- The choice of materials for the bottom filter

- Bottom filter materials, description and preparation

- Reverse way

- What tree is it made from?

- How to make it?

- How to install the structure according to all the rules?

- Will the bottom filter help in water purification

- How to make filter shields with your own hands

- Wood

- Process

- Metal

- Types of bottom filters for a well

- How to install a do-it-yourself bottom shield with a filter

- The procedure for mounting a shield made of wood

- Bottom filter maintenance

- Materials for the device of the bottom filter

- Wall filter in the well

- Bottom filter for a well with a wooden shield - step by step instructions

- Making a board shield for a bottom filter

- Laying the shield and backfilling the material of the bottom filter

- Video - Installing a bottom filter

- Bottom filter for a well with a wooden shield - step by step instructions

- Making a board shield for a bottom filter

- Laying the shield and backfilling the material of the bottom filter

- Video - Installing a bottom filter

The choice of materials for the bottom filter

All components must meet the following requirements:

- Have sufficient weight so that the components do not float.

- Do not rot, mold or deteriorate when wet for a long time.

- Remain neutral and not enter into chemical reactions with other elements.

- Possess the ability to create dense filter layers that do not allow small particles to pass through.

- All components of the system must be safe for humans and animals.

- Coarse-grained quartz sand. It lies in large quantities near rivers and lakes, so there will be no problems with the purchase. It is a free-flowing mass of yellow color with fragments up to 1 mm. Quartz sand very well binds the smallest particles in the water.

- Large and medium river pebbles. It is found everywhere on the banks of rivers. These are small stones with rounded edges. Their radiation background is within the normal range. Only naturally occurring gravel is suitable for our system. Slag samples are not suitable due to the large amount of toxic substances contained in its structure.

- Gravel. This is crushed loose rock. It contains many sandy or clay impurities that can absorb toxins. Therefore, do not pour into the well the material obtained by grinding used structures.

- rubble. It is obtained by crushing rocks. It has an irregular angular shape. Before buying, be sure to measure its background radiation, it is often elevated. Only gravel made from neutral minerals, such as jadeite, is suitable for wells.

- Jadeite or bath stone. It is a hard material with inclusions of silver and silicon. The bottom filter, which includes this mineral, acquires valuable properties: it cleans the liquid from heavy elements; disinfects water; does not absorb moisture; serves for a long time; neutralizes microorganisms that can cause allergies; improves plant growth after watering.The disadvantages include the need to buy stone far from the site, because it is mined in quarries that may be located in another area.

- Shungite. Its main purpose is water purification. This natural formation is petrified oil. Shungite can be used alone or in combination with gravel. It has very useful qualities: it purifies water from heavy metals, oil products, organics, microorganisms; removes the taste of iron; saturates the source with microelements, which help to multiply useful microorganisms for the spring. Shungite is recommended to be poured onto the bottom of wells dug in industrial areas and near highways. The material is quite expensive, and its use must be justified.

- Zeolite. Natural porous stone of volcanic origin, very expensive. It has a rare ability to absorb nitrates, heavy metal compounds and pheonins. Able to reduce radioactive levels.

- Geotextile. A dense synthetic material that is also used in cleaning systems. Its feature is to pass water through itself without changing its performance. Typically, the canvas is used in the case of the release from the bottom of the mine in small volumes of hydrogen sulfide or other gas. It is rarely used on its own, sometimes in combination with shungite. Most often, geotextiles are wrapped around wooden shields that are installed on quicksand.

- Polymer granules. Special synthetic bulk material with a silver finish. It is used to purify and disinfect water, but not everyone can afford to buy it because of the high cost.

- Gravel from old concrete products. Such pebbles absorb water well, but are not able to purify it.

- Expanded clay. It is too light and can float if it is badly pressed down. In addition, the substance emits substances harmful to humans.

- Granite crushed stone. Obtained after crushing rocks. In most cases, it has a small radiation background.

- lime crushed stone. Consists of compacted lime, therefore reduces water quality.

- Oak - does not rot wet for a long time. May add bitterness to liquids.

- Larch - does not change its properties when wet. Does not affect water quality in any way.

- Aspen - able to destroy some harmful microorganisms in the water, does not rot for many years.

- Juniper - is used if it is necessary to reanimate the well after a long period of inactivity.

Bottom filter materials, description and preparation

Pebble. The most accessible material. Silt and clay practically do not linger on the river stone, so it is enough to rinse it with a hose before laying it.

Gravel. Not to be confused with pebbles, as gravel is a rock. Loose material: if it dries, it will be covered with a small amount of lime. As part of the barrier, gravel acts as a disinfectant. It cannot be poured in the upper layer, since after it the water must be cleaned again.

There is one minus of this component - during operation, the stones absorb all the impurities and trace elements, and after a while they will begin to give them away. Therefore, the layer has to be completely replaced, and not washed. This usually happens once every 1.5-2 years.

Rubble. Crushed from large boulders in the mining industry. Pour on the lower and upper layers. It is considered a coarse filter. Before use, crushed stone is checked for compliance with environmental standards.

Jade.Outwardly, it is very similar to large pebbles, but with a greenish tinge. It is most often used as a heater filler in a sauna stove. Hard stone of round elongated shape. It is a natural "antibiotic" for water. It is able to detain and destroy harmful microorganisms. The downside is that such a stone is difficult to find in nature. Although it is found everywhere in hardware stores.

Shungite is a rock obtained as a result of mineral compounds and oil. It looks like black-gray coal, on the surface there is a deposit in the form of dust. Used as backfill in the middle layer, possibly instead of gravel. Absorbs harmful oil products and other substances. The downside of shungite is that it needs to be replaced after a while.

Geotextile is used together with other components. Usually it is laid on the bottom of the well before the first layer of stones. Since geotextile is a floating material, it must be pressed down. Due to its porosity, it will retain the smallest particles of dirt, as well as silt.

Reverse way

Coarse-grained quartz sand. You can find it along the banks of rivers. Quartz sand has a grain size of up to 1 mm, translucent with small inclusions of a dark color. The sand must be washed before laying in the well: put a layer of sand in a container, fill it with water, stir, leave for 20-30 seconds, then drain the water. Heavy large particles of sand will settle during this time, and the remains of silt and clay will remain suspended in the water. This procedure can be repeated several times until the water with sand is almost clear.

Quartz sand for well cleaning

River pebble. Like sand, it is found along the banks of rivers in the form of pebbles of different sizes and colors of a rounded shape.Pebble is a natural chemically neutral material with a normal radiation background. Pebbles before laying in the well also need to be washed under running water.

Pebbles for water treatment

Gravel is loose porous sedimentary rock. Grains of gravel come in different sizes, from a few millimeters to several centimeters. Gravel often has impurities of harder rocks, clay or sand. It is also used in drainage systems. It is impossible to take gravel used in other systems - due to the porosity, this material is capable of accumulating various dangerous contaminants.

Gravel for laying in a well

Rubble. Irregular-shaped stones of different sizes are mined mechanically. They can be from various minerals. Not every gravel is suitable for a bottom filter device. Limestone crushed stone is dusty and pollutes water, and is washed away with prolonged contact with it. Granite crushed stone is also not suitable - it has an increased radiation background. For the bottom filter, it is recommended to take crushed stone from neutral minerals that have the ability to purify water, for example, jadeite. You can buy it in stores selling bath accessories - this stone is most popular for stoves.

Crushed stone for laying in a well

Shungite, or petrified oil. It is used in water treatment systems to remove heavy metal compounds, organic contaminants and oil products from it. If the well is located near enterprises or roads, or the depth of the well does not exceed 5 meters, the addition of shungite will make it possible to disinfect it.

Shungite stone is perfect for water purification

What tree is it made from?

Someone stands up for oak: everyone knows that under the influence of water this wood only becomes stronger. Someone - for larch (recall: it is from larch wood that the piles on which Venice stands are realized). Some prefer juniper.

So why are aspen shields still in demand?

Due to the fact that its wood has the ability to disinfect water. Thanks to this, earlier in the villages this wood was actually used for wells - and not at all due to the fact that it “protects from evil spirits”.

The main thing is not to forget that for some time any shield, also aspen, will require replacement.

How to make it?

Aspen shield (as well as from every other wood) is quite easy to make. They knock down the boards as close as possible to each other, then draw a circle with a diameter slightly smaller than the diameter of the well, cut it off.

Closer to the center, you need to drill a couple of small (about 5 mm in diameter) holes. Or you can knock down boards with a half-centimeter gap between them.

How to install the structure according to all the rules?

Shungite is often poured onto such a shield. Spread shungite, a material containing carbon, on the bottom of the well. This is a real filter, it perfectly purifies water, both from inorganic and organic impurities.

Put a shield on top (it can be wrapped with non-woven material). Since it is not recommended to pump out well water to the end, in order for it to “fall into place” correctly, tie a couple of boulders to it.

From above it is necessary to pour sand or crushed stone (or sand with crushed stone). Layer thickness - from 35 to 90 cm.

Will the bottom filter help in water purification

No. And you yourself will draw the same conclusion, if you judge sensibly.A bottom filter is a filling of the bottom of a well made of sand, preferably quartz, and gravel or pebbles. And she really is able to purify water. But do we need a bottom filter in the well, let's figure it out.

How water is purified

Today there are many ways to purify water: physicochemical, biological, ion-exchange, electrical, osmotic. But within the framework of the issue under consideration (bottom filter devices), only one filtration method is of interest - mechanical.

The mechanical method of cleaning, despite its simplicity, is very effective. And in many cases, such purification of water from impurities is quite enough, or at least enough to remove most of the pollution.

Water treatment facilities

Such a filter works on the principle of a sieve or sieve, retaining dirt that is in the water in the form of a suspension. It is impossible to mechanically separate pollution at the molecular level, that is, what is dissolved in water.

Partially, this problem, as well as the elimination of bacterial contamination in the form of living organic matter, is solved by a combination of mechanical and biological treatment. This concept is embodied in the so-called English (or slow) filters.

They are a sand and gravel backfill in which sand and fine gravel of different fractions are laid in a certain sequence. The thickness of this backfill is about two meters. The purified water is supplied from above with a layer of about 1.5 m and, under the influence of gravity, slowly (0.1-0.2 m / h) seeps through the filter.

Schematic diagram of a slow filter. Photo from the site

After some time, a film of bacteria and algae forms in the upper layer of sand.This biological film serves to purify water: the total population of the living part of the filter eats nitrogen and other chemical compounds dissolved in water. Large debris is retained by the bottom of the filter - a layer of quartz sand.

The filter is considered "mature", that is, capable of purifying water to the drinking standard, only after the formation of this biofilm of a certain thickness. The thicker the film (the larger the colony of bacteria and algae), the better the cleaning.

But with a significant increase in the thickness of the biofilm, the filtration rate decreases. Therefore, periodically it is necessary to restart the filter, destroying the biolayer and forcing the microorganisms to arrange a new colony. This is exactly how water is purified in nature: microorganisms live on the surface and in the upper layer of the soil, and below the water seeps into the soil, consisting of sand and gravel.

Bottom filter device

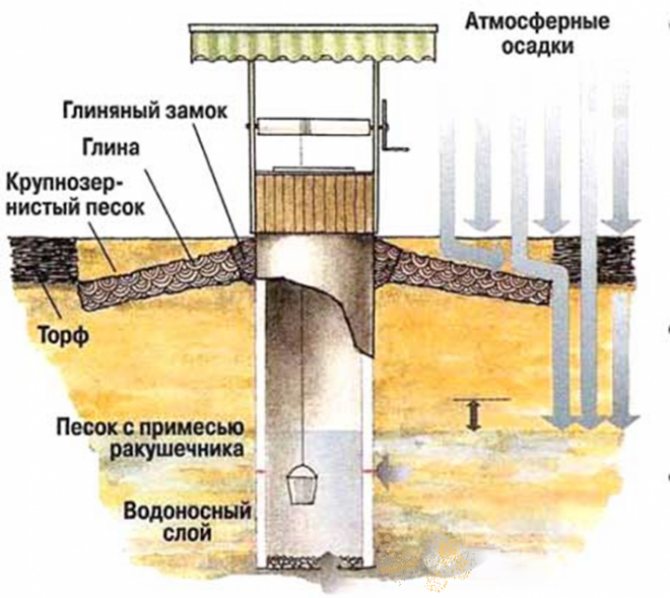

The well (if properly constructed) is filled through the bottom. That is, water enters it, infiltrated from the surface of the earth to the level of the first water horizon, which has passed at least 2 meters of filling the natural slow filter. Those who advise to definitely make a bottom filter usually offer such a scheme for its construction.

Scheme of the bottom filter device.

Question: how will an additional 600 mm of sand and gravel backfill at the bottom of the well help in water purification, if before that the water has already passed through the biofilm on the soil surface and 2000 mm of sand and gravel before entering the well?

Suppose that the well is not arranged quite correctly, and water enters it not only through the bottom, but seeps through the walls. You assume that the water in your well is not only underground, that is, it has undergone natural purification, but also upper.Will the bottom filter help clean it? Again, no.

Firstly, because the layer of sand and gravel is not thick enough, and secondly, the water in the slow filter moves down under the influence of gravity. In order for it to move upwards, being cleaned in the backfill, pressure is needed, but there is none in the well. And, finally, the main component of the biomechanical filter, the biological film of algae and bacteria, does not work there.

In addition to slow ones, there are also fast filters. They work only on the mechanical principle of cleaning. The thickness of the sand in them is much less, and the filtration rate is higher - up to 12 m/h.

Maybe the bottom filter works on the principle of a fast sand filter? And again no. Because the high filtration rate is provided by pressure, which cannot be in the well. And a small layer of sand allows you to retain only large particles, so fast filters, unlike self-sufficient slow ones, are used only as one of the parts of the water treatment system. Before a quick filter, the water is subjected to settling or coagulation, and after it it is additionally disinfected.

How to make filter shields with your own hands

Wood

It will take about one cube of the board. The tree must be carefully chosen:

- Aspen is the best material. It does not rot, even if it is constantly in the water. In addition, aspen itself does not absorb moisture. But she, passing through a tree, is disinfected.

- Oak is a very durable material. It almost never needs to be changed. Such a bottom shield will last 15–20 years. But there is also a significant drawback of such wood - the water becomes sweetish.

- Larch passes water quite well, even if the gaps between the boards are small. However, it also rots very well and absorbs water.Will have to be changed every two years.

Process

- It is necessary to knock the boards together so that a square is obtained - larger than the outer diameter of the well ring.

- Leave a space of 20–30 mm between the boards. This is necessary for the stable passage of water.

- Then we saw a circle slightly smaller than the inner diameter of the well shaft, by about 2–3 cm. It is advisable to wrap the finished product with geotextile.

- Now you can lower it into the well. This is done vertically to the very bottom, and only at the bottom it is unfolded and laid flat. To prevent it from floating up, large stones are laid on top and only then filter layers.

Metal

It is necessary to use only fittings or mesh made of stainless steel or galvanized. You can take a galvanized pipe with a diameter of 15 mm and assemble a lattice from it, laying it on top of each other and tying or bolting it together.

We leave the grid cell 2 by 2 cm. You can also use a multi-level grid layer. And they go down to the bottom. An iron shield can not be loaded with stones. However, it must be secured so that it does not sink. To do this, several holes are drilled in the wall of the ring at the level of the filter and reinforcement or long bolts are inserted into them, to which the shield is subsequently attached.

Having decided to strengthen the bottom of the well with your own hands, you need to follow the technology

It is important not only to make a bottom filter using stones, sand or any other material. It is necessary to additionally put an aspen shield at the bottom of the well. It is knocked down from wood, given the size of the mine

Then they set it on the bottom, and stones are poured on top. You can immediately equip a well ring with a bottom

It is knocked down from wood, given the size of the mine.Then they set it on the bottom, and stones are poured on top. You can immediately equip the well ring with the bottom.

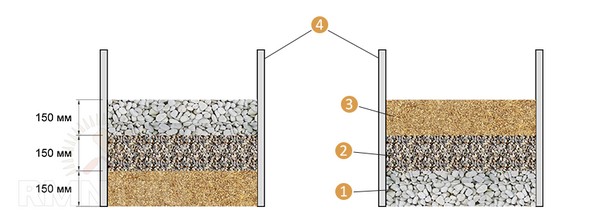

Before you start working on the bottom filter, you need to divide all the stones into 3 groups. The largest can be attributed to the first, to the second - to include medium-sized stones, and to the third hill - to put the smallest.

There are 2 following ways to backfill the bottom:

- Use large stones, then medium and small.

- Small stones are placed at the bottom, medium ones are placed on top. The last protective layer is formed from the largest ones.

If the bottom was covered with silt or the well is dirty, it needs to be cleaned. Only after that you can make a filter of stones. Before pouring stones, the well bottom can be closed with a round wooden shield. It can be replaced with a mesh or geotextile. This is a suitable material for a well. It does not rot, does not become moldy, so bacteria will not multiply on it.

Having chosen the installation of the shield, you need to take care of its reliable fixation. To do this, mount the pins in the walls of the well.

When laying geotextiles on the bottom, you should pay attention to the rate of water inflow. If the flow is strong enough, then it is better to lay 15-30 cm of material. After the shield must be covered with stones

Can be done in 1 day

After the shield must be covered with stones. You can do the job in 1 day.

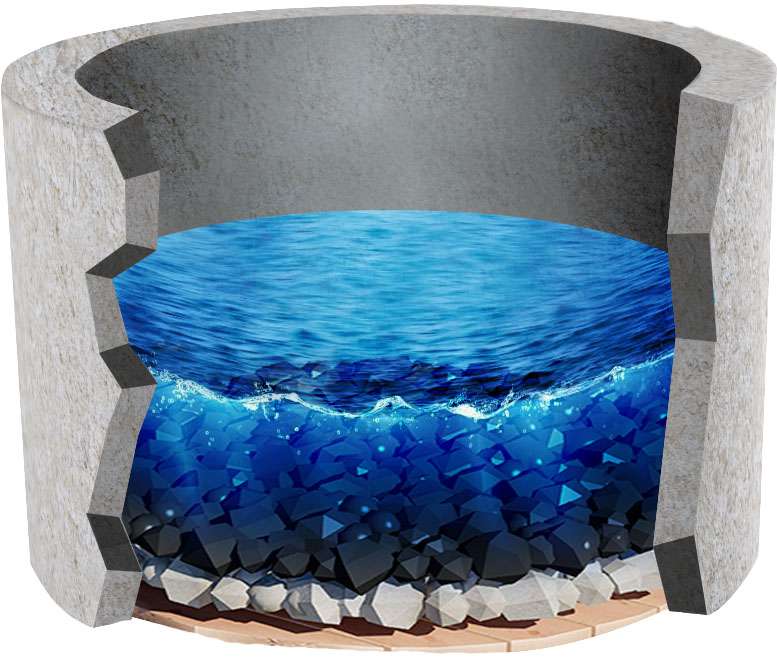

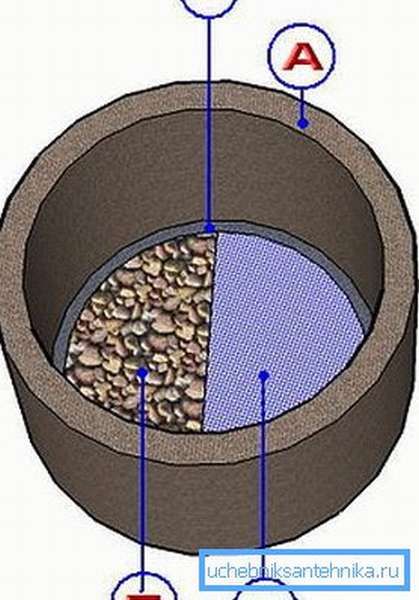

Types of bottom filters for a well

There are two main types of filters in use today:

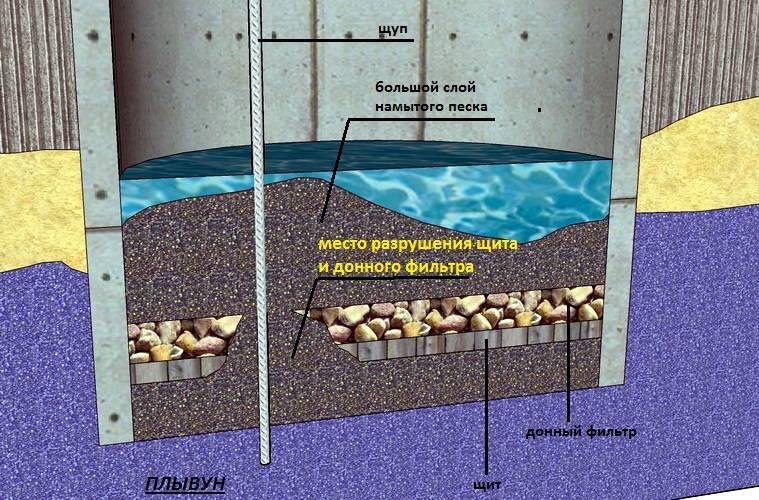

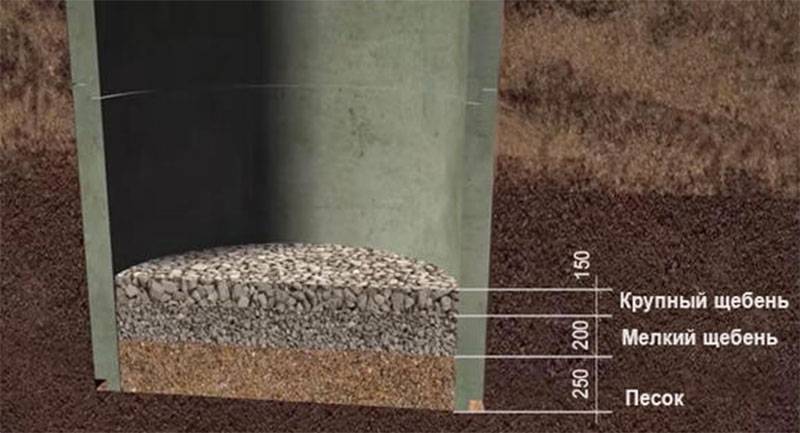

1.Straight. The bottom is covered with material with large fractions, fine-grained backfill is poured on top. This is the best option for a bottom with loose clay or quicksand.

How to install a direct bottom filter:

- removal of contaminants from the bottom,

- filling material 20 cm large fraction,

- crushed stone filling 30 cm of medium fraction,

- formation of the upper layer of sand and pebbles.

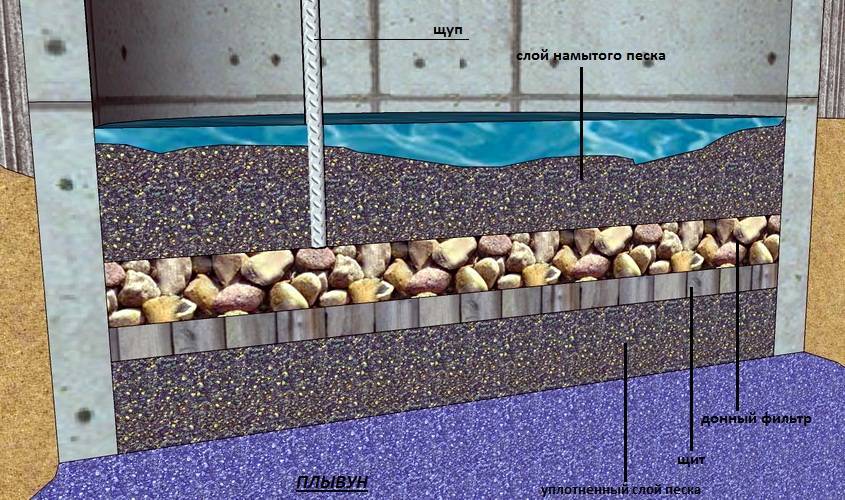

2. Reverse. Recommended for sandy wells with calm flow. Material with small fractions is placed at the bottom. Large ones form the top layer. The return filter keeps the sand from rising to the top. As a rule, river sand is placed on the bottom, then shungite, gravel with a fraction of about 1 cm, crushed stone with a fraction of 5 cm is used for the top layer.

Installation procedure for the reverse bottom filter:

- river sand,

- gravel, pebbles, shungite,

- pile of crushed stone and stones of large size.

The recommended layer thickness in both the first and second cases is at least 25 cm.

Both types of filter require periodic cleaning, as well as after several years of replacement of individual layers or the entire filter.

How to install a do-it-yourself bottom shield with a filter

In situations where the water at the bottom of the well moves too fast, as well as in the presence of quicksand nearby, it is necessary to protect the bottom from erosion. To do this, use a special shield, which is made from a mesh of metal or wood (aspen, oak, larch, juniper and other woods).

Wooden shields are more popular than metal ones, as they have the following advantages:

- are made from environmentally friendly materials,

- wood has disinfecting properties,

- availability of material, including cost.

As a source material are recommended:

- oak - durable, but can give water a specific flavor,

- larch - does not give an aftertaste, but has a shorter service life compared to oak,

- aspen - is highly durable, disinfects water, does not smell, does not rot for a long time, is one of the best materials for making a shield.

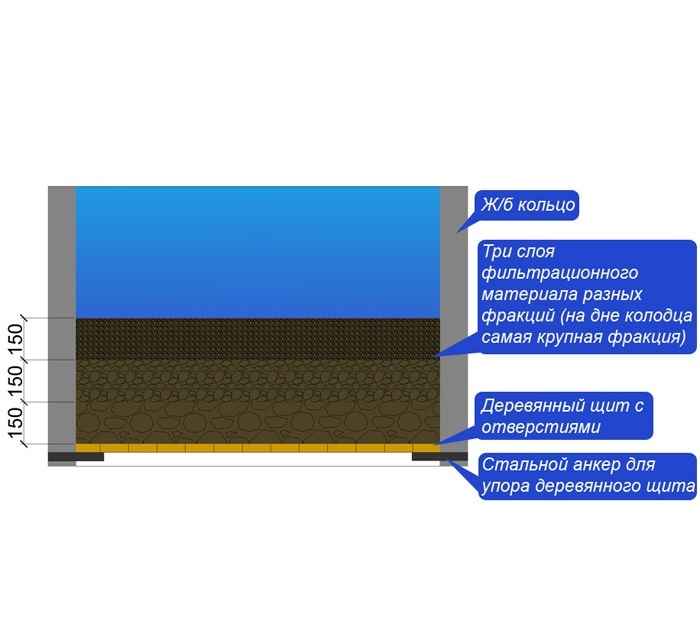

The procedure for mounting a shield made of wood

Work begins with measurements of the well. According to these measurements, a shield is beaten from wooden boards, then a hole about 1 cm in diameter is made in it and placed in geotextiles. Next, the shield is placed on the bottom, a bottom filter is placed on top of it. The shield must be changed every 5-7 years.

A homemade shield in a well can be made of a metal mesh with medium-sized cells.

Metal mesh advantages:

- high strength,

- reliable protection against sand,

- the mesh does not change the taste properties of water.

The grid should have small cells. You will need two metal rings, selected strictly according to the diameter of the well. Rings can be made of sheet iron or wire.

A mesh is laid between the rings and fixed with bolts. After that, they are placed in a well and fixed with locking pins. Pebbles, stones or shungite are placed on the grid.

It should be borne in mind that over time, the metal begins to rust and break, so it is recommended to install the grid only when the water is heavily polluted, and the well itself is located on powerful quicksand.

Bottom filter maintenance

GREAT VIDEO RELATED TO THE TOPIC

Over time, the bottom filter begins to become clogged with sand, silt, clay, so it needs to be cleaned at least once a year. Stones are removed from the well and washed with water, and the sand is completely replaced with new one. The materials are then placed back into the well.

A shield made of mesh or wood is inspected, if it is silted up, has begun to collapse, it is also replaced with a new one. Over time, if not washed and cleaned, the shield can completely collapse.

Materials for the device of the bottom filter

With the independent manufacture of this unit, the following components are well suited:

- River sand in grains no more than 1 mm. It is taken from the banks of the surrounding rivers. Before use, it must be thoroughly rinsed; only its large particles will be needed to equip the filter element.

- Pebbles from the banks of rivers look like stones of various sizes with rounded edges. It should be washed thoroughly before use.

- Gravel is a porous rock, it can have different sizes from 1 mm to 5 cm. Only clean stones for the well should be used, after washing them first. Reuse of such elements is not recommended.

- Crushed stone is a type of various minerals mined mechanically. It comes in various sizes. For wells, jadeite is suitable, which can be bought in stores with goods for arranging pools.

- Shungite is petrified oil. It can neutralize organic decomposition and oil products, purify water from iron. It is used provided that there are enterprises or highways nearby.

As you can see, before use, these materials must be carefully selected. Reuse of sand and porous compounds is prohibited.

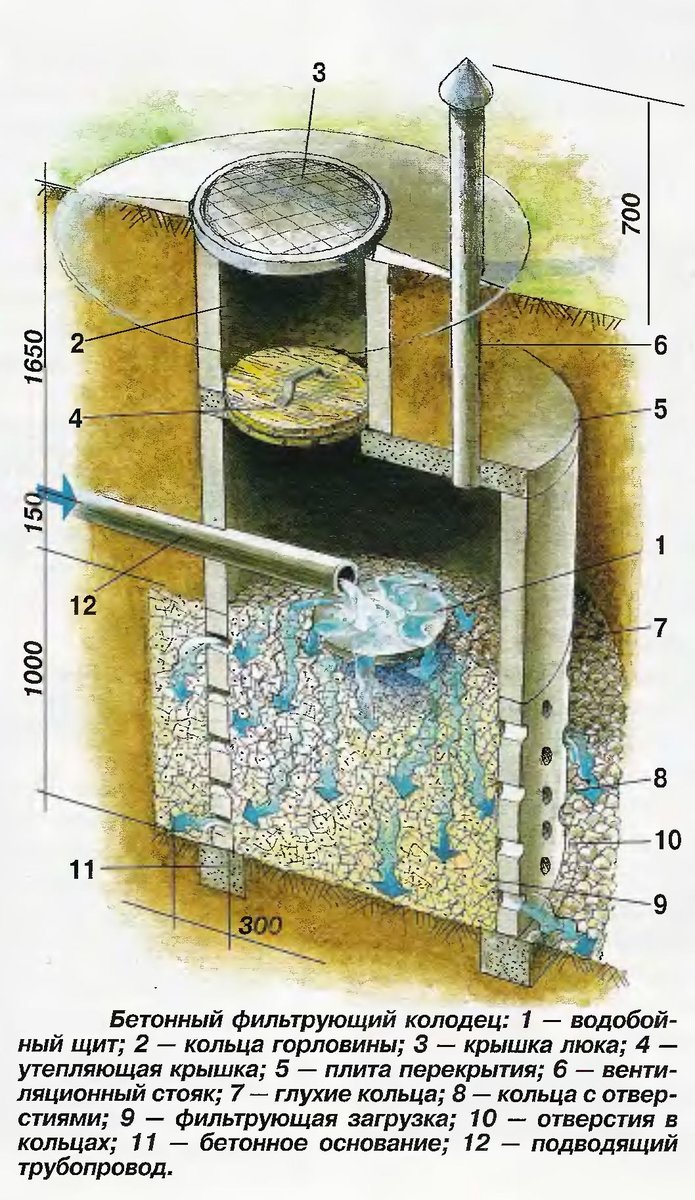

Wall filter in the well

In the case when the flow of water entering the well is very weak, and filtration is also carried out through its walls, then the installation of a bottom filter is not advisable. In such a situation, the best option would be to install a wall filter.

To make a wall filter, it is necessary to cut out V-shaped holes located horizontally in the lowest part of the well (lower reinforced concrete ring), where filter elements made of coarse concrete are installed.

Concrete for filters is prepared using medium fraction gravel and cement grade M100-M200 without the addition of sand. The cement is diluted with water until the consistency of the mixture becomes creamy, after which the pre-washed gravel is poured into it and mixed thoroughly. The resulting solution is filled with cut holes and left until completely hardened.

The size of the gravel for the solution must be selected taking into account local hydrogeological factors: the finer the sand fraction in the well, the smaller the size of the gravel

Bottom filter for a well with a wooden shield - step by step instructions

As an example, we give the arrangement of a bottom filter for a well with direct backfill and a wooden shield.

Wooden shield for the filter

Bottom filter installation

Making a board shield for a bottom filter

Step 1. Measure the inner diameter of the well. The wooden shield placed on the bottom should be slightly smaller so that during installation there are no problems with moving and laying the product.

Step 2. Choose the type of wood for the shield. Oak has a high durability, but at the same time it will turn the water brown at first. Larch is slightly less resistant to water compared to oak, but cheaper. However, most often, aspen is used for the shield under the bottom filter for the well, since it is poorly susceptible to decay under water. Wood should have as few knots and surface defects as possible - its durability depends on this.

Step 3Knock down a regular square board shield. At the same time, it is not necessary to connect them end-to-end with each other - the presence of gaps is permissible and even necessary. Use only high quality galvanized fasteners.

Step 4. Draw a circle on the surface of the shield, the diameter of which is somewhat smaller than that of the well.

Step 5. Using an electric jigsaw, cut the wooden board around the circumference.

Trimming a board shield

The shield is cut around the circumference

Pruning almost finished

Step 6. If even taking into account the quicksand, the flow rate in the well is not too large, drill many small holes with a diameter of 10 mm in the shield.

Ready-made shield for the bottom filter of the well. In this case, holes are not required - water will penetrate through the gaps between the boards

Laying the shield and backfilling the material of the bottom filter

Now that the plank shield made of aspen, oak or larch is ready, proceed to direct work with the well. Going down there, do not forget about safety - put on a helmet, check the condition of the cable, prepare a lighting device.

Step 1. If the well was in operation for a long time before the installation of the bottom filter, clean it of debris and silt.

Step 2 Install a board shield on the bottom and level it.

Shield ready to install

Installation of a board shield

Step 3. Next, your assistant should lower a bucket of gravel, jadeite or large pebbles. Lay the stones evenly over the surface of the shield. Create a layer of coarse backfill with a thickness of at least 10-15 cm.

Large pebbles are lowered into the filter well

Stones are evenly distributed over the surface of the shield

Step 4. Next, place gravel or shungite on top of the first layer.The requirements are the same - to ensure a uniform layer with a thickness of about 15 cm.

Second layer of bottom filter

Step 5. Fill in the last layer of the bottom filter - river sand washed several times.

Step 6. Provide water intake at a depth not reaching the bottom filter with a board shield. To do this, shorten the chain or rope on which the bucket descends into the well. If the water intake is carried out by a pump, raise it higher.

The well can be used 24 hours after the installation of the bottom filter

After some time - usually about 24 hours - the well can be used again. At the same time, monitor the quality of the water coming from there - if after a year or two it has acquired a sweetish taste and an unpleasant smell, this means that the board shield has begun to rot and it needs to be replaced. At the same time, do not forget to regularly wash and change the sand, gravel and shungite used when filling the bottom filter for the well.

Video - Installing a bottom filter

Bottom filter for well

Scheme of a well with a simple gravel pad, which in some cases is capable of performing the tasks of a bottom filter

The rising quicksand not only spoils the water with suspensions and impurities, but also can disable the pump or lead to displacement of the concrete ring of the well

well filter

Sand is filled with water

river sand

large pebble

Medium fraction pebbles

river gravel

rubble

Shungite

Jade

Trimming a board shield

The shield is cut around the circumference

Pruning almost finished

Ready-made shield for the bottom filter of the well. In this case, holes are not required - water will penetrate through the gaps between the boards

Shield ready to install

Installation of a board shield

Large pebbles fall into the well

Second layer of bottom filter

Bottom filter installation

Wooden shield for the filter

Scheme-section of a well with a filter made of wood and stones

Clean water in a well

Aspen shield for bottom filter

In this case, the bottom of the well is formed by clay rocks.

Extraction of river sand

The well can be used 24 hours after the installation of the bottom filter

Bottom filter for a well with a wooden shield - step by step instructions

As an example, we give the arrangement of a bottom filter for a well with direct backfill and a wooden shield.

Wooden shield for the filter

Bottom filter installation

Making a board shield for a bottom filter

Step 1. Measure the inner diameter of the well. The wooden shield placed on the bottom should be slightly smaller so that during installation there are no problems with moving and laying the product.

Step 2. Choose the type of wood for the shield. Oak has a high durability, but at the same time it will turn the water brown at first. Larch is slightly less resistant to water compared to oak, but cheaper. However, most often, aspen is used for the shield under the bottom filter for the well, since it is poorly susceptible to decay under water. Wood should have as few knots and surface defects as possible - its durability depends on this.

Step 3. Knock down a regular square shield from the boards. At the same time, it is not necessary to connect them end-to-end with each other - the presence of gaps is permissible and even necessary. Use only high quality galvanized fasteners.

Step 4. Draw a circle on the surface of the shield, the diameter of which is somewhat smaller than that of the well.

Step 5. Using an electric jigsaw, cut the wooden board around the circumference.

Trimming a board shield

The shield is cut around the circumference

Pruning almost finished

Step 6. If even taking into account the quicksand, the flow rate in the well is not too large, drill many small holes with a diameter of 10 mm in the shield.

Ready-made shield for the bottom filter of the well. In this case, holes are not required - water will penetrate through the gaps between the boards

Laying the shield and backfilling the material of the bottom filter

Now that the plank shield made of aspen, oak or larch is ready, proceed to direct work with the well. Going down there, do not forget about safety - put on a helmet, check the condition of the cable, prepare a lighting device.

Step 1. If the well was in operation for a long time before the installation of the bottom filter, clean it of debris and silt.

Step 2 Install a board shield on the bottom and level it.

Shield ready to install

Installation of a board shield

Step 3. Next, your assistant should lower a bucket of gravel, jadeite or large pebbles. Lay the stones evenly over the surface of the shield. Create a layer of coarse backfill with a thickness of at least 10-15 cm.

Stones are evenly distributed over the surface of the shield

Step 4. Next, place gravel or shungite on top of the first layer. The requirements are the same - to ensure a uniform layer with a thickness of about 15 cm.

Second layer of bottom filter

Step 5. Fill in the last layer of the bottom filter - river sand washed several times.

Step 6. Provide water intake at a depth not reaching the bottom filter with a board shield. To do this, shorten the chain or rope on which the bucket descends into the well. If the water intake is carried out by a pump, raise it higher.

The well can be used 24 hours after the installation of the bottom filter

After some time - usually about 24 hours - the well can be used again.At the same time, monitor the quality of the water coming from there - if after a year or two it has acquired a sweetish taste and an unpleasant smell, this means that the board shield has begun to rot and it needs to be replaced. At the same time, do not forget to regularly wash and change the sand, gravel and shungite used when filling the bottom filter for the well.

Video - Installing a bottom filter

Bottom filter for well

Scheme of a well with a simple gravel pad, which in some cases is capable of performing the tasks of a bottom filter

The rising quicksand not only spoils the water with suspensions and impurities, but also can disable the pump or lead to displacement of the concrete ring of the well

well filter

Sand is filled with water

river sand

large pebble

Medium fraction pebbles

river gravel

rubble

Shungite

Jade

Trimming a board shield

The shield is cut around the circumference

Pruning almost finished

Ready-made shield for the bottom filter of the well. In this case, holes are not required - water will penetrate through the gaps between the boards

Shield ready to install

Installation of a board shield

Large pebbles fall into the well

Second layer of bottom filter

Bottom filter installation

Wooden shield for the filter

Scheme-section of a well with a filter made of wood and stones

Clean water in a well

Aspen shield for bottom filter

In this case, the bottom of the well is formed by clay rocks.

Extraction of river sand

The well can be used 24 hours after the installation of the bottom filter