- How to make a bottom filter

- Materials used

- Types of bottom filters

- Causes of breakdowns and subtleties of choice

- Additional filter

- Selection of a filtration well

- Bottom filter for a well with a wooden shield - step by step instructions

- Making a board shield for a bottom filter

- Laying the shield and backfilling the material of the bottom filter

- Video - Installing a bottom filter

- Calculation of the number of filtration wells on the site

- Bottom filter for a well: choice of materials

- Will the bottom filter help in water purification

- What filter to install at the bottom of the well?

- Types of bottom filters

- Laying type

- Preparatory stage

- Shield making

- Strainer

- Service Features

- Appointment of bottom filters

How to make a bottom filter

This element cannot be purchased ready-made - it is made by hand from natural materials such as quartz sand, gravel, crushed stone, river pebbles, etc. Let's dwell on them in more detail.

Materials used

The choice of materials from which the bottom filter in the well will be made depends on their availability in your area, as well as on the requirements for water treatment.

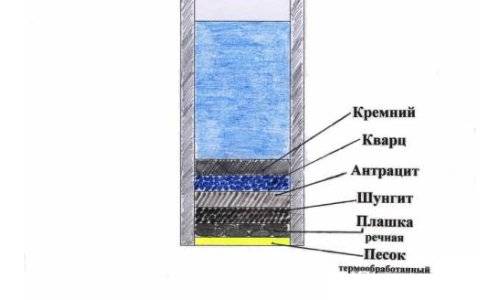

Quartz sand. Detains the smallest suspended particles, not passing them through itself. You can find it on the river bank.Before use, the sand is thoroughly washed, for which it is placed in a container, poured with plenty of water and mixed.

Muddy water after a short settling is drained. And so several times until almost pure water is obtained.

Gravel. It often contains impurities of clay, sand, soil, plant residues, therefore it also needs a similar washing.

Advice. If your well water is hard, use flint gravel - it will change the hardness values down.

- River pebble. The most popular material from which bottom filters for wells are made is easily accessible, natural, and does not require special preparation, except for rinsing with water.

- Zeolite is a porous mineral of volcanic origin, an excellent sorbent. It is able to absorb heavy metals, radioactive elements, phenol and other substances hazardous to health, and disinfect water. If you are not confused by the price of this material (about 600 rubles per 10 kg), be sure to use it.

Shungite is used in wells located near highways, industrial and livestock enterprises, as it purifies water from oil products, heavy metal compounds and harmful organic pollutants.

Important! For the manufacture of the filter, you can use only "fresh" materials that have not been previously used in other cleaning systems.

Types of bottom filters

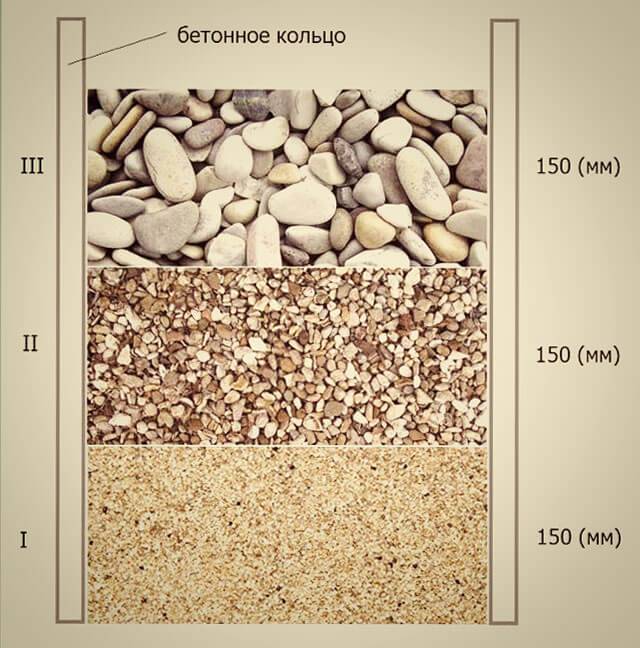

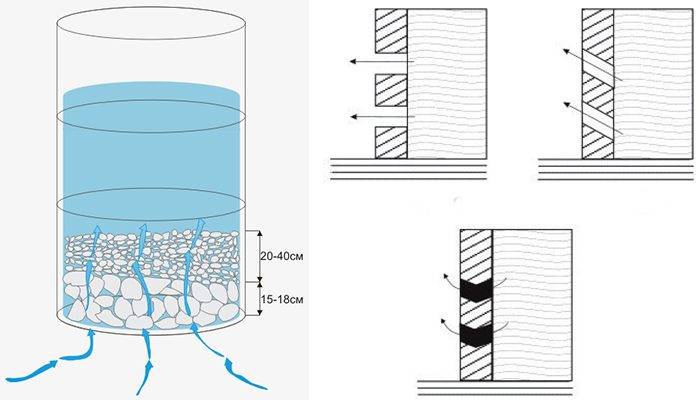

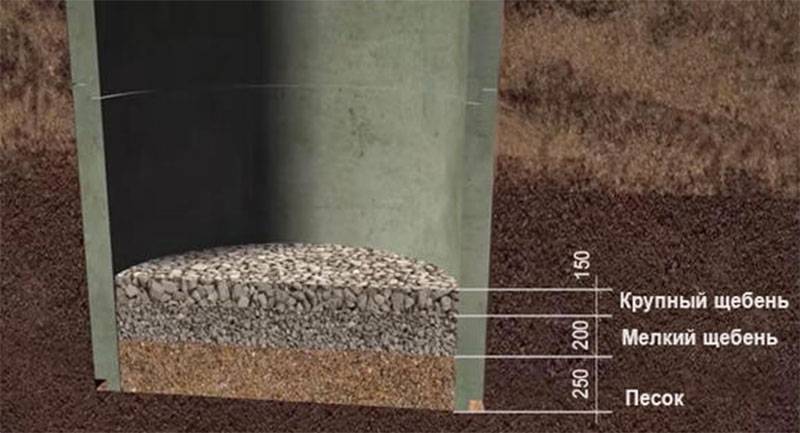

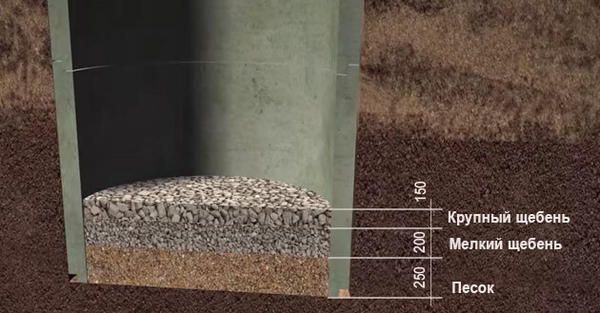

For high-quality water purification, a filling is always used, consisting of three layers of material of different fractions, the size of which differs by 5-6 times. The thickness of each layer is at least 10-15 cm.

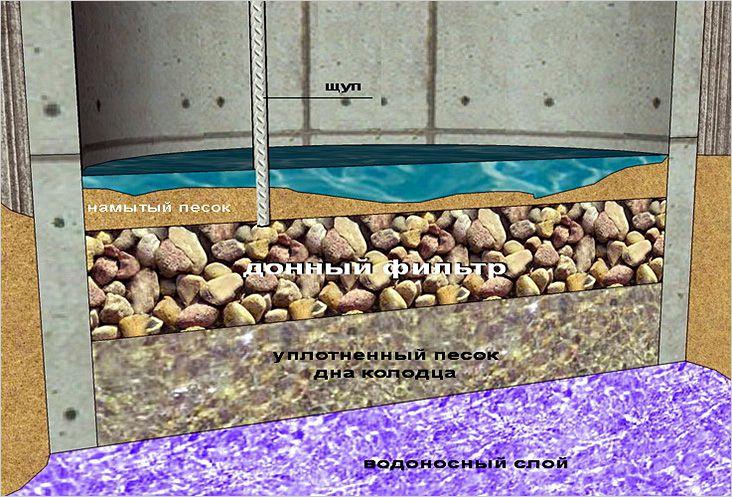

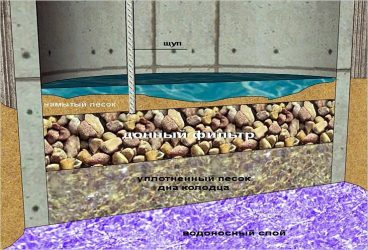

The bottom filter in the well according to the laying method can be direct or reverse, depending on the order of laying the layers.

- In wells with a sandy bottom, a return filter is arranged, laying down a layer of the smallest fraction - quartz sand or small pebbles, then a layer of medium-sized stones and, finally, large ones.

- If the bottom is loose clay, a direct filter is used, laid in the sequence coarse - medium - fine. It will not only purify the water, but also will not allow the clay to erode.

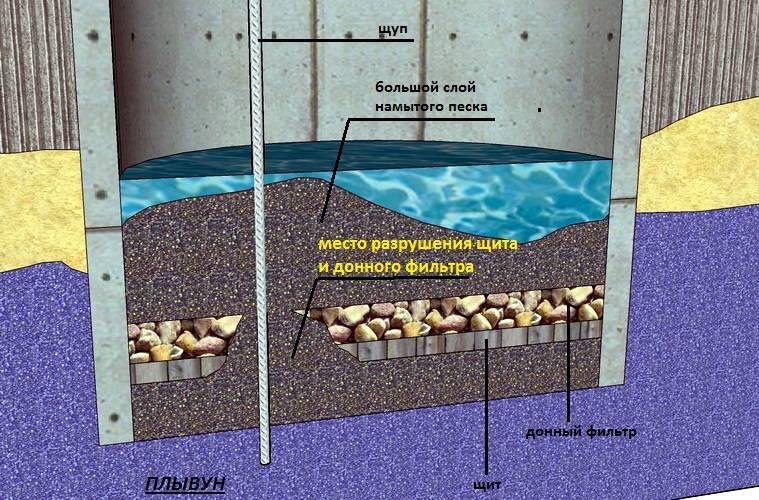

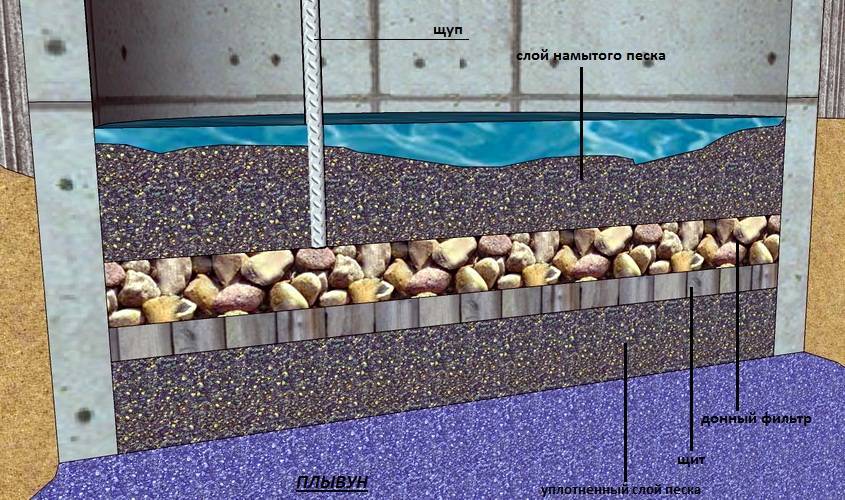

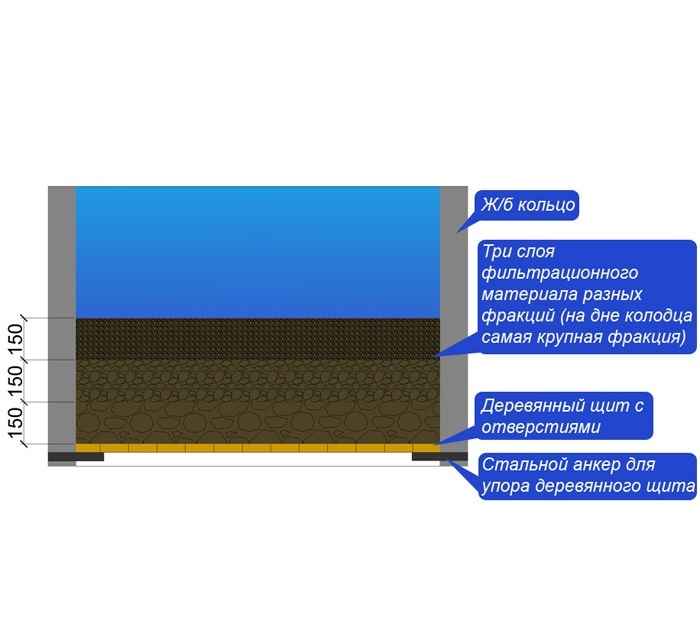

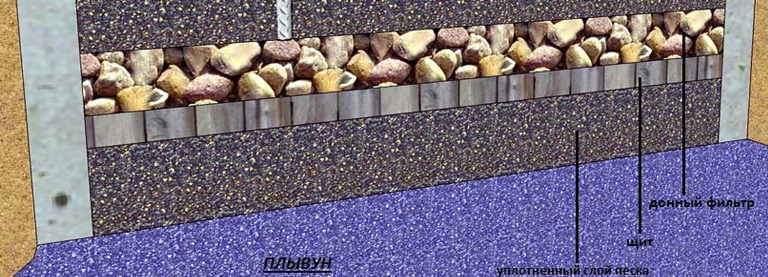

In the same order, only on a special shield, layers are laid if the well is built on mobile, water-saturated sand - quicksand. The shield is made a few millimeters smaller than the inner diameter of the well, from wood or metal mesh.

Photo of a quicksand at the bottom of a well shaft

For the manufacture of a wooden shield, oak or aspen boards are taken, which can withstand water for a long time. They are knocked down close to each other, after which a circle of the desired diameter is cut out of the resulting square and holes 0.5-1 cm in size are drilled in it. The finished shield is wrapped with geotextile and installed on the bottom of the well. Every 3-4 years it needs to be replaced with a new one.

Advice. If possible, make a shield from juniper boards. They have antibacterial properties and are able to disinfect water.

Bottom filter device in a well with quicksand

To make a metal shield, you will need a fine-mesh galvanized or stainless steel mesh and sheets of galvanized iron, from which you need to cut two rings of the diameter corresponding to the well. The mesh is inserted between them and fastened with bolts.

The shield is installed on a bed of large stones, fixed with pins built into the walls of the well, after which filter materials are laid on it.

Causes of breakdowns and subtleties of choice

Malfunctions with one of the main structural elements of the dishwasher can occur for various reasons. We suggest that you familiarize yourself with the possible problems in more detail, as well as give a number of tips on choosing a new TEN.

According to user reviews, the most common breakdowns of the electric heater in the dishwasher are the burnout of the spiral thread and the electrical short circuit at the tube outlets.

Burnout is a direct consequence of the thinning of a refractory element in a hermetically sealed heater.

Flow heating elements in dishwashers often burn out.

This may happen if:

- there is a leak in the heating element;

- there was a sharp jump in voltage in the power supply network (if such jumps are not uncommon, then it would not be out of place to buy and install a stabilizer);

- the filter is very dirty;

- the machine is not operated correctly (it is advisable to familiarize yourself with the rules for operating the dishwasher before using it);

- wear, accumulation of a significant layer of scale on the heating element (if the layer thickness exceeds 2-3 mm, then element failure is inevitable).

When ordering a spare part for self-replacement in online or service stores, you must specify the complete model data, including the serial number. The information is on the label of the machine. We have provided detailed recommendations for finding and choosing high-quality spare parts for dishwashers here.

Also, when choosing a heating element, it is important to pay attention to its technical characteristics: carefully check its general purpose, power and voltage parameters, diameter similar to the factory ones, and also the compliance of the device with a typical connection connector. We advise you to pay attention to the preservation of tightness at the output ends of the purchased device.

We advise you to pay attention to the preservation of tightness at the output ends of the purchased device. Important design features

On the plastic case of the heating block there are outlets for connection with nozzles and outlet ends for sensors

Design features are also important. On the plastic case of the heating block there are outlets for connection with nozzles and outlet ends for sensors

Electric instantaneous heaters quickly heat up, but consume a lot of electricity. We recommend that you take this into account: if you have a dishwasher and an electric kettle running at the same time, then the plugs can fly out, and the machine will turn off the power in the entire apartment.

Electric thermal heaters designed for dishwasher installations BOSCH are available in the following designs:

- submersible (wet) - contact with the working liquid medium, heating it;

- dry - surrounded for protection by a special flask made of durable composite material steatite.

The wide bulb of the dry heater helps to heat the water very quickly, prevents the accumulation of scale, protects the machine from dry plugs, it can be easily dismantled

In various modifications of Bosch dishwashers, sensors for the distribution of water flows, water turbidity and an electric relay, which is switched by a membrane moving under water pressure, can be installed on heating elements.

We suggest that you familiarize yourself with Checking and replacing the pressure switch in the dishwasher

For the Bosch dishwasher, heating elements are sold that are included with the pump. This is one single piece, therefore it is considered non-separable.Its cost is quite high and can vary in a wide price range: from 7,000 to 11,000 rubles.

Additional filter

When the water flow is weak or other circumstances make it impossible to bottom filter installation into the well, you can equip the wall additional option. In this case, the well will be filled through the holes in the wall, they should be in the lower part, have a horizontal and V-shaped shape.

For installation, a construction based on large-cell concrete is used. It consists of cement and gravel, while there is no sand in the composition. The components are diluted with water until a consistency similar to sour cream is obtained. Gravel is poured into the resulting mass and thoroughly mixed with it. Each stone must acquire a shell from the solution. Pre-made holes are filled with mass and left to harden. It is worth noting that the choice of gravel is carried out depending on the existing conditions, while the composition should prevent the ingress of sand.

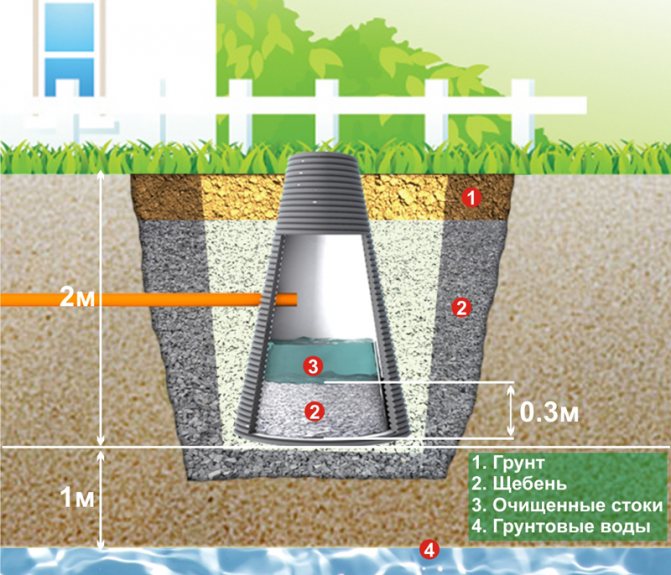

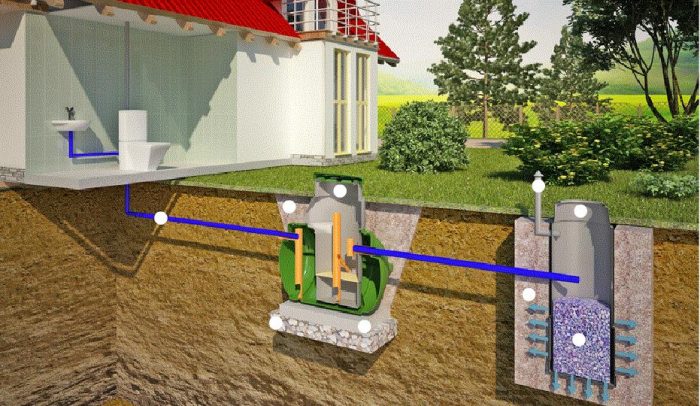

Selection of a filtration well

The choice of a filtration well is an important step, since an incorrect calculation can lead either to an overrun of the material or to a lack of well volume, which will lead to its frequent pumping. The main criteria that affect the proper arrangement of the well are:

- groundwater level at the site;

- the presence of an aquifer at the sewerage site;

- the proximity of the location of the water well for water consumption;

- type of soil.

The arrangement of the well is carried out on the soil, the structure of which contributes to unhindered filtration and drainage of water. These soil types include:

- sand;

- sandy loam;

- peat.

If you try to install a filter well, for example, on clay soil, then most likely the water will not leave it, which will lead to a waste of money

It is very important to take into account the filtration area, the term of use of the structure depends on it - the larger the area, the longer the operation

Bottom filter for a well with a wooden shield - step by step instructions

As an example, we give the arrangement of a bottom filter for a well with direct backfill and a wooden shield.

Wooden shield for the filter

Bottom filter installation

Making a board shield for a bottom filter

Step 1. Measure the inner diameter of the well. The wooden shield placed on the bottom should be slightly smaller so that during installation there are no problems with moving and laying the product.

Step 2. Choose the type of wood for the shield. Oak has a high durability, but at the same time it will turn the water brown at first. Larch is slightly less resistant to water compared to oak, but cheaper. However, most often, aspen is used for the shield under the bottom filter for the well, since it is poorly susceptible to decay under water. Wood should have as few knots and surface defects as possible - its durability depends on this.

Step 3. Knock down a regular square shield from the boards. At the same time, it is not necessary to connect them end-to-end with each other - the presence of gaps is permissible and even necessary. Use only high quality galvanized fasteners.

Step 4. Draw a circle on the surface of the shield, the diameter of which is somewhat smaller than that of the well.

Step 5. Using an electric jigsaw, cut the wooden board around the circumference.

Trimming a board shield

The shield is cut around the circumference

Pruning almost finished

Step 6. If even taking into account the quicksand, the flow rate in the well is not too large, drill many small holes with a diameter of 10 mm in the shield.

Ready-made shield for the bottom filter of the well. In this case, holes are not required - water will penetrate through the gaps between the boards

Laying the shield and backfilling the material of the bottom filter

Now that the plank shield made of aspen, oak or larch is ready, proceed to direct work with the well. Going down there, do not forget about safety - put on a helmet, check the condition of the cable, prepare a lighting device.

Step 1. If the well was in operation for a long time before the installation of the bottom filter, clean it of debris and silt.

Step 2 Install a board shield on the bottom and level it.

Shield ready to install

Installation of a board shield

Step 3. Next, your assistant should lower a bucket of gravel, jadeite or large pebbles. Lay the stones evenly over the surface of the shield. Create a layer of coarse backfill with a thickness of at least 10-15 cm.

Large pebbles are lowered into the filter well

Stones are evenly distributed over the surface of the shield

Step 4. Next, place gravel or shungite on top of the first layer. The requirements are the same - to ensure a uniform layer with a thickness of about 15 cm.

Second layer of bottom filter

Step 5. Fill in the last layer of the bottom filter - river sand washed several times.

Step 6. Provide water intake at a depth not reaching the bottom filter with a board shield. To do this, shorten the chain or rope on which the bucket descends into the well. If the water intake is carried out by a pump, raise it higher.

The well can be used 24 hours after the installation of the bottom filter

After some time - usually about 24 hours - the well can be used again. At the same time, monitor the quality of the water coming from there - if after a year or two it has acquired a sweetish taste and an unpleasant smell, this means that the board shield has begun to rot and it needs to be replaced. At the same time, do not forget to regularly wash and change the sand, gravel and shungite used when filling the bottom filter for the well.

Video - Installing a bottom filter

Bottom filter for well

Scheme of a well with a simple gravel pad, which in some cases is capable of performing the tasks of a bottom filter

The rising quicksand not only spoils the water with suspensions and impurities, but also can disable the pump or lead to displacement of the concrete ring of the well

well filter

Sand is filled with water

river sand

large pebble

Medium fraction pebbles

river gravel

rubble

Shungite

Jade

Trimming a board shield

The shield is cut around the circumference

Pruning almost finished

Ready-made shield for the bottom filter of the well. In this case, holes are not required - water will penetrate through the gaps between the boards

Shield ready to install

Installation of a board shield

Large pebbles fall into the well

Second layer of bottom filter

Bottom filter installation

Wooden shield for the filter

Scheme-section of a well with a filter made of wood and stones

Clean water in a well

Aspen shield for bottom filter

In this case, the bottom of the well is formed by clay rocks.

Extraction of river sand

The well can be used 24 hours after the installation of the bottom filter

Calculation of the number of filtration wells on the site

The number of wells is determined by the amount of water consumption during the day.One septic tank is usually equipped with 2-4 wells. In the meantime, the volume of the septic tank itself should be three times the daily water consumption. For example, if one person consumes up to 250 liters of water per day, then a family of 4 will need a septic tank with a volume of more than 3 m3.

The amount of load per 1 m2 of the filtration well is calculated taking into account the type of soil (for sand it is 80 l, for sandy loam - no more than 40). If the distance from groundwater to the well bottom exceeds a distance of 2 m, then the load can be increased by 20 percent. It is also possible to provide for an increase in the load on summer cottages, when wells are applicable, as a rule, only in summer.

Bottom filter for a well: choice of materials

River pebble has a neutral chemical composition and is a rounded stone of various sizes and colors. It can be found on river banks and must be rinsed under running water before use.

Gravel is a loose porous rock with a grain size of 2 cm. Suitable filter material should not contain clay or sand impurities.

Shungite has become widespread in purification systems due to the effective elimination of organic contaminants, oil products and metal compounds. This material is the best option for a well with a shallow depth, which is close to the road, as it disinfects the water.

Quartz sand has a transparent structure, characterized by the presence of dark inclusions.Before making a bottom filter for a well using sand, it must be cleaned by pouring it into a mold and adding water. The liquid is mixed and drained after 40-60 seconds. This is necessary so that large grains of sand are at the bottom, and particles of silt and clay are in suspension. If necessary, the procedure can be performed several times until clean water is obtained.

Crushed stone is a mixture of stones that have different shapes. Its extraction is carried out mainly by the mechanical method. Minerals of various types may be present in the basis of the material. But a do-it-yourself bottom filter for a well can not be made from any type of rubble. For example, the granite version is characterized by a high radiation background, and the building one, due to its limestone base, can pollute the liquid. It is also prone to blurring when in water for a long time. The best option is a material that has a neutral base with high cleaning abilities.

According to many owners, the water in the well became cleaner after installing an aspen shield with a seal in the form of river stones.

Also, some are of the opinion that it is better to leave the well in its original form, and use only a mound of sand and stones, such as shungite and pebbles, since other types are not able to provide proper cleaning, while their safety for health is in doubt.

Reviews about stainless steel bottom filters are mostly positive. The main advantage over wood is the absence of decay.

11 Weird Signs That You're Good in Bed Do you also want to believe that you're giving your romantic partner pleasure in bed? At least you don't want to blush and apologize.

20 photos of cats taken at the right moment Cats are amazing creatures, and perhaps everyone knows about it. They are also incredibly photogenic and always know how to be at the right time in the rules.

Our ancestors slept differently than we do. What are we doing wrong? It's hard to believe, but scientists and many historians are inclined to believe that modern man sleeps in a completely different way from his ancient ancestors. Initially.

13 Signs You Have the Best Husband Husbands are truly great people. What a pity that good spouses do not grow on trees. If your significant other does these 13 things, then you can.

Why do you need a tiny pocket on jeans? Everyone knows that there is a tiny pocket on jeans, but few have thought about why it might be needed. Interestingly, it was originally a place for Mt.

Why are some babies born with an "angel's kiss"? Angels, as we all know, are kind to people and their health. If your child has the so-called angel kiss, then you have nothing.

Will the bottom filter help in water purification

No. And you yourself will draw the same conclusion, if you judge sensibly. A bottom filter is a filling of the bottom of a well made of sand, preferably quartz, and gravel or pebbles. And she really is able to purify water. But do we need a bottom filter in the well, let's figure it out.

How water is purified

Today there are many ways to purify water: physicochemical, biological, ion-exchange, electrical, osmotic.But within the framework of the issue under consideration (bottom filter devices), only one filtration method is of interest - mechanical.

The mechanical method of cleaning, despite its simplicity, is very effective. And in many cases, such purification of water from impurities is quite enough, or at least enough to remove most of the pollution.

Water treatment facilities

Such a filter works on the principle of a sieve or sieve, retaining dirt that is in the water in the form of a suspension. It is impossible to mechanically separate pollution at the molecular level, that is, what is dissolved in water.

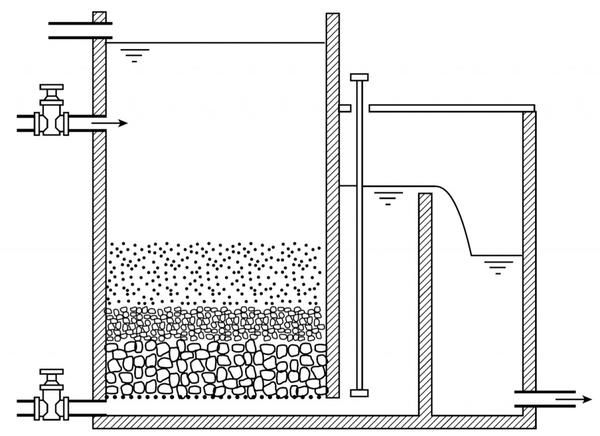

Partially, this problem, as well as the elimination of bacterial contamination in the form of living organic matter, is solved by a combination of mechanical and biological treatment. This concept is embodied in the so-called English (or slow) filters.

They are a sand and gravel backfill in which sand and fine gravel of different fractions are laid in a certain sequence. The thickness of this backfill is about two meters. The purified water is supplied from above with a layer of about 1.5 m and, under the influence of gravity, slowly (0.1-0.2 m / h) seeps through the filter.

Schematic diagram of a slow filter. Photo from the site

After some time, a film of bacteria and algae forms in the upper layer of sand. This biological film serves to purify water: the total population of the living part of the filter eats nitrogen and other chemical compounds dissolved in water. Large debris is retained by the bottom of the filter - a layer of quartz sand.

The filter is considered "mature", that is, capable of purifying water to the drinking standard, only after the formation of this biofilm of a certain thickness.The thicker the film (the larger the colony of bacteria and algae), the better the cleaning.

But with a significant increase in the thickness of the biofilm, the filtration rate decreases. Therefore, periodically it is necessary to restart the filter, destroying the biolayer and forcing the microorganisms to arrange a new colony. This is exactly how water is purified in nature: microorganisms live on the surface and in the upper layer of the soil, and below the water seeps into the soil, consisting of sand and gravel.

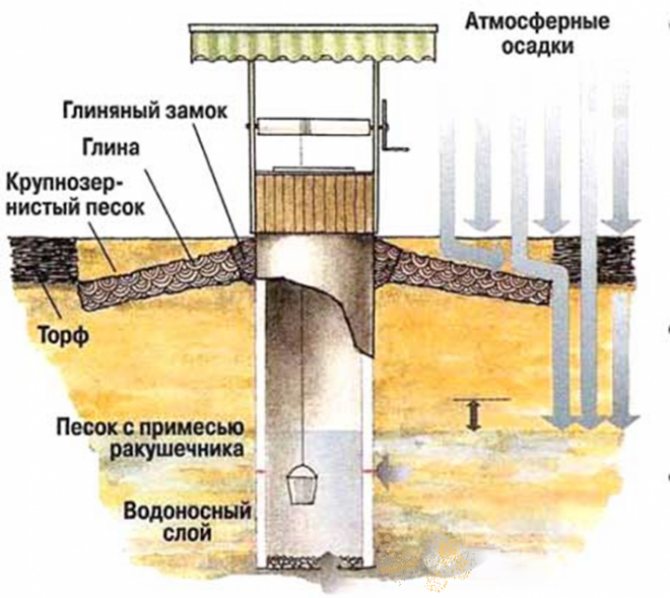

Bottom filter device

The well (if properly constructed) is filled through the bottom. That is, water enters it, infiltrated from the surface of the earth to the level of the first water horizon, which has passed at least 2 meters of filling the natural slow filter. Those who advise to definitely make a bottom filter usually offer such a scheme for its construction.

Scheme of the bottom filter device.

Question: how will an additional 600 mm of sand and gravel backfill at the bottom of the well help in water purification, if before that the water has already passed through the biofilm on the soil surface and 2000 mm of sand and gravel before entering the well?

Suppose that the well is not arranged quite correctly, and water enters it not only through the bottom, but seeps through the walls. You assume that the water in your well is not only underground, that is, it has undergone natural purification, but also upper. Will the bottom filter help clean it? Again, no.

Firstly, because the layer of sand and gravel is not thick enough, and secondly, the water in the slow filter moves down under the influence of gravity. In order for it to move upwards, being cleaned in the backfill, pressure is needed, but there is none in the well.And, finally, the main component of the biomechanical filter, the biological film of algae and bacteria, does not work there.

In addition to slow ones, there are also fast filters. They work only on the mechanical principle of cleaning. The thickness of the sand in them is much less, and the filtration rate is higher - up to 12 m/h.

Maybe the bottom filter works on the principle of a fast sand filter? And again no. Because the high filtration rate is provided by pressure, which cannot be in the well. And a small layer of sand allows you to retain only large particles, so fast filters, unlike self-sufficient slow ones, are used only as one of the parts of the water treatment system. Before a quick filter, the water is subjected to settling or coagulation, and after it it is additionally disinfected.

What filter to install at the bottom of the well?

The organization of a water source in a country or suburban private area helps owners to get rid of the issue of water supply forever.

In order to fully use a well or a well for the extraction of drinking water, you should make sure of its quality.

Considering what type of terrain the source was built on, you will need to install a bottom filter for the well. Its installation is carried out in the case of objective reasons.

Types of bottom filters

The bottom filter device can be built independently. To do this, you need to decide on its types: it will be direct or reverse. When constructing a direct filter, large pieces of broken bricks should be laid on the bottom of the well, on top of which a layer of its fine fractions is superimposed. The method is suitable for sources with loose soil with a possible quicksand.

A reverse bottom filter for a well is best done for a source built on sand with an inactive channel. The laying consists of the first layer of small rocks, and the second layer of larger pieces.

Such a filtration layer will protect the bottom from foreign objects, and also retain sand particles.

When creating a filter reverse action device the first layer consists of river sand, the second - of crushed stone with pebbles, and the third - with a gravel layer of 5 cm.

Laying type

The bottom well filter can be laid in two ways: direct and reverse, which have a difference in the sequence of layers. Direct laying is characterized by the lower layer of large stones, the second - from medium fractions, and a layer of fine gravel should prevail on top. The method is effective for floating rocks of the earth.

Reverse laying involves the top layer of large bricks, and the bottom of smaller ones. It is also possible to equip the bottom with a quartz dry mix of sand. Each layer, regardless of sequence, should be 15 cm.

Preparatory stage

When creating a bottom filter for a well, it is necessary to prepare a material that should not consist of chemical elements, not be subject to decomposition and dissolution. The best option is to lay the bottom of bath stones, which will become quite suitable for the construction of a large layer.

Before excavation, all rocks should be soaked in water and washed several times.

When creating a bottom filter, you can take synthetic rocks as a filler, such as geotextile or polymer granules. The materials are expensive, but contribute to 100% water purification and disinfection.

Shield making

If the well is located on floating soil, from the depths of which liquid arrives at a speed, then before laying the filter, a shield with holes is placed. As a basis, a bar or a metal grate is suitable.

A wooden round pallet can be knocked down with your own hands. To do this, you need ready-made boards that are knocked together. The design is cut to the size of the bottom of the well. A hole of 5 mm in size is made in the center. The shield can be wrapped with geofiber, after which you can start laying.

To prevent it from rising to the surface under the influence of water, the shield is piled on top with large stones. The shield is filled with pre-selected material. Before laying, the wooden structure should be treated with an antibacterial suspension.

Strainer

With a fine mesh metal mesh, a filter device can be created for a water source to delay the entry of sand particles.

-

To create it, a round sheet made of anti-corrosion iron is suitable.

-

The grid is interconnected by a wire.

-

Outside, the metal structure should be smaller than the inside by 5 mm. Lay it on a layer of stone.

-

Fixation is carried out using a pin stopper coming out of the walls of the well.

Thanks to the filtering device, regardless of the choice of material, it will help to obtain clean drinking water from the well in any season of the year.

Service Features

If the water intake is done manually, you should stretch the appropriate chain according to the size of the water source so that the bucket passes the bottom. This action will save the inventory and will not disturb the filter bottom.

During the cleaning of the well, the bottom shield is removed to the surface and cleaned.Observing simple rules, the water source in the suburban area will last a long period of time, providing high quality water

It is necessary to remember an important rule: before laying the bottom filter in the well, it is necessary to clean it thoroughly

Appointment of bottom filters

It should be noted right away that the manufacture of a bottom filter is not a prerequisite for the construction of each well. Rather, on the contrary, more often they try to avoid its use, making a hydraulic structure of considerable depth. The thing is that with such a filter, cleaning the well will be more time-consuming and expensive.

However, in some cases, a bottom filter is simply necessary:

If the soil at the bottom of the well is mobile, that is, they have a loose, viscous structure, then the installation of a bottom filter layer is necessary. This applies to wells built on clay or sand layers.

The installation of such a device is also necessary if water enters the hydraulic structure in a powerful jet. In this case, in addition to the filter itself, you will also need an aspen shield, which you can make yourself.

A significant drop in the water level in the well

It does not matter what reasons this is caused (seasonal drought or high flow).

If water from a hydraulic structure rises to the surface using a deep-well pump, especially a vibration type. In this case, the installation of a bottom filter is necessary to protect against turbidity and dirt, which the operating unit can lift from the bottom, forming a vortex flow in the water.

From the cases listed above, you can understand why a bottom filter is needed.Any of these situations, as well as their combination, can lead to pollution and cloudiness of the water from the well.

BC 1xBet has released an application, now you can officially download 1xBet for Android by clicking on the active link for free and without any registration.