- How to make your own cleaning structure for a well

- Bottom filter materials, description and preparation

- Reverse way

- Bottom filter care instructions

- Wall filter in the well

- Homemade filter on a hike

- Method one

- Method two

- Method three

- When and why is it needed?

- Maintenance and care of the bottom filter

- Bottom filter for a well with a wooden shield - step by step instructions

- Making a board shield for a bottom filter

- Laying the shield and backfilling the material of the bottom filter

- Video - Installing a bottom filter

- What is the bottom filter in the well filled with?

- Quartz sand

- Large and medium river pebbles

- Gravel of natural origin

- Geotextile

- Prohibited Materials

- Simple travel water filter

- How do you get quality water?

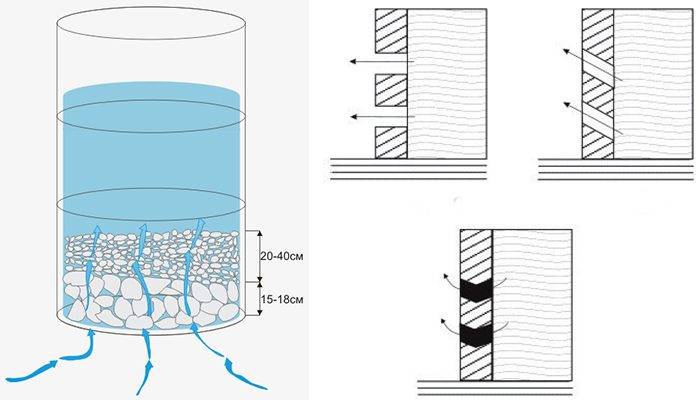

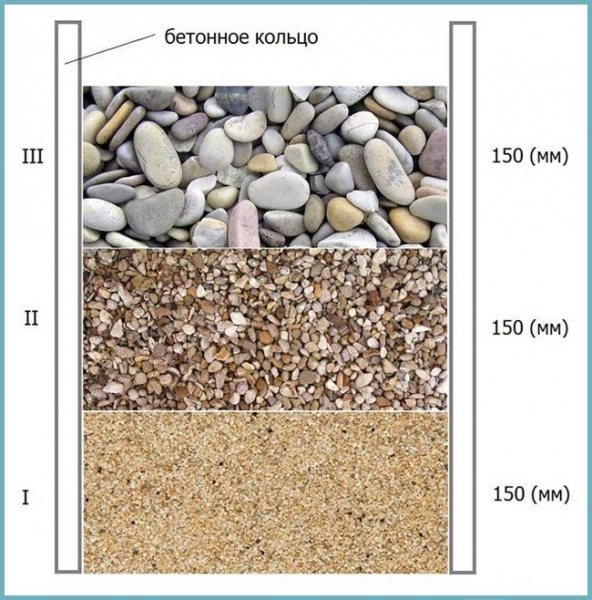

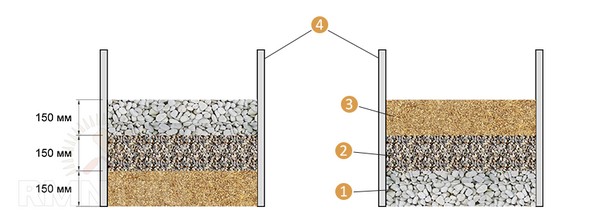

- Ways to install bottom filters

- We make a water filter with our own hands to clean well and borehole water

- Why filter well water?

- Overview of filtration materials

- The simplest plastic bottle filter

- Three-flask design for a full plumbing

- Conclusions and useful video on the topic

How to make your own cleaning structure for a well

How to make a do-it-yourself water filter for a well? The device of the cleaning system is simpler than it might seem.

The following materials and tools are being prepared:

- pipe made of durable plastic;

- stopper made of wood;

- mesh with the smallest holes (cells), preferably brass;

- drill, drill.

How to make a water filter: process description

- Initially, the total length of the sump is measured.

- At an angle of up to 60 degrees (minimum 35), it is necessary to drill small holes in a checkerboard pattern, leaving a minimum distance of 2 cm between them.

- The pipe is thoroughly cleaned of the remnants of chips, the zone “with holes” (25% of the total length) is wrapped, fixed with rivets.

- A plug (plug) is installed.

Passing through the mesh, small particles of dirt and sand will linger. Impurities of larger diameter settle in the sump. The water that has passed such filtration must be additionally boiled before use, since the purification system does not remove harmful substances (microbes, bacteria).

Bottom filter materials, description and preparation

Pebble. The most accessible material. Silt and clay practically do not linger on the river stone, so it is enough to rinse it with a hose before laying it.

Gravel. Not to be confused with pebbles, as gravel is a rock. Loose material: if it dries, it will be covered with a small amount of lime. As part of the barrier, gravel acts as a disinfectant. It cannot be poured in the upper layer, since after it the water must be cleaned again.

There is one minus of this component - during operation, the stones absorb all the impurities and trace elements, and after a while they will begin to give them away.Therefore, the layer has to be completely replaced, and not washed. This usually happens once every 1.5-2 years.

Rubble. Crushed from large boulders in the mining industry. Pour on the lower and upper layers. It is considered a coarse filter. Before use, crushed stone is checked for compliance with environmental standards.

Jade. Outwardly, it is very similar to large pebbles, but with a greenish tinge. It is most often used as a heater filler in a sauna stove. Hard stone of round elongated shape. It is a natural "antibiotic" for water. It is able to detain and destroy harmful microorganisms. The downside is that such a stone is difficult to find in nature. Although it is found everywhere in hardware stores.

Shungite is a rock obtained as a result of mineral compounds and oil. It looks like black-gray coal, on the surface there is a deposit in the form of dust. Used as backfill in the middle layer, possibly instead of gravel. Absorbs harmful oil products and other substances. The downside of shungite is that it needs to be replaced after a while.

Geotextile is used together with other components. Usually it is laid on the bottom of the well before the first layer of stones. Since geotextile is a floating material, it must be pressed down. Due to its porosity, it will retain the smallest particles of dirt, as well as silt.

Reverse way

Coarse-grained quartz sand. You can find it along the banks of rivers. Quartz sand has a grain size of up to 1 mm, translucent with small inclusions of a dark color. The sand must be washed before laying in the well: put a layer of sand in a container, fill it with water, stir, leave for 20-30 seconds, then drain the water.Heavy large particles of sand will settle during this time, and the remains of silt and clay will remain suspended in the water. This procedure can be repeated several times until the water with sand is almost clear.

Quartz sand for well cleaning

River pebble. Like sand, it is found along the banks of rivers in the form of pebbles of different sizes and colors of a rounded shape. Pebble is a natural chemically neutral material with a normal radiation background. Pebbles before laying in the well also need to be washed under running water.

Pebbles for water treatment

Gravel is loose porous sedimentary rock. Grains of gravel come in different sizes, from a few millimeters to several centimeters. Gravel often has impurities of harder rocks, clay or sand. It is also used in drainage systems. It is impossible to take gravel used in other systems - due to the porosity, this material is capable of accumulating various dangerous contaminants.

Gravel for laying in a well

Rubble. Irregular-shaped stones of different sizes are mined mechanically. They can be from various minerals. Not every gravel is suitable for a bottom filter device. Limestone crushed stone is dusty and pollutes water, and is washed away with prolonged contact with it. Granite crushed stone is also not suitable - it has an increased radiation background. For the bottom filter, it is recommended to take crushed stone from neutral minerals that have the ability to purify water, for example, jadeite. You can buy it in stores selling bath accessories - this stone is most popular for stoves.

Crushed stone for laying in a well

Shungite, or petrified oil.It is used in water treatment systems to remove heavy metal compounds, organic contaminants and oil products from it. If the well is located near enterprises or roads, or the depth of the well does not exceed 5 meters, the addition of shungite will make it possible to disinfect it.

Shungite stone is perfect for water purification

Bottom filter care instructions

When operating a source with a cleaning layer, consider the following:

- A wooden shield begins to deteriorate after a few years, so it must be changed periodically. If the product is not replaced in time, rotting wood will give the water an unpleasant taste and smell.

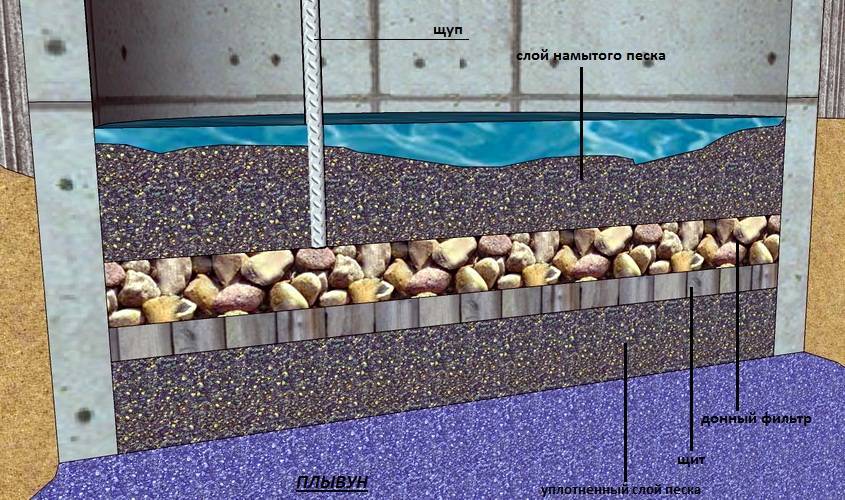

- Quicksand gradually sucks the shield, so after 5 years it must be reinstalled. To extend the service life, it is covered with geotextiles.

- Clean the filter annually. To do this, remove all gravel, sand and bottom shield from the mine. After inspection, it is necessary to make a decision on its replacement or continuation of operation. Follow the process of installing the product in the same way as for the first installation.

- When using a bucket, choose the length of the rope so that the container does not reach the bottom and does not muddy the water.

- Install the pump exactly in accordance with the operating instructions of the device manufacturer. Attach submersible products at a distance of 1 m from the bottom. Its details should not touch the walls.

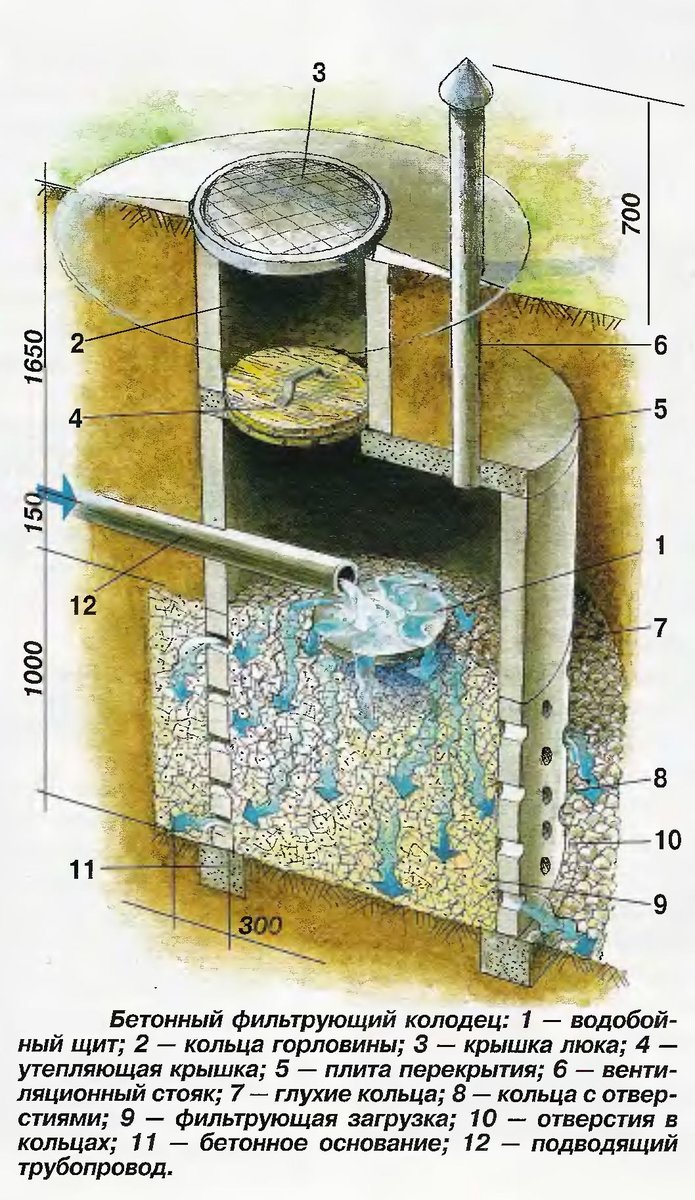

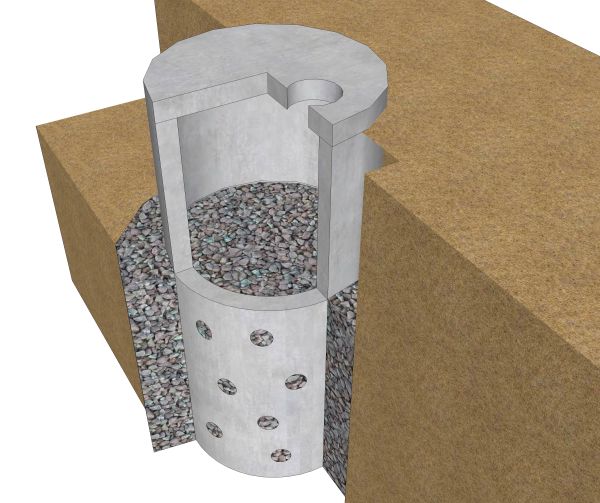

Wall filter in the well

In the case when the flow of water entering the well is very weak, and filtration is also carried out through its walls, then the installation of a bottom filter is not advisable. In such a situation, the best option would be to install a wall filter.

To make a wall filter, it is necessary to cut out V-shaped holes located horizontally in the lowest part of the well (lower reinforced concrete ring), where filter elements made of coarse concrete are installed.

Concrete for filters is prepared using medium fraction gravel and cement grade M100-M200 without the addition of sand. The cement is diluted with water until the consistency of the mixture becomes creamy, after which the pre-washed gravel is poured into it and mixed thoroughly. The resulting solution is filled with cut holes and left until completely hardened.

The size of the gravel for the solution must be selected taking into account local hydrogeological factors: the finer the sand fraction in the well, the smaller the size of the gravel

Homemade filter on a hike

It often happens that when going on a hike, we stock up on drinking water in insufficient quantities. There are no shops, wells in the area, but there are plenty of natural reservoirs, puddles, etc. How to make dirty water drinkable?

Method one

When collecting a camping first aid kit, we always put several packs of activated charcoal, bandages and cotton wool. We need all this and a plastic bottle for the filter.

- In a plastic bottle, cut off the bottom and turn over.

- We put a layer of cotton wool in the neck.

- We fold a strip of bandage in several layers (the more, the better) and put it on top of the cotton layer in a bottle.

- Pour crushed charcoal tablets on top, a layer of bandage and cotton wool on top.

Method two

You can do without a first aid kit.For this system, we need a plastic bottle with a lid, moss and coal from a fire (not very large so that it fits more tightly into the container) and a small piece of cloth.

You can do without a first aid kit.For this system, we need a plastic bottle with a lid, moss and coal from a fire (not very large so that it fits more tightly into the container) and a small piece of cloth.

- We make several small holes in the lid, put a fabric folded in 3-4 layers into it. Screw the lid into place. Cut off the bottom of the bottle.

- We fill the container with moss and coal in layers, starting and ending with moss. The more layers we put, the cleaner the water will be.

Method three

We make the most primitive filter. To do this, we need two containers (bowlers, mugs, etc.) and a bandage or a long strip of some cotton fabric.

We unwind the bandage equal to the height of the container taken 8-10 times. Fold it in half and twist it into a rope. Fold it in half again. We lower the folded end of the tourniquet into a container with dirty water to the very bottom, the free ends into an empty container.

- The water tank must be above the receiving tank.

- The free ends of the tourniquet should be lowered below the folded end in the water.

- The higher the level of dirty water, the faster it is filtered, so it makes sense to add dirty water to the upper tank.

- The free ends should not come into contact with each other and with the walls of the vessels.

- If you need to skip a large amount of water, you can make several flagella.

Water filtered in this way will not be perfectly clean and transparent. Mainly dirt, sand, suspensions, silt will be filtered out.

It is important to remember that such camping filters purify water only from dirt and turbidity. Bacteria and microbes are stored in it

Therefore, filtered water must be boiled before drinking.

When and why is it needed?

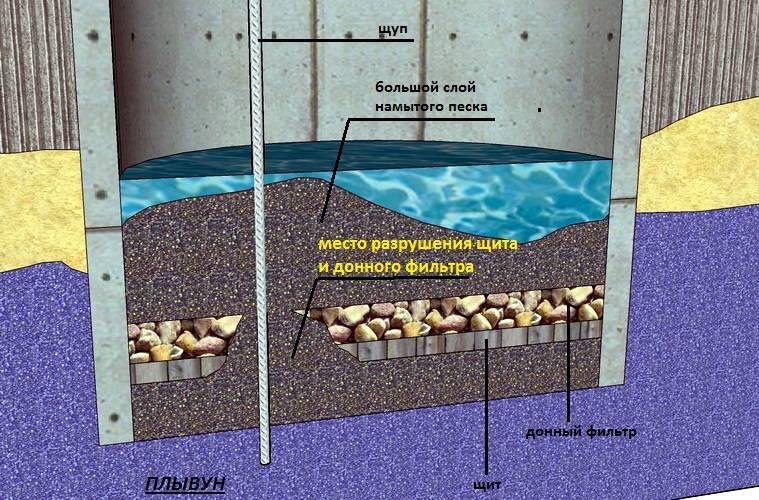

- A swimmer has formed. The problem of well water supply.Quicksand - a mixture of sandy rocks and fine-grained clay with soil. This combination gives an unstable shape of the bottom of the mine. When water is taken in by a pump and a bucket, sand rises, clay does not allow it to settle down. Therefore, the fluid during quicksand is cloudy and oily.

- The bottom is homogeneous, sandy. The sand is heavy, and in a calm state it is at the bottom. But when the pump is turned on, it will immediately rise from vibration and begin to penetrate into the nozzles, clogging them. The bucket is the same story.

- The soil around the well and at the bottom consists of loose clay. It creates the effect of the presence of silt in the mine. Due to the saturation of loose clay with water, it is agitated, and the liquid gradually becomes cloudy.

- The bottom of the well is made of dense clay. It belongs to the group of reliable soils. Such a bottom is a barrier. But there is a significant disadvantage - the low throughput of the material, over time, you still have to install at least the most primitive bottom filter.

Maintenance and care of the bottom filter

During operation, the filter for the well is clogged with fine fractions of sand and silt. This prevents water from entering. Maintenance is carried out to prevent:

- stones are brought to the surface;

- washed with clean water;

- new sand is poured.

After that, the filter product is installed again. (Recommended once a year).

The bottom filter is an inexpensive device, but it has great capabilities. It is necessary to strictly adhere to the technological process for its installation.

Attention should be paid to the quality of the material used and its origin. As a result, a person will enjoy clean drinking water with excellent taste for a long time.

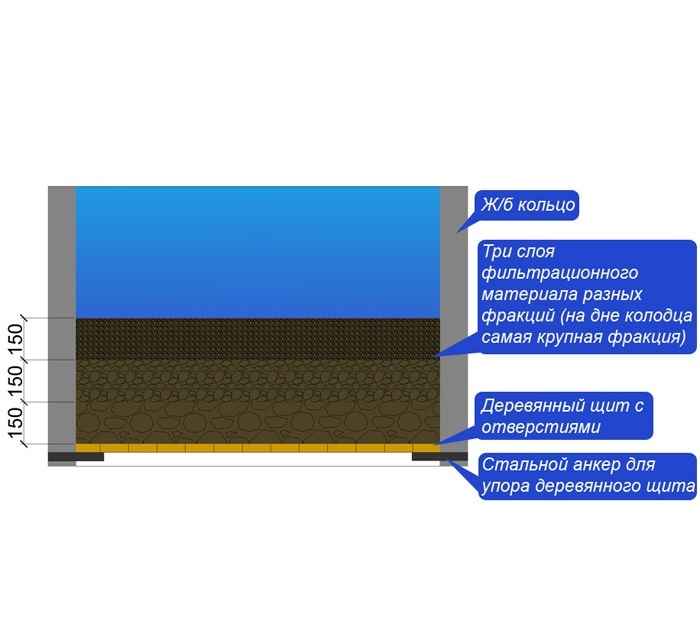

Bottom filter for a well with a wooden shield - step by step instructions

As an example, we give the arrangement of a bottom filter for a well with direct backfill and a wooden shield.

Wooden shield for the filter

Bottom filter installation

Making a board shield for a bottom filter

Step 1. Measure the inner diameter of the well. The wooden shield placed on the bottom should be slightly smaller so that during installation there are no problems with moving and laying the product.

Step 2. Choose the type of wood for the shield. Oak has a high durability, but at the same time it will turn the water brown at first. Larch is slightly less resistant to water compared to oak, but cheaper. However, most often, aspen is used for the shield under the bottom filter for the well, since it is poorly susceptible to decay under water. Wood should have as few knots and surface defects as possible - its durability depends on this.

Step 3. Knock down a regular square shield from the boards. At the same time, it is not necessary to connect them end-to-end with each other - the presence of gaps is permissible and even necessary. Use only high quality galvanized fasteners.

Step 4. Draw a circle on the surface of the shield, the diameter of which is somewhat smaller than that of the well.

Step 5. Using an electric jigsaw, cut the wooden board around the circumference.

Trimming a board shield

The shield is cut around the circumference

Pruning almost finished

Step 6. If even taking into account the quicksand, the flow rate in the well is not too large, drill many small holes with a diameter of 10 mm in the shield.

Ready-made shield for the bottom filter of the well. In this case, holes are not required - water will penetrate through the gaps between the boards

Laying the shield and backfilling the material of the bottom filter

Now that the plank shield made of aspen, oak or larch is ready, proceed to direct work with the well. Going down there, do not forget about safety - put on a helmet, check the condition of the cable, prepare a lighting device.

Step 1. If the well was in operation for a long time before the installation of the bottom filter, clean it of debris and silt.

Step 2 Install a board shield on the bottom and level it.

Shield ready to install

Installation of a board shield

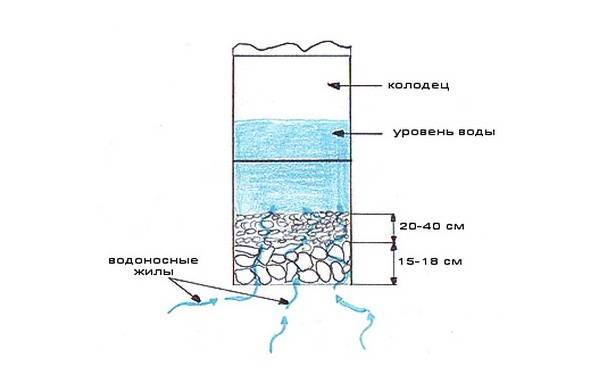

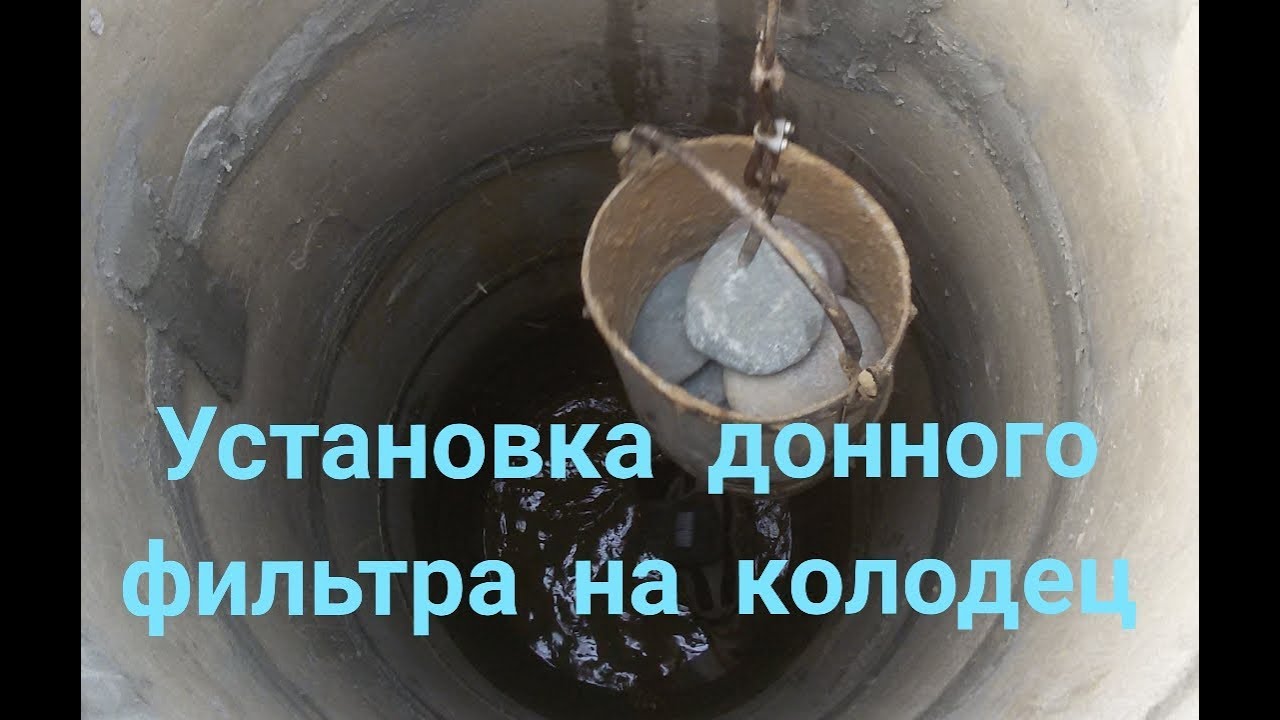

Step 3. Next, your assistant should lower a bucket of gravel, jadeite or large pebbles. Lay the stones evenly over the surface of the shield. Create a layer of coarse backfill with a thickness of at least 10-15 cm.

Large pebbles are lowered into the filter well

Stones are evenly distributed over the surface of the shield

Step 4. Next, place gravel or shungite on top of the first layer. The requirements are the same - to ensure a uniform layer with a thickness of about 15 cm.

Second layer of bottom filter

Step 5. Fill in the last layer of the bottom filter - river sand washed several times.

Step 6. Provide water intake at a depth not reaching the bottom filter with a board shield. To do this, shorten the chain or rope on which the bucket descends into the well. If the water intake is carried out by a pump, raise it higher.

The well can be used 24 hours after the installation of the bottom filter

After some time - usually about 24 hours - the well can be used again. At the same time, monitor the quality of the water coming from there - if after a year or two it has acquired a sweetish taste and an unpleasant smell, this means that the board shield has begun to rot and it needs to be replaced.At the same time, do not forget to regularly wash and change the sand, gravel and shungite used when filling the bottom filter for the well.

Video - Installing a bottom filter

Bottom filter for well

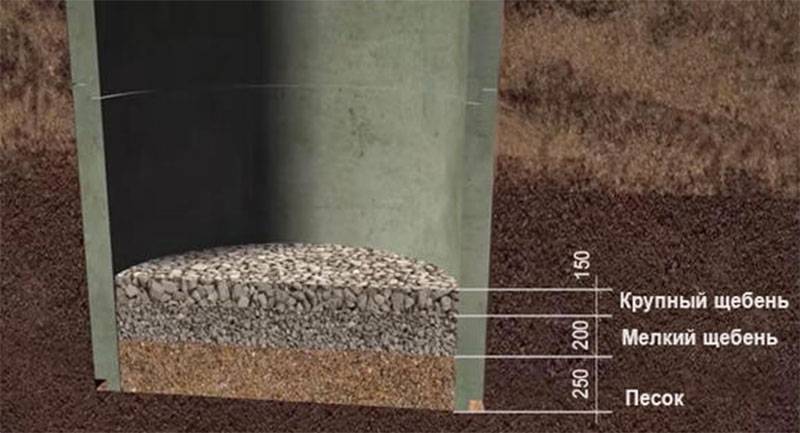

Scheme of a well with a simple gravel pad, which in some cases is capable of performing the tasks of a bottom filter

The rising quicksand not only spoils the water with suspensions and impurities, but also can disable the pump or lead to displacement of the concrete ring of the well

well filter

Sand is filled with water

river sand

large pebble

Medium fraction pebbles

river gravel

rubble

Shungite

Jade

Trimming a board shield

The shield is cut around the circumference

Pruning almost finished

Ready-made shield for the bottom filter of the well. In this case, holes are not required - water will penetrate through the gaps between the boards

Shield ready to install

Installation of a board shield

Large pebbles fall into the well

Second layer of bottom filter

Bottom filter installation

Wooden shield for the filter

Scheme-section of a well with a filter made of wood and stones

Clean water in a well

Aspen shield for bottom filter

In this case, the bottom of the well is formed by clay rocks.

Extraction of river sand

The well can be used 24 hours after the installation of the bottom filter

What is the bottom filter in the well filled with?

Perhaps the point is not how to fill the bottom filter, but with what. In addition to ordinary gravel or river pebbles, it is recommended to use the following materials for the installation of a filter layer at the bottom of the well:

- jade. Allegedly, this mineral is able to miraculously have an antibacterial effect. Jadeite is a silicate of aluminum and sodium, similar to jade.And, like jade, it is used to make jewelry. Cheaper varieties of jadeites are used as stones for sauna heaters due to their high heat capacity and inertness to water even when heated to high temperatures. No antibacterial properties of jadeite are known to mineralogists.

- zeolite. This mineral really has good adsorption properties and is used in filters, including water filters. It is also used to make mineral food supplements. However, the Commission on Carcinogenic Factors under the Ministry of Health of the Russian Federation allowed zeolite from only one deposit, Kholinsky, to be used in the food and medical industry.

- shungite. One of the varieties of carbon, occupies an intermediate position between anthracite and graphite. Indeed, it is used as a backfill for fast filters and for fixing a colony of microorganisms in slow ones. The sorption properties of shungite are no different from other coal fillings.

Quartz sand

Quartz sand is used to filter well water due to the fact that it differs from river and quarry sand in uniformity and high intergranular porosity, and hence, dirt capacity. For wells, coarse sand is taken. It is available in 25 kg bags. Quartz also purifies water from iron and manganese. It is allowed to use well-washed river sand if the filter consists of several layers of different materials.

Large and medium river pebbles

Pebbles - stones of natural origin, having a rounded shape and smooth edges (pellet). It can be collected on the river bank. Before backfilling, the pebbles are rinsed with water.If there is no reservoir near the site where the well is located, then you can buy this material in bags of 25 or 50 kg.

Gravel of natural origin

Soil for well water.

Another name for this material is crushed gravel. This is the same pebble, but it is mined in mountain quarries. The gravel has a more irregular shape. Only this type of crushed stone is suitable for a soil well filter. It is suitable for water purification in wells. You can not buy gravel for this purpose, which has already been used - pollution accumulates in the stones.

Geotextile

Pollution barrier.

Geotextile (geotextile) - a special woven or non-woven material made of polypropylene or polyester fibers, has filtering properties. It can be laid on the bottom or attached to a well shield.

Geofabric is used in wells density from 150 to 250 g/m². When using a material with a lower density, the risk of ruptures increases, with a higher one, the throughput deteriorates. Advantages of geotextile: does not emit harmful substances, it is easy to get it for washing.

Prohibited Materials

To equip a bottom well filter with your own hands, you can not use the following materials:

- quarry sand - it contains a large amount of pollution and impurities, especially clay;

- granite or slag crushed stone - due to high radioactivity, the possibility of releasing heavy metals;

- limestone crushed stone - quickly destroyed in an acidic environment;

- secondary crushed stone - its pores are filled with accumulated pollution;

- expanded clay - too light, floats in water.

Simple travel water filter

In order to design a water filter with our own hands, we will need:

- two identical plastic bottles with caps;

- a plastic tube with a diameter from the neck of a bottle;

- glue gun;

- a drill with a feather drill, or a strong sharp knife.

And now we will learn how to make a water filter:

- Unscrew both caps from the bottles and glue them together on the front side with a hot glue gun.

- Screw a feather drill with a diameter of 20 mm into the drill, and drill a through hole in the glued covers. In extreme conditions, it can be cut with a camping knife, but you have to tinker a little longer and be accurate.

- Insert a plastic tube into the resulting hole. Its length should be slightly shorter than the height of the plastic bottle.

- Take your bottles and screw them into the caps on both sides. One of the bottles will be put on a plastic tube.

Do-it-yourself water filter is ready! But how to purify water with it? Let's check:

- Unscrew the empty bottle from this device and fill it with water that needs to be purified. Take any cloudy water with mud to better notice the difference.

- Put the bottle on the table and screw the second part of the structure into it through the cap.

- Leave the bottle somewhere in the sun or, if possible, cover it with a black cloth to enhance heat absorption. And you can immediately use a black plastic bottle.

- After a few hours, check how our filter is doing. You will find that the liquid evaporates from the first container and passes through the tube into the catchment container, settling on its walls and flowing down. And the condensed water looks absolutely pure, just like bottled water from the store!

- When enough water has collected, unscrew the water collection bottle, turn it over and unscrew the cap with the tube - that's it, you can enjoy clean water! True, it is better to boil it before use, if you have heat-resistant dishes and the ability to make a fire.

If you try to make this filter with your own hands at home, then no problems should arise. In extreme conditions, of course, you will have to use a knife instead of a drill, and think about where to get a plastic tube, or what you can replace it with. But water bottles and super glue are usually carried by any travelers.

How do you get quality water?

One way is to install a bulk filter at the bottom. The need is primarily due to the condition of the soil in which the well is dug.

If there is dense loam at the bottom, then the cleaning device is not installed: in such wells, water is always of good quality. Equipment with a filter will not improve the situation, but will also aggravate it, as a barrier to water access will be created. Here the springs are struck, and the well is filled by means of very small channels. The degree of filtration is high, there are practically no impurities in the liquid.

The water becomes cloudy in the case of a bottom layer of clay interspersed with other soil. The liquid coming from the springs dissolves the loose soil and is enriched with substances of little use - this is undesirable. It is necessary to take into account the fact of filling the well pit. If the liquid rises high, then in this case the filter is not installed.

The main point is the exclusion of scooping from the bottom or in close proximity, so as not to muddy the water. In this case, a small stone (crushed stone, gravel) is used with a layer of up to 30 centimeters.Such a filter made of natural components will provide the necessary transparency, provided that the spring freely enters the well. When equipping a well in sandy soil, it is necessary to take into account the need to strengthen the walls. Sand tends to wash up and fill the provided space, clogging the source and deteriorating the properties of water.

A pump installed in a well with such a bottom quickly becomes clogged and requires frequent additional maintenance. To prevent this from happening, a wooden shield is included in the filter. Usually it is made from boards. Moisture-resistant wood species are chosen: oak, larch, aspen. Several holes are made in the shield. As an additional material, a metal mesh is attached to the shield, preferably stainless steel.

The shield is made in the following sequence. Measure its inner diameter (when the well is round) or perimeter (if quadrangular). The size is made 1.5-2 centimeters less than required. Determined by the type of wood. Choose the material with the least amount of damage. The presence of knots and cracks will affect the service life. Connect boards. It is allowed to have gaps between them up to 0.5 cm. Stainless steel screws or self-tapping screws are used as fasteners. Regardless of the choice of material, this part of the filter must be replaced every 4 years.

The general rule for using the well after installing the shield and filter filling is the time when it can be used. It makes up a day. Practice shows that with constant monitoring of the taste and smell of the liquid, it is possible to determine the service life of the shield.Used filter elements (stones of different fractions) should be washed periodically. This is a laborious process, which is the main disadvantage.

When using a well with a sandy bottom, it is necessary to collect water only from the upper layers of the well. By choosing it from the bottom, you will inevitably degrade transparency and quality.

The most unfavorable option for soil at the bottom is quicksand. This is a layer of soil - very moist and consisting of a mixture of clay and sand, which constantly enters the well. It is necessary to go through a layer of quicksand, reaching a denser soil. But when there is a quicksand, a bottom filter is a must. A shield with a metal mesh is also used. This type of soil tends to absorb everything in its path. If the shield is not installed, the stones intended for filtering will be covered with a layer of unwanted mixture.

Ways to install bottom filters

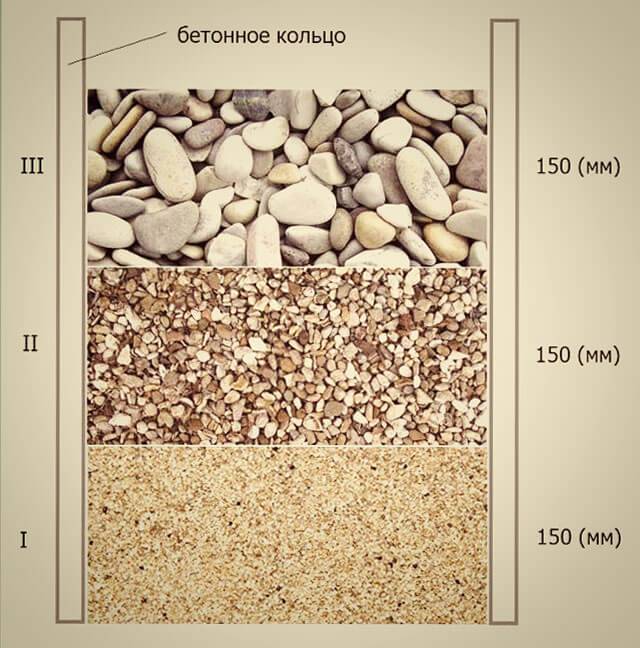

Today, two options for installing bottom filters are known: direct and reverse installation. The main difference is the order of filling the filter layers.

The direct way is to arrange the filter stones on the shield in order of decreasing size. The shield is used in sandy soils and with quicksand. Stones of a large fraction are laid on it, then medium ones and small ones on top.

The reverse method speaks for itself. Laying begins with small fraction stones, and large filter elements with this method are in the top layer.

The size of the filter stone bands in both methods usually does not exceed 150 mm. The difference in the amount of filler for each subsequent layer should be 6 times.

For filtration, components that are not hazardous to human health are used.In practice, natural components found in nature are used: wild stone of various sizes, gravel, coarse sand. Before being placed in the well, they are inspected so that organic matter does not accidentally get into it.

We make a water filter with our own hands to clean well and borehole water

The problem of drinking water purification is becoming relevant not only for citizens, but also for rural residents. To make water from a well or well drinkable, you can make a water filter with your own hands.

Why filter well water?

It would seem that what could be cleaner than well water, sung in ancient Russian epics? Alas, modern reality is not at all like a fairy tale. Water in private wells can be contaminated with a variety of substances, such as:

- nitrates;

- bacteria and pathogens;

- impurities that impair the taste and quality of drinking water.

For an excess of nitrates in drinking water, i.e., salts of nitric acid, one should “thank” the farmers who widely use fertilizers and pesticides in the cultivation of agricultural products. Some of these substances inevitably seep into the aquifer of the soil.

The simplest filter can be made from a plastic bottle with filler

Poor quality and damage to equipment lead to the fact that an admixture of rust, sand, etc. appears in the water. Drinking such water is simply unpleasant. Therefore, for giving it is recommended to buy or make at least a simple water filter.

Overview of filtration materials

The principle of operation of the filter is simple and familiar to everyone. It is necessary to pass water through a layer of filter material. The filler may be different:

- the cloth;

- cotton wool;

- paper napkins;

- gauze;

- sand;

- grass;

- coal;

- lutraxil.

You can buy charcoal at the store or make your own.

For regular use, other materials are used, mainly charcoal. It is laid in layers, alternating with sand, gravel, grass, etc. Lutraxil is a synthetic material made from polypropylene fibers.

The simplest plastic bottle filter

The use of conventional household filters for a small dacha is rarely convenient. Such devices require water to flow from the water supply under a certain pressure, and not every country house has a water supply with suitable characteristics. Pitcher filters purify water too slowly.

In addition, you will have to constantly change cartridges. Therefore, a homemade water filter made from a plastic bottle and a bucket with a plastic lid may be the most viable option.

Homemade water filter can be made from an ordinary plastic bottle

This filter uses charcoal and ordinary cloth as a filler.

The simplest filter for giving is made in this way:

1. Cut off the bottom of a plastic bottle.

2. Cut a suitable hole in the plastic lid of the bucket.

3. Insert the bottle into the hole with the neck down.

4. Fill the filter with media.

On top of the receiving container, you need to install a plastic bottle with a volume of 10 liters, in the bottom of which a filling hole has been made. For the manufacture of the filter, you can use a piece of 40 mm polypropylene pipe. The top and bottom of the pipe are covered with pieces of perforated plastic, which is recommended to be fixed with hot glue. The pipe is filled with charcoal.

Such a homemade filter should fit tightly into the neck of a standard ten-liter bottle. It remains to connect the receiving tank with the filter and the bottle. A full bucket of well water can be immediately poured into the installation, which will be filtered after a few hours. Thus, the house will always have a supply of clean drinking water.

Three-flask design for a full plumbing

Happy owners of a full-fledged water supply in a private house can make a three-flask home-made filter for water purification. For this you need:

- Buy three identical flasks.

- Connect the flasks in series with two quarter-inch nipples. In this case, it is necessary to strictly adhere to the in / out designations in order to observe the direction of water movement. The threads of the nipples should be sealed with FUM tape.

- The end holes of the flasks are connected to the quarter-inch tube with straight adapters.

- Connect the filtration system to the water supply with a tee that is cut into the water supply using a 1/2” connector.

- At the outlet, a standard tap for drinking water is connected to the filter system.

- Fill the flasks with filter material. You can use a polypropylene cartridge, a carbon filter and an anti-scale filler.

This is interesting: Walls in the corridor - finishing options

Conclusions and useful video on the topic

Do-it-yourself bottom filter device using materials of various fractions:

Bottom filter device using a wooden shield and shungite:

Production of an aspen shield for a bottom filter on quicksand:

The installation of filters for water from a well is not a complicated process that can be performed independently without the involvement of specialists and unnecessary financial investments.

The cost of a well filter device depends entirely on what materials you have chosen as filtrates. With proper installation and timely cleaning of the bottom filter, you will always have access to clean and tasty water.

Have questions about arranging a bottom filter for a well? Or do you have experience in arranging well filters and can you share useful information? Please ask your questions, leave comments and suggestions in the block below.