- Master class: how to make a simple do-it-yourself smoke generator

- A simple smoke generator for cold smoking: do it yourself

- Materials and tools

- The combustion chamber

- Chimney

- Do-it-yourself installation of a smoke generator for cold smoking: video and photo

- Useful tips: how does a homemade device work?

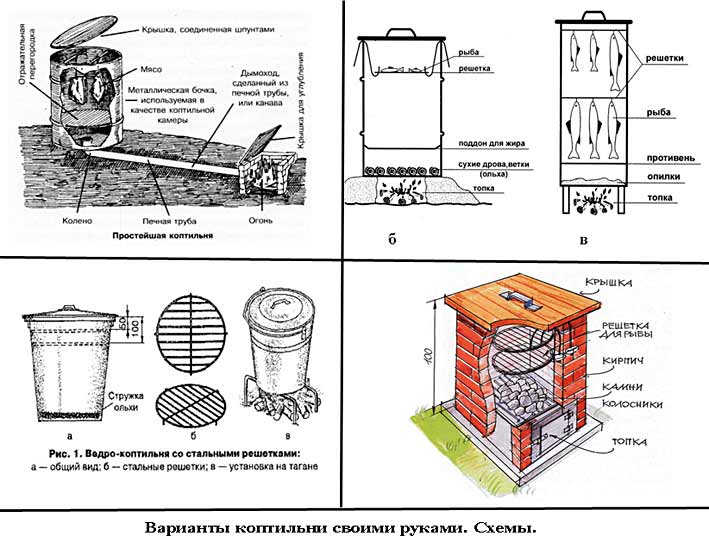

- A simple rustic way of smoking

- The simplest smoke generator from an electric stove

- How to make a hot smoked smokehouse from the refrigerator with your own hands (step by step, instructions)

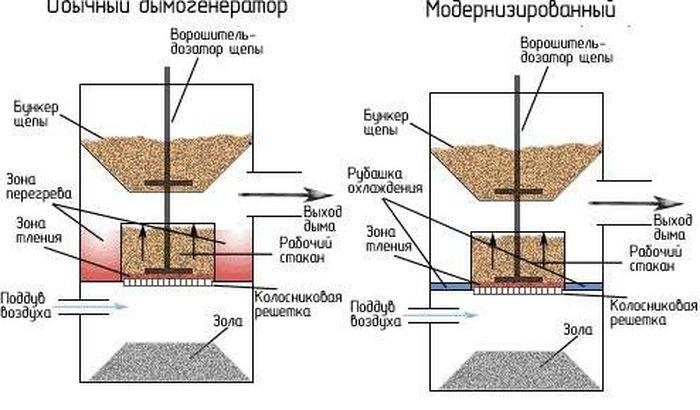

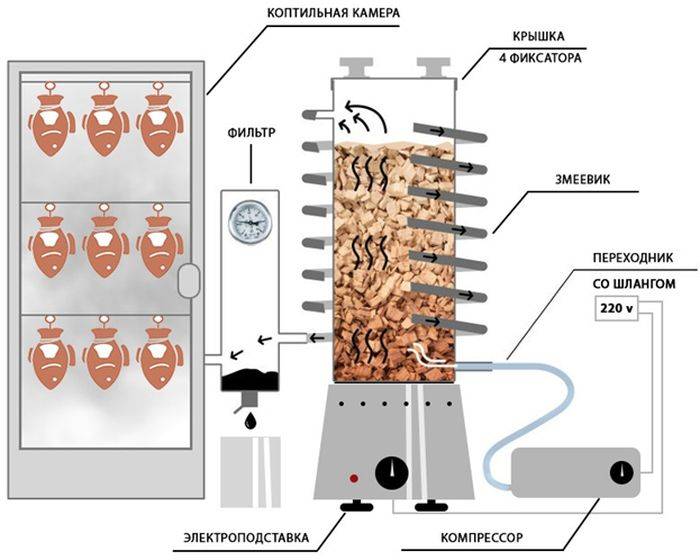

- Versions of the hot smoked smoke generator.

- Cold smoked smokehouse assembly instructions

- Camera

- Hearth

- Channel

- Cold smoked smoke generator

- User manual

- How to make a smokehouse from a barrel with your own hands

- How to prepare a barrel

- Types of smokehouses from a barrel

- Horizontal barrel smoker

- Vertical with firebox

- Smokehouse from two barrels

- How to cook in a barrel smoker

- Types of smokehouses

Master class: how to make a simple do-it-yourself smoke generator

The simplest smoke generator can be made with your own hands from three cans. Here is a small master class with detailed photos:

| A photo | Description of works |

| For a smoke generator, you will need to connect two tin cans. One of them needs to cut the bottom.To fasten cans, use metal tape and iron clamps. |

| In the lower jar with a bottom, make two holes opposite each other. They will be required to ignite the wood chips and provide oxygen. |

| The third bank is selected so that it is slightly smaller in size than the first two. A hole of such a diameter is punched in its bottom so that a tee can be installed. |

| The tee is fixed with a nut from the inside. Tighten the fastener tightly, the efficiency of the device depends on its tightness. |

| On one of the sides of the tee, screw a squeegee with a tube of small diameter. Use fum tape to seal the connection. |

| The ejector will require a thin copper tube of small diameter. On one side, a silicone air supply hose is attached to the tube. |

| Insert the tube as shown in the photo. It should protrude from the opposite side of the tee by a couple of centimeters. Seal the tube entry point with a gasket or sleeve. |

| Screw a tube of suitable diameter and length into the free hole of the tee, sufficient to connect to the smoking container. |

| The resulting design is an ejector. It will provide smoke to the smokehouse. |

| Wood chips are poured into the main container from two cans by about 2/3. |

| The ejector is fixed on top and tightly fixed in the device. |

| The silicone hose is connected to the compressor. In our case, an aquarium compressor with adjustable air supply is used. |

| The wood chips are ignited through the lower openings of the structure. It is convenient to use a gas burner for this purpose. |

| Do not forget that you can install the structure only on a non-combustible stand. Ashes from wood chips may fall from the bottom. |

| With the compressor turned on, the smoke generator will immediately produce fragrant smoke. |

| If you haven't got a smoking chamber yet, use a simple cardboard box. You can hang products on the needles in it. Don't forget to make a small hole in the box to let the smoke out. Thus, you have a simple cold-smoked smokehouse with a smoke generator, made by hand from improvised materials. |

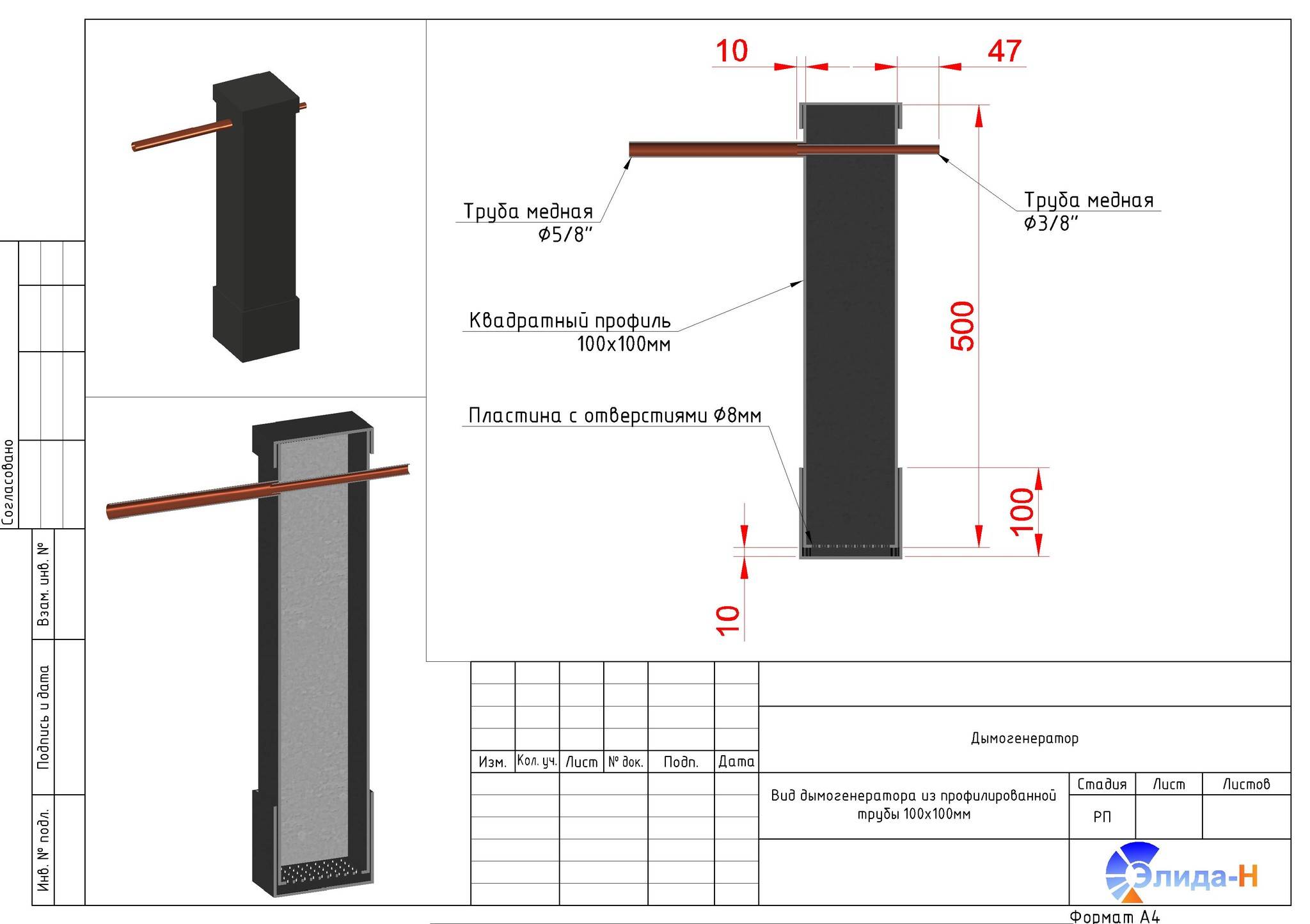

A simple smoke generator for cold smoking: do it yourself

There are also general principles that must be observed, regardless of the chosen technology. This will be the key to reliable and safe operation of the device.

Materials and tools

Of the tools, wrenches of various sizes are useful for fixing hardware. Cutting pipes and other parts is performed by a grinder. In some cases, a welding machine is required.

The combustion chamber

The height of the container varies from 0.5 to 1 meter. The diameter must be at least 9 cm. This will prevent chips from getting stuck. Specialty stores sell ready-made pipes that are ideal for the combustion chamber.

Chimney

- A ¾ pipe is attached.

- A ¾ cross is installed.

- A plug for revision is placed in the end.

- A chimney pipe is fixed, which will be connected to the smokehouse.

For better cooling, in some cases, a large diameter pipe is taken, equal in size to the diameter of the combustion chamber.

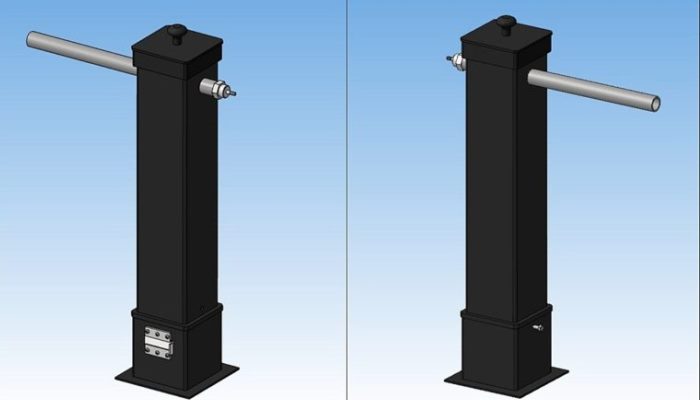

Do-it-yourself installation of a smoke generator for cold smoking: video and photo

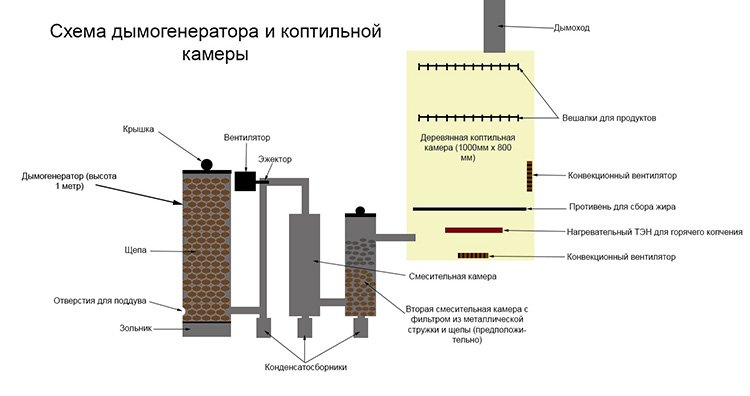

It is possible to make a quality smoke generator for cold smoking hands. Drawings and diagrams will allow you to create the best unit.

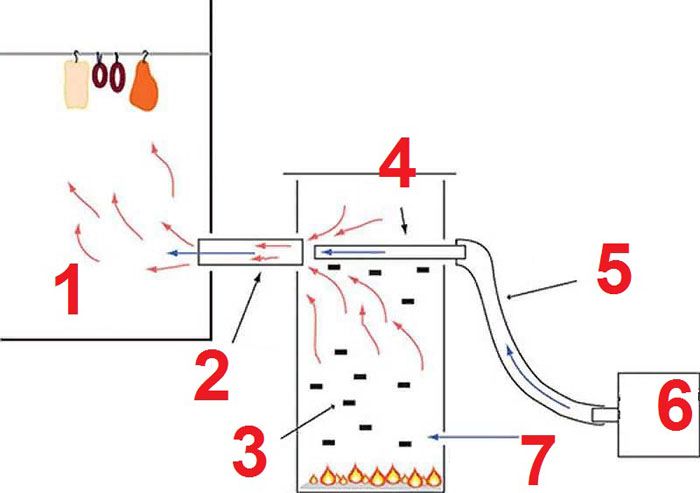

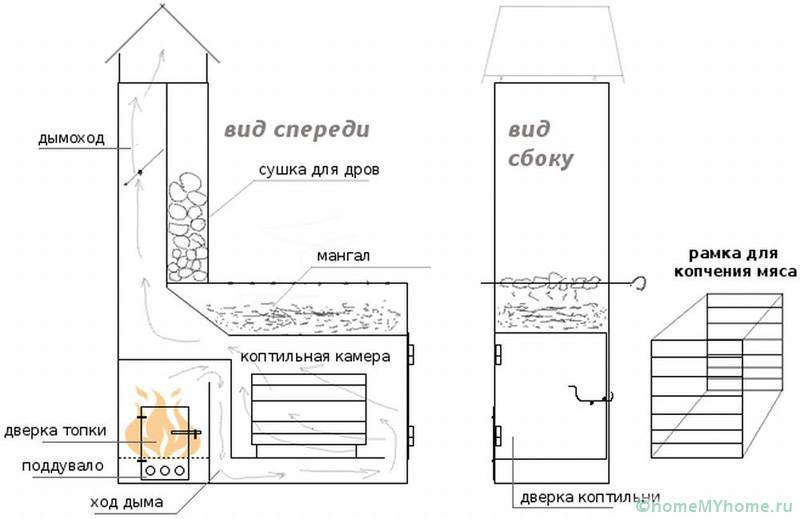

This diagram shows a smokehouse with a large chimney and a special place for drying firewood.

In order to save money, a coil part can be placed around the combustion tank. It is necessary to create high-quality circulation of air flows so that the heated body does not interfere with the cooling of the smoke.

A device for creating smoke, with all the necessary elements, can be assembled in a few days

For self-assembly, you will need the following items:

- pieces of metal pipe with a diameter of 25-40 mm for a smoke line;

- round or square tube;

- metal hose or corrugated pipe;

- tee connections;

- compressors;

- thermometer and special wires.

The diagram shows all the important components of a good smokehouse

You will also need a welding unit and a grinder. The drawing of a smoke generator for cold smoking allows you to consider all the components of the structure.

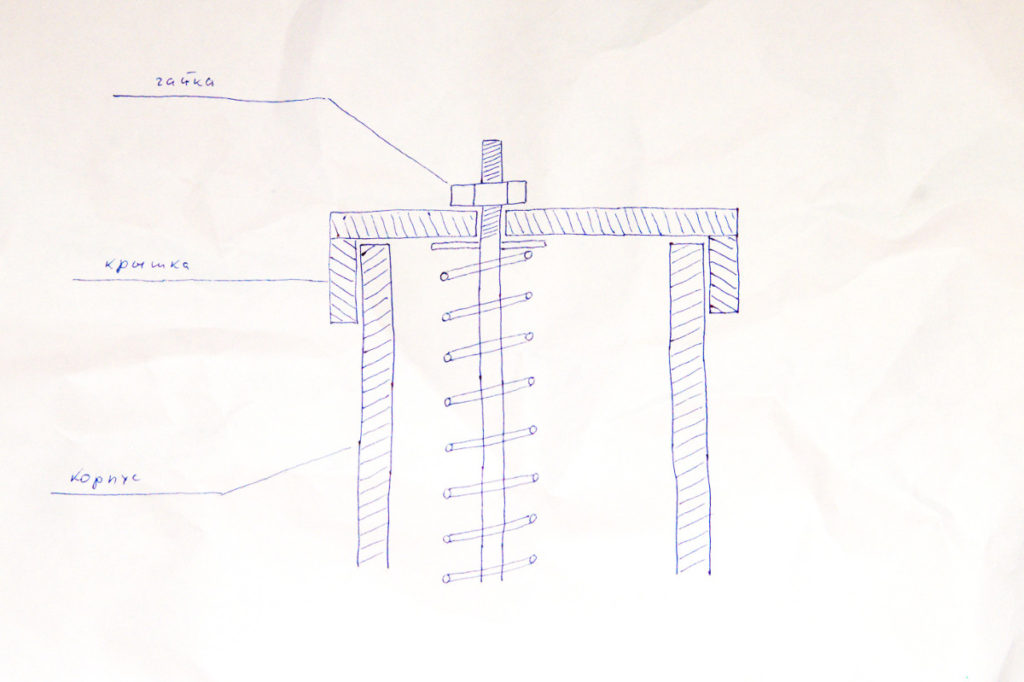

The installation of the structure has the following features:

- if the bottom is removable, then the doors on the side surfaces of the unit are not needed;

- the top cover must be without ventilation and chimney. It must be equipped with special elements for opening;

- a chimney is mounted on top of the unit. The fitting is welded to the wall in a perpendicular direction;

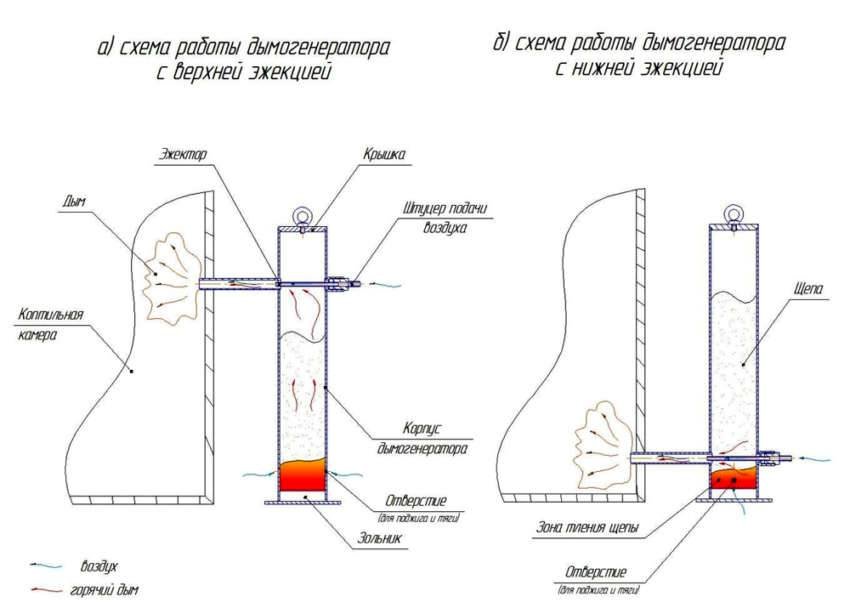

The chimney can also be mounted at the bottom

- thread is cut for fittings;

- after installing the chimney part, a tee element and two pipes are connected;

- the line from the compressor element is attached to the pipe leading down, a special pipe is mounted to the side fitting, leading to the smoking tank;

- instead of a fan, a cooler from a computer or a compressor for aquariums is used. In this case, it is necessary to create a constant circulation of the air flow.

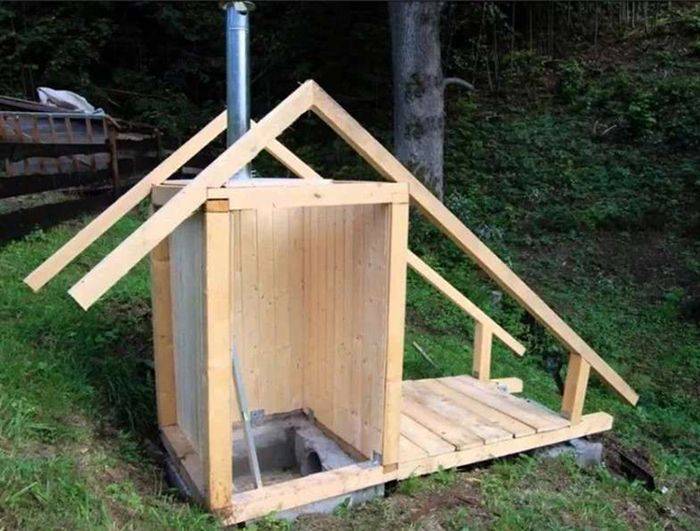

The smokehouse can be made from boards

The tee is attached to the cover, while the integrity of the walls on the side is not affected.

Useful tips: how does a homemade device work?

Do-it-yourself smoke generator for cold smoking is distinguished by mobility and compactness. The video allows you to see all the stages of installation of this unit.

You can make combined designs, some of which are purchased at the store, and some are made from what is at hand

Such an installation can be stored in the basement, garage or in a closet.

The number of products that can be placed in the unit depends on the volume of the tank

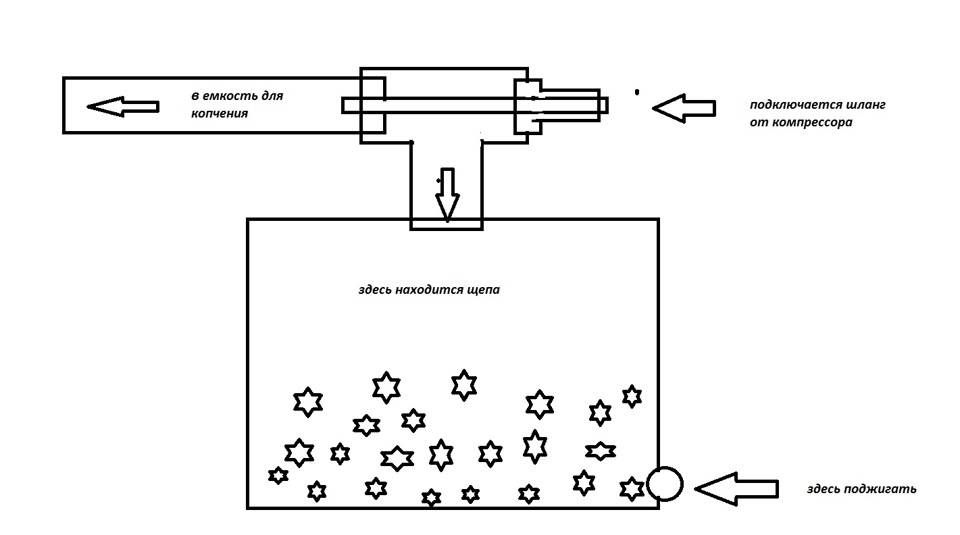

The device works as follows:

- the device is installed on a base of heat-resistant materials. It can be a concrete slab, ceramic tile or a metal table;

- this unit heats up quickly, and particles of burning material pour out of it;

- about 0.8 kg of sawdust, wood chips or shavings are loaded into the container;

- the lid closes well;

- the compressor pipe is connected, and the chimney is connected to the smoking chamber;

- fuel is ignited through a side hole;

- the fan turns on.

A smoking device can be built in combination with a stove

The temperature is determined using a thermometer. When creating this equipment on your own, you can use improvised materials. Pots, cans or any other containers in the form of a cylinder are suitable for the body. The chimney is made from any suitable pipe. Such an installation can work even without a fan. In this case, the traction will be weaker and the smoking process will be greatly delayed.

Smoking units are even made from old gas cylinders

With a certain material at hand, special tools and some skills, durable and high-quality smoke generators are created with which you can cook delicious smoked foods.

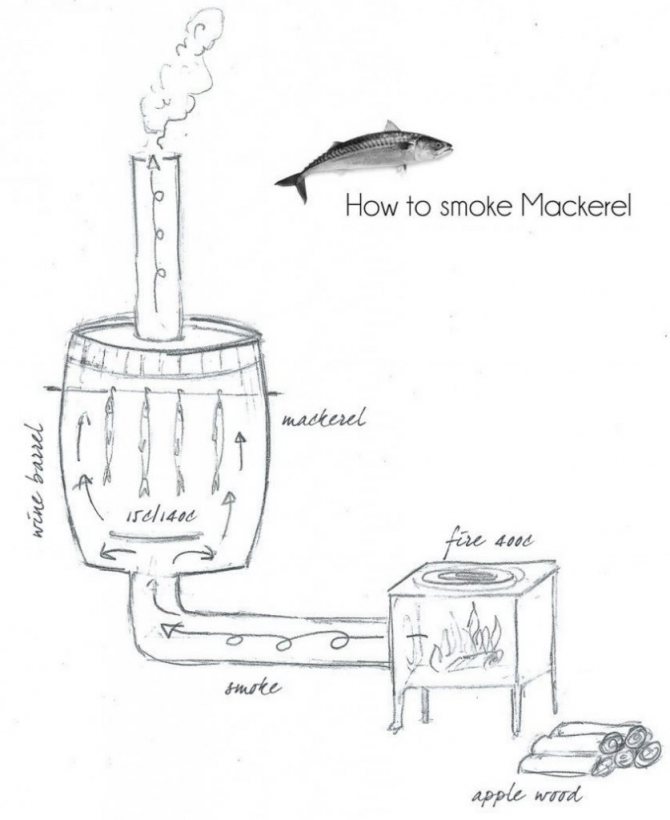

A simple rustic way of smoking

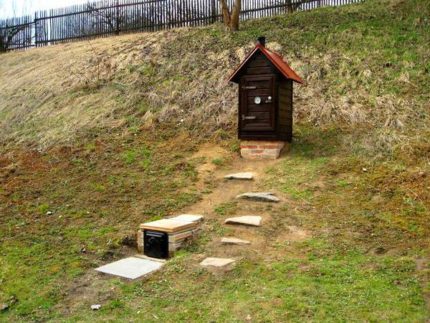

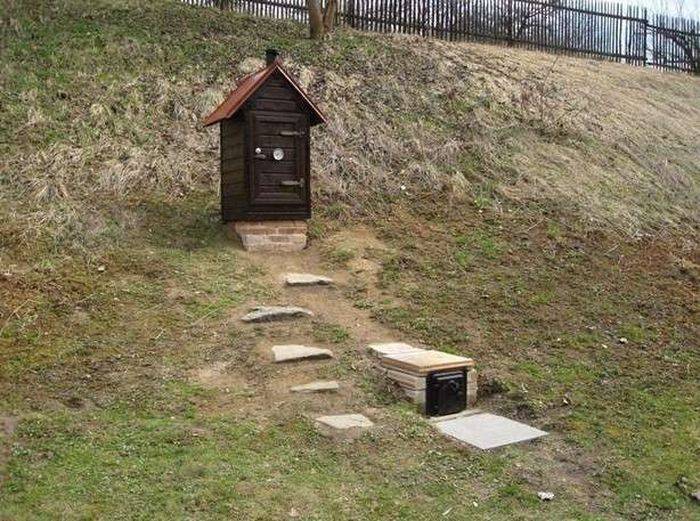

This design consists of two chambers interconnected by a chimney. The smokehouse is located on one side, on the other side there is a stove or hearth, which is the smoke generator.

The smokehouse is made from boards - it must be completely airtight. You can use a barrel. The chamber is located on a hill, always above the stove for good smoke movement

The smokehouse is made from boards - it must be completely airtight. You can use a barrel. The chamber is located on a hill, always above the stove for good smoke movement

The chimney must be 3 to 4 meters long so that the smoke intended for smoking is cooled to a suitable temperature.

Depending on how the smokehouse will be used, there are 2 types of chimney lining:

- If the smokehouse is stationary, then the chimney is made in the form of a brick channel or a metal pipe buried in the ground.

- If the structure is assembled in haste, then a trench dug under a slope is perfect.

Connect the chimney to the smokehouse from below for greater filling with smoke. A filter must be placed at the junction so that the soot is blocked and does not sit on the smoked products.

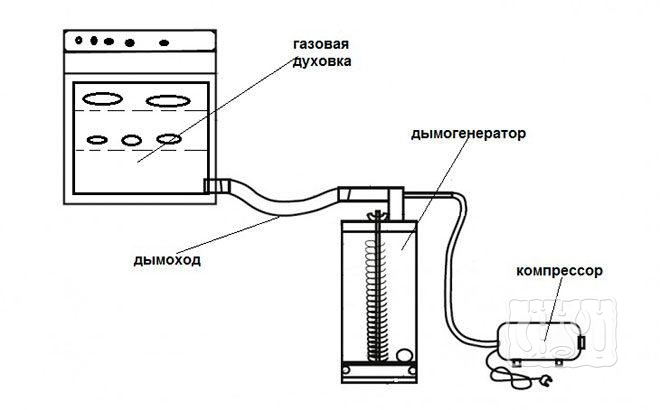

The simplest smoke generator from an electric stove

If you need smoked meats “right now”, you can use a very simple method: you need an electric stove, a barrel without a bottom or a piece of large diameter pipe, a wire mesh with a cell of at least 10 * 10 cm, a sheet of plywood or iron. Still - sawdust and "object of smoking".

The simplest cold smoked smoke generator can be built on the basis of an electric stove and a barrel

Such a cold-smoked smokehouse is usually placed on the street, in the backyard.It is necessary to clear the patch of vegetation, install an electric stove. On it - a metal container (which is not a pity to throw away). Sawdust is poured into the container.

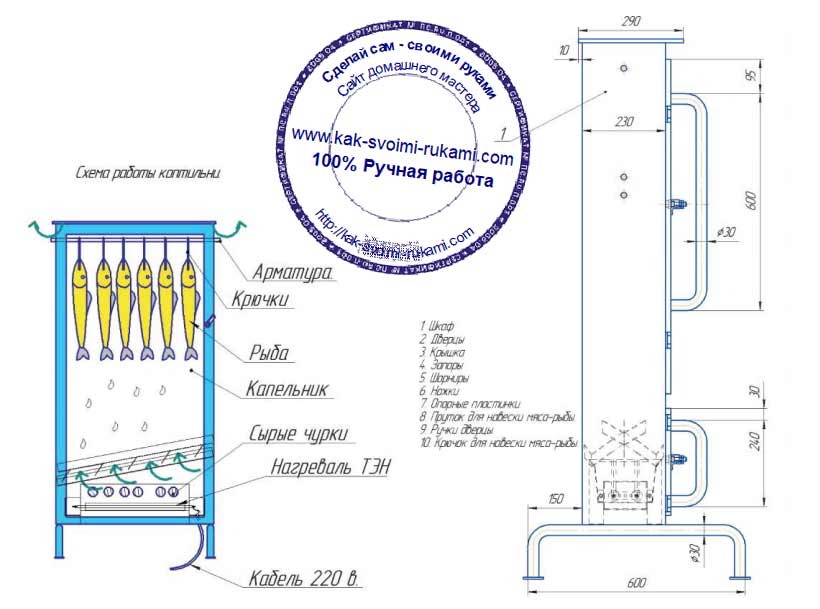

In the upper part of the barrel / pipe, stepping back from the upper edge of 10-5 cm, we drill four holes. They are located diametrically or opposite each other. We put pins in them. You can use metal rods, you can use sticks. The choice depends on the weight of the products to be stacked or what is available. The rods themselves can be arranged crosswise or as two parallels, located approximately 1/3 of the diameter of the smokehouse body. On top of this support we lay a grid, with products attached from below. We cover the smokehouse with plywood or a sheet of metal.

We drill holes in the upper part of the barrel, insert lattice rods with suspended products into them

Turn on tiles. After a while, the sawdust starts to smoke. The time of "work" on one tab depends on the amount of sawdust poured, but on average it is 3-5 hours. Then you have to set aside the body, add sawdust, put everything in place. Difficult, uncomfortable and fraught with "accidents". But the design is very simple, it is a "camping" option, which does not imply amenities.

This is a cold smoked smoke generator assembled.

Another disadvantage is to adjust the intensity of the smoke with a mono tile regulator, but doing it in this form is inconvenient - again, you have to move the case. You can get rid of these shortcomings if you make a door below. With its help, it will be possible to regulate the air flow and change the sawdust.

How to make a hot smoked smokehouse from the refrigerator with your own hands (step by step, instructions)

With the hot method, products are smoked at a temperature of at least 100 degrees.Accordingly, the process is fast - two hours is the maximum that may be required for the preparation of products. It is believed that with such a smokehouse from the refrigerator for fish, meat and other products, some of the vitamins are lost. In addition, there is a risk of formation of carcinogens.

The taste of products with cold and hot smoking methods is different, so when making the unit, you need to rely on your preferences. In the second case, the cabinet is easier to make than for cold smoking. No need to dig a trench and experiment with a four-meter pipe. The instruction will contain only a couple of points:

- Install refrigerator.

- Put the electric stove down, and place a container with wood chips on it.

Attention! For a hot smoked cabinet, it is important to understand in which mode to heat the stove. In no case should the fuel ignite, it must smolder, in order to increase the amount of smoke and minimize the risk of ignition, it is necessary to moisten the wood chips.

During hot smoking, in any case, there will be a lot of fat

Therefore, a pallet should be placed under it. A chimney is required at the top of the cabinet

During hot smoking, in any case, there will be a lot of fat. Therefore, a pallet should be placed under it. A chimney is required at the top of the cabinet.

You can also make a smoker from the refrigerator with a do-it-yourself smoke generator. This will improve the taste of food and speed up the cooking process. The device is sold ready-made or you can assemble it yourself. For it you will need an aquarium compressor (optimum power 60 l / h).

Versions of the hot smoked smoke generator.

Let's start with the simplest option.These are hot coals, on top of which raw grass, needles and leaves are thrown. Around such a fire, you can make a canopy of plastic film or cardboard and place the fish inside in a suspended state. A hot smokehouse in a traveling form is ready. Indeed, this method of quickly cooking freshly caught fish is often used on camping trips and fishing trips.

An ordinary electric stove can serve as a smoke generator for preparing a delicious meat or fish dish. It is installed inside the smoking chamber, connected to the network. A baking sheet with wood chips or pressed sawdust is installed on the tile, which begin to emit smoke when heated. So that our sawdust is not flooded with fat released during smoking, a moisture-collecting tray is provided above the smoke generator.

Exactly the same principle of operation of a heating element smoke generator, with the only difference that the heating elements must be fixed in the body of the smoking chamber, which adds to the headache.

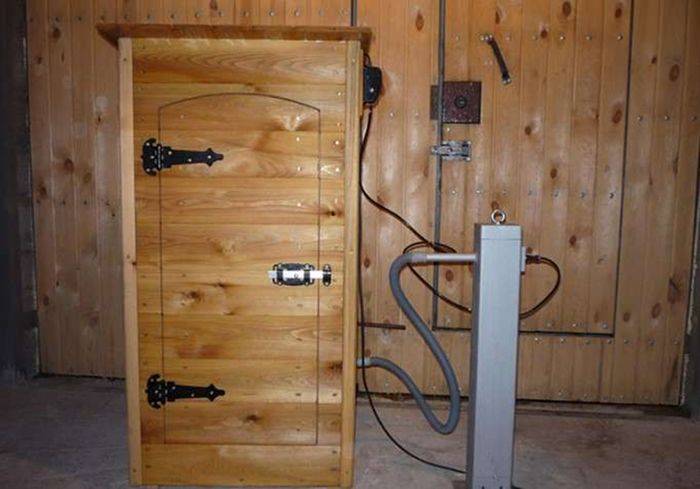

Cold smoked smokehouse assembly instructions

There are many councils where a chamber of similar designs is made from cardboard boxes, plastic barrels and other waste. Using cold smoke allows you to do this, but the smoker will last for a couple of uses. If there is a desire to constantly engage in smoking, they assemble a capital structure with their own hands.

Camera

For any chamber, a foundation of red brick or concrete blocks is first prepared. On one side, a passage is provided where the channel will be connected.

Under the brick chamber, a reinforced foundation will be required, in addition, it is more difficult to build it. It is easier to knock down a square house up to 1.5 m high, with a wall length of 1 m from the boards. First, the frame is knocked down from the timber.The elements are connected with self-tapping screws, the corners are reinforced with mounting metal corners.

Three sides of the frame are sheathed tightly with a board. The ceiling is also upholstered, only I provide a pipe for the exit of smoke. Here you can use galvanized or plastic. On the unsheathed fourth side of the frame, hinged doors are hung to load the product. Above the chamber from the bars, a gable roof frame is equipped, the smokehouse is covered with any light roofing material. Perfect for corrugated board.

Hearth

A hearth is built at a distance of at least 2 m from the chamber. The stove is laid out of red or refractory bricks. Provide a door to load raw materials and ash removal. Under the stove, it is desirable to concrete the base. In the back, a flap is provided. It is closed during ignition in order to exclude the first acrid smoke that forms with the start of combustion into the chamber with products.

Channel

Particular attention is paid to the design of the channel. Carcinogenic substances contained in the smoke will be deposited inside it.

The channel is usually started at the same time as the hearth, since it is connected to the back of the furnace.

The easiest way is to lay a metal thin-walled pipe with a diameter of 300-500 mm. However, over time, it becomes clogged with soot and requires cleaning. A channel dug in the ground is considered effective. Its sides are lined with red brick, the top is covered with sheets of metal to prevent soil collapses. Settling soot and condensate are debugged on the earthen bottom. Soil bacteria will process carcinogenic waste, there will be no need to clean the channel.

If the site has a slope, the camera is placed at a height, and the hearth is in the lowland.A path is laid out from the stones in steps, for the convenience of approach when loading products. You can smoke in such a smokehouse in any weather, since the chamber and hearth are protected from precipitation.

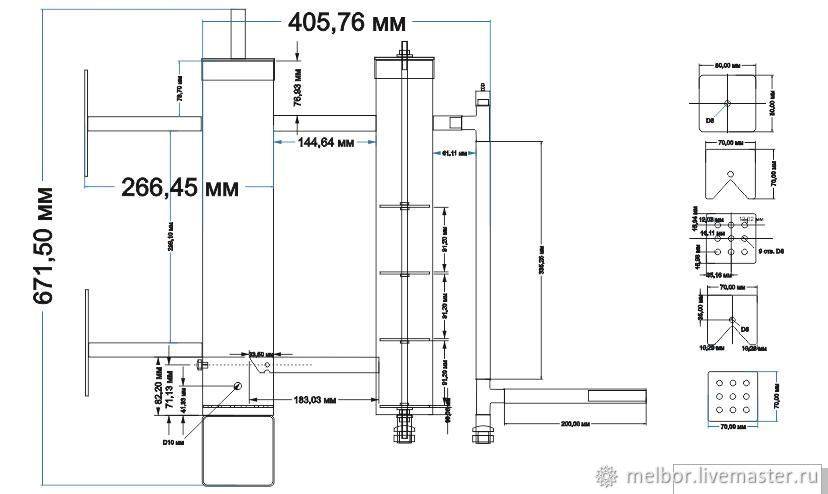

Cold smoked smoke generator

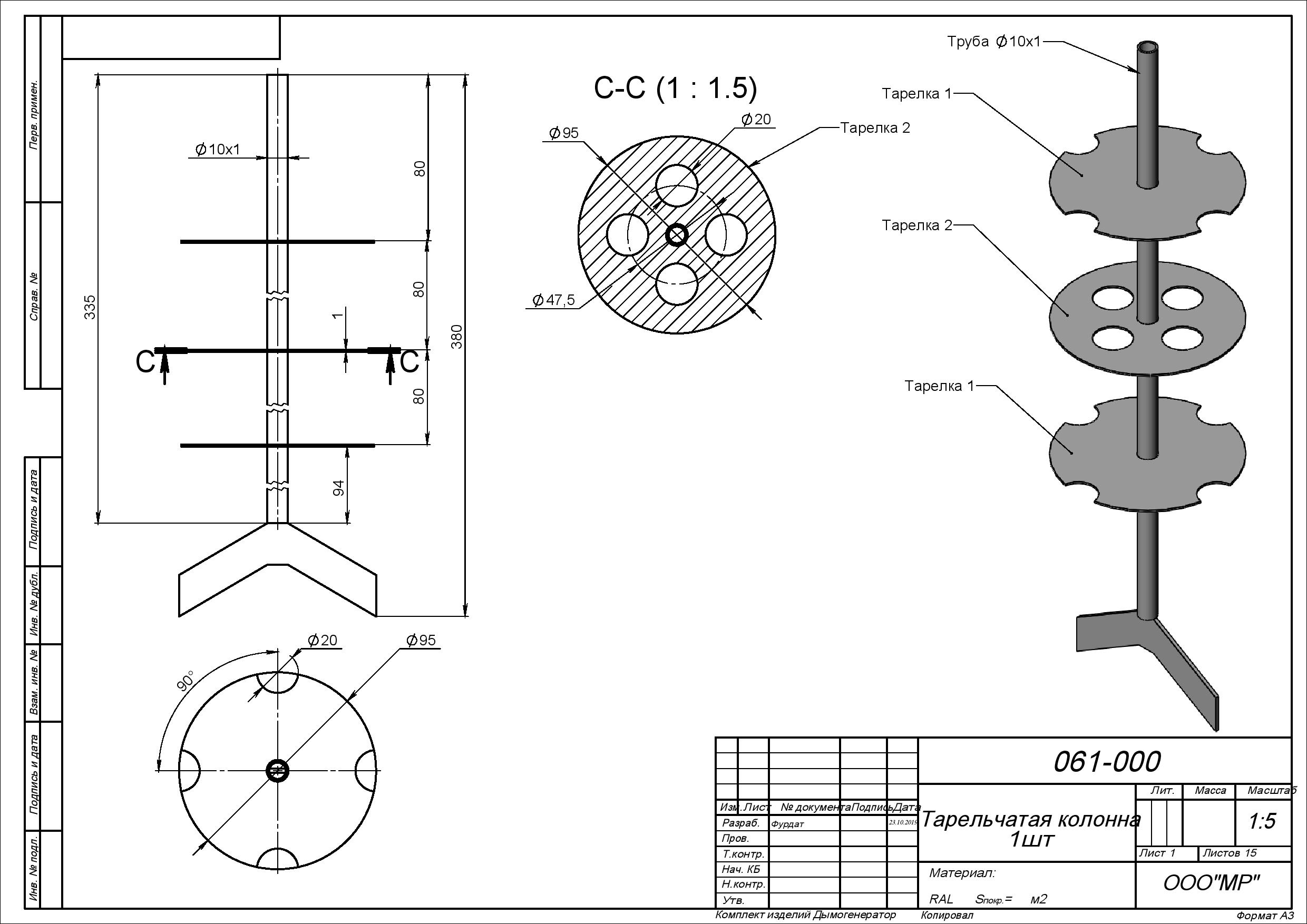

The lack of space on the site does not allow the construction of a long channel, the installation of a bulky hearth. The way out of the situation will be the manufacture of a smoke generator. From the materials you need the body of an old metal fire extinguisher or a pipe with a diameter of 100-150 mm. Additionally, you will need fittings, a compressor or a vacuum cleaner with an air blowing function, thin pipes for arranging a chimney.

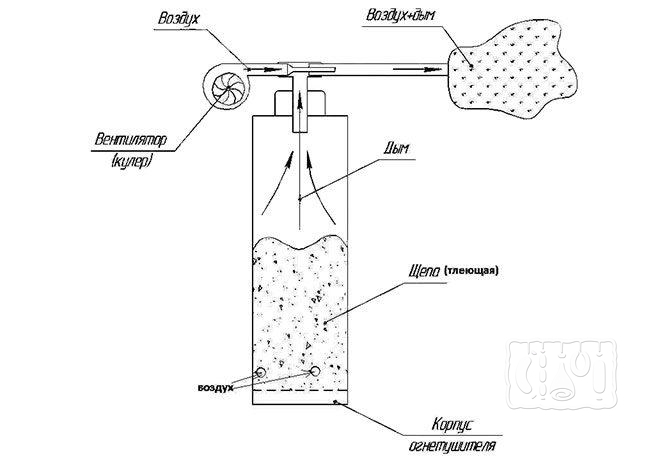

The design consists of 3 main nodes:

- a body inside which sawdust smolders without oxygen;

- smoke outlet pipe;

- cooling unit.

At the bottom of the housing, grates for smoldering sawdust are installed, an ash chamber is formed, and a fitting is welded in to supply air from the compressor.

The structure is connected to the chimney with a branch pipe, inside which an ejector made of a movable tube is inserted. The mechanism regulates the flow of smoke. Loaded sawdust is ignited through the bottom valve. The emitted smoke under the compressor discharge moves through the tubes into the chamber.

Often, an additional unit is installed between the smoke generator and the smokehouse chamber - a filter. It is made of a sump from a piece of pipe. The smoke passing through the filter cools down, carcinogens in the form of condensate are drained through a fitting welded into the bottom.

User manual

In order for the unit to use the functions inherent in the design as efficiently as possible, you should follow the rules for its operation:

- Before putting the smoke generator into operation, select the surface and install the unit.The surface must be even and reliably protected from fires, since not only ash, but also unburnt coals (the so-called heat) often spill into the holes in the generator.

- When placing wood-chip fuel in the housing compartment, first try to lay thin twigs and chips (10-20 mm) on the bottom, then you can use a larger material. Do not get carried away with the formation of "wells", as well as download too large branches.

- When using sawdust as fuel (they will lie denser than chips, branches or wood chips, which will slow down or even completely block the smoke exit), put on a pipe that is located at the top (thinner), a steeply wound spring (you can use a perforated steel pipe ). The quality of the material does not really matter, the main thing is to choose the right diameter (about 20 mm). The spring can be "tightly" fixed or made removable.

- After that, we place the products prepared for smoking in the smokehouse.

- Close the lid tightly. We connect the compressor with a fitting with a chimney, and the smokehouse with a generator.

- Ignite the fuel and start the compressor.

- Open the ash pan flap.

- When the smoldering of wood reaches an average level, if necessary, we adjust the air supply by the compressor and the ash damper.

It is absolutely easy to make a smoke generator with a damper and an ash pan with your own hands with welding skills. This does not require any expensive materials or special tools (except for welding).If you want to try cold smoking, be sure to make such a unit, it has excellent traction and allows you to get high-quality smoked products at the exit.

How to make a smokehouse from a barrel with your own hands

A barrel of 200 liters is ideal for a smokehouse. This is an almost finished smokehouse, it requires minimal work and a small set of tools.

Any barrel will do, no matter what was previously stored in it. The main thing is that the metal was of high quality, which will increase the life of the finished device

How to prepare a barrel

To eliminate all the substances that were previously in the barrel, it must be burned. To do this, firewood is laid in a barrel and a fire is made. After that, the barrel is cleaned from soot and soot.

Types of smokehouses from a barrel

A cold smoked smokehouse from a barrel has various manufacturing options. All of them have their advantages and disadvantages, which you should familiarize yourself with before assembling smoking equipment. This will allow you to choose the most appropriate option in each individual case.

Horizontal barrel smoker

In the manufacture of this type of smokehouse, the barrel is located horizontally. If the barrel does not have a lid, then a sheet of iron is welded on top.

Stepping back from each edge 10-15 cm, a door is cut out in the barrel. The cut-out door is welded with hinges to the barrel. For convenience, a handle and constipation are additionally welded. So that the lid does not fall inward, the edges of the cutout are welded from the inside with strips of sheet iron.

Just below the hatch, it is necessary to weld the guides for the grate. Install a drip pan even lower.

A hole for the chimney is cut out on either side, a 90 elbow and a pipe are installed.To adjust the output of the house, it is necessary to install a gate valve.

Wood chips are poured directly to the bottom of the container. The structure is completely finished. You can put it on fire, load food and start the smoking process.F.

Vertical with firebox

Such a smokehouse from a barrel is only suitable for hot smoking. A door for the firebox is cut out in the lower part of the body and fastened with hinges. A pallet is installed above the firebox, it performs two roles. The first serves as the vault of the firebox and the second is used as a pallet. Then holes for guides are drilled at different heights. A net or hooks for smoked products are installed on these guides. The top of the barrel is closed with a lid with a chimney. More details on how to make a smokehouse are shown in the video.

Smokehouse from two barrels

In this case, the first barrel is made by analogy with the horizontal one and will serve as a smoking chamber. The second barrel is installed vertically and acts as a firebox. At the junction of the barrels during smoking, a filter made of burlap or wet cloth is installed.

How to cook in a barrel smoker

Cooking delicacies in a homemade smokehouse is very simple. It is enough to place the prepared products on grates or hooks, close the structure and light the firewood.

Sawdust or wood chips are poured into the lower part of the finished structure. When the bottom of the smoker reaches the desired temperature, the wood chips will gradually begin to smoke. The smoking process will start, now you need to monitor the temperature, the amount of smoke and note the time.

Types of smokehouses

Do-it-yourself smokehouse can be of different types and have their own design features, which directly depend on the needs of the user and his building capabilities.The most popular are 3 types of smokehouses:

● mine (vertical); ● tunnel (horizontal); ● chamber.

The shaft smokehouse is the easiest to install and does not require a specific place for installation. Its structure resembles a canonical hut, at the top of which products hang. However, this type of smokehouse has a number of significant drawbacks, among which one of the most significant is the inaccessibility of smoking by fumigation, as well as small opportunities for adjusting smoke production.

A tunnel smokehouse requires a fairly large amount of work, most of which is land. It is also necessary to find a suitable site for its installation - it is necessary that it be on a slope. The hearth-smoke generator in such a horizontal device is located in a special chamber of a semi-closed type. Thanks to this, the smoking process can be carried out under any weather conditions. Depending on the length of the channel, both hot and cold smoking can be performed.

The chamber smokehouse is quite primitive in its device, but at the same time it is overall: the height is 1.5 meters, and the diameter is 1 meter

During construction, it is important to provide the required angle of inclination, which varies from 10 to 30 degrees.