- Expert advice

- Principle of operation

- Testing the engine

- Washing machine device

- Control

- Executing Devices

- Washing machine tank

- Checking the functionality of the mechanism

- We are looking for a breakdown of a direct drive motor

- We carry out diagnostics of the belt drive

- Step by step engine replacement

- Motor repair

- How does the sensor work?

- Interesting:

- Verification methods

- Causes of the malfunction

- Motor malfunction detection

- brushes

- Rotor and stator winding

- Lamella wear

- Which to choose?

- The main signs of a breakdown of the drain device in different models

- LG

- Samsung

- Ardo

- Indesit

- Conclusions and useful video on the topic

Expert advice

To avoid repairing the tachogenerator of the washing machine, it is recommended to install a reliable element called the Hall sensor. It is mounted on the engine of the device and is characterized by high performance. Many leading brands initially equip new generation washing machines with this device.

The slow operation of the loading drum does not always indicate a breakdown of the tachogenerator of the Atlant washing machine. Before replacing this part, you need to check the operation of the buttons. The banal sinking of the spin start button can lead to a decrease in the speed of the drum during the washing and spinning stages.

LG F-10B8ND

In addition to malfunctions of the tachogenerator, an overload of the drum can lead to a slowdown in speed. Often, housewives do not comply with the manufacturer's recommended parameters for using a washing machine. If you load more laundry into the drum than is provided for by the design features of the unit, this will lead to improper operation of the equipment at all stages.

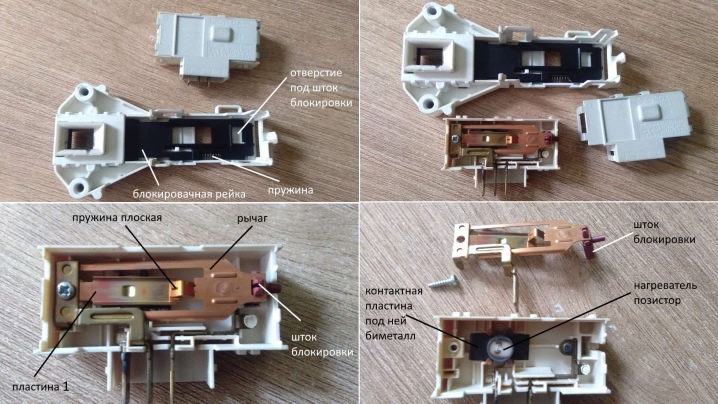

Principle of operation

Washing machine UBL is a hatch blocking device, which is an integral part of an automatic washing machine. Its main purpose is to lock the door of the device and ensure the safe operation of the device. If the element is broken and does not work, the automatic control system of the machine will not start the washing process.

In order to understand the principle of operation of this device, you need to pay attention to how it works. The design of the mechanism consists of the following elements:

- retainer;

- thermoelement;

- bimetallic plate.

The hatch blocking lock is located inside the plastic case. The blocking system and the lock are connected by a metal spring, which is located at the bottom of the hatch. At the moment of receiving a command from the control module to start washing, the hatch blocking device receives a certain discharge of electric current on the thermocouple. The heated thermoelement transfers thermal energy to the bimetallic plate, which, increasing, presses the latch. If a breakdown occurs in this working circuit, the hatch will not be blocked, and the machine will not start working.

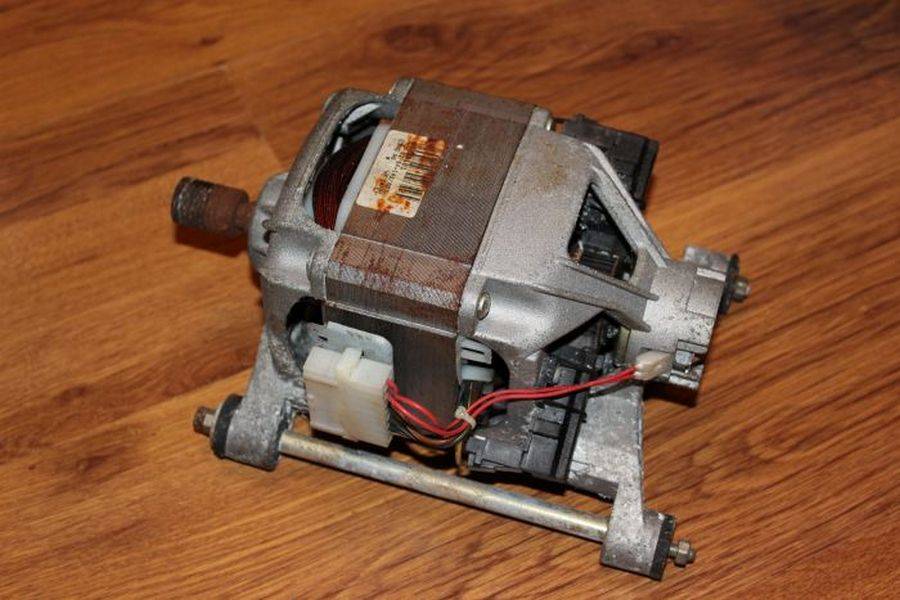

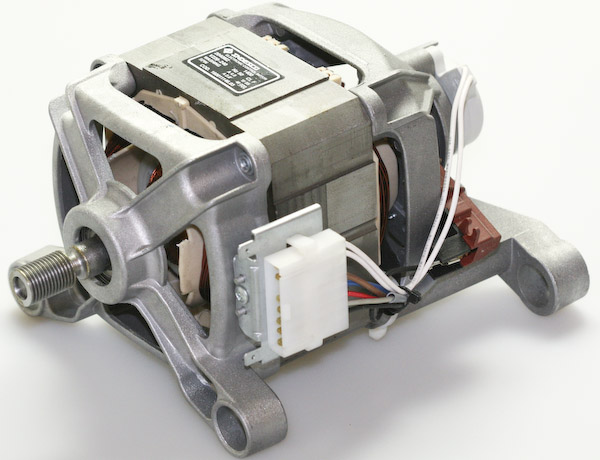

Testing the engine

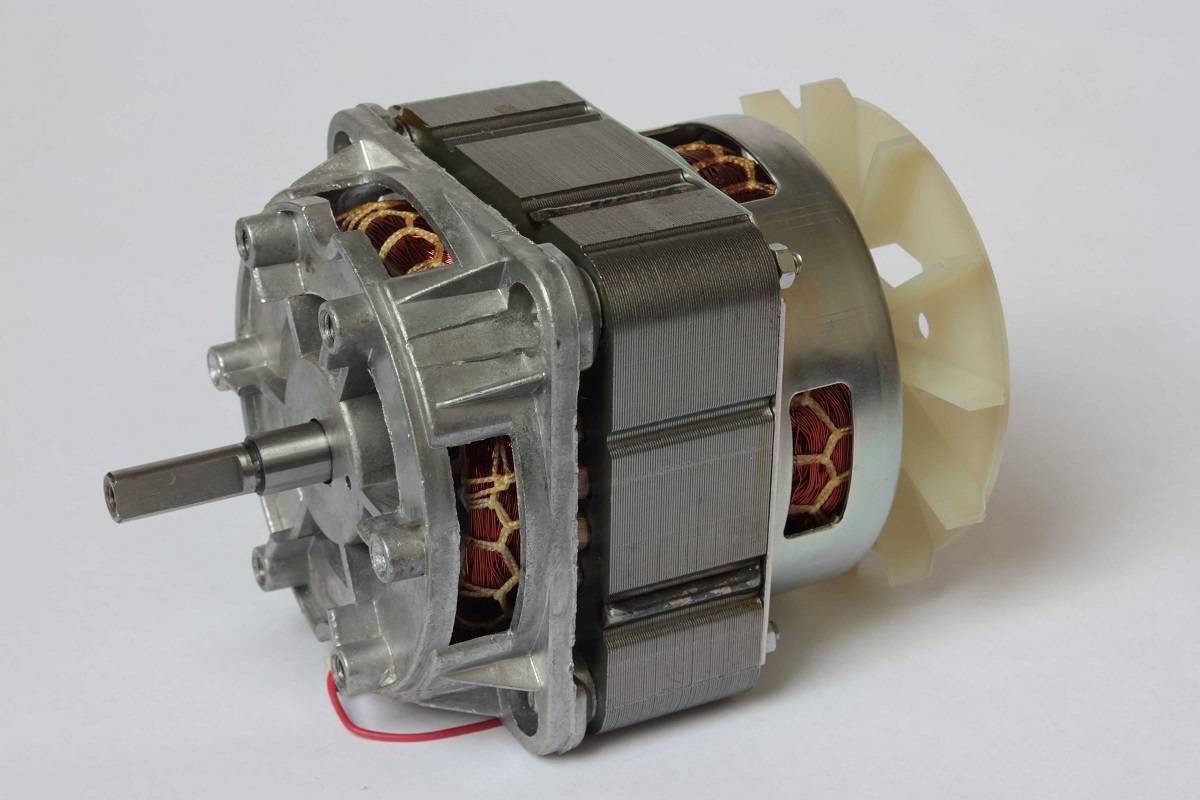

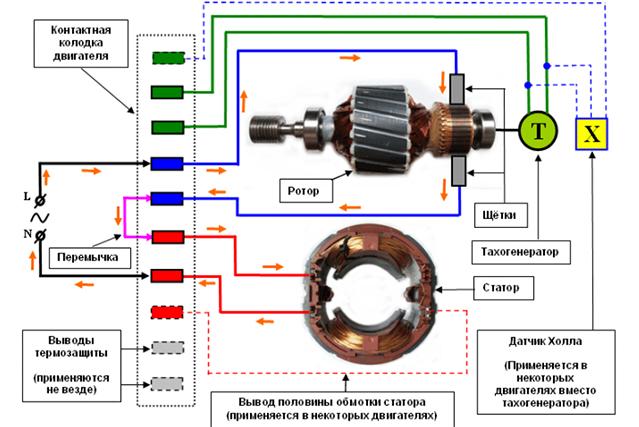

When the decision is made to independently test the engine, it is necessary to carefully study the device of the motor.On washers from Indesit, a collector-type engine is installed, which compares favorably with compactness and high power. An integral part of the device is a drive belt that connects to the drum pulley and starts the rotation process.

As for the internal mechanism, several separate parts are hidden under the body: a rotor, a stator and two electric brushes. The tachometer located on top controls the speed in revolutions. Experts use several methods to check the performance of the engine. But first you need to get it out of the washing machine.

- Remove the back panel of the washer by unscrewing the bolts around the perimeter.

- Loosen and remove the drive belt while rotating the pulley.

- Disconnect the line connected to the engine.

- We unscrew the retaining bolts and, swinging the engine to the sides, we get it out.

Washing machine device

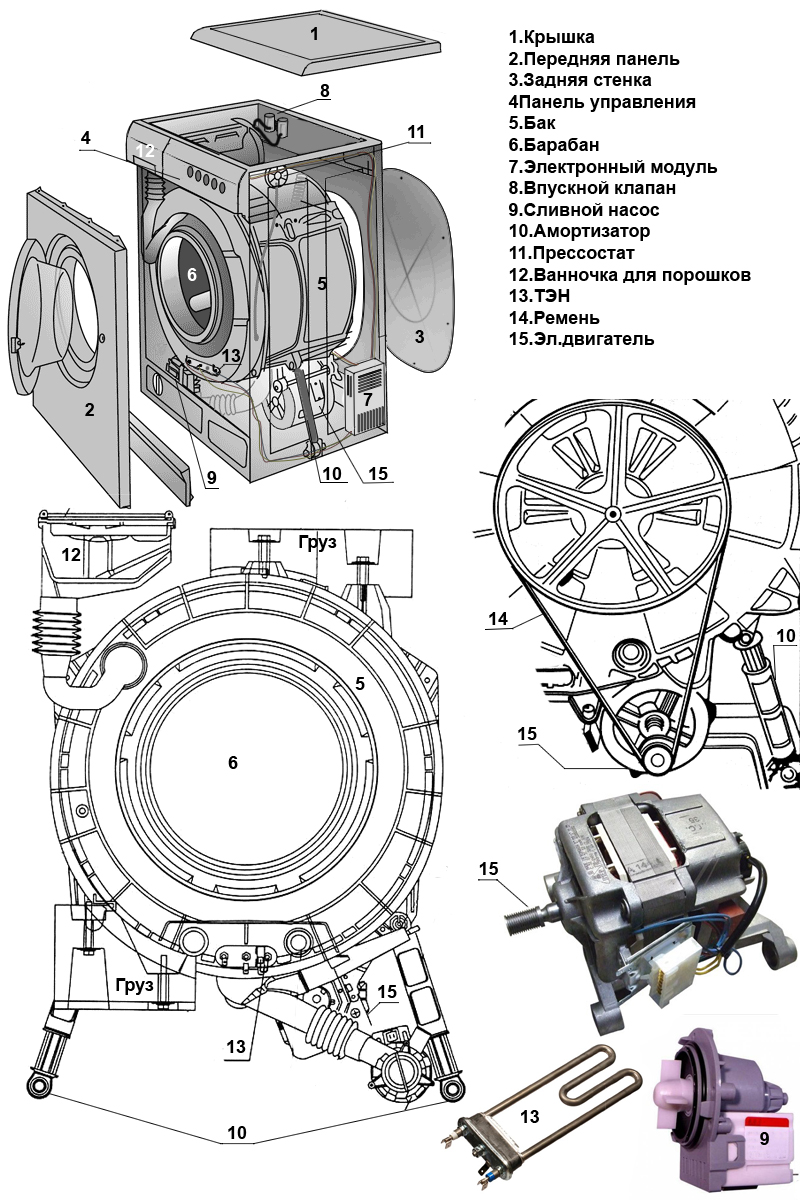

Few of the owners of the washing machine think about its device and principles of operation. However, in order to independently repair a malfunctioning washing machine at home, you need to know its internal structure and the purpose of the main components and parts.

Control

The main part in a modern washing machine is the control module. It is with the help of the control board, which is a metal substrate with many resistors, diodes and other elements, that all washing processes take place: starting and stopping the machine, heating and draining water, spinning and drying clothes.

From special sensors, the module receives information on how to act in a given period of time. The machine uses three sensors:

- pressure switch - shows the level of water in the tank;

- thermostat - determines the temperature of the water;

- tachometer - controls the number of engine revolutions.

The control module is not only the most important, but also the most expensive part of the washing device. If it fails, then the machine starts to “be weird” or refuses to do its job at all. Without special skills in repairing electronic equipment, you should not repair the board yourself. Most often, this part is completely changed or given to professionals for repair.

Executing Devices

Having received the appropriate instructions for washing from the hostess of the machine (mode, water temperature, the need for additional rinsing, etc.), and after checking the status of the sensors, the control module gives the necessary orders to the executing mechanisms.

- With the help of a special UBL device, the loading hatch door is blocked. The machine will be in this state until the end of the wash, and only 2-3 minutes after the water has been drained, the control module will signal to unlock the hatch.

- Water is supplied through the valve to the tank of the device. As soon as the pressure switch shows that the tank is full, the water supply will automatically stop.

- A tubular electric heater (TEN) is responsible for heating the water. From the module, it receives a signal about the turn-on time and the temperature to which it is necessary to heat the water in the tank.

- The engine of the machine is responsible for the rotation of the drum, which is connected via a belt or directly to the drum pulley. The moment of starting and stopping, as well as the speed of rotation, is controlled by the control module.

- Drainage of waste water is carried out using a pump. The drain pump pumps water out of the drum and sends it to the sewer pipe.

Such seemingly simple mechanisms under the control of an electronic module perform all the work of the washing unit.

Washing machine tank

Tank - a sealed plastic container that occupies most of the body of the washing machine. Inside the tank there is a drum for loading laundry and heating elements.

The washing machine tank consists of two parts connected by metal brackets or bolts. Water is taken in and drained through special pipes connected to the walls of the tank. To reduce the vibration that occurs when the drum rotates, the upper part of the tank is attached to the machine body with springs, and the lower part with the help of shock absorbers.

The drum is made of high quality stainless steel. Rotating in it, the linen is washed and wrung out, completely cleared of dirt. The rubber cuff located between a tank and a drum provides tightness of a design.

Checking the functionality of the mechanism

On sale there are cars only with inverter and collector motors, so we will consider these two varieties, we will omit the asynchronous one.

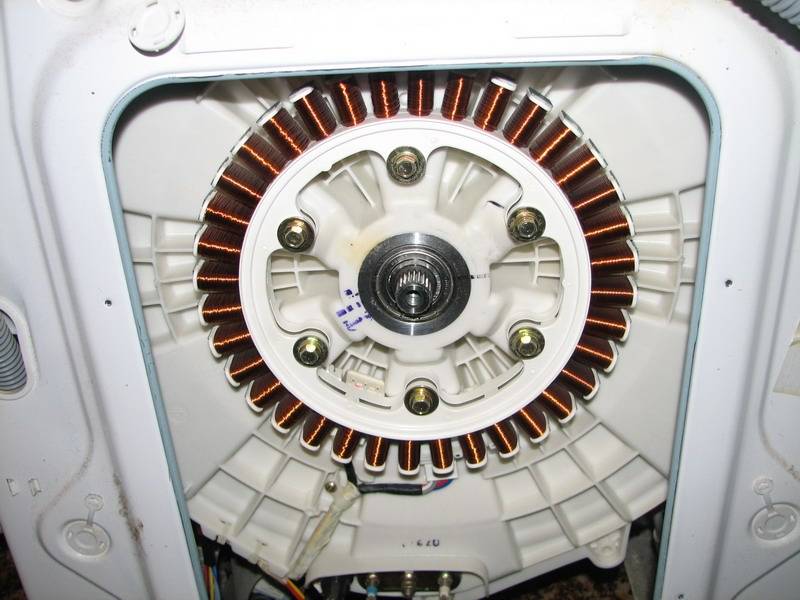

We are looking for a breakdown of a direct drive motor

The inverter is not intended for home repair. The surest option is to try system testing if your machine model is capable of this.

Self-diagnosis will issue a fault code, decrypt it and help you understand where the problem is and whether the services of a wizard are needed.

The testing method and error codes for each machine are different. Before testing, you need to free the drum from the laundry and close the hatch tightly

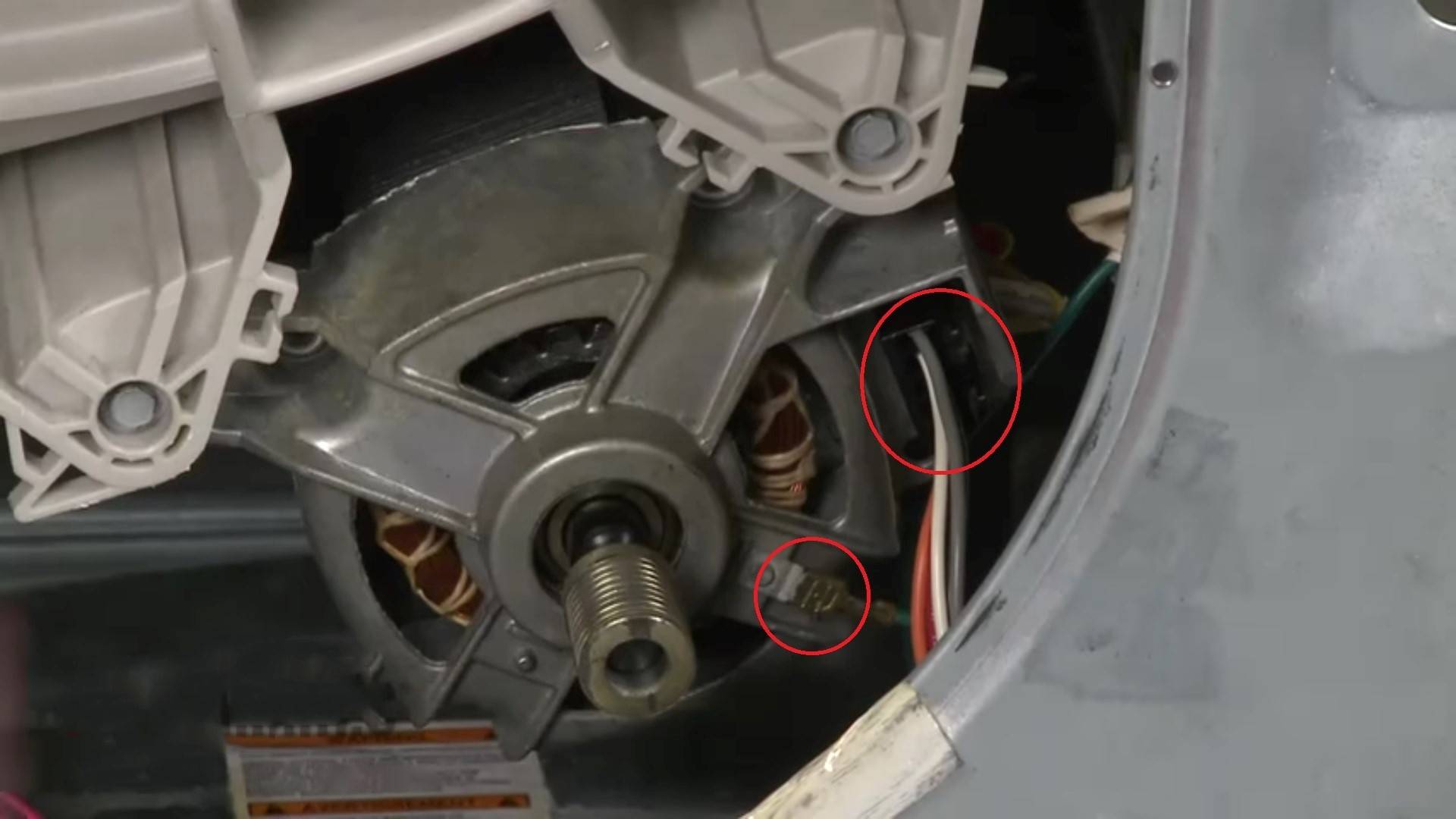

If you still want to remove the inverter, follow the correct algorithm:

- We disconnect the device from the mains. It is recommended to wait a few minutes for all elements to de-energize completely.

- We unscrew the bolts, remove the back panel.

- We find under the rotor the screws with which the wiring is attached, unscrew them.

- Before disconnecting the wires, we photograph or sketch them, so that later we can correctly connect all power sources.

- Remove the central bolt that holds the rotor. In the process, you need to hold the rotor to prevent rotation.

- We remove the rotor assembly, and behind it - the stator.

- Disconnect all wire connectors.

Now you can inspect the engine. It is unlikely that it will be possible to thoroughly test the operation of the inverter. What can be done? Check the integrity of the rotor winding.

Often in such engines the Hall sensor breaks. Whether it is workable - this can be found out only in the conditions of the workshop, if you replace the part with a new one.

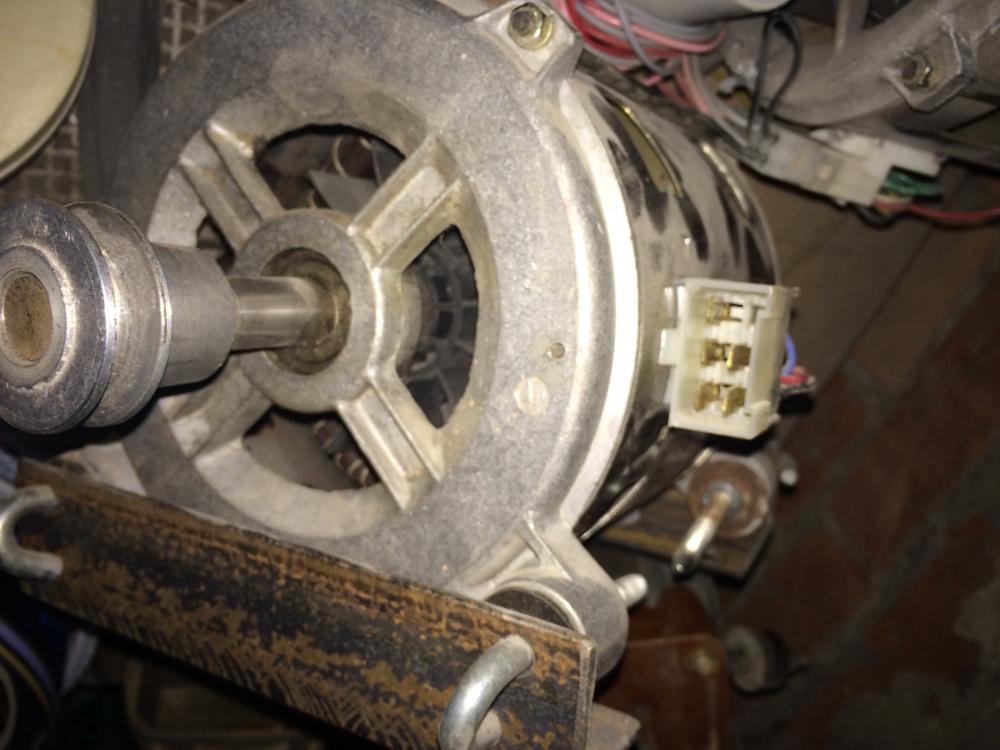

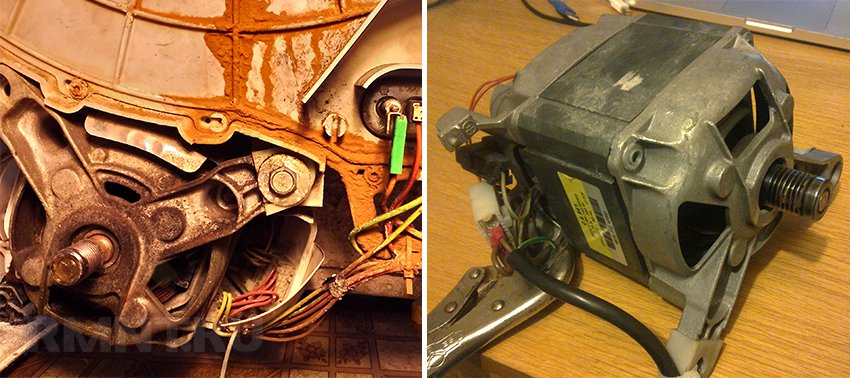

We carry out diagnostics of the belt drive

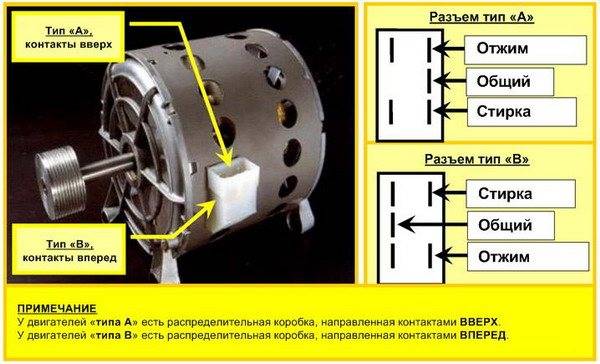

To check the manifold, you must first remove it from the housing. Why remove the back panel, disconnect the wires and unscrew the bolts. It is permissible to pick with a screwdriver in the places where the bolts are fastened, where dirt often accumulates and sticking occurs.

Now let's start diagnosing. We connect the wires of the stator and rotor windings according to the scheme. We connect it all to electricity. Everything is in order with the device if the rotor starts to rotate.

This test method has its own characteristics: the inability to test the operation of the engine in different modes, plus there is a risk of a short circuit from a direct connection

To avoid a short circuit, a ballast in the form of a heating element can be connected to this circuit. We connect the ballast from the side of the rotor. It will start to warm up, thereby protecting the engine from combustion.

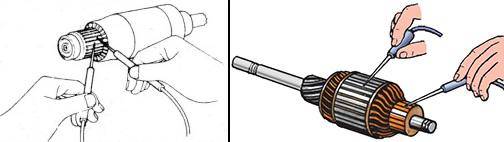

The collector is a construction of several parts and they all require verification. The first in line are the notorious brushes. They are located on the sides of the body. We take them out and look at them.

If they are worn out, they need to be replaced.A clear sign of such a need - the engine sparks during rotation. To buy new brushes, take your old ones with you and write down the information about the washing machine model.

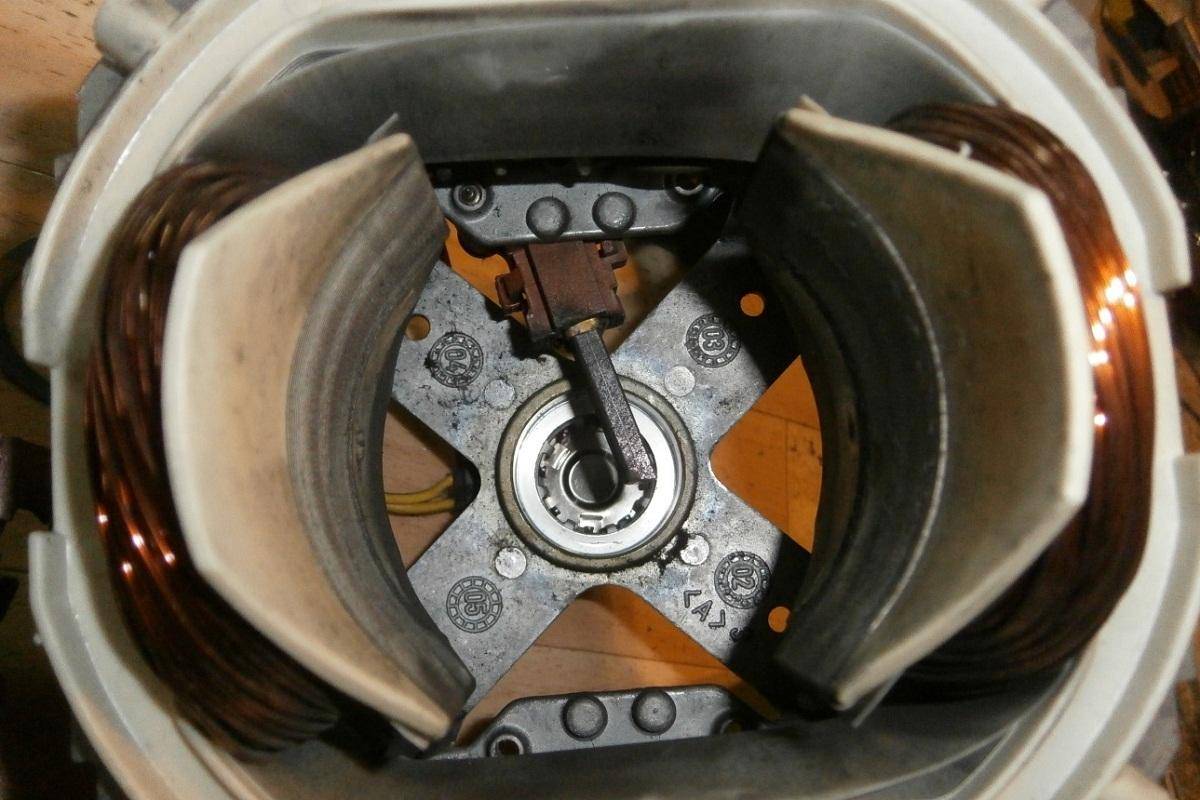

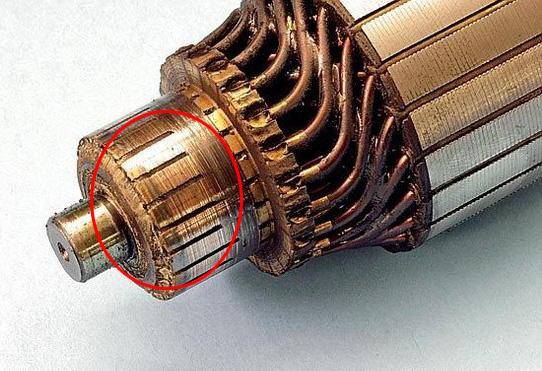

The next element is the lamellae. They serve as conductors-transmitters of current to the rotor. These parts are glued to the shaft and in the event of a jammed motor, their detachment is not ruled out.

If a lathe is available to you, small delaminations can be removed on it. Do not forget to clean the chips with fine sandpaper.

Pay close attention to burrs and delaminations on the lamellas, they are often the cause of unsatisfactory operation of the washer engine

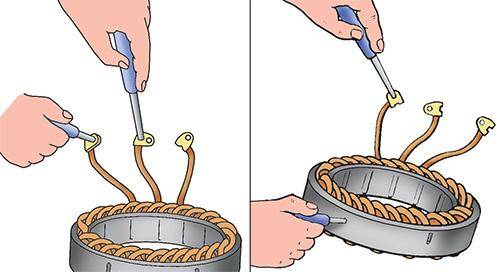

Now let's proceed to the stator and rotor windings. If a short occurs in them, the collector heats up, which causes the thermistor to fire. As a result, power is lost or the mechanism stops working altogether. We test the windings with a multimeter in resistance mode.

The stator is checked in buzzer mode. The ends of the wiring are alternately tested with probes. If no signal follows, the part is fine. You can determine the location of the circuit by connecting one probe to the wiring, and the second to the case.

The probes are applied to the engine lamella. The display shows less than 20 ohms - we have a short circuit, more than 200 ohms - a winding break

If the device is silent, this is normal. In the event of a breakdown, it will be necessary to create a new winding for self-repair, and for a non-specialist it is difficult.

If you still need to replace the engine, it is usually enough to simply install a new part in place of the old one. After all the manipulations, do not forget to turn on the machine and check its operation.

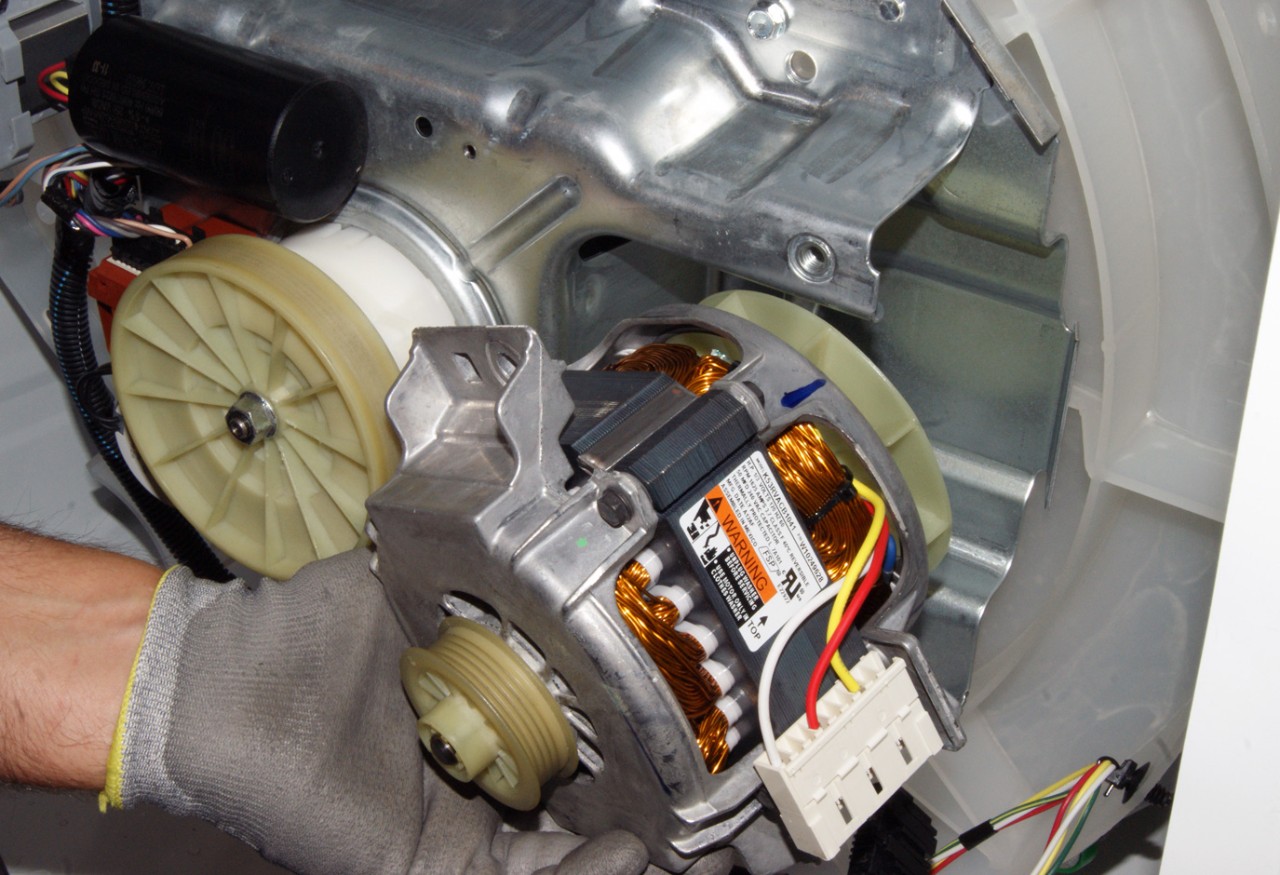

Step by step engine replacement

So, when all the necessary tools are prepared, you can proceed.

Progress:

- After making sure that there are no things in the drum of the machine, turn it off. It is advisable to prepare a rag and a bucket just in case. This may be necessary if stagnant water flows out from the inside during operation.

- Next, you need to remove the cover. Depending on the model, it can be on the back, front or side. In any case, each of them has fasteners that must be removed using the appropriate tool.

- Under the tank there should be a motor, which is mounted on four mounting grooves or brackets. It is attached to two of them with screws. Before removing the motor, you must carefully dismantle the belts, as well as the supply and ground conductors.

- You can unscrew the fasteners with a wrench.

- After the fasteners are removed, the motor can be dismantled. Sometimes it will take a little more effort, as the attachment points may be stuck.

- When the motor has given way, carefully pull it out and proceed with the repair or replacement.

The reassembly procedure will be the same. Carefully place the motor inside the washing machine, install with fasteners and close the lid.

The work seems simple, but in order to avoid surprises, it is better if it is performed by an experienced service center specialist.

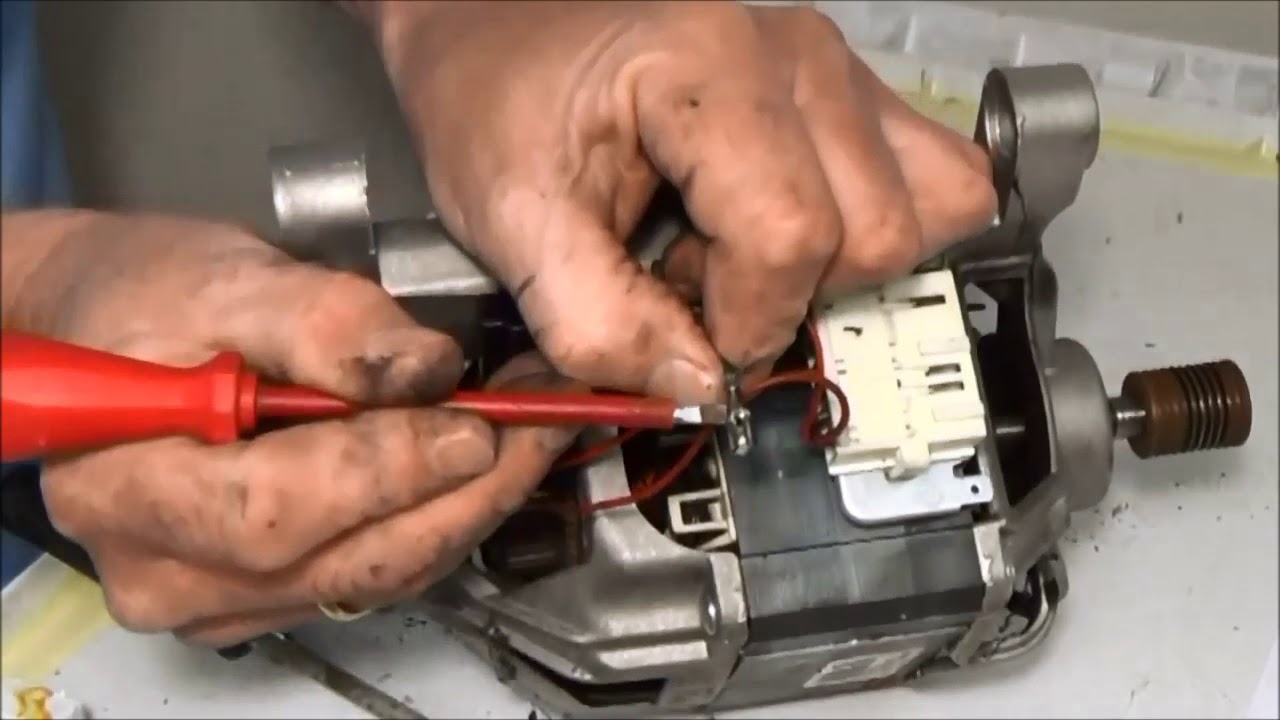

Motor repair

Before throwing away an important and expensive part, it is worth inspecting it, looking for faults - some of them you can fix yourself.

To find a breakdown, the motor must be connected to the network, before connecting the rotor and stator. If the motor brushes look frayed and spark during operation, they should be replaced with new ones. They can be in the middle of the engine or near the manifold. In the first case, the motor needs to be disassembled, and in the second, just pry off the mounts.

If unusual noise, overheating was noticed, then most likely the problem is in the winding. A multimeter will help verify this. It is necessary to attach the probes of the device to different groups of lamellas: if the difference in resistance is higher than 0.5 Ohm, there is a short circuit. Confirm the diagnosis of the presence of burning, a strong smell during work. If the lamellas have no resistance, the winding may break. It is unprofitable to rewind the rotor - it is better to buy a new one.

The rotor lamellas could also deteriorate, peel off, come off. If the defect is minor, then you can align them on a lathe, clean the gaps. Between them, you can not leave metal dust or burrs, measure with a multimeter for a short circuit. Completely torn, broken lamellae cannot be repaired.

Problems with parts are a consequence of a short circuit in the winding. Even after cleaning them well, it is not always possible to fix the motor. It is worth looking for a new rotor for the machine.

How does the sensor work?

It is important to understand what role the tachogenerator plays in the washing machine system. The sensor is made in the form of a ring with wires on it.

When the electric motor is running, voltage appears in the tachometer due to the magnetic field. The nominal value of the resulting voltage is directly related to the speed of rotation of the motor - the faster the engine spins, the stronger the voltage that occurs in the ring.

The Hall sensor is designed to control the speed of the motor. The principle of the element is as follows. For example, the engine starts to rotate harder to provide the spin set by the user. So, the engine needs to accelerate to 800 rpm.The control unit immediately sends a signal to the motor to increase speed, but at what point to stop picking up speed? It is the tachogenerator, which measures the number of revolutions of the engine, upon the occurrence of the set operating parameters, that will give a signal to the control unit to stop accelerating the electric motor of the washing machine.

Interesting:

Share your opinion - leave a comment

Many people do not think about the complexity of the mechanisms inside the washing machine. But it happens that the machine breaks down and often such an inconspicuous part as a tachometer or tachogenerator of a washing machine can be the cause of the breakdown.

Verification methods

There are two ways to independently check the health of the washing machine engine. In order to be able to use them, you need to have at least an elementary idea of \u200b\u200bthe engine structure and how it is powered. On the Internet, you can find many diagrams that display this important information in an accessible way.

Related article: DIY round bed: manufacturing sequence (video)

- The first test method involves applying voltage to the starter and rotor windings of the engine, after having previously connected these elements in turn. The disadvantage of this method is that it does not guarantee a 100% result, since even if the engine rotates under power, this does not mean that it will function properly under different operating modes of the washing machine.

- The second method will require special equipment, namely an autotransformer with a power of 500 watts or more. Using this device, you need to power the connected windings of the starter and rotor.This method is safer, as it allows you to control the speed of revolutions.

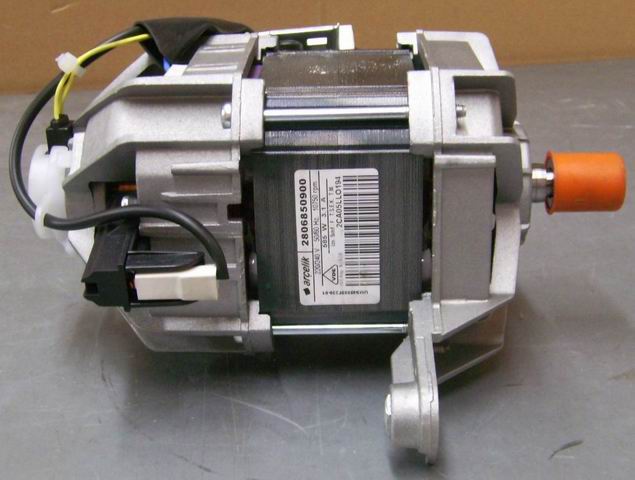

Causes of the malfunction

Owners of new LG models will not be interested in this article - inverter motors break down extremely rarely. But the owners of older versions of the CMA often face problematic engine operation. To find out if you need to replace the engine in a washing machine, follow these steps:

- dismantling;

- disassembly of the electric motor;

- functionality check.

Depending on the results of the check, it becomes clear what you have to do - do-it-yourself repair of the LG washing machine engine, contacting a master or replacing a worn device. Possible malfunctions of the collector motor:

- The brushes are worn out. The wear process is accelerated by regularly overloading the drum. Spinning at high speed also has a negative effect.

- A short circuit can lead to a break in the stator and rotor windings. Because of this, the engine cannot work at full power, the speed drops. A drop in rotational force may result in a complete stop of the device. Problematic windings lead to overheating of the body of the electric motor - because of this, thermal protection is triggered, which stops the operation of the ED.

- Lamella wear. This is due to the constant friction of the electric brushes. ED is unstable, loses its power.

According to statistics from service centers, motor repairs are most often done due to worn brushes. The second place is occupied by problems with windings, worn-out lamellas close the top three.

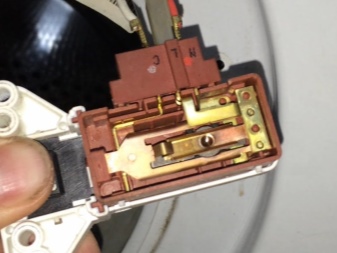

Motor malfunction detection

Collector motors have one important advantage - simplicity. Three things most often break here - brushes, lamellas, windings. Let's figure out how to inspect the nodes and identify the malfunction.But before that, let's try to start the engine, since we need to see if it will work or not.

To start the engine, you need to connect the rotor and stator windings in series, and then connect an AC source with a voltage of 220 volts to the remaining connectors. If all is well, the engine will start to rotate. At this time, we can determine its noise, identify sparkling brushes.

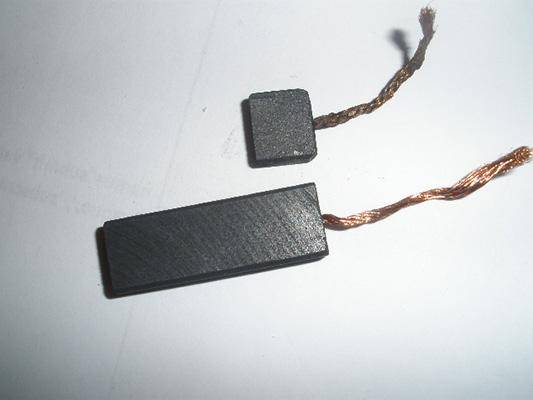

brushes

If your washing machine is about 10 years old, then the brushes will be in a terrible state - this is most often indicated by strong engine sparking. Worn brushes are small, you will see it right away. If the brush is intact, then it will be long enough, without chips or cracks. If this is not the case, then a replacement must be made. To replace the brushes, try to use original components - thanks to this, the service life of the repaired engine will increase. Choosing brushes for a washing machine and replacing them yourself is a simple but responsible task.

If your washing machine is about 10 years old, then the brushes will be in a terrible state - this is most often indicated by strong engine sparking. Worn brushes are small, you will see it right away. If the brush is intact, then it will be long enough, without chips or cracks. If this is not the case, then a replacement must be made. To replace the brushes, try to use original components - thanks to this, the service life of the repaired engine will increase. Choosing brushes for a washing machine and replacing them yourself is a simple but responsible task.

Rotor and stator winding

If the motor runs with strange noises or does not reach full power, it buzzes a lot or heats up, then the cause of this may be a malfunction of the windings. The windings are checked using the most common multimeter (in ohmmeter mode), by successively touching the probes to adjacent lamellas. The discrepancy in resistance should not exceed 0.5 ohms. If this is not the case, then we can diagnose an interturn short circuit.

If the motor runs with strange noises or does not reach full power, it buzzes a lot or heats up, then the cause of this may be a malfunction of the windings. The windings are checked using the most common multimeter (in ohmmeter mode), by successively touching the probes to adjacent lamellas. The discrepancy in resistance should not exceed 0.5 ohms. If this is not the case, then we can diagnose an interturn short circuit.

We also need to determine the performance of the stator - this is done in a similar way. Lastly, we check the closure of all windings to the stator or rotor iron (to the housing).To do this, we use a multimeter, attaching one probe to the body, and the second passing through the lamellas and the output of the stator windings.  If the windings are in good condition, then the resistance will be very high (tens and hundreds of megaohms).

If the windings are in good condition, then the resistance will be very high (tens and hundreds of megaohms).

Lamella wear

Diagnosing lamella wear is as easy as diagnosing brush wear. To do this, you just need to inspect the manifold, completely removing the rotor from the engine. Peeling of the lamellas, breakage of the supply contact, the presence of burrs - all this leads to the fact that the brushes begin to spark.

Diagnosing lamella wear is as easy as diagnosing brush wear. To do this, you just need to inspect the manifold, completely removing the rotor from the engine. Peeling of the lamellas, breakage of the supply contact, the presence of burrs - all this leads to the fact that the brushes begin to spark.

The reason for the peeling of the lamellas is the jamming of the rotor or the presence of an interturn short circuit. As a result, the lamella begins to overheat and flake off. If the contact is broken at the junction with the lamella, then there may be a variety of reasons, but it can be very difficult to return the wires back.

Which to choose?

At first glance, it may seem that the inverter motor has more advantages, and they are more significant. But let's not rush to conclusions and think a little.

In terms of energy efficiency, inverter motors are in first place. In the process of work, they do not have to cope with the force of friction. True, this saving is not so significant as to be taken as a full-fledged and significant advantage.

In terms of noise level, inverter power units are also on top

But you need to take into account the fact that the main noise occurs during the spin cycle and from draining / filling water. If in collector motors the noise is associated with brush friction, then in universal inverter motors a thin squeak will be heard.

In inverter systems, the speed of the automatic machine can reach up to 2000 per minute

The number is impressive, but does it make sense? After all, not every material can withstand such loads, because such a rotation speed is actually useless.

It is difficult to unequivocally answer which motor for a washing machine will be better. As can be seen from our findings, the high power of the electric motor and its overestimated characteristics are not always relevant.

If the budget for the purchase of a washing machine is limited and driven into a narrow framework, then you can safely choose a model with a collector motor. With a wider budget, it makes sense to buy an expensive, quiet and reliable inverter washing machine.

If you choose a motor for an existing car, then first of all you need to carefully study the issue of compatibility of power units.

The main signs of a breakdown of the drain device in different models

Most models of Samsung, LG, Indesit washing machines are equipped with a self-diagnosis system, which allows the owner to independently determine the cause of the breakdown by looking at the scoreboard (read more about how to identify faults and repair washing machines with your own hands, read here). The information screen contains error data in the form of numbers, characters, the meaning of which is found in the instruction manual.

If the machine does not have this function, the malfunction is determined by the following signs:

- after starting the pumping program, the system does not drain the water;

- the drain process is accompanied by extraneous noise, hum;

- some of the water remains in the tank after draining or pumping is slow;

- the washing machine turns off without draining the water completely;

- pump motor runs but no water flows out;

- control panel freezes while draining water.

Depending on the type of breakdown and the model of the machine, the malfunction is expressed by one or more signs or is supplemented by others. To figure out that the pump was the cause of the incorrect operation of the washing machine, first the unit is inspected for other damage, and the performance of other components and parts is checked.

LG

The following symptoms are typical for a pump failure in LG washing machines:

- strange, uncharacteristic noise in the lower right side of the case;

- poorly leaving water during draining;

- problems when turning on, turning off the pump;

- error code on the display.

Samsung

The first signs of a pump malfunction in a Samsung washing machine:

- The displayed error code on the digital screen. It usually appears after the washing process freezes at the moment the water is pumped out of the tank.

- The machine stopped working in the middle of a cycle with a full tank.

- The pump runs non-stop.

- Water leaves the tank irregularly.

To make sure that the pump is out of order, perform the following steps:

Check if the program set the spin function

If not, the mode is restarted.

Check the correct location of the drain hose, the absence of blockages in the filter.

Pay attention to the pump impeller. If the part stands still or turns with difficulty, you will have to deal with the pump.

Ardo

The breakdown of the drain pump in the Ardo typewriter is indicated by the error code E03, F4, which appear after an increase in the drain period. Typical symptoms of a malfunction:

- complete stop of the pump in the middle of the wash cycle;

- the motor runs loudly during pumping and draining water;

- pumping out water during the spin cycle is not in full;

- the machine does not respond to the specified programs;

- the washing machine turns off when the tank is filled with water;

- water enters the tank in insufficient quantity;

- The pump does not turn on or does not turn off.

A common reason for stopping is the ingress of foreign objects inside, for example, buttons, coins and other small things that block the work of the part and prevent the impeller from rotating. Or failure of the pressure switch, which does not send a signal to the control module about the need to supply water (how to repair the pressure switch with your own hands?).

Indesit

The malfunction of the pump in the Indesit machine is indicated by the error code F 05, which appeared on the screen of the information panel. In the absence of a scoreboard, the problem is reported by a combination of indicators that light up on the panel:

- spin;

- soak;

- extra rinse;

- superwash.

If the self-diagnosis does not work, the following symptoms indicate a broken pump:

- remaining water in the tub after washing;

- the process of pumping water is accompanied by a strong buzz;

- water is not drained with a given program;

- turning off the machine while draining the water after washing.

Conclusions and useful video on the topic

You can learn how to fix an engine that has come out of a standstill with your own hands from a useful video collection.

Washer repair if the inverter does not rotate:

How to check the collector with an ohmmeter:

We select the wire section for connecting the washing machine:

Each type of engine has its own advantages and disadvantages. Choose the variety according to your needs. If you prefer the most modern designs with excellent technical performance and the budget does not matter, choose an inverter. If you need reliable equipment for a relatively small price and you are ready to make repairs in case of a breakdown, buy a manifold. And do not forget to properly connect the machine to the mains.