- The principle of operation of a double-circuit gas boiler

- What are its advantages of energy-dependent species

- Overview of models and manufacturers

- Protherm

- Baxi

- Buderus

- "Rostovgazoapparat"

- Navien

- "Signal"

- "Conord"

- "Danko"

- Combustion chamber arrangement and types of smoke exhaust

- Open combustion chamber and natural draft through the chimney

- Closed combustion chamber and natural draft through a coaxial chimney

- Closed combustion chamber and forced draft

- Efficiency and gas consumption

- Instrument design

- heat exchanger

- The difference between an expensive wall-mounted boiler and a cheap one

- Features of double-circuit gas boilers

- Principle of operation and device

- Advantages and disadvantages of double-circuit boilers

- Placement of a double-circuit boiler

- Is it profitable to heat a house with a boiler with two circuits: the nuances

- Differences between an atmospheric gas boiler and a turbocharged one

- Boiler power

The principle of operation of a double-circuit gas boiler

The gas boiler is designed in such a way that it can operate in two modes: heating and hot water supply. When heating a room in the boiler body, a heat exchanger with a heat carrier is heated. It can warm up to temperatures ranging from 35 to 80°, depending on what result you need.

To turn on the heating mode, the gas boiler is equipped with a thermostat that reacts to a decrease in the temperature in the room.At the same time, it transmits a signal to the system, as a result of which the pump starts, creating a vacuum in the coolant return pipeline. As a result, the heated coolant enters the heating system. If at the same time the pressure in the system reaches 0.45 bar or rises above this mark, the relay contacts close and the burner starts to work. The start of these processes is controlled by a microprocessor.

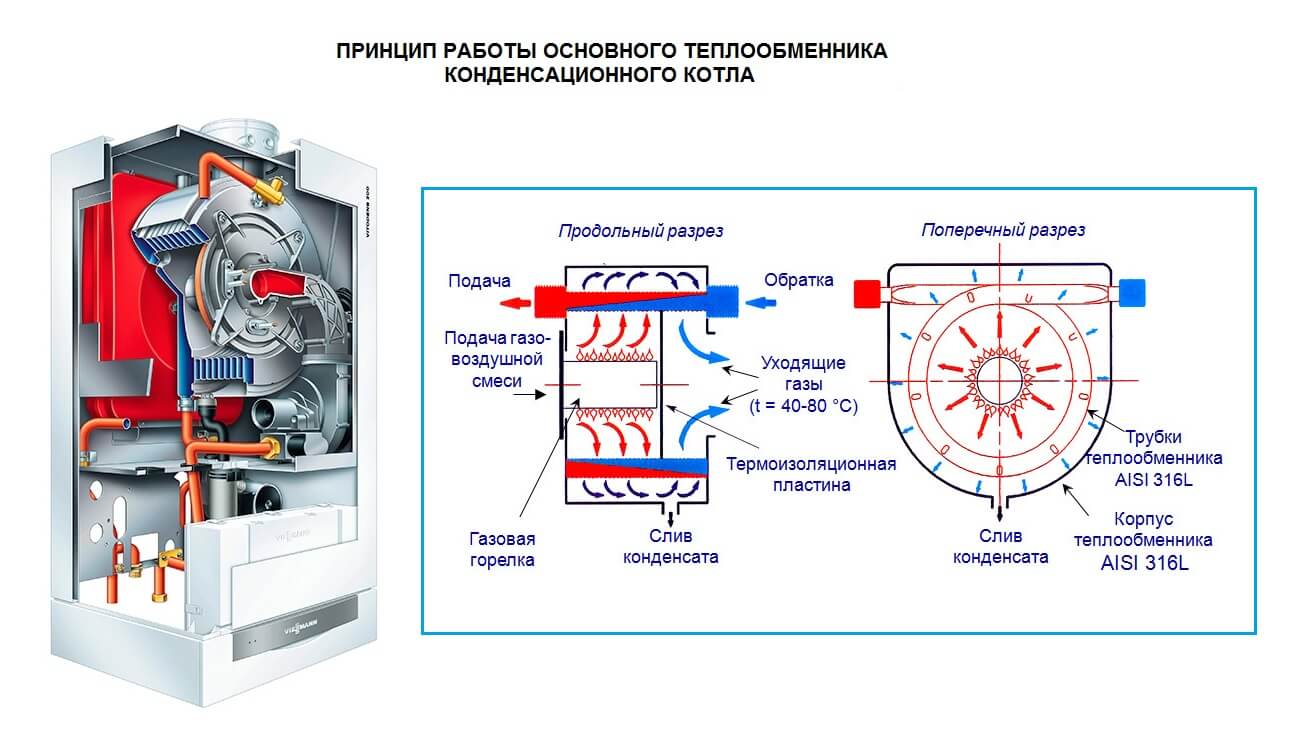

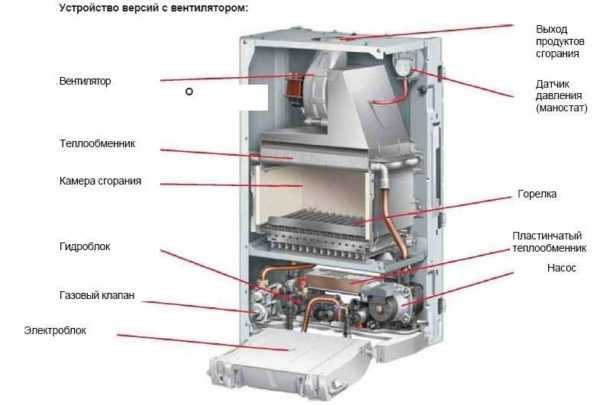

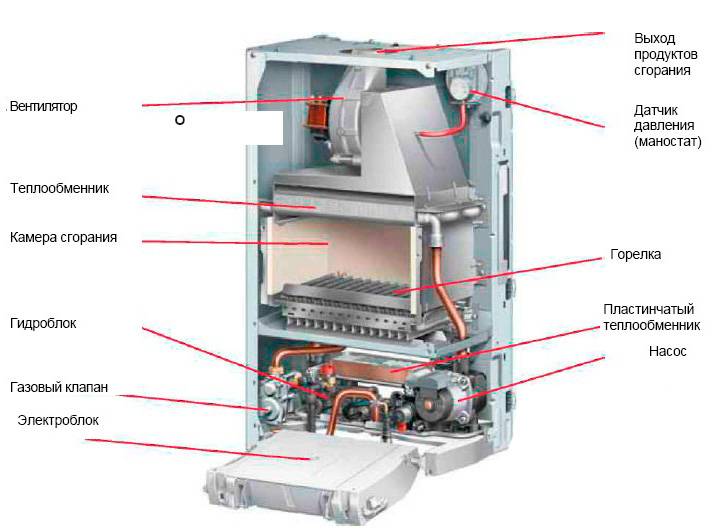

Scheme of the device of a gas boiler with a fan.

The first time after start-up, the gas boiler operates at minimum power, which gradually increases to maximum. If in the process of increasing the power the coolant is heated to the required temperature, then the power does not increase further and the operation of the device switches to the modulation mode. If immediately after start-up the operating power of the appliance is too high, the burner is switched off by the electronics. It can be re-ignited no earlier than after 3 minutes.

The burner occupies the lower part of the combustion chamber, which is a metal container with good thermal insulation. Above it is a heat exchanger. The burner starts to work at the moment when, in order to continue the correct operation of the system, it is required to heat the water, which in this case is used as a heat carrier. Simultaneously with the operation of the burner, the operation of the circulation pump also begins, which ensures the movement of the coolant through the pipeline of the heating system.

When the boiler's default operating parameters are reached, the gas supply will be reduced and the boiler will go into standby mode. When the temperature drops again, the temperature sensor will give a signal, which will lead to an intensive gas supply, due to which the burner will ignite.

Water from the heating circuit does not enter the hot water circuit thanks to the three-way valve. The coolant enters the pipeline of the heating system through the supply pipes and returns through the return pipes. That is, in the first heat exchanger, water moves in a vicious circle. Due to this, a minimum amount of plaque is formed on the inner surface of the pipes. Water is supplied to the second circuit from the water supply, as a rule, it contains much more impurities, which increases the likelihood of circuit failure. If this happens, the boiler can be used as a single-circuit, that is, only for heating.

What are its advantages of energy-dependent species

Non-volatile installations operate only on a mechanical principle, without needing to be connected to the power supply system.

This makes them indispensable in remote villages, in areas with dilapidated or overloaded electrical networks. Frequent shutdowns cause the heating to stop working, which is unacceptable in the conditions of the Russian winter.

Non-volatile models provide continuous heating of the house, regardless of external conditions. However, such possibilities limit the possibilities of non-volatile boilers. They work only on natural physical processes - the circulation of the coolant requires the installation of the heating circuit at a slight angle and is based on the rise of warm liquid layers upwards.

Smoke removal occurs under the action of conventional draft in the chimney. It should be borne in mind that natural processes proceed with minimal intensity and are unstable, therefore, external additional devices are usually installed - a turbo nozzle and a circulation pump.

They make the unit more productive, and operation in a non-volatile mode occurs only during a power outage.

If there is no power supply to the house at all, only the basic capabilities of the unit are used.

Overview of models and manufacturers

Consider the rating of the most popular manufacturers producing popular models gas double-circuit boilers floor modification.

Protherm

Protherm is a popular brand in Russia that produces gas boilers in an ideal price-quality ratio. The company's product range includes not only floor-standing, but also wall-mounted units, as well as models powered by electricity and solid fuel.

Protherm floor heating equipment is equipped with an electric ignition function, a built-in boiler of various sizes and stable heat sources. The company's product range includes both volatile and independent devices.

Protherm floor standing gas boilers are presented in the following collections:

- "Bear" - KLOM, SLZ17, PLO, TLO;

- "Grizzly KLO";

- "Wolf";

- "Bison NL".

Baxi

Baxi produces heating equipment of unsurpassed quality. The representative office of this company was opened in Russia in 2002. The Baxi assortment includes not only boilers, but also boilers for them, autonomous water heaters (AGV), accessories, remote control systems. Floor heating units of this company are produced with condensing and atmospheric burners. The category of condensing units is represented by the Power HT 45-150 and Power HT 230-650 models.

In the arsenal of instances with an atmospheric burner, there are highly effective collections:

- "Slim" with a cast-iron heat exchanger;

- "Slim HPS" - a series of gas boilers of the highest efficiency;

- "Slim EF" - a line of non-volatile cast iron units.

Buderus

Consumers leave good reviews about the products of the German brand Buderus. The range of this manufacturer is very rich and varied. Here you can find not only floor-standing boilers of excellent quality, but also control systems, water heaters, burners for equipment, radiators, gas-fired power plants, solar collectors and various components for engineering systems.

The company offers a choice of consumers gas units "Logano" made of cast iron with a power of 20-24 kW to 270 kW. All Buderus brand models have quality certificates.

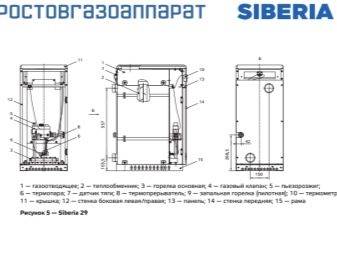

"Rostovgazoapparat"

A domestic company called Rostovgazoapparat is famous for its popular series of gas boilers - Siberia, RGA, AOGV. So, in the "Siberia" series floor equipment of the latest generation is presented. It is distinguished by affordable cost, efficiency, the presence of automation and modern design. The RGA collection includes devices for water heating and domestic hot water supply. They are great for small spaces. The AOGV series is represented by classic devices powered by gas.

Navien

Navien is the best boiler manufacturer in Korea. The range of the company includes floor-standing units powered by gas and diesel fuel. These products are represented by high-quality models with the abbreviations GA, GST, LST, LFA.Korean brand branded units boast excellent safety features, efficient smoke exhaust systems, high-quality steel heat exchangers and a frost protection system.

"Signal"

The Signal group of companies is engaged in the production of single-circuit and double-circuit boilers of various capacities and modifications, as well as stoves for baths and saunas.

The main advantages of branded heating units from the Signal company are:

- affordable cost;

- profitability;

- safety;

- ease of use.

"Conord"

This manufacturer is the largest manufacturer of heating equipment in Russia. Its range includes more than 50 units of modern gas and solid fuel heating units. Double-circuit floor models "Conord" are of brilliant quality, individual design and energy efficiency.

Heating devices of this brand are equipped with cast iron and steel heat exchangers. In addition, the Conord assortment also includes products with increased thermal performance and even industrial boilers of the appropriate power and dimensions.

"Danko"

The large company Danko is famous for its high-quality floor standing gas boilers, the cost of which varies from 20 to 80 thousand rubles. They can heat areas of 70-860 sq. m. Branded units have steel and cast iron heat exchangers.

Different products have different automation systems:

- "Sit" (Italy);

- Kape (Poland).

Combustion chamber arrangement and types of smoke exhaust

According to the method of oxygen entering the furnace (it is required to maintain an active flame), all double-circuit gas boilers are divided into two categories:

- with an open type combustion chamber (atmospheric boilers) - they take air directly from the room itself, in which the equipment is installed;

- with a closed-type combustion chamber (turbocharged boilers) - they do not draw in heated air from the room, but take it from the street through a coaxial chimney, which reduces heat loss.

The type of combustion chamber determines how exactly the output of combustion products should be organized: through the shaft to the roof of the house or directly through the wall.

Open combustion chamber and natural draft through the chimney

In boilers with open combustion chamber and natural draft flue gases are removed through a full-fledged vertical chimney that goes to the roof. This whole design has a simple device - for this reason, it is not expensive and, theoretically, more reliable. But the installation of atmospheric boilers is complicated.

The installation of such boilers is only allowed separately from living rooms, subject to all the rules for organizing a chimney and placing a boiler room:

- the diameter of the chimney pipe is at least 130–140 mm, and the length is 3–4 m;

- it is made of stainless acid-resistant steel or asbestos;

- the minimum area of the boiler room is 3.5–3.7 m2 with a ceiling height of 2.2–2.5 m;

- the room has at least one window from 0.6–0.7 m2 and good ventilation.

If at least one of the listed rules is not observed, it would be wiser to prefer a device with a closed combustion chamber, with a chimney outlet through the wall. Otherwise, at best, the equipment simply will not be able to work, and at worst, carbon monoxide will begin to accumulate in the room, which is life-threatening.

Closed combustion chamber and natural draft through a coaxial chimney

Parapet non-volatile gas boiler Lemax Patriot-16 assembled with a coaxial chimney.

Parapet gas boilers are neither floor-mounted nor wall-mounted. In addition to the method of placement, they differ in that they have holes in the body, so they can be used as a radiator and heat the room in which they are installed. They need a coaxial chimney, for which one pipe is inserted into another: the smoke is removed through the inside, and air from the street is sucked in through the intermediate gap.

Such equipment is installed anywhere, the main thing is below the line of window sills (for example, instead of a battery) and in any premises: a private house, a household. building, commercial building and even an apartment in a high-rise building. The only limitation is that the horizontal pipe section should not exceed 2.8–3.0 m.

Closed combustion chamber and forced draft

In boilers with a closed combustion chamber, there is an inflatable fan (turbine), which forcibly removes smoke from the furnace immediately to the street and automatically sucks in new air from the street through the same coaxial pipe. The devices are easy to install, because they are not demanding on the arrangement and size of the boiler room.

The main advantage of the turbine unit is that it does not have access to an open source of fire, which reduces the likelihood of carbon monoxide entering the house.

In general, gas boilers with a closed combustion chamber are installed in rooms for any purpose, but some nuances must be taken into account:

- the turbine located in the boiler creates a little additional noise;

- the coaxial pipe is brought out through, which affects the appearance of the wall;

- the exit of smoke at eye level does not allow you to be closer than 4-6 m from the pipe outside the house;

- the turbine unit consumes 40-50 W / h more than a standard chimney.

Forced draft appliances are more expensive than conventional ones, but they do not require the construction of a full-fledged chimney, so installation is cheap.

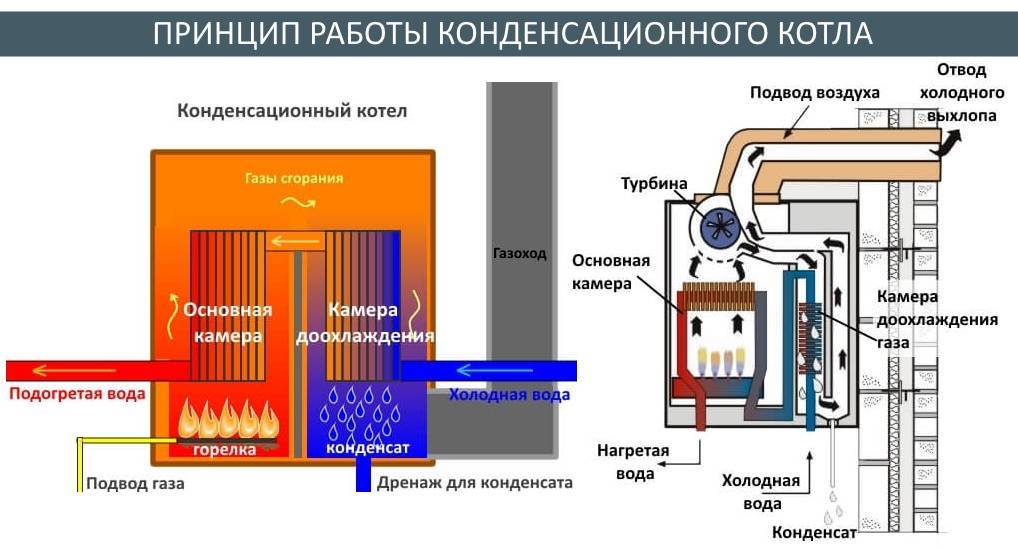

Efficiency and gas consumption

The coefficient of performance (COP) of a heating boiler is an indicator that directly affects the efficiency of its use of energy resources.

For standard gas units, the efficiency value is in the range of 90–98%, for condensing models 104–116%. From a physical point of view, this is impossible: this happens if not all of the released heat is taken into account, therefore, in fact, the efficiency of convection boilers is 86-94%, and condensing boilers - 96-98%.

According to GOST 5542-2014, 9.3 kW of energy can be obtained from 1 m3 of gas. Ideally, at 100% efficiency and average heat loss of 10 kW, fuel consumption for 1 hour of boiler operation will be 0.93 m3. Accordingly, for example, for a domestic boiler of 16–20 kW, with a standard efficiency of 88–92%, the optimal gas flow rate is 1.4–2.2 m3/h.

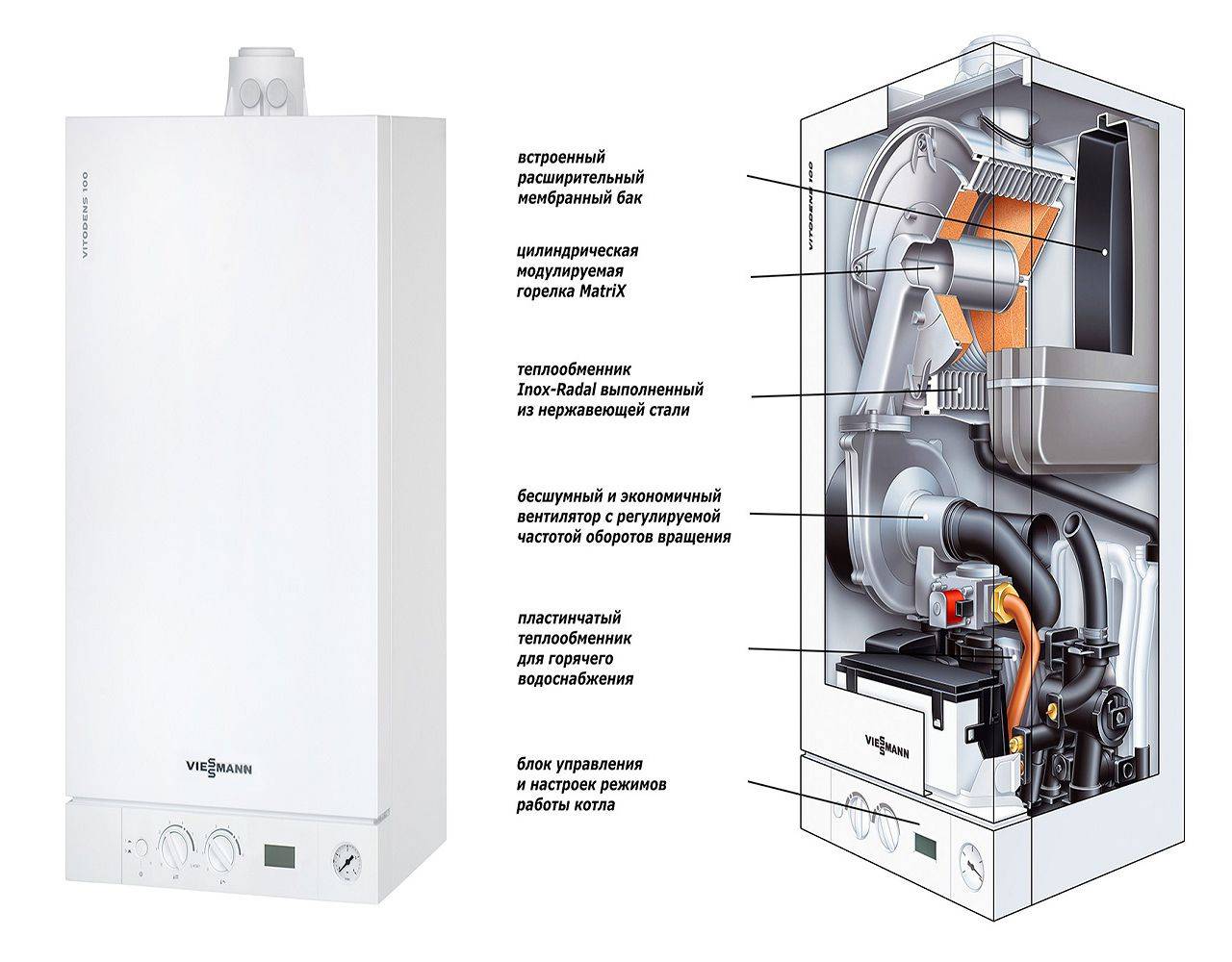

Instrument design

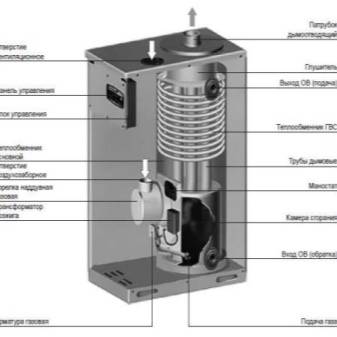

The water heater device includes the following main elements:

- burner;

- gas fittings (filters, taps, fuses);

- heat exchanger;

- built-in circulation pump;

- membrane expansion tank;

- automation.

heat exchanger

The main attention should be paid to the heat exchanger, which can be made of different materials, because the duration of the operation of the equipment depends on it. For example, wall-mounted gas boilers with a cast-iron heat exchanger will last for many years.

However, it is difficult to mount such units due to their large weight.

Devices with a copper heat exchanger weigh much lighter, and their price is much lower. The heat exchanger made of steel has a high heat transfer, but is prone to corrosion.

The difference between an expensive wall-mounted boiler and a cheap one

In fact, for the main task of heating your premises, it will be enough for you to choose the most budgetary wall-mounted gas boiler of brand X than the same brand, but from a more expensive segment. After all, their gas consumption will be exactly the same.

Everything else is not always necessary bells and whistles. Such as, additional noise insulation, energy-efficient pump, functions, fancy scoreboard, etc.

Even now, in order to save money, they began to use pipes and connections made of composite materials in cheap boilers, and metal in more expensive ones. Good or bad, time will tell.

It is important to understand one thing, if you choose a boiler for the purpose of normal home heating, then you can take at least the simplest gas unit. Read also:

Read also:

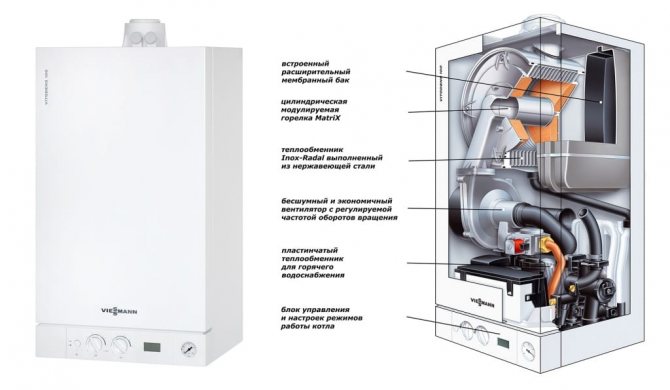

Features of double-circuit gas boilers

Double-circuit gas boilers are wall and floor, chimney and turbocharged, storage and flow. In addition, they are divided into single-stage, two-stage and modulating, depending on the type of burner flame control. The most economical are units with a modulating burner, which allows you to set the desired room temperature and heat the water to the required value.

Principle of operation and device

Each double-circuit boiler consists of a combustion chamber, a circulation pump, a three-way valve, a main and secondary heat exchanger and automation. The combustion chamber heats the media and generates heat.The pump forcibly circulates air in the carrier. The main exchanger is responsible for heating the room, and the secondary one for preparing hot water.

Automation controls the technical parameters of the device, checks the temperature of the carrier, controls the modulation, turns on and off various nodes, monitors the flame and fixes errors that occur.

The principle of operation is simple. When the temperature drops, the automation gives a signal to the circulation pump. Then the system begins to move, and the burner with the heat carrier is turned on. The heat carrier is heated in a heat exchanger and carries the gas throughout the system. After passing through all the radiators, the air returns to the boiler in a cooled form. Everything is reheated in the exchanger and when the desired temperature is reached, the burner turns off, and the carrier still circulates and enters the post-circulation mode. When the temperature of the heat exchanger drops, the circulation pump stops. When the room cools down by a degree, the movement of the entire system continues again.

With water heating, it happens in exactly the same way, only the water flow acts as a signal to turn on the heating function. That is, when the tap is opened in the sink, the burner ignites. Only in this way the three-way valve is switched over and the heat carrier inside the boiler is closed.

Advantages and disadvantages of double-circuit boilers

Units that belong to the specified type with some restrictions, but are still capable of providing hot water to two systems at once (heating, hot water supply). They also take up less space than their boiler counterparts. As a result, double-circuit boilers are more convenient to use.

Both types of gas boilers are easy to operate, efficient and durable. And they have an attractive appearance.

In addition, the competitive struggle of manufacturers has led to the fact that the difference in the cost of both types of units is gradually leveled.

Therefore, today you can find a double-circuit boiler whose price exceeds that of a single-circuit product slightly. Which in some cases can also be considered an advantage.

If we talk about the disadvantages of double-circuit boilers, then the most important is the inability to instantly provide hot water of the same temperature to all points of water consumption in a house or apartment.

So, in their heat exchangers, the amount of water that is needed right now is heated. That is, the stock is not created. As a result, the water temperature may differ from what is expected or change during use. This happens when the pressure changes, for example, after opening / closing the second tap.

When using a double-circuit boiler, often the water temperature differs at two different points of water intake - hot water can be delivered to the desired point with a delay, and significant. Which is inconvenient and leads to additional costs

As for installation, the installation of double-circuit boilers is a more complicated procedure, especially at the design stage. Since you will have to follow the numerous recommendations of the manufacturer

Placement of a double-circuit boiler

The main purpose of double-circuit boilers is small houses and apartments, where the equipment is located next to the kitchen, but not far from the bathroom.Short distances are a must for this type of boiler - the shorter the hot water path to the consumer, the better so that you do not have to wait too long for hot water to go.

Is it profitable to heat a house with a boiler with two circuits: the nuances

The rating of dual-circuit models says the following: users are satisfied with the operation of the device, so they are increasingly purchasing gas installations for heating.

Using this design saves a lot of money:

- Russian models are low cost and good quality: even cheap options will do their job in good faith.

- The use of natural gas as fuel for the operation of the best gas appliances allows you to reduce utility bills.

The rating of the best models indicates that the presence of a second circuit just solves the problem with the supply of warm water. An overview of the advantages of such devices allows customers to make the right choice.

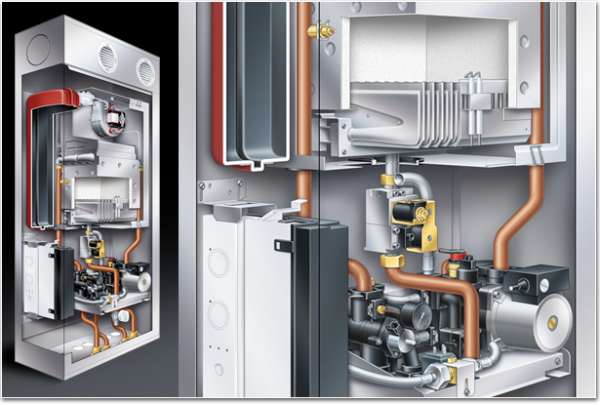

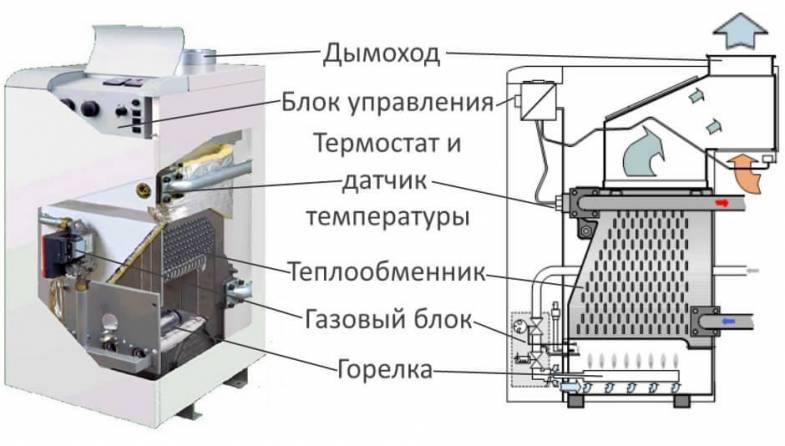

Differences between an atmospheric gas boiler and a turbocharged one

Gas equipment, on the basis of which autonomous heating systems are built, is represented on the market by two options. The consumer can now purchase either a turbocharged or atmospheric (chimney) type.

The first group is equipped with a coaxial chimney, as well as a closed combustion chamber. Due to the minimum requirements for the ventilation system, it can be installed in apartment buildings. A traditional chimney is required to operate an atmospheric boiler. It is installed in low-rise private buildings.

The main differences between atmospheric and turbocharged types of boilers are in the design and principle of operation of the gas burner.

In the main working unit of an atmospheric gas boiler, which is of an open type, air is taken from the room. The combustion process with the traditional release of its products takes place openly, therefore, for the installation of atmospheric equipment, a boiler room is equipped, separated from the residential area of the house.

An atmospheric type burner is a set of small nozzles through which gas passes under pressure. During combustion, the right amount of air enters the chamber, which intensifies the flame. As a result, during the heating of water in the system, the atmospheric boiler spends a minimum of fuel. Smoke is removed through a stainless steel chimney.

An open burner burns oxygen from the air mass of the boiler room during operation. Even if we take into account that this is a priori non-residential premises, a powerful ventilation device is required. After all, a constant supply of air is required for normal combustion.

The turbocharged boiler has a closed combustion chamber. Oxygen is driven into the chambers through a coaxial pipe by a fan. Equipment can be installed anywhere.

A feature of the wall-mounted turbocharged boiler is that the combustion chamber is made of copper, which limits the power to 35 kW. In floor boilers, it is made of cast iron, which can significantly increase power.

Atmospheric varieties of gas boilers need to be connected to a standard chimney with a vertical channel. Turbocharged can be equipped with a coaxial chimney - it is easier and cheaper to install

Boiler power

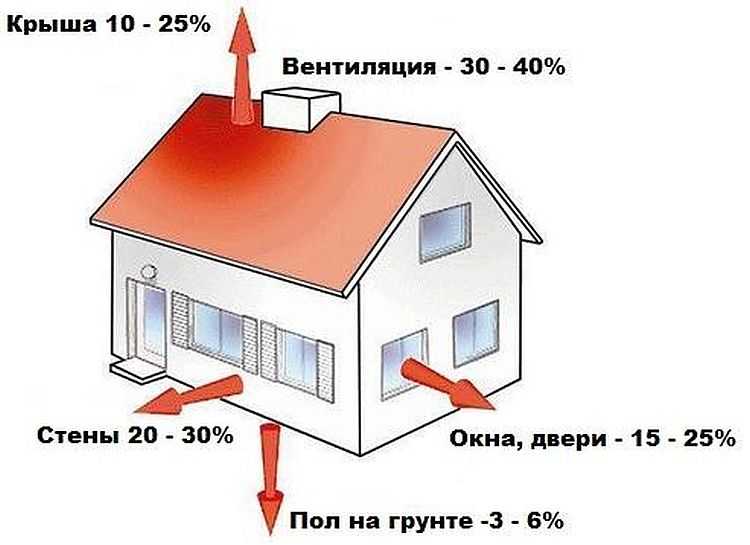

One of the key points in choosing a heating boiler is determining the required power.If we approach this with full responsibility, it is necessary to consider the heat loss of each room, if we are talking about an apartment or a building as a whole, if the boiler is selected for heating a private house. The calculations take into account the materials of the walls, their thickness, the area of windows and doors, the degree of their insulation, the presence / absence of an unheated room at the bottom / top, the type of roof and roofing material

Geographic location and a whole bunch of other factors are taken into account

Such a calculation can be ordered from a specialized organization (at least in GorGaz or a design bureau), if desired, you can master it yourself, or you can take the path of least resistance - calculate based on average norms.

Where does the heat leave the house?

Based on the results of all calculations, the norm was derived: 1 kW of heating power is required for heating 10 square meters of area. This standard is suitable for rooms with ceilings of 2.5 m, with walls with an average degree of thermal insulation. If your room falls into this category, divide the total area that needs to be heated by 10. You get the required boiler output. Then you can make adjustments - increase or decrease the resulting figure, depending on the actual conditions. It is necessary to increase the power of the heating boiler in the following cases:

- The walls are made of a material with high thermal conductivity and are not insulated. Brick, concrete fall into this category for sure, the rest - according to the circumstances. If you are choosing a boiler for an apartment, you need to add power if the apartment is corner. For "internal" heat loss through them is not so terrible.

- Windows have a large area and do not provide tightness (old wooden frames).

- If the ceilings in the room are higher than 2.7 m.

- If in a private house the attic is not heated and poorly insulated.

- If the apartment is on the first or last floor.

The design power is reduced if the walls, roof, floor are well insulated, energy-saving double-glazed windows are installed on the windows. The resulting figure will be the required power of the boiler. When looking for a suitable model, make sure that the maximum power of the unit is not less than your figure.