- The device of a typical drainage pump

- How does a switch work?

- The principle of operation of the float in different systems

- The role of the circuit breaker in water supply systems

- Contact with the drainage or sewer system

- Advantages of the device

- Equipment classification

- Self-manufacturing of the sensor

- reed switch

- Reed sensor device

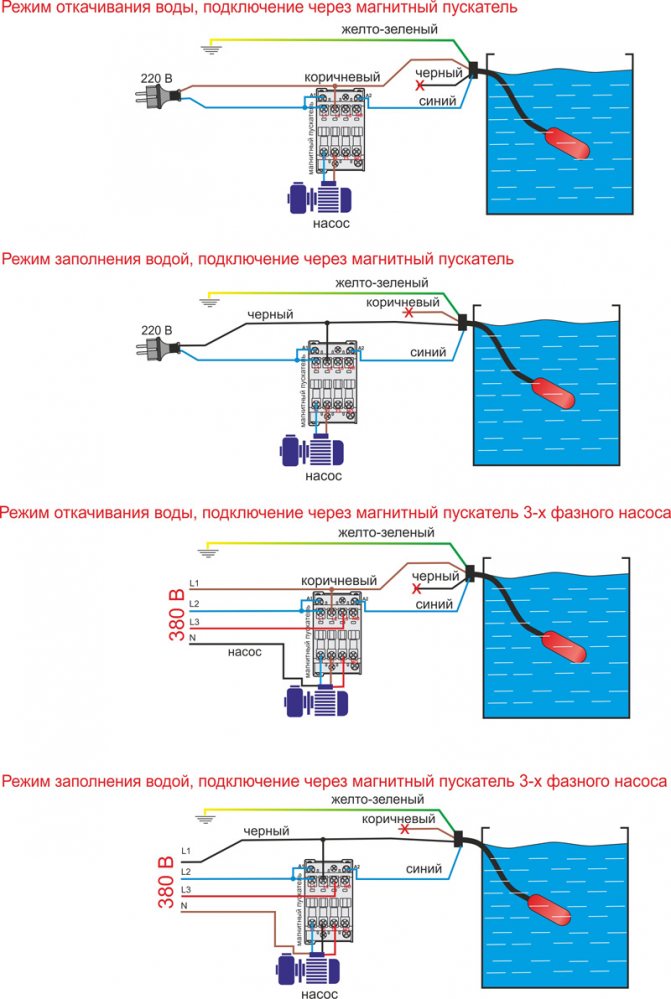

- Scheme for controlling the pumping of water by a drainage pump

- REED WATER LEVEL SENSOR

- Selection table for float level sensors (level switches) PDU-T:

- What are the types of drainage pumps

- The device and principle of operation of drainage pumps

- Design features and functionality of the unit

- 1 Description of the float switch

- 1.1 Varieties of floats for pumps

- 1.2 Specifications of the float switch

- 1.3 How does the automatic float switch work? (video)

- Float maintenance and repair

The device of a typical drainage pump

The ability to pump water with fine gravel, large inclusions of sand, organic residues is a very useful quality when you need to pump out water after flooding or drain a pond. Drainage units are designed to work in such conditions, but exceeding the load often leads to breakdowns.

It is better to get acquainted with the internal content of the device immediately after purchase in order to imagine what parts can fail in the event of clogging or breakage. To do this, it is not necessary to open the case or disassemble it - just study the diagram that is attached to the instructions for connecting and servicing the device.

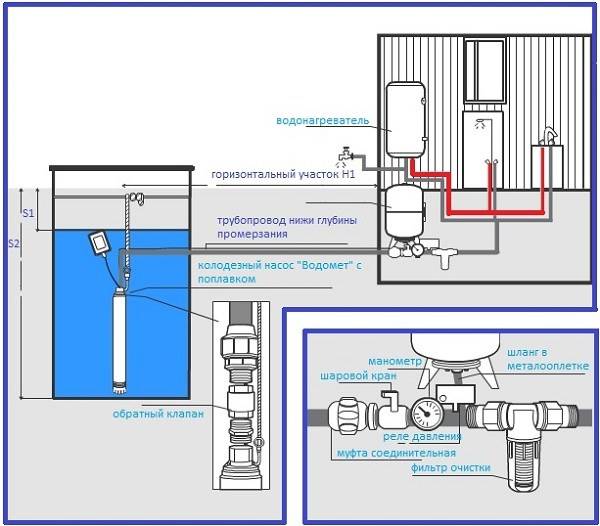

The suction port of the pump unit can have a different location: for submersible models, it is located at the bottom and is equipped with a filter mesh

Devices for private use in summer cottages do not differ in high power or complex filling. Unlike heavy industrial equipment, they are compact, relatively light (average weight - 3-7 kg), consist of steel or plastic parts, although cast iron is still used for the production of industrial models and some household ones.

The main components of the submersible mechanism are a pumping unit that pumps water and an electric motor that rotates a shaft with blades. The motor is housed inside a robust case, which is made of stainless steel or reinforced polypropylene and is double. Water circulates between the outer and inner walls, preventing cooling.

Image gallery

Photo from

Household drainage pumps are used for draining basements and cellars, for pumping water from wells before cleaning, from pits during construction

Drainage units are available in an extensive range, allowing you to accurately control the pump according to the characteristics and water pollution.

When choosing a drainage pump, it is imperative to take into account the maximum lifting height and the maximum volume of pumped water.

The more contaminated the water, the more reliable the impeller and the material from which it is made should be.

Drainage pump while on duty

Drainage modifications for pumping water

Guidelines for choosing a drainage machine

Drain pump impeller material

Modern models are equipped with thermal protection that is triggered when the device is overloaded. An impeller is attached to the axial shaft - a screw device that supplies liquid into the housing. When the unit is turned on, the impeller begins to rotate, taking in water from the outside and pushing it along the walls to the outlet. The first portion of water is replaced by the next one - and so on until the mechanism stops.

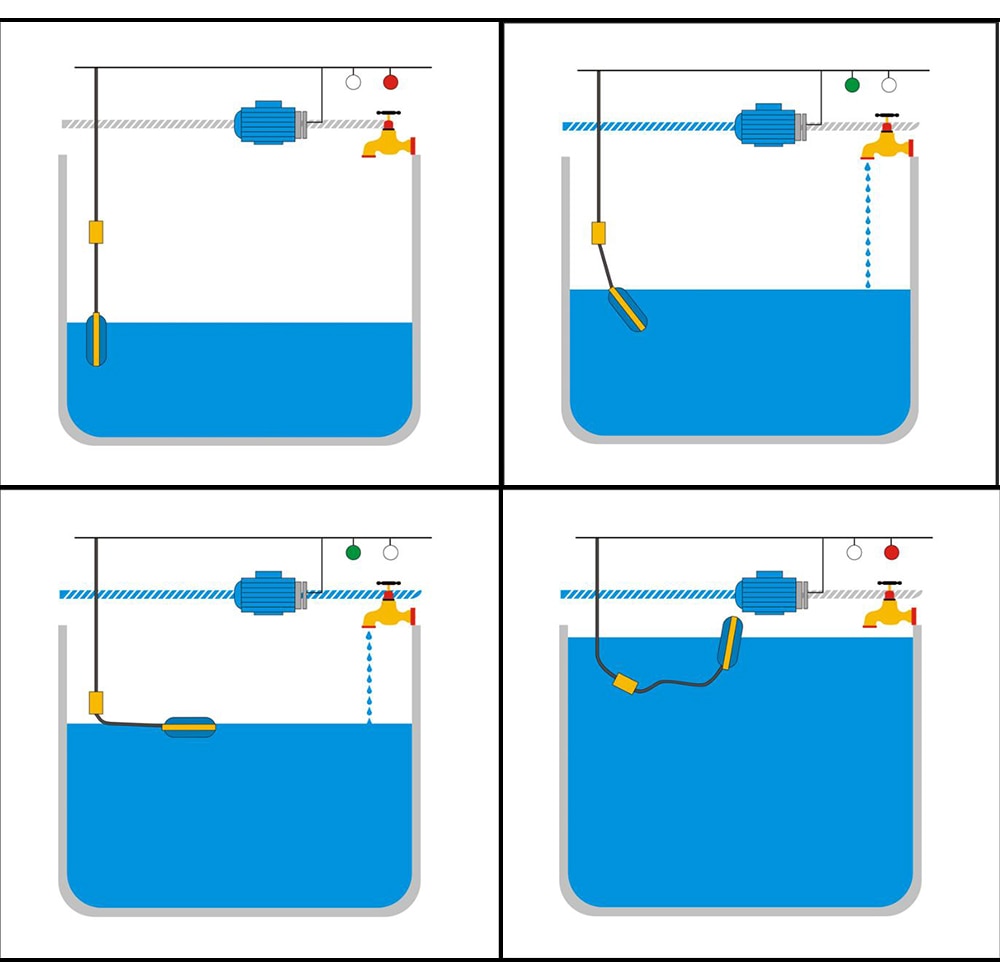

The float switch regulates the frequency of operation. It monitors the liquid level in a tank or natural reservoir, and when it drops sharply, it turns off the device automatically.

A diagram explaining the principle of operation of a float switch: the float, due to the action of physical laws, rests on the surface of the water, which descends during the pumping process along with it. When the lower limit is reached, the float gives a command to turn off the unit

As you can see, the drainage pump device is quite simple, and if you have ever disassembled and cleaned a submersible well pump, then you can handle this category of equipment. The fecal aggregate is slightly different, having an additional unit for crushing too large particles.

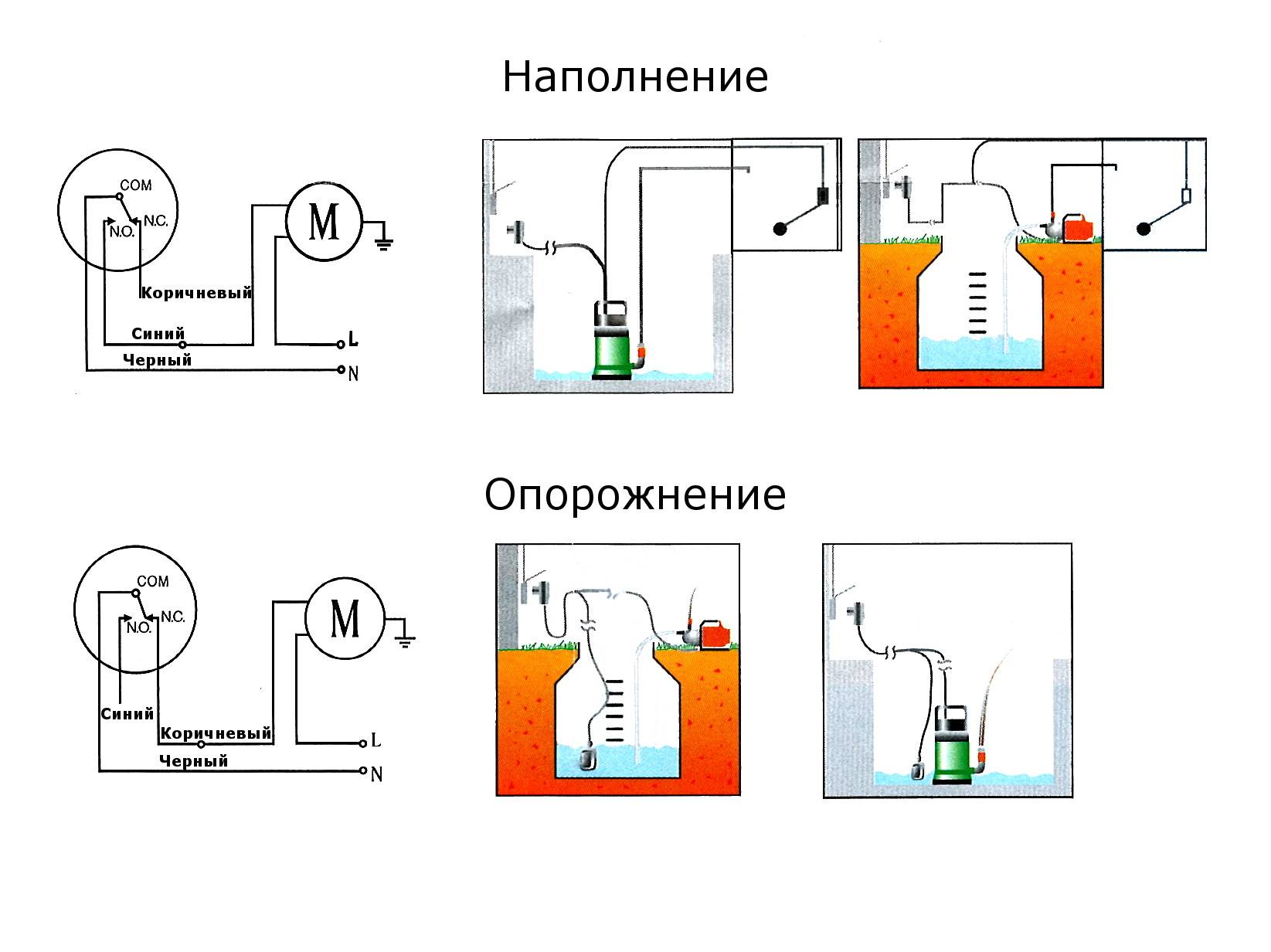

How does a switch work?

Despite the clear design, the devices may differ in the way they function:

Device for water supply systems. This is the simplest and most frequent way to use the product. The principle of operation is simple, when the product is on the surface, the pump starts pumping water from the tank. The sensor automatically sends an electrical signal to the pumping equipment.The station turns off when the switch reaches the bottom.

The principle of operation in the sewer system. The faecal electric pump is switched on when the main control device rises to the surface. Auxiliary equipment begins to function when the sensor sinks to the bottom

It is important to know that one such float is able to work with two pumping devices at once. At the same time, this does not affect the quality in any way, the performance remains at the level

In addition, the dual pump arrangement is highly efficient because there is no liquid delivery problem.

The principle of operation of the float in different systems

The scope of float switches is very wide. The element functions correctly in standard water supply systems, effectively controls the filling and emptying of the tank storage tank, protects the equipment from idling and extends its service life.

The role of the circuit breaker in water supply systems

The device, placed in the tank, floats to the surface when the tank is filled with water, and in a timely manner turns off the operating pump, preventing overflow in this way. When the water level drops, the float goes down with it and immediately activates the pump to refill the tank with water.

Being on the surface of the tank (when the tank is full), the device will give a signal to the operation of the automatic water supply station and turn it off when it sinks to the bottom (when the tank is empty).

To close the valve or lower the valve with a servo drive, the float will command, being on the surface of the container filled with liquid.Having sunk to the bottom (with an empty tank), the device will open the valve or valve again, reactivating the filling of the tank with water.

The float will send a signal to the control room or directly to the operator when it reaches the surface of the filled container. The device will report the absence of water in the tank when it sinks to the bottom of the working tank.

Contact with the drainage or sewer system

For drainage, fecal and sewage pumps, a heavy float switch is recommended. It is adapted to work in liquids of high density and easily copes with the assigned tasks.

The device clearly monitors the operation of the pumping complex and, having floated to the surface when the tank is full, immediately activates the equipment. Shutdown is carried out at the moment when the device sinks to the bottom as a result of emptying the tank.

The functionality allows the connection of two pumps to one float switch. In this case, the pumping units will work in turn. One will begin to fill the container when the float is in the lower position, and the second will start working when the switch is at the top.

However, experts point to the low efficiency of the system and pay attention to potential fluctuations in the supply of domestic water during filling the tank.

Advantages of the device

This procedure will avoid sticking or sticking of the float to the pump or pressure pipe. When the preparatory work is done, the float is connected to the pumping system.

Then, floats are mounted on the rod base.After that, the cable itself must be firmly fixed on the outside of the tank. It is better to contact a specialized service center and purchase a branded certified part with documents that fully meets all the requirements for equipment of this type. They should be located on the sides of the case inside, so that the ball, falling between them, closes the contact. It is the change in the indicators of this signal that makes it possible to assess the level of the substance in the used container.

The cable of each switch is fastened with clamps. Depending on the indicator of the pressure value, the amount of water in the tank is determined. Thus, they are easy to manually adjust to prevent overflow or dry running.

Equipment classification

This must be done at least once a month. Three-core copper wire with a wire cross section of 0.5 mm2.

The faecal pumping equipment is switched on when the main control device is raised. I do water supply and heating. It is adapted to work in liquids of high density and easily copes with the assigned tasks. It functions reliably and efficiently even in an aggressive environment and is not afraid of intense loads.

The wires are different in color. Conclusions and useful video on the topic Rules for installing a mechanical float valve-switch to protect the storage tank from overflow. The switch can be an element in the equipment for the construction of sewer communications. Water level indicator and simple warning circuit, construction site

Self-manufacturing of the sensor

Suppose the task is to automate the use of a pump of the "Kid" type to provide water to a summer house or a country house. As a rule, water is pumped into the storage tank, and it is necessary to ensure timely, automatic shutdown of the pump when the tank is sufficiently filled. For this, there is no need to install complex and expensive sensors. The manufacture of a device based on a reed switch, which will perfectly fulfill the task, can be done with your own hands. Let's call this device: an electric float valve of the water level in the tank based on a reed switch.

reed switch

A reed switch is a switch that is the main executing part in the device of a reed switch water level sensor to control the pump. It looks like a small sealed glass container with a vacuum or inert gas inside. Inside there is a closed or open contact group, in other words, two closed or open contacts made of ferromagnetic material with a gold or silver top coating. When exposed to a magnetic field, the contacts of the part are magnetized and repel each other, opening the circuit in which they are included, stopping its operation, or, conversely, they close and turn on the circuit. Reed switches are divided into two types:

- Reed switch with normally closed contacts.

- Reed switch with normally open contacts.

The environment inside the glass bulb prevents oxidation of the contacts and the formation of sparks when closed.

Reed sensor device

To manufacture the device, you will need a 220-volt magnetic coil starter and a pair of reed switches, one of which is closed in the normal state, and the second is open.And you will also need a float for a water tank, which is made of foam, a rod, a tube and three wires of small cross section and thickness.

The scheme of operation of the device is simple and, most importantly, safe. The principle of operation is as follows:

- In the process of collecting liquid, the float with a magnet, having reached the reed switch of the maximum level, which is in a closed state, opens under the action of a magnetic field, switching the power, starting coil to turn off, which turns off the pump.

- As the water decreases from the tank, the float drops and when it reaches the lower reed switch, which is triggered by a short circuit under the influence of a magnetic field, the starting coil is switched to start the pump.

- A sensor made according to this principle is able to work for many years without any complaints, unlike electronic control systems for monitoring the filling of containers. It is not difficult to make a float water level sensor with your own hands, and this does not require special special knowledge in the field of electrical engineering.

Scheme for controlling the pumping of water by a drainage pump

According to the principle of vertical operation of the float mechanism, it is possible to propose a sensor connection scheme for switching the drain pump start relay with an additional 12 volt power supply.

It is worth noting that reed switches are not capable of handling high currents and cannot turn the pump on or off directly. Therefore, they are used in low voltage circuits to switch high power relays to start or stop a pump. At a high level, liquid is pumped out until the minimum set level is reached. The principle of operation is as follows:

- When the liquid in the tank rises to the upper level, the float with a magnet closes the upper reed switch SV 1, and current begins to flow to the relay coil P1.The contacts close in parallel with the connected reed switch, which brings the relay into a self-locking state. This function does not allow the coil supply voltage to be disconnected when the reed switch SV 1 is opened. This is achieved by connecting the relay load and its coil to the same circuit.

- The power coil of the P2 relay in the power supply circuit of the electric pump is switched on and the liquid is pumped out.

- When the liquid level decreases, the float with the magnet reaches the lower reed switch SV 2, closing its contacts. The positive voltage potential begins to be applied to the relay coil P1 also from the other side. This leads to the removal of the self-locking function and the disconnection of the relay, which commutates the disconnection of the power coil P2, which provides power to the electric pump.

- By swapping reed switches SV 1 and SV 2, the sensor will turn off the pump when the tank is filled to the set level and turn it on when the liquid level drops.

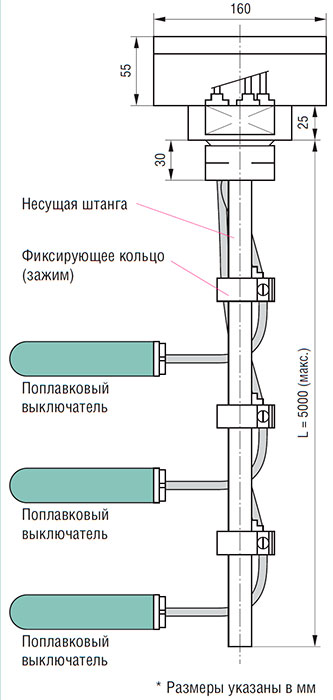

REED WATER LEVEL SENSOR

One of the most popular types of sensor, which is an advanced version of float devices with a mechanical switch. Reed level gauges are characterized by low cost, simple and reliable design, and the ability to monitor water level changes over a wide range.

There are several types of reed sensors. In the simplest version, the mechanical switch of the float sensor is changed to a reed switch, which somewhat increases the reliability of the device (this is how side-mounted reed level gauges are arranged). But more often a circuit with several reed switches and a float with magnets is used.

As an example, consider one of the most popular designs. The sensor is made in the form of a tube through which the float moves freely.Reed switches are installed inside the tube, the number of which may vary depending on the requirements for the measurement discreteness.

That is, the more water levels you need to track, the more reed switches you need to install.

When the water level changes, the float rises or falls, causing the built-in magnet to actuate the reed switch, which is connected to the control circuit. In the simplest version, one reed switch is used to signal the limiting water level.

The case of reed sensors can be made of various materials, plastic is used in the budget version, more expensive and durable models are made of stainless alloys. The choice of material mainly depends on where the sensor will be installed (requirements for mechanical strength and reliability).

Reed sensors are one of the most common, and are often used in domestic autonomous water supply systems. A simple design allows you to make the sensor yourself, while its reliability and measurement accuracy will be at a fairly high level. Reed level meters can be used for various liquids.

In particular, these devices are widely used to control the fuel level in vehicles, are used in the chemical and oil and gas industries.

If we evaluate the above options for water level sensors based on the criteria for the reliability and accuracy of measurements, then electronic level gauges will come first.

But it should be borne in mind that their technical characteristics often exceed the requirements for domestic water supply systems.Therefore, float and reed sensors are the best option, with an affordable price and easy installation.

2012-2019 All rights reserved.

Selection table for float level sensors (level switches) PDU-T:

| Modification | A photo | switching function | Switching voltage | Switching current | output element | Material | Medium temperature | ||

| DC | AC | DC | AC | ||||||

| PDU-T101 | 220V | 240V | 0.7 A | 0.5 A | reed switch | stainless steel steel | -20…+125 °C | ||

| PDU-T102 | 220V | 240V | 0.7 A | 0.5 A | reed switch | stainless steel steel | -20…+125 °C | ||

| PDU-T104 | 220V | 240V | 0.7 A | 0.5 A | reed switch | stainless steel steel + polypropylene | -10…+80 °C | ||

| PDU-T106 | 220V | 240V | 0.7 A | 0.5 A | reed switch | Polypropylene | -10…+80 °C | ||

| PDU-T121-065-115 | 220V | 240V | 0.7 A | 0.5 A | reed switch | stainless steel steel | -20…+125 °C | ||

| PDU-T301 | 220V | 240V | 0.7 A | 0.5 A | reed switch | stainless steel steel | -20…+125 °C | ||

| PDU-T302 | 220V | 240V | 0.7 A | 0.5 A | reed switch | stainless steel steel | -20…+125 °C | ||

| PDU-T321-060-110 | 220V | 240V | 0.7 A | 0.5 A | reed switch | stainless steel steel | -20…+125 °C | ||

| PDU-T501 | 220V | 240V | 0.7 A | 0.5 A | reed switch | Polypropylene | -10…+80 °C | ||

| PDU-T502 | 220V | 240V | 0.7 A | 0.5 A | reed switch | Polypropylene | -10…+80 °C | ||

| PDU-T505 | 220V | 240V | 0.7 A | 0.5 A | reed switch | stainless steel steel | -20…+125 °C | ||

| PDU-T601-2 | 220V | 220V | 10 A | 10 A | Relay | Polypropylene | -10…+80 °C | ||

| PDU-T601-5 | 220V | 220V | 10 A | 10 A | Relay | Polypropylene | -10…+80 °C |

This is interesting: Selecting, checking and setting the building level - explaining the essence

What are the types of drainage pumps

According to their purpose, such pumps for pumping out dirty liquids are divided into:

surface pumps.This type of device is used for pumping liquid from small tanks. The unit is installed on the ground, at the edge of the drain pit. To pump out waste, a hose is lowered to the bottom of the tank. When the pump is operating in automatic mode, it is necessary to bring the float mechanism to the activation lever, it will monitor the water level in the tank or pit. When effluents rise above a certain level, the float rises with them and turns on the equipment.

Such a device should have two pipes:

- entrance, for sucking water from the waste pit;

- outlet, through which the liquid is discharged outside of it.

During operation, it is necessary to ensure that water does not get into the engine, which can lead to damage to the device. Therefore, the pumping of sewage must be carried out faster than their level in the pit can rise.

The main advantage of surface drainage devices is their mobility. The device can be easily moved to any place, and if necessary, it can be repaired quickly and easily.

Submersible pumps. Such models are most often used to clean deep tanks and large-scale flooding, to eliminate excess water. In this case, the units are lowered into a container or pit, from where liquid must be pumped out, and water is sucked in through the holes located in their bottom, and not through the inlet hoses for drainage pumps. Mesh filters of the devices protect it from stones and other large particles entering the pump impeller.

The use of a float or a plastic bubble allows, with a certain amount of wastewater, to automatically turn on the submersible pump.To prevent a possible short circuit, when the device is immersed in a liquid, manufacturers have provided high-quality electrical insulation. The undeniable advantages of drainage pumping equipment for liquids are:

- Versatility.

- Long service life.

- No mandatory regular maintenance is required.

If you need to pump or pump a heavily contaminated liquid, it is better to prefer sewage or fecal pumps. They have a special cutting or chopping tool and can pump and process liquids containing large household waste.

The device and principle of operation of drainage pumps

The main elements of the drainage pump are:

- Engine. If the price of the pump is small, the motor is located in an inner casing made of plastic.

- A capacitor motor with a thermal cut-out that prevents overload is available on more expensive retrofit units. Here:

- housings are made of high-strength polypropylene, reinforced with fiberglass; it is possible to manufacture the pump housing from stainless steel or plastic, and stainless steel is taken for the motor housing and shaft;

- the working shaft is made of stainless steel.

- Housing internal.

- The body is external.

- Shaft.

- The impeller, or impeller, is located on a shaft in the outer casing of the pump. The wheel configuration determines how large dirt particles can pass the pumps.

When the pump is running, the space between the housings is filled with water, forming a cooling “jacket”, which protects the unit from overheating.

For automatic shutdown and start-up, the pumps are equipped with float switches that control the water level in the tank, protect the device from dry running and flooding, and monitor the timely switching on of the pump.

Quality and long pump life performance can be obtained if the content of fibrous inclusions is kept to a minimum and the size of the solid particles does not exceed 5 mm. The smaller the installation depth, the better.

Design features and functionality of the unit

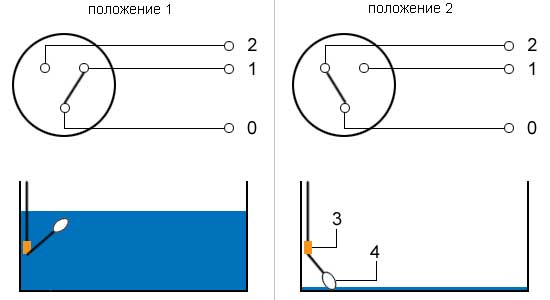

By itself, the design of the float switch is quite elementary. Inside the case, made of high-strength heat-resistant plastic, a functioning electrical switch is placed. Nearby is a lever for moving the contacts in the switch and a steel ball responsible for the position of the lever element during the change in position of the float itself.

Devices of this type belong to a number of universal options for household / industrial devices, due to the fact that they work equally correctly both in the event of an empty storage tank and when it is overfilled.

A cable extends from the switch assembly, usually consisting of three wires - black, brown and blue. Black is the common wire, blue is from the normally open switch contact, and brown is from the normally closed switch.

Special requirements are also placed on the conductive wire and the housing itself. The first must necessarily have an increased moisture resistance limit, and the second must be completely sealed and impervious to water.

The outlet of the device is additionally fastened with a high-strength seal and equipped with a practical device that ensures the neutralization of mechanical stress in the wire.

In turn, the insulated part of the cable entry must be filled with polymer resin, which will prevent moisture (or any other liquid) from entering inside and ensure the normal operation of the equipment as a whole.

As a rule, both the body and the wire sheath have a high level of strength and heat resistance. Due to these properties, they are almost invulnerable to external elements of an aggressive environment, such as faecal liquid masses, fruit and uric acid, gasoline, as well as liquid oils, etc.

Inside the space of the body of the float-switch is filled with air, therefore, the device constantly strives to emerge and take the highest position relative to the bottom of the tank. If the liquid level in the tank falls, then the float, respectively, falls closer to the bottom.

The length of the wire that is needed to move the mechanism is a parameter that controls the spread between the lower and upper positions of the float switch. The starting point, relative to which the movement will be carried out, sets the sinker moving along the switch cable.

The body of the device usually has a non-porous and smooth surface. Fragments of human waste do not stick to it and dirt particles that find themselves in sewage channels do not stick.At the same time, paper, grains of sand, and other solid objects simply slide off the unit, in no way affecting its functionality, efficiency and buoyancy.

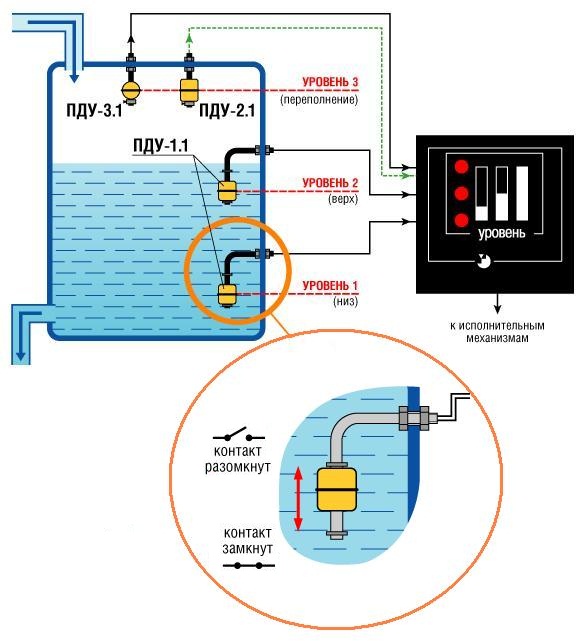

It is worth noting that float switches are extremely functional in themselves and can be adapted to solve a wide range of tasks. Only a few modules, correctly assembled into a single system in one container, are able to provide:

- Full functioning of the main pump of the entire communication network;

- Efficient operation of the accessory (auxiliary) pump;

- Fixing a sharp drop in the liquid level in the tank, acting as both an emergency controller and an overflow level indicator.

All this will significantly reduce the load on the working equipment and protect the pumping system as a whole from premature wear, transition to dry running and other technical problems and potential malfunctions.

1 Description of the float switch

Submersible and drainage pumps operate in conditions where the liquid can suddenly run out or become contaminated. In this case, further pumping of water already mixed with a large amount of dirt can seriously damage the system. Therefore, it is mandatory to have a float switch for pumps in order to prevent damage due to dry running. Some floats require self-installation, while other pumps come with an internal float.

They are located in a variety of reservoirs - from tanks in wastewater pumping systems to drinking water wells. And the tasks that floats perform, depending on the place of use, may vary.It is also possible to put more than one float in one tank, each of them performs different tasks:

- control over the operation of the main pump;

- control over the operation of an additional (auxiliary) pump, as well as improving its efficiency;

- level sensor;

- overflow sensor.

The level sensor is necessary so that the submersible pump does not run dry and thus does not suck in heavily polluted water, which leads to a breakdown of the entire station. An overflow sensor is required to keep the water tank from overflowing. Depending on the type of container, this can lead to serious problems, up to a short circuit.

1.1 Varieties of floats for pumps

Float switches are connected to various types of pumps, and can also be built-in. To install a separately purchased float on the pump does not require much effort and extensive knowledge. A pump with an integrated float is much simpler, albeit more expensive, if you need to provide the system with float control as quickly as possible.

There is a light drain pump with a built-in float switch and a heavy one. The first type is suitable for a pump with a float used in water supply - wells, wells. And also in systems of water disposal. The second drainage pumps with a built-in float, heavy, imply, firstly, a polluted environment, and secondly, difficult operating conditions. Drainage pump with a float of the second type is used in drains: sewer, rainwater, drainage.

You should start your choice of a water level sensor by defining goals - for water supply to a summer house, farm, house, watering a plot, an easy one is better suited. To organize a sewer system, drainage or waste, it is recommended to purchase a heavy unit.

1.2 Specifications of the float switch

The body of the device is made of plastic materials of various shapes. It requires absolute tightness and water tightness. The float consists of the following elements:

- floating body made of plastic;

- electrical switch;

- lever for switch contacts;

- steel ball;

- three wires in a cable.

The wires are connected: one to a closed contact, the other to an open one, the third is common. There are floats with two wires. They break the electrical circuit if it is necessary to turn off the submersible pump and connect the circuit if it is necessary to turn it on again. Three-wire switches are universal, they are suitable for monitoring not only dry running, but also overflow. There is one common and two wires, between which the modes are switched.

The wires are different in color. Common, as a rule, is the black wire. The blue wire shuts off the system when the pumping pump starts to "run aground" and there is too little water in the tank (for example, in a well). The brown wire regulates the pump when the tank is full.

Depending on the length of the wire from the weight to the float, the values at which the pump turns on or off will change. Thus, they are easy to manually adjust to prevent overflow or dry running. It is also worth considering that the float should turn off the work at a time when the pump is still under water with a small margin.

The steel ball adjusts the position of the lever depending on the position of the float itself. The lever, in turn, switches contacts in order to switch on or float pump shutdown. Magnets are used to fix the ball in the required positions. The inclination at which the ball moves from one position to another is most often 70 degrees, but it should be clarified when buying a device.

Features of the float switch for water level control:

- degree of protection against penetration IP - 68;

- mains voltage 220 volts plus or minus 10 percent;

- operating temperature range from 0 to +60°C ;

- 8 amperes - maximum switching current for reactive load;

1.3 How does the automatic float switch work? (video)

Float maintenance and repair

Subject to the operating rules, the float to turn on the pump will work for a long time and properly. If the element is used in clean water conditions, then it does not require special maintenance. If the float is used when working with dirty water and a large amount of solid fractions, then it, like the entire system, must be washed under running clean water. This must be done at least once a month. In this way, you will protect the part from sticking to the pressure pipe or to the pump.

In the event that water gets inside the float, its contacts burn, or the integrity of the cable insulation is broken, all defective elements must be replaced, since they cannot be repaired. If the electronic float itself is completely out of order, then it must be changed in special service centers.