump so that the liquid in the system does not boil. Correct and efficient operation of an electrode electric boiler for heating a private house is possible only with prepared water - it must have the required resistivity value. Measuring them yourself is not always convenient and simple, just like preparing water. Therefore, it will be easier and more reliable to buy a liquid specially designed for operation in electrode boilers.

Electric induction boiler

This type of electric heating unit for the home works on the basis of induction heating of a liquid with ferromagnetic alloys. The inductive coil is located in a sealed housing and does not have direct contact with the coolant that flows along the perimeter of the device. Based on this, not only water, but also antifreezes can be used as an energy carrier for heating a house.This electric home heating boiler is not equipped with a heating element or electrode, which improves its efficiency. Also, the absence of heating elements ensures complete safety during operation. This version of the boiler for heating the house is not subject to scale formation, practically does not break and does not flow.

The downside of induction models is only their higher cost and large dimensions. But over time, the size problem is eliminated - the old ones are replaced by improved models.

In addition to this classification, electric boilers for heating a private house are divided into:

- single-circuit (designed only for heating the whole house);

- double-circuit (provide not only heating throughout the house, but also water heating).

You also need to highlight:

- wall boilers;

- floor boilers (high power models are produced).

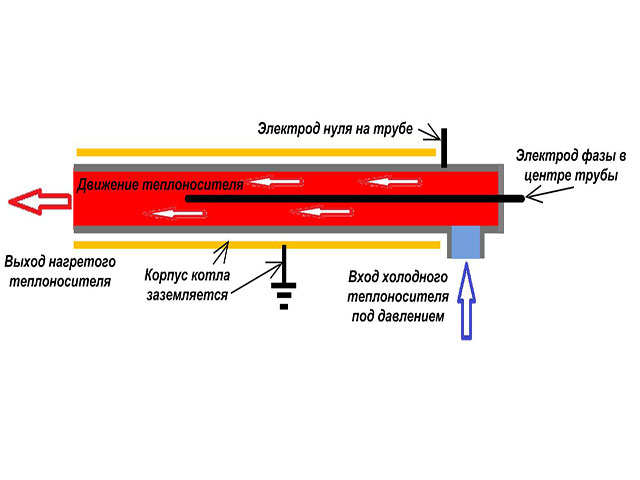

Electrode electric boiler for a private house

Its design can be with a two-sided supply of water to the place of heating from different sides (figure on the left) and from one side (figure on the right).

Principle of operation

Water is heated in the working space by passing an electric current through it between the electrodes, like in self-made boilers from two plates.

When using direct current, minus the source potential is applied to one electrode, and plus to the other. For variable circuits, a phase is applied to the first electrode, zero to the second electrode with the obligatory reliable grounding of the case through the PE conductor.

The water flowing around the electrodes is heated due to the passage of an electric current through it and is fed to the outlet fitting.

Feature of operation

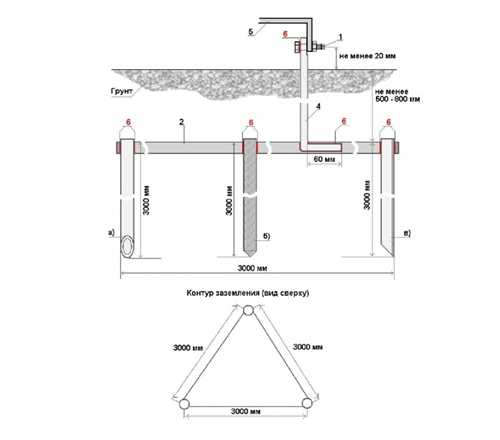

In this design, electrical safety is a weak point.Grounding damage in this design is unacceptable because, if zero breaks, the phase potential will instantly create an electric current path through water to a person, cause his defeat, create electrical injury and can lead to death.

Partially perform a protective function is capable of grounding the case. Under certain conditions, an emergency current can flow through it, which will turn off the circuit breakers.

As protection, it is imperative to use high-speed RCDs or difavtomatov, which constantly compare the current values in the phase and neutral conductors, instantly turn off the voltage in case of violations in the system. The state of the ground loop and its connection with the electric boiler must be constantly monitored.

For the passage of electric current through the coolant, the presence of dissolved salts is necessary, because pure distilled water does not have conductivity. During operation, salts precipitate, form scale, clog the lines, the boiler, the surface of the electrodes, which requires preventive periodic cleaning. It should be noted that technically it is not difficult to perform such work. For this, a convenient disassembly option is provided.

The advantage of this design is a high efficiency, which can be 95%, which is not achievable for boilers on heating elements.

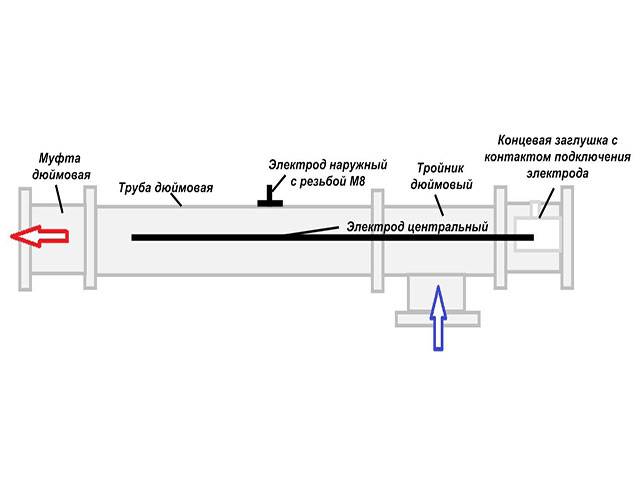

The layout of the electrode heating boiler

Through the tee, water enters and is fed to the outlet through the outgoing pipe. The inner phase electrode with wire connected can be removed for maintenance through the side cover. The zero of the circuit is fed to the contact screw of the inch pipe. Ground is connected to the chassis.

Comparative graphs of the operation of heating elements and electrode boilers clearly characterize their technical capabilities.

The electrode design is able to bring water up to 55 degrees per minute, and for the heating element analogue, the time is increased 10 times.

The lower graph characterizes the saving zone of the compared structures. As part of the electrode boiler devices:

- a grounded case is required;

- contact circulation pump at the inlet;

- the place of connection of the phase and neutral wires;

- coolant outlet through a tee;

- water temperature sensor to control the automatic shutdown and connection of electricity to the electrodes;

- switch box.

If there is a lack of power, it is allowed to install in series another model with similar characteristics. This complicates the design with the addition of a pump to a common control unit.

Such a scheme is allowed to increase the heating power, often used for concrete panel buildings with large heat losses.

Choosing an electric boiler

One of the most common electric boilers is a heating element. The principle of operation of this heating boiler is to heat the coolant (usually water) in the tank, using a simple electric heater (heater). With the help of a pump, hot liquid circulates through the heating system, giving off heat to the room.

The electrode boiler works differently. The electrode is placed in a pipe through which the coolant flows, the second pole is on the metal case of this pipe. The principle is based on the fact that water is an electrolyte and conducts electricity. The scheme will become clear if we recall the old army boilers, consisting of two blades. The principle of operation is approximately the same.When a strong enough current is passed through the water, it heats up.

The main and only advantage of such boilers is compactness. The diameter of the hole is within 7-10 cm. The length depends on the power and varies from 25 to 70 cm.

The disadvantages include:

- fragility. The electrode will eventually dissolve in water and will need to be replaced,

- Such boilers are demanding on the composition of the water. If the water is not saturated with mineral salts, no current will flow through the water. If, on the contrary, there are too many salts, this leads to a short circuit. The water starts to boil and evaporate.

The next type of electric boiler is induction.

The principle of operation of an induction boiler is that if a coil is wound on a ferromagnetic rod and a sufficiently large alternating current is applied, an electromagnetic field is formed. The induced electromagnetic field causes the particles of this rod to oscillate with increasing speed. He, accordingly, will begin to warm up.

Boiler device

A metal rod or other object made of a ferromagnet is placed inside a dielectric pipe. An inductor is wound outside. As soon as current is applied to the coil, the rod heats up and gives off heat to the passing water.

The advantages of this unit are durability, this boiler is devoid of wearing parts, and even scale inside the pipe has practically no effect on the efficiency of the boiler.

The most common type of electric boiler is radiator. This is an ordinary aluminum radiator, in the extreme section of which there is an electronic unit that includes a heating element and a thermostat. The battery is usually filled with water or an alternative coolant.

Who should be singled out as the best in this segment of boilers? What type to choose so that it is always warm in your private home? Marketers in this segment are trying very hard, promoting induction and electrode boilers. To this day, we are very skeptical about this topic (but we are) and would give our preference to conventional heating elements.

By right, Protherm Scat boilers and its complete analogue Vaillant Eloblock can be called the best in this segment. They can not be called cheap, but at the same time expensive. Although they are heating elements, they are fully automated and, due to their automation, allow additional savings on electricity.

The main criteria for choosing boilers

Hundreds of foreign and domestic manufacturers offer thousands of models of heating equipment. It is not easy for an unprepared buyer to navigate all this variety of goods. I want it cheaper and the quality is better.

All heating boilers differ in the type of fuel and are divided into the following categories:

- solid fuel (processing firewood, peat, pellets, coal);

- liquid fuel (units operating on diesel fuel);

- gas (conventional and condensing);

- electrical (requiring the supply of electricity);

- universal (using either gas or electricity).

Before choosing an option, it will not be superfluous to conduct a small analysis and find out which energy carrier is profitable to use in your area. After that, you should decide how safe, reliable and comfortable the boiler should be in operation in terms of every penny invested in it.

To choose one or another type of heating equipment, you must first familiarize yourself with the advantages and disadvantages of each of them.

In order not to make a mistake and not to waste your hard-earned money, you need to carefully consider the process of choosing equipment. To do this, it is necessary to take into account a number of nuances that significantly affect the final result.

When choosing a boiler, you should:

- to understand in detail the advantages and disadvantages of each type of boilers;

- calculate the optimal power of heating equipment for your home;

- determine the number of circuits;

- choose a place where the equipment will subsequently be placed.

The maximum permissible dimensions and weight depend on the location of the future location of the boiler. Indeed, for a small room it is impractical to choose a heavy cast-iron unit.

The choice of heating equipment must be approached responsibly. This is the only way to buy high-quality equipment that will last far more than one year.

Solid fuel boilers

Despite all the shortcomings, solid fuel boilers for heating a private house are used in most cases. Probably, this is largely due to habit and traditions, but the fact remains that there are more solid fuel boilers in our country than all others.

Solid fuel boilers work mainly on wood and coal

Basically, two types of solid fuels are used for heating - wood and coal. What is easier to get and cheaper to buy, so they basically drown. And boilers - for coal and firewood, you need to use different ones: in wood-burning solid fuel boilers, the loading chamber is made larger - so that more firewood can be laid. In TT coal boilers, the furnace is made smaller in size, but with thicker walls: the combustion temperature is very high.

Pros and cons

The advantages of these units include:

- Inexpensive (relatively) heating.

- Simple and reliable design of boilers.

- There are non-volatile models that work without electricity.

Serious disadvantages:

- Cyclic operation. The house is either hot or cold. To level this shortcoming, a heat accumulator is installed in the system - a large container with water. It stores heat during the active combustion phase, and then, when the fuel load burns out, the stored heat is spent to maintain a normal temperature.

- The need for regular maintenance. Firewood and coal must be laid, kindled, then the intensity of combustion must be regulated. After burning out, the firebox must be cleaned and the process restarted. Very troublesome.

The principle of operation of a conventional solid fuel boiler - Inability to leave the house for a long time. Due to the cyclical operation, the presence of a person is necessary: fuel must be thrown up, otherwise the system may freeze during prolonged downtime.

- The process of loading fuel and cleaning the boiler is a rather dirty task. When choosing an installation site, this should be taken into account: the boiler should be placed as close as possible to the front door so as not to carry dirt through the entire room.

Generally speaking, the use of a solid fuel boiler for heating a private house is an inconvenient solution. Although the purchase of fuel, as a rule, is relatively inexpensive, but if you calculate the time spent, it is not so cheap.

Long burning boilers

Long-burning boilers were developed to increase the interval between fuel fillings. They use two technologies:

- Pyrolysis. Pyrolysis solid fuel boilers have two or three combustion chambers.The fuel filling in them burns with a lack of oxygen. In this mode, a large amount of flue gases are formed, most of which are combustible. Moreover, when burning, they emit much more heat than firewood or the same coal. These gases enter the second chamber, where air is supplied through special openings. Mixing with it, combustible gases ignite, releasing an additional portion of heat.

The principle of operation of the pyrolysis boiler - Top burning mode. In traditional solid fuel boilers, fire spreads from bottom to top. Because of this, most of the bookmark burns, the fuel burns out quickly. During active combustion, the system and the house often overheat, which is very uncomfortable. When using top burning, the fire is kindled only in the upper part of the bookmark. At the same time, only a small part of the firewood burns, which evens out the thermal regime and increases the burning time of the bookmark.

Top burning boiler

How effective are these technologies? Pretty effective. Depending on the design, one bookmark of firewood can burn from 6-8 to 24 hours, and coal - from 10-12 hours to several days. But to obtain such a result, it is necessary to use high quality fuel. Both firewood and coal must be dry. This is the main requirement. When using wet fuel, the boiler may not even enter the smoldering mode, that is, it will not start heating. If you have a woodcutter with a two to three year supply of firewood or a large shed that stores coal, a long-burning boiler for heating a private house is a good choice. Better than normal.

How to choose the power of a gas boiler

Most consultants who sell heating equipment independently calculate the required performance using the formula 1 kW = 10 m². Additional calculations are carried out according to the amount of coolant in the heating system.

Calculation of a single-circuit heating boiler

- For 60 m² - a unit of 6 kW + 20% = 7.5 kilowatts can satisfy the need for heat

. If there is no model with a suitable performance size, preference is given to heating equipment with a large power value. - In a similar way, calculations are made for 100 m² - the required power of boiler equipment, 12 kW.

- For heating 150 m², you need a gas boiler with a power of 15 kW + 20% (3 kilowatts) = 18 kW

. Accordingly, for 200 m², a 22 kW boiler is required.

How to calculate the power of a double-circuit boiler

10 m² = 1 kW + 20% (power reserve) + 20% (for water heating)

The power of a double-circuit gas boiler for heating and hot water heating for 250 m² will be 25 kW + 40% (10 kilowatts) = 35 kW

. Calculations are suitable for two-circuit equipment. To calculate the performance of a single-circuit unit connected to an indirect heating boiler, a different formula is used.

Calculation of the power of an indirect heating boiler and a single-circuit boiler

- Determine what volume of the boiler will be sufficient to meet the needs of the residents of the house.

- In the technical documentation for the storage tank, the required performance of the boiler equipment is indicated in order to maintain the heating of hot water, without taking into account the necessary heat for heating. A 200 liter boiler will require an average of about 30 kW.

- The performance of the boiler equipment required for heating the house is calculated.

The resulting numbers are added up. The amount equal to 20% is subtracted from the result. This must be done for the reason that the heating will not simultaneously work for heating and DHW. The calculation of the thermal power of a single-circuit heating boiler, taking into account an external water heater for hot water supply, is done taking into account this feature.

What power reserve should a gas boiler have

- For single-circuit models, the margin is about 20%.

- For two-circuit units, 20% + 20%.

- Boilers with connection to an indirect heating boiler - in the storage tank configuration, the required additional performance margin is indicated.

Calculation of gas demand based on boiler power

In practice, this means that 1 m³ of gas is equal to 10 kW of thermal energy, assuming 100% heat transfer. Accordingly, with an efficiency of 92%, fuel costs will be 1.12 m³, and at 108% no more than 0.92 m³.

The method for calculating the volume of consumed gas takes into account the performance of the unit. So, a 10 kW heating device, within an hour, will burn 1.12 m³ of fuel, a 40 kW unit, 4.48 m³. This dependence of gas consumption on the power of boiler equipment is taken into account in complex heat engineering calculations.

The ratio is also built into the online heating costs. Manufacturers often indicate the average gas consumption for each model produced.

In order to fully calculate the approximate material costs of heating, it will be necessary to calculate the electricity consumption in volatile heating boilers. At the moment, boiler equipment operating on main gas is the most economical way of heating.

For heated buildings of a large area, calculations are carried out only after an audit of the heat loss of the building. In other cases, when calculating, they use special formulas or online services.

Gas boiler - universal heat exchanger, providing circulation of hot water for household purposes and space heating.

The device looks like like a small refrigerator.

When installing a heating boiler, it is necessary to correctly calculate its power.

Which electric boiler is better to buy for home

The design features of such devices allow you to install them anywhere where power from the mains is available. The units are used in combination with circulation pumps and expansion tanks to provide heat to the living space. Often additional equipment is purchased separately, but it can be built into the boiler body.

One of the main indicators of the device is power. The required value depends on the total area of \u200b\u200bthe house in which the installation is planned. Preliminary calculation is done very simply, according to the rule:

1 kW of power per 10 square meters of area.

When connecting rooms with high heat output to the heating system, such as corridors or annexes, it is better to use a power factor of up to 1.5.

Depending on the voltage, single-phase and three-phase models are distinguished. The first can work when connected to a 220 volt network and give out power up to 6 kW. Three-phase boilers are more productive, they are installed in country houses with an area of more than 60 m² and are supplied with power from a 380 V network.

It is also worth considering the principle of operation of an electric boiler:

- Models based on tubular electric heaters are affordable and reliable, but are prone to scale.

- Induction units are more compact and reliable, but their cost is much higher.

- Electrode devices are resistant to overheating and water leakage, but are the most difficult to maintain.

For more convenient use of the heating system, when buying an electric boiler, you should take into account the additional features of the unit. These include: power adjustment, temperature setting, protection against freezing, overheating and power surges.

Single-phase and three-phase electric boilers

The choice of a boiler should be taken responsibly, since you need to take into account all the nuances regarding the electrical service of your home. Power lines are not always able to cope with the load that increases after the installation of the boiler. To avoid such problems, visit the power distribution department to which you belong and specify (or ask for a calculation) the maximum power that they can provide. When calculating the required kilowatts, do not forget about household electrical appliances in your home.

Scheme of the structure of a single-circuit wall-mounted electric boiler: 1 - electrical cabinet; 2 — control lamps; 3 - temperature controller; 4 - thermometer/pressure gauge; 5 - power switches; 6 - main switch; 7 - expansion tank; 8 - cable entry; 9 - safety valve; 10 - pump; 11 - return line of the boiler; 12 - plug connection of the control circuit; 13 - safety temperature limiter; 14 - control system fuse; 15 - air valve; 16 - lining of the boiler with thermal insulation; 17 - water pressure switch; 18 - heating rods; 19 - boiler supply line

The electric boiler is quite simple: it contains a heat exchanger and a control and adjustment unit. There are understaffed models that are equipped with an expansion tank, filter and pump.

For heating private houses, small-capacity electric boilers are used: single-phase and three-phase.

Scheme of cascade connection of an electric boiler

Single phase electric boiler

A single-phase boiler is considered to be powered by a 220 V network. It will not be difficult to connect it, since all houses are equipped with the necessary voltage. The power of the device varies from 6 to 12 kW. It is advisable to use such a boiler for an area not exceeding 100 m². Features of an electric boiler for heating a house (220 V):

- works on the principle of a water heater (boiler, kettle);

- a conventional network (220V) is sufficient for operation;

- no special permission is required to install it.

Electric boiler for use in a private house

Three phase electric boiler

A three-phase boiler is more powerful than a single-phase one and is suitable for installation on an area of more than 100 m².In order for the network to withstand the load during the operation of the boiler, they are produced three-phase, that is, they are connected to a 380 V network. Features of a three-phase boiler:

powerful

It is necessary to take into account the heated area. At 10 m? 1 kW + 10-20% is required (for reserve);

operates from three phases (380 V), it is necessary to increase the power supply of current in the house;

it is necessary to obtain a special permit in the power supply to increase the power consumption and install the boiler;

the rated current that should be in each of the three phases varies from 6.1 to 110 A. This indicator affects the choice of the circuit breaker, wiring, its cross section (permissible indicators are indicated in the table below). Proper selection of the necessary elements will eliminate the possibility of fire.

Table "Values of cable cross-section and current of circuit breakers":

| Boiler power (up to the specified value) | Current value of safety circuit breakers, for single-phase boilers | Current value of safety circuit breakers, for three-phase boilers | Cable cross section for single-phase boilers | Cable cross section for three-phase boilers |

| 4 kW | 25 A | 4.0mm? | ||

| 6 kW | 32 A | 6.0mm? | ||

| 10 kW | 50 A | 10.0mm? | ||

| 12 kW | 63 A | 16.0mm? | 2.5mm? | |

| 16 kW | 32 A | 4.0mm? | ||

| 22 kW | 40 A | 6.0mm? | ||

| 27 kW | 50 A | 10.0mm? | ||

| 30 kW | 63 A | 16.0mm? | ||

| 45 kW | 80 A | 25 mm? | ||

| 60 kW | 125 A | 35 mm? |

Whatever boiler is installed for cheap heating of the house with electricity, in any case, it is necessary to provide a backup source of heat.

Mounting dimensions of the electric boiler Buderus Tronic 5000 N

Infrared heaters

There are several types of heaters that use radiation (radiation) as a transfer of thermal energy.This transmission method is considered the most effective for heating a room - first, objects that stand in the way of infrared radiation are heated, and then air is heated from them, due to secondary convection.

Video description

Clearly about infrared heaters in the video:

There are three fundamentally different types of infrared heaters:

-

reflectors, in which the incandescent spiral is enclosed in a quartz glass bulb;

-

panel - in a ceramic monolithic plate "sealed" heating element;

-

film - with carbon sputtering on a polymer film.

Heating a house with electricity of the first type refers to heaters operating in the short-wave range of infrared radiation.

Disadvantages - the lowest efficiency (due to the visible part of the radiation), the lack of precise temperature control and the high temperature of the case.

The infrared panel is so safe that it can be hung on wooden walls

Film heaters are the most efficient. Usually they are used as part of a warm floor, but in principle they can be mounted in walls or on the ceiling. But it is the installation as part of the floor covering that most of all corresponds to the correct and uniform heating of the room. The operation is controlled automatically using a pair of "temperature sensor-thermostat".

If there is not enough space on the floor, then the film heater can be mounted on any free plane

Convectors

Outwardly, convectors are very similar to panel ceramic heaters, but inside the metal case there is an “open” heating element, enclosed inside a plate radiator.The fundamental difference is in the method of heating - cold air enters the case through the bottom row of holes, in contact with the radiator, heats up and exits through the upper row of holes.

Stylish convector panel looks great in a modern interior

As with panel ceramic heaters, there are two types of thermostats - mechanical and electronic. And it is the electronic operation control that ensures the accuracy of adjustment and the ability to work in several modes:

- individual, with manual control, used to heat a separate room;

- group, operation of several devices under the control of one (common) thermostat, which ensures uniform heating of a large area or the same heating mode for several rooms;

- intelligent, control with a remote control, connection to a GSM module and control using standard commands from a remote terminal (mobile communication, Internet), connection to a router and control via a local network and / or Internet.

Video description

What is better to choose: an electric boiler or an electric convector - clearly in the video:

NOBO, a leading European manufacturer of convectors, produces two compatible smart control systems for electrical appliances. Including "warm floors" (through a thermostat) and any other household appliances that are connected to the network (through a shield, a "break" in the circuit or turning on / off sockets). To do this, they produce special thermostats, socket receivers and flush-mounted relay receivers.

One of two control schemes for a multi-zone electrical system

As a result - how to optimize electric heating

In addition to a competent selection of heating equipment, an efficient and optimal (in terms of costs) heating system with electricity is possible only with comprehensive insulation of the house - from the basement to the roof. Otherwise, the cost of heating a house that is blown through will be much higher, even despite the high efficiency of the heater itself, and heating a house with electricity is unlikely to be cheap.