- Classification depending on the purpose of use

- Which brand of drainage pump is better to choose

- Drain pump selection criteria

- Characteristics of the pumped medium

- Materials used in manufacturing

- Type of circuit breaker

- Drain pump performance

- The pressure of the device for pumping water

- Outlet diameter

- Drain pump installation

- How to choose?

- About drainage pumps

- Power Supply Options for Water Pumping Equipment

- Main selection factors

- Popular brands of equipment

- Operation and care

- Summing up

- The best surface pumps

- Surface Pump GARDENA 3000/4 Classic

- Surface pump AL-KO HW 3000 Inox Classic

- Surface pump Grundfos JPBasic 3PT

- Surface drainage pump AL-KO HWA 4000 Comfort – Powerful compact unit

Classification depending on the purpose of use

The choice of the type of pumping equipment depending on the purpose of use can be made on the basis of the following classification:

- All submersible pumps can be divided into three groups:

- downhole type units are suitable for installation in wells;

- drainage equipment is divided, in turn, into two types: pumps that work with clean water, and devices that can be used to pump dirty water;

- well units are installed in mine wells.

- All surface pumps can be divided into the following types:

- fountain;

- sewer installations, which are divided into units for external and internal use;

- pumping stations.

Which brand of drainage pump is better to choose

The TOP describes the products of 10 manufacturers, including many Russian companies. There are brands and budget, and the middle segment, and premium. Here are some of the leaders:

- Zubr is the largest Russian manufacturer of inexpensive and high-quality manual and electrical equipment for the home, garden, and construction. The company was founded in 2005 and offers professional pumps with an average power of 400 to 1000 watts. They have a low noise level, light weight, thoughtful protection against overheating, a long cable, and a durable case.

- Livgidromash - under this brand, goods are supplied to the CIS countries and beyond. They are characterized by a long service life, proven quality, small dimensions, reliable materials. With their help, water is pumped quickly enough, while its temperature can be an average of 50 degrees, and the amount of impurities is within 5%. One of the most popular series of the manufacturer is the "Gnome".

- Quattro Elementi - the company supplies the market with products for the garden and home with the best value for money. There are also drainage pumps with good characteristics in its assortment. The company's devices are distinguished by normal productivity, on average, about 7000 l / h, a decent power of about 600 W and dry cleaning of the tanks. They do not heat up, withstand long-term operation and are easy to use.

- Dzhileks Drainazhnik - the company produces equipment and consumables for working with water, it has devices for pumping it out of wells, wells, pools. Also in assortment there are offers for an irrigation of kitchen gardens. The best submersible drainage pumps of its products are made by good performance, decent power of the order of 800 W, a durable housing, and a heat-protected motor.

- Belamos - the company supplies wheelbarrows, burners, hoses, stoves, pumping equipment to the market. The latter is represented by fountain, borehole, vibration, drainage models, which are divided into submersible and surface. Both of them have excellent power and performance, which increases the efficiency and speed of their work.

- Patriot is an American brand under which a line of premium garden products has been produced for many years. All of them have certificates of quality and safety, serve for quite a long time and show their best side in irrigating gardens, cleaning pools, wells, and wells from water. The company's devices are easy to transport and operate, equipped with long cables and protective mechanisms against overheating.

- Stavr is a Russian brand of garden equipment and electrical equipment. The company operates in the middle price range, but at the same time produces professional devices. They are suitable for both domestic and commercial use, such as construction sites. Its pumps have everything you need for their full use - good power, high performance, long cable.

- Whirlwind is the leader among brands of pumping equipment in Russia. They are high powered, running at an average of 1100 watts.Among their advantages, it is worth highlighting a powerful water supply per hour, a considerable lifting height, and a durable, most often plastic case. The products are compact in size and adequate in weight, so they are easy to use.

- Unipump - the company specializes in the supply of professional high-quality pumps. They have convenient control, are safe for humans and are universal in use. With their help, you can pump water from pits, pools, wells. The equipment behaves well during long-term operation and serves without failures for years.

- Caliber is a budget brand of power tools and garden equipment that entered the Russian market in 2001. With affordable prices, the products have good quality and decent characteristics. Its products can be included in the rating of drainage pumps because of the power of about 800 W, the productivity of about 11 m3 / h, the lifting height of about 8.5 m. On average, their weight is 5.5 kg.

The best dry closets according to user reviews

Drain pump selection criteria

When considering how to choose a drainage pump, it is important to pay attention to some important parameters that are responsible for matching the functionality of this equipment to the stated system requirements.

Characteristics of the pumped medium

Before proceeding with the selection of the necessary model for pumping water, you need to understand what kind of liquid medium is to be pumped. Ideally, there should be no gravel, sand or dirt. In practice, they are used in flooded rooms, reservoirs and reservoirs. The accompanying documentation for each model describes the allowable solids values.

According to this indicator, they are divided into varieties:

- pumping water with fragments up to 5 mm;

- transportation of medium contaminated liquid with possible fractions up to 25 mm;

- for more polluted environments with possible fragments up to 38 mm.

In addition, it is important to take into account the temperature of the transported substance and its chemical composition. Indeed, for operation with aggressive components, it will be necessary to select drainage pumps with special technical abilities.

Materials used in manufacturing

The materials used determine the degree of reliability of the entire structure. Housing units for pumping water can be made of metal or durable plastic:

- Metal products are characterized by increased strength, provide more opportunities for the use of repair operations to restore functionality. This allows you to extend their service life.

- Durable plastic keeps the overall cost of equipment down, which is considered attractive to the average person.

No less important is the type of material for the production of working parts of drainage pumps for dirty water, namely the blades of a rotating element. They are made of stainless alloys and polymers with unique capabilities.

It is considered the best, high-quality polymer, it is able to be used under heavy loads. However, these items are not repairable. Stainless steel is much cheaper, it wears faster.

Type of circuit breaker

Basically, drainage pumps are equipped with automatic switches that can turn on the mechanism when the liquid reaches the required level.

They may look like:

- electronic special device, which is an expensive node;

- devices using a float, considered a cheaper alternative.

All of them work to stop the flow of water, turning off the electric motor, thereby protecting it from overheating.

Drain pump performance

This concept denotes the volume of a substance transported during a fixed time period:

- to meet the needs of everyday life, an indicator of approximately 10 m³ / h is enough;

- for professional use, more powerful devices are selected with an indicator of more than 100 m³ / h.

This is an important indicator, it is indicated in the attached documents.

The pressure of the device for pumping water

Average drainage pumps give out a jet of 5-50 meters:

- this indicator depends on the type of pumping equipment used, it indicates the permissible lifting height and the distance of its movement on a horizontal surface;

- this is an important performance characteristic indicated in the accompanying documentation;

- as a rule, it is calculated in a ratio of 1:10;

- if the lifting height is specified as 6 meters, then the horizontal withdrawal distance is equal to 60 m.

Naturally, this characteristic will be influenced by the diameter of the hose for transporting the liquid. For a domestic appliance, a lifting height of several meters exceeding the depth of the storage tank will be quite enough. It is always necessary to calculate this indicator with a margin.

Outlet diameter

To increase the efficiency of the device, you need to choose the right hose diameter:

- when transporting water, you will need a diameter in the range of 0.5-1.5 inches;

- if a contaminated liquid medium is to be pumped, a pipe with a diameter of at least 8 inches will be required;

- in addition, there are pipes for connecting in a horizontal or vertical plane.

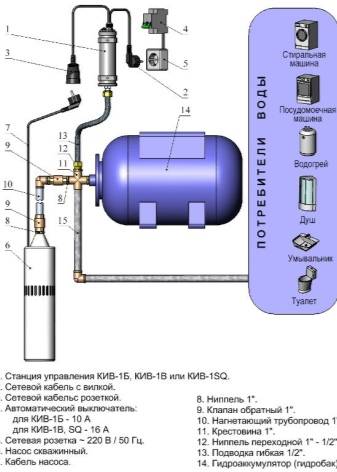

Drain pump installation

Drainage models for wells are distinguished not only by ease of installation, but also during operation. However, in order not to know the problems when using them, it is necessary to strictly follow the following rules during installation:

experts advise after unpacking the drainage pumping unit to check its completeness, and then carefully read the instructions for the model you purchased

Particular attention should be paid to the limitations of the equipment;

a pressure line must be attached to the pressure pipe. For fixing, use the connecting elements included in the kit;

if the model you purchased is equipped with a float switch and the pump will be used for stationary use, then in this case it is necessary to install a pressure line on the check valve;

if the device to be used for the well is equipped with a three-phase motor, then in this case it is worth checking the correct direction of rotation

The drain pump must be installed on a level surface. It is turned on and then immediately turned off. In this case, you must immediately notice in which direction the shaft rotates;

if the direction of rotation of the shaft is clockwise, then this indicates that the device was connected correctly;

if the shaft of the apparatus rotates in the opposite direction, then in this case it is necessary to swap the phases.

When the pump piping is connected, the following is used to check that the instrument rotates correctly:

- the unit is connected to the network, and then the feed is measured;

- after disconnecting the pump from the network, you need to change the phase, and then repeat the first paragraph again;

- they compare the supply power, after which they decide which option for connecting the phases is correct.

Equipment must be installed in a vertical position. In this case, the discharge pipe must be directed upwards. After that, the pump should be lowered to the bottom of the structure.

How to choose?

When buying a pump, it is necessary to take into account the individual characteristics and purpose of the device. For wells, there are borehole submersible models, for reservoirs, barrels and other containers - pumps specially designed for irrigation. By changing the intended purpose of submersible structures, you can simply disable them. Therefore, it is necessary to carefully study the parameters and characteristics of each of them before making a choice in favor of any.

When choosing, it is also necessary to take into account the size of the well and the depth of the bottom of the object where the mobile hydroelectric station will be lowered. Detailed information is contained in the appendix - technical documentation. Water levels are also taken into account. So, the dynamic indicator is the sum of the distance from the bottom of the reservoir to the surface line of the reservoir, and the static one is from the ground to the water edge. Given the static indicators, it is necessary to make calculations to determine the size of the water column, for this, subtract its digital value from the size of the well depth.

When choosing, it is necessary to take into account the quality of work on drilling wells. Drilling should ideally be done by crews using specialized equipment.Such wells are more reliable in comparison with wells made by the so-called cheap labor.

Submersible pumps for wells are more expensive, since the equipment takes into account the factor of protection against blockages and warranty service by specialists.

These small, at first glance, nuances must be taken into account if you correctly approach the process of choosing the right model. Correct wells are universal. They can install any type of submersible pumps - from simple to specialized models.

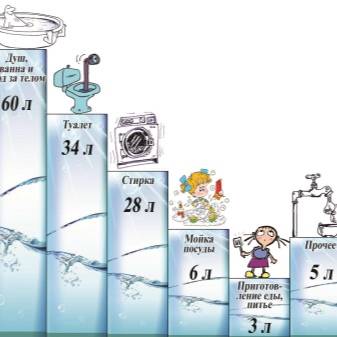

One of the main indicators when choosing a device is the quantitative water consumption per day. It should be taken into account that in winter and summer periods these indicators differ in the direction of increasing water consumption in the warm season. Irrigation consumption is also taken into account, based on the size of the irrigation area. If there is a small household, for example, pets, livestock, and so on, the daily water intake may increase.

As a precaution, you need to choose four-inch pipes for the well, which is slightly larger than pumps with a three-inch diameter. In fact, most of this equipment is just designed for more space. When calculating, you need to convert the measurement indicators to inches: divide the digital indicator by a factor of 2.54. Pumps visually differ in power: stronger ones in size and weight differ significantly from weaker ones with low performance.

It is better to choose pumps with a performance margin. To work at a depth of 40 meters, it is better to choose models for working at a depth of 50-60 meters. If the device for shallow depth is used at full depth, it simply cannot withstand such a load for a long time and will break.

The pumping device must be equipped with protection against idling, since in the event of emergency situations, it is necessary to immediately disconnect from the network. The protection is triggered by power surges, the indicators turn off the device in the event of a water supply interruption.

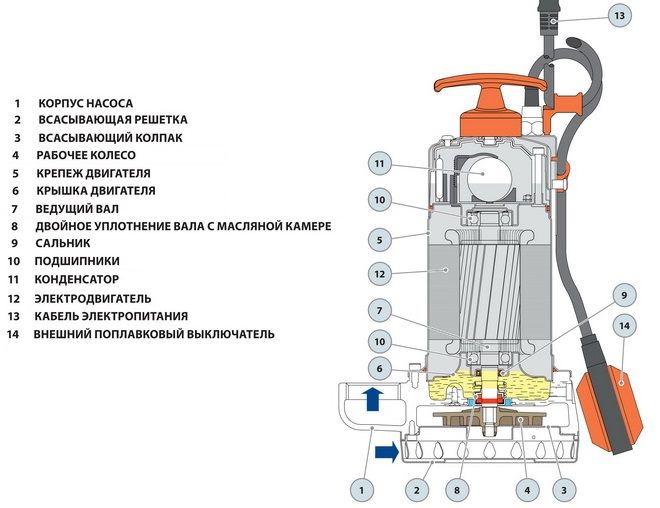

About drainage pumps

Depending on how the drainage pump is connected, surface and submersible devices are distinguished. The surface pump is placed on the ground, at the edge of the tank. A hose is connected to the bottom of the tank.

The submersible pump is lowered directly into the tank. Water is not sucked in through a hose, but through a hole in the bottom of the appliance.

You can set the automatic operation of the drainage pump: it will monitor the liquid level itself. As soon as the water rises above the set level, the pump will start to function.

When choosing a drainage pump, you need to take into account:

- the volume of water that must be pumped out at a time;

- the depth from which it is necessary to pump out;

- type and degree of fluid contamination.

Power Supply Options for Water Pumping Equipment

The pump unit can be powered by electricity and by liquid fuel. The first type of devices for the operation of the engine uses alternating current, as a result of which it is completely dependent on the electrical network. Therefore, an electric water pump is selected if it is present.

It is very important to take into account the voltage in the network, since a specific model of the unit is designed for a certain number of phases

Liquid fuel pumps are equipped with an internal combustion engine. Such units are characterized by smaller dimensions, mobility and ease of operation, repair and maintenance.

There are two types of liquid fuel pump units - gasoline and diesel.Gasoline pumps use a gasoline-oil mixture as fuel, which is prepared in a certain ratio of components. Such units are much quieter and have a lower cost. However, they consume quite a lot of fuel, as a result of which they are not economical. Diesel units use diesel fuel as fuel. The pumps operate with increased noise levels, but are characterized by high efficiency.

Note! Pumps for pumping water 220 V are more expensive than liquid fuel units.

Pumps for pumping water can be powered by electricity or liquid fuels.

Main selection factors

If it is intended to use the pump in a private courtyard, then it is usually installed at the stage of arranging the sewer system. Therefore, when choosing, take into account the length of the pipes through which the pumped-out effluents will be transported. It is this parameter that will help determine the required power of the equipment. But besides him, this parameter is also affected by:

- Pipeline location;

- Estimated volumes of pumped wastewater.

However, the brand of the manufacturer, as well as the cost, are considered no less important. It should be noted here that savings when buying a pump is unacceptable. You should not buy cheap models, because the period of trouble-free operation depends on their quality. Therefore, it is better to choose expensive equipment from a trusted manufacturer than to change it every year.

Popular brands of equipment

Grundfos models

One of the most famous companies involved in the production of drainage equipment is Grundfos. Its equipment is represented by several Unilift series:

- KP;

- AP;

- CC.

Moreover, submersible pumps for dirty water of this manufacturer are assembled exclusively from parts that are manufactured at the factories of the concern.

Their quality is subject to strict control at every stage of assembly. The electric motors in the equipment are also the development of the company's specialists and are assembled here. In addition, the pumps are equipped with high-tech electronic equipment, which has a positive effect on performance and minimized energy consumption.

The company does not forget about the external design of its products. All units of the manufacturer have an aesthetic appearance and are assembled using high quality materials.

Calpeda Model

You can also trust Calpeda equipment. It produces several series of dirty water pumps:

- GM10;

- GXR;

- GMV.

The equipment from this manufacturer is distinguished by high reliability and performance, it is completely safe to operate and economical.

At each stage of assembly, the pumps undergo strict control, which guarantees high quality products. All work is carried out exclusively at factories in Italy. For any model of equipment, the manufacturer gives a guarantee of three years.

There are, of course, other companies that make submersible pumps for dirty water. Their products differ in quality and value. For example, budget options are offered by Aquatica and Dnipro-M. The cost of their equipment is no more than $50.

Operation and care

In order for the submersible pump to work for a long time and efficiently, the following should be observed:

- Select a model in accordance with the manufacturer's recommendations;

- Comply with all operating requirements set out and attached instructions.

Since equipment of this type is located in water, it is almost impossible to check whether the case has warmed up or whether extraneous noise has appeared. Therefore, the operation of such units must comply with the requirements of the manufacturer.

Watch a video about Aquatica products:

Particular attention must be paid to the oil level in the chamber that protects the engine from water ingress. The check is carried out every 15 days. At the same time, the oil is changed after 200 hours of operation, and it is added as needed.

In this case, the oil is changed after 200 hours of operation, and it is added as needed.

Another important factor in the operation of a submersible pump is the correct connection to the power source. It is recommended to use a circuit breaker or a magnetic starter for this, corresponding to the motor power. Only if all these requirements are met, the pump will serve you for a long time.

Summing up

Having learned what the equipment used for pumping dirty water is and familiarizing yourself with its technical characteristics, you can easily choose the right model.

The best surface pumps

Drainage pumping stations that are installed "on the shore" are great for pumping water from one reservoir to another. In addition, such models are often used in cases where access to liquid is difficult.

The hose can be submerged to a depth of several meters, which is convenient, for example, for pumping water from a basement or a pond.

Surface Pump GARDENA 3000/4 Classic

The GARDENA 3000/4 Classic Surface Pumping Station is an excellent device for pumping water from any reservoir.The pump delivers up to 2.8 cu. m / h, so that even large volumes of water will not create problems for him. The maximum suction depth of the device is 8 meters, which is a good indicator for a conventional country pump - you can pump water from a well. At the same time, the pump power consumption is only 650 W, which will slightly affect the increase in power consumption even with regular use of the device.

Advantages of GARDENA 3000/4 Classic:

- Quality assembly;

- Small dimensions;

- Ease of operation;

- High reliability.

Pump Disadvantages:

- Plastic fittings;

- Difficulties with draining residual water.

Surface pump AL-KO HW 3000 Inox Classic

The AL-KO HW 3000 Inox Classic drainage surface pump is one of the most reliable devices on the market. Thanks to a powerful engine and high-quality fittings, the device does an excellent job of pumping large volumes of liquid for a long time, while its performance is 3.1 cubic meters. m/hour. One of the main advantages of the pump can be considered the possibility of connecting it to a 220 V network - it can also be operated at home.

The built-in hydraulic tank of 17 liters helps to maintain the pressure at a constant level, which can reach 35 meters. The mass of the pump is about 11 kg, which allows you to easily transport it and install it in any place. The built-in mechanical relay prevents possible overloads.

Advantages of the AL-KO HW 3000 Inox Classic pump:

- Low noise level;

- Light weight;

- Quality materials;

- Easy operation.

Installation cons:

- Plastic centrifugal pump;

- Low build quality.

Surface pump Grundfos JPBasic 3PT

The Grundfos JPBasic 3PT multifunctional drainage surface pump is suitable for serious work in critical areas. Thanks to a powerful engine, the device has a suction height of up to 8 meters, which allows you to pump out water even from deep wells. At the same time, the throughput of the installation is 3.6 cubic meters. m/h, which is optimal not only for irrigation, but also for water supply.

Strengths of the drainage pump:

- Stable work;

- Low noise level;

- Affordable cost;

- Quality build.

Disadvantages of installing Grundfos JPBasic 3PT:

- Slow exit to a stable mode of operation;

- Inconvenient location of the pressure gauge;

- Poor set.

Surface drainage pump AL-KO HWA 4000 Comfort – Powerful compact unit

The AL-KO HWA 4000 Comfort drainage pump without hydraulic tank is an excellent solution for private houses that need to provide water supply. Due to the suction depth of up to 8 meters, the unit can be used to pump water from wells or wells, and the design features allow the pump to work with liquids whose temperature does not exceed 35 degrees.

The pump is installed horizontally, and the automatic regulator built into it, which monitors the water level, will prevent “dry” operation. The unit consumes a minimum of electrical energy even at a power of 1000 W, and at the same time it can be connected to a 220 V socket with an ordinary plug. It is recommended to operate a clean water pump.

Advantages of the AL-KO HWA 4000 Comfort pump:

- High build quality;

- Excellent reliability;

- Small dimensions;

- Ease of operation.

Weaknesses of the installation:

- High price;

- No hydraulic tank.