- General information

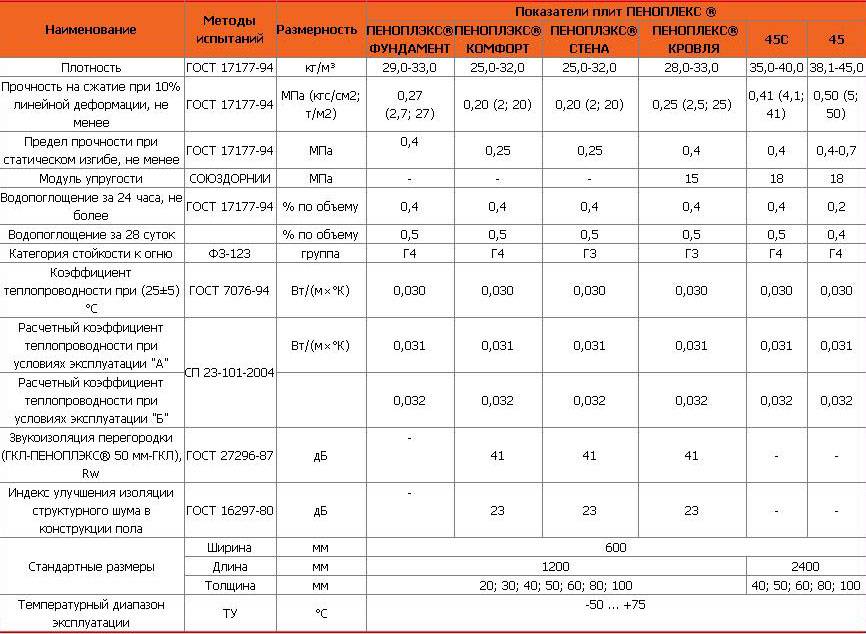

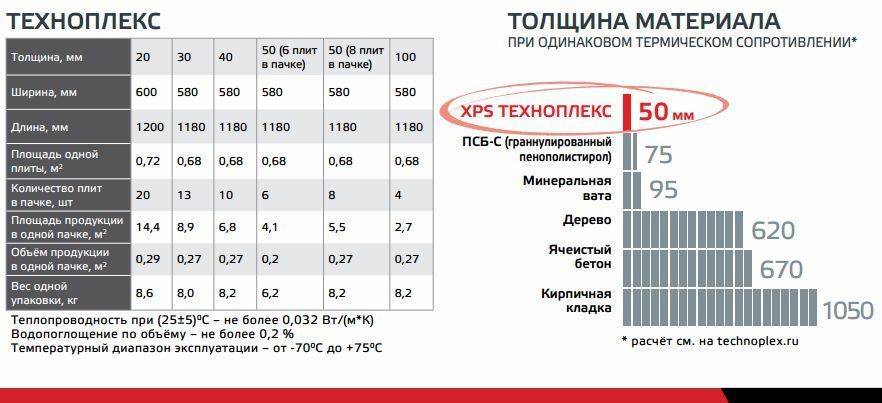

- Characteristics of penoplex

- Advantages and disadvantages of penoplex

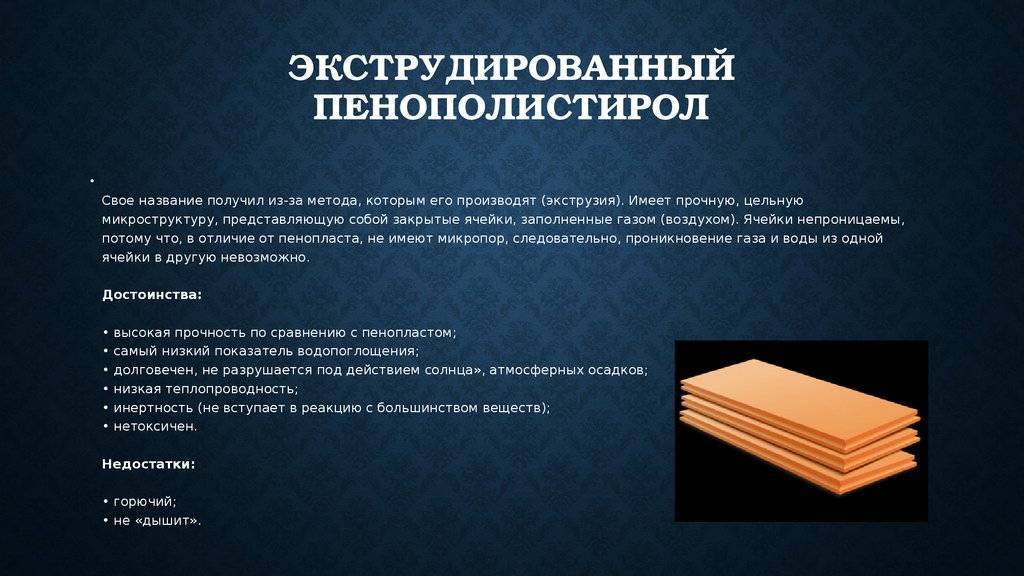

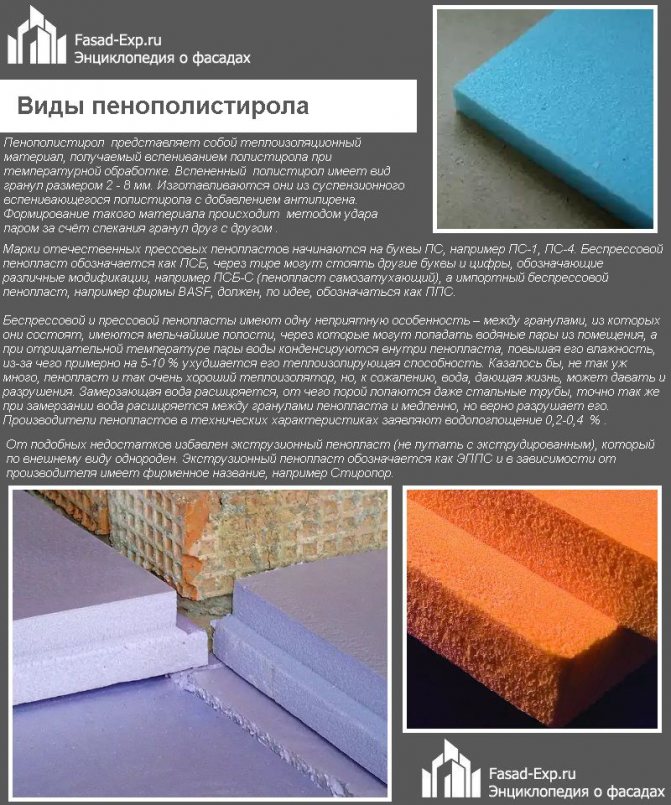

- Extruded polystyrene foam

- Penoplex

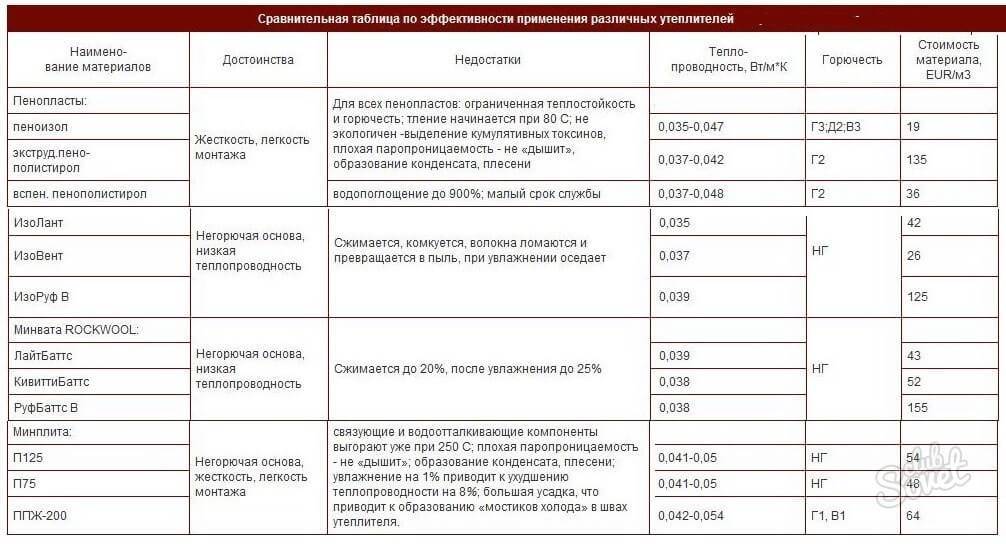

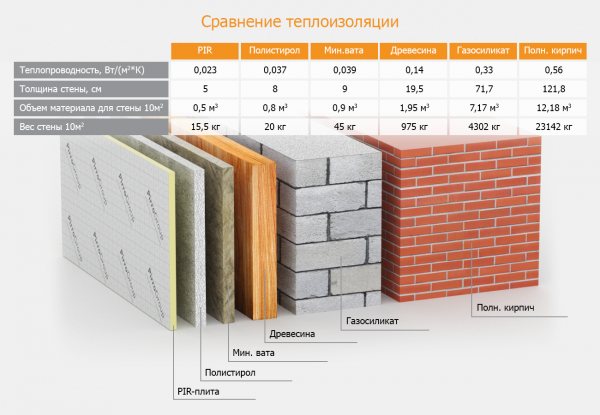

- Comparison results

- What should be the glue for extruded polystyrene foam

- Prohibited Ingredients of Styrofoam Adhesive

- Advantages and disadvantages of expanded polystyrene

- What to choose

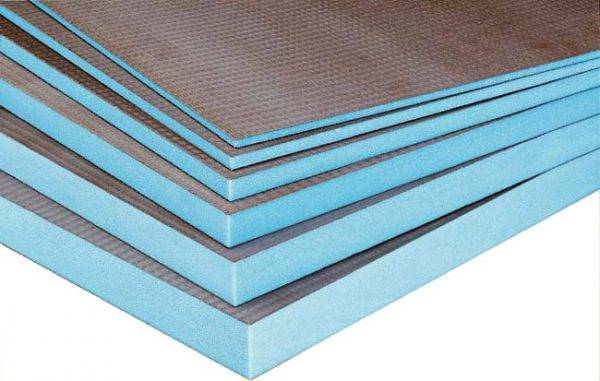

- What is EPPS?

- Pie wall when using styrofoam insulation outside

- Features of insulation based on expanded polystyrene

- Water absorption

- Vapor permeability

- Biological stability

- fire safety

- Technique for mounting foam blocks

- Minuses

- How to choose plaster

- Cement-sand

- Acrylic

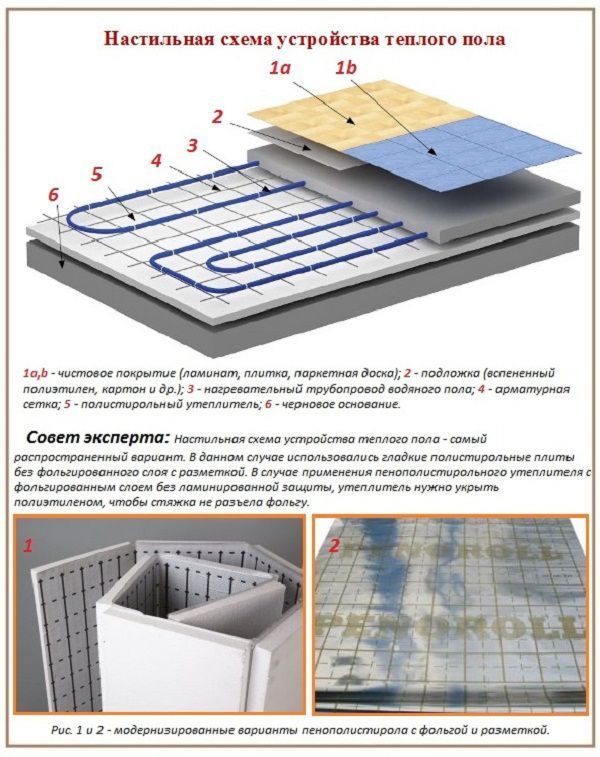

- Insulation of concrete floors with extruded polystyrene foam

- Equipment and consumables

- Stage one. Floor preparation

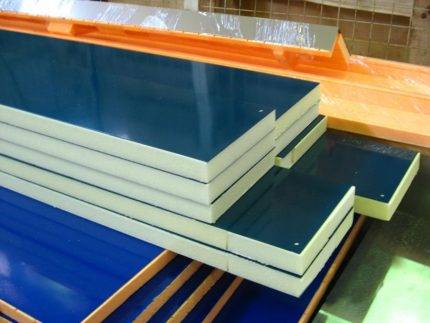

- Stage two. Extruded polystyrene foam laying

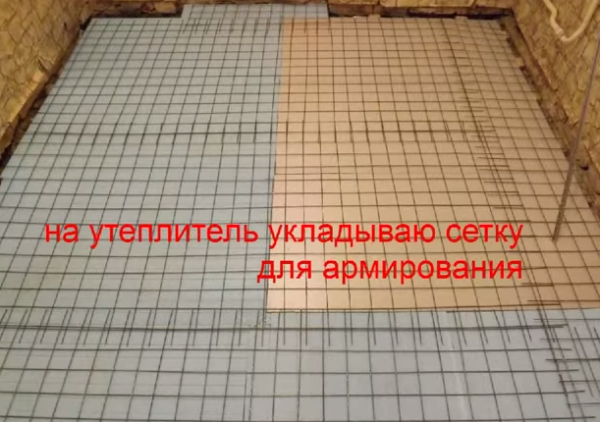

- Stage three. Screed

- How easy is it to calculate the thickness of the insulation

- The main advantages of the material

- Useful video polystyrene foam and its characteristics

- Factors affecting thermal conductivity

- Finally

- Do you have accurate measurements at home?

General information

Characteristics of penoplex

Penoplex in another way can be called extruded polystyrene foam. This is a popular material in the construction market.It has high thermal insulation properties. It is widely used for insulation of facades and roofs, as well as for interior work. The production of expanded polystyrene began in 1941 in the United States. It received its technical properties thanks to the most complex processing using extrusion.

The feedstock is placed in the reactor and subjected to high temperatures and pressure. As a result, the available components are saturated with the gaseous component. When the pressure is released, the mass begins to expand, forming foam. At the same time, the temperature also decreases, which turns the substance into a solid. The mass is passed through extruders. It becomes like multi-layered plastic. Most of the extruded polystyrene foam is occupied by air, purified from water vapor and having low thermal conductivity.

High production technology makes it possible to obtain a material that does not allow gases and water vapor to pass through, even if the installation of foam plastic is carried out incorrectly. Closed cells of foam plastic with a size of 0.1–0.2 mm are filled with liquid when exposed to moisture. Further water does not pass, remains in the pores.

Advantages and disadvantages of penoplex

Extruded polystyrene foam

EPP is not deformed, it serves reliably for a long time. He is not afraid of temperature changes. It does not lose its properties from -100 to + 75 degrees. It can be mounted even in the conditions of the harsh North.

The antiseptic properties of expanded polystyrene lie in the fact that it is not subject to decay at all. It is a pleasure to work with him: installation is simple. Penoplex plates do not cause allergic reactions when in contact with it.

Penoplex

The material is light and has a small thickness from 20 to 150 mm.The price-quality ratio pleases consumers. Extruded polystyrene foam is inexpensive, many who decide to renovate a private house or build a new residential building can buy it.

Comparison results

What should be the glue for extruded polystyrene foam

Glue for penoplex must have the following qualities:

- moisture resistance;

- resistance to temperature extremes;

- high adhesion;

- do not emit harmful substances;

- not be too liquid so as not to leave streaks.

Prohibited Ingredients of Styrofoam Adhesive

Glue for foam plastic should not contain certain components that adversely affect the structure of materials, corroding it.

The composition of the adhesive for extruded polystyrene foam should not include:

- solvents;

- formaldehydes and formalin;

- aromatics such as benzene and toluene;

- polyester and coal tar;

- combustible substances: gasoline, kerosene, diesel fuel.

Advantages and disadvantages of expanded polystyrene

The technical characteristics of polystyrene foam indicate the maximum suitability of the material for internal insulation:

- Light weight. The material is 98% gas.

- Vapor resistance. Polystyrene is an excellent vapor barrier, and extruded polystyrene foam - XPS - almost completely eliminates the penetration of water vapor through its thickness.

- Low thermal conductivity. The presence of air bubbles ensures high heat retention.

- No response to moisture.

- Strength, easy to cut, available in a convenient form for work - plates.

- In terms of fire, the material is neutral, it burns only in the presence of an initiating flame, it itself cannot be a source of fire.

- Low price (for XPS this item is not entirely correct, but the quality of the material is worth it).

There are also disadvantages:

- With a sufficiently high strength, PPS is brittle and breaks or crumbles under deforming loads.

- Does not withstand contact with solvents such as gasoline or acetone.

- When heated above 60 degrees, PPS can release phenols.

- Afraid of fire, therefore not recommended for indoor installation.

Comparison of thermal insulation materials

The last point is quite weighty, since the insulation of external walls is carried out around heating radiators, which can significantly heat up areas of insulation that are in close proximity. Another disadvantage of PPS is its vapor tightness, but in this case this is just an advantage.

What to choose

For example, if you want to insulate a garage or a wooden house on the site, choose cheaper polystyrene foam. 10-15 years of service life of the foam will be quite enough for this type of building. If funds permit, purchase extruded polystyrene foam. Just do not forget that ultraviolet rays destroy the foam.

If you want to improve the thermal insulation of your house or apartment for many years, it would be wise to choose polyurethane foam. The costs will be higher, but you will enjoy the benefits of insulating your home for many years to come. Higher costs for quality installation will pay off over time.

You may be interested in information on how to insulate walls from the inside with foam.

Read about the technology of wall insulation with polystyrene foam here.

We also bring to your attention an article about the advantages and disadvantages of extruded polystyrene foam.

For an overview of the advantages and disadvantages of expanded polystyrene, see the video:

What is EPPS?

In everyday life, this material can be found under the name "styrofoam", but this is fundamentally wrong. These two materials differ significantly from each other. For example, extruded polystyrene foam (EPS) is one of the most resistant to deformation and durable varieties, and its heat-shielding properties hardly suffer from this.

High-strength XPS is made on special production lines by chemical extrusion of the original raw material, which is pure polystyrene granules.

With the help of special equipment, the raw material is converted into foam, from which, in turn, small granules are produced. During the solidification process, these granules are pressed into layers of the desired shapes and sizes, after which they can be used not only for insulating houses, but also for other purposes.

It is due to its fine porosity that XPS is an order of magnitude more durable than conventional polystyrene foam. Compressed under high pressure and at high temperature, such granules give the material greater strength, hardness and reliability.

It is due to its fine porosity that XPS is an order of magnitude more durable than conventional polystyrene foam. Compressed under high pressure and at high temperature, such granules give the material greater strength, hardness and reliability.

The main difference between extruded polystyrene foam and press foam lies in the characteristics of its granules. They are smaller, which makes this building material more resistant to physical stress. The size of the granules of the heat-insulating material produced by extrusion does not exceed 0.1 mm, while the granules of the non-pressed material can reach up to 10 mm.

In foreign interpretation, EPPS can be referred to as XPS. It is produced in several varieties.After the abbreviation "XPS" in the markings of this material there are numbers from 25 to 45, which indicate its density.

The higher the value, the higher the density of the material. Particularly dense extruded material can even be used to insulate asphalt pavement, for example, Penoplex products.

Now that we have figured out what EPPS is, we will discuss in detail all its pros and cons.

Pie wall when using styrofoam insulation outside

A wall pie is called layers of materials that are stacked in a certain order, each of which performs its own functions to ensure a normal microclimate in the room.

When thermally insulating brick walls with polystyrene laid outside, the wall pie looks like this:

- internal plaster;

- outer wall;

- adhesive solution for gluing polystyrene foam;

- insulation (polystyrene foam);

- adhesive solution for gluing the next layer;

- fiberglass mesh;

- adhesive composition;

- primer;

- finishing plaster.

Internal and finishing plaster can be replaced with other finishing materials, which are provided by design solutions.

Features of insulation based on expanded polystyrene

Water absorption

Styrofoam absorbs water on direct contact. The water absorption of the insulation depends on its density, structural features, manufacturing technology and the duration of contact with moisture. Water penetration is less than 0.021 mm per month.

Vapor permeability

The vapor permeability of expanded polystyrene does not depend on the density and degree of foaming. The value has a permanently low value of 0.05 mg/(m*h*Pa).

Biological stability

Expanded polystyrene consists of hydrocarbons, is not a breeding ground for rodents and other living organisms. Under forced conditions, rodents can act on the insulation if it is an obstacle / barrier to access to water and food or to meet other physiological needs.

fire safety

Expanded polystyrene, in the presence of a flame retardant component, refers to self-extinguishing materials. It has a flammability class G3. Reducing the combustibility of expanded polystyrene is also achieved when carbon dioxide material is used to "inflate" the granules of the material.

When choosing expanded polystyrene (polystyrene) as a heater, it should be borne in mind that a material with a high density will have lower thermal insulation properties. Foam insulation, with low density and strength, needs maximum protection against mechanical stress. Even dense insulation requires additional protection.

Technique for mounting foam blocks

- Before starting the installation of foam, it is worth cleaning the surface of any structures that will interfere with the work in the future. After that, a visual assessment of the surface is carried out to identify the presence of destructive processes on the wall. If cracks, chips, drops were identified, then it is worthwhile to start with restoration operations aimed at correcting these shortcomings.

- Then the wall is treated with a deep permeability composition, which will increase the adhesion of the surface and destroy the reproduction of microorganisms, mold and fungus. Solutions can be applied by mechanical staining methods or by spraying.

- The next step is to draw up a plan for installing thermal insulation sheets on the surface.This step will allow you to develop a clear structure for the installation of sheets and the number of cuts to fit the foam to the area. This will reduce the amount of damaged material, which will help save not only the foam for subsequent work, but also reduce the amount of financial losses. It is better to arrange the arrangement of panels on the wall so that blocks of material are applied in a checkerboard pattern.

- The subsequent installation process is almost identical to the process for installing extruded polystyrene foam. However, for the installation of this type of thermal insulation, both adhesive solutions and mechanical fastening of sheets are most often used.

Be careful when working with regular foam, as it is quite easy to destroy it if careless with it.

Minuses

If the ceiling is insulated with extruded polystyrene foam, you should also be aware of its minor drawbacks. There are only two of them:

Complete isolation of the room. This means that when sticking polystyrene foam to the ceiling, the created layer will not let air through and the room will need good ventilation.

Release of toxic substances during combustion. The insulation itself will not burn, but, in case of fire, it heats up to a high temperature and begins to release harmful substances

However, in the event of a fire, this nuance will not be the most important.

The remaining disadvantages of such insulation can be considered the same for all types of polystyrene insulation boards.

How to choose plaster

In order to protect the insulation material, manufacturers suggest using special formulations designed for application to foam.

There are only two types of them - these are acrylic and cement-sand.Which is better the first or second facade plaster on expanded polystyrene, we will now figure it out.

Cement-sand

If we talk about the price, then cement-sand mixtures are much cheaper. And, of course, the most popular. But an attractive price does not give a long result.

Such a coating will last only 2-3 years and then the integrity of the layer will begin to collapse, as a result of which the insulation will suffer from the external environment.

In order not to have to re-install the heat-insulating layer, it is necessary to re-plaster it beforehand, removing the unsuitable coating. It must also be said that cement-sand mixtures are gray. To give a more presentable appearance to the coating, you need to use staining.

Acrylic

Acrylic mixes are much more expensive, but they will last much longer. In addition, they fit well on the base, you can choose already painted mixtures and at the same time you can make not only a smooth coating, but give it an interesting texture, for example, bark beetle, lamb or rain.

Apart from the high cost, the only drawback of acrylic mixtures can be considered color instability. Bright colors fade quickly when exposed to sunlight.

Given all the advantages and disadvantages of plaster mixtures, it should be said that it is better to choose acrylic as a decorative finish. They will last much longer and look much more attractive.

Insulation of concrete floors with extruded polystyrene foam

Insulation of the concrete floor with polystyrene foam

Often, the heat insulator is laid on a bare concrete base and poured with a screed.Of course, you can put wooden logs on the base (we'll talk about this a little later), but in this case, all the advantages of concrete are lost. Therefore, everyone must decide for himself which option suits him best.

Now - directly to the workflow.

Equipment and consumables

Before proceeding with the installation, you need to prepare everything you need. The work will require the following materials:

- XPS boards;

- cement, sand;

- reinforcing mesh;

- liquid Nails;

- waterproofing primer mixture;

- polyethylene film;

- self-leveling floor (for initial and finishing processing).

XPS boards

We also add that the material is easy to install, because it can be cut with a regular knife. As for the equipment, it should be as follows:

- perforator;

- sealant gun;

- electric drill;

- a screwdriver (although a regular screwdriver will do);

- pencil;

- level;

- roulette;

- knives.

After preliminary preparations, you can begin to prepare the base.

Stage one. Floor preparation

Step 1. First, the old flooring is dismantled (down to bare concrete).

The first step on the way to floor insulation will be the dismantling of the old coating.

Step 2. All debris is removed, the surface is cleaned of dust and dirt.

Preliminary preparation

Step 3. The floor is treated with a primer mixture in accordance with the manufacturer's instructions.

Primer screed

Step 4. Once the primer dries, the floor is checked for drops using a building level. If differences of more than 0.5 cm are found, then they are poured with a leveling mixture.

Checking the evenness of the base

Step 5After that, the finishing bulk floor is poured with a thickness of 3-5 cm (as an option, a geotextile fabric with a density of at least 300 g / m² is laid; both methods will effectively level out small irregularities).

Stage two. Extruded polystyrene foam laying

Step 1. First, a damper tape is glued along the perimeter of the room at the bottom of the walls, which is necessary to compensate for thermal expansion.

Edge band fastening

Step 2. The surface is covered with a waterproofing layer - you can use a plastic film for this. Waterproofing is necessary to prevent the penetration and condensation of moisture, otherwise the insulation may lose its properties. The film is laid with an overlap of 10-15 cm and with access to the walls to a height corresponding to the thickness of the entire "pie".

Step 3. Next, expanded polystyrene is laid (it must be dense - about 100 microns). Laying is done manually, there are special mounting grooves along the edges of the plates, so there will be no difficulties with this. The plates are installed end to end, no additional fastening is required. If necessary, the material is cut into the desired pieces using a conventional knife.

Extruded polystyrene foam laying

Step 4. Upon completion of laying, the insulation is covered with a layer of vapor barrier film. The canvases are laid with the same overlap of 10-15 cm and with a similar release on the walls. All joints are sealed with mounting tape.

Stage three. Screed

Step 1. A reinforcing mesh is laid on top of the vapor barrier film.

Reinforcement

Step 2. The surface is poured with a concrete screed 3-5 cm thick.The solution can be prepared by yourself (preparation - sand + cement in a ratio of 3: 1) or purchased ready-made.

Filling the screed

At this installation work is almost completed. The laying of the flooring can be carried out only after the concrete has completely dried, otherwise the technological strength of the coating is not guaranteed.

Screed grout

By the way, for the rigidity of the structure, OSB boards can be laid, and this can be done directly on top of the screed if the floor surface is leveled.

How easy is it to calculate the thickness of the insulation

In the described way, the thickness of walls and floors from extruded polystyrene foam is calculated, the necessary parameters of the insulation for the roof are determined. For those who do not want to bother with complex calculations, it can be advised to use the services of specialists from companies involved in the production and sale of insulation, or special calculators that can be found on the Internet. These services are designed specifically for those who are not familiar with heat engineering, who are not very well versed in construction, but, nevertheless, want to carry out home insulation work on their own.

| Going towards the consumer, one of the most famous companies in the construction market. Penoplex has changed its product line. Now it has become easier for an inexperienced buyer to choose extruded polystyrene foam for insulation of various thicknesses. Plates are produced under the names "penoplex wall", "penoplex foundation", etc., which immediately brings a significant amount of clarity. |

For example, we give recommendations on what should be the thickness of extruded polystyrene foam for the floor. These are general numbers that you should just focus on.Specific calculations will tell more precisely.

- To insulate the floor of the first floor, the thickness of the extruded polystyrene foam must be at least 50 mm.

- On the second floor and above, floor insulation can be performed with foam plastic 20-30 mm thick.

- If you want the foam on the floor to also perform soundproof functions (it protects against impact noise to a certain extent - a joy for the neighbors below, whom you will protect from loud stomping), then the thickness of the extruded polystyrene foam boards of 40 mm is the minimum value.

Now let's touch on such an issue as the thickness of the walls of extruded polystyrene foam. Warming here can be internal and external. Manufacturers do not recommend using thick foam boards for internal insulation, as this can lead to excessive moisture condensation, blocking of walls and, as a result, the spread of fungus and mold. In this case, it is necessary to use a vapor barrier. The optimal thickness of extruded polystyrene foam for interior wall cladding is considered to be no more than 20-30 mm. Moreover, many builders do not recommend doing this at all, preferring other, more moisture-permeable materials.

Wall insulation from the outside is a more acceptable option. But here, too, it must be taken into account that extruded polystyrene foam is more suitable for basement insulation. Its thickness usually ranges from 50 to 150 mm. If calculations show that with the existing thermal resistance of the wall, the thickness of the extruded polystyrene foam will be less than 3 cm, then it is better not to take on the insulation at all. The smaller the difference between the existing figures and the norm, the more economically unprofitable it is to carry out external thermal insulation.

We repeat once again: you can find out the specific thickness of extruded polystyrene foam for the insulation of a particular building in several ways:

The main advantages of the material

In fact, polystyrene is the same plastic, only endowed with different qualities. But from the fact that it is somewhat lighter and less dense, it does not cease to be exactly plastic, and therefore all the advantages of this material are inherent in it.

In order for the owner not to bother with facing the front side after the building is insulated, the manufacturers came up with an excellent way out. They began to produce sandwich panels, in which a sheet of extruded polystyrene foam is initially equipped with a decorative panel of any material to choose from.

In order for the owner not to bother with facing the front side after the building is insulated, the manufacturers came up with an excellent way out. They began to produce sandwich panels, in which a sheet of extruded polystyrene foam is initially equipped with a decorative panel of any material to choose from.

One of the main advantages of expanded polystyrene is the lightness of the material, but its other advantages are also no less significant:

- Resistance to fungal infections. As you know, a fungus needs something to eat in order to live. But synthetics, like food, do not suit him.

- The material does not rot or decompose. Only natural, biological materials are subject to rotting and decomposition. EPPS, initially, is a product synthesized from artificial polymers, and therefore there can be no decomposition.

- Compression resistance. XPS, especially high density, is able to withstand huge loads.

- No moisture absorption. Anyone knows that a plastic bag is waterproof. This quality is not alien to expanded polystyrene.

- Frost resistance. The material does not freeze through, because there is simply no moisture in it. It is airy, but, at the same time, absolutely “dehydrated”.

- Low degree of thermal conductivity.As already mentioned, this material is literally filled with air, namely air is the most intense heat insulator.

From the fact that XPS, in essence, is a plastic, it has a low vapor permeability, which in many cases can be considered a positive quality. So, polystyrene foam is successfully used for attic insulation.

Plus, polystyrene is resistant to most chemicals.

The building, insulated with EPPS, is, as it were, enveloped in a layer of air, since polystyrene foam, with all its strength characteristics, is unusually airy.

The building, insulated with EPPS, is, as it were, enveloped in a layer of air, since polystyrene foam, with all its strength characteristics, is unusually airy.

Also an impressive plus can be considered that:

- XPS, with its extreme strength, has a very low weight, which reduces the load on the foundation if the material is used in the insulation of the upper part of the building.

- It is very resistant to temperature extremes. Temperature jumps almost do not expand or narrow its structure, as is the case with denser substances and materials.

- It is very easy to install, and since it can be easily cut even with a sharp knife, it is extremely easy to form a block or segment of non-standard geometry of the desired size from it.

- Installation work on the insulation of buildings using EPS can be carried out at temperatures from -50 to +70 degrees Celsius, that is, practically all year round and in any climatic zone.

- It adheres well to other building materials. Even plaster adheres perfectly to it.

And if you add here the durability of the material, you might get the impression that EPPS is a panacea for all ills.But, unfortunately, the insulation made from expanded polystyrene has a number of its drawbacks.

Useful video polystyrene foam and its characteristics

April 06, 2018

A person who buys a thing is always interested in its quality. Good quality usually determines the longevity of a purchase. When buying clothes, for example, he sensibly assesses the period of wear - from one season to several years. Then it will simply go out of fashion, dilapidated, or it will need to be repaired. When choosing finishing materials for repairs, a person also assumes that they are not eternal, and someday they just want to change. But there are things when buying which, we are only interested in their durability. I don't think anyone would want to buy a new drill or lawn mower for their house just because the old ones are out of fashion. Or, guided by the same principle, change the pump in your own boiler room. Moreover, we want such things to work forever! Unfortunately this is not possible. At the same time, even a complete breakdown of such mechanisms is not associated with great difficulties in replacing them. But there are materials that are quite difficult to change, if they lose their properties and, as a rule, this will be associated with high costs.

Here we will talk with you about the durability of insulation. In particular, insulation with non-extruded, foamed polystyrene foam, or as we call it - polystyrene foam. We do not consider extruded polystyrene foam as wall insulation now for a number of reasons that we will not mention in this article. A lot has been written about the service life of a mineral plate, but for polystyrene, it is difficult to find any results of serious research.

When building a house, a person hopes for the reliability of what he builds. He wants his children and grandchildren to use the creation of his hands, and for as long as possible, without any unnecessary repairs.

In Russia, houses are now insulated. And not because it has become accepted, but because it is necessary. On the face and economic benefits and comfort. Warming, as a rule, is inside, in a layer. In monolithic construction for insulation, the foam is placed between various blocks, facing bricks. In private, low-rise housing construction, after appropriate preparation and laying of a special reinforcing mesh, plaster is laid on it, making the so-called "wet" facade. The construction of sip or sandwich panels involves the laying of foam at the stage of their production, when between OSB sheets or painted rolled steel, a layer of expanded polystyrene is fixed by gluing. In general, almost always, any insulation is protected, in a layer. Minplita, for example, is afraid of moisture, and after it gets inside, it becomes useless as a heater, so it must be securely covered from precipitation. They have little effect on the foam, but one of its few drawbacks is that it is afraid of the sun, or more precisely, ultraviolet radiation.

In general, it is clear that given the inaccessibility of the location of the insulation, replacing it if it loses its low thermal conductivity and mechanical strength will not be easy, and sometimes almost impossible. For example, in the case of construction with sip or sandwich panels, this will essentially be tantamount to new construction.

Factors affecting thermal conductivity

Styrofoam boards are made in various thicknesses.Therefore, there are numerous factors that affect the thermal conductivity of a material.

- Layer thickness. To achieve high-quality energy saving, it is necessary to make the layer thicker. For example, a 5 cm layer will transmit less heat than a 1 cm layer.

- The structure of the material. Its porosity enhances the insulating qualities. This is because the cells contain air. And it retains the thermal conductivity of the foam well.

- Humidity. During storage, the foam must be protected from moisture. It adversely affects the characteristics of the material, even vice versa.

- Average layer temperature. If the temperature rises, there will be consequences. The efficiency of using the insulator will become worse.

Finally

Extruded polystyrene foam is a material that embodies the best qualities of modern insulation. It provides effective and reliable thermal insulation of a wooden house. An important condition for high-quality insulation is the competent performance of work. Incorrectly made thermal insulation eliminates all the advantages of XPS. To avoid mistakes, it is recommended to contact specialists.

The company "Master Srubov" offers professional services for the thermal insulation of wooden houses with polystyrene foam in Moscow and the region. We guarantee high quality and fast turnaround time.

You will find all our coordinates in the "Contacts" section.

Calculate the cost of painting and insulating your home right now

Do you have accurate measurements at home?

I measured myself There is a project for the house Measurers came I want to call a measurer

By clicking on the button, you consent to the processing of personal data

What means it is necessary to process a log house before painting

Thermal insulation with polynor - profitable, simple, reliable

Oil OLIA - natural protection for your home

Product overview Rubio Monocoat