- Types of chimneys

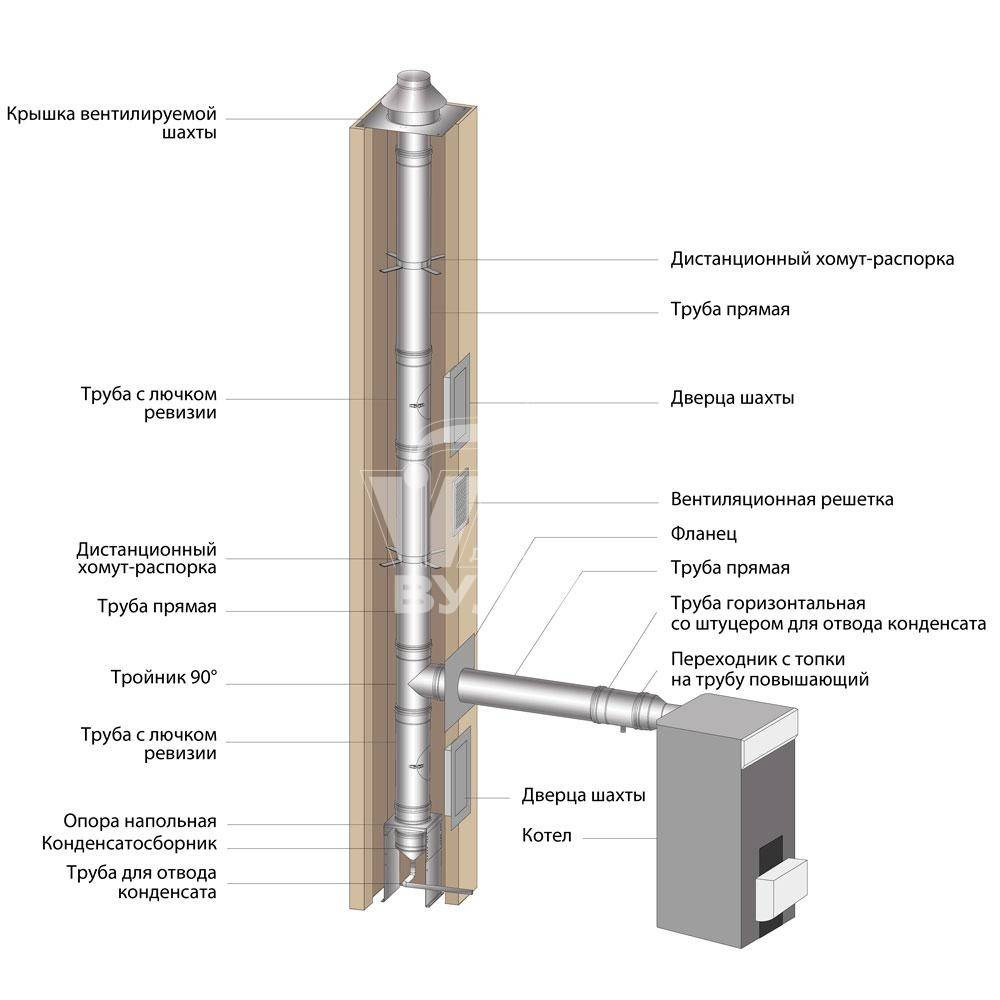

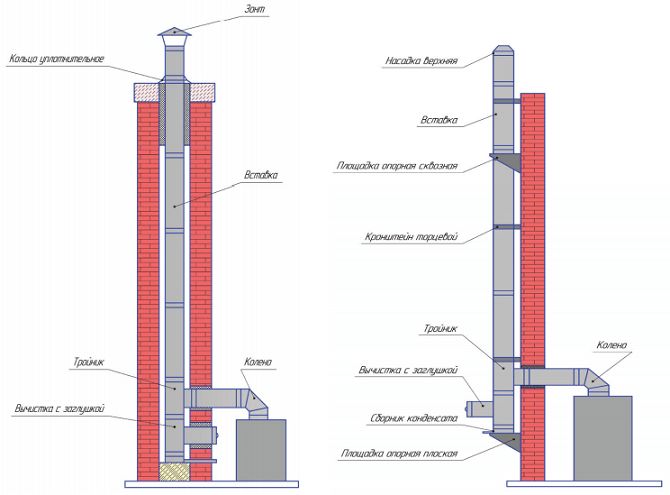

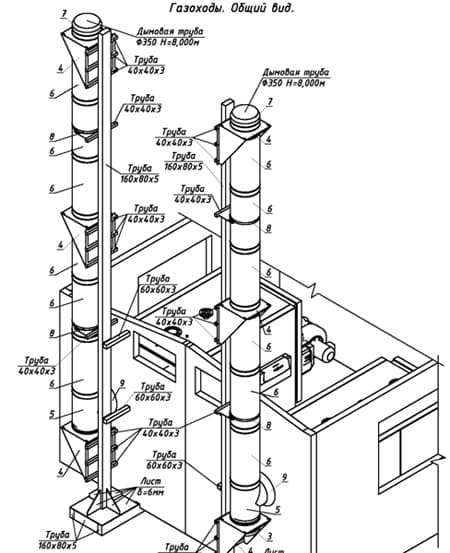

- The device of a metal sandwich chimney

- Materials for installing a metal structure

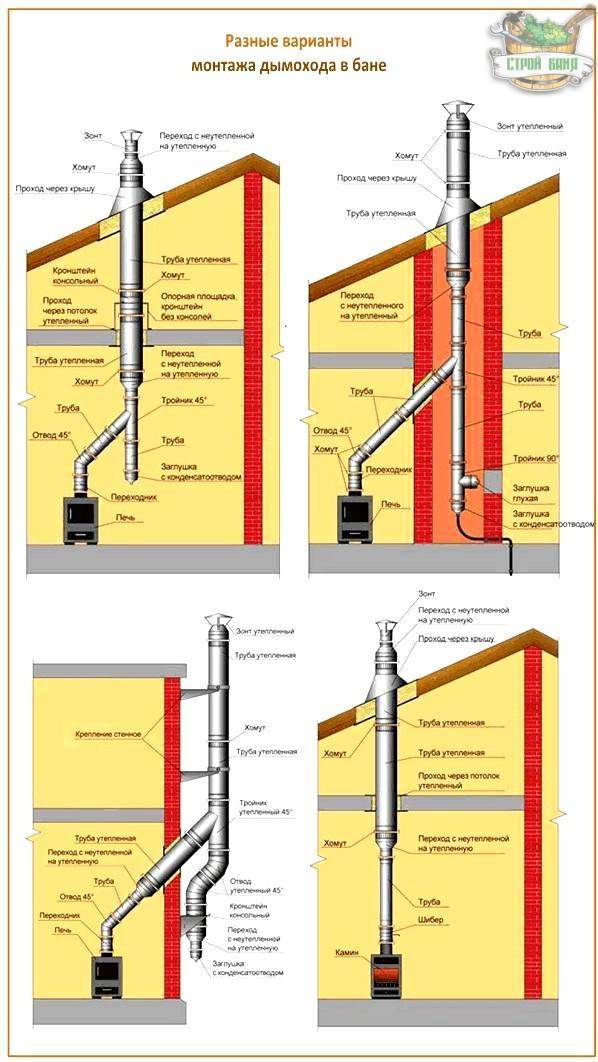

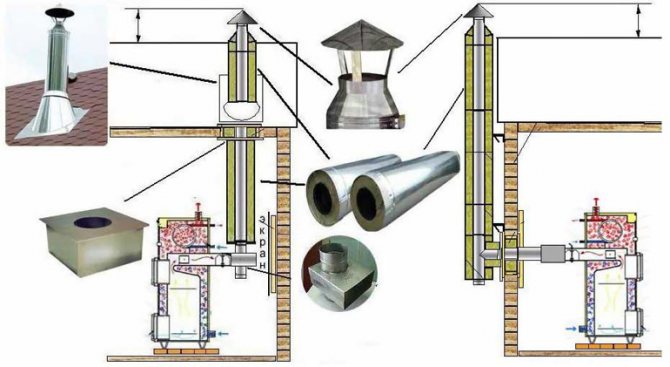

- Schemes of installation of a sandwich chimney

- Inner pipe tips

- Installation of pipelines that remove flue smoke

- Operating rules

- Designing chimneys for boiler rooms is a complex multi-stage process

- Geography of completed projects

- Finished drawings and projects of chimneys

- Manufacturing

- Heat insulator thickness

- Production of various parts for the chimney

- Umbrella

- spark arrestor

- shiber

- Stainless steel chimneys

- Chimney types

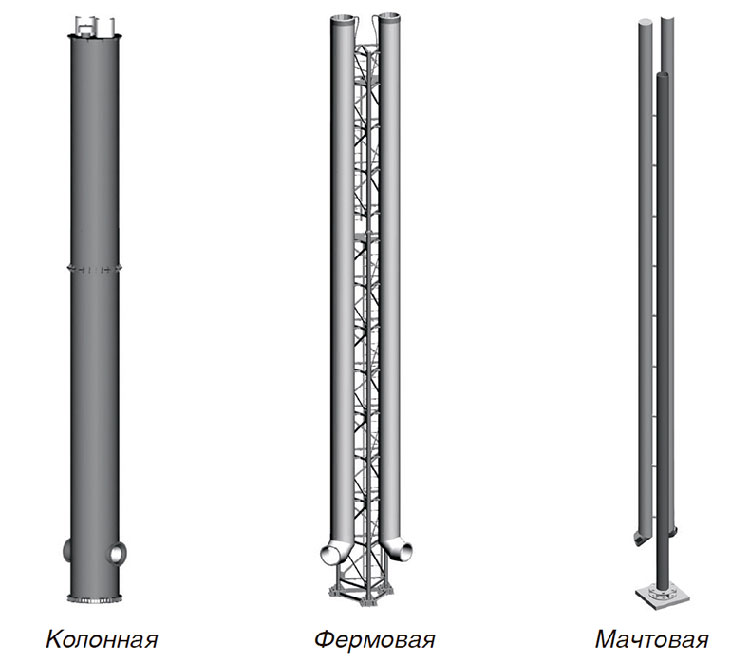

- Self-supporting

- Column smoke structures

- Features of facade and near-facade chimneys

- Truss pipes

- Mast

- Features of the care of the spark arrester

- How to make a spark arrester on chimneys?

- We mount the deflector and fasten the finished spark arrester

- Varieties of spark arresters

- Spark Arrestor-Housing

- Spark arrester-deflector

- Hydrofilters

- Common mistakes and problems when installing chimneys

- Selection and calculation

- Turnkey gas installation design

Types of chimneys

To date, the following types of chimneys are used for boiler equipment:

- Column chimneys. Such structures are separate structures.The bearing element of the pipe in this case is the shell, for the production of which high-carbon steel is used. The entire structure is attached to an anchor basket installed on the foundation.

- Farm industrial pipes. To fix such pipes, a self-supporting truss is used, installed in the same way as in the previous case.

- Facade and near-facade pipes. Such structures are fixed using special brackets attached to the frame, which, in turn, is attached to the wall using vibration-isolating parts. The bulk of the facade pipes falls on their own foundation.

- Frameless self-supporting pipes. This type of pipe is installed directly on the roof of the building and fixed indoors.

- Stretched mast pipes. Another type of free-standing structures, fixed by means of an anchor basket, poured into the foundation. The gas pipelines of the mast pipes are attached to the support with clamps.

Boiler pipes can have either one or several shafts, which must be taken into account when designing and calculating the future structure.

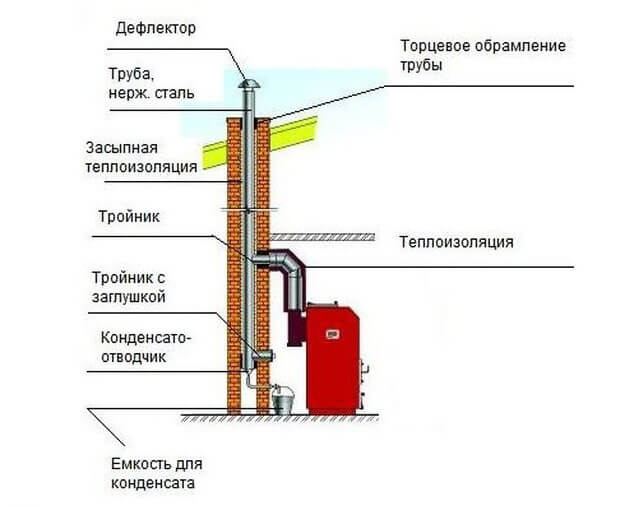

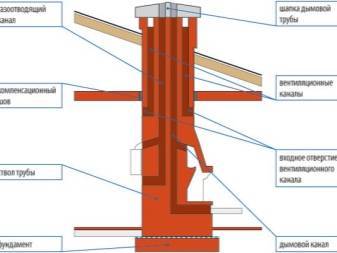

The device of a metal sandwich chimney

Steel chimneys are popular both in industrial construction and for the improvement of the private sector. Their installation resembles the assembly of a ceramic structure, respectively, it is easier than the construction of a brick pipe. Let's consider in more detail how to make a metal chimney correctly, avoiding mistakes.

Materials for installing a metal structure

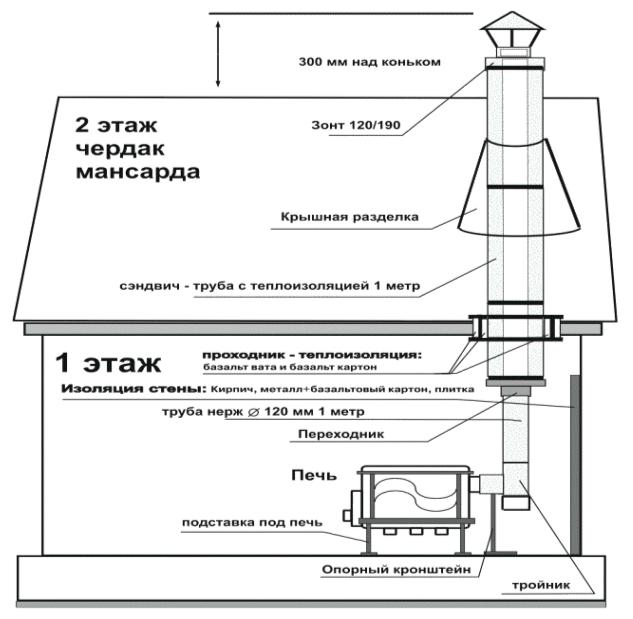

A sandwich chimney is a sealed system of pipes and adapters leading from a heat generator to the roof space.It can pass inside the building (internal) and outside, along the wall (external).

A sandwich pipe is a three-layer part consisting of two steel pipes, between which a layer of insulation is laid. Fragments of stainless steel are connected by welding

Non-combustible thermal insulation material has a different thickness - on average from 2.5 cm to 10 cm. Manufacturers most often use one of the best materials - dense basalt wool (from 200 kg / m³).

To assemble the chimney, you will need to connect several parts of various shapes, using the method of connecting tapered ends and sockets. Simply put, one element is inserted into another. From the outside, the joints are reinforced with overhead clamps, which are tightly tightened after installation.

The advantages of a three-layer design: protection of the chimney, minimal formation of condensate, organization of stable draft, the ability to install the system both on the inside and outside of the house

When installing a steel chimney inside the building, the holes in the ceilings and roof are much smaller in diameter than for brick or ceramic counterparts.

Schemes of installation of a sandwich chimney

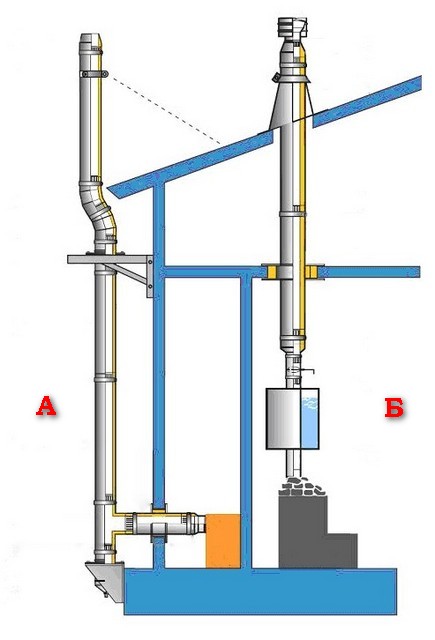

Let's consider two schemes for installing a sandwich chimney: with an internal arrangement, which requires the organization of holes in the roof and ceilings, and with external installation, which is made from the outside and is installed parallel to the wall of the house.

Each of the schemes has advantages: the internal equipment generates less condensate, the external device is easier to implement and is produced with only one opening.

The internal installation scheme is often used in baths, since a steel pipe can simultaneously heat both stones and a water tank.If the bath is not installed separately, but is an extension to the house, this is the most appropriate and effective option.

The disadvantages of the internal system are the need to make holes in the ceilings and roof, as well as a decrease in usable space.

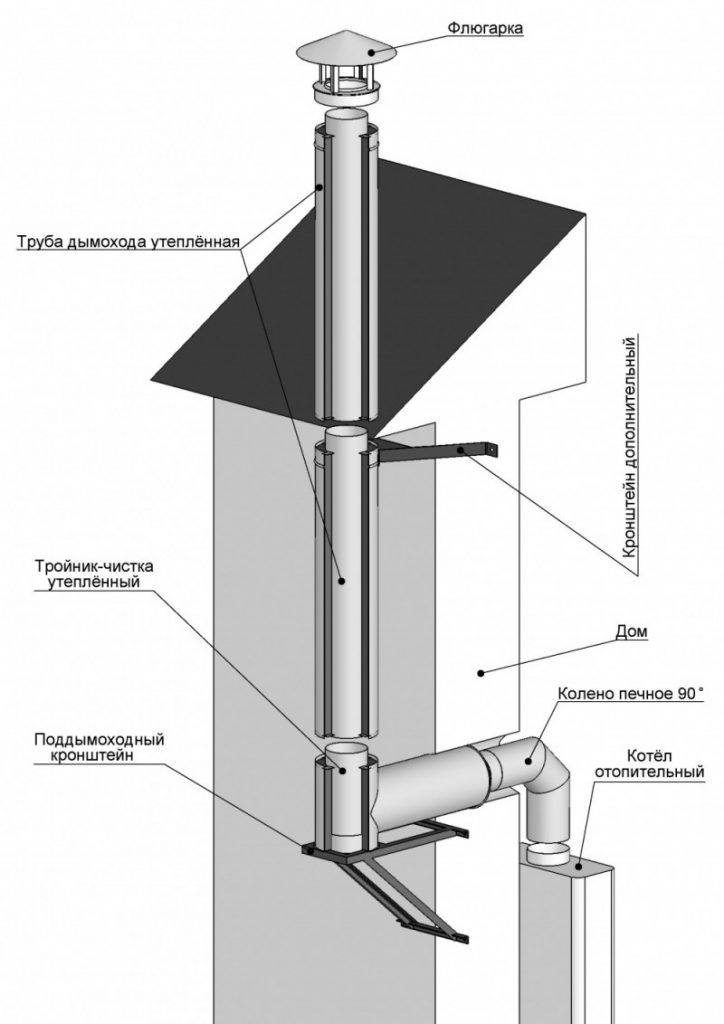

To install an external system, it is enough to make one hole in the wall and ensure the vertical position of the pipes using brackets. The outlet of the pipes to the outside reduces the risk of poisoning by combustion waste. Minus - the arrangement of additional protection from the effects of the external environment.

The order of installation work:

- connection to the boiler (or other heat source) adapter;

- punching a hole in the wall (average size - 40 cm x 40 cm), upholstery with fireproof material;

- installation in the wall of a passage block with thermal insulation;

- installation of a horizontal pipe section from the boiler (furnace) to the hole in the wall;

- arrangement of the support unit from the outside (platforms on brackets);

- installation of a vertical pipe;

- fastening at the top of the cone and head.

When assembling, it is necessary to focus on the technical documentation prepared during the drafting process.

Inner pipe tips

When choosing an internal model, you need to remember some technological nuances

For example, it is important to install a valve in the transition area from the boiler so that it is possible to save heat

Docking of two adjacent elements in the transition section is prohibited. The location of the attic rafters and beams should be taken into account: the farther they are from the chimney, the better. Read more about self-assembly of a sandwich chimney in this material.

Transitions through floors and roofs require the use of fire-retardant thermal insulation materials, such as mineral wool, and the installation of protective blocks, which can be called a "sandwich in a sandwich"

Installation of pipelines that remove flue smoke

The work related to how to connect the boiler to the chimney is not a complicated process; its implementation does not require special skills and abilities.

But before proceeding with the installation of the smoke exhaust structure, you should carefully study the device of a particular model, as well as the principles and nuances of the connection.

In addition, when using pipe products with different diameters, it is imperative to purchase a special chimney adapter for a solid fuel boiler - it will completely eliminate the possibility of leakage of combustion products and loss of traction.

To fix the chimney pipes to the walls of the house, special parts are used - self-tapping screws or rivets. In some situations, additional supports, stands and other elements may be required. Their list is usually attached to the product.

Operating rules

- If the house has two solid fuel boilers or, in addition to the heating device, there is also a fireplace or stove, it is forbidden to combine two chimney outlets of various devices into one. An individual smoke exhaust system is installed for each building.

- It is strictly forbidden to make changes to the design of the smoke exhaust system that are not provided for by the project for this heating device.Unauthorized change of components and elements of such a design can end very sadly, because the chimney is an element of increased danger both in terms of the formation of a fire, and in the event of a leak, possible poisoning by fuel combustion products.

- The boiler must be installed in a non-residential, well-ventilated area. The air volume must correspond to the minimum values for the boiler of the given power, otherwise such a heating system cannot be put into operation.

- The chimney must be at least 0.5 meters above roof level, unless forced flue is used in the flue system.

- In the event that a pipe longer than 2 meters is used to connect the boiler to the chimney, such a connecting insert must be securely fastened.

- During the winter months, it is necessary to regularly inspect the chimney cap for frost and complete blockage.

- It is forbidden to use boilers if there is a blockage of its internal cavity due to freezing, soot formation or for other reasons.

- When installing the chimney, it is forbidden to come into contact with combustible materials throughout the entire length of the pipe.

Designing chimneys for boiler rooms is a complex multi-stage process

The design of the structures we describe for boiler houses consists of several stages:

- choice of building type;

- carrying out calculations of the gas path and aerodynamics of the pipe;

- selection of a pipe height that would ideally meet all the requirements of SNiP;

- calculation of the diameter of the structure;

- calculation (and subsequent comparison with the recommended indicators) of the gas velocity in the pipe;

- establishment of indicators of self-draught of a smoke product;

- performing calculations on the stability and strength of the structure;

- preparation of technical specifications for the arrangement of the foundation;

- determination of the type and method of fastening the structure;

- thermal calculations.

Geography of completed projects

Pipes for installation in boiler houses are now made from hot-rolled sheets (the diameters of the resulting products range from 57-219 mm) and cold-rolled sheets (the diameter of the finished product in this case is 10-76 mm). At the same time, the production of chimneys with other sections is also allowed, if their customer puts forward such requirements. They are made most often from steels of the 20th and 10th grades, and stainless steel is often used. Finished products are necessarily subjected to tests for impact strength and non-destructive testing. At the last stages, drawings of the pipe are created, as well as an accurate estimate of the funds that will need to be spent on its construction.

Finished drawings and projects of chimneys

- watch

Mast chimneys are designed to remove flue gases from boilers operating on liquid,… - watch

The self-supporting chimney is designed to remove combustion products and provide natural draft in the fuel… - watch

The facade (wall) chimney consists of separate insulated sectional chimneys and elements of the… - watch

Stretch chimneys are a single-stem vertical steel structure, fixed with a steel… - watch

Truss chimneys are a steel lattice tower of SRB and heat-insulated gas suspended on it… - watch

The columned chimney is a structure made of a metal bearing outer shell and a gas outlet.

Information is provided on the designs of furnaces and chimneys, methods of their construction, equipment and construction mechanisms used in construction, on building materials, labor costs and the principles of organizing the construction of an industrial ... thermal power stations” on ash collectors, issues of air basin protection and chimneys of thermal power plants, written by professors… more The book is a textbook on the course “Boiler installations” for students of higher technical educational institutions. In the introduction, the general scheme of the boiler plant is considered and described, and the main definitions are given. The first part of the book is dedicated to… more Industrial safety of smoke and ventilation industrial pipes: a collection of scientific papers based on the materials of the consulting and methodological seminar, June 19, 2008 / Exercise. on technological and environmental… more The book describes the organization and technology of repair of metal, brick and reinforced concrete gas ducts and chimneys of power plants. The mechanization of the repair of the flue and chimneys is considered. Information is given on safety and fire safety… more In the book of the author of the Republic of Hungary, traditional and modern designs of chimneys of household stoves are considered. Their device and operating rules are described.

The main attention is paid to the laying and repair of pipes. For a wide circle..

more Recommended for publication by the Structures Dynamics Section of the Scientific and Technical Council of the TsNIISK im. Kucherenko.Guidelines for the calculation of buildings and structures for the action of the wind. — M.: Stroyizdat, 1978. . . . With. /Center, scientific-research. in-t st… more The book summarizes the experience of specialized expert organizations and provides the following: — Methods for calculating the bearing capacity and resource of industrial buildings and structures to ensure industrial safety expertise; — I… read more

CHAPTER 1. Classification and main elements of industrial chimneys

Classification of pipes according to technological purpose and main structural material

The classification of pipes according to technological purpose and main design is given… read more

Manufacturing

There are many commercial designs of spark arresters, ranging from simple to complex designs. They can be used in individual cases, but it is necessary to know the geometrical parameters of the upper part of the chimney. In the event of a difference in size, an adjustment or fabrication of a transition element will be required.

If you have the necessary locksmith tools and certain skills, you can make a spark arrester on the chimney with your own hands. You will need:

- Stainless steel in sheets 1–2 mm thick. The smaller size will burn out faster, the larger one is more difficult to work with;

- Mesh of the same material with a cell size of 2–5 mm. A smaller section reduces traction and quickly becomes covered with soot, a larger one reduces the efficiency of spark extinguishing;

- A set of self-tapping screws for metal. It is better to use with a protective coating, for example, galvanized;

- Locksmith tools: drill, metal shears, hammer, pliers, screwdriver, tape measure, marking tool.

Materials and tools needed to make a spark arrester with your own hands.

Becausemetal work, it is recommended to use gloves. For convenience, you will need a workbench or desktop.

Stages of work on the manufacture of a spark arrester for a chimney for a bath with your own hands:

Dimensions are taken from the top of the chimney. A draft design is being carried out;

Cardboard templates are made. Prototyping of the future chimney spark arrester is underway. Adjustments are being made;

Separate parts are cut out of metal according to cardboard templates: case, cover, fasteners;

Assembly in progress. Connections are made using self-tapping screws or stainless steel rivets. You can use soldering or welding, but this will significantly complicate the process, because. not everyone has special equipment and skill in working with stainless steel;

The finished product is installed on the chimney

It is important to check the strength of the fastening, because on the roof the wind force is always stronger, and the design of the spark arrester has a certain windage;

To determine the operability of the assembled device, it is necessary to heat the furnace. It is best to do this at night, so even small sparks will be noticeable.

As fuel, it is advisable to use dry knotty, with an abundance of knots, logs. Such firewood not only burns well, but also produces a large number of sparks when cracked. Periodic stirring with a poker in the firebox will help.

A well-designed and properly assembled spark arrester for a do-it-yourself bath chimney is able to reliably extinguish sparks with good traction. Thus, the fire safety of the structure, outbuildings and the environment will be ensured.

Heat insulator thickness

Conceived for the removal of exhaust gases, boilers are equipped not with conventional single-wall chimneys, but with “sandwich” models. Manufacturers offer mainly two types of such pipes:

- with a thickness of insulation 5 cm;

- with insulation 10 cm.

The choice of a chimney in this case will depend on the region in which the house with the boiler is located. It is believed that in most regions of Russia it is enough to use sandwich pipes with a 5 cm thick insulation. Chimneys insulated with 10 cm basalt wool are usually installed when assembling the heating system only in houses located in the northern regions of the country.

Production of various parts for the chimney

Various accessories can be made by yourself.

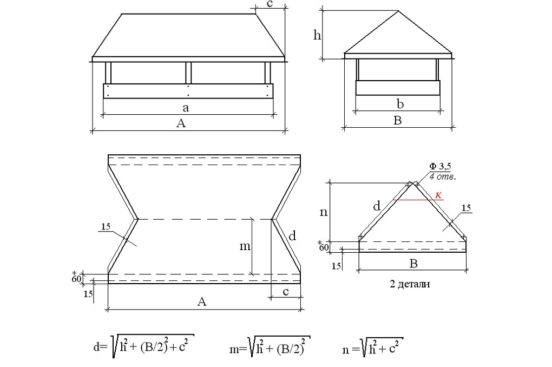

Umbrella

This element should be made of galvanized steel. The easiest way is to make it in the form of a half-cylinder - then it will be easy to attach racks made from a corner to it.

If the base of the umbrella is round, then it will fit tightly on the chimney and will not let air through at the junction

Another option is to make an umbrella in the form of a 4-sided pyramid. This is also an easy way - a square sheet of steel is simply bent diagonally, but when cutting a workpiece, you will need to provide "lugs" for attaching racks.

You can install an umbrella made in the form of a house roof on a brick pipe

spark arrestor

The spark arrester is just a metal mesh with a cell of no more than 5 mm, which is installed on the pipe head. It can be made from thin wire or from a plate about 1 mm thick, in which many holes are drilled. The mesh is soldered or riveted to the shell, which, in turn, is attached to the pipe.

The spark arrester must be fastened to a brick chimney with dowels or nails driven into the seam, to a steel chimney - using a clamp covering the shell.

shiber

A damper for a round chimney can be made like this:

- A short piece of pipe of the appropriate diameter is taken.

- Two holes are drilled in it located opposite each other.

- A steel bar about 10 mm in diameter is inserted into these holes, one end of which is bent (this will be the handle).

-

A disc with a diameter slightly smaller than the inner diameter of the pipe is welded to the rod inside the pipe.

To exclude the possibility of completely blocking the chimney by negligence, a sector of ¼ of its area can be cut out in the disk

Stainless steel chimneys

Alloyed stainless steel withstands working environment temperatures up to +850°C, on some objects resistance to temperature peaks of +1200°C is observed. High-quality material from conscientious manufacturers has a life of active operation of 25 years, subject to the manufacturer's recommendations for storage and use, an indicator of 50 years is achieved. Stainless steel products are marked with the standard of the American Institute of Steel and Alloys AISI. Operation of gas ducts marked AISI 321, AISI 304, AISI 316 is allowed.

When producing products from less heat-resistant grades, “burning out” of materials is observed after 10-15 years. Even under the condition of not intensive operation of structures. The correct choice of marking helps to increase the term of active operation up to 25-50 years. During production, stainless steel can be reinforced with an admixture of titanium.Materials increase the resistance of structures to corrosion as a result of the aggressive effects of gases.

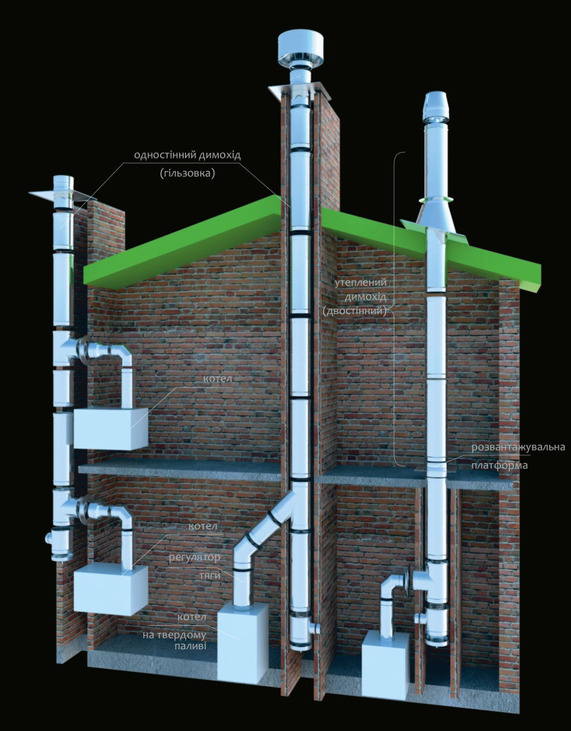

Chimney types

Installation of pipes is possible from different materials. There are metal, brick, ceramic, polymer structures. Install reinforced concrete, stainless products. I recommend choosing gas outlets that have smooth gas path surfaces.

Chimney types.

Chimney types.

Gas outlets made of brick today are practically not mounted. A large number of irregularities are found in the masonry. In the recesses, toxic products of combustion accumulate, destroying the brick.

According to the type of pipe construction are:

- self-supporting;

- mast;

- columned;

- facade and near-facade;

- farm.

To choose the best option for your home, you should consider the features of each variety.

Self-supporting

The presented variety is single- and multi-barrel, which depends on the number of boilers in the system. Three-layer sandwich pipes are assembled from several sections. The gas path is made of stainless steel. The material is not subject to the negative effects of aggressive chemicals. The advantages of self-supporting chimneys are:

- ease of assembly and maintenance;

- the possibility of supplementing the structure with a ladder, an observation deck, an inspection hatch.

I recommend fixing the gas outlet with anchor bolts and installing stiffeners. Strengthening the chimney increases stability and service life.

Column smoke structures

A free-standing column-type chimney is fixed on a reinforced concrete base using anchor blocks. The structure is reinforced with a shell with a diameter of up to 3 m.

Column type chimney.

Column type chimney.

This is an iron casing, characterized by high strength.Inside it is allowed to install several stainless steel trunks. The advantages of the design are:

- connection of several boiler installations is possible;

- mounted even on unguarded sites;

- robust design is protected from mechanical damage;

- occupies a small area;

- looks aesthetic.

When creating column structures, installation of thermal insulation will be required. Basalt wool will prevent the accumulation of condensate inside the pipe.

Features of facade and near-facade chimneys

The barrel is made of a sandwich pipe consisting of several sections. The structure is fixed with brackets to the facade. A foundation step is not required. Among the advantages of facade and near-facade chimney structures, I can name:

- minimal construction and maintenance costs;

- construction without arranging the foundation;

- comfort of service during operation;

- simple installation.

If repairs are required, only one section is changed. It is not necessary to dismantle the entire structure.

Truss pipes

Several trunks are fixed on a metal truss. The frame requires additional treatment with anti-corrosion compounds. Combustion products are removed through a three-layer metal pipe with a heater.

The design is characterized by low weight and high resistance to wind load. The presence of the frame allows you to quickly perform repairs and preventive maintenance.

Mast

A mast is used as a supporting structure. 1-3 gas outlets are mounted to it. The mast is installed on the foundation with anchors. Chimneys have the following advantages:

- possibility of installation in seismic areas;

- high structural strength;

- compact dimensions.

The structure is insulated.The protective outer layer is made of galvanized steel.

Features of the care of the spark arrester

The complexity of maintaining a spark extinguisher installed on a chimney depends on the model chosen by the building owner.

The first option is a hat made of metal mesh. In this case, it is necessary to periodically check its condition - it can become clogged with combustion products, other debris brought by the wind.

Such a grid, especially when fuel with a high resin content was used for the firebox, needs to be cleaned of soot and burning quite often. Also, if the material for manufacturing was chosen cheaper, it will soon be necessary to replace the spark arrester with a new one.

When cleaning a structure in which the mesh is installed as a damper designed to collide with sparks, the structure will have to be disassembled. And this is a certain inconvenience.

Frequent walks to the roof to clean the mesh can also hardly be called a pleasant experience. Yes, even when from time to time you need to change the metal mesh on the chimney. Therefore, it is better to immediately select a better material for the manufacture of a spark arrester.

The second option is a deflector with a mesh inside. Here, it will also be necessary to periodically clean the metal cells of the grid, which are clogged with combustion products. After all, the more debris the mesh element of the device collects on itself, the more difficult the process of removing smoke will become. And this is fraught with big troubles.

The third option is a deflector with a skirt. Here it is necessary to periodically check that leaves, butterflies and birds do not close small holes designed to remove water from rain and melted snow. It is not necessary to remove the device from its workplace and clean it. This is the easiest model to maintain.

The fourth option is spark arresters made of metal alloys that are susceptible to corrosion. Such products will quickly become unusable. This must be taken into account at the stage of material selection.

To protect yourself from having to build a spark arrester every year, it's best to choose good quality 5mm stainless steel right away. The same applies to the metal mesh - it must be wear-resistant, preferably stainless steel.

The grid for the manufacture of the spark arrester must be heat-resistant, wear-resistant with a thickness of partitions up to 5 mm

Checking the spark arrester is carried out without fail when cleaning the chimney.

How to make a spark arrester on chimneys?

Making a spark arrester with your own hands is very simple, for this you don’t have to buy expensive materials or tools, almost everything you need is probably in stock with a zealous owner of the house. Before work, it is only necessary to accurately determine the design of the future device, remove all dimensions from the chimney, draw a sketch in compliance with all dimensions, according to which the metal will be cut, and the spark arrester itself will be assembled.

In order to make a spark arrester for a pipe with your own hands, you need to prepare the simplest tools and materials:

Spark arrester device.

- metal bars with a diameter of up to six millimeters (preferably one mm so that gases can freely pass through the grate). Instead of bars, you can use a piece of metal mesh;

- a sheet of metal with a thickness of one millimeter;

- grinder, metal scissors;

- simple pencil, ruler;

- steel rivets (aluminum will not give reliable fixation);

- welding machine and clamps for fastening the material before welding.

It is better to carry out all work on a horizontal surface, first measure the dimensions from the chimney. It is recommended to immediately decide on the design, draw a sketch with the exact dimensions, which will be necessary when cutting the material, assembling the device itself for installation on the chimney.

The process of installing spark arrester equipment is very simple:

- First, a sketch is drawn for the future device.

- After that, steel up to 1 mm thick is cut according to the project (depending on the size of the chimney itself).

- A metal mesh with 5 mm cells is also cut according to the dimensions of the installed chimney. This can be done with the help of prepared wire cutters or scissors for metal.

- A pipe with a diameter suitable for a chimney is cut in such a way that a base for installing a grid is obtained from it.

Further work on the manufacture of a spark arrester includes:

- Bars that are placed parallel to each other on the grid, leaving a part for attaching to the pipe. We press them with a hammer, all joints are welded with a welding machine.

- The resulting mesh should be wrapped around the pipe, pressed with clamps. You need to tap on the grid with a hammer - this way the stress will be removed from the metal.

- After bending, all edges and joints are welded.

You can take a ready-made, previously purchased piece of mesh, which is attached to the base pipe in the same way.

We mount the deflector and fasten the finished spark arrester

Now we make a deflector for the pipe. We cut out a visor in the form of a circle from a sheet of metal, bend it (all folds are attached from above with rivets), we get a small cone with a diameter larger than the diameter of the main pipe. This will be our visor.

The deflector is attached to the grid and the base of the spark arrester using metal strips welded or fixed with ordinary steel rivets. The ready-made spark arrester can be installed on chimneys using various mounting options for this (depending on the material of the chimney itself). These can be self-tapping screws, bolts, it is necessary to provide for the possibility of dismantling for.

Spark arresters are an additional element that are equipped with pipes to protect buildings from fires, they are placed on the top of the chimneys. This is a specially installed mesh and a deflector that prevent sparks from reaching the roof surface. All of them, passing through the grate, are simply extinguished on its cells.

It is recommended to install such a device for baths, saunas, when covering the house with flammable materials. In addition, the spark arrester keeps birds, foreign material, twigs, and other debris out of the chimney, greatly reducing the frequency of chimney sweeps. Installing a spark arrester ensures the greatest possible safety. You can make such a device with your own hands, for this you need the simplest materials and tools, the installation itself takes a minimum of time.

Varieties of spark arresters

The chimney spark arrestor can be made by hand or purchased a more complex model.

There are three main types that differ in their device, method of extinguishing sparks, additional functions:

- casing - the simplest option;

- deflector, further improving traction;

- liquid.

Spark Arrestor-Housing

This is the simplest type, which is easy to make yourself.Of the materials for manufacturing, stainless steel is most suitable, characterized by strength, corrosion resistance, resistance to high temperatures.

Spark Arrestor-Housing

The easiest way to make a plug for a pipe with drilled holes

It is important to correctly calculate the diameter of the holes, which does not impede traction, but does not allow sparks to pass through. The size of the plug itself must exceed the diameter of the pipe so that the device can be easily put on and taken off

Spark arrester-deflector

This type spark arrester on the chimney has a more complex structure.

The principle of operation of the deflector is to use the force of the wind to increase traction. The aerodynamic device can be of different types.

They use a narrowing of the body in any part of it, annular holes in the body, a mini-turbine, a set of rotating visors and other devices. Directed air flow, obtained due to the force of the wind, enhances the draft in the pipe.

Spark arrester-deflector

And equipping the deflector with a mesh or perforation ensures effective extinguishing of unburned fuel particles. Deflectors are more aesthetically pleasing than shrouds and can serve as a decorative roof decoration.

The most common deflectors:

- TsAGI;

- Volpert;

- Grigorovich;

- H-shaped;

- Poppet;

- Rotating;

- Vane.

Hydrofilters

A water spark arrestor is used mainly for barbecues to protect the chimney from fire.

Water spark arrestor

This is a complex structure, which includes:

- smoke hood;

- frame;

- ventilation system;

- metal grid;

- fat filters;

- device for spraying water;

- valve for water supply;

- pressure meter;

- device for separating smoke and water;

- dirty water disposal device.

Common mistakes and problems when installing chimneys

We will analyze the most common problems that arise after installation. By the way, some of them arise not only with the independent installation of the chimney, but also with experienced craftsmen.

- Traction overturning. This is a phenomenon in which flue gases enter the furnace back, and through it into the room. There can be two reasons for the problem: incorrectly selected pipe height or strong wind. In both the first and second cases, installing a deflector can help. This simplest device is installed at the upper end of the chimney and creates an additional vacuum. If the installation of the deflector did not help, you will have to lengthen the pipe.

- Loose flue pipes. This problem is especially common with self-assembly. As mentioned earlier, any chimney needs at least 2 brackets. But some craftsmen believe that one indoors is enough, because the pipe is small. This leads to loosening of the outer part of the chimney, which is fraught with damage to the entire chimney. The solution to the problem is obvious: install an additional bracket.

- Condensation on the chimney and nearby surfaces. This problem is especially relevant for the chimney section in the attic space, where the appearance of additional moisture threatens to damage the roof. In order to solve this issue, it is enough to arrange additional thermal insulation.

There is nothing mystical about installing a chimney. If you wish, you can save a lot of money by making all the consumables yourself. The main thing is to do everything qualitatively and follow a clear sequence of actions.

Selection and calculation

Quality design boiler house chimney and the determination of its necessary characteristics should be made on the basis of special calculations. In this case, it is necessary to be guided by the provisions of the specialized section of SNiP

The main attention in the preparation of the project, determining the required diameter and height is given to ensuring full traction. It should meet the needs of heating equipment with a margin. Calculation should be entrusted only to qualified specialists

Calculation should be entrusted only to qualified specialists.

At the preliminary design stage of smoke exhaust ventilation:

-

calculate the aerodynamic properties of the chimney according to wind loads (with a margin);

-

select the height and cross section according to the fuel used;

-

calculate the required thickness of the chimney;

-

choose a fastening method;

-

prepare drawings, estimates and technical materials.

It is recommended to select the height taking into account the hourly fuel consumption, the ash content of the combustion process and the sulfur concentration. Brick boiler pipes in height can be 30 - 70 m. Reinforced concrete outlet channels can reach a height of 300 m. Other options - no more than 30 m.

Turnkey gas installation design

The design of gas boiler houses with a license consists in drawing up and calculating a scheme for heating, gas supply and gas ducts. To do this, you must definitely familiarize yourself with the norms of SNiP "Gas boiler houses" and take into account the characteristics when installing heating units and gas ducts.

The design of a gas boiler house should take place in a certain sequence and in accordance with the following points (norms):

- Architectural and construction schemes and drawings are carried out in accordance with the norms of SNiP. Also at this stage, the wishes of the customer (in the calculations) are taken into account.

- The calculation of the gas boiler house is carried out, that is, the amount of necessary thermal energy for heating and supplying hot water is calculated. In other words, the power of the boilers that will be installed for operation, as well as their emissions.

- The location of the boiler room. This is an important point in the design of gas boilers, since all working units are located according to the standards in one room with a certain calculation. This room can be in the form of an extension or a separate building, it can be inside a heated facility, or on a roof. It all depends on the purpose of the object and its design.

- Development of schemes and plans that help gas boiler equipment to function. The class of automation and the heat supply system should be taken into account. All gas supply schemes for the boiler room must be equipped in accordance with the norms of SNiP. Do not forget that these installations are quite dangerous and proper development is very important. The development must be carried out by qualified turnkey specialists who are licensed for this.

- It is necessary to check the object for safety by conducting a special examination.

With improper, unlicensed design of gas boilers, you can incur large financial costs (fines), as well as be in danger during operation. It is better to entrust the installation of equipment of this class to companies that install turnkey gas boilers. Companies are licensed to perform these works, and this guarantees long-term operation of the gas installation and compliance with all SNiP standards.