- Common errors and installation problems

- Chimney installation

- Device and principle of operation

- Device and principle of operation

- Do it yourself or order

- Chimney materials

- Mounting

- Chimneys for brick fireplaces

- Disadvantages of brick structures

- Making a simple chimney

- Fireplace Chimney Design Basics

- Installation: recommendations and diagrams, the main stages of the installation of the chimney

- General requirements

- Installation steps

- Video description

- Connecting a ceramic chimney

- Video description

- Performing installation work

- Regulatory requirements for the installation of chimneys

- Norms for the installation of a smoke exhaust system

- Boiler structures and chimney outlet

- Methods for installing chimneys

Common errors and installation problems

Excessive inclination, a large number of bends and their incorrect radius, the presence of horizontal areas and exceeding their allowable length weaken the draft in the circuit and contribute to the formation of soot buildup in it.

In the case of a complex brick chimney, it is quite difficult to correct the situation, sometimes the problem is solved by liner or installation of forced-type smoke exhaust equipment (smoke exhauster). If this is not possible, the structure will have to be disassembled and redone.

The open-type modular steel structure is easily disassembled, which means that it will not be difficult to remake it.

Low mine height.

With a pipe height of less than 5 meters, the traction force is significantly reduced. If the ventilation and flue pipes are located in the same module and the height of the latter is insufficient, the risk of drawing gases back into the ventilation increases.

The error is corrected by building up the chimney pipe to the required level.

Too small or large section.

Not only reduces traction, but can also break the tightness of the circuit as a whole.

The draft is corrected by installing a weather vane or turboprop on the chimney head, which protects the circuit from blowing out and the effect of reverse draft in windy weather. However, in calm they will be useless.

Unsuitable material and construction defects.

The material must comply with the technical parameters of operation, and the installation must be carried out in strict accordance with the regulations.

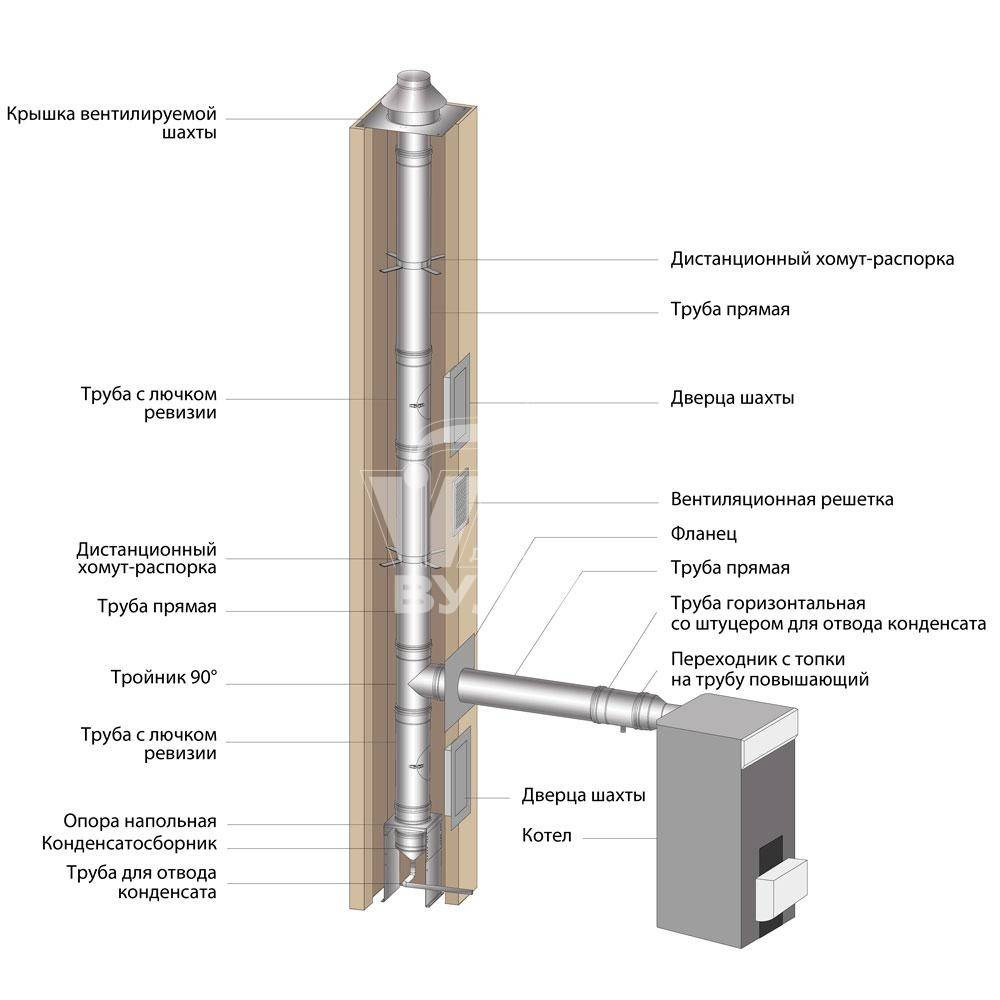

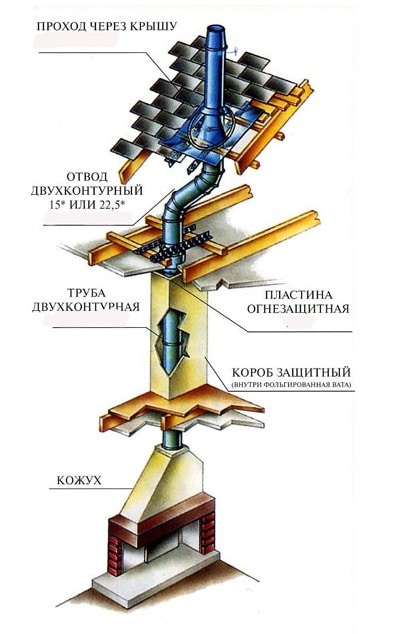

Chimney installation

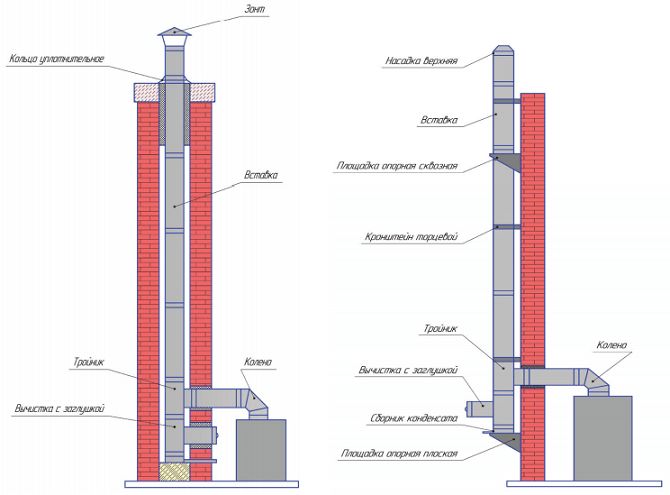

For each chimney, the order of installation, assembly and fastening is decided individually:

- during the construction of a brick smoke-exhausting structure, a foundation is required, compliance with the correct arrangement of the rows of masonry. The composition of the solution is important, a mop, a cap and sometimes a chimney are needed;

- for a ceramic chimney, a foundation is needed, a reliable fastening of modular elements. When connected, a revision with a tee is required;

- installation of a stainless steel chimney needs fastening and brackets, bends are used to ensure the deviation of the channel from the vertical. Passages are being made that go through the ceilings and the roof, and a head and a chimney are also needed.

Device and principle of operation

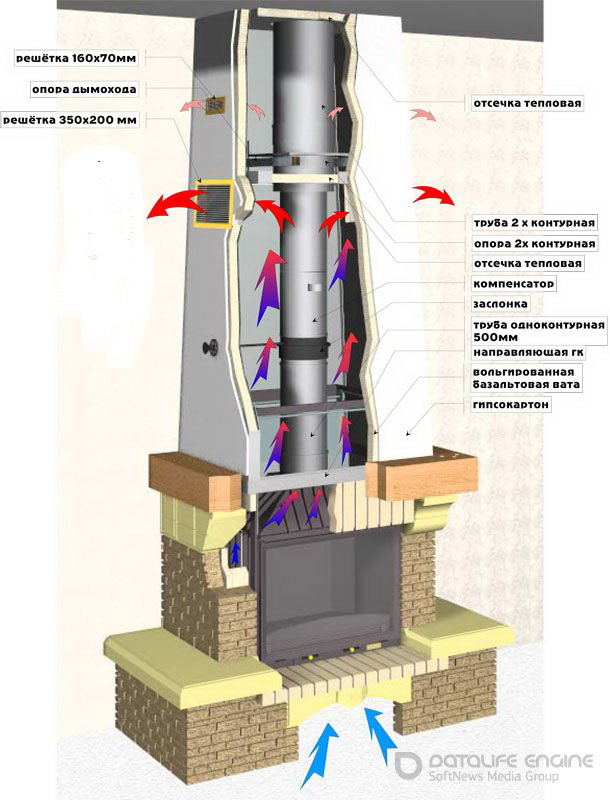

Chimneys for fireplaces or stoves are channels through which a mixture of gases, which is the products of fuel combustion, is removed from the furnace of the heater into the atmosphere.The design of these elements of the heating system is made in the form of a pipe or a brick shaft, the tightness of which determines whether the system works correctly. Chimneys for fireplaces and stoves are necessary, since without them it is impossible to operate heat-generating devices, the operation of which is as follows:

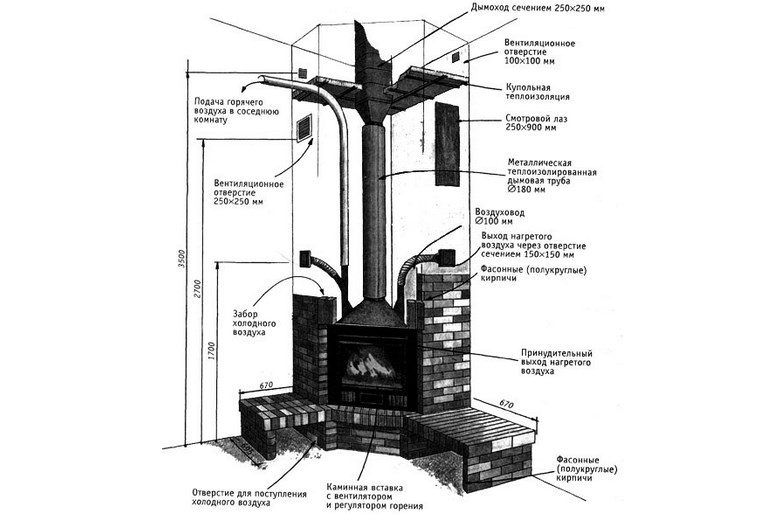

Scheme of work and air circulation in the fireplace

Scheme of work and air circulation in the fireplace

- Fuel is placed in the furnace of heat-generating equipment (stove, fireplace, boiler). Basically, the devices operate on wood, gas, compressed or coal, fuel oil.

- The fuel is ignited by an open flame source, as a result of which the system produces a large amount of heat, which is used to maintain the optimum temperature in the room, and smoke.

- Smoke, which is a product of fuel combustion, consists of a mixture of carbon dioxide and carbon monoxide, ash, soot, and other aggressive chemicals. The temperature of the smoke entering the chimneys for fireplaces or stoves reaches 400-500 degrees, therefore, obeying the law of convection, it rises, making room in the furnace for cooler air.

- The design of the smoke exhaust ducts is a vertical sealed shaft through which hot smoke rises only upwards. Thanks to this process, fresh air saturated with oxygen enters the furnace, which is necessary to maintain combustion.

To properly make a smoke exhaust channel for a stove or fireplace, you need to carefully study the information about the heater specified in the instructions, as well as calculate the volume of gas in the furnace. Mount chimney for fireplace do-it-yourself is quite difficult, since this complex design requires special knowledge and experience that only experienced craftsmen can boast of.

Device and principle of operation

Chimney pipes are a channel through which fuel combustion products are removed and the fireplace cannot be operated without them:

- Fuel is placed in the furnace of the heating device, in most cases it is coal, firewood or gas.

- After a fire is ignited, a large amount of heat is generated to heat the room and smoke, which is a product of combustion. Among the products removed through the chimney channel are carbon monoxide, ash particles, soot and other toxic substances. The temperature of the smoke at the moment it enters the chimney is approximately 500ºC.

- In accordance with the laws of convection, all combustion products enter the channel and rise up, and the same volume of cool air enters in their place.

- The design of the chimney is a vertical channel, hot smoke moves up through it. As a result, a new portion of air enters the fireplace, which is required to maintain the combustion process.

Do it yourself or order

At first glance, there is nothing complicated in installing a chimney with your own hands, however, this is not entirely true. First of all, it should be remembered that the design must be absolutely safe, which means it must be strong, airtight and with good traction. And this will require from the “stove-maker” at least the relevant knowledge and thoroughness, and at the maximum - certain experience and skills.

On the other hand, entrusting such a responsible job to a builder whose professionalism and integrity you doubt is not the most reasonable decision. After all, poorly done work can subsequently turn into a fire or carbon monoxide poisoning.

But for the independent implementation of the project, you will need to make every effort:

- study a number of building regulations and technical information about the heater,

- make the necessary calculations

- carry out construction and installation in a planned manner, often at length and with great care.

Chimney materials

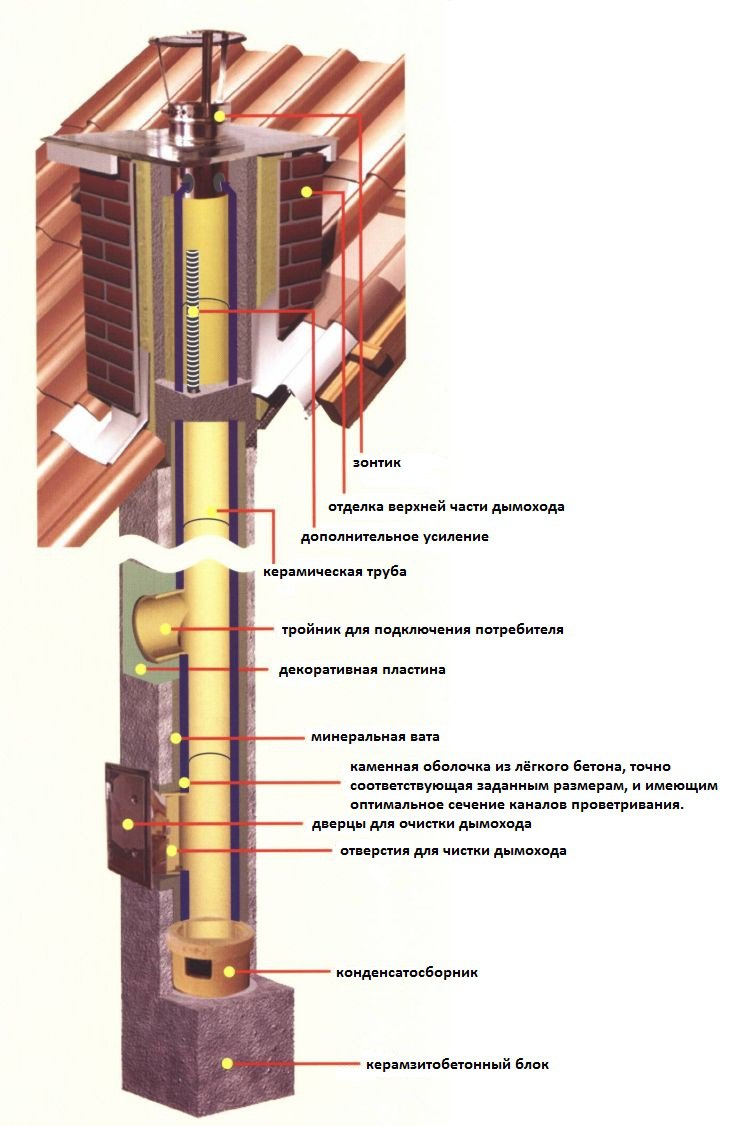

The installation of a fireplace and the installation of a chimney largely depend on the materials of their manufacture, each of which has certain properties:

- ceramics is resistant to high temperatures, differs in heat capacity and durability, but its cost is the most expensive;

- stainless steel is easy to install, has a low weight, is not affected by acids;

- brick is characterized by durability and heat capacity, but it has a lot of weight;

- asbestos-cement pipes are allowed to be used only when the temperature of the flue gases going outside will not exceed 300 degrees.

Mounting

To install a brick chimney, it is necessary to prepare the foundation. In the process of performing work, the following rules must be observed:

- For laying it is necessary to use a solution, which includes lime and sand.

- The cross section of the chimney must be done with a small margin.

- If the structure is mounted in a wall, then it should be anchored every 30 cm in a checkerboard pattern. Anchors should be inserted into the wall no more than 20 cm, and reinforcement should be selected with a diameter of 10 mm.

- To increase the stability of the chimney, it is required to reinforce the masonry and ventilation risers every 3 rows with reinforcement 6 mm thick.

- Open areas of the chimney must be insulated with mineral wool.

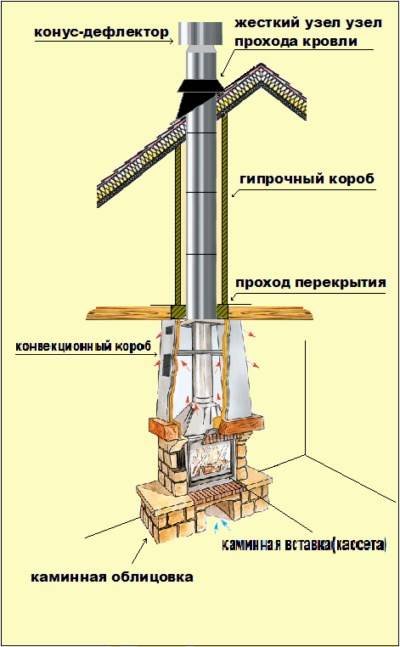

When installing a stainless steel chimney, a metal screen is installed above the fireplace, and the pipes themselves must be insulated for fire safety. The best option is to use sandwich pipes, they do not need to be insulated. Ceramic pipes must be mounted on a reinforced platform.

In the ceiling or roof, whether in a private house or in a public building, holes are cut 25-50 cm larger than the pipe. This must be done to equip the fire belt, which will protect the ceiling and roofing elements from possible fire.

When installing pipes from factory elements, they should be assembled according to the designer's scheme. It is necessary that the joints are airtight, and the elements are fixed to each other and attached to the foundation and at the junction points of the ceiling and roof.

Chimneys for brick fireplaces

It is believed that the chimney system is only made with high quality when there is no smell of smoke in the room where the hearth is located, and the firewood in the firebox lights up immediately. If a brick fireplace pipe is installed in a private household, a chimney is usually built, which is combined into a single structure with a ventilation riser. For masonry, red full-bodied ceramic bricks are used.

When building a smoke exhaust structure, it is necessary to adhere to a number of rules:

- To lay out the masonry, you need to use a lime-sand mixture.

- When the chimney system is inserted into the wall, regardless of what material it is lined with, it is questioned. At the same time, they adhere to a 30-centimeter step, the anchors are inserted into the walls, adhering to a checkerboard pattern, to a depth of 20 centimeters, using reinforcement with a cross section of 1 centimeter.

- To increase the stability of the masonry of the ventilation riser and chimney, it must be reinforced every third row with class A1 fittings with a 6 mm cross section.

Disadvantages of brick structures

The chimney for a brick fireplace has disadvantages, the main of which is considered to be a short service life of such structures, which does not exceed 7 to 10 years. The fact is that frequent and significant temperature drops in the cold season lead to the appearance of condensate, and it either freezes or thaws. As a result, over time, brickwork begins to collapse.

To reduce the impact of negative moments, you can:

- expand the cross section of the external chimney walls up to 25 centimeters in those places where they are above the roof surface;

- insulate these sections of the chimney with mineral plates.

The chimney will last longer if you install a cap on top of it, which will protect against precipitation.

One of the significant disadvantages of brick chimney structures is the presence of a rough inner surface, since this circumstance leads to a decrease in draft efficiency compared to smooth pipe walls.

Making a simple chimney

This variety is very easy to implement. Such a device does not have an otter and fluff.

- In order for the structure to be as strong and stable as possible, it is necessary to first make a frame, which can be knocked down from simple wooden bars;

- It is fixed and fixed directly at the level of the ceiling;

- Sheets of metal are used for sealing;

- Protective aprons must be laid out in a ditch, having previously bent them;

- All edges and cracks are treated with sealant;

- The inner channel is plastered and rubbed. The surface should be as smooth as possible;

- Masonry is carried out according to the standard scheme without extensions.

You can view photos of chimneys from the side of the facade and the house, as well as detailed diagrams of examples, in this article.

Fireplace Chimney Design Basics

At the stage of creating a chimney project and during further preparatory work for construction, it is necessary to choose the right material with which it will be built. Moreover, you need to know exactly how this device will be heated. There are cases when installed pipes and connections in the chimney of the fireplace are found not designed to function with the type of fuel purchased, as a result of which it is necessary to urgently change either the type of fuel or dismantle unsuitable pipes or other components.

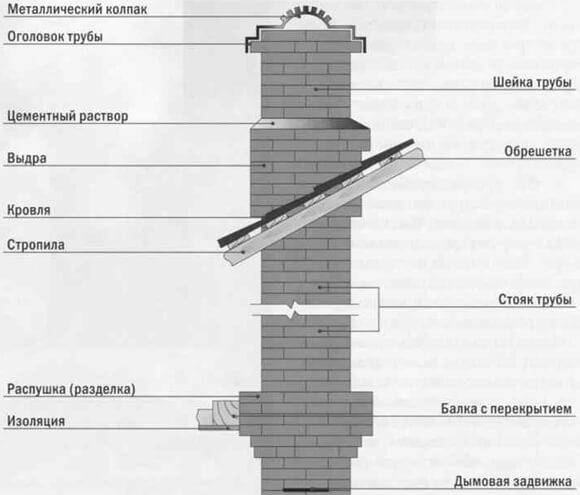

Fireplace chimney: 1 - Effective part of the height; 2 - Headrest height; 3 - Cutting; 4 - Overlap; 5 - Sandy backfill.

A common example is brick fireplace chimneys, which work great with wood fuels, but are completely unsuitable when using gas sources of heat.

The important point is how correctly you choose the height and diameter of the chimney. Incorrect selection of any of these parameters will affect the efficiency of the heating system, reducing it to the minimum mark, this can lead to poor results.

Is there a real possibility to build a universal chimney?

As already mentioned, the fundamental basis for any pipe is the material with which it is made.Some manufacturers offer potential customers modern chimney systems, which in their numerous advertisements they call universal, able to work in all weather conditions and, surprisingly, with any of the existing types of fuel. Experts can say with confidence that there are no such systems. Of course, it is not ruled out that individual chimney systems are able to work well in different variations of connections and with various types of fuel. However, here it must be understood that if the device works well under such conditions, this will not mean at all that it is qualitatively different from an ordinary fireplace chimney.

Installation: recommendations and diagrams, the main stages of the installation of the chimney

The installation of the chimney is divided into several stages - this is the preparatory work, the installation itself, then the connection, start-up and, if necessary, debugging of the entire system.

General requirements

When combining several heat generating installations, a separate chimney is created for each of them. In exceptional cases, a tie-in to a common chimney is allowed, but at the same time, a difference in height of at least one meter must be observed.

First, the parameters of the chimney are designed and calculated, which are based on the recommendations of the manufacturers of gas boilers.

When summarizing the calculated result, the inner section of the pipe cannot be less than the diameter of the boiler outlet pipe. And according to the check according to NPB-98 (fire safety standards), the initial speed of the natural gas flow should be 6-10 m / s. And besides, the cross section of such a channel must correspond to the overall performance of the unit (8 cm2 per 1 kW of power).

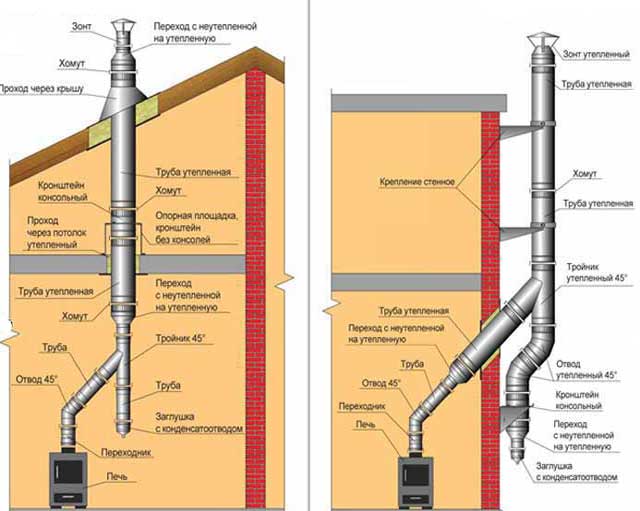

Installation steps

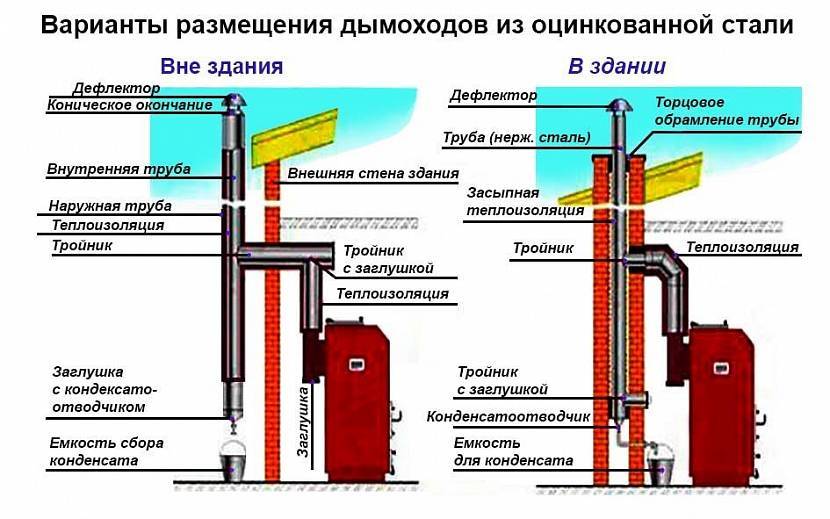

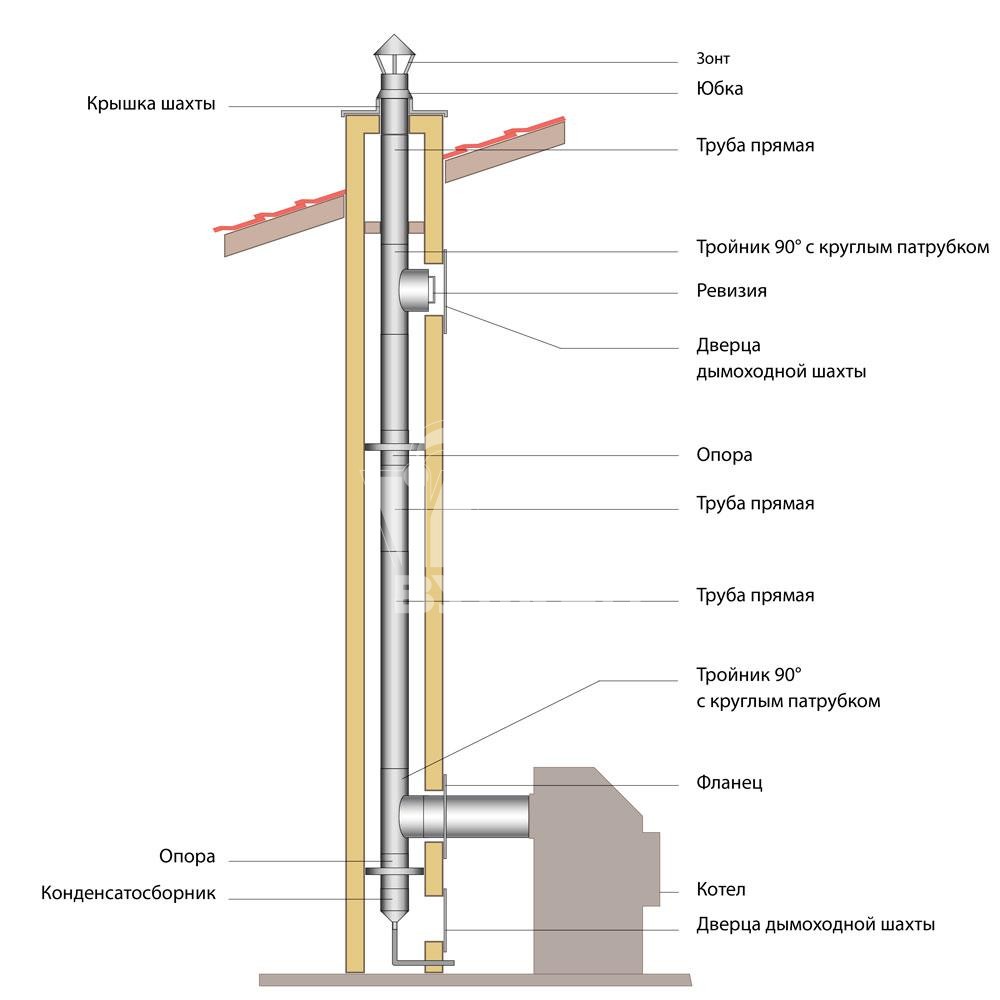

Chimneys for gas boilers are mounted outside (add-on system) and inside the building. The simplest is the installation of the outer pipe.

Installation of an external chimney

Installing a chimney at a wall-mounted boiler is done as follows:

- A hole is cut in the wall. Then a piece of pipe is inserted into it.

- A vertical riser is assembled.

- The joints are sealed with a refractory mixture.

- Fixed with wall brackets.

- An umbrella is attached to the top to protect it from rain.

- An anti-corrosion coating is applied if the pipe is made of metal.

Proper installation of the chimney guarantees its impermeability, good draft, and prevents soot from accumulating. Installation performed by specialists will significantly reduce the cost of maintaining this system.

In the case of arranging an opening for a pipe in the roof of a house, special boxes with aprons are used. In this case, the design as a whole is influenced by such factors as:

- The material from which the pipe is made.

- Exterior design of the chimney.

- Type of roofing.

The main factor influencing the choice of design is the temperature of the gas that passes through the pipe. At the same time, according to the standards, the distance between the chimney pipe and combustible materials must be at least 150 mm. The most advanced is the assembly system by segments, where all elements are assembled by cold forming.

Video description

How the chimney pipe is installed, see the following video:

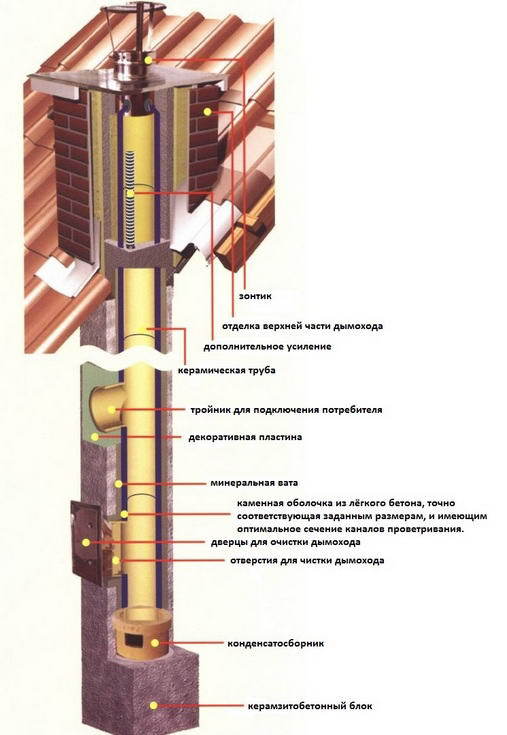

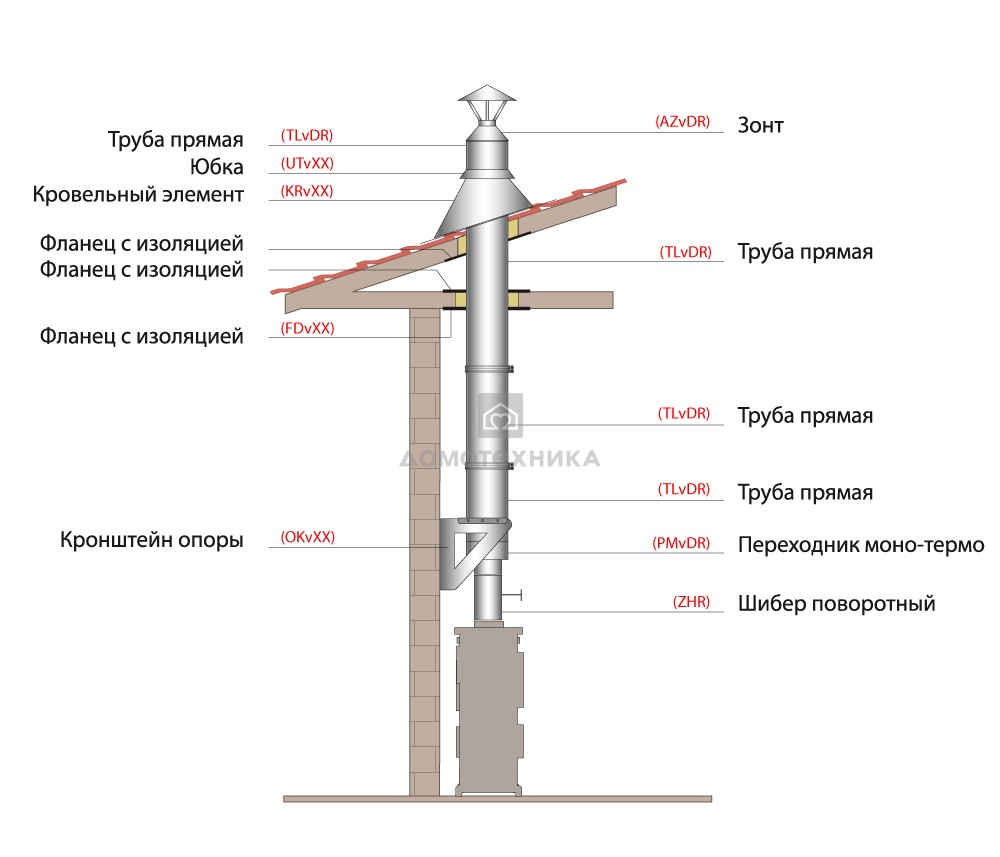

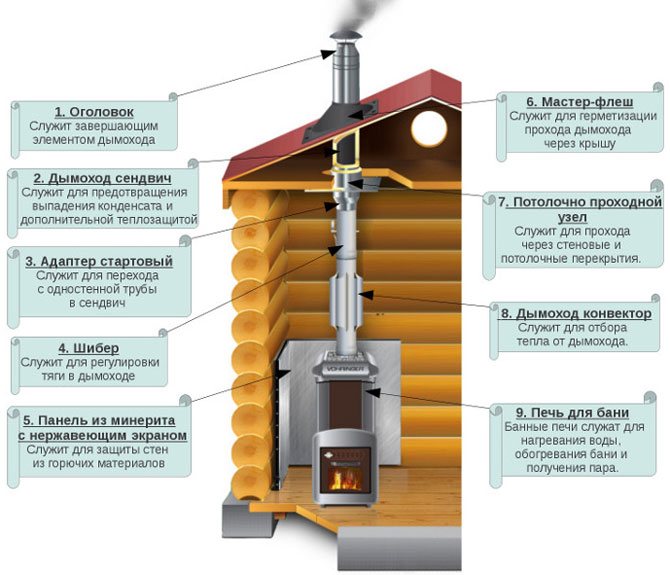

Connecting a ceramic chimney

Ceramic chimneys themselves are almost eternal, but since this is a rather fragile material, you need to clearly imagine how the connection (docking) of the metal part of the chimney and the ceramic one is correctly performed.

Docking can only be done in two ways:

By smoke - a metal pipe is inserted into a ceramic

It is important to remember here that the outer diameter of the metal pipe should be smaller than that of the ceramic one. Since the thermal expansion of the metal is much greater than that of ceramics, otherwise the steel pipe, when heated, will simply break the ceramic one.

For condensate - a metal pipe is put on a ceramic one.

For both methods, specialists use special adapters, which, on the one hand, are equipped with a gasket for contact with a metal pipe, and on the other, which contacts directly with the chimney, are wrapped with a ceramic cord.

Docking should be carried out through a single-wall pipe - it has a higher heat transfer coefficient. This means that the smoke will have time to cool down a little before it reaches the adapter, which ultimately extends the life of all materials.

Video description

Read more about connecting to a ceramic chimney in the following video:

VDPO shows great requirements for chimneys for gas boilers, because of this, it must be installed by specialized teams. Since competent installation guarantees not only long-term operation of the device, but also makes living conditions in a private house safe.

Performing installation work

Installing a chimney in a house can be done not only with the help of a master, but also with your own hands, however, the first thing to do is to choose the appropriate type of chimney hood, taking into account the type of heating boiler, its functionality, type of fuel and other parameters.

Do-it-yourself installation of chimneys, the price of which depends on the chosen type and materials of manufacture, also implies whether you are going to build a brick or steel chimney. A brick chimney is often installed for similar stoves and fireplaces made of brick, while steel and other systems are often connected to modern fireboxes and innovative boiler equipment.

If it is necessary to use fuel such as firewood, coal or peat to work and kindle your heating unit, it is quite possible to do with assembling a brick chimney with your own hands. If the system is more modern, capable of heating to the highest possible temperatures, and liquid-based fuel or gas is used for operation, the brick surface of the chimney hood simply cannot be corrected and will begin to crack, in this case, give preference to a ceramic or modular chimney.

A turnkey chimney for classic solid fuel stoves and fireplaces is often assembled from brick, as it can be made in the wall of the house a special box or the so-called shaft. However, in order for such a hood to function correctly and at full capacity, the chimney must be in a strictly vertical position and have ventilation ducts and special doors through which soot can be removed throughout its length.

A brick chimney, the price of which is quite high due to complex installation, is often plastered inside, but this must be done with high quality so that the plaster does not begin to fall off during subsequent work and exposure to high temperatures

Plastering the chimney inside will not allow a large amount of soot and other combustion products to accumulate on the surface, it is also important that the design is made in the shape of a cone and does not differ in complexity and intricacy

In order to decide and choose a chimney of suitable length, section for your stove, fireplace or boiler, it is necessary to take into account such indicators as the area of \u200b\u200bthe house and the power of the heating unit. If we take into account the existing norms and requirements for construction, remember that one outlet channel should be about five meters long, but not more than six.

The installation of gas chimneys or ventilation made of stainless steel also requires a special and competent approach, although such a design is assembled according to the principle of a designer, however, in order for you to get a high-quality hood at the end, it is important to adhere to the existing plan and the designated sequence of work

In modern model hoods and chimneys made of stainless steel, heating is carried out strictly in the direction from below and gradually rises upwards, in this case, special attention must be paid to the quality of the joining of each element that is inserted into the previous one, if necessary, the edges of the joints must be sealed with a special heat-resistant substance.a stainless chimney should not just be inserted into one another, but joined and fixed with special clamps, while all joints and joints of such an exhaust structure should be in your field of vision and in no case be masked in walls, ceilings and other objects

a stainless chimney should not just be inserted into one another, but joined and fixed with special clamps, while all joints and joints of such an exhaust structure should be in your field of vision and in no case be masked in walls, ceilings and other objects.

The chimney, for which stainless steel is chosen as the main material of manufacture, should not be tightly connected to the bracket itself, in this case, experts recommend leaving a little margin of about 1-2 centimeters between them, since the bracket may undergo slight expansions when heated.

It is strictly forbidden for gas-fired boiler equipment to come into contact with any other communications located in the house, as this may result in a fire or explosion.

Regulatory requirements for the installation of chimneys

The main and only purpose of the chimney is to remove exhaust gases from the heating boiler into the atmosphere outside the building where the stove, boiler or fireplace is installed. At the same time, the efficiency of the heat-generating equipment directly depends on its proper installation.

You can put a boiler in the house with excellent efficiency, but make miscalculations when installing the chimney. The result is excessive fuel consumption and lack of comfortable air temperatures in the rooms.The chimney must have the correct section, location, configuration and height.

If the house has two boilers or a stove and a fireplace in different rooms, then it is better to make separate smoke exhaust pipes for each of them. The option with one chimney is allowed by SNiPs, but only a professional stove-maker can correctly calculate it.

The diameter of the chimney is selected depending on the heating equipment used. When installing the boiler, it is already set by the manufacturer with a drain pipe. It is forbidden to connect pipes of a smaller section to it, and it is simply not necessary to connect a larger one. In the second case, to increase traction, you will have to mount a gearbox, which costs a lot of money.

In the case of a fireplace or a Russian brick oven, everything is somewhat more complicated. Here you will have to make engineering calculations, taking into account the fuel used and the size of the furnace. It is much easier to take a ready-made brick oven project that has been tested by time. Fortunately, there are many options with a well-defined order of brickwork.

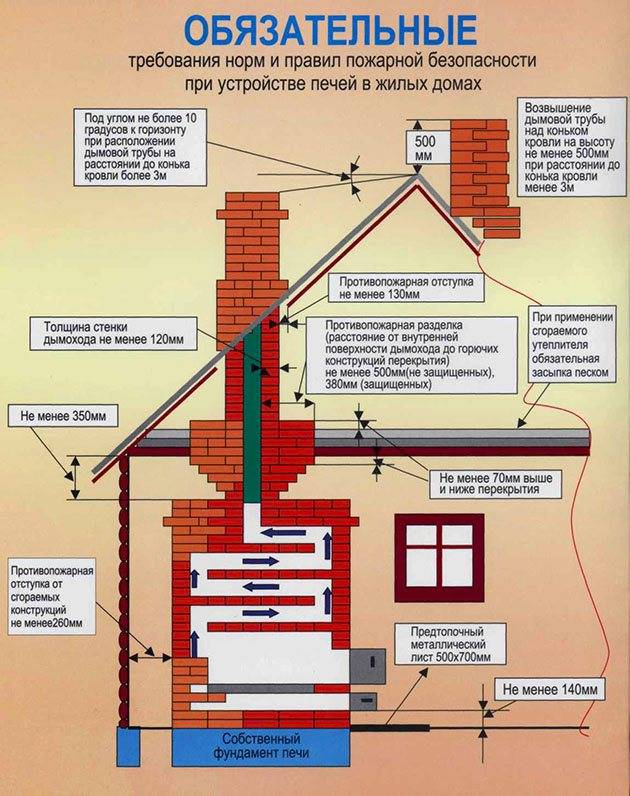

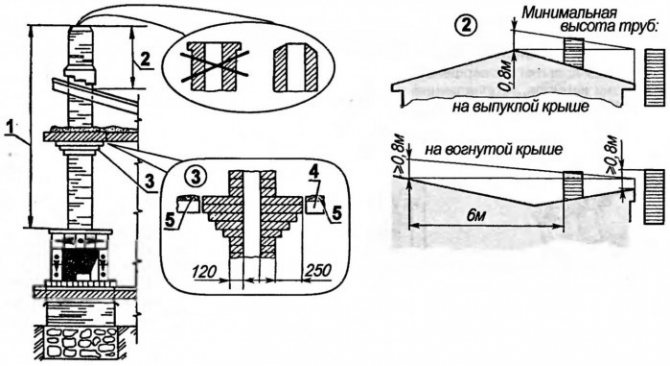

The height of the chimney pipe above the roof is determined by its distance from the roof ridge

The higher and longer the chimney, the stronger the draft. However, this can lead to overheating and destruction of its walls. Plus, a strong increase in draft is a prerequisite for the occurrence of turbulence in the chimney, which is accompanied by a hum and low-frequency noise.

If the pipe is too low, the ridge can turn into an insurmountable obstacle to the smoke coming out of it. As a result, a reverse draft effect will occur with the flue gases tipping back into the furnace. How to normalize it will be discussed in this material.

During normal operation of the chimney, the horizontal wind flow, flowing around the section of the pipe above the roof, turns up. As a result, rarefied air is formed above it, which literally “sucks” smoke from the exhaust. However, the ridge of a pitched roof and even a tall tree in the immediate vicinity of the house can interfere with this process.

Norms for the installation of a smoke exhaust system

Building codes prescribe the chimney to be done as follows:

- Its length from the grate to the top point should be from 5 meters (an exception is possible only for buildings without attics and only under conditions of stable forced draft).

- The optimal height, taking into account all possible bends, is 5–6 m.

- The distance from a metal chimney to structures made of combustible building materials should be from a meter.

- The horizontal outlet immediately behind the boiler must not exceed 1 m.

- When passing roofing, walls and ceilings inside the house, a channel made of non-combustible materials should be equipped.

- To connect the metal elements of the pipe, the sealant should be used exclusively heat-resistant with a working temperature of 1000 ° C.

- The chimney must rise at least 50 cm above the flat roof.

- If a non-brick chimney is built 1.5 meters or more above the roof level, then it must be strengthened without fail with stretch marks and brackets.

Any slopes and horizontal sections will inevitably reduce the draft in the chimney pipe. If it is impossible to make it straight, then bends and displacements are best done from several inclined segments at a total angle of up to 45 degrees.

In addition to observing purely building rules that guarantee the high efficiency of the chimney and stove, it is also necessary to take care of fire safety, for which special indents and screens are made

When arranging ventilation and chimney shafts in parallel in one structure above the roof, in no case should they be covered with a common cap. The outlet from the stove must necessarily rise above the ventilation pipe, otherwise the draft will decrease, and the smoke will begin to be sucked back into the house. The same applies to individual, but adjacent hoods and chimneys.

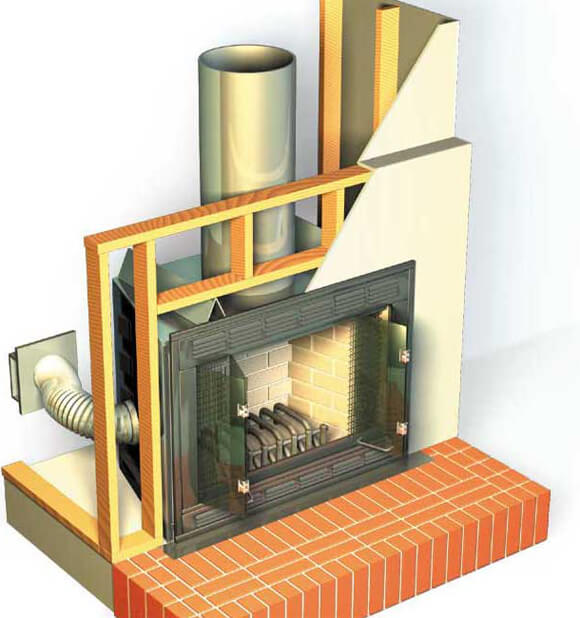

Boiler structures and chimney outlet

Structurally, a gas boiler is a device consisting of a gas burner, to which gas is supplied through the nozzles, and a heat exchanger, which is heated by the energy obtained during the combustion of gas. The gas burner is located in the combustion chamber. The movement of heat occurs with the help of a circulation pump.

In addition, modern types of gas boilers are equipped with various self-diagnosis and automation modules that allow the equipment to be used offline.

When choosing a chimney, pay attention to the type of combustion chamber of the boiler. It is from its design that the method of taking in the air necessary for the combustion of gas will depend, and as a result, the optimal type of chimney

Different types of chimneys are suitable for different types of combustion chamber

The combustion chamber for gas boilers is of two types:

- open - provides natural traction. The air is taken from the room where the heating equipment is installed. The removal of combustion products is carried out by means of natural draft using a chimney with an exit through the roof;

- closed - provides forced draft. The intake of air for combustion of fuel occurs from the street. In rare cases, air can be taken from a special room equipped with forced ventilation. For the simultaneous removal of flue gases and intake of fresh air, a coaxial type chimney is used, which is led out through the nearest load-bearing wall.

Knowing the type of combustion chamber, you can easily select or make a chimney that is suitable for the design. In the first case, when the boiler is equipped with an open combustion chamber, a conventional thin-walled or insulated chimney is used.

For boilers with a closed combustion chamber, a coaxial chimney is used, which is a structure consisting of pipes of different diameters. A pipe with a smaller cross section is fixed inside a pipe with a larger diameter by means of special racks. Through the inner channel, carbon dioxide and other combustion products are removed, and through the gap between the outer and inner pipes, fresh air enters the closed combustion chamber.

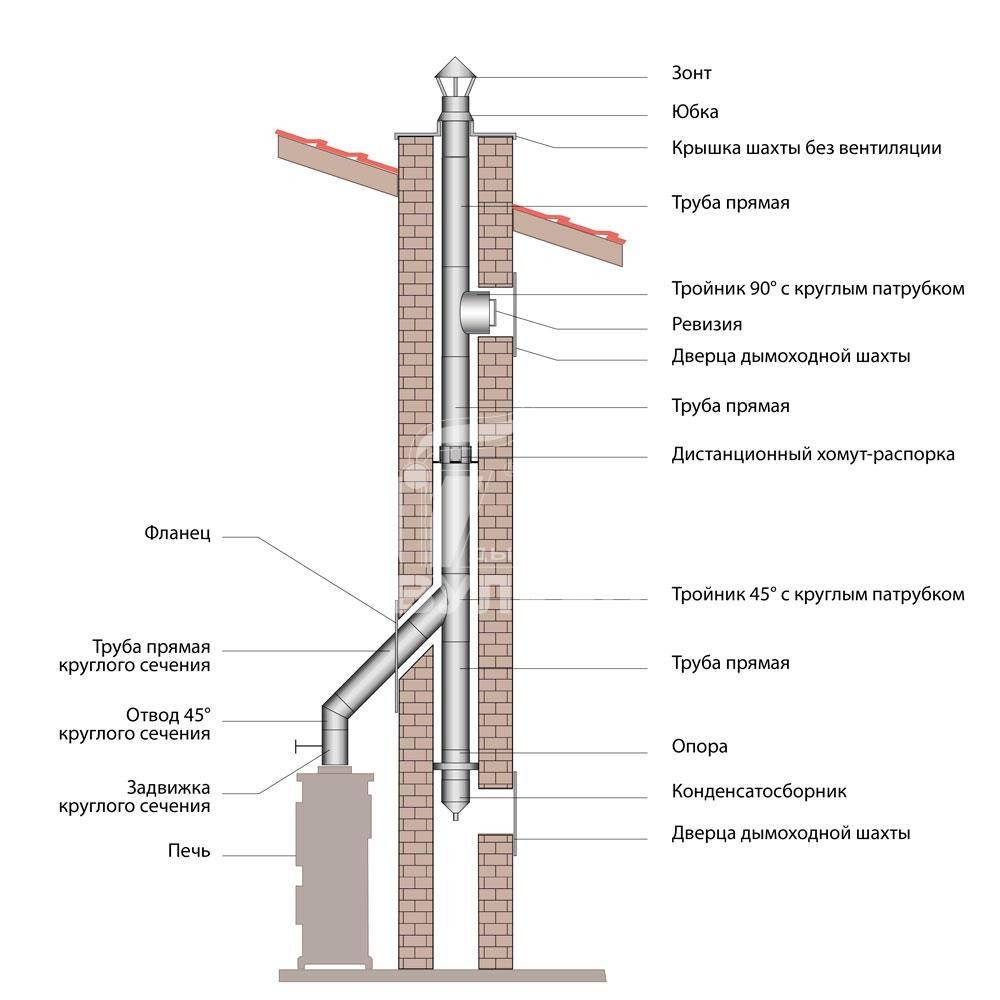

Methods for installing chimneys

According to the method of installation, chimneys are divided into:

- internal - chimneys made of metal, brick or ceramics. They are both single-walled and insulated double-walled structures. Arranged vertically upwards. Perhaps the presence of several knees with an offset of 30o;

- outdoor - coaxial or sandwich chimneys. They are also located vertically upwards, but the chimney is brought out horizontally through the load-bearing wall. After the pipe is removed, a 90° swivel elbow and support brackets are installed to allow installation in the desired direction.

The chimney can be led outside through the wall in the immediate vicinity of the boiler or in the traditional way through the roof

When choosing a chimney device, the dimensions of the building in which the equipment is located should be taken into account. For small buildings, it is more advisable to use external chimneys, as they allow you to bring the chimney outside the room.

In other cases, one should build on personal capabilities. If space permits and it is possible to perform high-quality insulation in the places where the pipe passes through the floors, then an internal chimney will be the best solution. Especially if the structure is lined with brick or protected by a ceramic box.