- Foundation construction

- Necessary materials

- Main steps

- Chimney Requirements

- Chimney materials for boilers

- Structure design: rules and approaches

- Chimney device

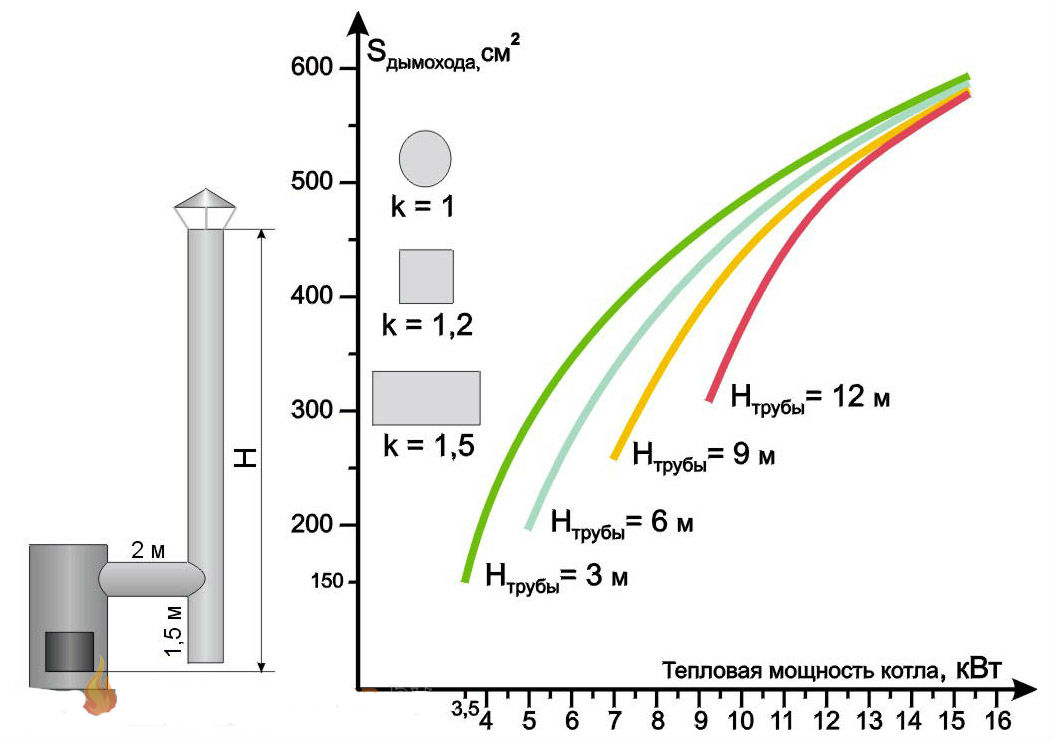

- Calculation of the parameters of the chimney

- What is it and why is it needed

- Elevated location

- What is worth knowing

- Height above the skate

- Operation of chimneys

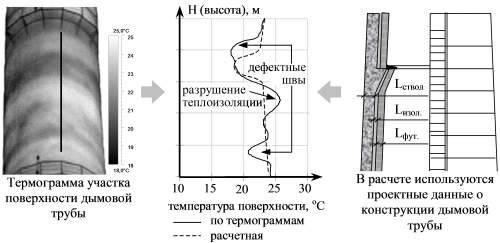

- Main types of calculations for industrial chimneys

- Pipe Aerodynamics Calculation

- Determining the height of a structure

- Strength and stability of the pipe

- Thermal calculation

- Location of flues

- General Criteria

- Kinds

- Strength characteristics of the chimney: instructions for operation and installation of communication of any diameter with the foundation

- Conclusions and useful video on the topic

Foundation construction

Necessary materials

Before building the foundation, it is required to prepare all the necessary materials, which include:

- sand,

- gravel or broken brick,

- concrete mix. The grade of concrete B15 is optimal, but a higher class of mixture can be used,

- metal reinforcement with a cross section of at least 12 mm,

- refractory brick,

- any waterproofing material.

Main steps

Foundations for chimneys are built according to the following scheme:

- a place is chosen for installing the furnace and chimney.It is desirable that the chimney does not come into contact with the walls of the residential building, since additional condensation may form with such an arrangement. The foundation of the furnace and chimney should be located at some distance from the foundation of the house,

Optimal options for the location of the furnace and chimney in a residential building

- in the place of the proposed installation of the furnace and chimney, a pit of appropriate overall dimensions is dug,

- formwork is set around the perimeter of the pit, which can be made independently from improvised boards,

- the bottom of the pit is approximately 20 cm covered with a mixture of sand and gravel (broken brick). Thanks to this operation, it is possible to level the bottom of the pit and establish a “cushion” for the future foundation,

- the sand and gravel mixture is covered with a layer of waterproofing material to reduce the formation of condensate that can destroy the concrete pour,

- metal rods are laid as reinforcing elements. The use of bars is a prerequisite for pouring, as reinforcement helps to increase the strength of the concrete base,

The initial stage of building a foundation for a chimney

- concrete is being poured. The thickness of the concrete layer should be 200-300 mm. Concrete must be level or slightly above ground level,

The main stage of foundation construction

- the foundation for the chimney is laid with another layer of waterproofing,

- further, it is advisable to perform brickwork to the level of the floor of the dwelling. Some builders neglect this step.However, additional masonry will give the chimney additional stability and almost completely eliminate seasonal fluctuations in the structure, which will lead to fewer losses and lower maintenance and seasonal restoration costs.

The final stage of foundation construction

The construction of a foundation for a chimney is required only when installing a massive structure. Most often, the foundation is equipped immediately for both the stove (fireplace) and the chimney. The design does not require an exact calculation. It is enough to know the general rules for the installation of foundations.

The foundation for the chimney pipe: the need, calculation, installation on their own Heavy chimneys require the assembly of a separate foundation, which will give the structure stability and additional reliability. How to make a foundation on your own, you can find out by reading the article.

Chimney Requirements

The chimney removes and disperses harmful products of fuel combustion into the atmosphere

It is important to design and build it correctly. Otherwise, the inner walls will be clogged with soot, ash, soot, blocking the outlet channel and preventing the removal of smoky masses, making it impossible for the boiler room to work.

There are technical standards that clearly regulate the parameters of chimneys:

- Brick structures should be made in the form of a cone with a height of 30 to 70 m, a diameter of 60 cm. The minimum wall thickness is 180 mm. In the lower part, gas ducts with revisions for inspection must be equipped.

- Metal pipes used for the installation of chimneys are made of 3-15 mm sheet steel. The connection of individual elements is carried out by welding. The height of the chimney must not exceed 40 m.The diameter can be from 40 cm to 1 m.

- To ensure the stability of metal structures, brackets or anchors are installed at a distance of 2/3 from the height of the pipe, to which extensions are attached.

- The height of the chimney (regardless of the material of manufacture) should be 5 m above the roof of buildings located within a radius of 25 m.

The dimensions of the structure are calculated taking into account the volume of the furnace and climatic conditions, so that draft is provided at any air temperature.

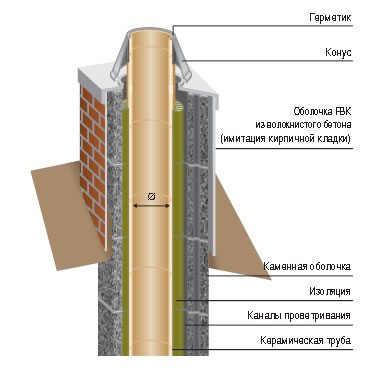

Chimney materials for boilers

The choice of material for the chimney is not only a technical, but also an aesthetic issue: it is desirable that these elements not only do not dissonate, but even emphasize the overall style. And yet the main task solved by the chimney is a stable exhaust of combustion products. Reliable, non-smoking, fireproof, no condensate leaks. To do this, you need to correctly select the cross section and material of the pipes, which can be made of:

- of stainless steel;

- sandwich pipes;

- ceramics.

Stainless steel is more suitable than other materials for smoke extraction from boilers with a closed combustion chamber. Sandwich pipes are a convenient solution that does not require additional thermal insulation work, a successful element of modern design. Ceramic chimneys - high accumulation and resistance to caustic condensate. Chimney ceramics can become separate design objects in a classic interior.

Each material has its advantages, weaknesses, its own price category. You can ask our managers about the expediency of choosing the material or design of the chimney for the boiler, the completeness of its components.

Structure design: rules and approaches

At the heart of all design work are the functional requirements for boiler room chimneys:

- operating modes must comply with environmental standards;

- ensuring good permeability of gases and emissions with their subsequent dispersion in the atmosphere;

- creating natural traction.

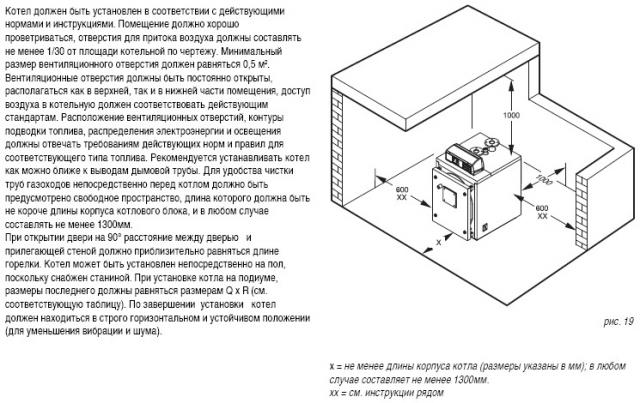

Installation of chimney systems is carried out according to a project developed in accordance with the rules

Installation of chimney systems is carried out according to a project developed in accordance with the rules

The correct choice of the type of pipe, calculation of its diameter, height, aerodynamics fundamentally affects the fulfillment of the above requirements. A competent design process involves carrying out calculations to determine the stability, strength of all components of the structure, taking into account both the foundation and the fastening mechanisms.

The sequence of stages in the design of flue boiler pipes is as follows:

1. Determining the type of construction. The following factors serve as criteria:

- the proposed location of the pipe;

- whether there is a need for additional fastening;

- technical characteristics of boiler equipment.

2. Calculation of the aerodynamics of the structure. Parameters such as the type of thrust (it can be injected artificially or naturally) and wind load are taken into account.

3. Calculation of the height of the chimney and its diameter. The input data for this are the type and volume of fuel burned.

4. Calculation of stability and strength, determination of the type and method of fastening.

5. Drawing up a drawing, technical documentation and cost estimates.

For private construction, it is possible to carry out an independent calculation of the chimney, but such an approach to resolving the issue will not allow obtaining a passport, as well as technical documentation.

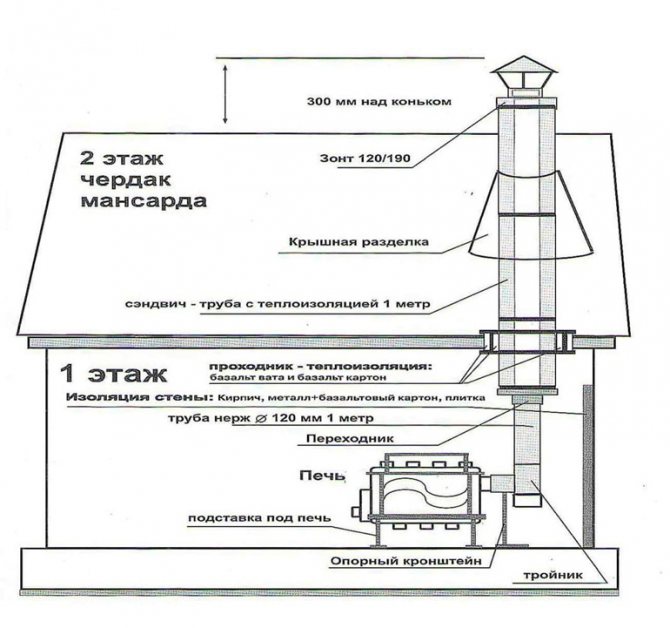

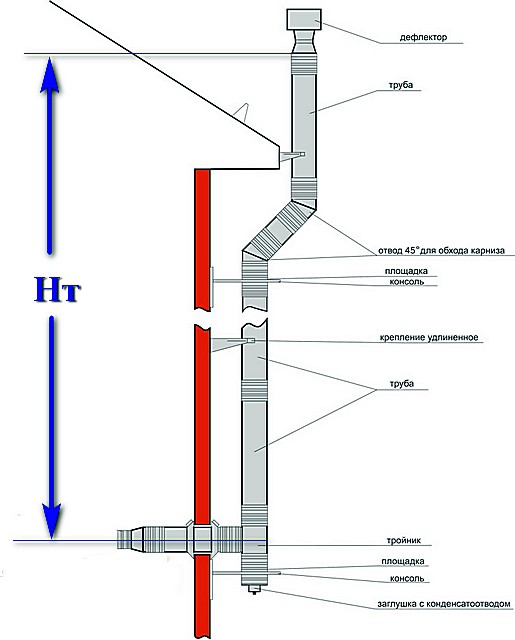

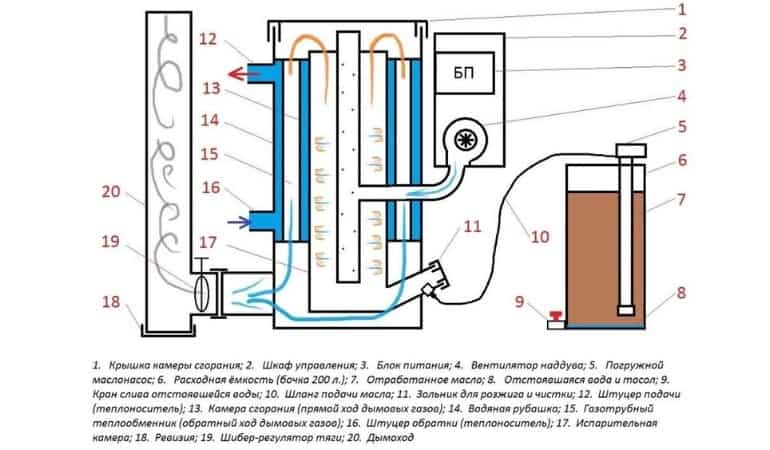

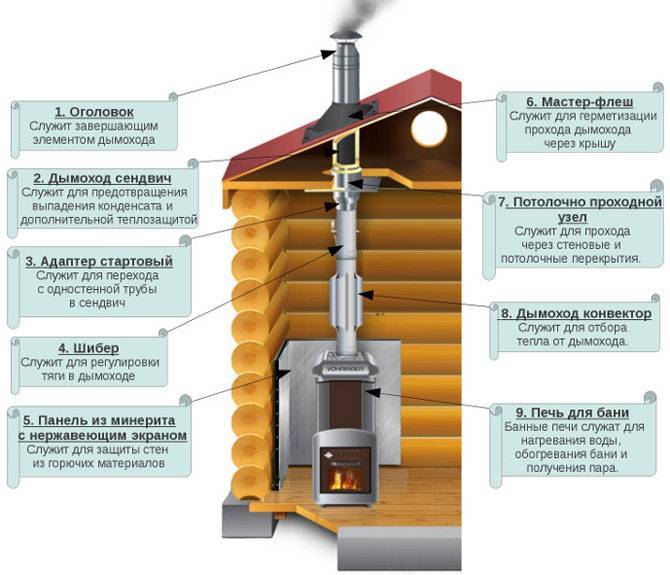

Chimney device

All chimneys, regardless of the material used, location and design, have a similar structure.

They always contain the following components:

- Chimney - a vertical or partially inclined channel (pipeline) of rectangular, square or round section for the removal of combustion products. Made from durable flame retardant material.

- The condensate trap is located in the lower part of the chimney after the tie-in of the boiler flue and serves to collect condensed vapors contained in the flue gases. Equipped with a dump valve. Absent in wall-mounted chimneys, made double-walled with a heat-insulating layer.

- Draft adjustment device - rotary or retractable damper.

Calculation of the parameters of the chimney

Properly selected height and cross-sectional area of the chimney is the key to its reliable operation. Almost all industrial boilers have recommendations for these values.

For equipment with a thermal power of up to 90 kW, the following values are recommended:

| Boiler performance, kW | Chimney diameter, cm | Pipe cross-sectional area, cm2 | Pipe height, m |

| 20 | 13 | 196 | 7 |

| 30 | 15 | 196 | 8 |

| 45 | 18 | 378 | 9 |

| 65 | 20 | 540 | 10 |

| 90 | 25 | 729 | 12 |

What is it and why is it needed

The largest chimney is located in Kazakhstan and its height (just imagine) is as much as 420m! The state district power plant, where it is located, was built on a coal mine, and could provide electricity to half of the republic.You will not find such large-scale chimneys in Russian cities, but this does not reduce their role for our comfortable existence.

A chimney is a structure designed to remove and disperse fuel combustion products into the atmosphere. Without a properly designed and installed pipe, the correct operation of the boiler room is impossible.

In addition, the chimney of central and autonomous heating creates natural draft. The draft arises due to the temperature difference between the hot gases inside the pipe and the outside air.

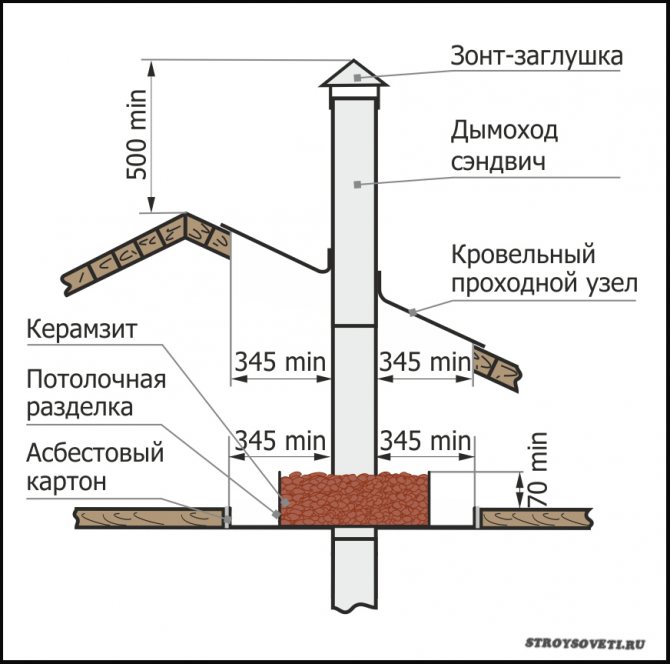

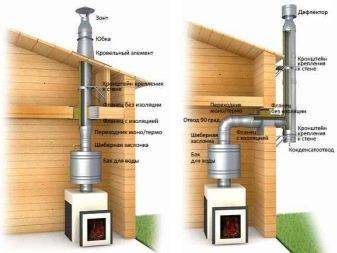

Elevated location

When the external outlet of the channel is located on a flat roof, the element must rise above the coating by at least 0.5 m. If the distance between the outlet and the ridge of the pitched roof is less than 1.5 m, the operation of the gas ducts is carried out when the element protrudes 0.5 m above the ridge. When the exit location exceeds the specified distance, a new rule takes effect. The height of the top point of the structure must correspond to the height of the roof top of the object. Pipe connections are made with crimp clamps using thermal sealants. External fastenings are provided with brackets on dowels or anchors with a distance of 2 m.

What is worth knowing

The above calculations will be correct only when there are no very tall trees growing near the house and no large buildings are located. In this case, the chimney with a height of less than 10.5 m may fall into the zone of the so-called "wind backwater".

To prevent this from happening, the outlet pipe of the boiler room of a private house located in such a place should be increased. At the same time, in order to choose the optimal option for the height of the pipe, you should:

- find the highest point of a nearby large building;

- draw a conditional line down from it at an angle of 45 ° to the ground itself.

Ultimately, the top edge of the assembled chimney should be located above the line thus found. In any case, a country building should be designed in such a way that the exhaust gas pipe of the boiler room is subsequently located no closer than two meters to tall trees and neighboring buildings.

They usually increase the height of the chimney even if the roof of the house is sheathed with combustible material. In such buildings, the outlet pipe is most often increased by another half a meter.

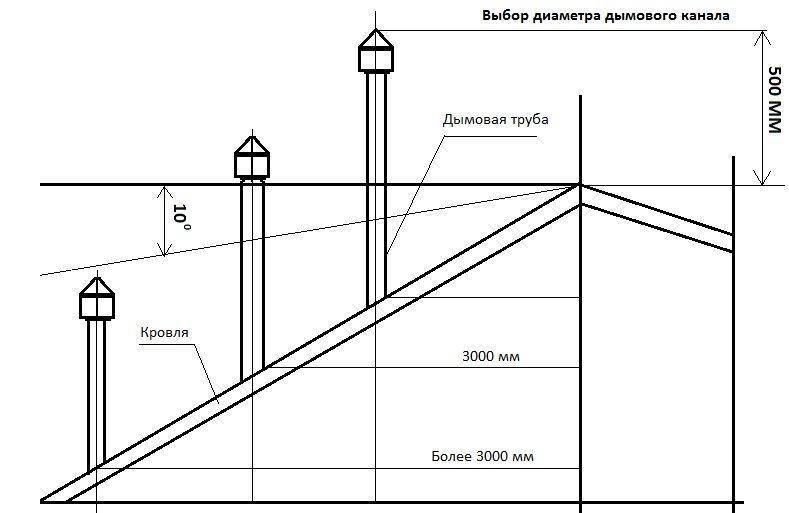

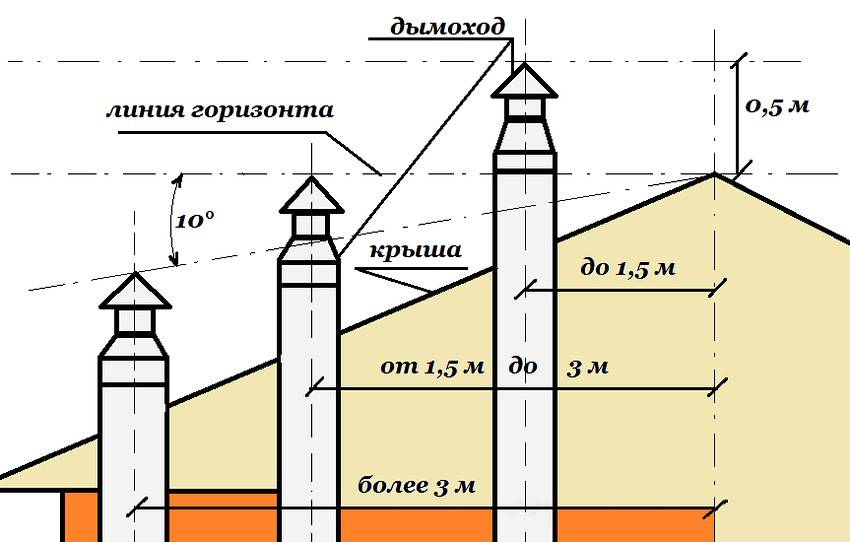

Height above the skate

In order for the heater to function without problems, the effect of wind pressure must be taken into account when installing the chimney pipe. What it is? Winds, the structure of the roof and its uneven heating cause turbulent air flows over the building. These air turbulences are capable of “overturning” thrust, or even causing counterdraught. To avoid this, the height of the pipe should be at least 500 mm from the ridge.

In addition to the location of the ridge, it is also necessary to take into account high structures on the roof or next to the building, and trees growing near the house.

If the distance from the pipe to the ridge is three meters, then it is permissible to make the height of the chimney flush with the ridge. If the distance is more than three meters, the height can be determined using the diagram shown in the photo.

Avoid turns and horizontal sections. When designing the location of the chimney, you should make no more than three bends of turns, and also avoid horizontal sections longer than one meter. If a horizontal section cannot be avoided, the channel should be laid with at least a slight slope.

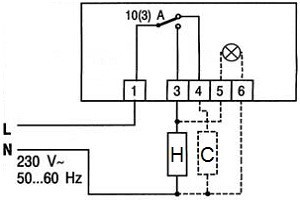

Operation of chimneys

Proper design and competent installation of pipes - and the boiler room works like clockwork. But choosing a chimney and installing it with high quality is only half the battle. Regardless of whether the chimney is brick, ceramic or made of steel modular elements, it is necessary to regularly clean it, removing soot that has settled on the walls.

With regular use of the device, preventive cleaning should be carried out at least twice a year - at the change of seasons. Brick chimneys are more prone to soot accumulation due to the rough inner surface and rectangular duct section. For cleaning and repair it is necessary to provide cleaning hatches.

If the boiler room runs on liquid or gaseous fuels, the flue gas temperature may not be high enough and condensate will form. To remove it, it is necessary to provide for the installation of a condensate trap in the smoke exhaust duct.

The device of the chimney according to all the rules and proper operation contribute to the heat in the house and fire safety.

Main types of calculations for industrial chimneys

The design of industrial chimneys requires complex, multi-stage calculations

Pipe Aerodynamics Calculation

This part of the design is needed to determine the minimum capacity of the structure.

It should be sufficient to ensure the trouble-free passage and further removal of fuel combustion products into the atmosphere, when the boiler is operated in maximum load mode.

It should be noted that an incorrectly calculated pipe capacity can cause gases to accumulate in the duct or boiler.

Competent aerodynamic calculation makes it possible to objectively evaluate the performance of the blast and traction systems, as well as the pressure drop in the air and gas paths of the boiler house.

The result of aerodynamic calculations are the recommendations of specialists on the height and diameter of the chimney and optimization of sections and elements of the gas-air path.

Determining the height of a structure

The next point of the project is the environmental justification of the size of the pipe, based on calculations of the dispersion of harmful products of fuel combustion in the atmosphere.

The height of the chimney is calculated based on the conditions for dispersing the emission of harmful substances.

At the same time, all sanitary standards for commercial and factory enterprises must be observed, as well as the background concentration of these substances should be taken into account.

The last characteristic depends on:

- the meteorological regime of the atmosphere in a given area;

- air mass flow rate;

- terrain;

- flue gas temperature and other factors.

During this design stage, the following is determined:

- optimal pipe height;

- the maximum permitted amount of emissions of harmful substances into the atmosphere.

Strength and stability of the pipe

Calculations are also needed to determine the design of the pipe

Further, the chimney calculation method provides for a set of calculations that determine the optimal stability and strength of the structure.

These calculations are made to determine the ability of the selected design to withstand the effects of external factors:

- seismic activity;

- soil behavior;

- wind and snow loads.

Operating factors are also taken into account:

- pipe mass;

- dynamic vibrations of equipment;

- thermal expansion.

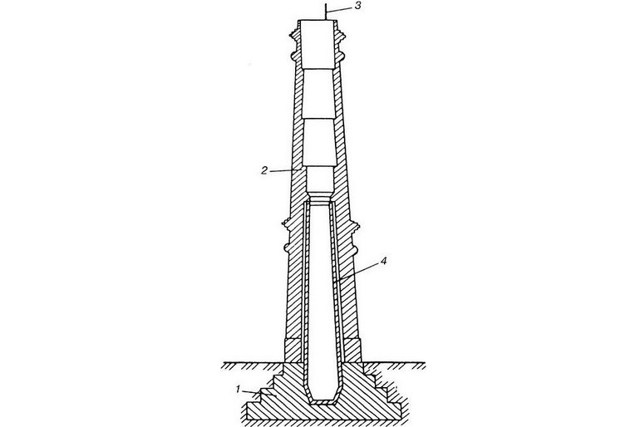

Strength calculations make it possible to choose not only the design and shape of the structure's shaft. They allow, and to calculate the foundation for the chimney: determine its design, depth, footing area, etc.

Thermal calculation

Thermal engineering calculation is required:

- to find the thermal expansion of the material of the industrial smoke pipe;

- determining the temperature of its outer casing;

- choice of type and thickness of insulation for pipes.

Location of flues

The chimney as close as possible to the ridge rib is the optimal solution for operation. The ridge barrier will not become an obstacle to the impact of air currents on the product. Positive result: financial savings in the installation and operation of the smoke channel. Fire safety requirements allow any optimal location of the flue relative to the ridge. The owner of the premises, taking into account safety requirements, independently determines the distance. In practice, options are being implemented for using boilers with chimneys almost in the center of the facility, at a considerable distance from the ridge. They are characteristic, mainly, in the arrangement of premises with industrial furnaces. At industrial facilities equipped with boilers, the minimum removal of the chimney from the ridge rib is practiced.

General Criteria

The total requirements for chimneys for gas boilers are as follows:

- Structural sections should have a slope of no more than 30 degrees.

- The maximum length of any branch to the side is 1 m.

- Lack of ledges and cross sections.

- The maximum number of knees is 3.

- The permitted radius of the rounded part is not inferior to the diameter of the used smoke elimination pipe.

- The presence of an inspection hatch on the corners.Condensate is discharged through it, and the system is cleaned.

- If the shape of the chimney is rectangular, then one side of it should be twice as wide as the second side, i.e. an elongated configuration of the product is not allowed.

- Arrangement of a dropper and revisions at the bottom of the pipe.

- Any deflections of the components of the structure are excluded.

- If the chimney increases, one structural link is strung on the second at least half the diameter of the pipe.

- No gaps between structural components.

- Joints are not allowed in those places where the pipe passes through partitions and ceilings. There must be strong thermal insulation.

- All components of the system are connected very tightly.

- The minimum possible inclination of the pipe in relation to the boiler is 0.01 degrees.

- Absence of irregularities and roughness on the inner walls of the pipe.

- The horizontal elements of the chimney must have a total length of no more than 3 m for buildings under construction and 6 m for built houses.

- The minimum distance separating the pipe from easily combustible surfaces is 25 cm, from non-flammable materials - 5 cm.

A separate issue is the installation height of the chimney in relation to the ridge element of the roof. Here are the options:

- If there is a horizontal distance from the ridge of more than 3 m, the pipe is placed above the abstract line laid down from it to the horizon at a slope of 10 degrees.

- When the chimney is located 1.5 - 3 m from the ridge, the pipe is located on the same level with it (the ridge).

- With a horizontal distance of no more than 1.5 m, the pipe must be placed at least 50 cm from the ridge.

The chimney must exceed the adjacent roof area by at least half a meter.In the presence of a flat roof, this parameter develops up to 2 m.

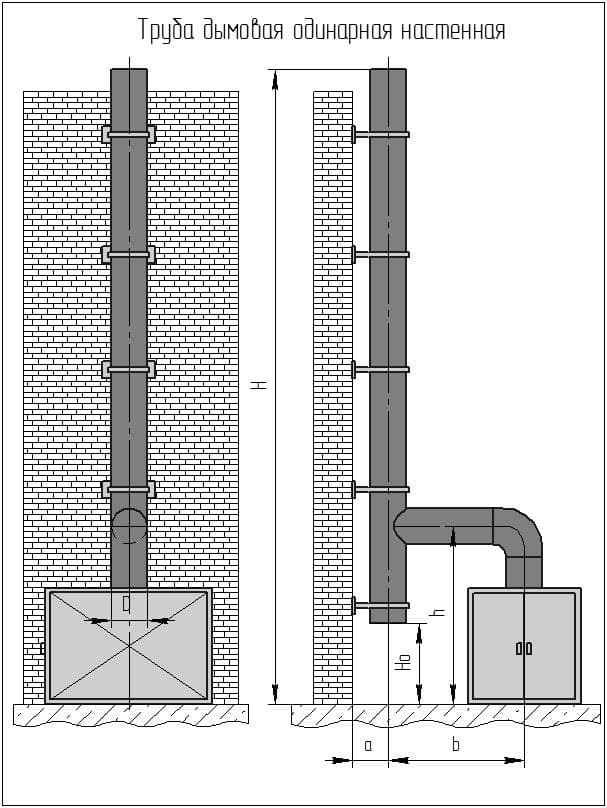

Kinds

Structurally, chimneys for different types of boilers may differ.

We are talking about the following options for chimneys.

- A vertical duct, usually made of brick, that is built into the inner wall of the house along with ventilation shafts.

- A vertical metal pipe that runs inside the building and goes to the roof. This option can be described as an internal attachment.

- Attached solutions that are attached from the outside in the house wall. Usually they are made of brick.

- Steel pipes that are located on the outside of the house. They can be attached to a wall or attached to a special metal-rolled lattice mast.

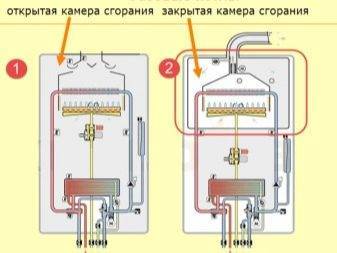

The house may even be chimneyless, but here everything will depend on the type of boiler.

There are two types of boilers:

- with an open combustion chamber;

- with closed combustion chamber.

An open combustion chamber boiler usually requires a chimney, especially if it runs on solid fuels. Although such a need will be for any boiler equipment, both for solid fuel and for gas-powered. True, in the variant with the latter, the need for it will not be so great.

For a wall or floor solution with a closed combustion chamber, the chimney is not needed so much due to the tightness of the chamber itself. The same will be true if chimney boilers are used.

Now we should talk about some of the characteristics of each chimney option.

Consider the disadvantages of outlet brick devices.

- The internal surface of brick solutions is extremely uneven, which will cause strong soot deposits from burning fuels, especially solid ones.

- Moisture in the form of condensate, which will form on the brick, sooner or later will begin to penetrate into the structure of the material, and it will begin to collapse due to the temperature difference.

- Typically, brick chimneys are made in the shape of a rectangle, which significantly reduces the characteristics of the aerodynamic thrust, when compared with a round shape, and significantly increases the resistance to gas flow. The force of natural traction will also be less.

- If the chimney is attached from the outside of the building, then due to the temperature difference, it may begin to separate from the wall and a crack will form between them. And if the chimney was built later than the house itself, then the size of the crack can be significantly larger. Although such a pipe is quite suitable for use with a solid fuel boiler, because it has good durability, and it will also look good against the background of a brick house. In general, if such a design is finalized, then almost all of these disadvantages can be corrected.

The option of two steel pipes or a sandwich with an insulating layer is an excellent solution today. A similar chimney is usually created from several sections one or two meters long, which have a small mass. This allows them to be installed even by one person without assistance. The advantage of this option is that the inside will be smooth, on which soot and any other combustion products do not remain at all, and condensate will flow freely into a special pipe.

A good solution would be a coaxial metal chimney.Through the section of the internal type, various combustion products exit, and oxygen enters the combustion chamber from the outside between the walls.

Strength characteristics of the chimney: instructions for operation and installation of communication of any diameter with the foundation

From what material is used in the construction of the boiler pipe, the correlation of dimensions is determined. For example, brick structures do not require a separate foundation, since the latter is laid at the development stage of the furnace. This cannot be said about heavy raw materials for production. Calculation of a metal structure for strength directly depends on the amount of fuel burned in 1 hour. To correctly calculate the safe dimensions of steel and reinforced concrete structures, the following characteristics are taken into account:

Foundation type - sole area, pouring depth. For heavy structures, a monolithic filling platform is arranged or concrete slabs are laid with loops for attaching steel cables

It is important to take into account the seismic features of the terrain and seasonal ground movements.

Climatic conditions - wind speed, rainfall. In areas with increased rates, the thickness of the walls of the boiler chimney and the emphasis are increased by several orders of magnitude, unlike quiet regions, it will become a nuance and design feature of the pipes - you will have to calculate the throughput with these indicators.

Flue gas velocity

Depending on the type of fuel, the pipe material and, accordingly, the strength are calculated based on the weight of the decay products. Heavy coal off-gases, which also contain soot, require maximum structural rigidity. In addition, their temperature can affect the inner surface of the chimney.

The presence of forced draft fans. External force, in addition to natural draft, affects the design features of the chimney and strength. The power of the units is taken into account and the boiler room chimney is calculated from them.

For brick and reinforced concrete chimneys, the minimum diameter is 1.2 m. For steel structures, the parameter is 3.6 m.

Conclusions and useful video on the topic

A video with a visual demonstration of the process of calculating the height of the smoke channel for arranging a boiler room:

Here the author of the video shared his own experience in calculating and installing a chimney for a solid fuel boiler:

Another video to help the amateur designer:

It is not so important what fuel the boilers in the boiler room use. In any case, you can not do without a flue gas system

The main requirements that chimneys must meet are good draft and throughput, and consistent environmental standards.

Do you want to ask a question about a controversial or unclear point that you met when reading the information? Do you have useful information on the topic of the article that you want to share with site visitors? Please write comments in the box below.