- What to look for when choosing

- How does a smoke generator work?

- Homemade smokehouse from a pipe: how to do

- Materials and tools that will be required

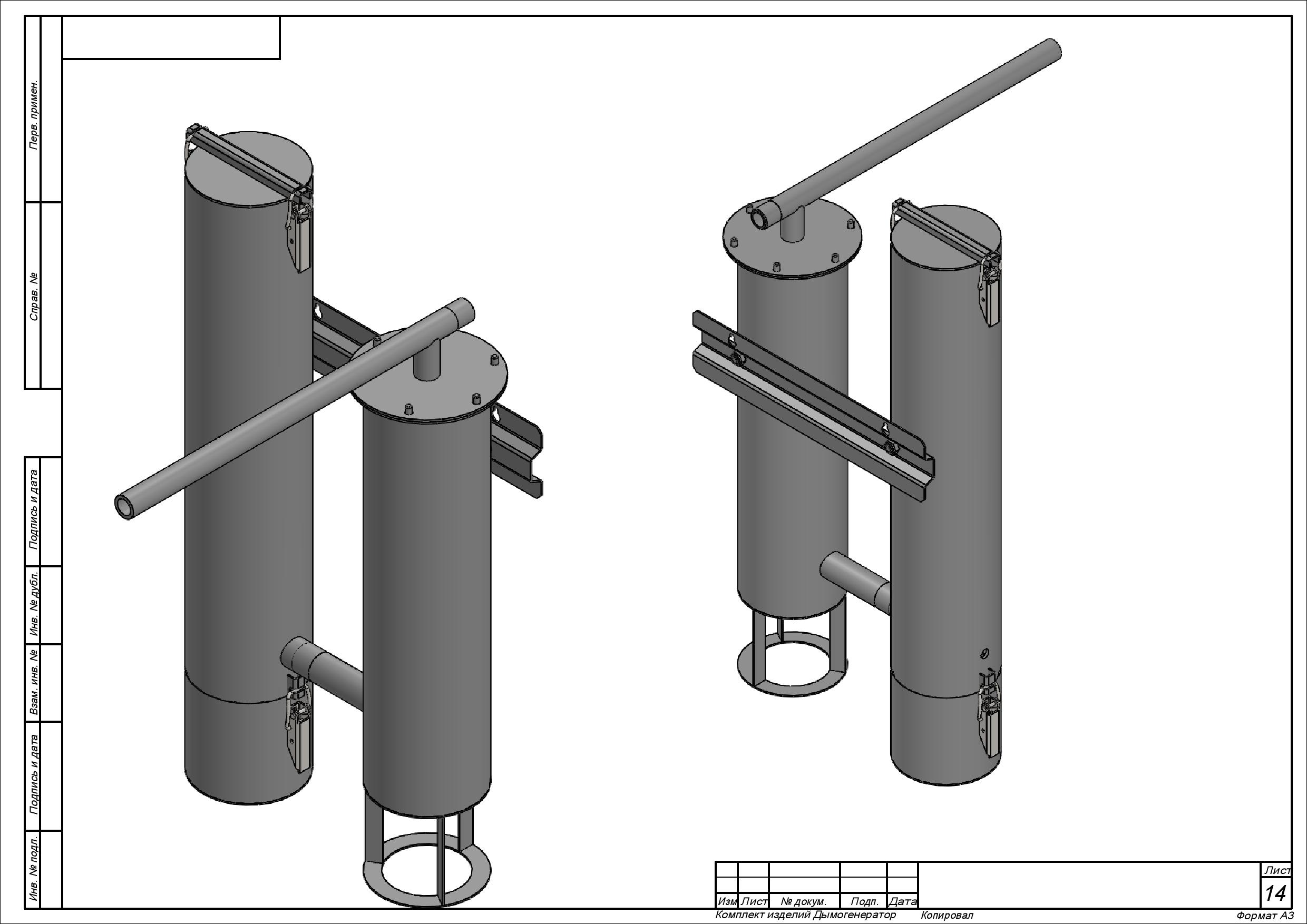

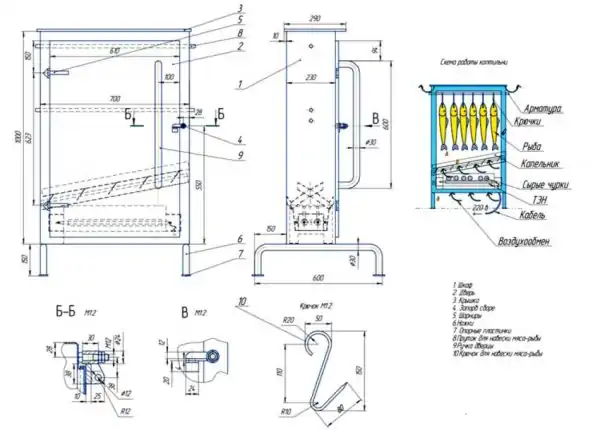

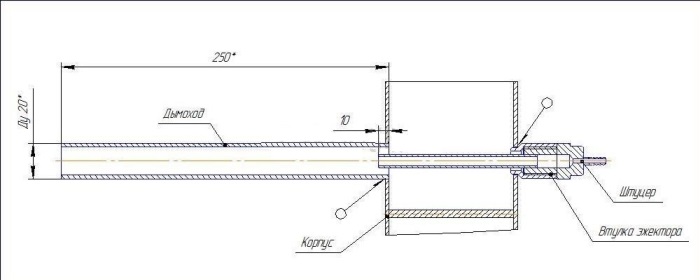

- Drawing of a smoke generator from a pipe

- Step by step assembly

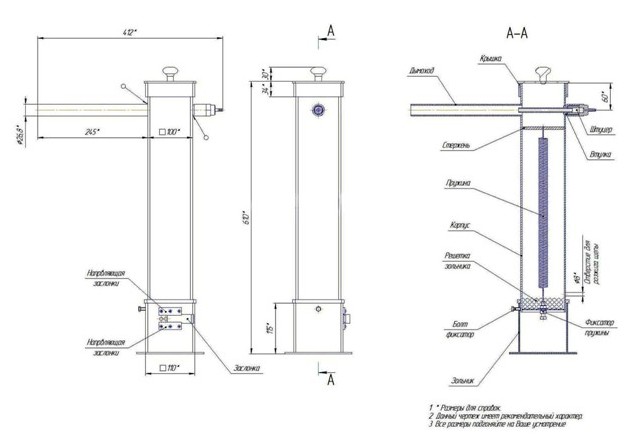

- Cold smoked smokers with smoke generator, dimensional drawings

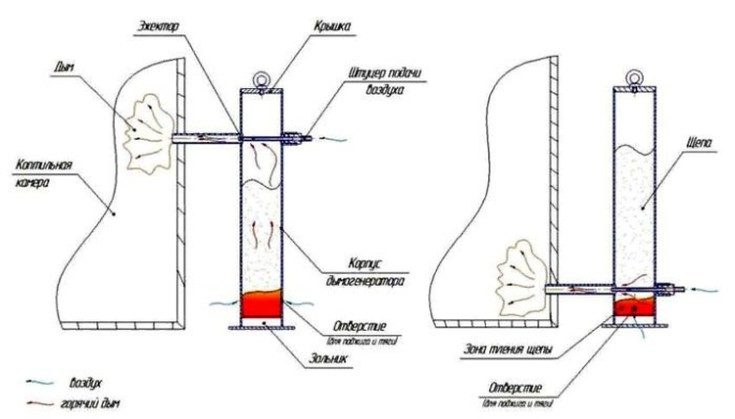

- Do-it-yourself smoke generator for cold smoking: drawing

- How to make a smoke generator with your own hands: making an ejector

- What to make a compressor for a smoke generator with your own hands?

- What is smoking, its advantages, what is smoke obtained from

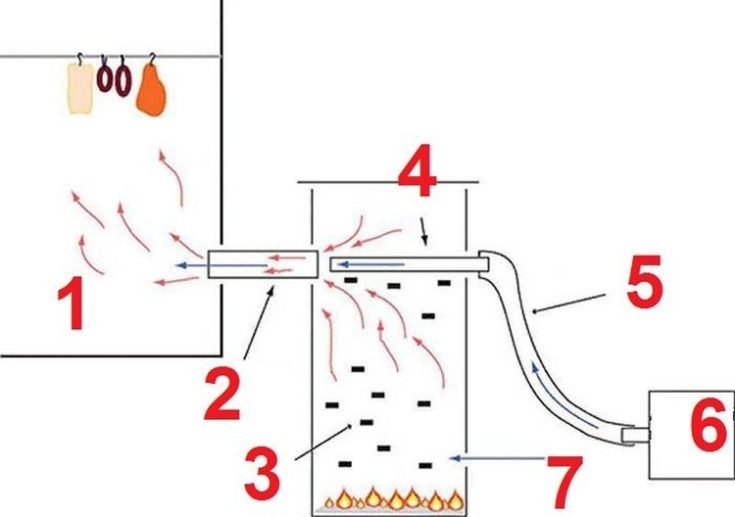

- Do-it-yourself smoke generator device for cold smoking

- Ejector

- Smoke generator compressor

- Smoking chamber

- Modernization

- Adjustable traction

- Ash pan

- Condensate collection

- What are smokehouses

- Durable fixed construction

- Lightweight version of the smokehouse

- Mobile based compressor

- What is a smoke generator and why is it needed

- Manufacturing and assembly of structural elements

- Frame

- Ejector and chimney

- Spring and ash pan grate

- Ash pan

- Lid

- Assembly

- How does a smoke generator work?

What to look for when choosing

What advice can our editors give you for the most profitable purchase?

Pay attention to the following:

- Appearance of the device.This parameter mainly depends on the materials used by the manufacturer. Stainless steel looks great, plus it lasts longer and is easy to clean. Steel at least 1.5 mm looks optimal. Larger thickness, respectively, is better. Most of today's rating models have a 2 mm wall.

- Simplicity of design. The lid should be wooden - such material will not leave burns. Also look at models with a removable bottom - this will greatly simplify the process of cleaning a contaminated smoke generator.

- Smoke delivery method. It is better if the nozzle is located at the bottom of the device. Why? Firstly, with this arrangement, less chip consumption is required. Secondly, harmful resins from condensate will not get on your products. And thirdly, the smoke will get into the smokehouse faster. In general, some pluses.

- Buy only a fully equipped smoke generator. Do you want to enjoy delicious food cooked in a new appliance right after purchase? Then be sure to ensure that the package contains the necessary items (compressor, mounting bolts, heat-resistant hoses, timer, smoker, lighter and wood chips).

- The presence of instructions and recipes. With them, you will quickly master the management of a new device.

How does a smoke generator work?

Before making a smoke generator, I carefully studied the principle of its operation. The whole point lies in the hydrolysis decomposition of wood in the absence of oxygen. Chips are thrown inside the structure, the device is turned on and it is heated.

Since oxygen does not enter the container, the wood chips begin to smolder. Ready-made generators are closed-type structures equipped with covers.In factory models, you can find the equipment of devices with a sawdust dispenser, as well as temperature controllers.

More about the principle of operation of the device:

- The device is placed on a heat-resistant base - a ceramic, concrete or metal plate. The unit heats up quickly, so particles of raw materials can spill out of it.

- 800 grams of sawdust is poured inside the pipe, the lid is covered.

- A chimney pipe is attached, as well as a compressor.

- Fuel is ignited through the side hole.

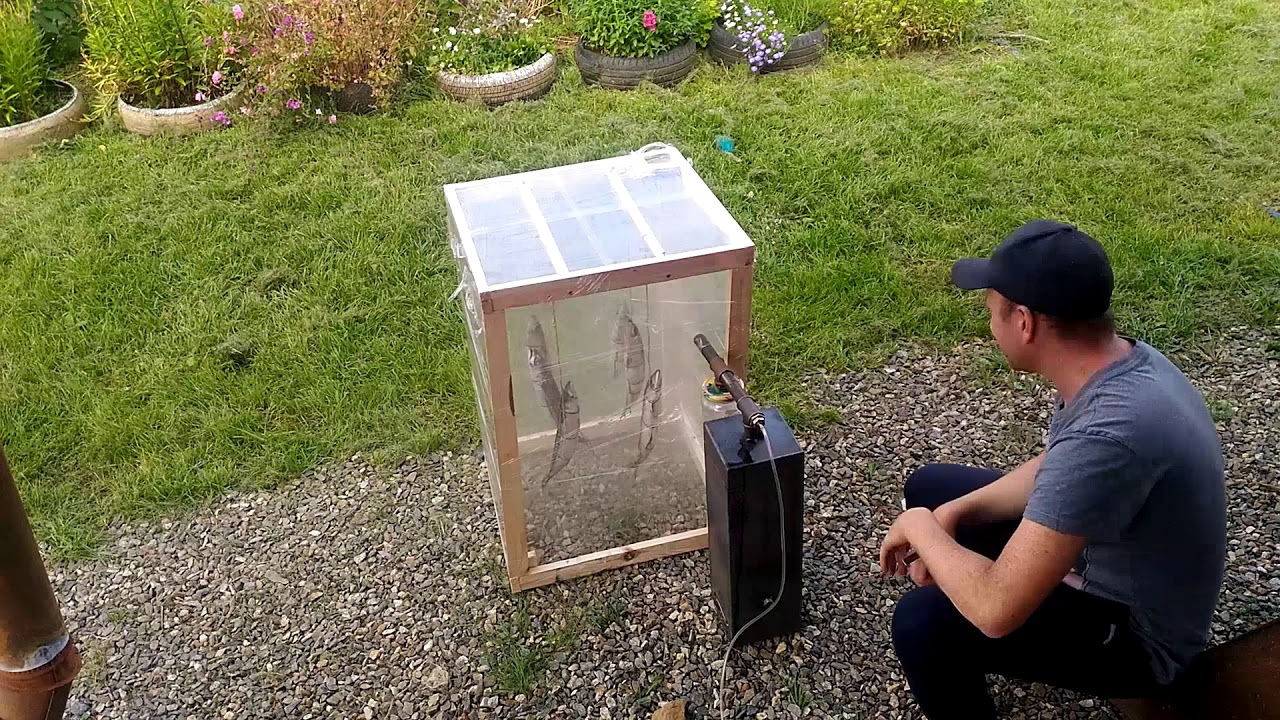

The thermometer controls the smoking temperature. From the pipe supplying smoke, a container for smoking is arranged separately. The smoke generator sends burning steam into this container, where the product is located, for example, fish. For some time, the product is smoked and smoked. During the process, the food must be turned on the opposite side to the generator so that the smoking is uniform.

Homemade smokehouse from a pipe: how to do

A pipe smoker is one of the simplest options that you can easily make yourself.

Materials and tools that will be required

For a homemade design, you need to prepare:

- steel pipe with a diameter of 10 centimeters;

- plastic corrugation - the length should not exceed three meters, or you can use a metal sleeve;

- a piece of metal tube - up to 40 cm with a diameter of 2.5-4 cm;

- a small compressor - an aquarium is suitable;

- fitting docking, which will have the same diameter as the smoke channel;

- switch and electrical wires;

- thermometer.

From the tools you need to prepare a welding machine and a grinder. It is advisable to have at least minimal experience with these tools in order to avoid injury during the generator assembly process and to do everything correctly and accurately.

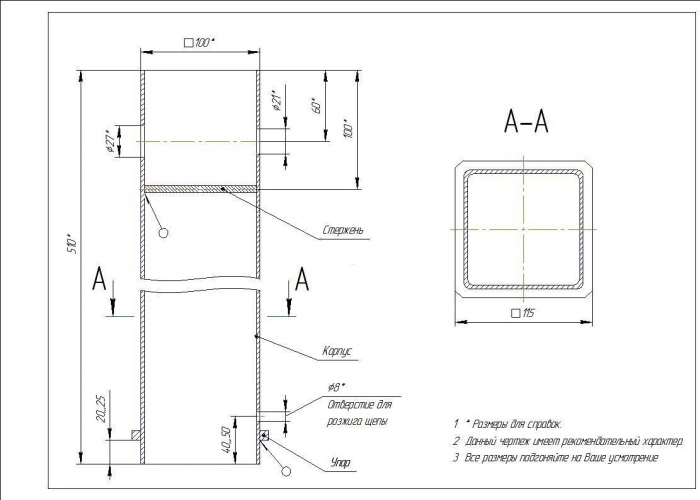

Drawing of a smoke generator from a pipe

In order to make it easier to carry out the assembly process, it is worth studying the drawings of a smoke generator from a pipe.

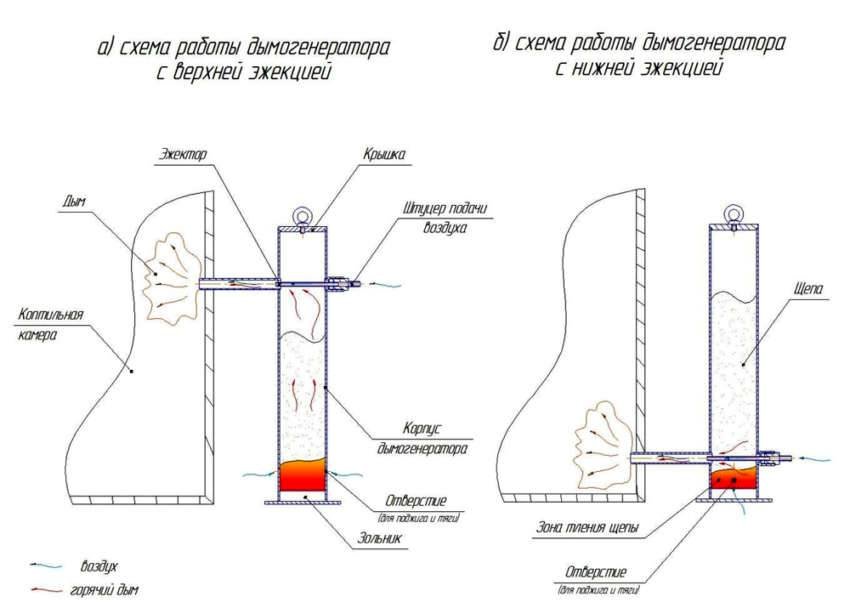

Drawing of a smoke generator from a pipe with a lower and upper ejector.

Step by step assembly

It is necessary to use all the materials prepared in advance to assemble a smoke generator, which will be used for cold smoking, with your own hands from a pipe.

- First of all, the camera is made. As a rule, the average height of the smoke generator is 70-80 centimeters. At the top there should be a cover that could be removed. This is necessary in order to be able to pour fuel into the device without problems. A small container is made in the lower part, where the ash will fall.

- In the simplest versions of the generator, the wood chips are poured onto the bottom of the device, which is welded tightly to the edge of the pipe. In this case, the structure is turned over for cleaning. An ash pan is not provided in such a home-made smoke generator.

- There is also another design option. Wood chips are poured onto a grate, which is pre-mounted at a certain distance from the bottom of the device. The ash that remains after the fuel burns out will pour through the grate. Usually, the bottom in such devices is removable. You can also add a damper to clean the ash pan. This option is considered the most labor intensive.

- Regardless of the option chosen, a small hole is drilled in the lower part of the homemade generator, the diameter of which will be 5-6 millimeters. A minimum amount of air will enter the device through it so that the sawdust slowly smolders.

- If the hole is larger, it may cause a fire.

- In the upper part of the structure, about 7-9 centimeters below the upper edge of the pipe used, another hole is made. With it, a chimney pipe will be attached to the smoke generator.

Next comes the ejector. This device is used to suck the smoke from the smoke generator and direct it to the chimney. A small-diameter tube, into which pressure from the compressor will be supplied, enters a couple of centimeters into the chimney pipe, which has a larger diameter.

- After all the most important parts are connected and fixed, you only need to finally assemble a homemade smoke generator and check how efficiently it works.

- Chips must be placed inside the structure. It is enough to use 700-800 grams of fuel. It is best to use sawdust from deciduous or fruit trees, which will make the finished smoked meat not only tasty, but also quite fragrant.

- Next, you need to tightly close the lid of the device and install the constructed structure in a certain place next to the wall of the smokehouse. If the smoke generator is freestanding, then a hose must be connected to the chimney, which will be directed directly to the smokehouse.

- Then fuel is ignited through a small side hole and the compressor is turned on.

- Now it remains only from time to time to ensure that the sawdust smolders evenly and does not fade, so that delicious and fragrant home-made smoked meats are obtained.

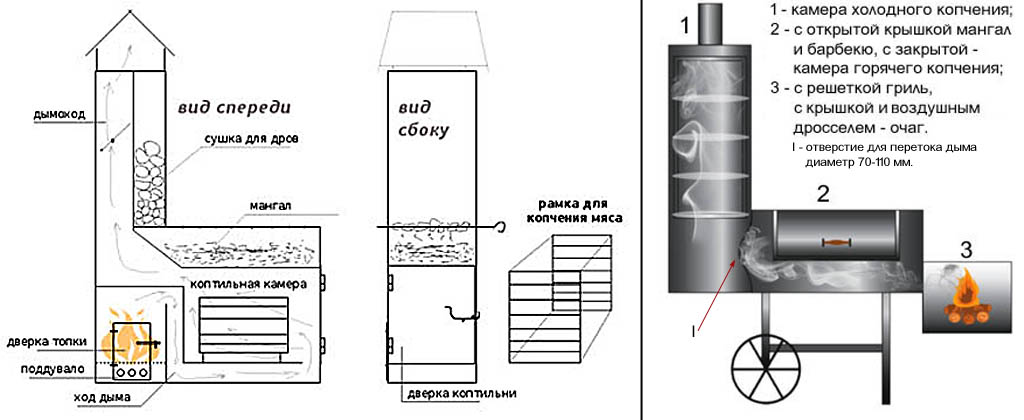

Cold smoked smokers with smoke generator, dimensional drawings

The cold smoked smokehouse (HK) has its own characteristics that distinguish it from other devices:

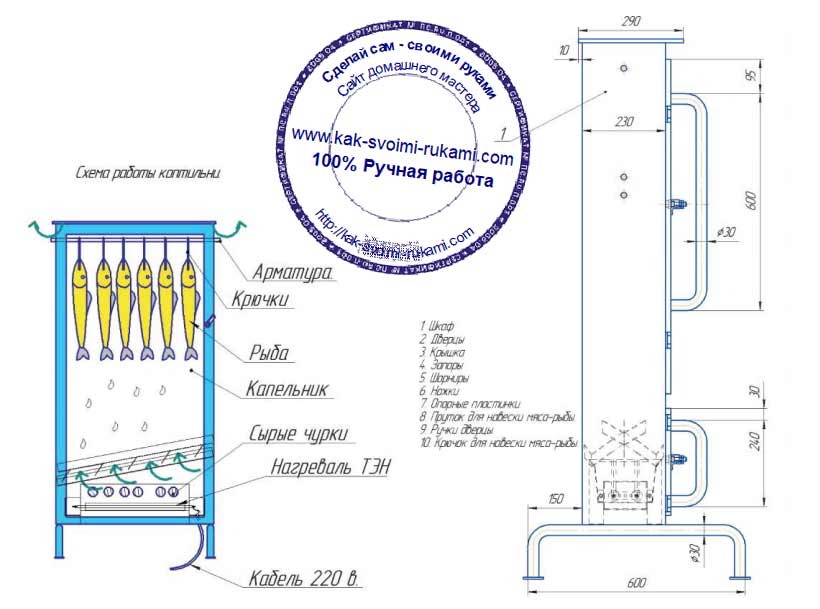

Photo 1. Drawing of a cold smoked smokehouse made of metal. The dimensions of all elements are indicated.

- Finding a smokehouse and a smoke generator at a certain distance from the chamber itself. Usually the fire is located at a distance of 5-10 meters from the smokehouse, depending on the size of the chamber, the required temperature of the smoke and the temperature in the stove or fire used.

- The presence of a sealed pipe between the smokehouse and the smoke generator through which the smoke passes.

- The need to provide filtration of combustion products.

Photo 2. Drawing and computer reconstruction smoke generator for cold smokehouse smoking.

The simplest cold device circuit is as follows:

- A fire or stove located below the smokehouse, divided into an area with coal (firebox) and an area with smoldering sawdust and twigs that give smoke. The smoke generator is laid out with refractory bricks or poured with temperature-resistant concrete, a small brick structure or a metal box may be located on top to prevent smoke from escaping.

- Any suitable metal or refractory plastic pipe is used as a chimney pipe. It can be just a trench, covered from above with metal sheets or roofing material and sprinkled with earth to seal the smoke.

- A smoking chamber (smoke cabinet) with a hole at the bottom where smoke passes, with a grate or with hooks for arranging meat or fish preparations. From above, the element can be covered with a metal lid, roofing felt or dense material.

Important! The size of the smokehouse depends on the tasks and expected volumes of products.The device should be larger than a hot smokehouse for the home, since it makes no sense to smoke 2-3 small fish or a piece of meat for 3-5 days

A standard smokehouse should hold 5-10 kg of blanks.

Do-it-yourself smoke generator for cold smoking: drawing

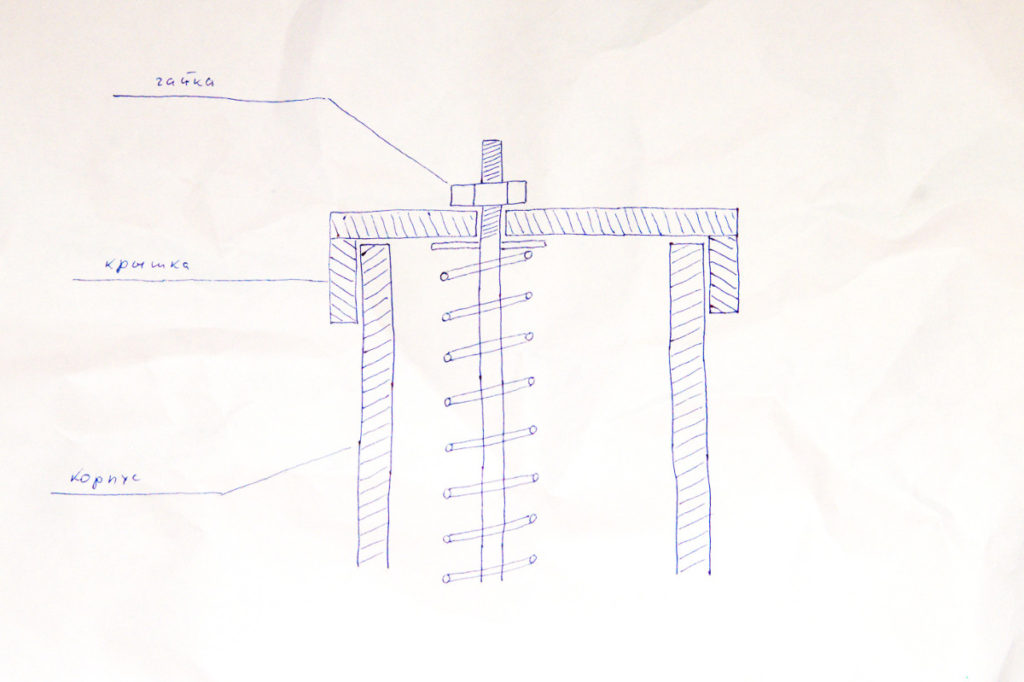

Drawing up a drawing is a necessary preparatory stage that allows you to perform the appropriate calculations and mark them on paper. The diagram necessarily indicates the body of the smoke generator, which can be round or square.

The body of a homemade smoke generator is used as a chamber that is filled with fuel. The walls of the device must have good tightness. Otherwise, the smoke formed during the smoldering of sawdust will dissipate into the surrounding space.

To make a smoke generator for cold smoking with your own hands, you need to use the drawings

The devices for smoking products themselves are divided into varieties depending on the design features and purpose. Today you can find overall stationary devices or, conversely, more compact, portable ones. A damper may be present in the design of the smokehouse. This element allows you to increase the flow of air into the chamber, which contains the fuel.

A homemade cold smoked smokehouse can have two fireboxes. This design is aimed at increasing traction in the system. Smoke generators are used in both hot and cold smokehouses. The drawing indicates all the constituent elements of the device. Be sure to include the ejector and its dimensions, as well as the compressor, in the circuit.

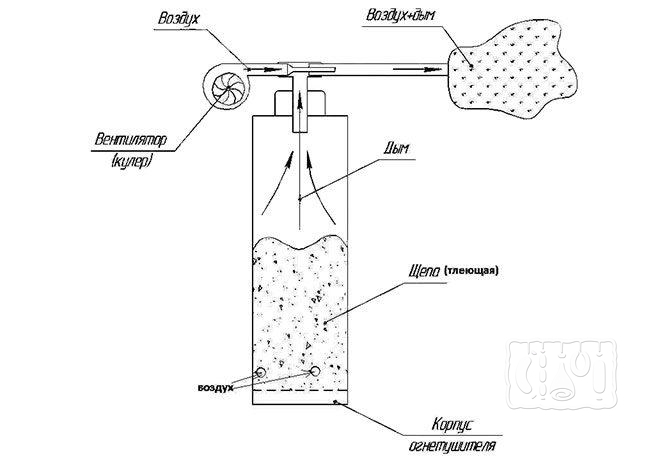

How to make a smoke generator with your own hands: making an ejector

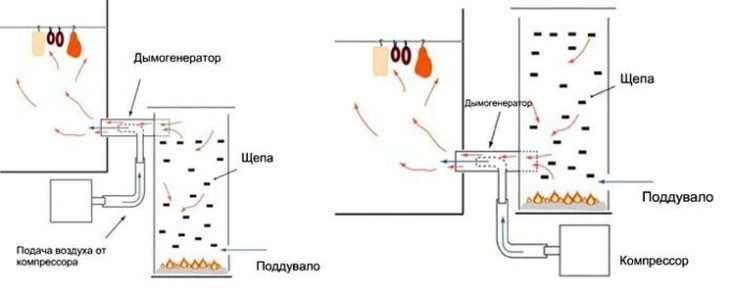

An ejector is a device that is a tube and is used to create the required draft in a smoke generator. This device is classified by location. Depending on this factor, two types of ejectors can be distinguished:

lower;

Any smoke generator for a cold smoked smokehouse consists of a container, a pump (compressor) and an ejector

top.

The first option is not recommended by experts for smokers made by hand. This is due to the fact that such placement prevents the flow of air, which, accordingly, is reflected in the draft in the structure. Tubes installed at the bottom require constant monitoring, which is not very convenient. When drawing up a drawing of a smoke generator, it is necessary to think over the location of this tube in advance and fix it in the figure.

Avoiding traction problems is quite simple. All that is needed is to place the ejector in the upper half of the smoke generator. This move has several advantages. Installing an ejector in the upper part helps to increase the volume of the combustion zone. The fuel located inside the chamber smolders more slowly in this case, and the likelihood that it will go out is also reduced.

This is how the ejector for the smoke generator is assembled with your own hands. A drawing, a photo and a step-by-step instruction - all this allows you to competently assemble this product.

Scheme of the ejector for a cold smoked smoke generator

What to make a compressor for a smoke generator with your own hands?

The compressor is considered one of the most important parts of the device that generates smoke for smoking products. It can be purchased separately, and then attached to the structure.But most often for these purposes various improvised materials are used, which can be found in every apartment or house.

Related article:

Do-it-yourself air blower can be made from an old cooler. This computer part is the best suited to increase the flow of air into the structure. It is necessary to follow the procedure for transforming the cooler into a compressor.

First of all, you need to take a plastic bottle and cut off its upper part. Next, use glue to attach the fan to the inside of the cut plastic element. On the other side (to the neck) a hose is connected. The second outlet of the tube is connected to the smoke generator. This design does its job very well. Its only drawback is its unpresentable appearance.

Do-it-yourself compressor for a smoke generator can be made from an old computer part - a cooler

Another common option is to buy an aquarium compressor for a smoke generator. Many people note that the smoke machine can work without a compressor. But the efficiency of such an installation is lower, since air enters it naturally.

Thus, to increase performance, it is recommended to assemble a compressor. Moreover, it is not necessary that it has a complex structure. A simple do-it-yourself fan for a smoke generator greatly simplifies smoking, and it takes no more than an hour to produce it.

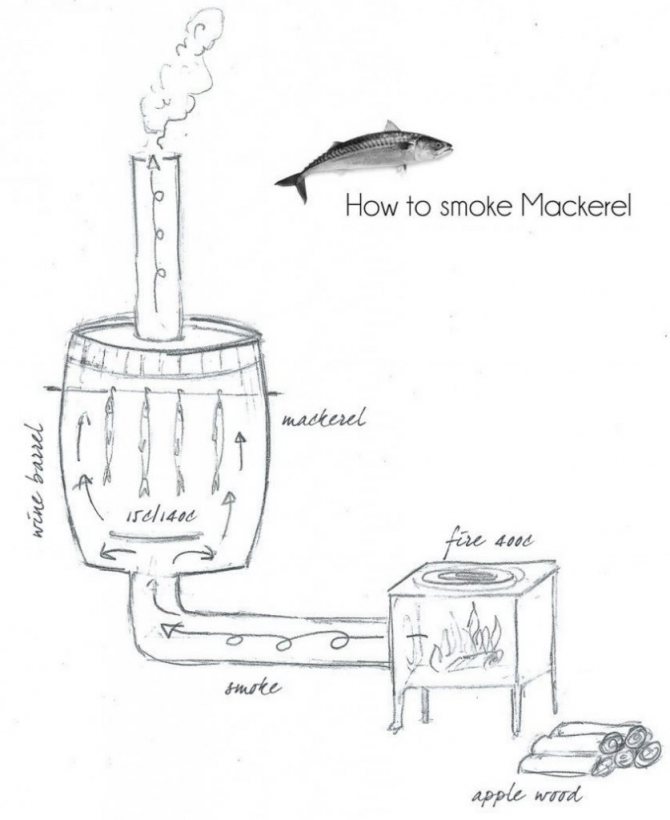

What is smoking, its advantages, what is smoke obtained from

Smoking is a technology of cooking products by heat treatment using smoke. The role of dishes here is played not by a pot or pan, but by a smokehouse.The device has a chamber where the products are located. The operator makes sure that the incoming smoke fumigates them evenly, maintains the temperature required by the recipe.

Smoking is popular due to 3 benefits:

- Any product, especially meat and fish, contains various bacteria that can harm human health. Some parasites are not destroyed by freezing and from being in salt. Smoke neutralizes all bacteria, making the product 100% safe to consume.

- After smoking, foods retain more vitamins and other nutrients in their composition than after boiling, frying or cooking in the oven.

- Smoking has a preservative effect on food. They can be stored for a long time without being jarred or frozen.

Smoking does not mean that the product must simply be placed in the smoke. If this is done in the usual way over smoldering firewood or weeds burned in autumn, meat or fish will simply have to be thrown away. Products will be covered with soot, it will be impossible to eat them.

The smoke in the smokehouse is also obtained by burning wood, but using a different technology. From this, the products acquire a golden color. Additionally, the aroma is important, and it depends on the type of wood used for burning:

- Alder is considered a versatile material. It is suitable for smoking fish, meat and vegetable products.

- Oak is more often smoked with red meat, such as pork or beef.

- Willow gives off a specific aroma suitable for smoking game. Hunters use this method to prepare elk or bear meat. It is good to smoke marsh fish with a willow, which has a specific smell of silt.

- Cherries are good for smoking products of plant origin. This category includes vegetables, berries, nuts.

Wood in the smokehouse is usually used with wood chips or sawdust. Raw materials are bought, obtained independently from dry branches of fruit and other deciduous trees. Pine, spruce and all other types of resinous wood are not used for smoking.

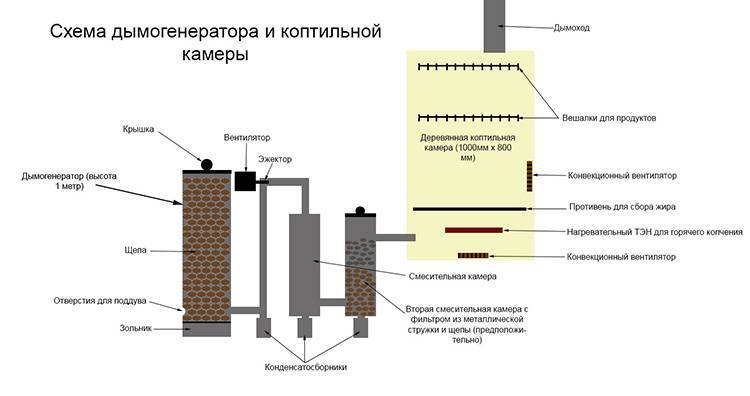

Do-it-yourself smoke generator device for cold smoking

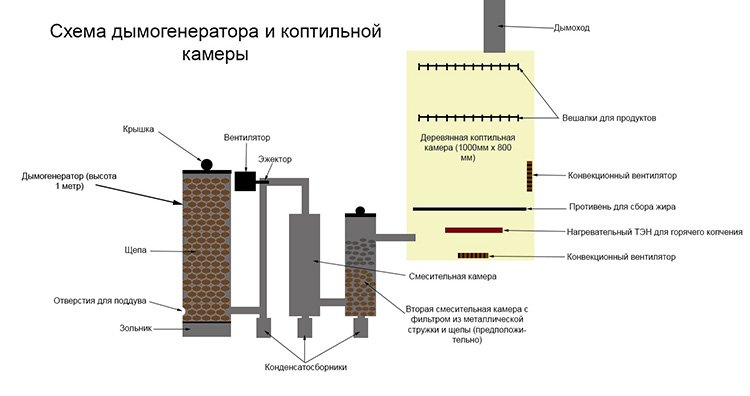

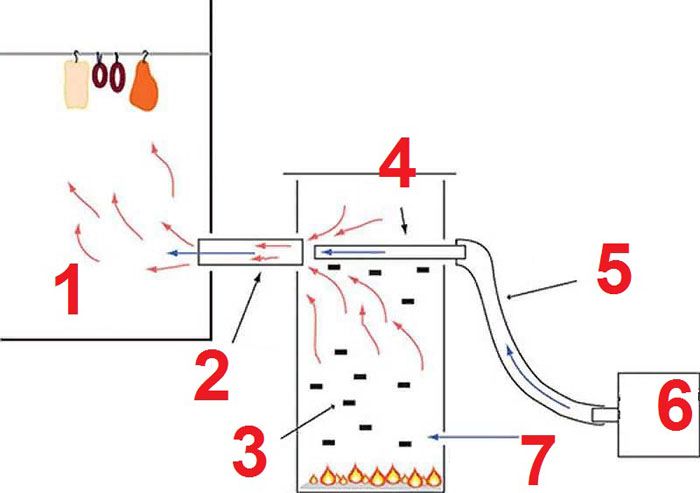

- The figure shows a chamber (1), in which products are placed on hangers for further processing.

- Wood sawdust (3) is poured into a firebox of a suitable size, made of a sufficiently strong heat-resistant material.

- Thrust adjustment here is organized using a blower (7).

- The compressor (6) supplies fresh air through a flexible hose (5) and a spigot (4).

- The container is closed on top with a lid.

- Therefore, the smoke is directed through the connecting tube (2) to the smoking chamber.

Ejector

Experts recommend using the first option. With the top placement of the ejector, you can enjoy the following advantages:

- the volume of the combustion area increases. The probability of attenuation of solid fuel is reduced;

- in this embodiment, it is easier to ensure slow smoldering. Consequently, less often you will have to replenish the supply of firewood;

- the top location of the ejector with forced air supply creates sufficient traction. Additional smoke filtration with a layer of backfill will come in handy;

- lower - contributes to the ingress of large particles into the chimney, makes it longer to reduce the operating temperature in the smoking chamber;

- proximity to the heated area reduces the service life of the nozzle, increases the risk of damage to welded joints.

Smoke generator compressor

This connection of the compressor minimizes the thermal effect on the ejector, which prolongs the life of the unit. At the same time, sufficient air flow velocity is provided to supply smoke to the food processing area.

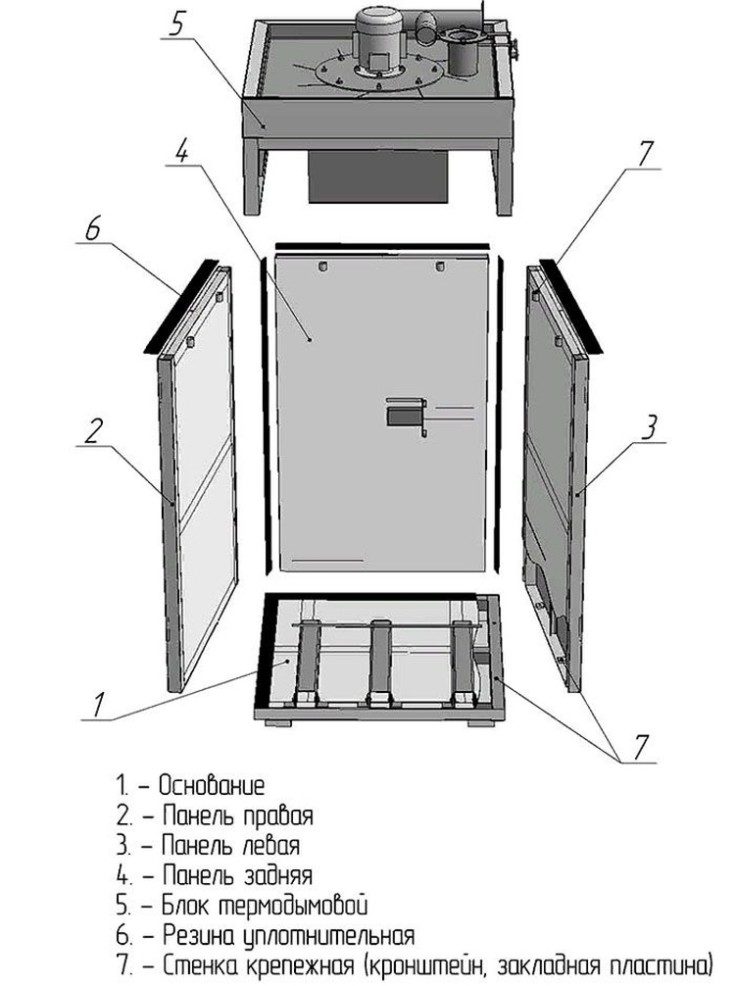

Smoking chamber

The figure shows an example of a factory smoking chamber. It is easy to guess that an old refrigerator is quite capable of performing such functions. While maintaining the optimum temperature conditions, the components of its design will not be damaged.

Modernization

The design described above is fully operational. But it has many shortcomings, not very convenient. Based on the results of its use, improvements and improvements were made.

Adjustable traction

One of the main disadvantages of the described design is the poor regulation of the intensity of combustion. It can be slightly changed by adjusting the compressor capacity. An adjustable blower can be added to the design. It can be done according to the principle of the gate:

- In the lower part of the body (above the place where the stack is attached), weld a piece of a round pipe 10-15 cm long.

- Drill two holes that are located strictly one opposite the other.

- Take a rod that goes into these holes. Its length is 20 cm more than the diameter of the pipe.

- Cut out a circle from a sheet of metal (2-3 mm thick). Its diameter is slightly smaller than the inner diameter of the pipe.

- From the bar to make a "handle" (bend it).

- Insert a handle into the holes, weld the cut circle.

Ash pan

Another drawback is that ash wakes up through the grid. You can put the smoke generator on a metal plate, but you can make an ash pan. By the way, the gate can be made in an ash pan.This will be more correct, since the air suction can be almost blocked, which cannot be achieved with a gate in the housing - air enters through the grid.

The ash pan is made from a piece of pipe with a slightly larger cross section than the pipe on the body. If you don't have one, you'll have to weld it. The bottom is welded to a piece of pipe, a thin strip of metal is welded to the body along the perimeter. The body is inserted into the ash pan (the legs are also welded to it).

Condensate collection

During the operation of the smoke generator for cold smoking, condensate is released. This complicates life, especially if the temperature outside is low. You can solve the problem by making a collector for condensate. For this:

- we lower the outlet pipe of the smoke generator down,

- at the lowest point we install a container for condensate, welding two pipes to it - one opposite the other;

- on the opposite side, the pipe rises again and enters the smoking cabinet.

With such a device, a significant part of the condensate is in the tank. The problem is not so acute.

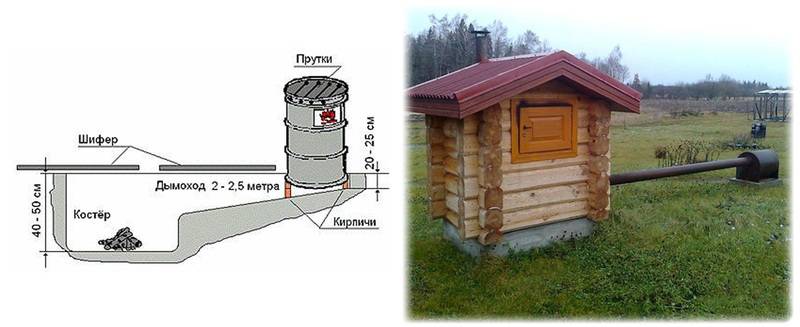

What are smokehouses

Back in the Middle Ages, people learned to naturally get rid of unwanted impurities during smoking. They dug adits or laid long pipes between the firebox and the smoking chamber. In this case, the smoke mixture is cooled to 30 degrees and moisture and tar condense on the walls of the chimney. Thus, all harmful substances and soot have time to settle, and already clean, purified smoke enters the product.

Durable fixed construction

You can build a stationary smokehouse with your own hands.

The task of the installation, which was used by our ancestors (it is also called a chimney), is to cool the smoke to the desired temperature.At the same time, the product is processed in a sparing mode, without loosening its consistency and with the preservation of all natural components. Increasing the shelf life of the delicacy is another useful feature of the cold smoke mixture.

For the construction, you will need to dig two holes at a distance of three to four meters from each other, observing a slope between them of about 20 degrees. Ideally, it is better to use the natural terrain of the site. A pit on a hill is made 60x60 cm or wider, depending on the desired production volumes. Depth - two bayonets.

For the firebox, they dig a smaller recess, about 50 cm wide and 70 cm long, the same depth. The trench between them is laid based on the material. When laying a pipe, the trench can be narrow, and if it is masonry, then three bricks wide. It is not worth deepening much, it is enough to sprinkle the structure with earth - for aesthetics.

After the end of the earthworks, a foundation is laid on the sand and gravel pillow. For a smokehouse - tape (it is possible without formwork), at a level with a chimney, for a firebox - solid, 10 cm below the level of the pipe.

After it dries, laying is done. The side walls of the smoke generator are laid out from refractory bricks on a clay mortar with the addition of salt and liquid nails. Such an elastic mixture will not crack at high temperatures and will provide the necessary tightness. From above, the structure is covered with a sheet of iron or laid with a brick on a reinforcing grid.

If the farm has an oven door, then the width of the smoke generator is adjusted to fit it. Although it can not be installed using a metal shutter.But still, to regulate the draft, it is desirable to provide a conveniently closing cover, as well as an ash pan that is separated from the combustion chamber by a grate (grate). A pipeline is installed in the finished structure, which is also lined with bricks or stones.

In the absence of the necessary slope between the chambers on the strip foundation, an artificial elevation is laid, for example, from a cinder block in three rows. Here you can use the usual cement mortar, but with the obligatory control of the level of the building.

The smoking chamber itself is a flight for fantasy. It can be laid out of red brick or make a frame and sheathe it on both sides with clapboard. The Internet is replete with design options that ennoble the summer cottage. The main thing is tightness, a wide door and the presence of shelves and hooks for products. If the cabinet is placed on a cinder block box, the bottom can be omitted, replacing it with a grate.

We melt, check - and the smokehouse is ready.

Lightweight version of the smokehouse

To simplify the design, you can perform the unit in a different way.

A large barrel can replace a smoking cabinet. A hole for the pipe is cut at the bottom. Just above the chimney, spacers are provided for placing a bowl of sand of a smaller diameter as a grease receiver. From above, on removable skewers, hooks are attached or a grill is installed. The container is covered with burlap and pressed down with a lid with oppression.

The same functionality can be achieved with an old refrigerator. Craftsmen remove the internal plastic trim from it and sheathe the unit with wood.Shelves are installed, and a grease receiver is installed above the smoke hole, if desired, a place is allocated under it for an electric stove to heat up the smoke in cold weather or organize safe hot smoking.

The firebox does not have to be made of bricks. With small volumes and no desire to tinker, you can dig a hole according to the given dimensions, lay it on top and bottom on a sheet of iron and cover it with a damper.

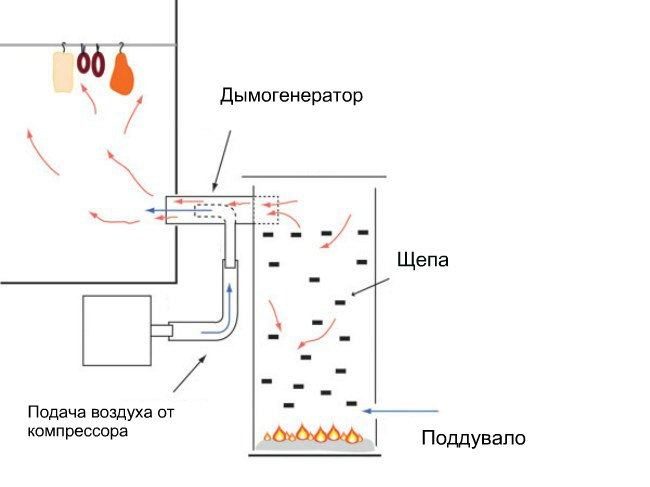

Mobile based compressor

Progress does not stand still. Increasingly, the smokehouse is being made compact, while not inferior in functionality to a stationary one. To do this, you need a smoke generator made from an air blower. This eliminates the need to lay a long chimney. In a mobile device, the smoke from the nozzle already has the temperature necessary for cold smoking.

To begin with, let's touch on the principle of the injection unit.

What is a smoke generator and why is it needed

With a hot or cold type of smoking, in any case, a fire is needed for smoke. For a cold smokehouse, the smoke temperature should not exceed 40°C. To reduce the temperature of the incoming smoke, the fireplace is placed away from the smoking chamber, and a sealed chimney is laid between them, in which the incoming stream is naturally cooled. For better cooling, the chimney is sometimes buried in the ground.

Cold smoke naturally preserves food

Cold smoke naturally preserves food

The cold smoke generator greatly simplifies this design. By itself, it is a compact device into which wood chips or sawdust of alder and oak are poured.In this design, sawdust slowly smolders, and the outgoing smoke has a low temperature. The smoldering process is started using an electric or gas heater, and the movement of smoke is provided by a blowing compressor.

Cold smoking preserves and gives a unique flavor to meat, fish and lard, homemade cheeses for a long time. Such products are of guaranteed quality, without chemicals harmful to the body, which are stuffed with sausages by modern manufacturers.

A home smokehouse will allow you to significantly save your home budget, because all smoked products are not cheap

A home smokehouse will allow you to significantly save your home budget, because all smoked products are not cheap

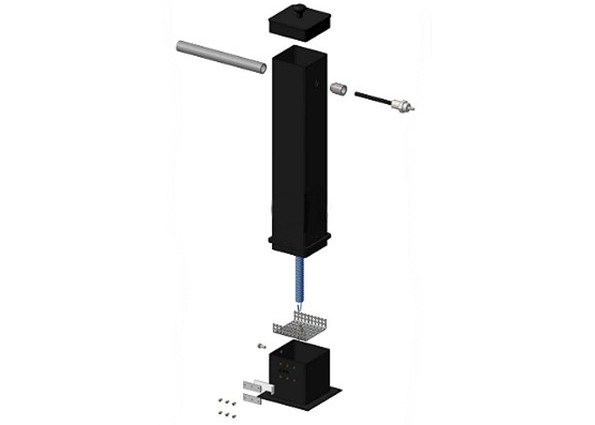

Manufacturing and assembly of structural elements

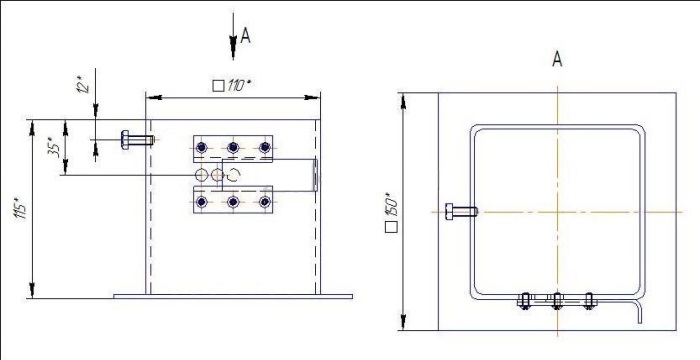

Frame

We take a square pipe (10x10x3 cm, 50 or more centimeters long; you can use a pipe even up to 1 meter, but you should not get carried away, since it is more difficult to manage a device that is too large, for example, to clean it). Such dimensions of the pipe will allow filling the smoke generator with sawdust to ensure its operation for at least 10 hours, which is how long it will be possible to produce cold smoking on one filling.

We drill coaxial holes in the pipe at a distance of 6 cm from the upper end, which will be needed for the ejector sleeve and the chimney. We select the diameter, taking into account the outer diameters of these devices.

Stepping back from the upper end by 10 cm, by welding inside, we fasten the steel rod according to the width of the pipe, it will act as the upper spring hook.

We weld the stop, which serves as a limiter when connecting the ash pan to the generator housing. For the manufacture of the stop, a plate with dimensions of 11.5x11.5 cm and a thickness of 0.6-0.8 cm is cut out with a square-shaped hole according to the dimensions of the body pipe itself.

We drill a hole for igniting wood from the bottom end by 4-5 cm.

Ejector and chimney

In the holes that were made in the body, we weld an ejector sleeve on one side, and a 3/4 pipe on the other. The size of the sleeve must be selected according to the fitting. If we use a KAMAZ pipe, then we first solder it to the fitting. If there is no turning experience, contact a professional turner.

The main dimensions of this assembly are the diameter (of the inner and outer tubes of the unit) and the length of the inner tube entering the outlet system of the device.

The outlet parameters are equal to the diameter of the passage of the pipe 3/4 inch. For the inner tube, a diameter of 6-8 mm will be optimal.

When the blower is weak, the inner diameter of the tube for the ejector is 6-10 mm. The optimal entry of the smaller pipe into the larger one (3/4) is 2 centimeters. Before a test run, make the inner tube with a margin. If necessary, it can be shortened to the optimal size according to the results of the experiment.

The ejector is an important working element of the smoke generator. It is installed before exiting the combustion chamber. If the intake pipe is located at the bottom of the chamber, then this assembly is installed outside - on the pipe, which serves as a link between the lower intake pipe and the upper pipe, which supplies smoke to the smoking chamber.

Spring and ash pan grate

We select the size and load of the spring. It will be inserted into the generator housing, provide good traction and simplify the passage of smoke into the ejection zone. Any spring will do, including an old door spring - the main thing is that it should be in the generator case along the length with a kilogram load.

We are engaged in the manufacture of an ash pan grate.To do this, we use a perforated sheet (the holes should be no larger than the fuel chips, and the ash should pass freely through them). We bend the sheet in a U-shape, find the center, insert the M8x45 bolt, counter it on both sides. At the end of the bolt we make a hole a little more than the wire diameter of the spring. You can use a standard cotter pin bolt.

Ash pan

Making an ash pan is easy. We use a square pipe (11.0x10.0x0.3 cm, 10 cm high) and a base plate (15.0x15x0.5 cm), weld the lower plane to it. The size of the base plate can also be used differently.

To fix the ash pan to the generator housing, we drill an M8 hole into which the bolt will be inserted. Then we drill 3 more holes for the damper itself (Ø8 mm) and 6 holes for mounting the guides (M4).

In addition to igniting the fuel, the damper is needed in order to regulate the draft and intensity of smoldering.

Lid

It is made according to the same principle as the ash pan. However, we make a handle on the top plate by welding. When making the top cover, you do not need to drill additional holes, such as holes for ventilation or those used to form a chimney. But the sides welded along the edge will come in handy, they will allow you to tightly put the lid on the body of the smoke generator.

Assembly

The order of assembly of the smoke generator is presented in this illustration:

The design of the assembled device is shown in this drawing:

How does a smoke generator work?

Cooking food by smoking is a long process. A traditional appliance requires a certain amount of firewood and must work for several days. Burning continues uninterrupted. The smoke generator for cold smoking produces smoke, which is fed into the cabinet with processed blanks.As a result, products pre-marinated with a special method are transformed into delicious dishes ready to eat.

The cold smoked smoke generator device has a simple design, which you can mount yourself. It will be different from a hot smoked smoke generator. Materials for this are sometimes at hand. The temperature inside the smoke cabinet is not very high, so the products do not burn. Smoke is obtained from smoldering sawdust, wood chips or shavings. The task is to make the combustion constant, uniform and somehow feed it into the cabinet. You can set up automatic operation.

A simple design is arranged as follows.

- Fuel (firewood) is smoldering in one of the chambers.

- The chamber, in which the food products are hung, is connected to it by a cylinder with a soldered branch pipe having a branch. Air moves through it under low pressure.

- The flow moves to the second chamber, followed by smoke from the smoke generator.

The combustion chamber, equipped with a device that creates a stream of smoke and air directed to the products, is nothing more than a smoke generator. Its size should be optimized according to the principle: the larger it is, the longer the process. To make it with your own hands, an aluminum milk can, a fire extinguisher body, and an old thermos are suitable.

But the best solution is to create a smoke generator from a steel pipe with parameters: diameter up to 10 cm, length - 0.5 m. One side must be closed with a lid by welding. The second is open, but a hole is made on the side for ignition. You will also need a side hole for connecting a branch pipe (short tube - outlet), through which the air driven by the compressor will flow.

The location of the pipe is important.Optimally, it should be located farther from the combustion area for the following reasons.

- If this is not the case, then the combustion chamber will have height restrictions, which will cause the wood to fade.

- And also the service life of the smoke generator can be reduced. Intensive smoke extraction means fast combustion.

- The draft inside the smoker will decrease, especially at times when the compressor is not working.

- If the nozzle is low, chips can get inside, block the passage.

- In the high temperature area (bottom) at the nozzle, the service life may be reduced.

The intermediate part of the smoke generator can be made from pipes with a diameter of up to 25 mm. It is welded to two chambers (smokehouse and combustion) when installed in the gap of the pipe. This part, in turn, is made from the same pipe, to which a tube with a smaller diameter must be welded. Air from the compressor will go through it.

But you can make a smoke generator without a compressor, which we talk about in the articles "Do-it-yourself smoke generator without a compressor".

There are other options for manufacturing the intermediate part. Pipes can be connected using a thread with a tee - a fitting between them.