- Factors affecting the fuel consumption of diesel boilers

- The principle of operation of a diesel boiler

- Classification

- Power selection

- Fuel consumption calculation

- Heat exchanger material - what depends on it?

- Single or double circuit?

- The method of heat generation - which is better?

- Do you need a replacement burner?

- Manufacturers overview

- What are combined boilers

- Alternative heating of the house with diesel fuel

- What to look for when choosing a diesel boiler

- Equipment classification

- Power

- Determination of fuel consumption

- Boilers for heating and heating

- Heat exchanger: choice of material of manufacture

- Heating principle

- 5 Kiturami TURBO HI FIN 13

- Servicing the heating device

- For me, a diesel boiler is beneficial

- Fuel consumption

- How to reduce the consumption of diesel fuel for heating a house

Factors affecting the fuel consumption of diesel boilers

When choosing heating equipment, it should be remembered that in terms of which a diesel boiler is characterized, fuel consumption is, although important, but not a determining characteristic of the efficiency of a home heating system. Liquid fuel boilers consist of the following main units:

- boiler bodies with a steel or cast iron heat exchanger;

- burners with fuel supply pump;

- autonomous heating systems;

- solar storage containers.

Boilers with cast iron heat exchangers have a capacity of 16 to 1000 kW, so if it is not enough to heat a large cottage, you will have to choose steel heat exchanger, allowing to reach a power of 30,000 kW, however, during its operation it is necessary to maintain a constant temperature of the coolant not lower than + 60ºС, otherwise the intense corrosion process will quickly disable the steel walls of the heat exchanger. This feature leads to increased diesel boiler fuel consumption, as well as constantly high room temperatures. Cast iron heat exchangers, unlike steel ones, last up to 50 years, however, only under the condition of normal operation: without sudden temperature changes and when using a high-quality coolant.

Economic efficiency autonomous heating systems largely depends on the characteristics of the burner, whose tasks include the preparation of the air-fuel mixture and its combustion. One of the main indicators of the burner, affecting the efficiency of the entire heating system as a whole, is way to regulate its power. Now the trading network offers:

- inexpensive single stage burners operating only in maximum mode - 100% (temperature control is performed by turning off the burner);

- two-stage - can work in two power modes - 40% and 100%;

- smoothly two-stage - with smooth power control ranging from 40% to 100%;

- modulated - capable of smoothly changing power in the range from 10% to 100%, which makes it possible to adjust the temperature regime of the heating system depending on weather conditions (in addition, burners of this type can significantly reduce diesel boiler fuel consumption, and also due to the absence of sudden temperature changes to extend the service life of thermal equipment).

Automatic control of the heat supply system although it requires tangible costs, it makes it possible to safely operate diesel heating boiler in offline mode, allows you to adjust its operation depending on the temperature in the room and the weather outside. All this leads to savings of up to 15% of liquid fuel, which ultimately pays for the costs of acquiring automation.

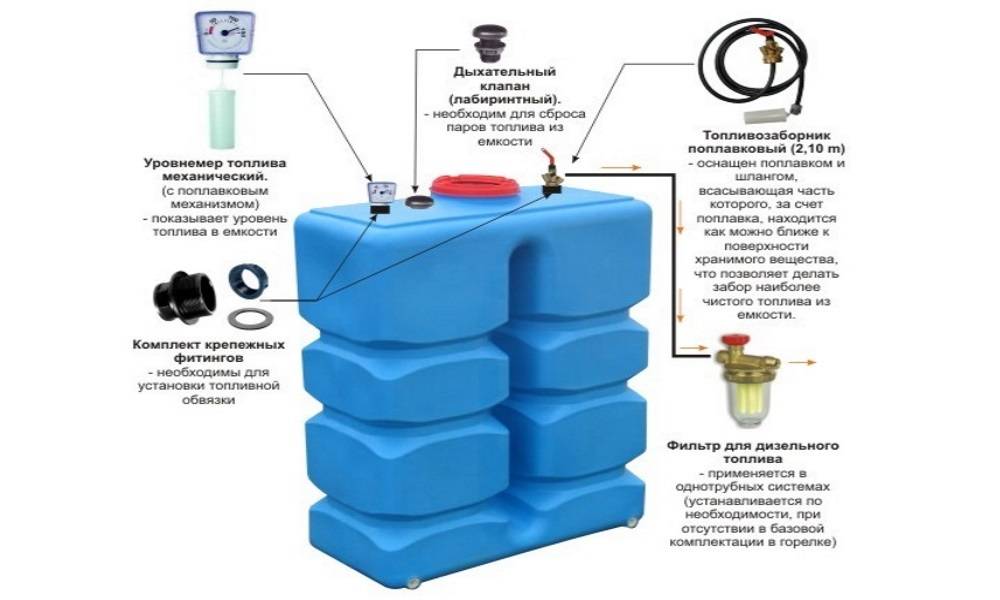

Fuel storage tank should be chosen based on the optimal mode of its refueling - 2 times a year, subject to continuous operation of the heating system during this period at full capacity. Tanks made of various materials with a capacity of 500 to 2000 liters are on sale, so choosing the right one will not be difficult.

The principle of operation of a diesel boiler

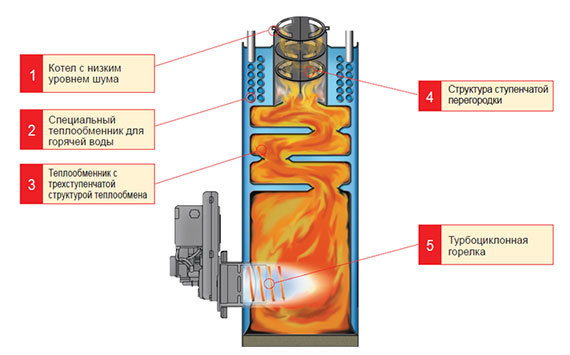

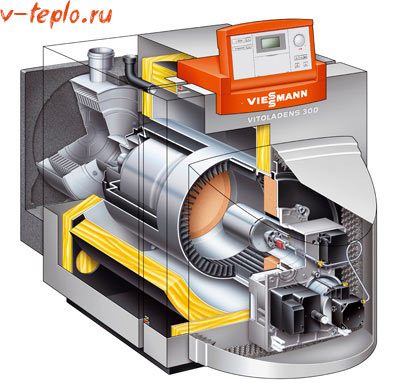

In order to understand the principle of operation, consider the basic components of a diesel boiler and their purpose:

- A pump that ensures the supply of diesel fuel to the burner.

- A fan that provides air to the combustion chamber.

- Chamber for fuel preheating. Not installed on all devices. Inside, the fuel is heated and filtered before being fed to the burner.

- Diesel burner. It receives fuel, which is sprayed into the combustion chamber through the nozzle. A fan or turbine is used to create pressure inside. According to the power control method, the following configurations are distinguished:

- Single stage models with constant output.

- Two-stage devices with two modes

- Modulating burners, the power of which varies depending on the set temperature.

- The combustion chamber. Most models are cylindrical.It mixes air blown by a fan and atomized diesel fuel. With the help of electrodes, the resulting mixture is ignited.

Sectional diesel boiler

Metal heat exchanger. It consists of tubes that are heated by the heat released during the combustion of fuel. Inside them is a coolant, which is carried through the radiators with the help of a circulation pump. Made from stainless steel, copper or cast iron.

Chimney. Combustion products and residual vapors are discharged here. In modern configurations, there is also a part of the heat exchanger here, heated by the outgoing smoke and steam, which makes it possible to increase the efficiency of the device.

Electronic control system. Coordinates the operation of all units of the oil boiler according to user settings.

The body is made of steel and is additionally glued on the inside with a heat-insulating gasket.

The pump pumps fuel into the preheating chamber, then it enters the diesel burner and is sprayed through the nozzle into the combustion chamber under pressure from the internal fan. On the other hand, oxygen supplied by a fan enters the furnace. The electrodes create a spark and ignite the mixture of air and fuel.

The heat is transferred to a heat exchanger, which is located around and on top of the combustion chamber. Inside it, the coolant is heated, which circulates through the heating system. The products of combustion are removed through the chimney. All nodes are coordinated by an electronic control system, on which the required operating mode and temperature are set.

Kiturami boiler control system

Double-circuit models are also produced with an additional heat exchanger for domestic water.Usually it is located above the main one and allows you to provide the house with hot water.

If you want to provide domestic hot water with a single-circuit boiler, you must additionally install an indirect heating boiler. Some double-circuit devices are equipped instead of a second heat exchanger with a small indirect heating boiler.

Classification

The choice of model depends on the set of necessary characteristics: power, heat exchanger material, type of combustion implemented in the boiler, as well as the need for hot water supply.

Power selection

The most important characteristic, the correct choice of which determines the heating efficiency and economical fuel consumption. The power of diesel heating equipment is measured in kilowatts, it is indicated in the technical documentation for any boiler. For the calculation, there is a special technique that takes into account all the nuances.

It is more convenient for an ordinary consumer to focus on the area of \u200b\u200ba heated private house - this indicator is also indicated in the main characteristics of any model. As a rule, for a temperate climate, you can use a simple formula: the total area of \u200b\u200ball the premises of the house is divided by ten, as a result, the required boiler power is obtained. For colder climates, this value should be increased by 20-30%.

A simplified method for calculating power is relevant only for houses of a simple layout with a ceiling height of up to 3 m. For multi-storey buildings with heated stairs, it is better to calculate based on the volume of the premises.

Fuel consumption calculation

The consumption of diesel fuel directly depends on the power of the boiler, on average it is calculated as follows: the power of the boiler in kilowatts is divided by 10, and the hourly consumption of diesel fuel in kg in heating mode is obtained.In the temperature maintenance mode, the consumption is reduced by 30-70%, depending on the degree of thermal insulation of the house. On average, the consumption of household heating boilers in a medium-sized private house is 0.5-0.9 kg.

Heat exchanger material - what depends on it?

The heat exchanger in diesel boilers can be made of steel or cast iron. Both materials have both advantages and disadvantages:

- boilers with a steel heat exchanger are lighter and cheaper, react faster to temperature changes, are more resistant to local overheating, but they are highly susceptible to corrosion;

- a stainless steel heat exchanger is durable, not afraid of aggressive compounds, has a uniform heat distribution, while their price is slightly higher;

- the price of boilers with a cast-iron heat exchanger is higher, they are heavier, more brittle and can crack during sudden temperature changes, but they are more resistant to corrosion and durable when used in an aggressive environment;

When diesel fuel is burned, a large amount of soot containing sulfur compounds is formed. Combining with condensate, they form weak acids, which leads to rapid corrosion of the boiler elements and its failure.

Condensation can be avoided with the help of a properly installed return system to the boiler, which will be discussed in the relevant section.

Single or double circuit?

Diesel boilers for a private house can not only provide heating, but also heat water for domestic needs. Such boilers are called double-circuit.When choosing a double-circuit boiler, it is necessary to increase the design power by 20%, otherwise it may not be enough for efficient heating and water heating.

When buying, you need to evaluate the feasibility of buying a dual-circuit model, if the hot water consumption is negligible, it is better to install a separate water heater and not complicate the heating system.

The method of heat generation - which is better?

According to the principle of heating the coolant, diesel boilers are of the traditional type and condensing, using additional condensate energy. They have increased efficiency and lower fuel consumption, but the price is higher.

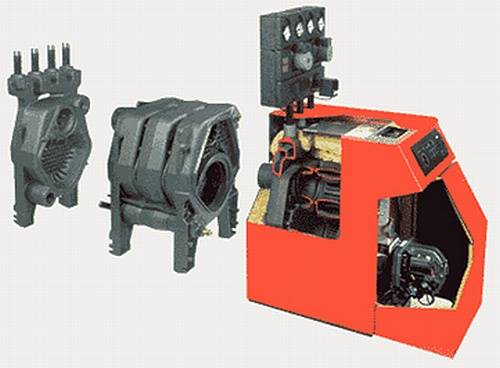

Do you need a replacement burner?

Diesel burners are very similar in design to gas burners, so there are many models on the market that allow you to use any of these burners in one boiler. Replacing them is so simple that it does not require calling a wizard - you can do it yourself at a convenient time.

If a diesel boiler is purchased as a temporary source of heating, and it is planned to connect to a gas main in the foreseeable future, it is better to choose a model adapted to replaceable burners.

Manufacturers overview

Ferroli devices made in Italy are an example of reliable, economical and safe equipment.

It is also important that the products that are supplied to the Russian market are designed taking into account the climatic features of the territory of our country.

The diesel boiler for heating the Ferroli building can be called suitable for heating systems of residential buildings and cottages.

Heating appliances running on diesel fuel do not depend on the ability to connect to communications.

In addition to all this, it is necessary to say about one more advantage of these boilers, namely the possibility of replacing it with a liquid fuel gas burner. What makes this model of diesel boilers universal. Thus, it will be possible to switch the heating system to gas in the future.

Disadvantages of Ferroli devices, including:

- the need to store large volumes of fuel, which specialized tanks can handle;

- you need to constantly check the fuel level so that the system does not stop working.

If we consider all products by functionality, then we can see that the devices from the GN1 series provide the opportunity to heat rooms and heat water for domestic needs. The power of such equipment is 91 kW. But the GN2 line can only heat the air.

The Korean company Kiturami, which produces Turbo devices, also supplies diesel boilers to the Russian market. The products of this company combines reasonable price and high quality. The boilers are equipped with a circulation pump, which allows the coolant to be delivered to the system much faster. Such equipment perfectly copes with space heating and water heating. They may well be used to heat the house and heat water to a certain temperature.

The efficiency is quite high, which allows you to spend fuel more efficiently. In addition to all this, Turbo boilers are equipped with special sensors that ensure safe operation.

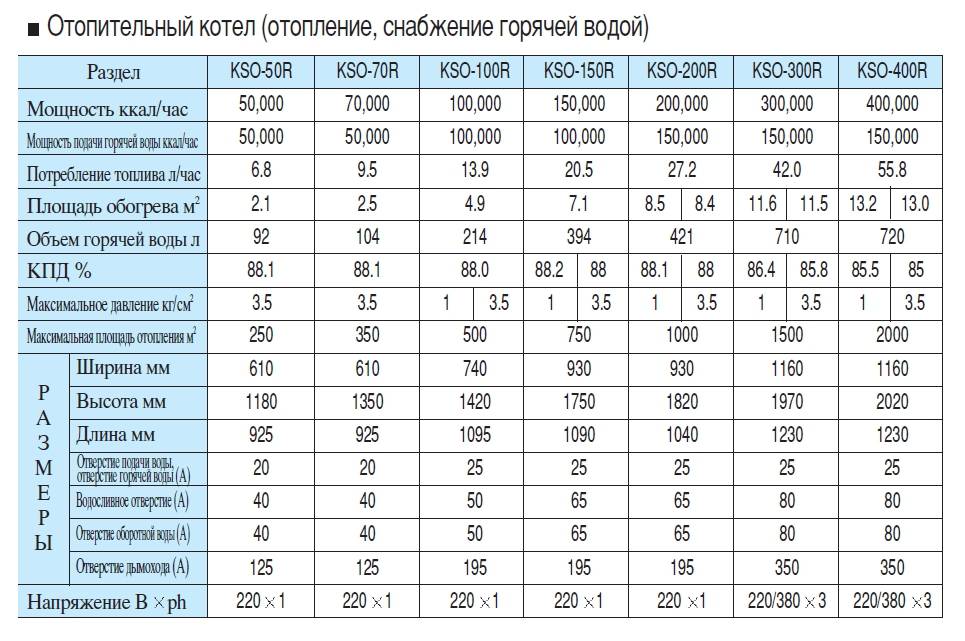

The heating boiler of the Turbo model, running on diesel, has a turbocyclone burner, and is carried out with greater efficiency. KSO series devices, if necessary, can be converted to work on other fuels.

In all units for heating systems, manufacturers from Korea are equipped with special sensors, which ensures safe operation and automatic control of the system.

Another Korean company, Navien, produces equipment suitable for heating a country house. The salient features of this equipment are:

- low level of generated noise;

- modern automatic control system;

- convenient set.

If we talk about diesel-powered boilers manufactured by Russian companies, then it is worth saying that in most cases these are specialized models. Such equipment is characterized by low efficiency, not exceeding 70%.

Diesel Russian-made boilers are assembled on the basis of designs developed back in Soviet times, namely:

- AOZhV

- Flame

- KChM

All these systems are outdated and do not meet modern requirements.

As is clear from the above information, a diesel boiler is quite economical. With its installation and subsequent operation, you can significantly save money on the purchase of fuel.

However, it should be said that a diesel boiler with its high efficiency and low fuel consumption is suitable for large houses and detached buildings. The fact is that such equipment requires the presence of a boiler room and a fuel storage room, as well as the organization of communication between them. All this will pay for itself only if you need to heat large areas.

What are combined boilers

In some cases, diesel heating can be used not as the main, but as an additional method.On sale today you can find combined boilers that operate on both diesel and gas fuels or diesel fuel and coal. Such equipment is more expensive, but in the future it will be possible to spend much less on heating, and there will be no risk of being left without heat at all in case of any network problems.

On ordinary days, gas heating can be used for the house, and if there are drops in the gas supply, a diesel burner starts up. In this case, fuel consumption will not be too high, and the owner of the house will be able to prevent the heating system from freezing without extra expenses.

In addition, connecting to the gas pipeline will still require drawing up a project and obtaining an official permit, and a specialist will have to carry out the work. It will not be easy for a massive bulky boiler to find a suitable place in the house; the boiler room must comply with all fire safety rules.

Should you choose diesel heating for your home? This issue will remain controversial for a long time, since such fuel has both pluses and minuses.

In Russia, it still remains insufficiently demanded, although with the advent of new economical models, the situation began to change. Diesel heating is expensive, but very reliable, and your home will be reliably protected from the cold during the entire heating season.

Andrey Levchenko

Author of publications on topics: Attic windows | Round fence | Log house with five walls | Repair of the house from cylindering | Production of cylindering | House layout | Cottage from cylindering | Electric induction boiler | Solar panels | Canadian log house | Log bath | Wall insulation | Cottage - glued laminated timber, etc.

Alternative heating of the house with diesel fuel

What could I do to make solar heating at home a little less expensive, and could use a diesel boiler as the main source of heat for the house?

The first thing I think about is using a waste oil burner. I put such a burner for testing and collect virtually free fuel, where I can - at service stations, at express oil change kiosks, and so on.

What are the disadvantages of this option? The first and most basic is the price of the burner. The cost of the burner for testing is 60,000 rubles. Which is comparable to the purchase of almost 2 tons of diesel fuel.

Secondly, working off also needs to be collected, spending gasoline and time, transporting it in cans to the house, defending it somewhere and storing it at this time.

And, thirdly, I'm not the only one so smart. More than once I have already watched comrades who collect mining at the service station and take it out for their own needs. This is exactly the same topic as with our own production of pellets. Looks like it's free. But in fact, it turns out that it is easier to heat with briquettes than to make pellets yourself from “free” sawdust.

There is, of course, also solar oil and light oil. But it also has its pitfalls. Starting from the fact that a standard burner will not be guaranteed to work on these types of fuel, and ending with the complete impossibility of obtaining this fuel in some regions.

Here the analogy with the coal-fired boiler Carborobot suggests itself. The boiler is good, no doubt. But in our region there is no fuel for it, there is no coal of the required fraction, there are no good suppliers. And to carry from somewhere - it turns out to be unrealistically expensive.

by autoruMAX » Mar 05, 2012, 06:39 pm

Good afternoon There was a problem of organizing a boiler house in the domain, you need to choose a diesel boiler for 30 kW, in pair with it, an electric boiler for 12 kW (which one is better?) A hydraulic arrow for 8 circuits - 5 for heating - a pool heat exchanger - a heated floor 1 circuit for an area of 70 mkv

the main question about a diesel boiler is which is better, which chimney is better for it? (height from the boiler room to the ridge is 14m - there is a place under the chimney - a shaft 1.5x0.7m)

how to connect boilers

in the future (in 3-4 years it is possible to switch to main gas) and increase the area from 300 to 500 mkv

water supply separately - completely on an electric boiler 300l (what a good one - so that a few tenns and spare parts if it's easy to buy)

For a diesel boiler, the most important parameter is trouble-free and so that you can, for example, buy a pair of burners and change as needed

Uv members of the forum, pliz does anyone have such a device, I want to know how much fuel it eats per day, how it works, what area it heats. I have a house of 2 floors 160 squares, lined with bricks, mp windows, maybe someone who knows which is the most economical of the well-known brands, write pliz here or on soap. Thanks in advance

Why did you opt for diesel equipment?

All I know is that fuel consumption is from two liters per hour and above. It would also be interesting to hear what people in the know have to say.

Uv Semyon, we don’t have mains gas and normal voltage, only liquid fuel remains, because you need to heat when there is no one at home, if there was someone all the time, you would heat with firewood

The fact is that you will need electricity in any case for the operation of automation and pumps.Simply, my personal opinion is that you can find an alternative to diesel fuel in the absence of main gas. It will be more environmentally friendly and cheaper to maintain. Unfortunately, it is impossible to write in detail here, they will consider it as advertising.

Cheaper to hire a stoker.

SemenSV, straight intrigued. Admit what there is an alternative to diesel fuel, in addition to gas and electric boilers. (firewood and coal do not count, as they require constant presence).

An alternative is wood pellets (pellets), which are produced by drying and hot pressing of woodworking rests without the use of binders. Moreover, the production of this type of fuel is mainly in Russia, and is used to a large extent in Europe, because. they have traditional energy sources are expensive. Due to their qualities, pellets are an environmentally friendly type of fuel, and the ash residue is no more than 1%.

Boilers on pellets are quite expensive, in comparison, for example, with diesel boilers - 2-2.5 times more expensive. But if you calculate the maintenance costs and fuel costs, then pellets are more profitable.

Everything that was written here was not on the rights of advertising, but only for clarification on the question asked.

What to look for when choosing a diesel boiler

Such a unit has a minimum of parts and components, so the diesel plant is able to work properly for a long time.

When choosing a device, you should pay attention to the following indicators:

First of all, attention should be paid to the power indicator. For a room that was built in accordance with all norms and standards of SNiP, it is necessary to take into account a boiler with a capacity of 15 kW for heating 150 sq.m. area

The material of the heat exchanger is one of the most important selection criteria. It is worth remembering here that the cast-iron element heats up longer, however, it also cools down for a longer time than a steel heat exchanger. Lightness and simplicity of execution speak in favor of steel, however, in terms of efficiency, such boilers are inferior to cast-iron models. The principle of operation of the system is single-circuit or double-circuit. A diesel boiler operating on one circuit will fit well in a larger cottage, the heat generated by the boiler is enough to heat the entire area. In the layout, it is best to use a separate boiler to provide hot water. Double-circuit boilers are most often installed in small houses, which is economical and reasonable. With such a device, there is enough power for heating and for providing the house with hot water.

area. The material of the heat exchanger is one of the most important selection criteria. It is worth remembering here that the cast-iron element heats up longer, however, it also cools down for a longer time than a steel heat exchanger. Lightness and simplicity of execution speak in favor of steel, however, in terms of efficiency, such boilers are inferior to cast-iron models. The principle of operation of the system is single-circuit or double-circuit. A diesel boiler operating on one circuit will fit well in a larger cottage, the heat generated by the boiler is enough to heat the entire area. In the layout, it is best to use a separate boiler to provide hot water. Double-circuit boilers are most often installed in small houses, which is economical and reasonable. With such a device, there is enough power for heating and for providing the house with hot water.

These are the most important parameters to consider when choosing an installation.But among other things, you need to carefully look at different manufacturers. European models of boilers are distinguished by their efficiency and reliability. However, their stable operation most often requires high quality diesel fuel. In some cases, it would be much more reasonable to purchase an inexpensive Russian boiler that will serve without trouble for many years, providing the house with heat even during severe frosts.

Advice. The fact that their maintenance and repair is much cheaper than expensive parts and components for boilers from European manufacturers also speaks in favor of Russian-made diesel boilers.

Equipment classification

Depending on the requirements for the equipment, a specific model of the boiler is selected. Characteristics that are important when choosing a heating boiler:

- power;

- combustion type;

- material for the manufacture of the heat exchanger;

- fuel consumption;

- additional possibility of heating water.

View of a liquid fuel boiler from the inside

Power

The efficiency of diesel fuel consumption and the efficiency of the unit depend on the power consumption. The generally accepted unit for measuring power is kilowatts. This characteristic is necessarily reflected in the documentation attached to the boiler.

The selection of the model by power must be carried out based on the area of \u200b\u200bthe heated room of the house. The calculation of the required power is quite simple: the area of \u200b\u200ball rooms is summed up, and the resulting amount must be divided by 10. This formula determines the power of the boiler for a house located in a temperate climate.

This calculation method is suitable for rooms in which the ceiling height is not more than 3 m.If the building is located in an area with a cold climate, then the calculated power of the unit must be increased in the range from 20 to 30%.

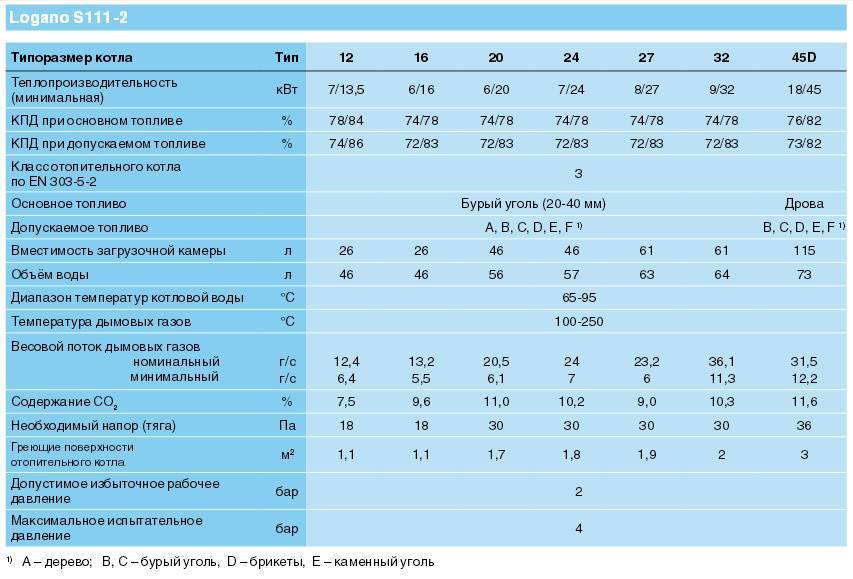

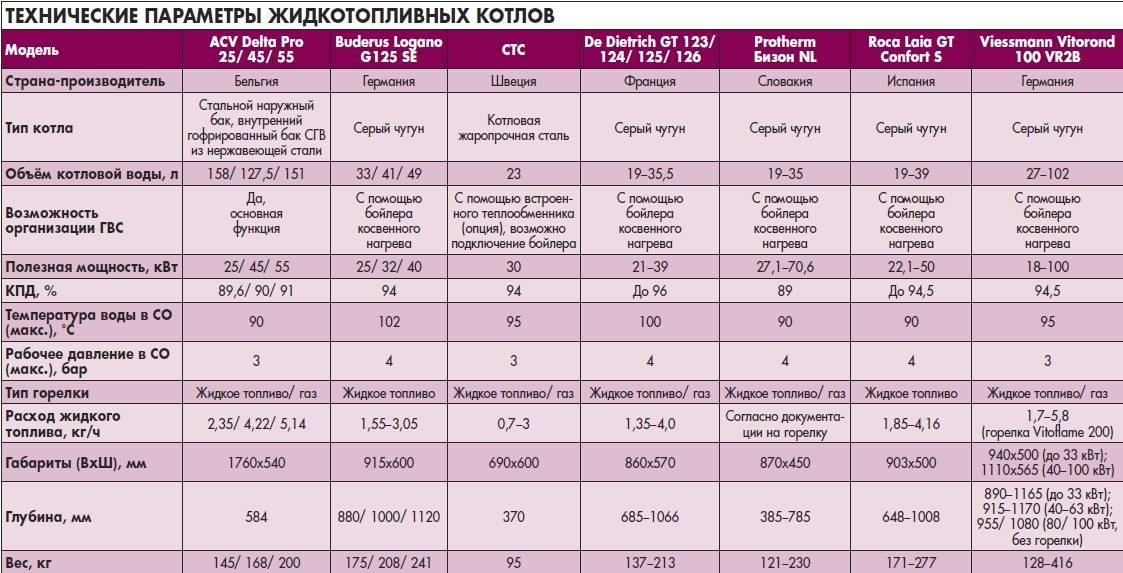

Comparison of the power of boilers of different types in the table

Determination of fuel consumption

Diesel heating of a private house requires a significant consumption of diesel fuel. This indicator depends on the power of the boiler equipment. You can calculate the amount of fuel using the formula: divide the boiler power by 10. The resulting quotient is the hourly fuel consumption (in kilograms) during heating.

In the keep warm mode, fuel consumption is significantly reduced. How economically diesel fuel will be spent at the same time depends on the quality of the thermal insulation of the building. With a weak one - a decrease in the volume of consumption will occur by a third, with a good one - up to 70%. The average fuel consumption for a private house usually ranges from 500 to 900 grams.

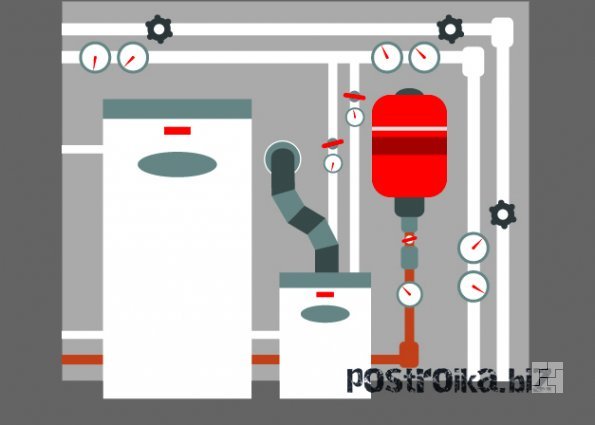

Boilers for heating and heating

Diesel boilers can serve not only for heating the house, but also for heating water. Devices that combine both of these functions are called dual-circuit.

If you need just such an option, the calculated power must be increased by a fifth. This factor must be taken into account immediately. Otherwise, the power of the diesel boiler may not be enough for both water heating and heating.

Heating system for home heating and water heating

Heat exchanger: choice of material of manufacture

The material of the boiler heat exchanger is one of the important parameters. In the process of fuel combustion, soot is formed, which, when combined with condensate, leads to corrosion and failure of the unit. Each heat exchanger material has its strengths and weaknesses, including resistance to corrosion and temperature extremes.

Cast iron

The heat exchanger made of cast iron has a higher resistance to corrosion compared to steel. But at the same time, it can crack from a temperature difference. Cast iron is heavier than steel and is more expensive.

Steel

The steel case is lighter and cheaper than cast iron, is resistant to temperature extremes, but is subject to corrosion. Stainless steel has the best performance. But such a boiler will cost more.

When choosing a diesel boiler, you can build on financial opportunities, but do not forget about the quality and duration of operation.

Heating principle

According to the principle of heating, diesel fuel boilers are of two types:

- condensation;

- traditional.

Condensing ones are more efficient, since additional energy from condensate is used. This allows you to use fuel more economically. The price for this type of boiler is higher.

5 Kiturami TURBO HI FIN 13

The most popular oil-fired boiler for the home is the Kiturami TURBO HI FIN 13 model. A heater with an efficiency of 90.8% can not only generate heat for a building of 150 square meters. m, but also to supply residents with hot water. The low price does not affect the quality of the device, all parts are made of high quality durable materials. There are a number of options that increase comfort during operation. You can control the boiler using the remote control, and the functions of absence and presence, shower mode, on-timer are responsible for the economical consumption of diesel fuel. The need for maintenance is determined by the built-in self-diagnosis system.With a long absence from the house, the device can maintain a minimum level of heat thanks to the anti-freeze option.

Owners of private houses consider diesel boiler Kiturami TURBO HI FIN 13 is an inexpensive and economical heating device. The negative quality of the model for many users is noisy work.

Servicing the heating device

It is necessary to service the diesel fuel boiler regularly and this can be done at home with your own hands. Basically it consists in cleaning the burner. The burner component is a fuel filter, it must be cleaned as it becomes dirty. It depends on the quality of the fuel. Sometimes this should be done once a week.

Cleaning the chimney is also very important for the normal operation of the heating boiler. It can be carried out less frequently than cleaning the burner, approximately 2 times per season. Chimney cleaning can be done by hand.

Ignition electrodes, which may be supplied with the burner, must also be cleaned 2 times a season. This should be done with a swab soaked in solvent. The nozzle that makes up the burner cannot be cleaned. If it gets dirty, you need to change it (this can be done at home with your own hands, since this is not a difficult process). If the replacement is not done on time, then the burner does not function well. And as a result, low efficiency and poor operating parameters of the unit for heating. In some heating models, you need to change the nozzle in the burner once a season. In order not to adjust the burner again, you need to install the same nozzle as before.

Sometimes, after cleaning the filters and replacing the nozzle, the burner does not start the first time. This happens because the lines are not filled with fuel. It is necessary to turn the burner on and off several times, and it will start.But still, if the fire does not light up, you need to make sure that the fuel is of high quality without impurities, water.

There are several reasons why the burner does not work:

- Fuel is not supplied to the heating boiler;

- Air does not enter. If, when the heating boiler is turned on, there is no noise from the operation of the air pump, this means that it does not work;

- No spark. This problem can occur if the ignition electrodes are too clogged or the distance between them is incorrect;

- Too much oxygen enters the system. The instructions for using the burner indicate which parameters to change in order to restore normal air supply. This can be done by hand. But this will only help if all the components are in order.

The solar heating boiler is made of steel or cast iron. Models made of cast iron are considered to be of better quality heating installations. Since the operation of the cast-iron unit (in particular the burner) is much longer, and it is not afraid of corrosion that occurs from the appearance of condensate.

Rice. 4 Model with cast iron heat exchanger

Rice. 4 Model with cast iron heat exchanger

A steel heating boiler, of course, is cheaper and lighter, but it also breaks down faster. At the same time, corrosion processes shorten the service life.

For me, a diesel boiler is beneficial

I constantly read negative reviews about diesel boilers, and so I want to dissuade everyone. It has been in the country for many years, there are no problems with it. The house is large, two-story, with an area of approximately 145 sq.m. in winter he eats no more than 12 liters per day, while at home Tashkent. A year ago, I spent 3 kW underfloor heating and a couple of converters, each 1 kW, and so the fuel consumption was reduced to 6 liters per day. At the same time, the temperature outside reaches -25 C.I take fuel on a call, a fuel truck arrives and pours as much as you need into the tank, if you take more than 500 liters, then delivery is free.

The boiler is made of steel, power is approximately 25 kW, double-circuit model. We live with my family in the country only on weekends, the house is completely heated in an hour of boiler operation. So I can say with confidence that he has more than enough power. In general, I am satisfied with the boiler.

+ Pros: Fast warm-up, simple and convenient

Cons: None for me

Fuel consumption

The main reason for the widespread use of boilers that consume diesel fuel is its low consumption. When calculating the power of the appliance, it should be based on the energy consumption required to heat the water. The approximate consumption of a diesel heater is 10 kilowatts per liter of fuel if the efficiency is 91 percent. The cost of diesel fuel today is about 32 rubles, therefore, this is how much every 10 kilowatts of energy will cost.

Now let's compare how much power is required for electric boilers. The efficiency of this equipment is on average 95 percent. The cost of 1 kilowatt of electrical energy is 5 rubles, which means that 10 kilowatts will cost about 50 rubles. The conclusion is obvious: a diesel heating boiler has about half the fuel consumption.

Note! If diesel fuel is used as fuel, then the calculations should be made as follows. The burner power must be multiplied by the indicator = 0.1

This will allow you to calculate the amount of fuel consumed per hour of operation. Tellingly, the result of these calculations is measured in kilograms.

Let's take a small example.Let's say the area of the heated room is 200 square meters. And to heat such a room, you need a diesel boiler with a capacity of 20 kilowatts. We multiply this figure by the 0.1 indicator mentioned above and get 2. It turns out that this is how many kilograms of diesel fuel the unit needs for an hour of continuous operation at maximum power. If we talk about consumption per day, then in this case it will be equal to 48 kilograms. Everything is simple.

The duration of the heating season is on average one hundred days per year. During all this time, the heating equipment will operate at maximum power, so it will need the amount of fuel (we have diesel fuel) to the maximum volume. For all one hundred days, the boiler uses 4,800 kilograms of fuel.

Norms and requirements for a boiler room in a private house

We advise you to read our guide on what requirements must be met in order to equip a boiler room in a private house, see the details here

As you can see, despite the fact that the cost of electric and diesel appliances is different, the amount of thermal energy in both cases is almost the same. The conclusions are obvious, there is nothing special to talk about. And if you want to save on heating, you can safely purchase a diesel boiler!

Note! As you know, when diesel fuel burns, a large amount of soot and soot is formed as a result. And if the thickness of soot deposits is, for example, 2 millimeters, then fuel consumption will increase by about 8 percent because of this.

For this reason, it is recommended to periodically clean the heater.

How to reduce the consumption of diesel fuel for heating a house

But very quickly, the cost of diesel fuel was pulled up to the cost of gasoline, and now it costs more than 95th gasoline.

First, I started heating the house more with a wood-fired boiler during the day when I could afford it. The TT boiler stood in parallel with the diesel fuel, and thus the consumption of diesel fuel became noticeably lower.

Secondly, I began to "look for fleas" in the insulation of my home. And there were a lot of them. When you have cheap fuel, you don't think about it.

But when heating becomes prohibitively expensive, you begin to look differently at the cracks in the windows, at the unused heat from the warm air removed through the ventilation and at the blowing of the front doors.

As a result, the windows in the house were replaced, a recuperator was installed and an external vestibule was built to the front doors.

I am now looking at fuel consumption after these events and I see that I managed to reduce the consumption of diesel fuel by almost 2 times.