- gas generator for car

- Gas generator: device and principle of operation

- Generating Plant Fuel Options

- What happens inside the gas generator

- Features of the operation of various converters

- Method number 3 - Homemade stations

- Fuel for gas generating boilers

- Advantages of gas-fired heating installations

- Disadvantages of gas generating plants

- Advantages

- Model overview

- Portable models

- Indigirka

- Indigirka 2

- kibor ovens with electric generator

- thermoelectric generator

- Operating tips

- The mechanism and principle of operation of a wood-fired gas generator

- Do-it-yourself gas from firewood

- conclusions

gas generator for car

The plant that produces wood gas for the machine must be light in weight and size. But at the same time, the metal must be of sufficient thickness, otherwise it will quickly burn out.

The filtration system must be especially carefully thought out. Since solid particles of soot will quickly destroy the mirror of the engine cylinders.

If a filtration system is made according to all the rules, it will not be harmful to the internal combustion engine! The gas at the outlet is of the highest quality, the octane number corresponds to 100 gasoline.

The engine, as a rule, wears out faster not because of the composition of the gas, but because it has to work at higher speeds in order to burn faster.

To install a gas generator on a car with your own hands, you need to find a suitable place for it. On trucks, this is usually behind the cab. On cars, either in the trunk, or hung from the back, or placed in a separate trailer.

Trailer gas generator set has its advantages:

Trailer gas generator set has its advantages:

- The ability to unhook the installation and use the car on gasoline.

- It is easy to transport and use the unit for other needs.

- A useful place is not taken from the car.

- Easier to make repairs.

- A place to store fuel.

Bumps and potholes on the road will benefit the gas generator, because the firewood is shaken and mixed, which means it burns better!

Gas generator: device and principle of operation

A gas generator is a device that converts a liquid or solid fuel into a gaseous state for further combustion in order to generate heat.

Generating Plant Fuel Options

Units operating on fuel oil or mining have a more complex design than models using various types of coal or firewood.

Therefore, it is solid fuel gas generators that are most often found - fortunately, fuel for them is available and cheap.

As a solid fuel in a gas generator use:

- wood, brown and coal;

- fuel pellets from wood waste;

- straw, sawdust and firewood;

- peat briquettes, coke;

- a husk of seeds.

Particularly thrifty owners prepare briquettes from sawdust with their own hands.

Gas generation is possible from all these types of fuel.Energy release depends on the calorific value of different types of fuel.

Moreover, more heat is obtained from the combustion of raw materials in a gas generator than from the use of solid fuel in boilers. If the efficiency of a conventional wood-burning boiler varies between 60–70%, then the efficiency of a gas-generating complex reaches 95%.

But here it is necessary to take into account one nuance. The boiler burns fuel to heat water, while the gas generator only produces fuel. Without a heater, stove or internal combustion engine, there will be zero sense from a home-made gas generator.

The resulting gas should be used immediately - it is not economically profitable to accumulate it in any container. To do this, you will have to install additional equipment that depends on the power supply.

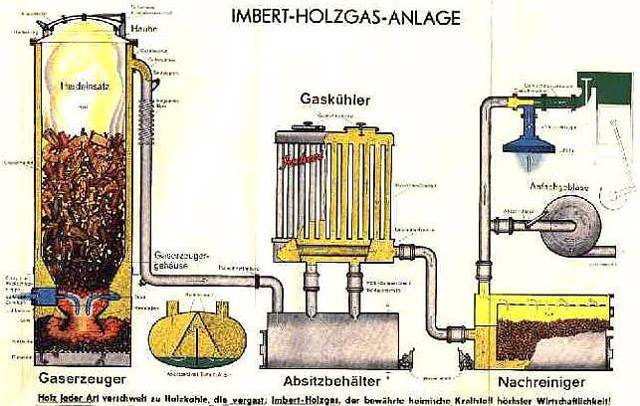

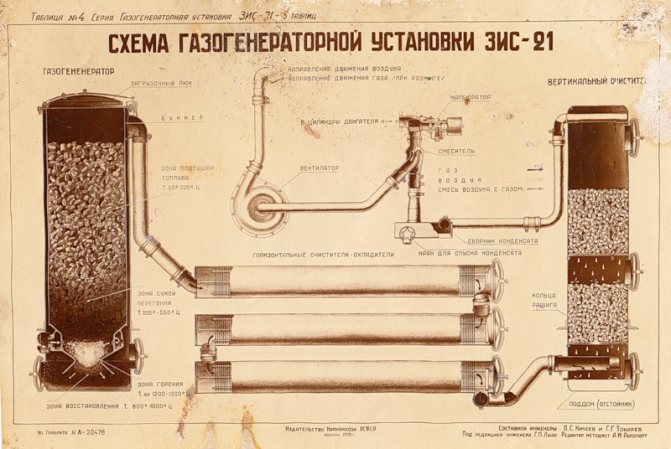

In Soviet times, gas generators were even used to operate trucks, the gas produced is enough to run an internal combustion engine

What happens inside the gas generator

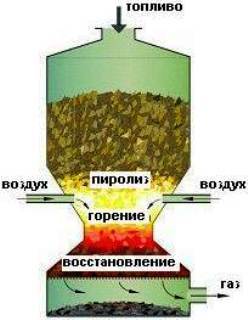

The operation of the gas generator is based on the pyrolysis of solid fuel, which occurs at high temperatures and low oxygen content in the furnace. Several chemical reactions take place simultaneously inside the gas generating device.

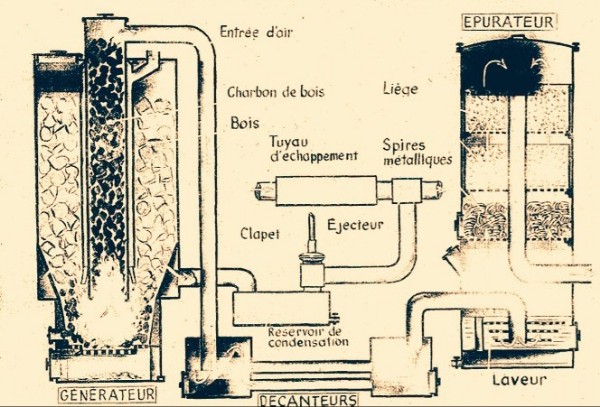

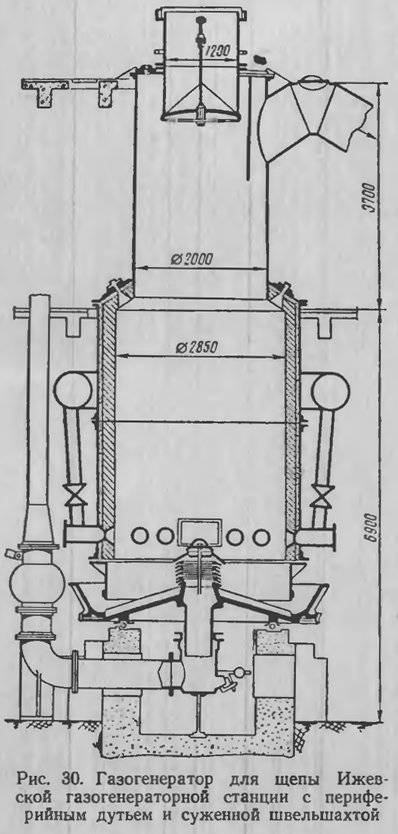

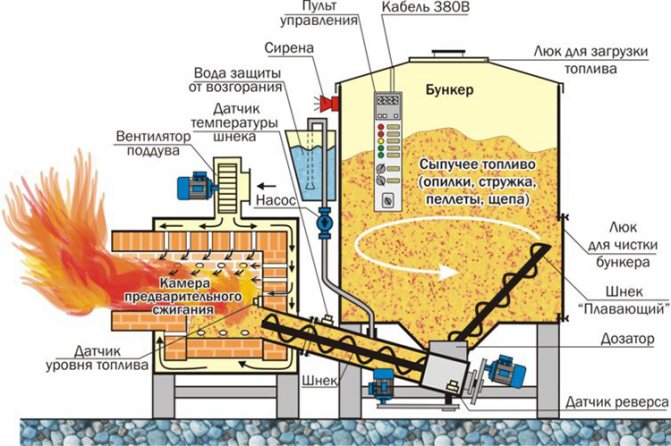

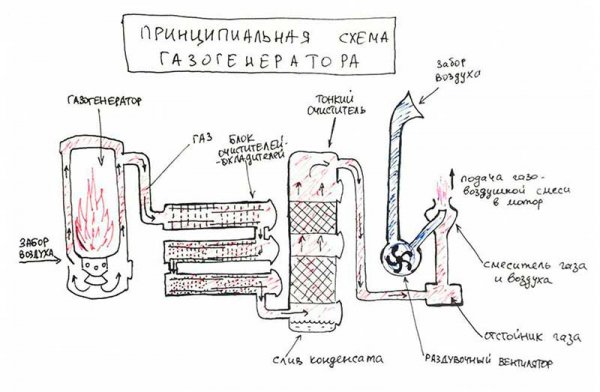

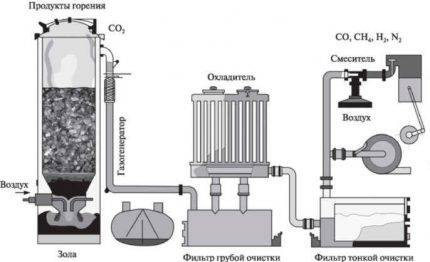

The scheme of an industrial gas generator is a rather complex installation with many separate devices, each of which has its own operation (+)

The scheme of an industrial gas generator is a rather complex installation with many separate devices, each of which has its own operation (+)

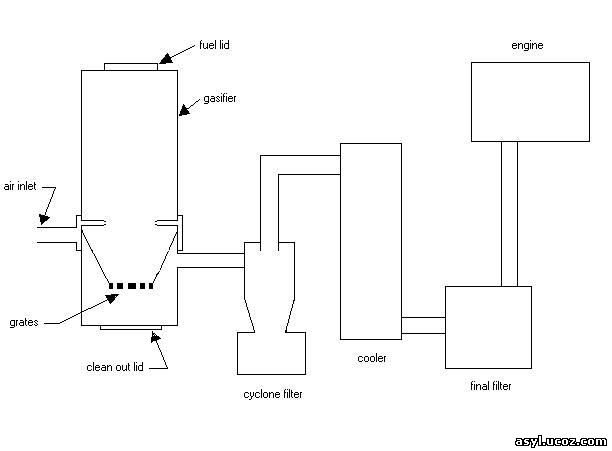

Technologically, the process of generating combustible gas is divided into three consecutive stages:

- Thermal decomposition of fuel. The process proceeds under conditions of oxygen deficiency, which is supplied to the reactor by only a third of what is necessary for conventional combustion.

- Purification of the resulting gas. In a cyclone (dry vortex filter), the gas cloud is filtered from flying ash particles.

- Cooling.The resulting gas mixture is cooled and subjected to additional purification from impurities.

In fact, it is the first process that occurs in the block as such of the gas generator - pyrolysis. Everything else is the preparation of the gas mixture for further combustion.

The pyrolysis chamber of a home-made gas generator is divided into a bunker with solid fuel (1), a firebox (2) and an ash pan (3)

At the outlet of the gas generating plant, a combustible mixture of carbon monoxide, hydrogen, methane and other hydrocarbons is obtained.

Also, depending on the fuel used in the pyrolysis, water in the form of steam, oxygen, carbon dioxide and nitrogen are added to them in various quantities. According to the described principle, pyrolysis heating boilers also operate, demonstrating high efficiency.

Features of the operation of various converters

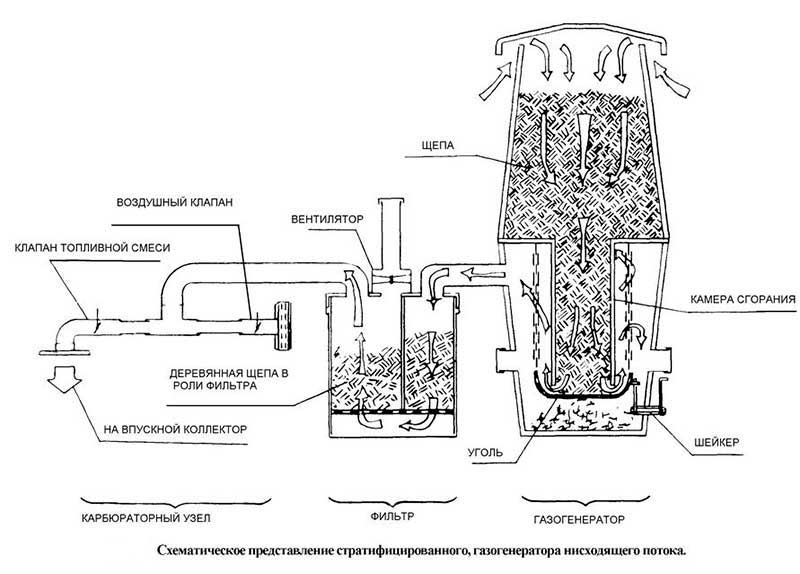

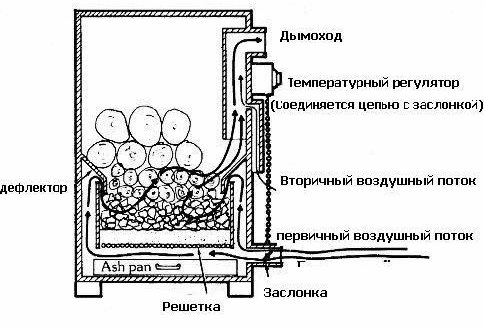

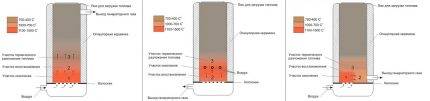

According to the design and technology of internal processes, gas generators are:

- straight;

- converted;

- horizontal.

They differ in points of air supply and output of the generated gas.

The direct process proceeds when the air mass is injected from below and the combustible mixture exits at the top of the structure.

The inverted option involves the supply of oxygen directly to the oxidation zone. At the same time, it is the hottest in the gas generating device.

It is quite difficult to make an injection into it on your own, therefore this principle of operation is used only in industrial installations.

With a direct gas-generating process, a large volume of tar and moisture is formed at the outlet, the reverse one is too difficult to implement with your own hands, and the horizontal one has reduced productivity, but an extremely simple design (+)

With a direct gas-generating process, a large volume of tar and moisture is formed at the outlet, the reverse one is too difficult to implement with your own hands, and the horizontal one has reduced productivity, but an extremely simple design (+)

In a horizontal gas generator, the outlet pipe with gas is located immediately above the grate in the zone of combination of oxidation and reduction reactions. This design is the simplest in independent execution.

Method number 3 - Homemade stations

Also, many craftsmen create home-made stations (usually based on a gas generator), which they then sell.

All this indicates that it is possible to independently make a power plant from improvised means and use it for your own purposes.

Next, consider how you can make the device yourself.

We recommend: Cooling towers of open and closed types: their design, operating modes, photo

Based on thermoelectric generator.

The first option is a power plant based on a Peltier plate. We note right away that a home-made device is only suitable for charging a phone, a flashlight, or for lighting using LED lamps.

For manufacturing you will need:

- A metal case that will play the role of a furnace;

- Peltier plate (sold separately);

- Voltage regulator with installed USB output;

- A heat exchanger or just a fan to provide cooling (you can take a computer cooler).

Making a power plant is very simple:

- We make an oven. We take a metal box (for example, a computer case), unfold it so that the oven does not have a bottom. We make holes in the walls below for air supply. At the top, you can install a grate on which you can place a kettle, etc.

- We mount the plate on the back wall;

- We mount the cooler on top of the plate;

- We connect a voltage regulator to the outputs from the plate, from which we power the cooler, and also draw conclusions for connecting consumers.

POPULAR WITH READERS: What are smart sockets, their types, device and principle of operation

Everything works simply: we kindle firewood, as the plate heats up, electricity will be generated at its terminals, which will be supplied to the voltage regulator. The cooler will also start to work from it, providing cooling of the plate.

It remains only to connect consumers and monitor the combustion process in the stove (toss firewood in a timely manner).

Based on a gas generator.

The second way to make a power plant is to make a gas generator. Such a device is much more difficult to manufacture, but the power output is much greater.

To make it you will need:

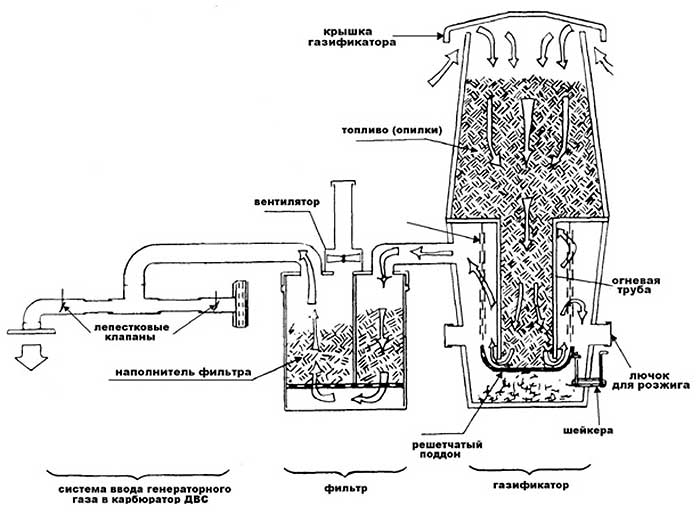

- Cylindrical container (for example, a disassembled gas cylinder). It will play the role of a stove, so hatches should be provided for loading fuel and cleaning solid combustion products, as well as an air supply (a fan will be required for forced supply to ensure a better combustion process) and a gas outlet;

- Cooling radiator (can be made in the form of a coil), in which the gas will be cooled;

- Capacity for creating a filter of the "Cyclone" type;

- Capacity for creating a fine gas filter;

- Gasoline generator set (but you can just take any gasoline engine, as well as a conventional 220 V asynchronous electric motor).

After that, everything must be connected into a single structure. From the boiler, gas must flow to the cooling radiator, and then to the Cyclone and the fine filter. And only after that the resulting gas is supplied to the engine.

This is a schematic diagram of the manufacture of a gas generator. Execution can be very different.

For example, it is possible to install a mechanism for the forced supply of solid fuel from a bunker, which, by the way, will also be powered by a generator, as well as various control devices.

Creating a power plant based on the Peltier effect, there will be no special problems, since the circuit is simple. The only thing is that some safety measures should be taken, since the fire in such a stove is practically open.

But when creating a gas generator, many nuances should be taken into account, among them is ensuring tightness at all connections of the system through which the gas passes.

In order for the internal combustion engine to work normally, you should take care of high-quality gas purification (the presence of impurities in it is unacceptable).

The gas generator is a bulky design, so it is necessary to choose the right place for it, as well as ensure normal ventilation if it is installed indoors.

Since such power plants are not new, and they have been manufactured by amateurs for a relatively long time, a lot of reviews have accumulated about them.

Basically, they are all positive. Even a home-made stove with a Peltier element is noted to fully cope with the task. As for gas generators, the installation of such devices even on modern cars can be a good example here, which indicates their effectiveness.

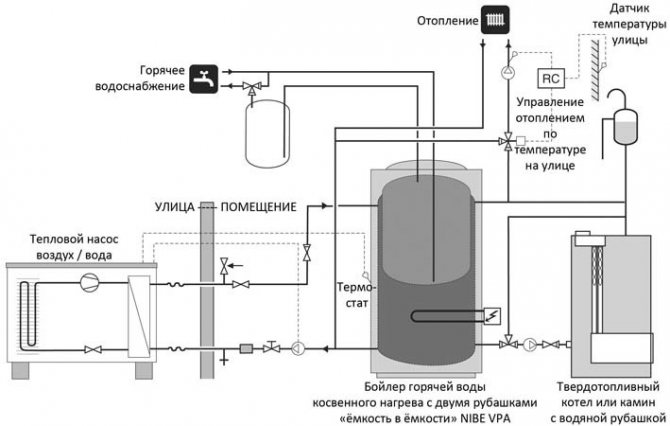

Fuel for gas generating boilers

The undoubted advantage of gas generating boilers is the fact that they can operate on almost any type of solid fuel. That is, they can be loaded with ordinary chopped firewood, as well as any types of wood waste (sawdust, shavings) and briquettes, pellets and the like made from wood waste.In addition, gas generators are practically waste-free production: the fuel in them burns almost without residues.

Advantages of gas-fired heating installations

The installation of heating systems powered by gas-generating boilers operating on wood fuel has the following undoubted advantages:

- Extremely high fuel combustion efficiency. In any plant designed to burn wood fuel, but not using the pyrolysis effect, the efficiency cannot rise above 90 percent.

- Gas generator sets are non-volatile and can be installed even in buildings that do not have a connection to a stationary power grid. Note that during the war, gas generators were placed even on cars. The energy independence of the gas generator set also reduces the cost of its operation.

- Almost any type of wood fuel can be used in a gas generating plant, from classic firewood to wood waste. The use of wood waste, sawdust, wood chips and so on significantly reduces the cost of gas generating systems. However, remember that out of the total amount of fuel at a time, the percentage of wood waste should not exceed 30 percent.

- Large volumes of the combustion chamber allow gas-generating boilers to operate for a long time from one fuel load, which facilitates the operation of such an installation.

Disadvantages of gas generating plants

Despite all the attractiveness of heating and heating systems based on gas generating installations, such devices also have certain disadvantages. The disadvantages of gas generating systems generally coincide with the disadvantages of conventional solid fuel boilers.

A solid fuel boiler, unlike automated liquid or gas systems, has limited autonomy. Such a boiler always needs a human operator who will add fuel as it burns. Also, the gas-generating boiler must be regularly serviced, cleaned of soot and soot. Despite the almost complete combustion of organic wood fuel in gas-generating boilers, decay products are still present in such systems.

The acquisition of a system with a gas-generating boiler is quite costly financially. According to rough estimates, a gas-fired boiler will cost you one and a half times more than a conventional solid fuel boiler. But the difference in cost should pay off after a few heating seasons, based on the higher efficiency of the gas-fired boiler.

Also, when operating gas generating installations, it is necessary to use only dry fuel. On wet wood or sawdust, the pyrolysis process may simply not start. Therefore, gas-fired boilers are often equipped with a drying chamber in which the fuel reaches the desired condition.

Advantages

It should be noted that the operation of these units is fully automated and does not require constant user participation. In particular, regular refueling is not needed, it comes from the line (cylinder) as needed.In addition, gas generators use the cheapest fuel - natural or liquefied gas (LHG). At the same time, they consume it very economically, even in the mode of long battery life. If we talk about the cost of these units, then it does not greatly exceed the prices of similar devices that consume gasoline or diesel.

Given the fact that the gas generator engine will last many times longer, since the gas does not cause corrosion of metal elements. Also, parts in the cylinder-piston group are subjected to less wear, and the oil needs to be changed much less frequently, due to the reduced effect of gas on it. What kind of gas you use - you can determine by knowing which gas supply source your gas stove is connected to. If the gas stove is connected to a gas cylinder, then you are using liquefied propane-butane gas.

If the gas stove is connected to an intra-house gas pipeline (which in turn is connected to a street gas pipeline), then you are using natural gas called methane. Gas-fired power plants are considered comfortable and easy-to-use equipment, since they are equipped with special casings to protect against moisture, precipitation and corrosion. They are also equipped with a specific protective base, which allows you to install the units on any surface.

Gas generators are in no way inferior to diesel and gasoline ones, but, on the contrary, have a number of advantages, such as:

- Great fuel economy. The use of LPG significantly reduces costs. Savings up to 40% compared to gasoline. From the calculations, we found that due to fuel savings, gas equipment pays off within a year. Gas consumption is indicated in the description.

- fuel efficiency.LPG engines are more efficient and require less maintenance than traditional gasoline engines.

- Extending the lifespan. The use of LPG puts less stress on the engine, which prevents excessive wear and mechanical problems.

- Small amount of emissions into the atmosphere. LPG produces fewer exhaust emissions than gasoline, including CO², NO and SO, making it virtually environmentally friendly and the best choice for you.

- Reduced noise level. You will not only breathe clean air, but also experience less discomfort due to the low noise level.

Model overview

You can buy a wood-burning electric generator in specialized companies. It is convenient to contact them and get comprehensive information on the websites of these companies:

We bring to your attention several models of such furnaces-generators intended for domestic needs.

Portable models

They are represented by wood chips and grills equipped with an electrically converting element. Such a stove is good for warming up food on a hike, you can warm a mug of tea on it, fry a small piece of meat and charge gadgets at the same time. They are not designed for more.

They are represented by wood chips and grills equipped with an electrically converting element. Such a stove is good for warming up food on a hike, you can warm a mug of tea on it, fry a small piece of meat and charge gadgets at the same time. They are not designed for more.

For example, the BioLite CampStove stove can run on any wood fuel: twigs, chips, cones. It delivers up to 5W of power and is equipped with USB. To boil a liter of water, quite a bit of wood is enough, and it will take literally 5 minutes. The price of BioLite CampStove is 9,600 rubles.

Indigirka

The Indigirka stove is the most famous model of wood-burning power generators. This stove heats a room up to 50 m3, weighs 37 kilograms, it is made of heat-resistant steel and has been serving for decades. The volume of the furnace is 30 liters.The output voltage of the Indigirka is 12 volts, the maximum output power is 50 watts. Of course, the main purpose of the stove is heating, a convenient cast-iron burner allows you to cook food or warm tea. As an electric generator, the stove is able to work already 15 minutes after ignition.

Read also: Overview of household power plants

Package Included

- Cable with crocodile clips,

- Cable with a connector like a car cigarette lighter,

- USB 5 volt.

Of course, 50 W is not much, but 2-3 LED lamps for lighting, a 10-inch TV and a mobile phone charger will “pull” such an electric generator.

Indigirka 2

This is an updated model that is slightly larger and generates 10 more watts of electricity, that is, 60, which gives additional possibilities.

The cost of such a stove is about 30,000 - 50,000 rubles, depending on the configuration and supplier.

kibor ovens with electric generator

Kibor presents two models of wood-fired power generators. The first model weighs only 22 kilograms, has a furnace volume of 30 liters, and an output power of 25 watts. Such a furnace costs 45,000 rubles.

A more powerful model is capable of producing 60 watts. It is larger in size, weighs 59 kilograms, and has a firebox volume of 60 liters. Price - 60,000 rubles.

thermoelectric generator

It is not necessary to buy a whole furnace with an electric generator. You can purchase separately a thermoelectric generator that is mounted on hot surfaces and adapt it to an existing furnace. Such a unit costs about 15,000 rubles.

Operating tips

For residential heating, it is recommended to install safety equipment. Control can be achieved using pressure and temperature control devices that are installed on fittings welded to the skin. It is also desirable to install a restrictive valve that will operate when the temperature rises to a certain level of risk.

An important aspect of operation is the correct loading of fuel, namely sawdust. Therefore, it is necessary to make a special device in the form of a funnel from a pipe (thin metal). The main thing is that the sides of the cone are as flat as possible.

The mechanism and principle of operation of a wood-fired gas generator

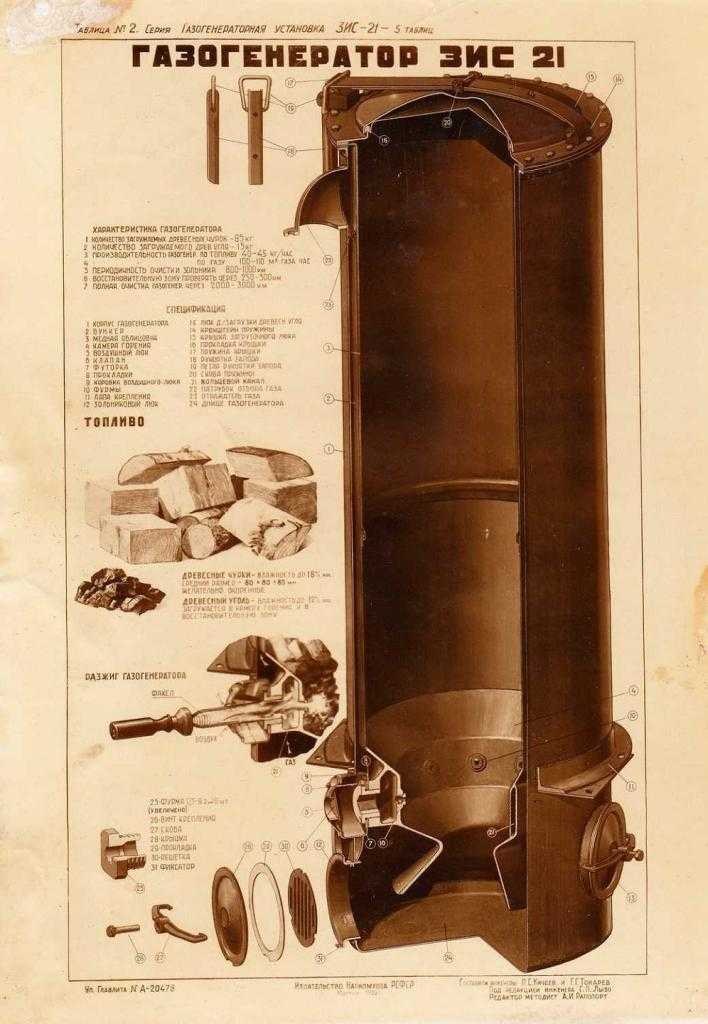

In appearance, the gas generator seems to be a high-tech device stuffed with a variety of related devices. However, understanding the physical and chemical processes taking place inside, the home master comes to the conclusion that it is not difficult to assemble such a structure with your own hands. The wood burning boiler consists of the following components:

- Heat resistant steel body.

- Chamber for loading firewood and combustion at high temperatures. It is equipped with grates and loading hatches - for fuel and ash removal. A sawdust boiler requires a steel mesh.

- Distribution box for air with a non-return valve, communicating through holes with the chambers where the main process takes place.

- Branch pipe for the output of generated gases to the appropriate wiring.

- Coolers and filters. The resulting product at the outlet is cleaned of impurities, acids and resins.

The components are easy to understand and, with the skills of welding, do-it-yourself wood-fired gas generators are made quickly. The efficiency of a handicraft installation is no worse than that of a factory unit.

Do-it-yourself gas from firewood

Getting gas from firewood was widely used during the Second World War. Liquid fuel went to the front line, many destroyed oil refineries spurred the invention of gas obtained from firewood.

At that time, firewood was more affordable than oil products. Therefore, Soviet and foreign equipment was equipped with gas generators. On wood gas worked: tanks, cars and motor vehicles.

In the 21st century, after the rise in the price of liquid fuel, people remembered the technology and began to produce gas from firewood with their own hands.

The gas production technology is simple. Firewood is loaded into the gas generator, set on fire. After the firewood is kindled, the oxygen supply decreases, the firewood begins to smolder, carbon monoxide is released, which rises hot, enters the cooling coil, is filtered through filters, the cooled and purified gas enters the gas combustion chamber. Combustible gas heats the room faster than solid fuel.

conclusions

By creating a home gas generator for heating a house or operating an internal combustion engine, you can get a device that allows you to partially replace natural gas and generate electricity, reducing wood consumption by increasing efficiency and increasing the burning time of one portion of solid fuel. The burning time of one bookmark of wood in the furnace of a gas generator, when using the resulting gas as an additional energy carrier, reaches 8–20 hours. The operation of the equipment is quite simple, except for periodic cleaning, and only filter elements require replacement.

Despite these advantages, it is impractical to install a home-made wood gas generator on a car. The savings will not be as significant as a decrease in the level of comfort of using the vehicle and unpredictable consequences for the internal combustion engine. The only compelling argument in favor of such a decision can only be problems with the purchase of gasoline.

An acceptable option is to assemble a gas generator for a private house with your own hands. In this case, the device will become a source of gas for a heating boiler, gas stove and a small home power station.