- Drain pump selection criteria

- Characteristics of the pumped medium

- Materials used in manufacturing

- Type of circuit breaker

- Drain pump performance

- The pressure of the device for pumping water

- Outlet diameter

- Advantages and disadvantages

- Types of drainage pumps

- KARCHER SP 5 Dirt is the best choice for dirty water

- Overview Karcher SP Dirt Dirty Water Drainage Pumps

- What it is?

- Main types

- Surface pump

- Submersible pump

- Universal pump

- Criteria for a competent choice

- Scope of the unit

- performance and pressure

- Suction valve location

- Float automatic shutdown

- Specifications

- What it is?

- Design features of devices

- Well

- How to choose the right pump

Drain pump selection criteria

When considering how to choose a drainage pump, it is important to pay attention to some important parameters that are responsible for matching the functionality of this equipment to the stated system requirements.

Characteristics of the pumped medium

Before proceeding with the selection of the necessary model for pumping water, you need to understand what kind of liquid medium is to be pumped. Ideally, there should be no gravel, sand or dirt. In practice, they are used in flooded rooms, reservoirs and reservoirs.The accompanying documentation for each model describes the allowable solids values.

According to this indicator, they are divided into varieties:

- pumping water with fragments up to 5 mm;

- transportation of medium contaminated liquid with possible fractions up to 25 mm;

- for more polluted environments with possible fragments up to 38 mm.

In addition, it is important to take into account the temperature of the transported substance and its chemical composition. Indeed, for operation with aggressive components, it will be necessary to select drainage pumps with special technical abilities.

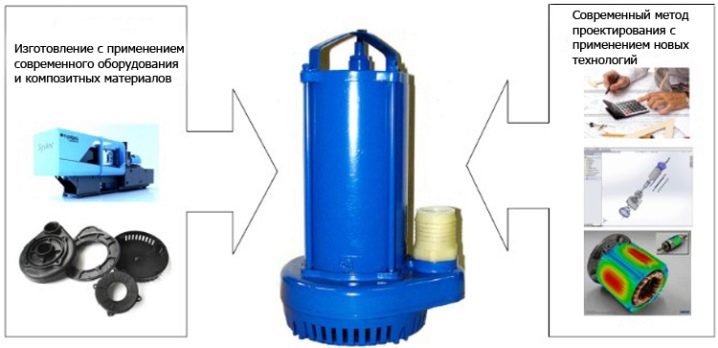

Materials used in manufacturing

The materials used determine the degree of reliability of the entire structure. Housing units for pumping water can be made of metal or durable plastic:

- Metal products are characterized by increased strength, provide more opportunities for the use of repair operations to restore functionality. This allows you to extend their service life.

- Durable plastic keeps the overall cost of equipment down, which is considered attractive to the average person.

No less important is the type of material for the production of working parts of drainage pumps for dirty water, namely the blades of a rotating element. They are made of stainless alloys and polymers with unique capabilities.

It is considered the best, high-quality polymer, it is able to be used under heavy loads. However, these items are not repairable. Stainless steel is much cheaper, it wears faster.

Type of circuit breaker

Basically, drainage pumps are equipped with automatic switches that can turn on the mechanism when the liquid reaches the required level.

They may look like:

- electronic special device, which is an expensive node;

- devices using a float, considered a cheaper alternative.

All of them work to stop the flow of water, turning off the electric motor, thereby protecting it from overheating.

Drain pump performance

This concept denotes the volume of a substance transported during a fixed time period:

- to meet the needs of everyday life, an indicator of approximately 10 m³ / h is enough;

- for professional use, more powerful devices are selected with an indicator of more than 100 m³ / h.

This is an important indicator, it is indicated in the attached documents.

The pressure of the device for pumping water

Average drainage pumps give out a jet of 5-50 meters:

- this indicator depends on the type of pumping equipment used, it indicates the permissible lifting height and the distance of its movement on a horizontal surface;

- this is an important performance characteristic indicated in the accompanying documentation;

- as a rule, it is calculated in a ratio of 1:10;

- if the lifting height is specified as 6 meters, then the horizontal withdrawal distance is equal to 60 m.

Naturally, this characteristic will be influenced by the diameter of the hose for transporting the liquid. For a domestic appliance, a lifting height of several meters exceeding the depth of the storage tank will be quite enough. It is always necessary to calculate this indicator with a margin.

Outlet diameter

To increase the efficiency of the device, you need to choose the right hose diameter:

- when transporting water, you will need a diameter in the range of 0.5-1.5 inches;

- if a contaminated liquid medium is to be pumped, a pipe with a diameter of at least 8 inches will be required;

- in addition, there are pipes for connecting in a horizontal or vertical plane.

Advantages and disadvantages

The positive aspects of surface drainage pumps include the following:

- The units are extremely easy to operate, so they can be used almost anywhere without any preparatory work.

- Drainage pumps, even with a significant viscosity of the pumped medium and the presence of a large amount of pollution in it, are capable of developing high pressure (some models of screw pumps - up to 300 atm).

- All parts in contact with the pumped medium are made of high-strength materials that can withstand chemical and mechanical (abrasive) effects from pollutants well.

- Drainage pumps can work for a long time without interruption.

- Surface pumps are always visible, easy to maintain and less expensive than submersible pumps.

- Cannot be used with a source depth of more than 8 m.

- They make a loud noise during operation.

- In winter, they need protection from freezing.

In addition to the above, pumps of this type require some skills from the user to properly fill the unit and install the suction line.

Types of drainage pumps

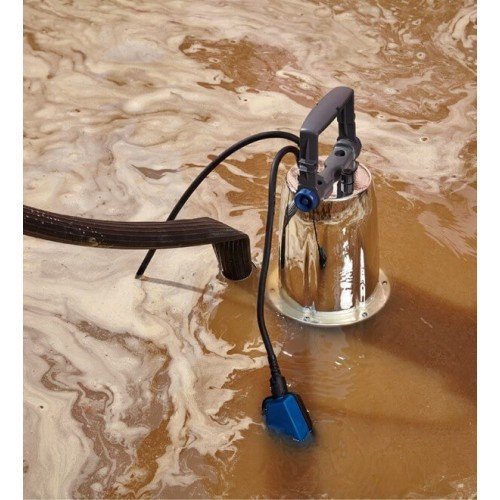

The entire range of drainage pumps is divided into two categories according to the place of their installation:

-

Surface.

-

Submersible.

Surface option

The first are installed on the ground next to the tank from which dirty water will be pumped out. The latter descend directly into the liquid.

submersible model

Compared to surface submersible drainage pumps, they are more efficient, compact, safe and durable. Plus, they work not so noisy, the water dampens most of the sounds. However, they are somewhat more difficult to repair than their counterparts designed for surface mounting.

KARCHER SP 5 Dirt is the best choice for dirty water

KARCHER SP 5 Dirt

Low-power, compact (weighs less than 5 kg) pump, designed specifically for working with contaminated liquids with an admixture of fractions up to 20 mm in diameter. An optional pre-filter is included to protect the impeller from oversized particles.

The submersible device has options for a float switch and a switching level, which allows you to automate the drainage process. Another feature is the Quick Connect feature for quick connection of 1 ¼" hoses.

The device is able to operate in manual (provides a minimum level of residual water) and automatic (reacts to the water level) modes. Installed in a vertical position.

Advantages:

- good middle class model for cleaning cellars and garden ponds

- the service life of the device is extended due to the presence of a ceramic mechanical seal with an oil chamber

- easy to carry and hold thanks to a special handle

- height can be adjusted

Flaws:

no adapter for connecting 1 ½" hoses

Overview Karcher SP Dirt Dirty Water Drainage Pumps

Drainage pumps | TOP 10 Best: choose assistants for pumping clean and dirty water + Reviews

TOP 20 Best children's washing powders: review and recommendations for choosing + Reviews

What it is?

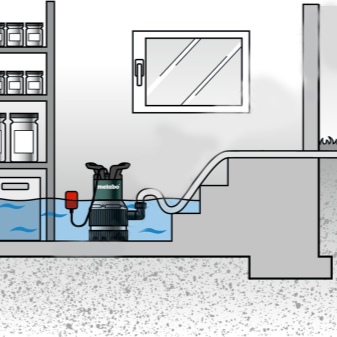

Domestic class drainage pumps are designed for pumping slightly contaminated water from basements, wells, wells, septic tanks, swimming pools and construction pits. They are mainly used by owners of private houses. They pump out flood waters from basements so that the existing strip or pile foundation is not subjected to prolonged and excessive exposure to moisture. However, such pumps can also be found in public utilities.

Appearance

A conventional pump designed for wells and wells is designed to work exclusively with clean water. In contrast, the drainage analogue is already able to cope with impurities up to 30-35 mm. It has a wider working chamber inside. At the same time, the drainage technique should not be confused with fecal models. The latter are mostly equipped with special grinders and are capable of pumping solid particles up to 50 mm in diameter.

Possible pump modifications

Main types

- on wells - used to cleanse the bottom of silt deposits;

- fecal - equipped with special filters capable of retaining fibrous contents such as hair or threads;

- proper drainage - used to pump out not very dirty water from basements and pools;

- borehole - designed to clean drinking and technical wells from silting and sand.

Also, the equipment is divided into two large groups:

- surface pumps;

- descending into the water, that is, submersible.

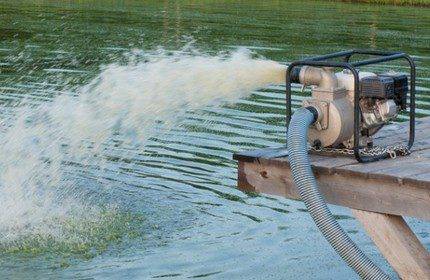

Surface pump

Surface-type units are often called garden units, as they are designed for very little water pollution. Particles of dirt and impurities must not exceed one centimeter!

For operation, the pump is attached to a special platform (platform), and the liquid intake hose is lowered into the working volume filled with water. For example, in a home pool.

Pumps of this type do not have a long service life. They are designed for occasional use. Daily pumping of water, for example, from a public reservoir for the purpose of irrigation, is guaranteed to disable the device.

Advantages:

- ease of maintenance and installation;

- can be used anywhere where there is an opportunity to connect to the electrical network.

Flaws:

- it is impossible to use for work with great depth (maximum five meters);

- short service life;

- increased noise in metal models;

- short service life of plastic cases.

For the cold season, it is recommended to drain the water from it, dry it in the sun and send it to storage in the utility room.

Submersible pump

Dirt passes freely through the wide chamber of the housing without harming the pump. Such devices are household and industrial. The former will fully satisfy the needs of the owners of country houses and plots - they are quite economical in terms of electricity consumption and have good technical characteristics. Industrial designs are massive and powerful units with high energy consumption that will not reveal their potential when used for domestic needs.

Advantages:

- reliability;

- versatility.

Flaws:

- high price;

- the need to take into account all the technical parameters (an error when buying is not ruled out).

Submersible pumps will work efficiently if the owners paid attention to the following when buying them

- The location of the suction hole - the lower it is, the more thoroughly dirt and water will be removed from the bottom or floor. In reservoirs with a muddy bottom, as well as in very polluted wells and wells, the unit must not be lowered to the bottom. A strong stream of dirt will not allow the pump to work. It must be raised above the bottom or placed on a stand. There are also models with a water intake in the upper part of the body. For them, placement in the bottom mud is not critical.

- Automatic shutdown is an expensive but practical option. The owners do not need to stand near the switched on unit. As soon as the water runs out, the alarm float will automatically turn off the pump and protect it from overheating when running dry.

- Performance is a parameter that affects the scope of the device. It is believed that a capacity of 120 liters per minute is sufficient for irrigation. But for pumping you need a more powerful unit.

Such a pump will also be an invaluable assistant during construction work. With it, you can easily and quickly pump out moisture from construction pits.

Universal pump

Universal models. This type can be safely attributed to pumps designed for feces. They work completely immersed in liquid.

Advantages:

- power;

- strength and reliability;

- long service life;

- the presence of a grinder inside the body (designed for solid impurities);

- can be used to work in very dirty water.

Flaws:

high price.

With such a reliable unit, you can clean any sewage pit, as well as water the garden using a dirty pond.

Criteria for a competent choice

When choosing a suitable model for domestic needs, you should focus primarily on what functions it is designed to perform, what characteristics it has.

Scope of the unit

When planning to use the unit only for watering garden beds from a nearby reservoir or for draining a flooded cellar, you can get by with a device with a capacity of 120 l / min.

You intend to use the pump when arranging the drainage system - give preference when choosing more powerful units

The size of solid elements that the unit is able to "digest" is indicated in the instructions for a particular model. On sale you can find models designed only for slightly polluted water, in the structure of which only a small amount of sand may be present. A wide range also includes units that successfully cope even with small stones.

When planning to use the unit for pumping dirty water, including fibrous structures and various-sized debris, it is worth considering the option of purchasing a fecal pump.

Units for pumping highly contaminated liquids are equipped with grinders capable of grinding solids into small fractions

In addition, units of this type are made from materials with increased strength, and are not afraid of exposure to an aggressive environment. Therefore, they have a longer service life than conventional garden pumps for dirty water.

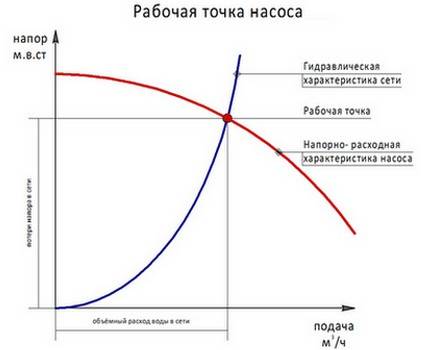

performance and pressure

When purchasing a pump for dirty water, pay special attention to its technical characteristics:

- Productivity - the amount of pumped fluid per minute.

- Head - the ability to push water to a certain height.

When calculating the required power of the device, it should be taken into account that the ratio of the length vertically and horizontally will be 1:4. This means that one meter of vertical pipeline will correspond to four meters of horizontal.

Taking into account this ratio, it will not be difficult to calculate the maximum suction depth of the pump for specific conditions.

Taking into account this ratio, it will not be difficult to calculate the maximum suction depth of the pump for specific conditions.

If you have any doubts when performing calculations for choosing a device, additionally consult a specialist.

Suction valve location

Suction holes can be located in the bottom of the device or its upper part above the engine compartment. Devices whose suction valves are located in the bottom of the housing show much greater efficiency. They are able to pump water out of the reservoir almost without residue.

When installing such a device at the bottom of a polluted pool or natural reservoir, you should be prepared for the fact that at the time of pumping out, in addition to water, it will also “grab” settled silt deposits

For drainage of reservoirs and filled tanks, it is worth choosing units whose suction valves are located on the body in the upper part. "Upper" pumps are more durable due to the fact that the placement of the suction pipe above the engine compartment minimizes the risk of damage to the working chamber when large particles enter.

When working with pumps whose suction holes are located at the bottom of the device, experienced owners recommend placing the units on special stands.

Float automatic shutdown

Although automation increases the cost of equipment, it helps to prevent overheating of the motor.

The float is a device in the form of a plastic floating box. Inside it is placed an electric cable and a steel ball. It reacts to changes in the water level and closes/opens the switch contacts.

The presence of such a float automates the process and protects the internal mechanisms of the device from overheating when running dry

The main advantage of the device is that it simultaneously performs two functions: it acts as a water level sensor and serves as an actuator for controlling the pump.

Having spent a little more money on a device equipped with an automation system, you can not worry that after pumping out the water it will work “dry”. The only thing is that once every few months it is recommended to flush the float switch with a jet of water under pressure from contamination. Preventive cleaning will prevent the float from sticking to the outlet pipe.

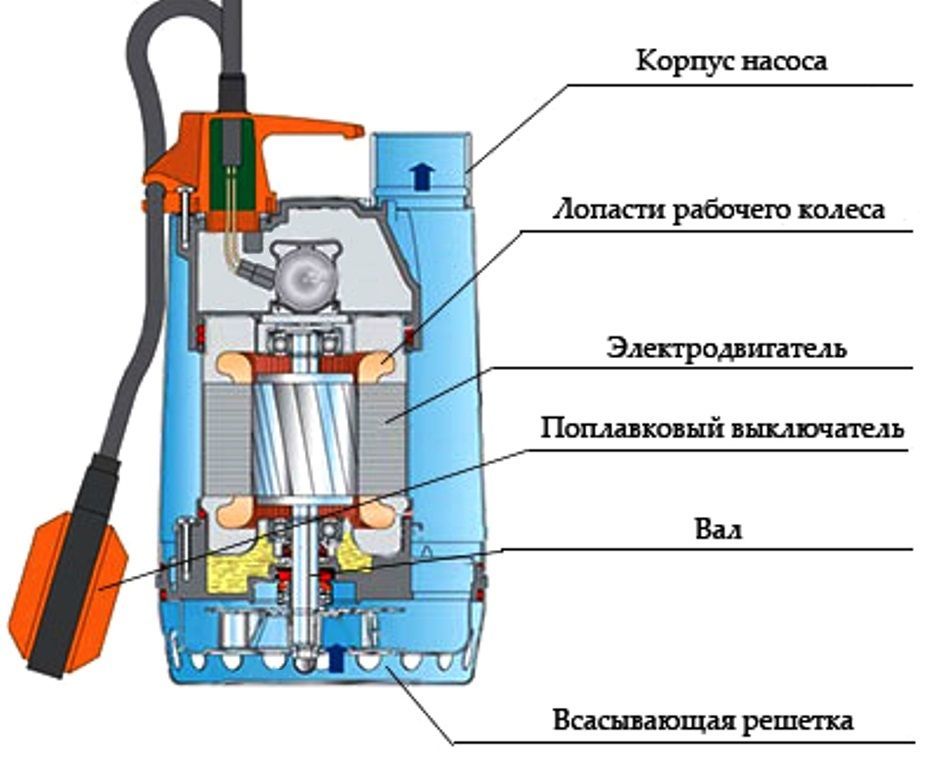

Specifications

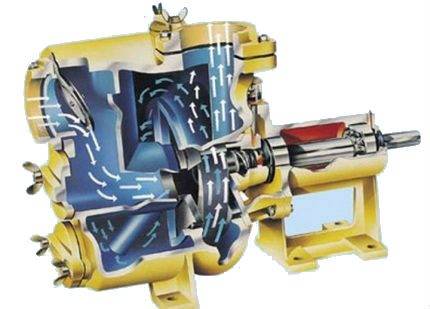

Simplified designs consist of the following parts:

- Electric motor.

- Shaft with impeller. It can be located directly on the motor or separately. From its placement, the purpose of the part does not change: it is responsible for moving water inside the equipment. The component is made of stainless steel.

- Pump assembly equipped with suction pipe. Through its holes, water enters the pump. Using the diameter of the holes, the dimensions of the passed particles are determined.

- Body part. The domestic pumping station is made of plastic or steel. Thanks to such materials, the device is mobile and convenient to use.Plastic is highly sensitive to interaction with solid particles, so these pumps often break down and need to be repaired.

- Float type switch. With its help, flooding and the operation of the product “dry” are excluded, since it automatically turns on and off depending on the amount of water.

The operation of the pump is quite simple: when the device is activated, the electric motor starts, which rotates the shaft with the impeller. A zone with rarefied air appears around the rotating blades, due to which the pressure in the chamber decreases. Water is drawn into the nozzles with holes and moves inside the pump. Due to the action of centrifugal force, the liquid moves to the outlet and exits into the outlet hose.

Traditional drainage pumps are not suitable for handling hot liquids. They can operate at high temperatures for a short period of time, as the motor cools down, transferring thermal energy to the liquid. If the pump is required for the constant transfer of hot liquids, a special type model will need to be purchased.

The material from which the pump is made affects the reliability of the product. According to GOST, submersible models can be made from composite raw materials combined with stainless steel. There are also models that are completely made of stainless steel.

The dimensions of the particles filtered by submersible pumps are considered an important indicator. Some device models can only interact with the smallest particles, the size of which does not exceed 10 mm. They are designed for pumping a conditionally clean liquid (water after a washing machine, washing unit, shower).

Other models can handle larger particles as large as 12,35,50mm. With the help of such equipment, it is allowed to pump more dirty waters with a high content of sand.

Flow-pressure qualities are also an important characteristic. It includes indicators of flow and pressure of the liquid. Household products have a maximum flow rate that does not exceed 14 cubic meters per hour, the pressure of devices reaches 10.9 cubic meters.

Drainage pumps have manual or automatic control. Automation is considered more convenient and reliable. In such products, a float switch is provided, which reacts to the water level and is located exactly on the surface. If the float goes down, the equipment will automatically shut off. When the float is raised, the system turns on.

Discharge nozzle orientation: horizontal or vertical models available

Choosing the right orientation is considered an important task, especially if the pump is integrated into an already finished drainage system.

What it is?

A drainage pump was made to pump fluid out of flooded basements. In the future, an expansion of the scope of the device began to be observed. Modern pumps are designed for pumping slightly contaminated liquid from wells, pools and pits, as well as for pumping and cleaning the well. Some pumps are used in factories. Many models can pump liquids containing impurities up to 10 mm in size.

A drainage pump is a special device that is made for certain actions. It is not allowed to use the application for purposes other than intended.Although the drainer is operated when cleaning a shallow well and a mine-type well, such devices are not suitable for constant interaction.

Drainers have the following advantages:

- The equipment can be mounted autonomously or in stationary mode.

- The device has a float-type switch, which is responsible for controlling the filling of the liquid.

- The devices are made of durable materials that are not subject to corrosion and other irritants from the external environment.

- Drainage pumps are small and light. Due to its compactness, the device is considered mobile.

- Devices can pump out liquids that contain solid particles. Some models are characterized by the processing of fiber and some chemical components of a non-aggressive type.

- The equipment is characterized by high efficiency rates along with maximum immersion depth and high technical properties.

- The drain pump does not require special care.

Design features of devices

The main purpose of pumps designed for pumping out is to drain storage tanks and remove accumulated moisture during floods. And in case of emergencies and empty the flooded basements and cellars.

Modern models of pumps for pumping dirty water can be used to solve many problems:

- clean the well shaft from silt and sand deposits;

- remove "flowered" water from an open reservoir in the garden;

- apply in the arrangement of the drainage system.

Unlike downhole devices, such pumps are capable of passing fibers, solids and small stones. Thanks to this, they are indispensable universal assistants in the performance of economic tasks.

With the help of these devices it is very convenient to water the garden beds on the site by throwing the suction hose into a nearby reservoir

The design of any garden pump for dirty water has a similar package. The device consists of a metal or plastic case, inside which an electric motor and a pump unit are placed.

When the motor is turned on, a vacuum is created inside the case. Under the action of low pressure, the liquid is sucked into the chamber, passing through which it moves to the outlet hose and is pushed out with force.

The operation of any pump is based on the principle of water retraction: liquid seeps through the inlet and, after passing through the chamber, is ejected into the outlet

The operation of any pump is based on the principle of water retraction: liquid seeps through the inlet and, after passing through the chamber, is ejected into the outlet

Depending on the method of creating a vacuum inside the chamber of the device, the pumps are divided into three groups:

- Centrifugal - work due to the fact that under the influence of the rotation of the blades of the wheels and the working part, the liquid is drawn into the body. Under the pressure of centrifugal force, it is pressed against the wall and then pushed out into the outlet.

- Vibrating - based on the effect of the electromagnetic field created by the coil. The metal core, equipped with a flexible diaphragm, being drawn into the coil, creates a low pressure, under the action of which fluid is sucked into the hydraulic chamber. When the curved diaphragm returns to its original position, the pressure inside the chamber increases, and the water is pushed out into the outlet pipe.

- Vortex - work by rotating a metal disk with blades, referred to as a vortex wheel. Under its action, the water is twisted into a vortex spiral, creating a powerful pressure at the outlet.

For pumping contaminated liquid at the household level, site owners mainly choose vibration and centrifugal devices.

Garden pumps for dirty water are able to pass liquid through themselves, without harm to mechanisms and assemblies, particles of dirt "caliber" up to 5 mm

Vortex-type models are extremely rarely used in pumping water with impurities and inclusions, since they are very sensitive to suspended particles in water. We also recommend that you familiarize yourself with our other material, in which we described in detail the principle of operation of drainage pumps and posted tips on choosing them.

Well

Like all other types of devices, well pumps are surface and submersible. Mainly, well pumps are designed to supply clean water to the house. They can also be used to obtain technical water with a minimum impurity content. However, they cannot pump out dirty water.

Often, a well pump pumps water for the entire plumbing in a house, which can be multi-story. Therefore, well models have a high pressure so that water is supplied under normal pressure to all points of water intake. The same drainage pumps, in principle, do not need such a pressure, since it is rarely necessary to move the pumped water over long distances.

The main difference between a well pump and a well pump is an additional cooling mechanism for the first one.Submersible well models are equipped with a cooling jacket, thanks to which it does not overheat during operation. Due to the presence of this jacket, their diameter is noticeably increased in comparison with downhole devices. If you need a good well pump for permanent water supply in the house, take Grundfos SB 3-35 A, with a capacity of 3 m3 / h and a head of 34 m.

How to choose the right pump

When choosing a unit, it is necessary to pay attention to the conditions of its operation, the selection of the required power, pressure and features of the model.

- The operating conditions of the drainage pump are to comply with the permissible parameters of fluid contamination. In order for the equipment not to fail, you should carefully read how much impurities in the form of sand, stones or silt may be present in the water.

- The power of the pump is calculated based on the size of the tank from which you want to pump water, and the time you expect to spend on this work. So, for example, if the volume of pumped water is 40 m³, and the operating time is reduced to 5 hours, then the pump power should be at least 8 m³ / h.

- The choice of the pressure of the equipment depends on the height to which the water must be raised, and on the distance to which it must be diverted. One meter of vertical water rise is equal to 10 meters of horizontal supply. Therefore, if the instructions indicate a water pressure of 8 meters, this means that this unit will be able to pump water over a distance of 80 m in the horizontal direction and 8 meters in the vertical direction.

- The equipment model is selected depending on the surface on which the pump will be mounted and on the purpose of its operation.Decide how you are going to install the unit, whether you need to completely drain the tank, after which the pump will not be required, or the water will constantly arrive, and the unit will continuously pump liquid.

In addition to the main characteristics, when choosing, one should also take into account what material the equipment is made of. For industrial production, drainage pumps are produced mainly from cast iron. This prolongs their service life, but significantly affects the weight and dimensions of the device. For domestic use, the model should be more compact and light. The material of manufacture, of course, affects the cost of the product.

- The most short-lived and cheapest models are made from various polymeric materials. It can be reinforced polyamide, polypropylene and other types of plastic. Such pumps are prone to frequent breakdowns, which cannot always be repaired.

- More expensive models have a plastic case. The main mechanism of the pump is made of stainless steel. Such equipment is not exposed to corrosion and chemical elements, which, accordingly, prolongs its service life.

- The most durable and strong pumps are made without the use of plastic. The main materials of manufacture are steel and cast iron. For everyday use, such models are still quite heavy, but they are resistant to damage and chemical attack.