- Types of chimneys depending on the material

- Steel pipe chimney

- Prefabricated elements for a steel chimney of gas equipment

- Conditions for the arrangement of smoke channels for gas boilers in accordance with SNiP

- Natural and forced ventilation of the boiler room

- Gas chimneys

- What materials are suitable for gas chimneys?

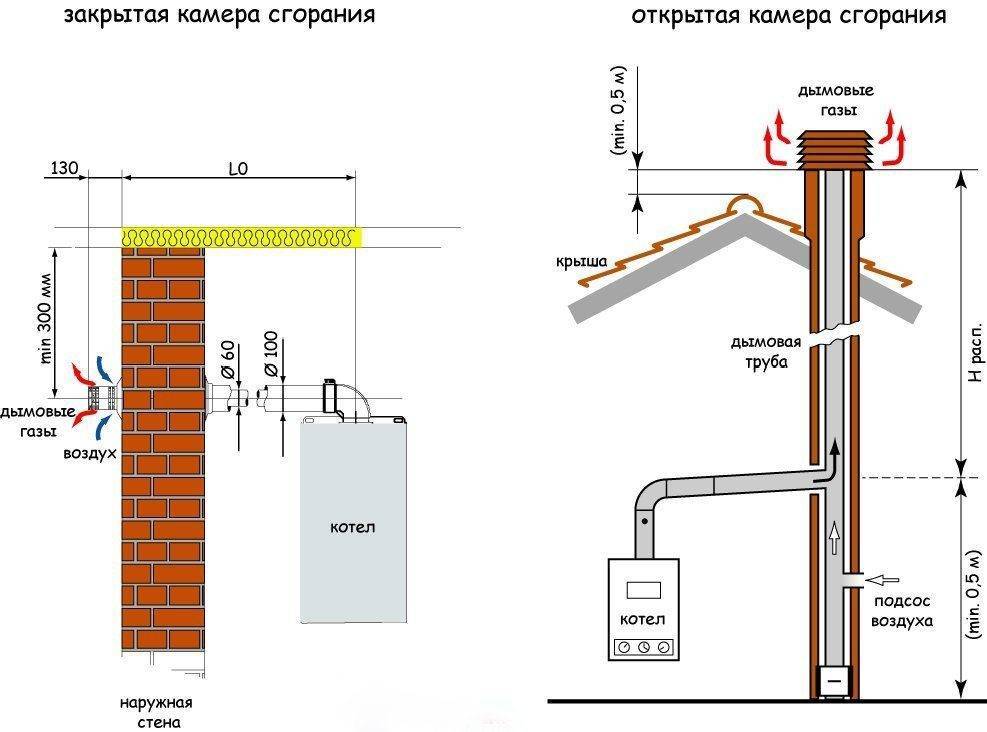

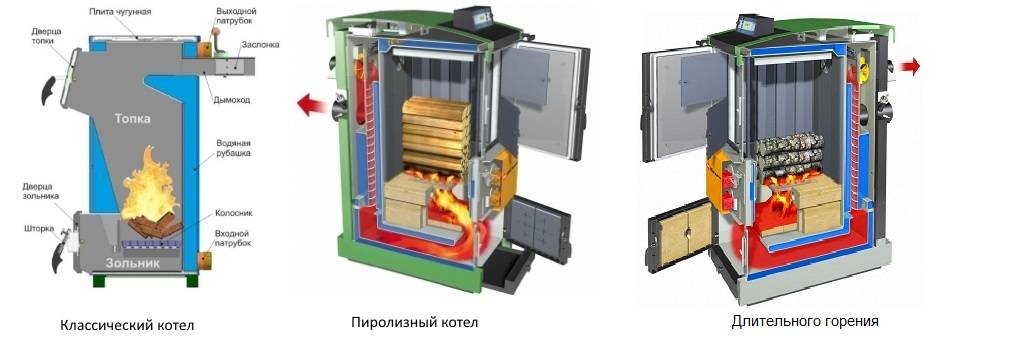

- Does the type of boiler affect the choice of chimney?

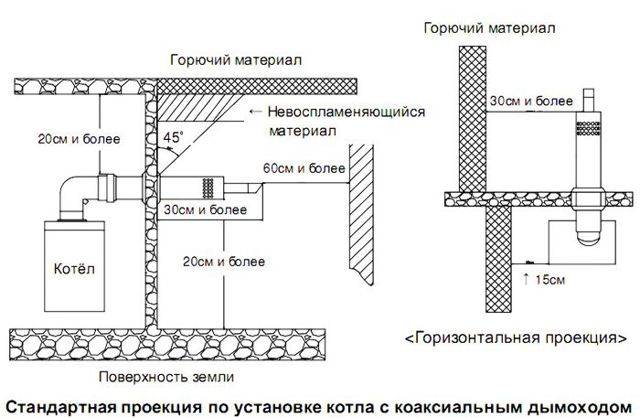

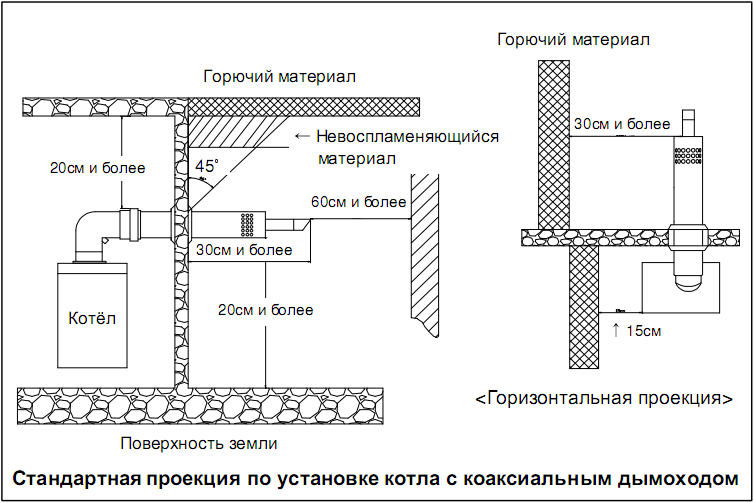

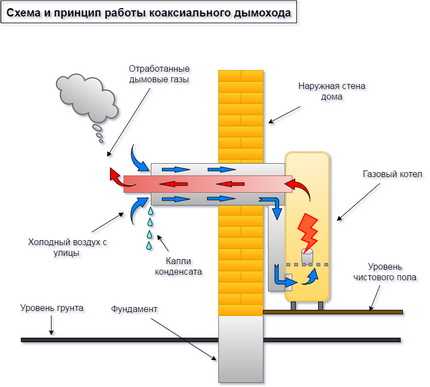

- How to install a coaxial chimney?

- Is it possible to change the chimney?

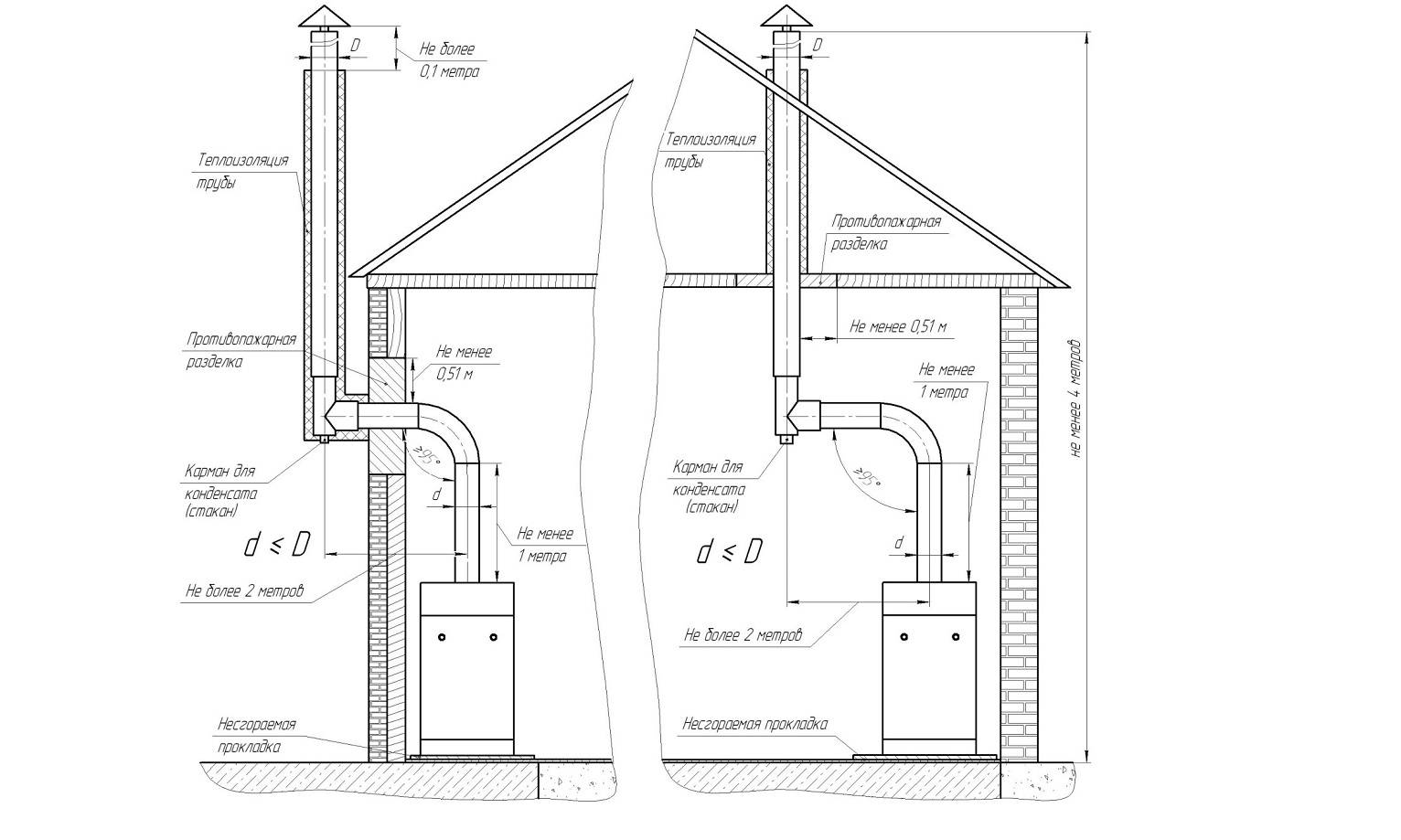

- Mounting Features

- Installing a sandwich chimney

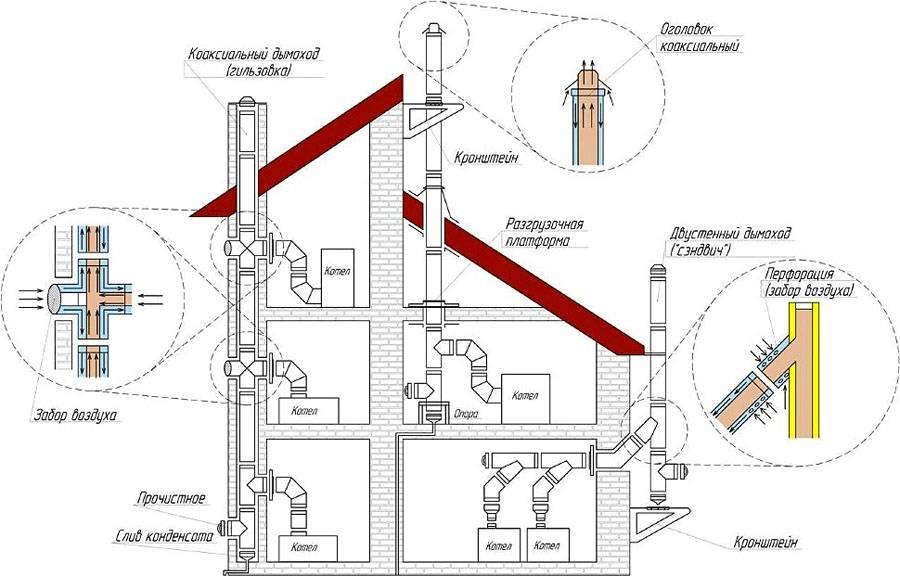

- Chimney for several boilers

- Installation Requirements

- We install a chimney with our own hands

- Pipe slope

- What is unique about coaxial design?

- Principle of operation

- Requirements for the material for the manufacture of chimneys

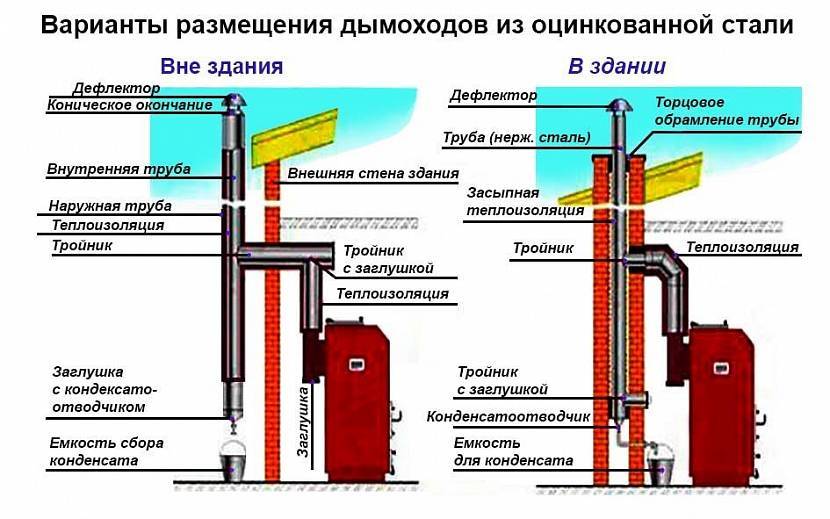

- Options for gas ducts for a country house

- Selection Guide

- Chimney of solid fuel boiler

- The installation of a chimney can be considered using the example of a double-circuit design

- Conclusion

Types of chimneys depending on the material

Brick chimney is used very rarely nowadays. For the device of such a pipe, the construction of a supporting foundation is required. The brick eventually undergoes destruction from the inside and can pass a certain amount of gases.

Brick chimney is used very rarely nowadays. For the device of such a pipe, the construction of a supporting foundation is required. The brick eventually undergoes destruction from the inside and can pass a certain amount of gases.

For some interiors, a decorative brick chimney is used, but a stainless steel pipe is laid inside. The operation of a mixed chimney is actually quite effective.

Steel pipe chimney

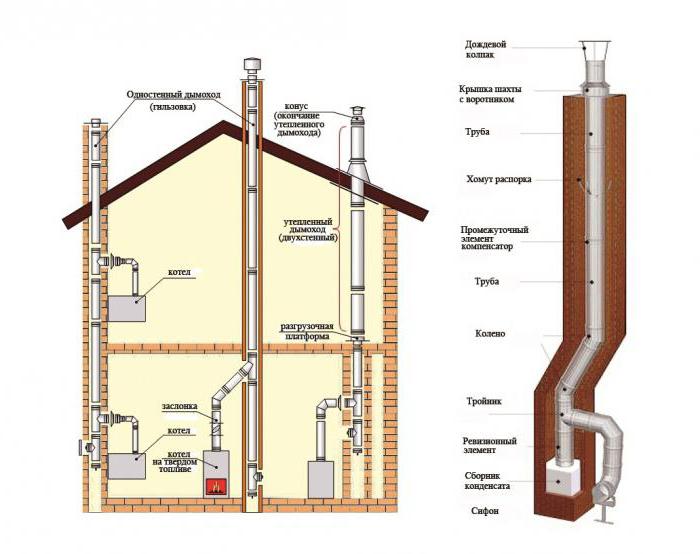

- The single pipe is used for insertion into a masonry structure, for repair work or for a temporary test installation.

- A double-walled pipe or sandwich is very often used for a chimney. Its principle is based on the work of pipes of large and small sizes, nested one inside the other. The gap between their walls is filled with insulation, which prevents condensation from forming on the walls of the chimney.

- The coaxial version of the chimney is used in those heating systems when combustion requires air supply and smoke outflow at the same time. Chimneys designed for double action have two pipes, as in a double-walled version, only the space between their walls is not filled with insulation, but serves to move fresh air. Smoke is removed along the inner diameter.

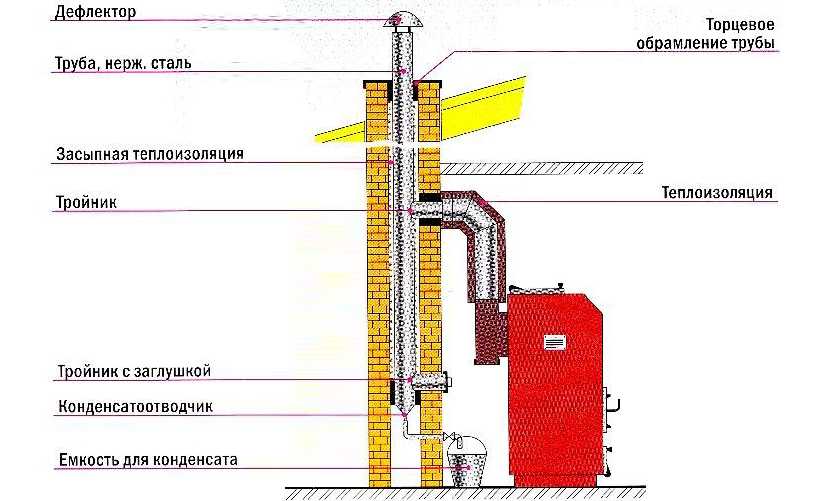

Prefabricated elements for a steel chimney of gas equipment

- Couplings for connecting the outlet of a gas boiler and a pipe.

- The main pipes, produced for ease of installation, are 1 m long.

- A tee for cleaning and checking for clogging of the pipe, installed in a horizontal section.

- Condensate collection tee, mounted at the point where the chimney turns into a vertical position.

- Corners for turning pipes from a gas boiler.

- Compensator for softening the linear expansion of the chimney when the temperature changes.

- Node for designing the channel exit through the overlap.

Conditions for the arrangement of smoke channels for gas boilers in accordance with SNiP

A separate chimney should be provided for each gas appliance. As an exception, it is allowed to connect two boilers to the same smoke extraction system. But this can be done with an interval of 0.75 m from the previous tie-in.

Ensure mandatory sealing of pipes and their connections to prevent leakage of carbon monoxide into the interior of the house.

Perform all measures to remove condensate from the pipes. In order to prevent its formation, it is recommended to insulate the outer sections of the pipes.

The internal cavity of the chimney must be free of obstructions, dirt and soot throughout. All pollution leads to a decrease in traction.

The size of the pipe cannot be less than the size of the outlet from the gas boiler, the same width or more is allowed. A round section of the pipe is considered ideal, sometimes a rectangular or square one is possible.

It is not recommended to put various umbrellas and visors on the top of the chimney on the roof. All of these devices reduce thrust and can cause reverse thrust under certain weather conditions.

Natural and forced ventilation of the boiler room

According to the method of updating the airspace, natural and artificial (or forced) ventilation are distinguished.

Natural ventilation operates without the use of fans, its efficiency is due solely to natural draft, and, consequently, weather conditions. Two aspects affect the pull force: the height of the exhaust column and the temperature difference between the room and the street. At the same time, the air temperature in the street must necessarily be lower than that in the room. If this condition is not met, reverse draft occurs and ventilation of the boiler room is not ensured.

Forced ventilation provides for the installation of additional exhaust fans.

Usually these types are combined into one exhaust system of the boiler room.

When calculating it, it is important to take into account that the air drawn out to the street should be equal in volume to the air injected into the room. To ensure that this condition is met, check valves are installed.

Gas chimneys

What materials are suitable for gas chimneys?

Due to the characteristics of the chemical composition of the smoke that appears during the combustion of gas, the main requirement for the material is resistance to chemical aggressive environments and corrosion. Thus, there are the following types of gas chimneys:

1. Stainless steel. The best option. Their advantages are light weight, resistance to various corrosions, excellent traction, operation up to 15 years.

2. Made of galvanized steel. Not the best option compared to stainless steel. Provides poor traction, more prone to corrosion. Operation no more than 5 years.

3. Ceramics. Gaining popularity. Operation up to 30 years. However, the high weight of the chimney must be taken into account when laying the foundation. The maximum thrust is only possible with vertical installation without errors.

4. Coaxial chimney. It has increased efficiency and safety, but at the same time a high price. It is a pipe within a pipe. One is for smoke removal, the other is for air supply.

5. Brick chimney. Shows negative qualities when using gas heating. Operation is short. It is permissible to use a brick chimney left over from stove heating only as an outer casing for an insert made of a more suitable material.

6. Asbestos cement. Outdated variant.Of the positive aspects - only low price.

There are a lot of options for holding a gas chimney. When choosing a material, it is worth starting from its quality characteristics. Do not save on your health and the safety of your loved ones.

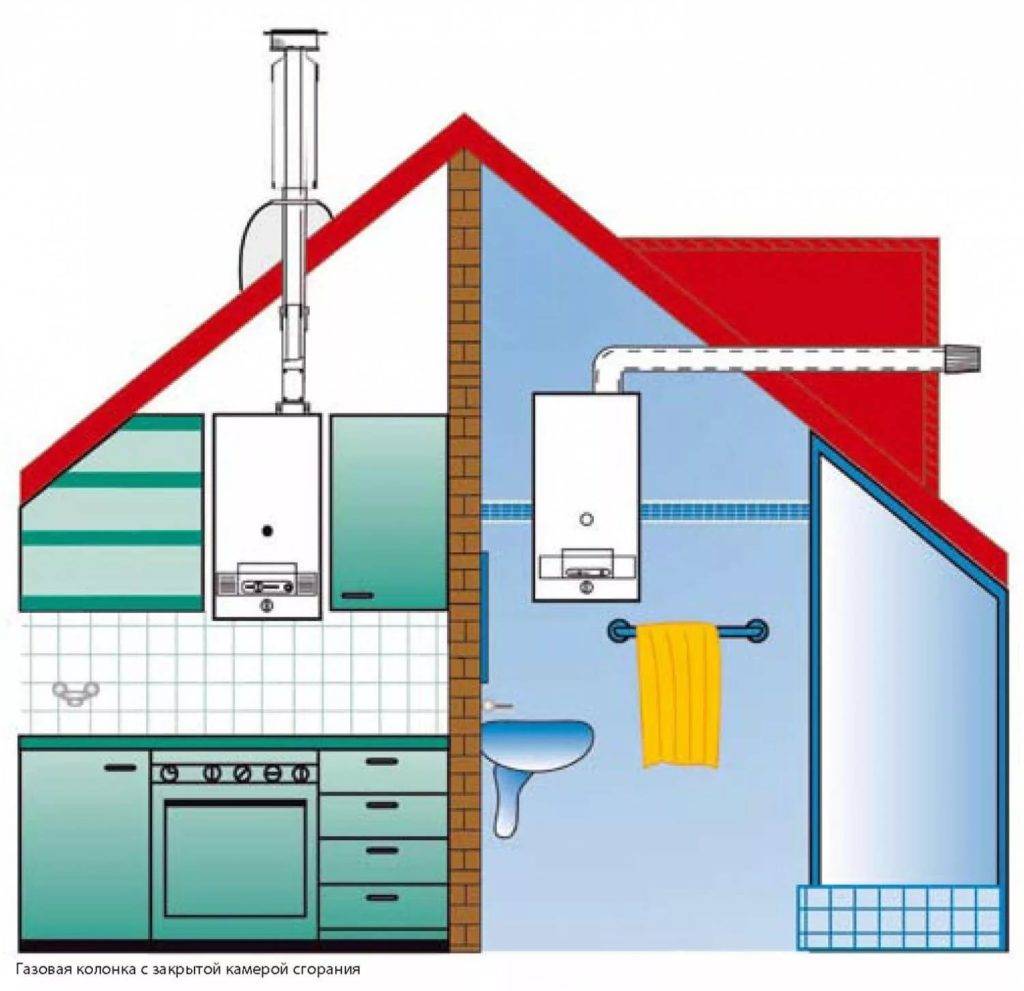

Does the type of boiler affect the choice of chimney?

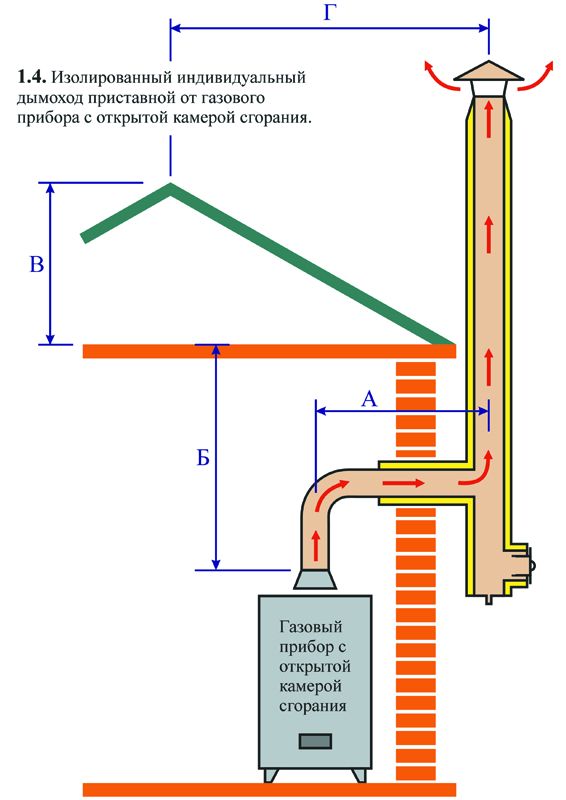

The design of the chimney depends entirely on which boiler will be used - closed or open type. This dependence is explained by the different principle of operation of the boilers.

The open type is a burner with a heat carrier coil located on it. Air is needed to operate. Such a boiler requires the best possible traction.

Installation is carried out:

- Outside way. When conducting a chimney, you can use the external installation method by bringing a straight horizontal pipe through the wall, and then lifting it up to the required height. This method requires a high-quality heat-insulating layer.

- In an internal way. It is possible to pass the pipe internally through all the partitions. In this case, 2 slopes of 30° are acceptable.

The closed type is a chamber with a nozzle where air is injected. The blower blows the smoke into the chimney. In this case, the best solution would be to choose a coaxial chimney.

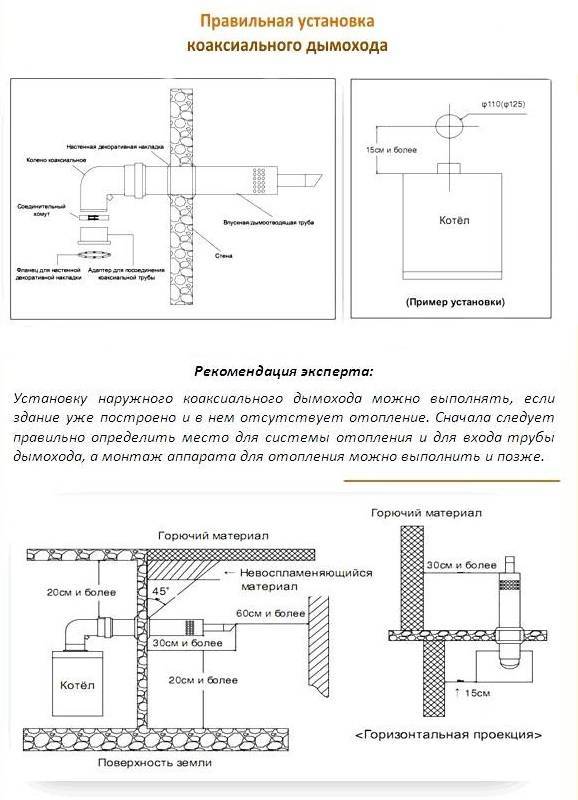

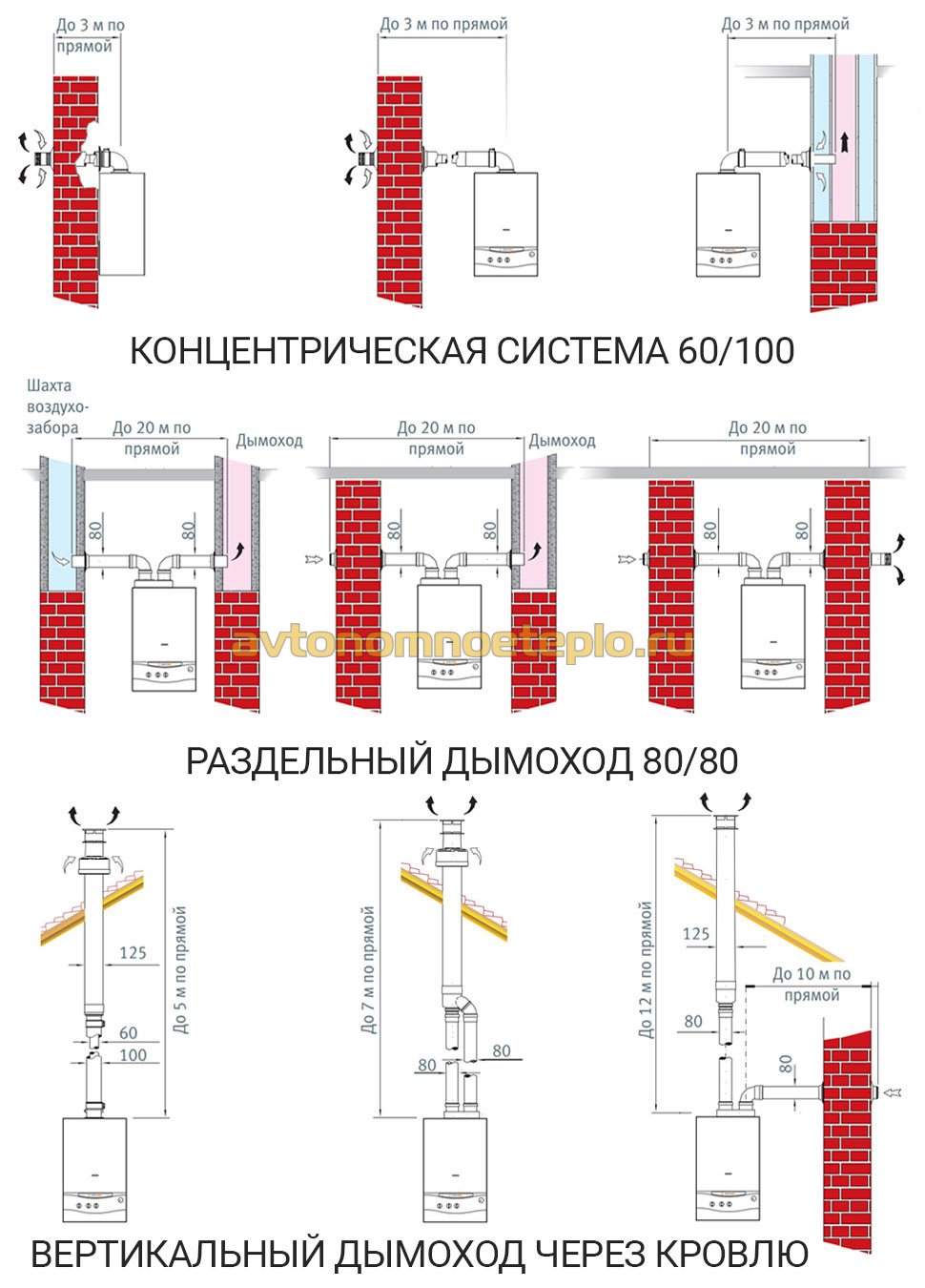

How to install a coaxial chimney?

The main positive characteristics of this type of chimney are:

- Easy installation;

- Safety;

- Compactness;

- By heating the incoming air, it cools the smoke.

Installation of such a chimney is permissible both in a vertical position and in a horizontal one. In the latter case, a slope of no more than 5% is required to protect the boiler from condensate. It should be borne in mind that the total length should not be more than 4 m.For installation, you will need to purchase special adapters and umbrellas.

Is it possible to change the chimney?

Often there are cases when the owner decides to switch from solid fuel to gas. Gas equipment requires a suitable chimney. But do not completely rebuild the chimney. It is enough to sleeve it in one of the ways:

1) Use of a stainless steel pipe. A stainless steel pipe of suitable length is installed inside the existing chimney. Its diameter must be no less than the boiler pipe, and the distance between the pipe and the chimney is filled with insulation.

2. Furanflex technology is more expensive, but more durable. An elastic pipe under pressure is installed in the chimney, where it takes shape and hardens. Its advantages are in a seamless surface that provides complete tightness.

Thus, you can significantly save on materials, while complying with all regulatory requirements.

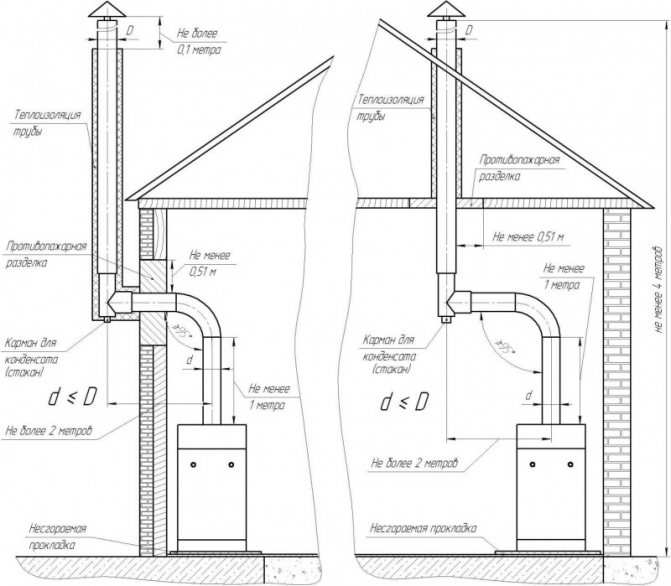

Mounting Features

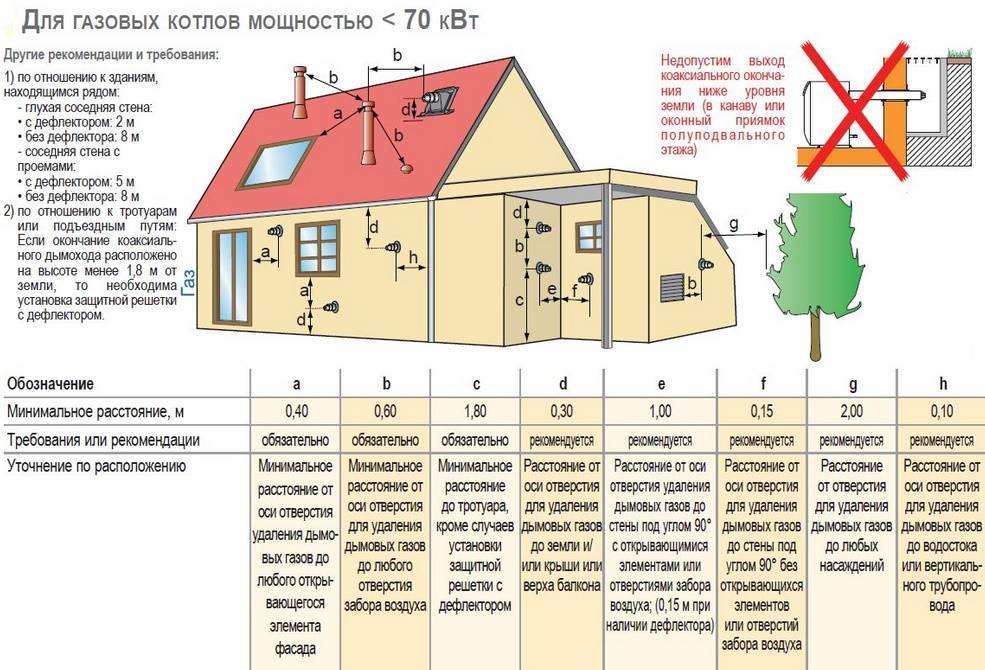

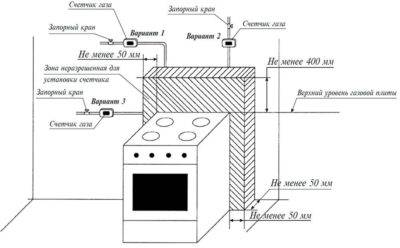

There are a number of stringent requirements that must be met when installing a smoke exhaust system. These include the location of the chimney in the room relative to internal structures. Let's summarize the data in a table:

Table 1. Distances for laying smoke channels of gas boilers through the outer wall of the house (without creating a vertical channel)

| Location of outlet | The smallest distances, m | |||

| to natural draft boiler | to boiler with fan | |||

| Equipment power | Equipment power | |||

| up to 7.5 kW | 7.5–30 kW | up to 12 kW | 12–30 kW | |

| Under the vent | 2,5 | 2,5 | 2,5 | 2,5 |

| Near the vent | 0,6 | 1,5 | 0,3 | 0,6 |

| Under the window | 0,25 | — | — | — |

| Next to the window | 0,25 | 0,5 | 0,25 | 0,5 |

| Above a window or vent | 0,25 | 0,25 | 0,25 | 0,25 |

| above ground level | 0,5 | 2,2 | 2,2 | 2,2 |

| Under parts of the building protruding more than 0.4 m | 2,0 | 3,0 | 1,5 | 3,0 |

| Under building parts protruding less than 0.4 m | 0,3 | 1,5 | 0,3 | 0,3 |

| Under another branch | 2,5 | 2,5 | 2,5 | 2,5 |

| Next to another outlet | 1,5 | 1,5 |

A distinctive feature of gas-fired boilers is their high efficiency. Therefore, the temperature of the outgoing gases is low, condensate forms quickly, and the system must be installed taking into account the reduction of the harmful effects of condensate on the pipe walls.

All joints must be strictly sealed.

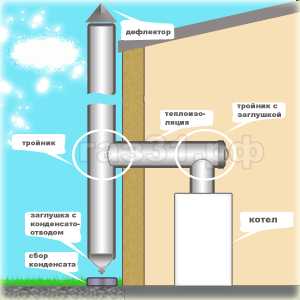

Installing a sandwich chimney

The first stage of mounting the attached structure is to punch a hole in the outer wall and prepare for laying a horizontal section. In a house built from combustible materials, the opening is made taking into account the fire indent (38 cm from the edge of the wooden wall to the inner pipe of the sandwich) and the installation of the flange of the passage assembly, as shown in the photo.

Work on the installation of a modular sandwich and connection to a gas boiler is carried out in the following sequence:

- Assemble the lower part of the attached chimney, including 2 tees and a condensate drain section. Attach a horizontal section extending into the hole.

- Try on the assembly to the wall and determine the mounting location of the support platform. Fix it and install the lower part by leading the pipe into the wall. Observe the vertical, controlling the position of the node with a building level.

- After fixing the lower part of the flue, mount the vertical section. Connect the straight sections in such a way that the upper shell is put on the lower one, and the flue pipe, on the contrary, is inserted inside (assembly "by condensate").

- Fasten the wall-mounted chimney channel at intervals of no more than 2.5 m. The brackets should not fall on the joints of the sections.

- Lay the horizontal section of the sandwich up to the gas boiler and put on the adapter. Fasten the chimney with clamps to building structures with a maximum spacing of 1.5 m.

- Connect the heat generator to the chimney with a piece of single-walled stainless pipe.

Straight sections are simply inserted into each other and fixed with clamps; it is not necessary to smear the joints with sealants. If trimming is necessary, then the lower end of the section is shortened, where the insulation is flush with the metal plates. A protective cone is mounted on the upper section of the chimney.

Detailing for interior installation

The laying of the smoke exhaust channel inside the building is carried out in a similar way, only you will have to go through the structures twice, or even three times. Everywhere the same rules for the arrangement of cuttings are observed when crossing combustible ceilings and walls. At the end, you need to carefully seal the roof at the place where the pipe passes, as is done in the video:

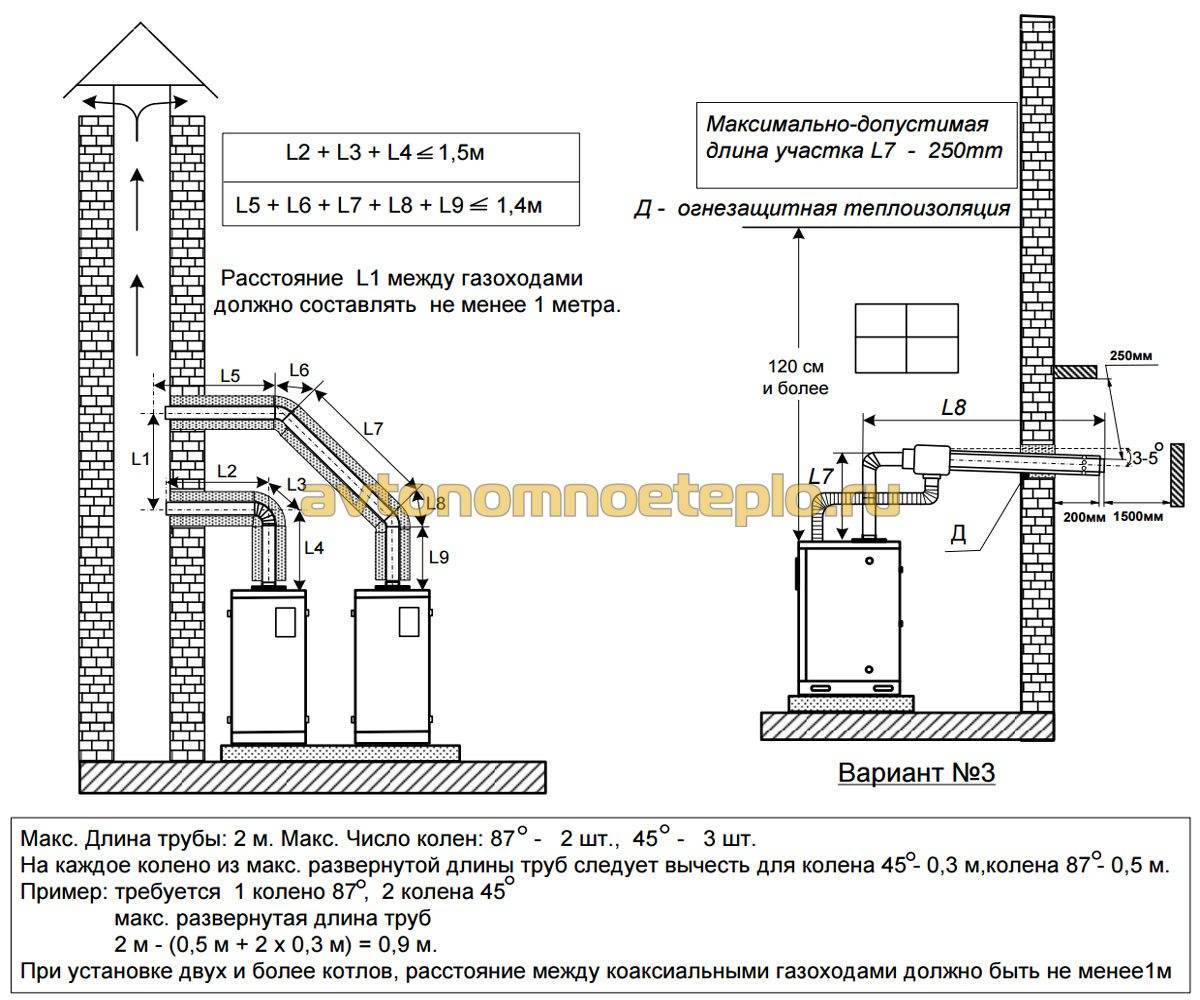

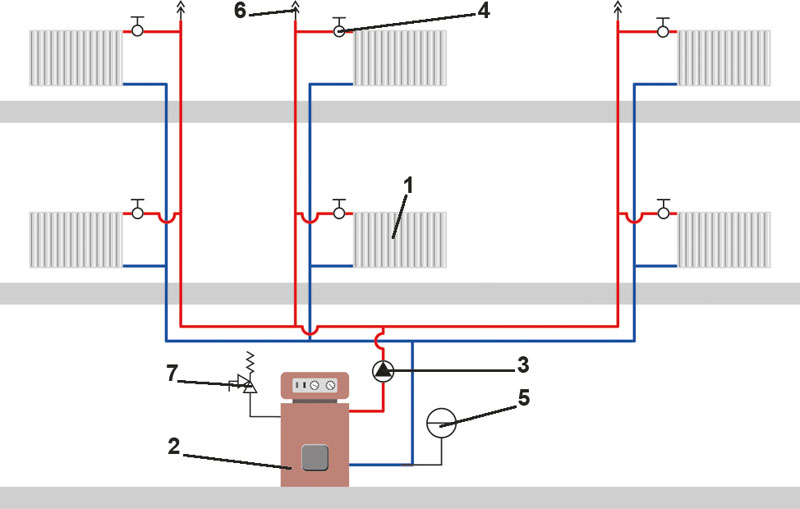

Chimney for several boilers

Naturally, the construction of several chimneys will be more expensive, but you should not ignore the requirements of SNiP and risk your own safety for the sake of this savings. If the house has not only a heating boiler, but also other heating equipment, then the following rules must be taken into account:

- No more than 2 heating devices can be connected to one chimney.

- Moreover, the holes for the output of combustion products for these devices must be located at different levels.

- The entrances to the chimney must be at a distance of more than 0.5 meters from each other.

- The entry of combustion products from two gas appliances at the same level is possible only when there is a dissecting insert installed in the chimney.

- Moreover, the height of the parallel entrances to the chimney equipped with a divider must be at least 1 m.

- During the organization of the chimney, you should not choose porous materials with a low density. The pipeline must not cross living rooms.

- It is also prohibited to install these structures on glazed balconies. In rooms through which the pipeline passes, it is necessary to organize good ventilation.

- The chimneys of boilers that process gas into thermal energy most often have a shell-type design.

Taking into account the plug-in scheme, the channel is mounted on the floor slab of the heating device itself. But it is possible to connect to wall chimneys using nozzles no larger than 35 cm. When connected to a wall chimney, there must be a gap of at least 15 cm between the combustible ceiling and the bottom of the nozzle. A distance of at least 0.5 meters must be arranged between the combustible ceiling and the top of the nozzle.

There are differences in the arrangement of sections of intersection of chimney pipes between non-combustible and combustible structures. The passage of the pipeline through a non-combustible structure must be provided with a mounting support.

Installation Requirements

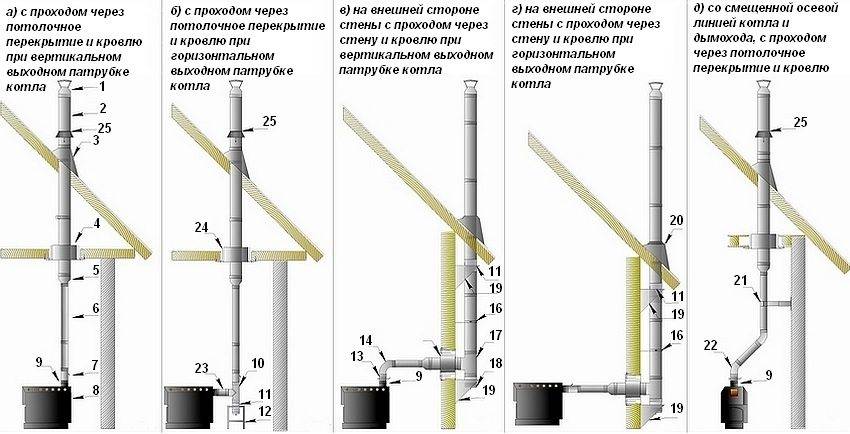

Types of installation:

- Horizontal. Mounted when passing through the wall.

- Vertical. Mounted when passing through the roof.

- General. It is used in apartment buildings with modular heating, several boilers are connected to one "riser".

Most often, horizontal installation is carried out along the shortest path to the street. Curves are added as needed when using 45° and 90° turns. It is worth remembering that as the chimney becomes more complex, the hydrodynamic resistance of the chimney increases. Each 90° turn in resistance is equal to 1 meter of pipe, 45° - 0.5 meters.

Photo 4.Scheme of a horizontal installation of a coaxial chimney. The structure should be at a slight slope.

When passing through the roof, an additional node for passing through the ceilings and the roof, as well as a deflector cap and a condensate trap, will be required.

The specification for the boiler must indicate the necessary requirements for the chimney. They must be observed, as otherwise the heating efficiency may deteriorate. As a rule, the length does not exceed 3 meters. When designing, be aware of the increased resistance of corners and bends.

With horizontal placement, the slope towards the street must be observed. This is necessary so that the resulting condensate drains and does not enter the boiler. Recommended parameter: 1 cm per meter of chimney.

From the boiler to the passage of the wall, it is better to ensure a distance of 50 cm. The incoming air will warm up and there will be no icing of the pipes inside the room.

Inside the building, the distance to the ceiling is important: 35 cm. Outside, the distance from the ground is important - at least 2.2 meters

From the end of the chimney to neighboring buildings there should be at least 60 cm, ideally at least 1.5 meters.

The exhaust must be quietly dispersed into the atmosphere.

The nearest windows and ventilation openings should be at a distance of 60 cm from the exit of combustion products.

The length of the part of the pipe protruding to the street is at least 30 cm.

Attention! Connection inside walls is not allowed! A solid section must pass through the wall. Warming in most cases is not required. When the pipe passes through the wall, the hole is filled with non-combustible insulation

When the pipe passes through the wall, the hole is filled with non-combustible insulation

Warming in most cases is not required. When the pipe passes through the wall, the hole is filled with non-combustible insulation.

We install a chimney with our own hands

We prepare the necessary tools: puncher, level, tape measure, pencil, Phillips screwdriver.

Before installing the boiler, be sure to lay the route for the passage of the chimney. The pipe should not rest against the wiring, communications.

Important! When designing, a slope towards the street of at least 1 cm per meter is required!

We assemble the chimney according to the manufacturer's instructions. To do this, we attach the inner part of the pipe to the adapter, then we put on the outer part through a flexible coupling. We clamp the connection with a plastic clamp.

Using a perforator, we make a hole in the wall 5-10 mm wider than the chimney pipe.

We put on a decorative sleeve, thread the chimney through a hole in the wall. We put on the boiler connector, fix the adapter with screws to the boiler. Be sure to check whether the chimney is tightly seated.

We fill the gap between the pipe and the wall with non-combustible insulation: basalt wool. Mounting foam should not be used - it may be difficult to dismantle or repair.

We press decorative extensions to the wall. They prevent the passage of steam into the insulation and remove the cold bridge. Extensions can be glued to the wall with silicone sealant.

Pipe slope

Horizontal chimneys can be mounted both with a slope towards the ground and towards the boiler. In the first case, the condensate will be discharged outside the low-rise building under the action of gravity and go into the soil. Thus, chimneys are usually installed in the southern regions of the country.

In the northern regions of Russia, it is impossible to install pipes in this way.In the winter season, the flowing condensate can form frost at the end of the chimney. At the same time, due to ice, air will stop flowing to the heating unit, which sooner or later will lead to its breakdown.

In the middle lane and in the north of the country, coaxial chimneys are still installed with a slope towards the boiler. In this case, it becomes necessary to use a condensate trap. Without it, moisture will begin to drain directly into the boiler, which, of course, will adversely affect its operation and service life.

In any case, wherever the pipe is directed - to the ground or to the boiler - its slope, according to the regulations, must be at least 3 °.

What is unique about coaxial design?

The concept of "coaxial" implies the presence of two objects inserted one into the other. Thus, a coaxial chimney is a double-circuit structure of pipes of various diameters, located one inside the other. There are jumpers inside the device that prevent parts from touching. The equipment is installed in heat generators equipped with closed combustion chambers. These include, for example, gas boilers.

The coaxial chimney is designed in such a way that the inner pipe is designed to remove combustion products into the atmosphere. The larger outer diameter is used to supply fresh air for combustion.

Thanks to the special design of a standard coaxial chimney, it performs two functions at once: it creates an uninterrupted supply of air necessary to ensure the combustion process, and removes combustion products to the outside. The length of the device most often does not exceed two meters. It is mainly intended for horizontal placement and is displayed outside through the wall.Less commonly, you can find a structure that is brought out through the ceiling and roof.

The special design of the coaxial chimney allows it to operate on a completely different principle from a conventional device. The oxygen necessary for combustion enters the boiler from the outside. Thus, there is no need to provide a constant supply of fresh air into the room by ventilation, which is inevitable for traditional smoke ducts. In addition, a number of problems typical of standard chimneys are successfully solved:

- Reduced heat loss by heating the outside air from the internal hot smoke exhaust pipe, resulting in a higher system efficiency.

- Reducing the risk of fire in the areas of contact between flammable surfaces and the smoke duct, since the inner pipe, giving off heat to the outer one, is cooled to safe temperatures.

- The high efficiency of the system allows complete combustion of the fuel, so unburned particles are not released into the atmosphere and do not pollute it. A boiler equipped with a coaxial chimney is environmentally friendly.

- The combustion process, including the supply of oxygen and the removal of gases, takes place in a closed chamber. It is safer for people, since combustion products dangerous for them do not enter the room. Therefore, additional ventilation is not required.

- Save space due to the compact dimensions of the device.

- A wide range of chimneys designed for systems of various capacities.

Principle of operation

The principle of operation of duct ventilation

The equipment is an installation of exhaust or supply ventilation for processing air flows and supplying it to the boiler room.The device is a component of the heating system and is often connected to a central pipe. Air comes directly from the street or through the air duct. A complex system consists of metal boxes or pipes between which functional devices are mounted. The outer elements are weatherproof.

- A fan with a two-phase electric motor supplies air to the boiler room or to a common air duct.

- Filters purify the air, coarse types or electrostatic sedimentation method are used. Coarse elements are placed in front of fine filters, protect them from breakage and are easily replaced.

- Heating or cooling devices change the temperature of the incoming stream. Heat pumps, electric heaters or evaporators are used.

Balancing devices, shock absorption and noise isolation in the system eliminate vibration and reduce sound during operation. The vibrations are isolated and damped by obstacles, and the fan is placed on spring supports.

Requirements for the material for the manufacture of chimneys

The following requirements are imposed on the material for the manufacture of pipes intended for the removal of flue gases:

- resistance to high temperatures;

- high anti-corrosion qualities;

- chemical inertness.

Gas pipe

Gas pipe

Inside, on the walls of the chimney pipes, due to constant temperature changes, condensate constantly forms, in which there is an increased content of sulfuric acid.

Therefore, it is extremely important that the chimney material does not react chemically with acids, and also perfectly resists corrosion. When buying, you should also separately clarify that the thickness of the inner layer is at least 0.05 cm

Options for gas ducts for a country house

To discharge combustion products with a relatively low temperature (up to 120 ° C) emitted by gas boilers, the following types of chimneys are suitable:

- three-layer modular stainless steel sandwich with non-combustible insulation - basalt wool;

- a channel made of iron or asbestos-cement pipes, protected by thermal insulation;

- ceramic insulated systems such as Schiedel;

- brick block with a stainless steel pipe insert, covered from the outside with heat-insulating material;

- the same, with an internal polymer sleeve of the FuranFlex type.

Three-layer sandwich device for smoke removal

Let us explain why it is impossible to build a traditional brick chimney or put an ordinary steel pipe connected to a gas boiler. The exhaust gases contain water vapor, which is a product of the combustion of hydrocarbons. From contact with cold walls, moisture condenses out, then events develop as follows:

- Thanks to numerous pores, water penetrates into the building material. In metal chimneys, condensate flows down the walls.

- Since gas and other high-efficiency boilers (on diesel fuel and liquefied propane) operate periodically, frost has time to grab moisture, turning it into ice.

- Ice granules, increasing in size, peel the brick from the inside and out, gradually destroying the chimney.

- For the same reason, the walls of an uninsulated steel flue closer to the head are covered with ice. The passage diameter of the channel decreases.

Ordinary iron pipe insulated with non-combustible kaolin wool

Selection Guide

Since we initially undertook to install an inexpensive version of the chimney in a private house, suitable for do-it-yourself installation, we recommend using a stainless steel pipe sandwich. Installation of other types of pipes is associated with the following difficulties:

- Asbestos and thick-walled steel pipes are heavy, which complicates the work. In addition, the outer part will have to be sheathed with insulation and sheet metal. The cost and duration of construction will definitely exceed the assembly of a sandwich.

- Ceramic chimneys for gas boilers are the best choice if the developer has the means. Systems such as Schiedel UNI are reliable and durable, but too expensive and out of reach for the average homeowner.

- Stainless and polymer inserts are used for the reconstruction - lining of existing brick channels, previously built according to old projects. Specially fencing such a structure is unprofitable and pointless.

Flue variant with ceramic insert

A turbocharged gas boiler can also be connected to a conventional vertical chimney by organizing the supply of outside air through a separate pipe. The technical solution should be implemented when a gas duct has already been made in a private house, brought to the roof. In other cases, a coaxial pipe is mounted (shown in the photo) - this is the most economical and correct option.

Noteworthy is the last, cheapest way to build a chimney: make a sandwich for a gas boiler with your own hands. A stainless pipe is taken, wrapped in basalt wool of the required thickness and sheathed with galvanized roofing. The practical implementation of this solution is shown in the video:

Chimney of solid fuel boiler

The mode of operation of wood and coal heating units involves the release of hotter gases. The temperature of the combustion products reaches 200 ° C or more, the smoke channel warms up completely and the condensate practically does not freeze. But it is replaced by another hidden enemy - soot deposited on the inner walls. Periodically, it ignites, causing the pipe to heat up to 400-600 degrees.

Solid fuel boilers are suitable for the following types of chimneys:

- three-layer stainless steel (sandwich);

- single-wall pipe made of stainless or thick-walled (3 mm) black steel;

- ceramics.

Brick gas duct of rectangular section 270 x 140 mm is lined with an oval stainless pipe

It is contraindicated to put asbestos pipes on TT-boilers, stoves and fireplaces - they crack from high temperatures. A simple brick channel will work, but due to roughness it will become clogged with soot, so it is better to sleeve it with a stainless insert. Polymer sleeve FuranFlex will not work - the maximum operating temperature is only 250 ° C.

The installation of a chimney can be considered using the example of a double-circuit design

Chimneys for a gas boiler are being installed in the direction of the structure from the bottom up, that is, from the heating objects of the room towards the chimney. With this installation, the inner tube is put on the previous one, and the outer tube is inserted on the previous one.

All pipes are fastened to each other with clamps, and along the entire laying line, every 1.5–2 meters, brackets are installed to fix the pipe to a wall or other building element. A clamp is a special fastening element, with the help of which not only the parts are connected to each other, but also the tightness of the joints is ensured.

The laid sections of the structure in the horizontal direction up to 1 meter should not come into contact with elements that pass close to the communications. The working channels of the chimney are placed along the walls of buildings.

Be sure to install a bracket on the wall every 2 meters of the chimney, and the tee is attached using a support bracket. If it is necessary to fix the channel on a wooden wall, then the pipe is lined with non-combustible material, for example, asbestos.

When attaching to a concrete or brick wall, special aprons are used. Then we bring the end of the horizontal pipe through the wall and mount the tee necessary for the vertical pipe there. It is necessary to install the brackets on the wall after 2.5 m.

The next step is to mount, lift the vertical pipe and bring it out through the roof. The pipe is usually assembled on the ground and the mount for the brackets is prepared. The fully assembled volumetric pipe is difficult to install on the elbow.

To simplify, a hinge is used, which is made by welding pieces of sheet iron or cutting a pin. Typically, the vertical pipe is inserted into the tee pipe and secured with a pipe clamp. The hinge is attached to the knee in a similar way.

After raising the pipe in a vertical position, the pipe joints should be bolted where possible. Then you should unscrew the nuts of the bolts on which the hinge was fastened. Then we cut or knock out the bolts themselves.

Having selected the hinge, we attach the remaining bolts in the connection. After that, we stretch the remaining brackets. We first adjust the tension manually, then we fix the cable and adjust it with screws.

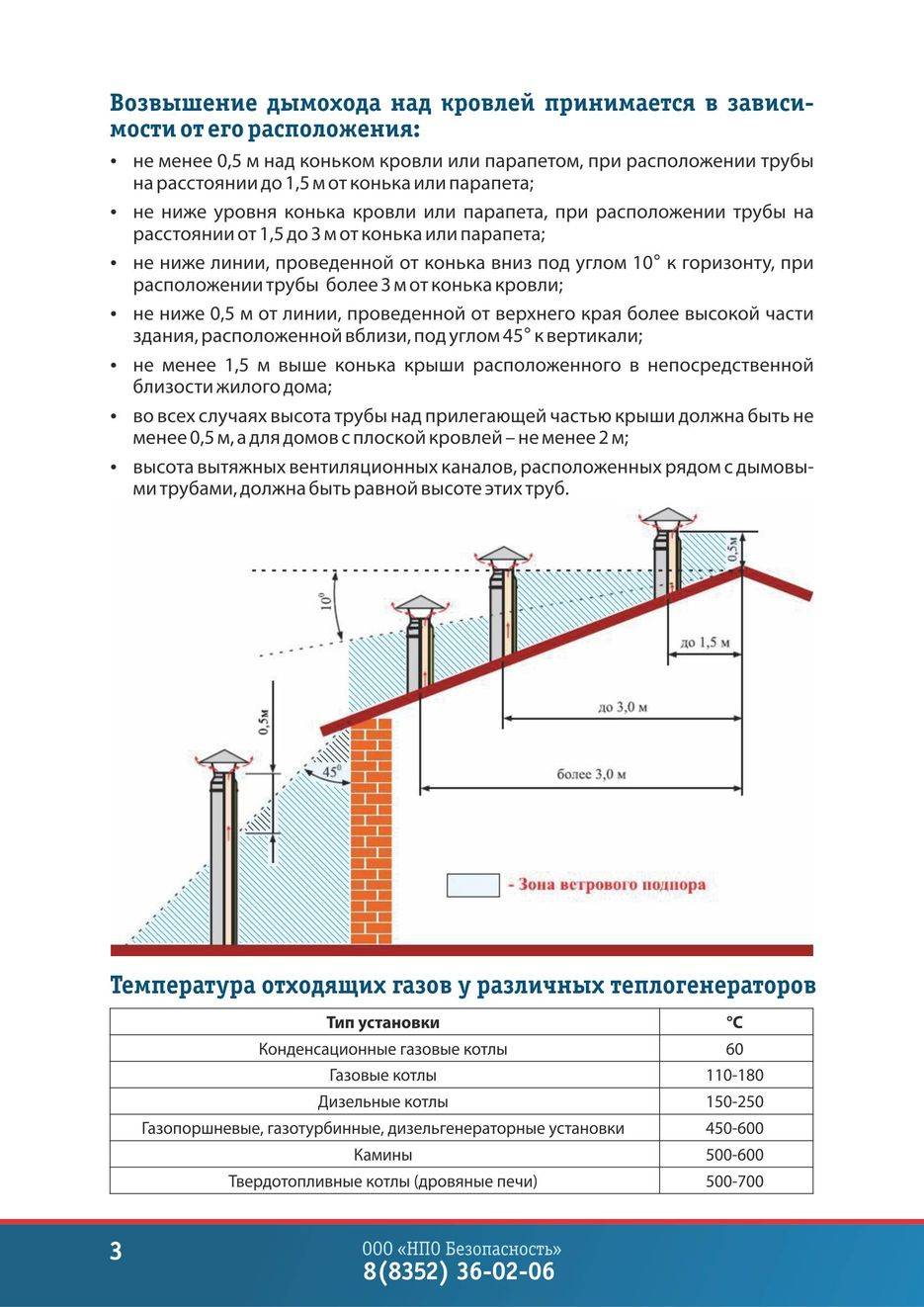

Necessary distances to be observed when the chimney is located outside

The installation is completed by checking the chimney draft. To do this, bring a burning piece of paper to the fireplace or stove. Draft is present when the flame is deflected towards the chimney.

The figure below shows the distances that must be observed in various options for the location of the chimney from the outside:

- when installed on a flat roof, the distance must not be less than 500 mm;

- if the pipe is removed from the roof ridge to a distance that is less than 1.5 meters, the height of the pipe must be at least 500 mm in relation to the ridge;

- if the chimney outlet installation is located at a distance of more than 3 meters from the roof ridge, then the height should not be more than the expected straight line.

The setting depends on the type of duct directions required for the combustion of the fuel. In the interior of the room, there are several types of directions for the chimney channel:

Support bracket for chimney

- direction with a rotation of 90 or 45 degrees;

- vertical direction;

- horizontal direction;

- direction with a slope (at an angle).

It is necessary to install support brackets for fixing the tees every 2 meters of the smoke channel, it is necessary to provide additional wall mounting. In no case, when installing a chimney, horizontal sections higher than 1 meter should not be created.

When installing chimneys, consider:

- the distance from metal and reinforced concrete beams to the inner surface of the chimney walls, which should not exceed 130 mm;

- the distance to many flammable structures is at least 380 mm;

- cuttings for non-combustible metals are made for the passage of smoke channels through the ceiling to the roof or through the wall;

- the distance from combustible structures to an uninsulated metal chimney must be at least 1 meter.

The connection of the chimney of a gas boiler is carried out on the basis of building codes and the manufacturer's instructions. The chimney requires cleaning up to four times a year (see How to Clean a Chimney).

In order to optimally calculate the height of the chimney, it is necessary to take into account the type of roof and the height of the building:

- the elevation of the chimney pipe must be at least 1 meter when installed on a flat roof and at least 0.5 meters above a non-flat one;

- the location of the chimney on the roof must be made at a distance of 1.5 meters from the ridge;

- the height of an ideal chimney has a height of at least 5 meters.

Conclusion

Of course, the chimney is not just a pipe, but one of the most important parts of the heating system. She is responsible for the safety of the residents of the house, for the absence of fire, for the microclimate in the building. Any violations in the chimney, even microcracks that are imperceptible at first glance, can lead to disaster. Carbon monoxide, sparks, smoke, back draft or weak draft indicate a violation of the chimney. In such cases, immediate action must be taken.

When designing and installing a chimney, you can handle it yourself. To do this, first of all, it is necessary to study the standards, documentation of the boiler, if any. Carry out preparatory work, purchase everything you need. But if you don’t have the skills to install a chimney, you should invite a specialist for a detailed consultation, even if you have confidence in your abilities. If there is the slightest uncertainty, it is better to hire an experienced team of craftsmen.