- The design of the stove-potbelly stove: features, principle of operation, device of heat exchangers

- Photo gallery: common types of heat exchangers

- Calculation of the main parameters of a potbelly stove with a water circuit

- Chimney for potbelly stove

- Material for the manufacture of the chimney

- Making a metal chimney for a potbelly stove

- Pipe installation

- Pipe Care

- warm brick

- Which is better to choose

- Drawing and diagrams

- Mounting Features

- Chimney Care

- Voting: what is the best modern stove-stove?

- Brunner IRON DOG

- Fixing the pipe

- Seam sealing

- Types of chimney pipes

- Fabrication and installation of the structure: how to make a chimney

- Phased installation of a chimney 100, 110 mm through the wall: how to calculate the diameter of the pipe

- Conclusion

The design of the stove-potbelly stove: features, principle of operation, device of heat exchangers

A potbelly stove with a water circuit works as follows:

- Firewood is loaded into the furnace.

- They kindle a fire, the heat is transferred directly to the water tank or to the heat exchanger coil.

- Hot water enters the heating or water supply system.

- Remains of heat and combustible gases are removed from the room through the chimney.

- The ashes fall through the grates into the ash pan.

In the design of the unit with a water circuit, two principles of energy collection are used:

-

Direct collection of thermal energy. The heat exchanger circuit is located inside the stove.From the contact of an open flame and the boiler tubes, heat transfer immediately begins. The water in the radiator boils and enters the heating system. From there it is sent to the water supply pipes. The heat exchanger experiences large temperature differences (contrast between water temperature and heat inside the oven).

-

Collecting the secondary radiation of the heater. The boiler circuit is located outside the heater. Being outside, it collects the secondary thermal radiation of a heated metal surface. The degree of heating of the heat exchanger is lower than in the previous case, temperature differences are not so significant. The water in the circuit of the device begins to heat up after heating the stove.

Photo gallery: common types of heat exchangers

Mineral salts form inside the boiler. Therefore, instead of water, it is more advisable to use antifreeze or antifreeze, which contain additives that prevent the formation of mineral deposits.

The most common designs of heat exchangers:

- a water tank built into the stove - a capacitive boiler;

- tube boiler - a tank in the form of a water jacket around a stove or chimney - a capacitive heat exchanger;

- main boilers - a coil of a coil or a conduit passing in the active heat transfer zone.

Calculation of the main parameters of a potbelly stove with a water circuit

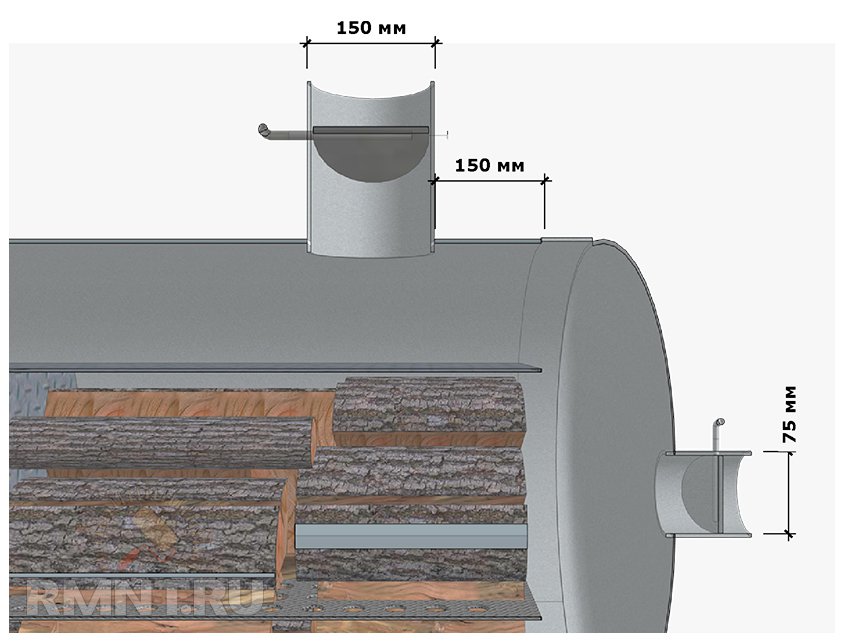

To calculate the dimensions of a stove with a water circuit, a drawing, drawing or sketch of a future device is required. This will help avoid manufacturing errors.

Having chosen a suitable project, we determine the parameters: length, height, width. We consider the dimensions of the furnace compartment, the length and diameter of the pipe, the height above the floor.

Potbelly stoves are characterized by high temperatures inside the boiler, therefore metal with a thickness of more than 3 mm should be used. Or once every 2-3 years to carry out scheduled repairs.

In the manufacture of potbelly stoves, thick-walled alloyed metal is used.

Chimney for potbelly stove

Material for the manufacture of the chimney

Before proceeding with the manufacture of the chimney pipe, which will be installed on the potbelly stove, it is necessary to determine the material that will be used.

Taking into account the fact that the potbelly stove is a portable stove, we immediately refuse brick chimneys. In this case, we have few options: either asbestos-cement or metal pipes. Most heating experts still recommend using metal chimneys: they are both lighter and easier to manufacture.

It is about them that we will talk in more detail.

Most heating experts still recommend the use of metal chimneys: they are both lighter and easier to manufacture. It is about them that we will talk in more detail.

Cast iron stove with steel chimney

Making a metal chimney for a potbelly stove

So, we decided on the material - we will make a chimney from a metal (stainless steel) pipe. However, it is not enough just to stick the chimney pipe into the corresponding hole in the potbelly stove - the chimney must be correctly installed and optimally located.

Potbelly stove on the street

As a rule, a simple chimney for a potbelly stove installed indoors consists of two parts - internal and external. These parts are connected in the attic or at the level of the roof space.

Such a "double-knee" design makes it relatively easy to replace the lower burned-out segment of the chimney without dismantling the entire system.

By the way, you can not buy steel pipes, but bend them from a steel sheet, but this will require certain skills from you. On the other hand, then you can make a pipe for a potbelly stove of exactly the diameter that you need.

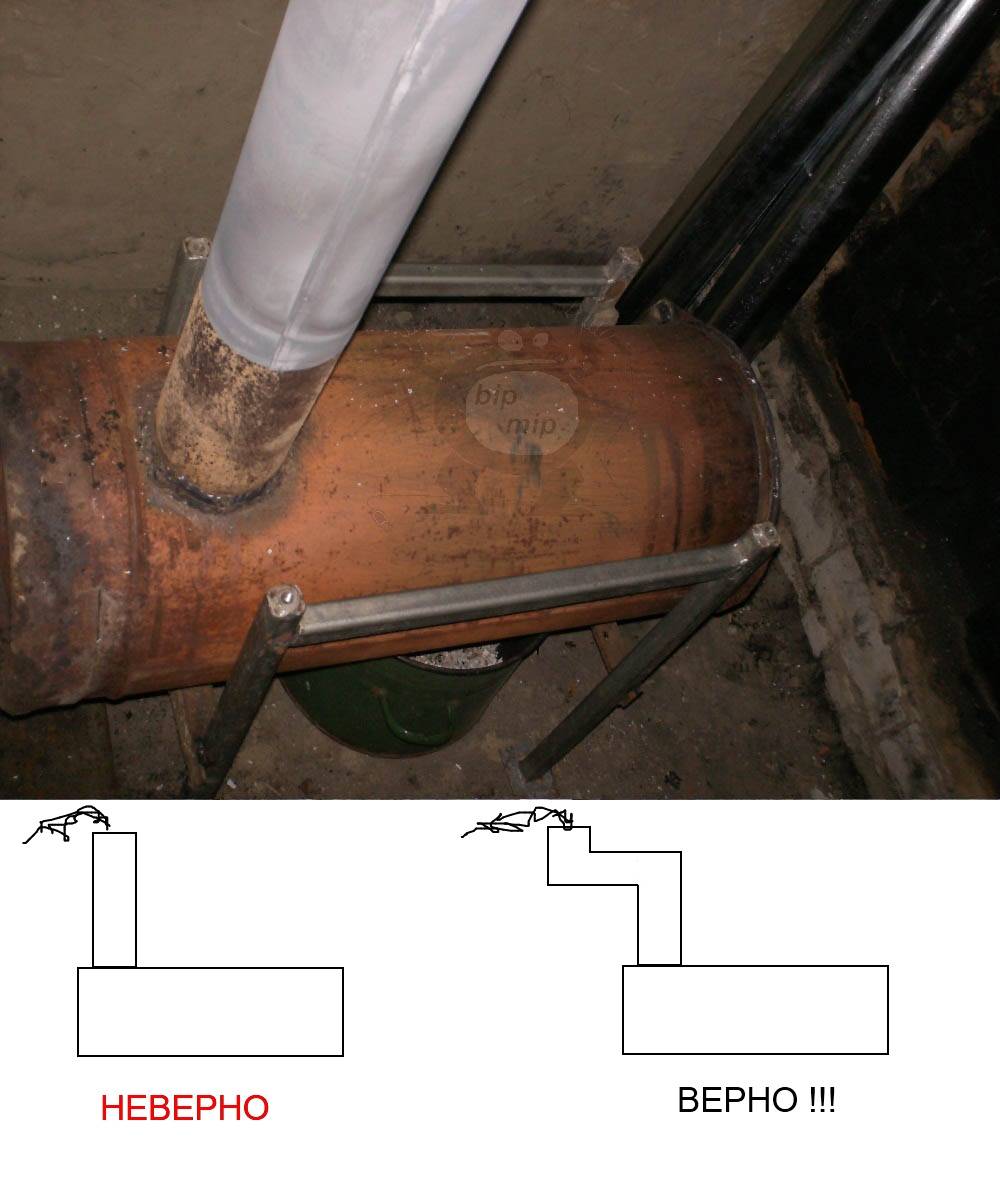

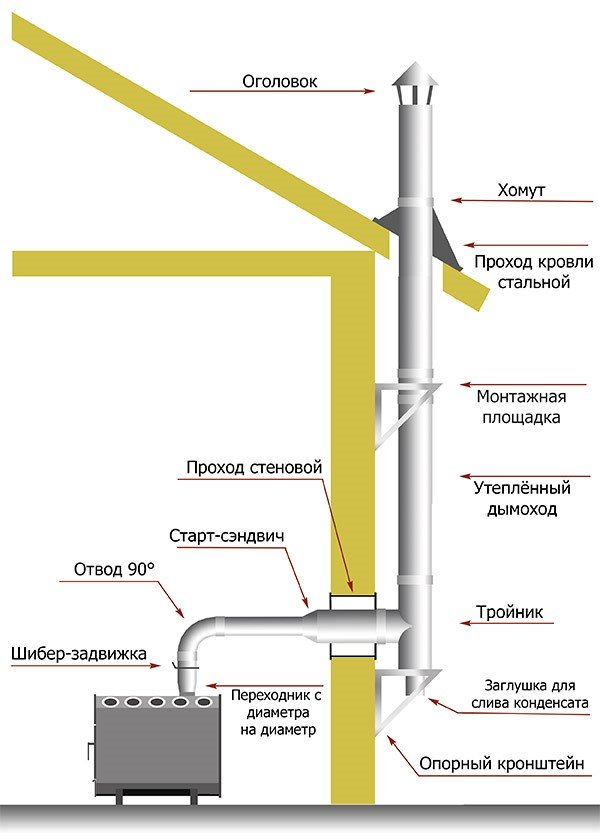

Pipe installation

To install a chimney of standard dimensions, we need the following materials:

- Knee 100x1200mm (1 pc.)

- Knee 160x1200 mm (2 pcs.)

- Butt elbow 160x100 mm (3 pcs.)

- Tee 160 mm with plug

- Mushroom 200 mm

Also, depending on the characteristics of the room in which the potbelly stove with our chimney will be installed, you may need a passage glass, a rain visor, thermal insulation, etc.

Also, to seal the joints between pipes, we may need an asbestos cord or a special sealant.

After all the materials are ready, we proceed to assemble the pipe for the potbelly stove:

- We fix the first section of the pipe on the chimney or the furnace pipe.

- We build up the pipe elbow to the overlap.

Chimney hole

- In the floor slab we make a hole with a diameter of at least 160 mm for the chimney outlet. We remove the thermal insulation along the edges of the hole to prevent its ignition.

- We insert a passage glass into the hole, and then we pass the potbelly stove pipe through it.

- We join the pipe with an external chimney.

- To ensure optimal operation of the chimney, we provide thermal insulation of the outer part of the chimney, wrapping it with thermal insulation and coating it with bitumen.

Chimney outlet through the window

We strengthen the fungus on top of the chimney, which protects the pipe from precipitation and small debris getting inside.

Pipe Care

In order for the chimney (and with it the potbelly stove itself) to work properly, it must be looked after:

- At least once a year, we check the outer surface of the pipe for defects - burnouts, rust, cracks.

- Similarly, the pipe must be cleaned annually. To do this, you can either use special chemical compounds that are burned in the furnace along with firewood, or simply burn a few aspen logs in a potbelly stove. Aspen gives a very high temperature, which perfectly burns out soot.

- It is unlikely that it will be possible to use mechanical cleaning agents (ruff, weight, etc.), because the chimney of the potbelly stove is not very durable.

The manufacture and arrangement of both the furnace itself and the pipes for the potbelly stove is a difficult task only at first glance. Of course, you will have to sweat and carefully study the proposed instructions - nevertheless, it is quite possible to do this without resorting to the help of specialists. So keep it up!

warm brick

A potbelly stove on wood, coal and other types of fuel can significantly increase its efficiency. To do this, it is enough to build a screen of baked clay bricks around it with your own hands. If you look closely at the drawings of such a mini-building, you can see that the bricks are laid at a short distance from the walls of the stove (about 10-15 cm), and if desired, around the chimney.

Bricks need a foundation. Do you want the masonry to last a long time? Then pour the base at a time to form a monolith. The material for the foundation is better to take concrete, which should be reinforced with steel reinforcement with your own hands. It is desirable to make a reinforcement layer at a distance of approximately 5 cm from the surface of the concrete pad.

Ventilation holes are made at the bottom and top of the brickwork, which will ensure the movement of air (heated masses will go up, cold air flows from below). Ventilation also prolongs the life of the metal walls of the potbelly stove, postponing the moment of their burnout due to cooling by circulating air.

Bricks laid around the stove accumulate heat, and then give it away for a long time, warming the air in the room even after the potbelly stove goes out. In addition, brickwork additionally protects the objects surrounding the stove from fire.

If desired, the stove can be completely laid out of brick. Such a structure is beneficial in that it will last for many years without additional effort on the part of the owner. However, there are also certain disadvantages. The disadvantages of this option include the following:

- the process of laying out such a stove is quite laborious and is suitable only for those people who have experience in masonry with their own hands;

- a brick potbelly stove is quite expensive, as it requires the use of refractory materials, including fireclay bricks and special clay for mortar.

In order to get a small potbelly stove on wood, it is enough to lay out a cone measuring 2 by 2.5 bricks, 9 bricks high. In the combustion chamber, 2-4 rows are laid out from fireclay bricks. Ordinary clay baked brick is suitable for a chimney, into which you must remember to insert a stainless steel sleeve.

Whatever the method of making a miniature stove or a potbelly stove with your own hands, you make them according to a drawing or by eye, the main thing is that at the output you get an effective heater, and in an expanded configuration also a hob for cooking.Look around for suitable materials (barrels, sheet metal, etc.) and go to your own homemade stove or even a potbelly fireplace!

How to make a wood splitter with your own hands? How to install a sandwich chimney with your own hands It is not difficult to build a chimney for a boiler with your own hands Do-it-yourself metal stove How to make a smokehouse yourself at home or in the country

Which is better to choose

Factors:

- type of potbelly stove;

- the volume of the furnace department;

- method of attachment to the structure;

- location in the room;

- the need to carry the stove;

- chimney material;

- pipe design requirements.

In fact, the chimney is already selected for a specific type of stove, and not vice versa. Otherwise, the operation of the heating system will be incorrect. This is especially true for the minimum pipe diameter requirement.

If you have experience, you can independently make the necessary type of chimney. But it is required to strictly observe all the basic rules for calculation and design. If there is no experience or it is not enough to fully comply with all the conditions of manufacture and installation, then it is better to order.

It is worth considering that the installation work already with the existing material also has its own nuances and features.

The choice of material depends on the potbelly stove itself, as well as their availability. The choice of material is based on the required structural features and the nature of the heating system, that is, whether it is stationary or mobile.

Stone or brickwork is used for permanent installation. A cheaper material will be a galvanized pipe, which has enhanced properties in relation to ordinary tin. It is this material that should be used for collapsible design options, as well as, if necessary, convenient replacement of segments.

The cheapest material is considered to be ordinary tin. There is a nuance in the form of a requirement for the size of the wall. The pipe must be thicker than 0.5 cm, since otherwise it cannot be installed indoors according to the fire safety regulations.

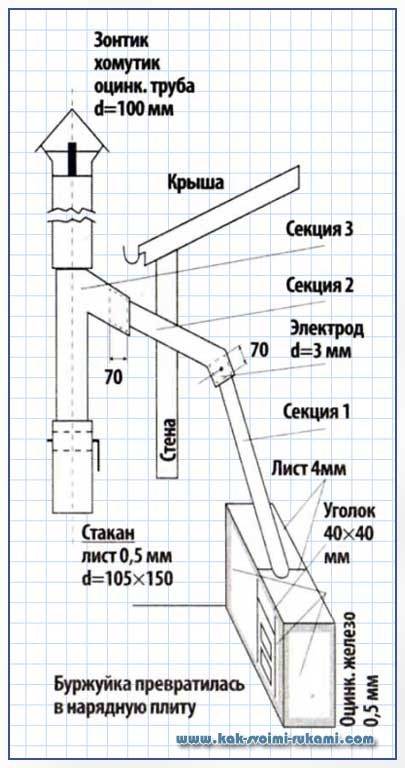

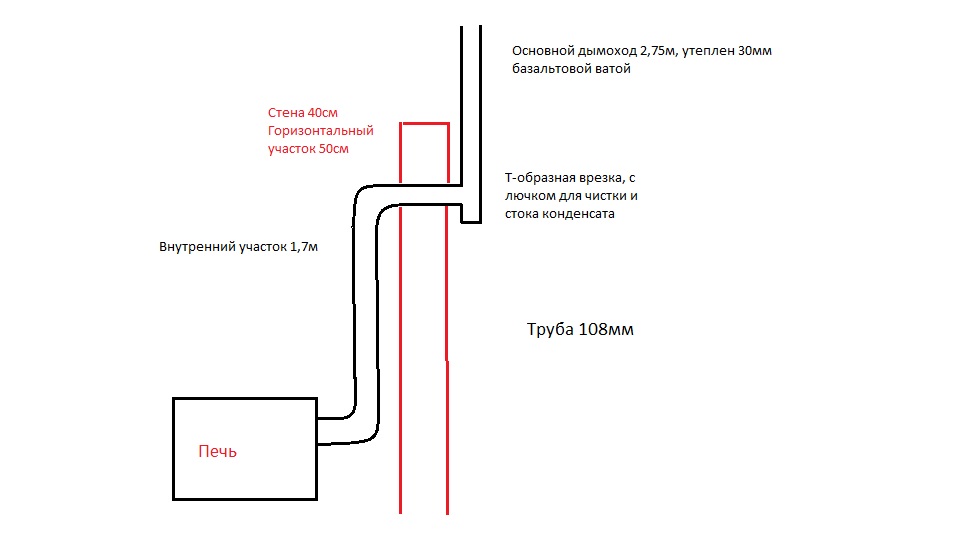

Drawing and diagrams

The drawing is a preliminary diagram in the form of a drawing. But it must indicate the actual required dimensions, which will help to make the correct installation based on all the rules and instructions. The drawing is made in any form before installation. It is required to install a chimney according to the regulations of the construction mini project.

The whole system is built on the basis of a proportion of 1 to 2.7, since this is a prerequisite for full-fledged traction.

The volume is multiplied by 2.7 and we get the result in millimeters. Example: the oven has a volume of 50 liters. Multiply 50 by 2.7 = 135 mm. For convenience, you can add up to 5 mm, that is, a pipe diameter from 13.5 to 14 cm is suitable.

Mounting Features

Among the installation there are several features that are taken into account when working. Rules:

- installation begins with the lower sections;

- the passage through the walls is treated with insulating materials until the pipe is installed there;

- the regulations for the location of joints relative to walls and ceiling are observed;

- one diameter is used for the pipes of the entire chimney.

The main rule of installation is the full compliance with all the rules of construction work and safety.

Failure to comply with all regulations for the construction and arrangement of the heating system is also considered a problem. All these miscalculations affect the final result.

Chimney Care

First of all, good care of the smoke exhaust pipe from the potbelly stove ensures the safety of people and property in the room.

It also gives an equally important property - good heat transfer from the chimney and traction. And in order for the chimney to faithfully serve the entire period allotted to it, at least once every six months it is necessary to conduct a visual inspection of the chimney. The metal should not show signs of burning, corrosion, it should not burn through, crack or rust.

The metal should not show signs of burning, corrosion, it should not burn through, crack or rust.

The presence of one of these defects is a signal of the need to urgently replace the damaged area: smoke will enter the room through the cracks, which, at least, will negatively affect the health of the people in it. In addition, burning through and cracking in certain places, the metal of the chimney can give slack, and the entire pipe will soon simply collapse.

Folk cleaning methods will come in handy here - you can use the method of cleaning the chimney with potato skins. It is strictly forbidden to use an original, but dangerous way to raise the temperature to the limit so that the soot burns out and fly out: high temperatures not only contribute to the rapid wear of thin metal, but can also easily provoke a fire.

Potbelly stove - the best option for those who need a portable and convenient stove

And the only problem - the construction of the chimney - is no longer a problem! It turns out that making a high-quality and efficient chimney for a potbelly stove is quite easy, it is only important to follow the technology. A ready-made chimney does not require increased attention, only regular, but rare care, for which it will pay back with years of good work!In order for the stove-potbelly stove to always have good draft, and there is no smoke in the room, it is necessary to carry out preventive measures that will help keep the chimney in order

In order for the stove-potbelly stove to always have good draft, and there is no smoke in the room, it is necessary to carry out preventive measures that will help keep the chimney in order.

Any chimney requires periodic preventive maintenance:

In order for the pipe to be clean from soot deposits, it is necessary to periodically add chemicals specially designed to loosen carbon deposits to the burned firewood. For the same purposes, aspen firewood is also used, which helps to clean the internal walls. To clean the pipe with their help, only aspen firewood is used for preventive fireboxes. It is desirable that they do not burn out quickly, but smolder for the maximum possible time in the furnace. To create such conditions, the draft is artificially reduced by closing the blower after the firewood flares up well. Annually carry out mechanical cleaning of the pipe from carbon deposits and rust. To do this, you can use a special cleaning brush with a load.

After each cleaning, be sure to revise the surface, carefully lowering the light bulb into the chimney. This is necessary in order to detect burnouts or cracks in time.

Since any chimney must be of the highest reliability, and all segments must perfectly match each other when joined to seal them, it is recommended to install parts made exclusively at a professional level.It must be remembered that the ingress of carbon monoxide into the room from poorly sealed seams or burnt holes is, without exaggeration, a mortal danger.

Tags: potbelly stove, cottage, chimney

Voting: what is the best modern stove-stove?

| A photo | Name | Rating | Price | |

|---|---|---|---|---|

| The best factory models of Russian-made stoves | ||||

| #1 | Potbelly stove POV-57 | 99 / 1005 - votes | Learn more | |

| #2 | Termofor Fire-battery 5B | 98 / 100 | Learn more | |

| #3 | META Gnome 2 | 97 / 100 | Learn more | |

| #4 | Furnace Potbelly stove Teplostal | 96 / 1003 - votes | Learn more | |

| Popular potbelly stoves from world brands | ||||

| #1 | Keddy | 99 / 100 | Learn more | |

| #2 | Guca Lava | 98 / 100 | Learn more | |

| #3 | Vermont Castings | 97 / 1001 - voice | Learn more | |

| #4 | JOTUL | 96 / 1001 - voice | Learn more | |

| #5 | Brunner IRON DOG | 95 / 100 | Learn more |

What would you choose from modern bourgeois stoves or would you advise to purchase?

Brunner IRON DOG

Save the voting results so you don't forget!

You must vote to see the results

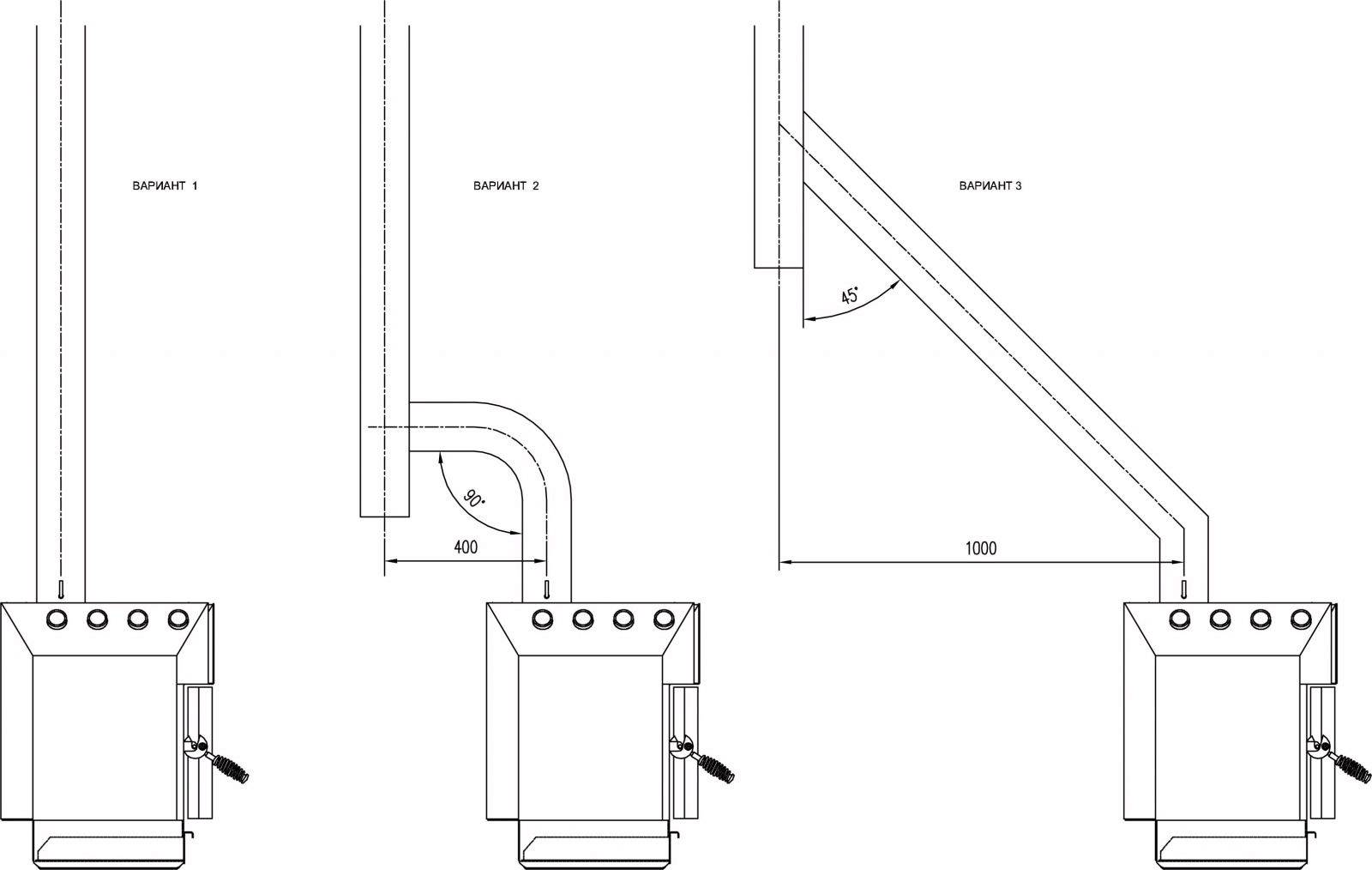

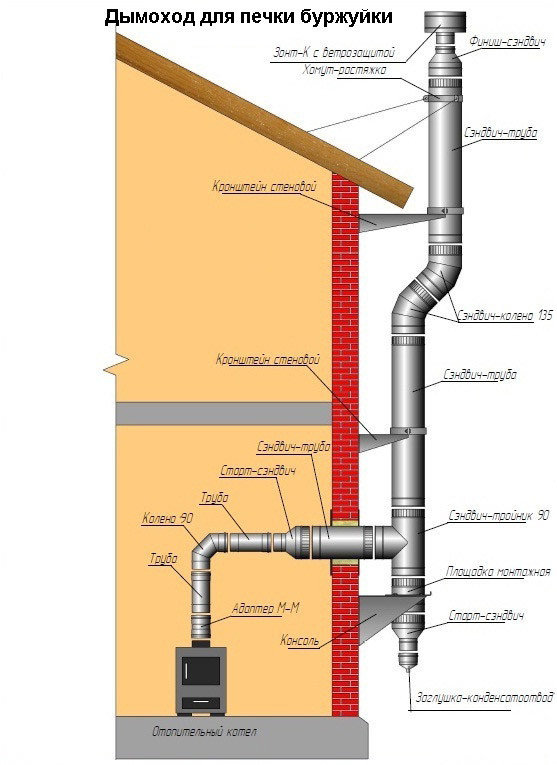

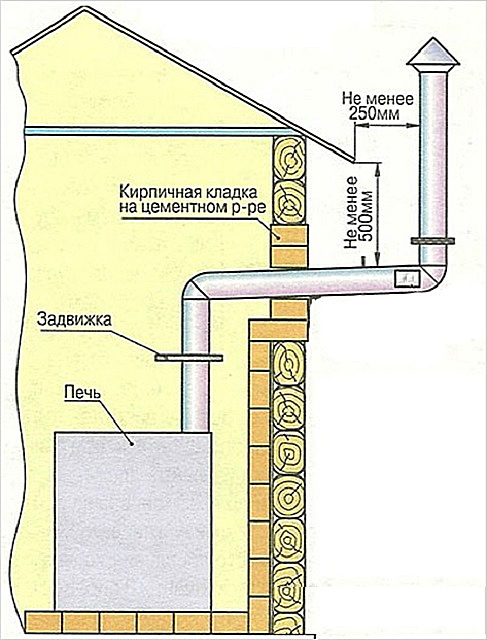

After the potbelly stove is installed and ready for operation, it is necessary to install a chimney that can function properly, keep the heat in the room and at the same time prevent combustion waste from entering the air of the room where the stove is installed. To do this, you need to correctly calculate the diameter of the pipe, its length and think about how it will bring smoke to fresh air.

The outlet of the pipe above the roof should be located according to certain rules:

- The chimney is located at a distance of up to 1500 millimeters from the roof ridge, which means that the outlet of the pipe should be located at a height of 50 centimeters above the top of the ridge,

- With a distance to the visor of 150-300 centimeters, the outlet of the pipeline can be placed on the same level with it,

- If the chimney is located near the edge of the roof, then its outlet should be slightly lower than the ridge, or on the same level with it,

The second option for the pipe exit is through the wall, and not through the roof. In this case, the end of the chimney should be located just below the top of the roof ridge.

Do-it-yourself installation work should begin with the choice of a place where the outer and inner elements of the furnace should be connected. An attic or space under the roof is perfect for this purpose. The first element of the future chimney is installed on the potbelly stove itself, on which the second, third and so on are placed next (depending on how many sections the chimney will include).

It is necessary to extend the flue pipe until it reaches the previously determined place at the junction of the two elements.

In the ceiling, you need to make a hole, the diameter of which will be 5-10 cm larger than the diameter of the pipe: this will be required in order to cover the pipe at the point where it passes through the floors with heat-insulating material. If there are insulating materials or other easily flammable objects in the cracks between the ceilings or near the pipe, they must be removed: when the pipe warms up from the smoke and its temperature rises, the risk of fire of the heat-insulating material will increase with it.

A passage glass is inserted into the cut hole in the ceiling, through which the chimney pipe must be passed. Then you need to dock the pipe coming from the inside of the room with the outside of the chimney. The chimney should end above the roof level, approximately 10 cm above it.The place where the hole for the pipe outlet will be cut out is equipped according to the same principle as the pipe outlet inside the building:

- the hole must be larger than the chimney pipe itself;

- a layer of heat-insulating material must be placed between the roofing materials and the pipe.

Fixing the pipe

The smoke outlet pipe is passed through a hole in the roof and fixed with a sheet of tin or other metal. As an alternative to tin, you can also use another non-combustible fixative - bricks, which are installed in the gap between the chimney and the roof. However, in order for the bricks to hold the pipe firmly, a stand must be built for them from the inside. All cracks in this place are covered with ordinary clay.

Seam sealing

After the entire structure is assembled, you need to take the sealant and, without sparing it, lubricate all the joints and seams to prevent smoke from entering the living room from the chimney

Sealant for these purposes must be selected with special attention - only one that is not afraid of high temperatures is suitable

Unfortunately, some sealants will simply "melt" on a hot pipe, while others will dry out easily. One way or another, but the sealant, which is unstable to high temperatures, will lose its properties and will not be able to protect the room from smoke.

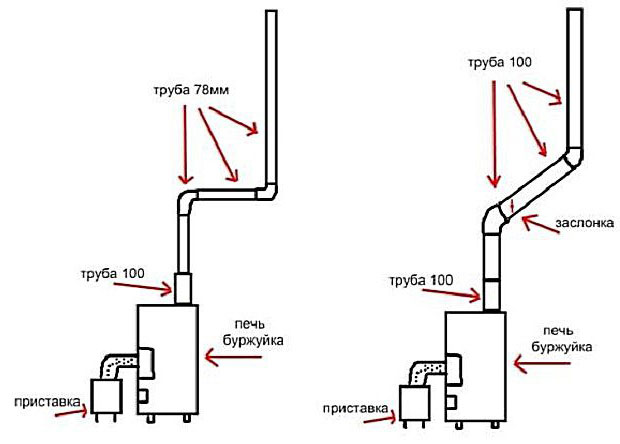

Types of chimney pipes

Various materials are used for the manufacture of a smoke exhaust pipe.

Initially, depending on the material of manufacture, there are 2 options:

- Take finished pipes manufactured at the factory;

- Make pipes from stainless steel sheets or other sheet metal.

The cheapest way is to make pipes yourself

Here, the undoubted advantage is that the pipe will be of the desired diameter, which is especially important for home-made stoves

The second advantage of homemade pipes is the cost. For their manufacture, you can use improvised material, or purchase metal sheets with a thickness of 0.6 mm or more. And better in 1 mm.

An elementary option for assembling a chimney for a potbelly stove involves the use of finished steel pipes and a corner element. A smoke channel is assembled from them and welded to a homemade stove:

- A branch pipe is welded to the top of the stove, built from a used gas cylinder. The inner diameter of the pipe must be equal to the outer diameter of the pipe installed in it

- According to the design dimensions, a smoke channel is assembled. The assembly uses a 108 mm pipe and an elbow, the components in the example are connected by welding

- An assembled chimney is installed on the stove-potbelly stove. Through a hole in the wall, connect the outer part of the pipe and weld it to the main

The outer part of the pipe is assembled from separate links, taking into account the standard height. The pipe must be at least 50 cm above the roof, located near tall buildings or trees.

Step 2: Assembling the smoke channel

Step 3: Taking the chimney out of the potbelly stove

Step 4: Construction of the outer part of the pipe

Among the most common materials are the following:

In addition to these options, the market offers many other products. So, you can find pipes made of heat-resistant glass, from which it is quite possible to build an exotic chimney. But this is done extremely rarely - skill is needed to install and connect individual structural elements to each other.

Quite often it happens that the chimney pipe heats up to incredibly high temperatures.

This entails a danger, since the risk of fire increases several times!

In order to minimize it, first of all, you need to isolate all combustible elements nearby.

Next, the insulation is laid around the chimney pipe.

This must be done without fail, because without a high-quality thermal insulation layer around the chimney, you risk your life and health every day.

So, let's look at the main causes of the problem:

- The chimney is made of a single-walled metal pipe without a heat insulator, which is completely unacceptable. It is mandatory to replace single-layer chimney sections with sandwich pipes, or simply supplement them with a heat-insulating layer;

- There may be errors in the design of the sandwich pipe. It should be remembered that this design is installed in such a way that the condensate formed inside cannot get on the outer surface of the chimney.

Pipes for the chimney system can be made by hand or purchased at a specialized store. The main advantage of hand-made pipes is low cost. In addition, it becomes possible to make a pipe of the required diameter, which is perfect for any home-made stove.

For manufacturing, you need a metal sheet with a thickness of 0.6-1 mm. A sheet of metal is folded into a tube and fastened along the seam, using rivets and heat-resistant sealant. However, it is much easier to purchase a finished product. Chimney pipes made of various materials are on the market:

- become;

- bricks;

- ceramics;

- vermiculite;

- asbestos cement.

You should not opt for inexpensive asbestos-cement pipes, since asbestos-cement is not intended for use at temperatures above 300 ° C. A pipe made of this material is very heavy, which will cause inconvenience when assembling the system. In addition, the asbestos-cement product absorbs condensate, due to which the functionality of the chimney may be impaired.

The construction of a brick chimney will entail significant costs. Doing the right laying of a chimney for a potbelly stove with your own hands is very problematic, so you will need to contact specialists. The brick structure has a considerable weight, which will require additional reinforcement of the foundation.

For the device of a potbelly stove, metal pipes made of stainless steel or alloy steel are best suited. Metal products have a number of advantages:

- light weight;

- ease of assembly;

- long service life.

Fabrication and installation of the structure: how to make a chimney

Bourgeois stoves are simple in design, so for such heating systems it is not worth equipping a brick chimney. This is an expensive and unprofitable option for this type of furnace. You can make a chimney for a potbelly stove with asbestos-cement pipes with your own hands. However, such smoke ducts have a number of disadvantages:

- Low resistance to high temperatures. The maximum allowable temperature inside the pipe is 280C.

- Due to the rough surface of the inner walls of the pipe, there is a problem with creosote build-up of combustion products.

- Risk of ignition. Due to low temperature resistances and accumulated soot, a pipe fire can occur.

- Susceptibility to acid corrosion.As a result of the combustion of fuel products, oxides are released that destroy the internal walls of the structure.

- Poor resistance to condensation. Subsequently, there is a fetid smell of dampness and stains in the area of the discharge channel.

Chimney for potbelly stove with shutter

The potbelly stove is compact in size, therefore, the best material for installing a chimney is metal pipes.

Self-installation of a chimney made of ferrous metals is carried out with strict observance of the rules and safety measures. To weld the joints of individual elements of a metal chimney, you need a tool such as a welding machine.

Phased installation of a chimney 100, 110 mm through the wall: how to calculate the diameter of the pipe

To install the chimney to the potbelly stove, we perform the following steps:

- First of all, you need to calculate the diameter that is suitable for connecting to the back wall of the furnace.

- If the potbelly stove is located outdoors, then we cut a hole in the wall of the appropriate diameter and weld the chimney with one elbow or connect it through the pipe.

- For installation within the premises, we first prepare an axonometry of the future chimney (project or drawing on paper). We assemble the structure and then connect it through the pipe to the potbelly stove.

- If the stove is located in the kitchen, where there is an exhaust system, then a special corrugated pipe is used, which is connected through a tee.

- The most important stage is the passage of the ceiling. A special passage glass is installed between the ceiling and the attic, the size of which should be larger than the cross section of the ceiling.To eliminate the risk of fire and negative temperature effects, an asbestos cord is used for furnaces, which envelops the pipe in the ceiling.

- We use a heat-resistant oven sealant to pre-lubricate each joint and wall contact.

- At the end, you can install a spark arrester on the exhaust pipe. This device will secure nearby flammable materials.

Conclusion

Installing an exhaust pipe for a potbelly stove is not a difficult process and can be carried out independently, without the involvement of specialists. The main thing is to follow the fire safety rules, do not allow the chimney to come into contact with easily flammable materials and monitor the tightness of the structure.

With a responsible approach to the installation of a potbelly stove and the installation of a chimney, as well as proper operation, there will be no problems when using the heating system. If the installation of the entire system is incorrect, then like a boiler or a fireplace, a potbelly stove can cause a fire.