- Use of chimneys

- Design features

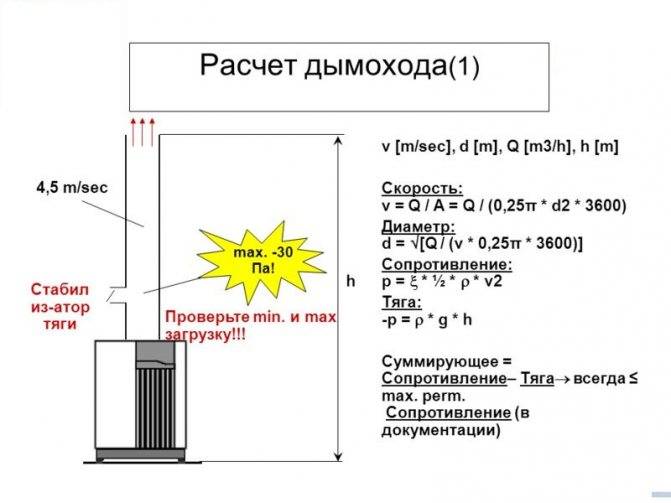

- Calculations of the main parameters

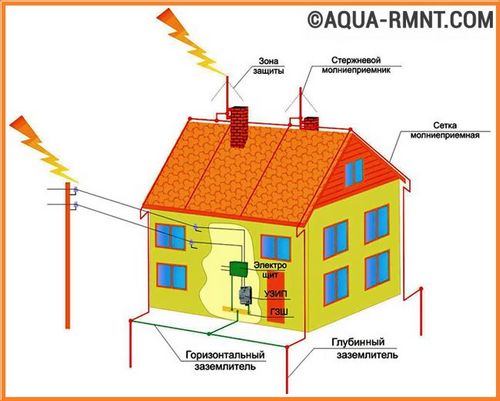

- Lightning protection

- Thrust Height Calculation

- Story

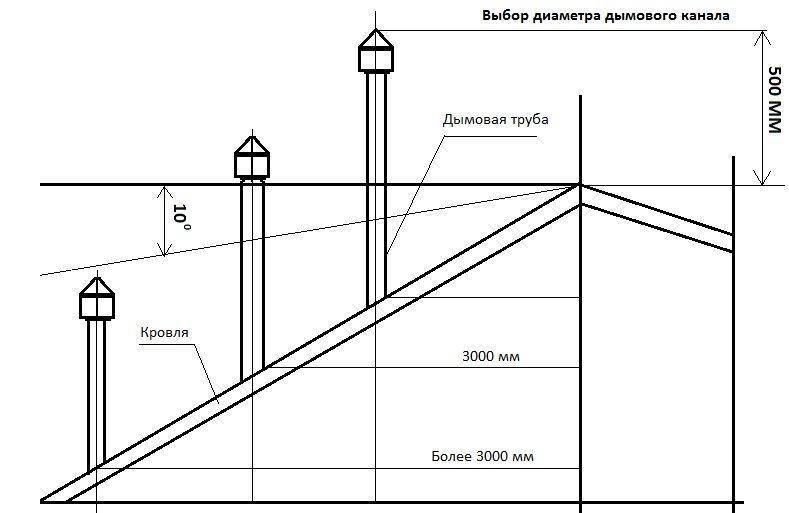

- Chimney height.

- chimney prices

- Lightning rod installation and installation principles

- Necessary security measures: lightning protection of the boiler room

- Calculation of a chimney for a boiler room

- Structure design

- Stages of calculations

- Why Calculations Are Necessary

- Construction types

- Required Documentation

- Types and designs

- How is the chimney

- Height above the skate

- Operation of chimneys

- Maintenance and cleaning

- Chimney Requirements

- What is worth knowing

- Chimney location and wind direction: how to prevent turbulence

- Mounting Features

Use of chimneys

Design features

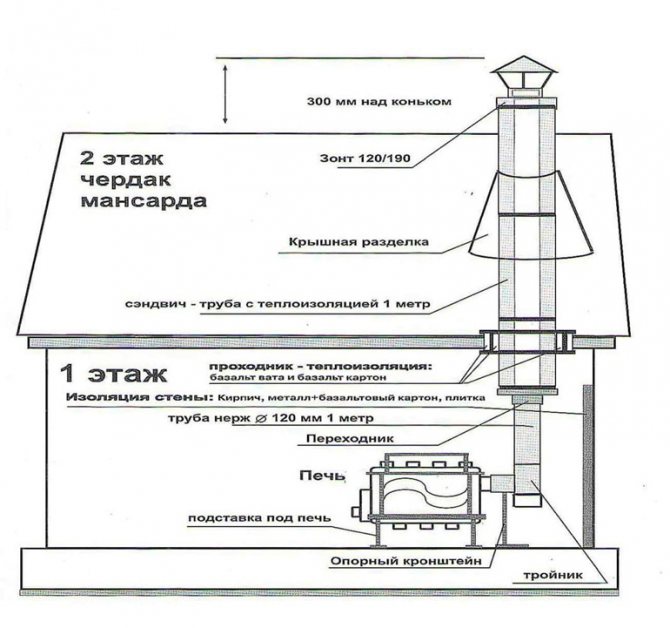

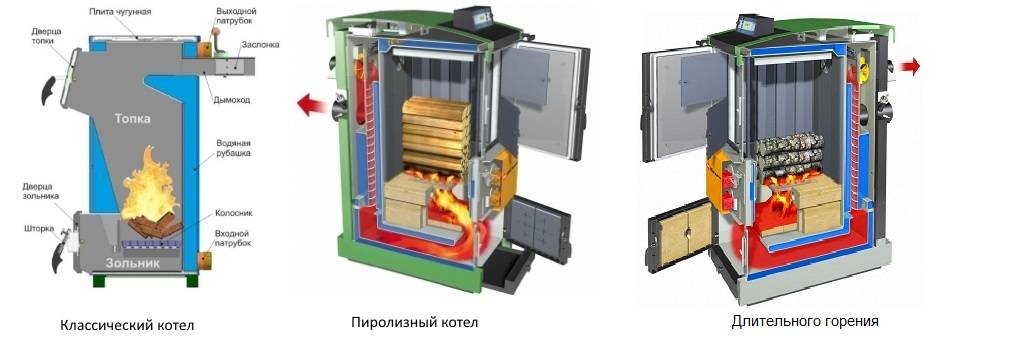

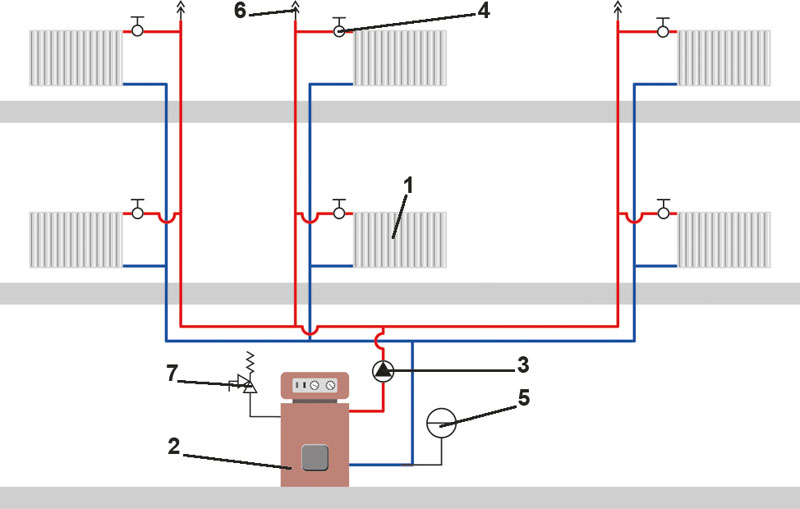

In addition to the internal equipment, an important detail is also a chimney, which is mounted on a thermal installation. The efficiency of the entire system largely depends on how accurately the calculation of the chimney of the boiler room was performed, and how correctly this design was installed.

There are several varieties of such pipes:

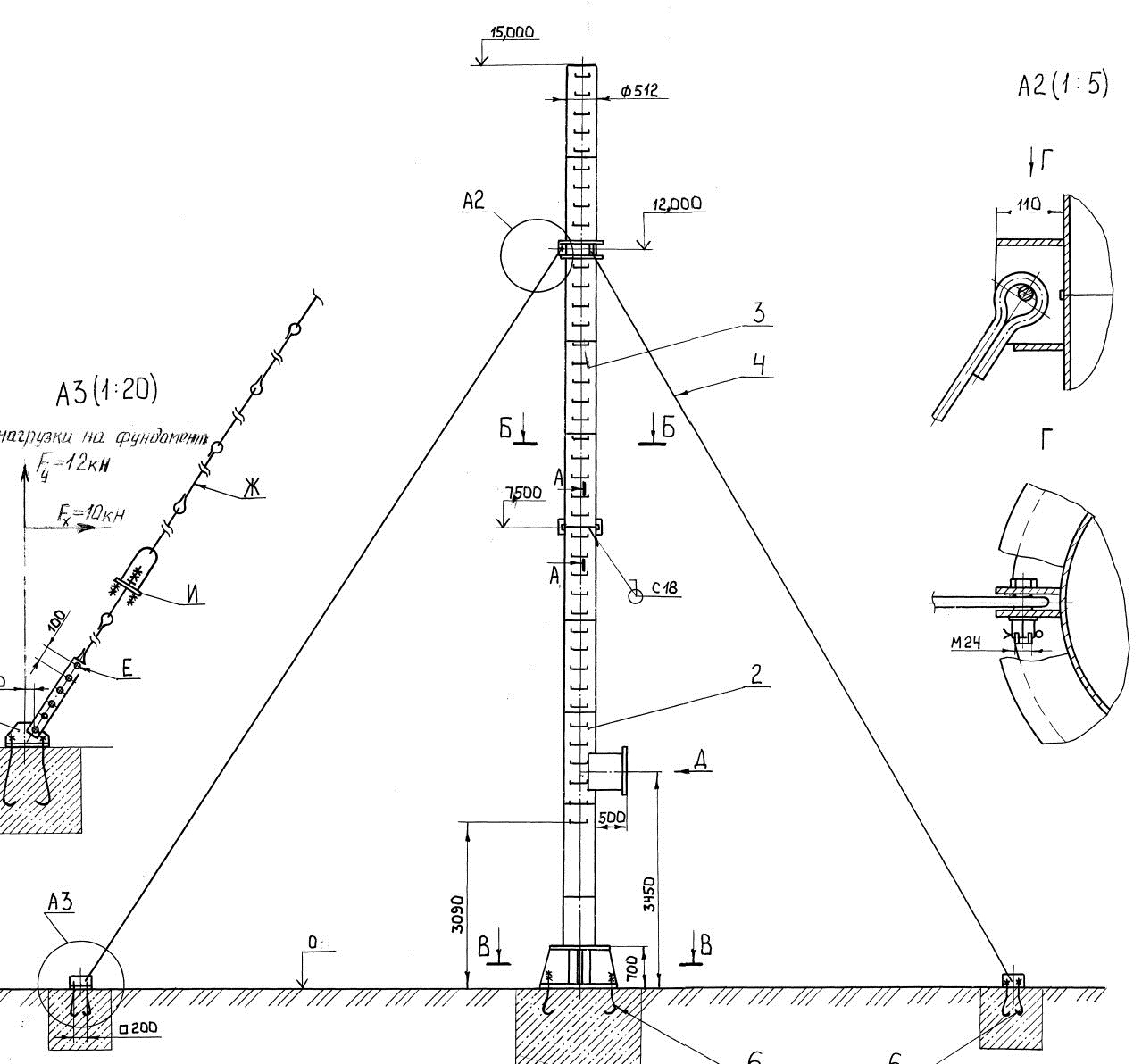

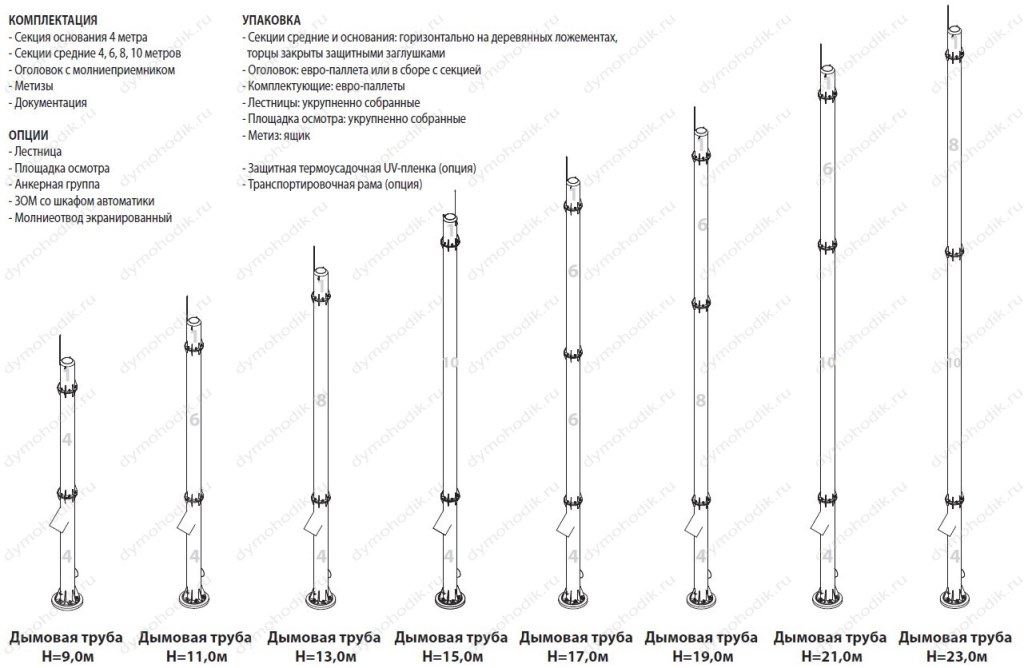

- Farm. The internal chimney is attached to self-supporting steel trusses installed on the ground and secured with deep anchors or an anchor basket in a monolithic reinforced concrete base.

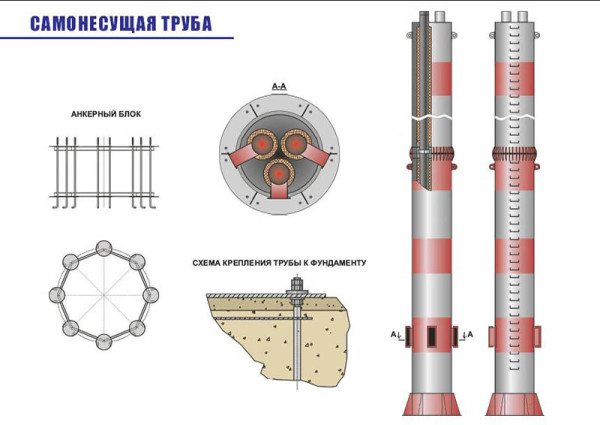

- Self-supporting.They are assembled from several chimneys surrounded by a heat-insulating contour and fixed inside a steel self-supporting shell. The outer structure bears a static load and also resists wind influences.

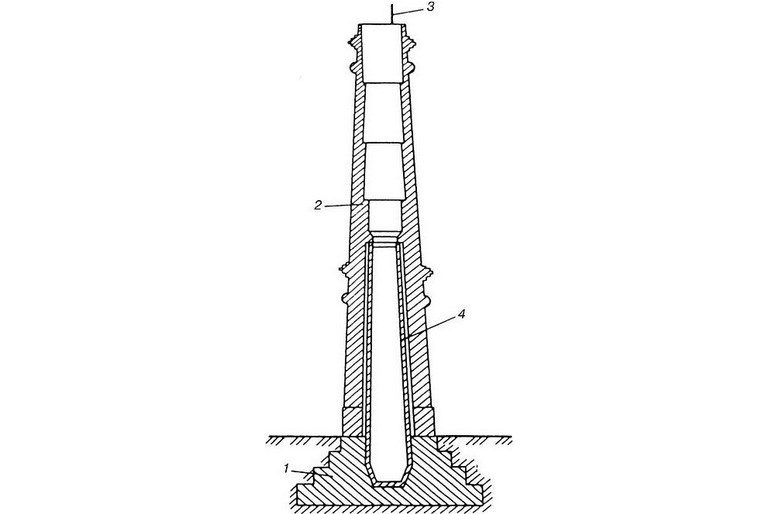

Elements of a self-supporting chimney

- Front. The easiest to install, some of them can even be installed by hand. They are a prefabricated or monolithic steel chimney fixed either directly on the wall or on a system of wall brackets.

- Mast. A seamless thick-walled steel pipe is used as a smoke outlet, the lower part of which is fixed with anchors on the base plate. To resist wind loads, the structure is fixed with cable braces.

Facade construction

It should be noted that most of these structures have significant dimensions and weight. That is why the installation or dismantling of the boiler pipe is carried out mainly by specialized organizations. The only exceptions are small chimneys of private houses, as well as the small-sized facade systems mentioned above.

Calculations of the main parameters

For the design and construction of an efficient chimney, it is necessary to calculate in advance its main parameters, which include the height of the chimney of the boiler room and its inner diameter. The easiest way to do this is with the help of special calculator programs that can be found on the network, but even without them you can find out at least approximate numbers.

For household boilers of low power, the initial data will be approximately the same:

- The incoming gas temperature is up to 200C.

- The movement of gas in the pipe is 2m/s or more.

- Height according to SNIP - not less than 5 m from the grate and not less than 0.5 m from the ridge (for industrial models - at least 5 m higher than the tallest object within a radius of 25 m).

- Natural gas pressure - 4 Pa or more.

As an example, we calculate the diameter of an insulated steel pipe (thermal coefficient B = 0.34) required for the operation of a boiler house in which 10 kg of firewood with a moisture content of 25% and an outlet temperature of 150C are burned per hour.

The volume of gases required for fuel combustion is 10m3/kg:

- We calculate the volume of gases at the pipe inlet per second using the formula Vr= m*V*(1+t/273)/3600, where m is the fuel mass and V is the gas volume.

- We get Vr = (10*10*1.55)/3600 = 0.043 m3/s.

- Using the formula for the volume of a cylinder, we determine the square of the diameter D2 = (4∙0.043)/3.14∙2 = 0.027.

- Therefore, the minimum diameter of the chimney will be 0.165 m.

As you can see, the calculations of even one parameter are rather complicated. This is another argument in favor of the fact that the design of chimneys, especially those designed to support the operation of boilers with high power, should be done by professionals.

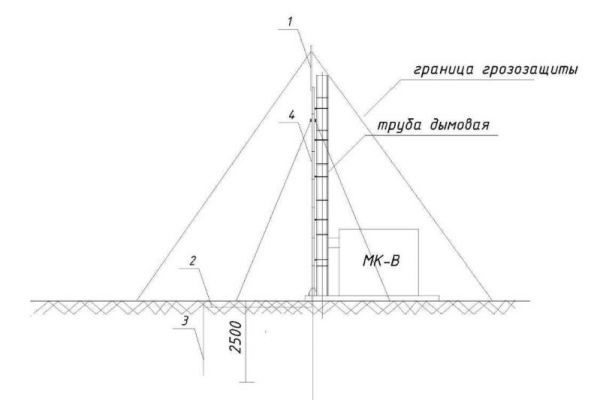

Lightning protection

Taking into account all the features in the preparation of the project, proper installation, regular inspection of boiler chimneys to identify defects and eliminate them in a timely manner are prerequisites for efficient operation. However, sometimes external factors can cause the system to fail.

One of these factors is lightning, and therefore high pipes must be protected from its effects:

On non-metallic chimneys, steel or copper-plated lightning rods are mounted. Their number can vary from one (structures up to 50 m) to three (from 150 m and above).In some cases, the rods are replaced with steel ring plates, which are attached to the end.

Lightning protection scheme of non-metallic structure

For concrete pipes, the role of lightning rods is played by internal reinforcement. To increase the efficiency of its functioning, the upper edges of the rods are connected by welding.

The steel pipe itself plays the role of a lightning rod

Naturally, in this case it is important to ensure high-quality grounding.

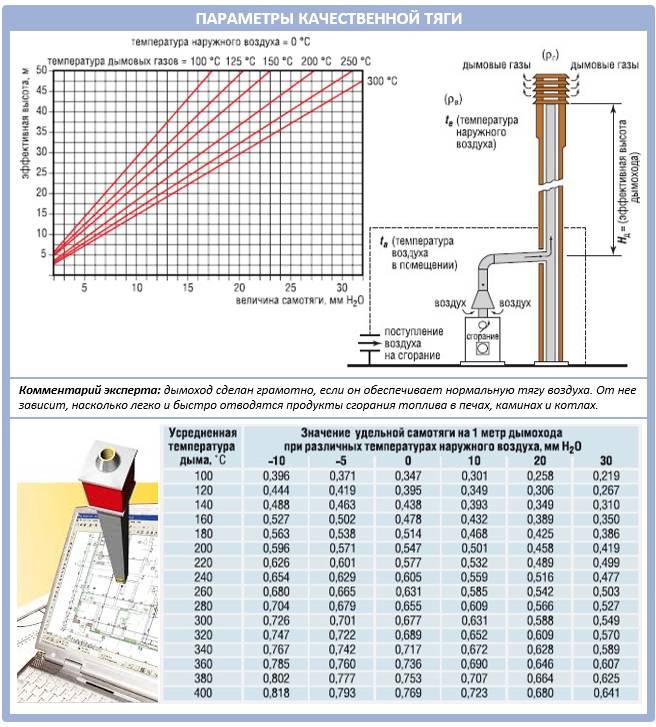

Thrust Height Calculation

This indicator is very important for solid fuel boilers. Manufacturers of such equipment usually indicate the minimum required height of the chimney to create normal natural draft in the instructions for its installation. However, if necessary, the calculation of the height of the chimney by draft can be performed independently.

For this you need to use the following formula:

hc \u003d H * (pv - pg).

Here H is the height of the chimney from the branch pipe of the solid fuel unit, pv is the air density, pg is the density of CO.

The air density for calculation by this method is determined as follows:

pv \u003d 273 / (273 + t) * 1.2932, where

1.2932 is the air density under accepted standard conditions, and t is the temperature in the boiler room (usually +20 ° C).

The parameter ρg from the formula is determined from special tables using the following formula:

Yav = (Y1 + Y2)/2, where

Y1 - t of carbon monoxide at the inlet to the chimney, according to the technological documentation, and Y2 - t gases at the outlet of the pipe. The last parameter is determined by the following formula:

θ2=θ1 — НВ/√(Q/1000), where

Q is the power of the heating unit, and the coefficient B has the value:

- for a “sandwich” galvanized pipe - 0.85;

- for ordinary steel - 0.34;

- for brick - 0.17.

Story

This instrument is one of the most ancient.The first mention of such devices arose in the period of about 3600 years. Many civilizations used pipes - and Ancient Egypt, and Ancient China, and Ancient Greece, and other cultures used the likeness of pipes as signaling instruments. For many centuries this was the main role of this invention.

In the Middle Ages, the troops necessarily had trumpeters who were able to transmit a sound order to other units located at a considerable distance from each other. In those days, the trumpet (musical instrument), although it did not fully fulfill its functions, was nevertheless an elite art to play on it. Only specially selected people were trained in this skill. In calm, non-war times, trumpeters were obligatory participants in holidays and knightly tournaments. In large cities, there were special tower trumpeters, signaling the arrival of significant people, the change of seasons, the advance of enemy troops, or other important events.

Shortly before the advent of the Renaissance, new technologies made it possible to produce a more perfect musical instrument. The trumpet began to participate in the performances of the orchestra. In addition, trumpet players have become much more virtuoso by learning the art of the clarino. This word denoted the transmission of diatonic sounds with the help of blowing. can be safely considered the "golden age of the natural pipe". Ever since the classical and romantic age, which puts melody as the basis of everything, has come, the natural trumpet has receded into the background as incapable of reproducing melodic lines. And only for the performance of the main steps of the scale in orchestras was the trumpet used.

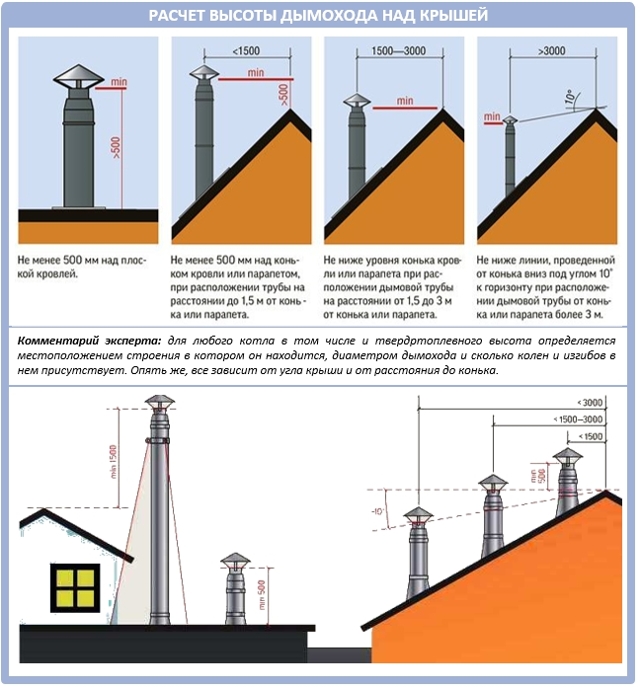

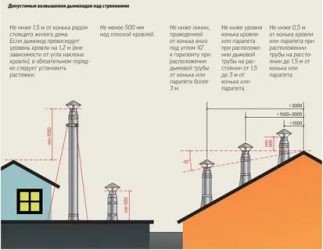

Chimney height.

Here we can do without complicated calculations.

Yes, of course, there are rather cumbersome formulas by which the optimal height of the chimney can be calculated with great accuracy. But they become really relevant when designing boiler houses or other industrial installations, where they operate with completely different power levels, volumes of fuel consumed, heights and diameters of pipes. Moreover, these formulas also include an environmental component for the emission of combustion products to a certain height.

There is no point in giving these formulas here. Practice shows, and this is also, by the way, stipulated in building codes, that for any of the theoretically possible solid fuel appliances or structures in a private house, a chimney pipe (with natural draft) with a height of at least five meters will suffice. You can find recommendations to focus on an indicator of six meters.

This refers to the height difference between the outlet of the device (for furnaces it is often considered - from the grate) to the upper edge of the pipe, without taking into account the put on umbrella, weather vane or deflector

This is important for those chimneys that have horizontal or inclined sections. We repeat - not the total length of the pipe used, but only the height difference

The height of the chimney is exactly the difference in height between its inlet and outlet, and not the total length of the pipe, which can have horizontal or inclined sections. By the way, one should always strive to minimize the number and length of such sections.

So, the minimum length is clear - five meters.Less is impossible! And more? Of course, it is possible, and sometimes it is even necessary, since additional factors may interfere due to the specifics of the building (it’s commonplace - the height of the house) and the location of the pipe head relative to the roof or neighboring objects.

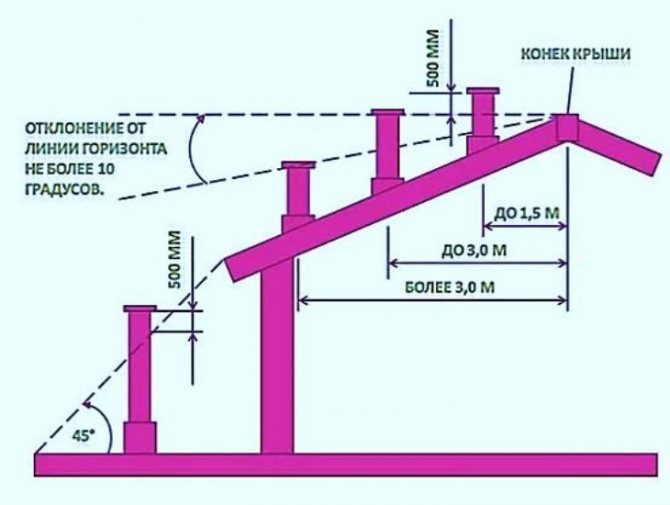

This is due to both fire safety rules and the fact that the pipe head should not fall into the so-called wind backwater zone. If these rules are neglected, then the chimney will become extremely dependent on the presence, direction and speed of the wind, and in some cases the natural draft through it may completely disappear or change to the opposite ("tip").

These rules are not so complicated, and taking into account them, it is already possible to accurately determine the height of the chimney.

chimney prices

flue pipe

Basic rules for the location of chimneys in relation to the elements of the roof of the building

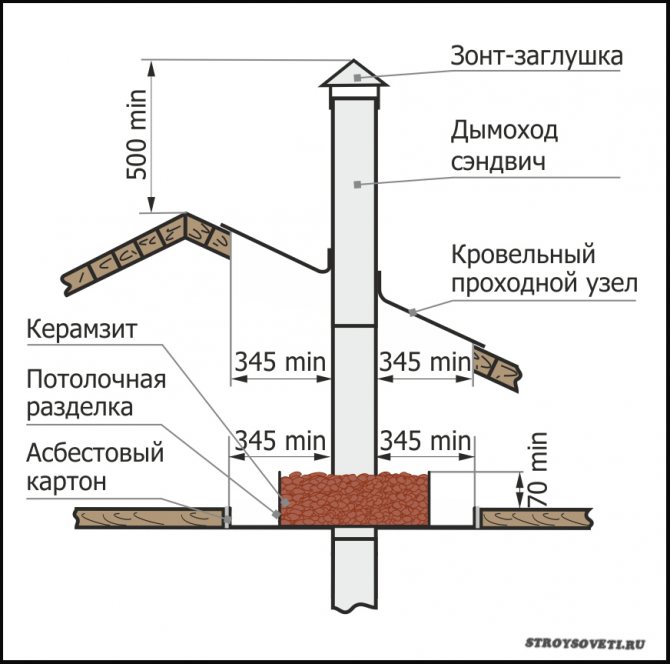

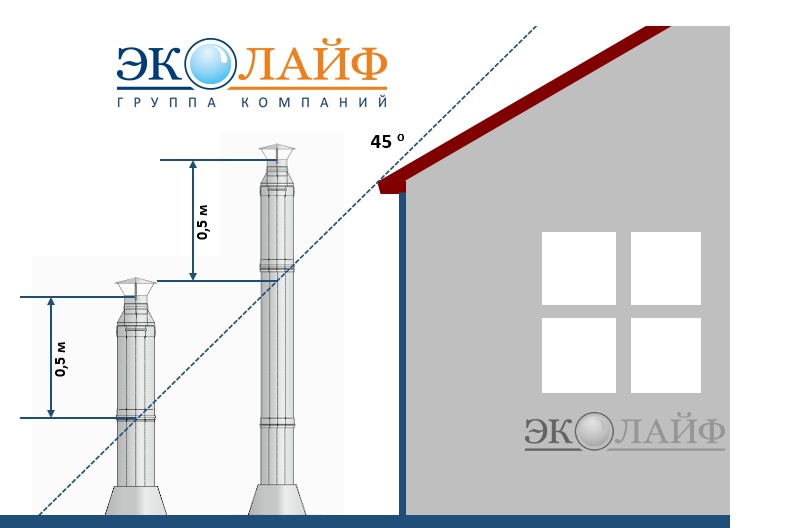

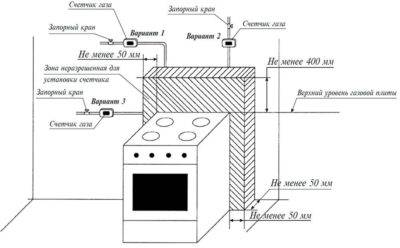

First of all, no matter which roof the chimney passes through, the cut of the pipe cannot be closer than 500 mm from the roof (pitched or flat - it doesn’t matter).

On roofs of a complex configuration, or on a roof adjacent to a wall or other object (say, the edge of the roof of another building, extension, etc.), the wind backwater zone is determined by a line drawn at an angle of 45 degrees. The cut of the chimney must be at least 500 mm higher than this conditional line (in the upper figure - the left fragment) ..

The same rule, by the way, also applies when there is a tall third-party building next to the house. object - a building or even a tree

The figure below shows how the graphical construction is performed in this case.

A zone of dense wind support can also be created by tall trees near the house.

On a pitched roof, the height of the pipe section protruding above the roof depends on the distance from the ridge (left fragment of the upper diagram).

- A pipe located at a distance of up to 1500 mm from the ridge should rise above it by at least 500 mm with its edge.

- When removing from 1500 to 3000 mm, the upper edge of the pipe must not be lower than the level of the ridge.

- If the distance to the ridge is more than 3000 mm, the minimum allowable location of the pipe cut is determined by the line passing through the top of the ridge, drawn at an angle of -10 degrees from the horizontal.

To reduce the dependence of traction on the wind, special caps, deflectors, and weather vanes are used. In some cases, the use of a spark arrester is also required - this is especially true for solid fuel appliances.

It remains to sit down at the drawing of your house (existing or planned), determine the place of the pipe and then finally stop at some of its heights - from 5 meters or more.

Lightning rod installation and installation principles

Before proceeding with the installation of a lightning rod for a chimney, it is necessary to familiarize yourself with all the rules and recommendations. Grounding will become effective only if you perfectly follow all the recommendations for chimney protection. You will need to do everything possible to ensure the safe operation of the chimney. Then the lightning will not be able to break its integrity.

In order to ensure this, the following guidelines must be followed:

- Placement of lightning rods around the pipe must be carried out in the order of symmetry. In this case, you will need to take into account that one of the lightning rods should be directed towards the "wind rose".

- If the chimney does not exceed 30 meters, then it is necessary to equip it with three lightning rods. If the pipe exceeds this height, then another lightning rod should be added.

- Several lightning rods at the top of the pipe must be equipped with a special copper ring. It should be fixed to the brickwork using pre-prepared bronze plates. Bronze fasteners should be immersed in the brickwork by 15 centimeters.

- With the help of vertical fittings, you will need to make branches from the copper circle. Between them there should be a distance of 120 centimeters.

- The length of the rods together with the dissolution of the bundle must be at least three meters.

- Each rod must have a wire at the ends.

- All rods that are on the chimney must also be combined.

- All lightning rods must be connected to external groundwater.

- The center plate of your design must be placed in the center of the underground pool.

This is the most common grounding option, which helps to reliably protect the chimney lightning protection structure. This type of grounding is used in many large enterprises. Also view, the features of lightning and lightning protection.

Necessary security measures: lightning protection of the boiler room

For all non-metal structures, lightning protection must be present. Metal lightning rods are inserted into the pipes and grounded with a down conductor - a steel bar with a diameter of 1.2 mm, which is attached to the pipe wall using brackets. Grounding is completed by a metal pin driven into the ground.

According to the instructions for installing lightning rods for boiler rooms, their number depends on the length of the chimney. For a 15-50 meter structure, one rod will suffice.Higher pipes up to 150 meters require the installation of 2 meter-high lightning rods. Over 150 meters - at least 3 down conductors.

The metal structure acts as a natural current collector and does not need protection.

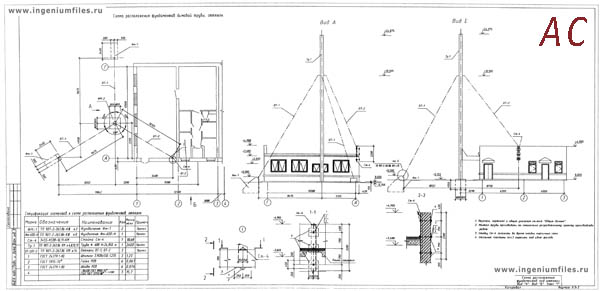

Calculation of a chimney for a boiler room

The operability of the system directly depends on how the design of the chimneys of boiler rooms was carried out, which includes the following actions:

- Construction analysis;

- Aerodynamic calculation of the pipe and gas overpass located in the boiler room;

- Selection of the optimal pipe dimensions necessary for its operation;

- Calculation of the speed of movement of gases in the building and comparison of the results obtained with the standards;

- Calculation of natural draft in the chimney;

- Carrying out calculations that determine the strength and durability of the structure;

- Calculation of thermal characteristics;

- Choice of type and method of fixing the pipe;

- Display of the future design on the drawing;

- Drawing up a budget.

The calculation of the aerodynamic characteristics makes it possible to select the optimal height and diameter of the pipe required for the operation of the system. Also, at the design stage, it is necessary to take into account the equipment that will be used in the boiler room - this determines the volume and nature of the movement of gases that, if the calculation is incorrect, can destroy the created structure.

However, draft calculation is necessary in any case: boiler equipment emits a lot of harmful substances into the atmosphere, therefore, before installing the boiler room chimney, an environmental justification will have to be presented.

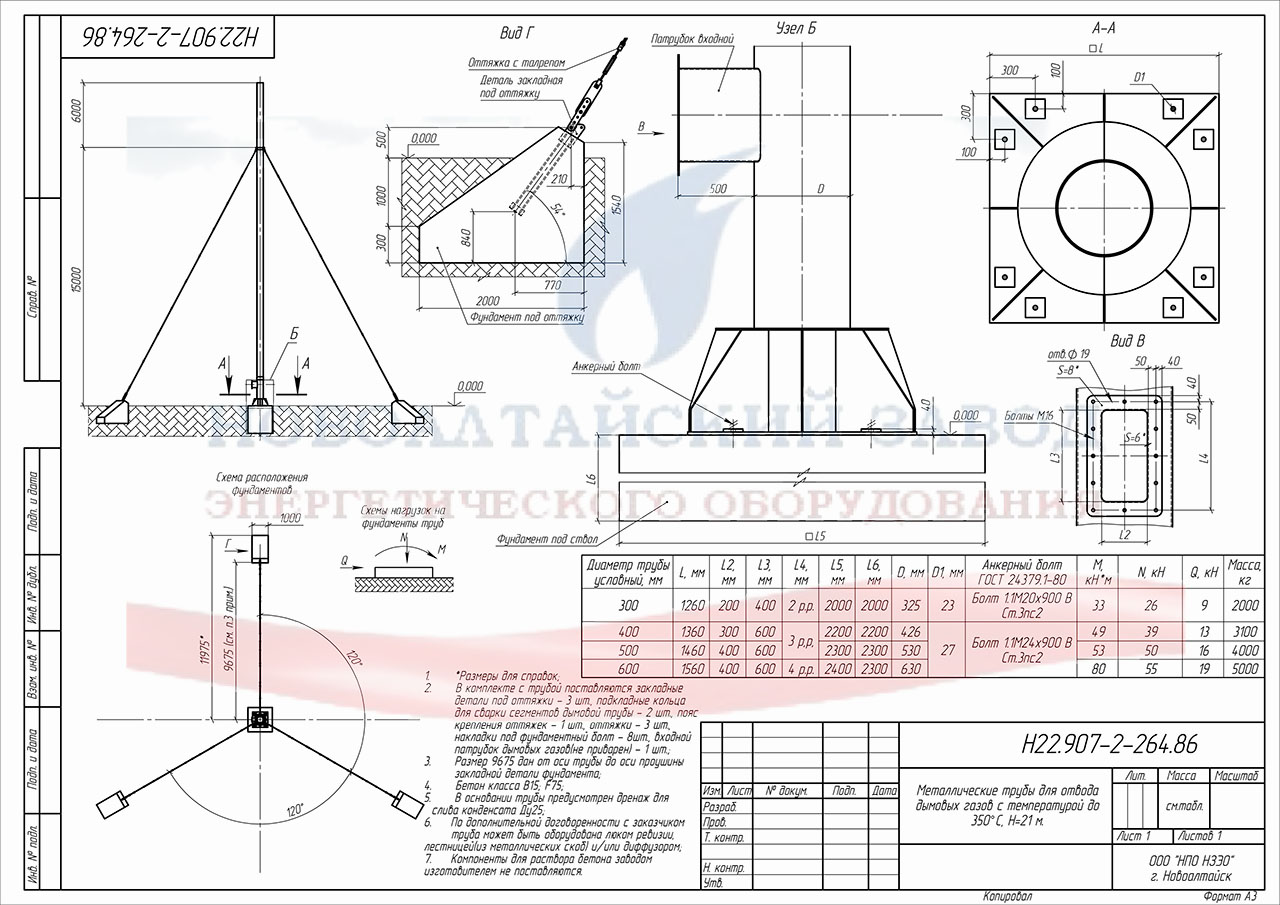

Based on the data obtained, a technical task is drawn up, according to which gas pipelines are connected to the pipe and a drawing of the boiler room chimney is created. The terms of reference also display information about the foundation of the structure and its grounding. For pipes of non-standard sizes, you will have to additionally develop an individual passport.

Structure design

Chimney drawing

Stages of calculations

Industrial chimneys of boiler rooms require a multi-stage design.

This process includes the following items.

- Determining the type of structure.

- Aerodynamic calculations of the pipe itself, as well as the gas path in the boiler room.

- Finding the optimal height of the structure.

- Determining the pipe diameter.

- Calculation of the velocity of gases in the designed structure, and its comparison with acceptable values.

- Determination of the self-traction that the pipe will have.

- Calculation of the structure for strength and stability, followed by the preparation of terms of reference for its foundation.

- Thermal engineering calculation of the structure.

- Determination of the method and type of pipe fastening.

- Creation of building drawings.

- Drawing up a budget.

Why Calculations Are Necessary

Aerodynamic calculations are needed to determine the height and diameter that a chimney for a boiler room should have in order to ensure its efficient operation.

This part of the industrial chimney project is determined by the capacity of either individual boilers or the entire boiler equipment as a whole, for the passage of a given amount of flue gases from the units at a certain temperature.

In the latter case, this parameter is needed, to a greater extent, for environmental justification, in order to take into account the dispersion of harmful substances.After calculating the cross section and height that the chimney for the boiler room will have, a new stage of the industrial chimney project follows.

it preparation of terms of reference for connecting gas ducts of boiler equipment to it and developing its drawings.

The package of this documentation makes it possible to create terms of reference for projects of the pipe foundation, its lightning protection and grounding. If a non-standard structure is installed, then an individual passport for it, as well as an instruction manual, are developed in parallel.

Construction types

Frameless self-supporting pipe

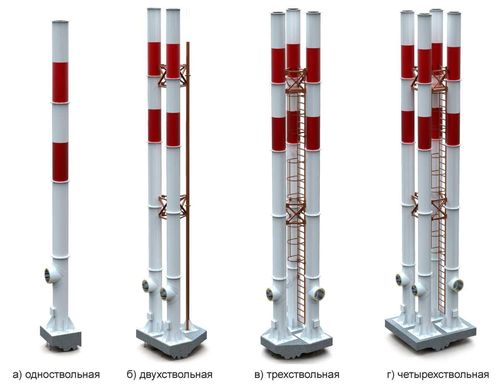

At the moment, chimneys for boilers can have the following designs.

- Chimney columns, in fact, are independent free-standing structures.

The supporting structure of such a pipe is a shell made of high-carbon steel and is fixed to the anchor basket, poured into the foundation. - Farm chimneys of industrial boiler rooms are fixed on a solid and reliable self-supporting truss. That, in turn, is fixed to the anchor basket, poured into the foundation.

- Near-facade and facade structures are mounted on a frame to the wall of the building using wall brackets. Such a design transfers wind loads to the facade through special vibration isolating elements. The near-facade pipe additionally has its own lower foundation, transferring the weight load to it.

- A frameless self-supporting smoke pipe for a boiler room is placed on the roof of the building and fixed indoors.

- A guyed mast structure is a free-standing structure fixed on an anchor basket, which is poured into the foundation. The flue of such a pipe is fastened with clamps to the column.

- In the boiler room, the chimney can be either single-barrel or multi-barrel.

Required Documentation

Code of normative and technical documentation for chimneys

The design, manufacture and construction of chimneys must be carried out in accordance with the existing regulatory and technical documentation.

- The calculation of the height of the structure is carried out according to OND No. 86.

- Determination of wind loads - according to SNiP No. 2.01.07-85.

- Structural strength is calculated according to SNiP No. II-23-81.

- Foundation design is carried out according to SNiP No. 2.03.01-84 and 2.02.01-83.

- If a chimney is being constructed for a gas boiler, SNiP No. II-35-76 "Boiler installations" must be used.

- When using an electrical analogue, they are guided by SNiP No. 11-01-03 "Housings, shells and casings for the installation of electrical equipment."

- In the manufacture of a concrete pipe, SNiP No. 2.03.01-84 "Reinforced concrete and concrete structures" is used.

- The construction of a steel analogue requires compliance with SP No. 53-101-98 "Manufacturing and quality control of steel structures".

- In addition, GOST 23118-99 "Steel building structures" is used.

It should be remembered that no matter what the chimney for a gas boiler is by design, only accurate calculations, competent manufacture and proper installation will allow it to be operated for a long time.

Types and designs

As mentioned above, pipes for boiler chimneys are made from different materials. Brick pipes or reinforced concrete have a common design solution. But steel - differ in several types.

Types of chimney designs:

- Column, classic. The most popular type. It is a steel column with a base poured into the foundation.

- Enhanced with farms.Are used for large industrial boiler houses and combined heat and power plants. Here the farm - a metal structure of longitudinal and transverse rods - is joined to the anchor basket and supports the chimney of large diameter and mass in a vertical position;

- Frameless (simplified). An example of such a design can be found in any private house equipped with a stove or heating boiler. This option is easy to assemble and low cost, it consists of the chimney itself and the chimney-element connecting it to the fireplace or stove.

- Mast type structures. They differ in the largest height and are usually installed within the city. The chimney trunk is attached to the frame - a column reinforced with metal stretch marks;

- Embedded. They are carried out in the wall of the house, most often from the side of the facade. The role of the supporting frame and foundation is performed by the wall of the building. The chimney is attached to the frames with special brackets.

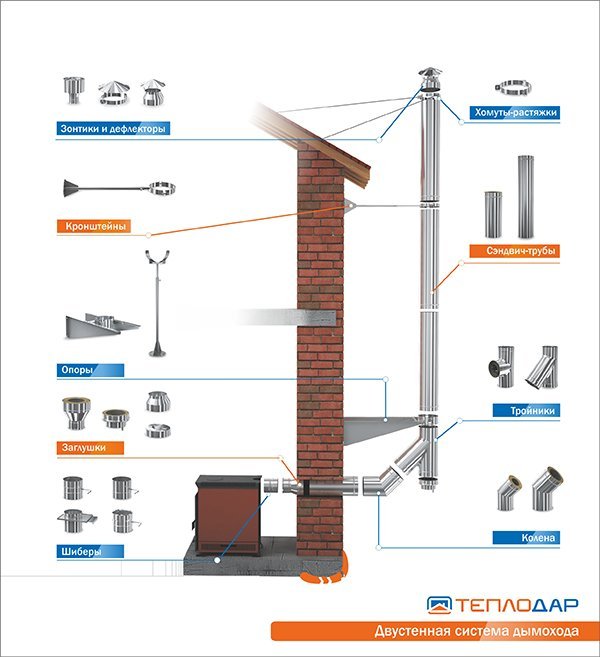

How is the chimney

If the design of the chimney does not meet the technical requirements, soot, ash, smoke, soot settle on the walls of the channel, clog it and make it difficult to remove gases. This situation can be avoided only by observing all the rules and regulations for the installation of industrial chimneys.

The main elements of a boiler room with a brick pipe:

- Foundation (basement);

- Trunk;

- Lightning rod;

- Lining.

The laying of the trunk is carried out in stages, by 5-7m. The wall thickness decreases from bottom to top. Its minimum is 180mm. Pipes have the shape of a cone (to give stability). The bottom of the structure is lined with refractory bricks from the inside. A gap is left between the lining and the pipe to compensate for the thermal expansion of the material.

The total height of brick chimneys is 30-70m, diameter - from 0.6m.

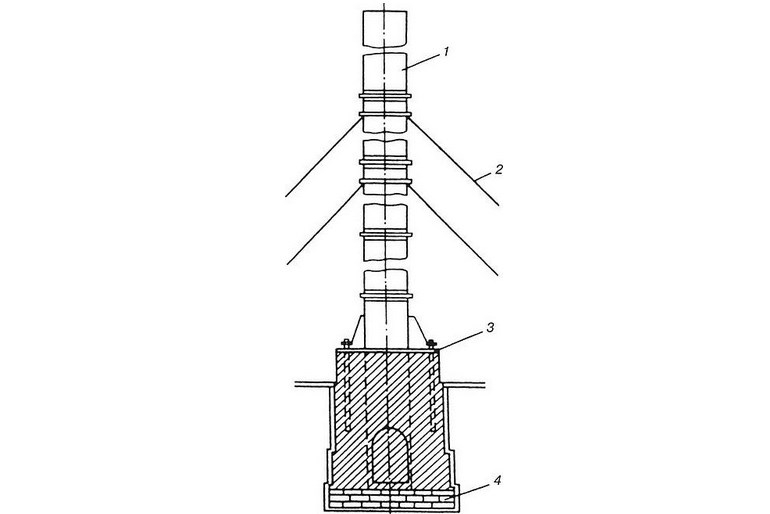

Elements of a boiler room with a metal pipe:

- Trunk;

- Stretch marks;

- Cast iron stove;

- Foundation.

Steel pipes for boiler rooms are made from sheet steel, from 3 to 15 mm thick. Separate sections of the pipe are connected by welding. The cast iron plate is fixed to the foundation, the barrel is mounted to it. To ensure the stability of the structure at a height equal to 2/3 of the height of the common chimney, stretch marks are installed. Stretching is a steel rope, made of wire with a diameter of 5-7 mm.

The height of the metal pipe is no more than 30-40m. Diameter - 0.4-1m. The main advantage is lightness, ease of installation and dismantling and low price of structural elements. The main disadvantage of steel is a very short service life (usually up to 10-25 years).

In addition to metal and brick, smoke channels for a boiler room can be reinforced concrete. Reinforced concrete pipes are strong, but have low corrosion resistance, therefore, they are made with laying the interior finish, which protects the inner walls of the channel from aggressive gases.

Height above the skate

In order for the heater to function without problems, the effect of wind pressure must be taken into account when installing the chimney pipe. What it is? Winds, the structure of the roof and its uneven heating cause turbulent air flows over the building. These air turbulences are capable of “overturning” thrust, or even causing counterdraught. To avoid this, the height of the pipe should be at least 500 mm from the ridge.

In addition to the location of the ridge, it is also necessary to take into account high structures on the roof or next to the building, and trees growing near the house.

If the distance from the pipe to the ridge is three meters, then it is permissible to make the height of the chimney flush with the ridge.If the distance is more than three meters, the height can be determined using the diagram shown in the photo.

Avoid turns and horizontal sections. When designing the location of the chimney, you should make no more than three bends of turns, and also avoid horizontal sections longer than one meter. If a horizontal section cannot be avoided, the channel should be laid with at least a slight slope.

Operation of chimneys

Proper design and competent installation of pipes - and the boiler room works like clockwork. But choosing a chimney and installing it with high quality is only half the battle. Regardless of whether the chimney is brick, ceramic or made of steel modular elements, it is necessary to regularly clean it, removing soot that has settled on the walls.

With regular use of the device, preventive cleaning should be carried out at least twice a year - at the change of seasons. Brick chimneys are more prone to soot accumulation due to the rough inner surface and rectangular duct section. For cleaning and repair it is necessary to provide cleaning hatches.

If the boiler works on liquid or gaseous fuel, the flue gas temperature may not be high enough and condensation will form. To remove it, it is necessary to provide for the installation of a condensate trap in the smoke exhaust duct.

The device of the chimney according to all the rules and proper operation contribute to the heat in the house and fire safety.

Maintenance and cleaning

During the operation of boiler rooms, chimneys wear out, so they constantly require maintenance and repair.These works are carried out by workers with special skills and knowledge.

The most exposed part of the chimney is the head, because it is under pressure from the inside, influenced by temperature and the environment. In case of destruction, it is possible to carry out spot repairs to the brickwork or concrete structure. With strong damage, you will have to rebuild them.

When cracks appear on brick and concrete chimneys, cracks and crevices are sealed with special mortars, destroyed bricks are replaced with new ones. In case of damage to the metal sections of the chimney, they are replaced.

The protective inner coating, called the lining, is most susceptible to destruction. It requires constant close attention, periodic inspections and diagnostics. If a violation of the integrity is detected, the workers carry out the grouting of the damaged areas. If spot repairs fail to save the situation, a complete replacement of the coating is performed.

Another duty of specialists is to repair the clamping rings to prevent them from cracking. If it is not possible to return the functionality of the old element, additional rings are installed.

Maintenance includes painting the surface of the chimneys. Such work involves the use of the method of industrial mountaineering, tk. it is most effective in terms of the use of mechanisms and additional equipment.

Because not only smoke and gases pass through the chimney pipe, but also ash with soot, during operation these elements are layered on the walls, as a result, the permeability will be reduced or completely disappear. To prevent such a situation, the inner pipe is periodically cleaned by a team of specialists.

Cleaning is mechanical and chemical.In the first case, the procedure is used if the pipe is not too high and the equipment is able to cope with the blockage. However, chemical cleaning is most in demand, because. this allows you to easily reach any area inside the structure and avoid mechanical damage to the pipe surface.

The most difficult and costly part of maintenance is the dismantling of the boiler room chimney due to the end of its service life or the inability to repair damage through major repairs.

Chimney Requirements

The chimney removes and disperses harmful products of fuel combustion into the atmosphere

It is important to design and build it correctly. Otherwise, the inner walls will be clogged with soot, ash, soot, blocking the outlet channel and preventing the removal of smoky masses, making it impossible for the boiler room to work.

There are technical standards that clearly regulate the parameters of chimneys:

- Brick structures should be made in the form of a cone with a height of 30 to 70 m, a diameter of 60 cm. The minimum wall thickness is 180 mm. In the lower part, gas ducts with revisions for inspection must be equipped.

- Metal pipes used for the installation of chimneys are made of 3-15 mm sheet steel. The connection of individual elements is carried out by welding. The height of the chimney should not exceed 40 m. The diameter can be from 40 cm to 1 m.

- To ensure the stability of metal structures, brackets or anchors are installed at a distance of 2/3 from the height of the pipe, to which extensions are attached.

- The height of the chimney (regardless of the material of manufacture) should be 5 m above the roof of buildings located within a radius of 25 m.

The dimensions of the structure are calculated taking into account the volume of the furnace and climatic conditions, so that draft is provided at any air temperature.

What is worth knowing

The above calculations will be correct only when there are no very tall trees growing near the house and no large buildings are located. In this case, the chimney with a height of less than 10.5 m may fall into the zone of the so-called "wind backwater".

To prevent this from happening, the outlet pipe of the boiler room of a private house located in such a place should be increased. At the same time, in order to choose the optimal option for the height of the pipe, you should:

- find the highest point of a nearby large building;

- draw a conditional line down from it at an angle of 45 ° to the ground itself.

Ultimately, the top edge of the assembled chimney should be located above the line thus found. In any case, a country building should be designed in such a way that the exhaust gas pipe of the boiler room is subsequently located no closer than two meters to tall trees and neighboring buildings.

They usually increase the height of the chimney even if the roof of the house is sheathed with combustible material. In such buildings, the outlet pipe is most often increased by another half a meter.

Chimney location and wind direction: how to prevent turbulence

According to all building codes and regulations, the chimney must rise above the roof at a certain distance. This is necessary so that the air on the protruding parts of the roof does not cause back draft due to turbulence.

The reverse draft can be seen with one's own eyes in the form of smoke, which pours from the fireplace directly into the room.But the extra height of the chimney is also not needed, otherwise the draft will become too strong and you won’t wait for heat from such a fireplace: the firewood will be incinerated like a match, not having time to give heat.

That is why it is so important to calculate the height of the chimney as accurately as possible, especially taking into account the direction of the winds acting on the ground:

If the pipe is located too close to dense trees or a high wall, it must be built up with asbestos-cement or steel pipe.

In this video you will also find valuable device tips chimney and solving problems with its height:

Mounting Features

- Installation of the boiler pipe starts from the bottom (foundation);

- For a gas boiler, from an economic point of view, the use of steel pipes is most beneficial. But it is worth remembering that the maximum height of a metal pipe is 30m;

- Tall structures are excellent conductors of electricity. Lightning protection is performed in accordance with the requirements of RD-34.21.122-87;

- The design of the lightning rod is determined based on the design features of the smoke exhaust system. For a non-metallic chimney, the length of the lightning rod is usually 1m. For every 50 m of the structure, 1 lightning rod is installed;

- Metal chimneys do not require special protection - they themselves act as a current collector;

- All insulating elements must be earthed.