- Varieties of gas hoses

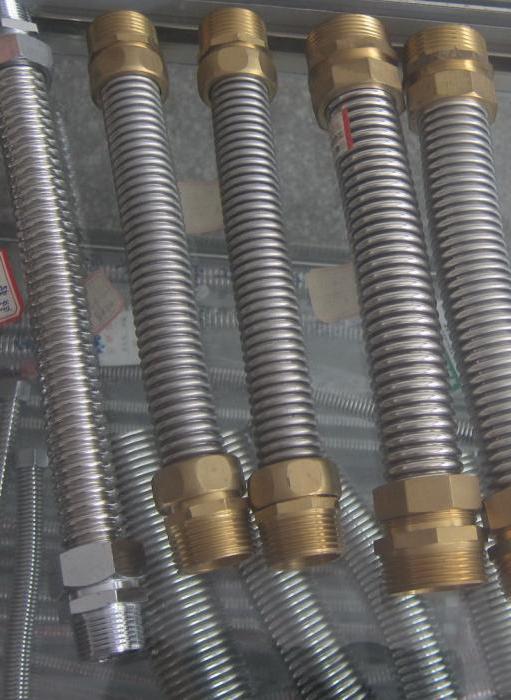

- Bellows gas hose: best for gas stove

- Main advantages and disadvantages of using bellows hoses

- Correct installation

- Choice of gas fittings

- For steel pipes

- For polyethylene pipes

- For metal-plastic pipes

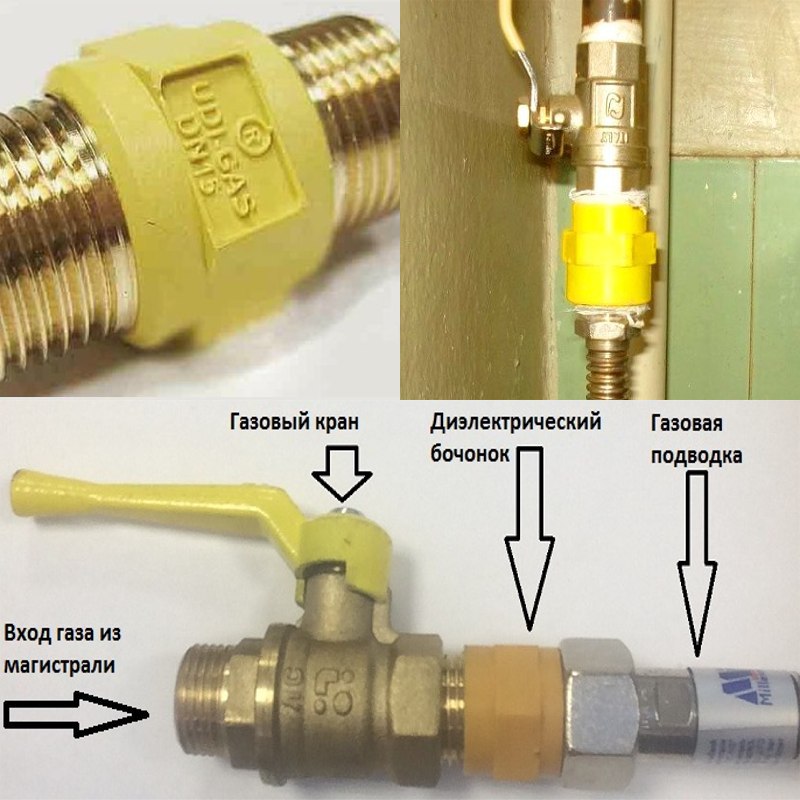

- Types of dielectric cut-offs

- Option #1 - bushings

- Option #2 - Couplings

- The procedure for installing a dielectric on gas

- The purpose of the dielectric coupling for gas

- Service life of gas hoses

- Hose connections

- Metal-plastic for gas

- Installation rules

- Gas hoses for gas stoves: which one is better, the main rules for choosing

Varieties of gas hoses

If we consider gas hoses, then we should divide them into three varieties, which differ from each other in the material of manufacture. Thus, bellows eyeliners can be found on sale; rubber sleeves, which are supplied with a metal braid; as well as rubber-fabric elements. Flexible eyeliner based on rubber-fabric sleeves is the softest, this quality can be called negative, since the mechanical rigidity is at a minimum level. The advantage is that rubber products are not able to conduct electricity. Metal braided hoses are more common today among consumers.The reason for this popularity is expressed in low cost. Such a gas sleeve differs from water connections in that a yellow stripe can be found on its surface. The bellows-type flexible hose is characterized by maximum rigidity and reliability among other types of hoses. For such a product, you will have to pay the highest cost, the regulatory documentation recommends the installation of products of this type. This is due to the fact that such a material perfectly copes with the effects of high pressure, which is created by a gas stream.

Bellows gas hose: best for gas stove

If you ask a specialist what kind of hose for a gas stove should be, most likely, he will offer to purchase exactly the bellows version for installation. It is this type of hose that is considered the most reliable for connecting the hob to the central gas supply. In addition to gas stoves, it is used to connect columns and gas boilers used for individual heating. The bellows is an elastic corrugated shell that protects the inner layer from mechanical and other types of damage.

The high demand for bellows hoses is due to the high technical characteristics and reliability of the devices. Products easily tolerate high pressure, which is created by the gas flow in the pipe. Ease of connection is provided by two fittings designed for connection to the gas pipe and directly to the device. All components of the hose are made of high quality stainless steel, which guarantees maximum service life.

The bellows gas hose is considered the most reliable for connecting the hob to the central gas supply.

The price of a gas hose for a gas stove of this type is much higher than the cost of other product options, but the service life is at least 10 years longer than the service life of other devices. So, the minimum time during which you can safely use a bellows hose is 25 years, although some companies give a 30-year warranty. The final price is usually influenced by the manufacturer and the size of the product.

You can find out how much a gas hose for a gas stove costs (depending on the characteristics) from this table:

| Connector diameter, inch | Length, m | Price, rubles |

| 1/2 | 0,4 | from 250 |

| 0,8 | from 290 | |

| 1 | from 320 | |

| 1,5 | from 400 | |

| 3 | from 780 | |

| 4 | from 950 | |

| 5 | from 1150 | |

| 3/4 | 0,6 | from 350 |

| 1 | from 450 | |

| 2 | from 700 | |

| 2,5 | from 900 | |

| 3 | from 1050 |

Main advantages and disadvantages of using bellows hoses

Simple models of bellows hose are presented in the form of corrugated products, which are distinguished by the presence of a round section. If you choose a more expensive option, then additionally for protection there will be a metal sleeve or a polymer coating. The modernized version of the bellows hose has a built-in thermal protection valve, which automatically shuts off the gas supply when the temperature rises critically. Of course, this option will also affect how much the hose costs, but the losses that can be incurred in the event of a gas leak will be much higher. Other advantages of bellows hoses:

- easy to bend and stretch;

- withstand loads up to 6 atm.;

- are operated in a wide temperature range from -50 to +200 °С;

- are made of high-quality materials that comply with all GOST standards;

- meet the technical requirements of domestic use;

- the maximum possible service life is up to 30 years from the date of installation;

- withstand the influence of electric current up to 1.5 kW;

- a large selection of hose lengths for connecting a gas stove - from 0.4 to 5 m;

- compatibility with most types of gas equipment and various fittings;

- the presence of a coating that protects the base of the hose from the effects of various household chemicals used for cleaning and disinfecting the kitchen.

Simple models of bellows hose are presented in the form of corrugated products

Additional safety of the hose is provided by an electrically insulating polymer layer that protects not only from mechanical stress, but also from high-frequency currents that are created by some household appliances, such as a microwave oven. Due to the strength of the hose, manufacturers guarantee the integrity of the connection even under the condition of natural anomalies, such as an earthquake, when the stability of the building is violated.

The relative disadvantages include only the price, which is several times higher than the cost of similar products from other groups. However, the presence of a large number of positive characteristics, which include a significant service life, cover this drawback.

Correct installation

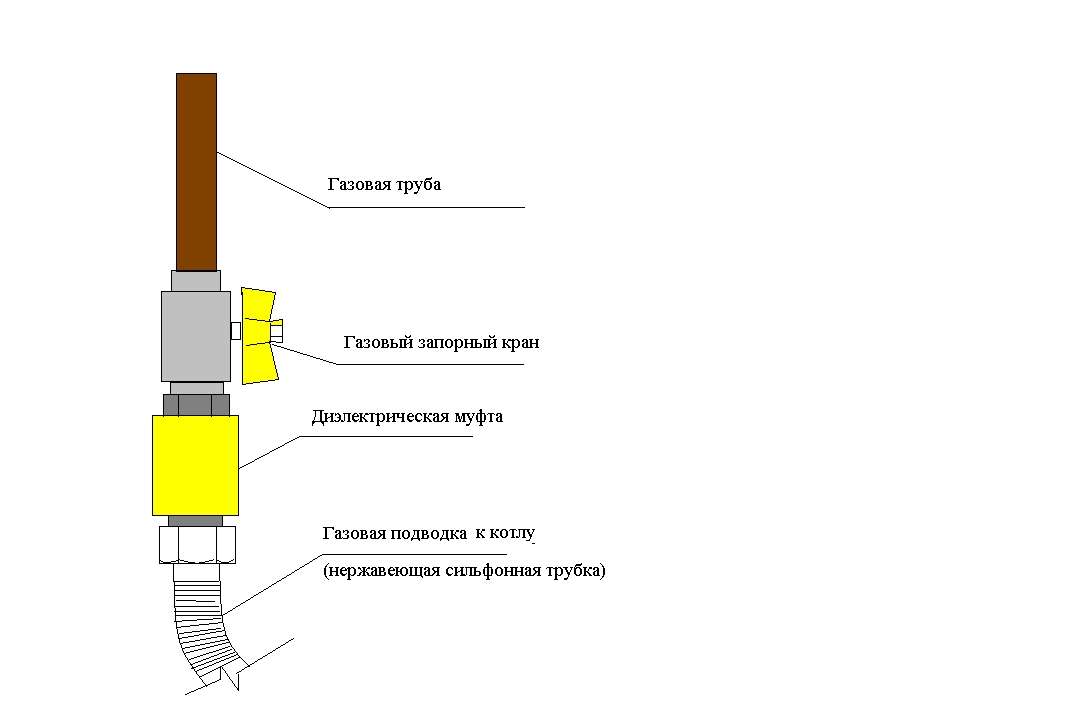

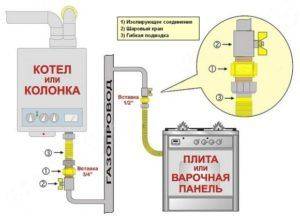

Installing a dielectric insert in a gas pipe

Installing a dielectric insert in a gas pipe

An insulating sleeve or gas insert must be inserted between the gas cock and a bellows or other type of connection. It is necessary to install the element taking into account safety requirements; before starting the installation, it will be necessary to turn off the tap without fail and not open it until all the necessary steps have been taken to eliminate possible leaks.Installation must be carried out by employees of the gas service who have the appropriate qualifications and access to this type of work. During installation you will need:

- Prepare a pair of adjustable wrenches, one of them is designed to hold the body from the valve, the second is to unscrew the nut from the liner connecting the tube to the gas-fueled device.

-

Install a sealant of any type, for example, polymer, on the ends of the insert, then put the dielectric inside the gas pipeline manually.

- Holding the valve with one key, tighten the second coupling or sleeve until it stops; during installation, make sure not to accidentally tear off the threaded coating and damage the element body.

- Screw the nut from the bellows-type hose to the other part of the coupling, while holding the insert with an adjustable wrench, then tighten the connecting parts as tightly as possible.

When a standard gas dielectric is installed, you will need to check the docking areas for the level of tightness. For this purpose, use a small brush or shaving brush, which is carefully lathered. Soapy solution must be applied to each supply, as well as the joint, then slowly open the gas supply valve. In the presence of foam or bubbles, the valve is closed and the joints are re-examined. It is possible to use a gas unit only after bubbles cease to form in the solution. The tightness test should never be carried out with matches or a lighter, if there is a leak, a fire can cause a gas explosion.

Connecting equipment to a gas pipe using a dielectric insert

Connecting equipment to a gas pipe using a dielectric insert

Installation of gas units and additional components is carried out with particular accuracy, since the safety of building residents directly depends on the correct connection of parts. The hoses are mounted according to the principle of open installation, the sleeves should not be hidden or covered with furniture or household appliances, the element itself, as well as the dielectric sleeve or gas coupling, must be mounted from the outside. Do not use too long or short hoses to connect the equipment, because due to pressure this part can become shorter, in addition, it must not be stretched. The sleeve may sag after joining the pipe, but it must not be twisted or kinked.

When installing a dielectric adapter for domestic gas, it must be ensured that steam or water does not enter the hose, which can provoke the oxidation of metal parts. Cooking surfaces are placed away from the gas pipelines, in the presence of atypical threads in the plates and other equipment, adapters are used for connection.

Choice of gas fittings

Various fittings for gas equipment and docking of individual elements of the system are not suitable for every pipe. Connection to the gas pipeline and its branching to the points where various devices operating on blue fuel are installed are carried out by those products that are most suitable for each other.

For steel pipes

If a steel pipe is used during the installation of the gas pipeline system, the fittings for it are taken from the same material. The element size is ½ inch, which is enough for unobstructed gas flow.

The fitting and the steel pipe are connected in two ways - threaded detachable and welded one-piece.The second method is used for joining and fastening together the structural parts of the gas pipeline by welding them with an annular seam between adjacent elements or using electric arc technology.

If it is necessary to create a temporary connection at the connection point of a gas stove or boiler, the threaded method is used. To begin with, on the pipe, with the help of a die, a squeegee with turns is cut. To ensure tightness, a sealant (fum-tape, tow) is placed over the entire area. Screw on the locknut, and then the fitting. In the same way, they make attachment points for gas equipment by connecting the fitting to the threads on it.

It is required to paint the pipe to prevent its destruction under the influence of harmful factors. Inside the room, you can choose any color, and it is customary to paint the outer areas in yellow.

For polyethylene pipes

When creating a gas supply from polypropylene pipes, plastic fittings are used, they are connected by welding. Such a system is durable and tight. To carry out all the work, you will need special equipment. During installation, adjacent elements are heated and glued together, becoming one.

To create a detachable connection, combined fittings are used, which on the one hand are a polypropylene base, on the other - a metal thread. First, one side is welded, and then the gas equipment is connected by screwing the coupling onto the coils.

Due to the need to connect pipes of different diameters, the connecting elements are produced in different sizes.

For metal-plastic pipes

When working with metal-plastic pipes, brass fittings are used, which have high strength and a long service life. As in the case of metal and polypropylene systems, fastening is carried out using a one-piece and detachable method using various products.

The most reliable and easy to use are press fittings equipped with a special capsule around the fitting.

Connection of a geyser with a gas pipeline: educational program

Types of dielectric cut-offs

Let's consider in more detail types of dielectric cut-offs.

In everyday life, two types of dielectrics are used for a gas hose or pipe: simple bushings resembling liners and threaded couplings. Consider how the inserts differ and choose the best solution for your own installation.

Option #1 - bushings

We must say right away that you will not need bushings to install a gas stove or mount a column, since they have not very many other purposes. The task is the same - to protect against stray currents.

But they are mounted where there are flange connections and bolts are used. Simply put, bushings are used for electrical insulation of flanged fasteners.

Dielectric inserts are made of polyamide PA-6. They are resistant to external influences and have a long service life.

_

Exploitation - the stage of the life cycle of an object, at which its quality is implemented, maintained and restored (healthy state). (GOST R 51617-2000)

Specifications of gas bushings:

- elasticity and high degree of adhesion to metal elements;

- ability to withstand multiple alternating loads.

- frost resistance - withstand low temperatures up to -60 ° C;

- petrol and oil resistance at temperatures up to +120 °C;

Products are marked by diameter in mm, for example, from M 8 to M 24. You can also specify the height of the shoulder and the length of the bushings there. The manufacturer indicates the diameters of suitable flanges, bolts, washers in special tables.

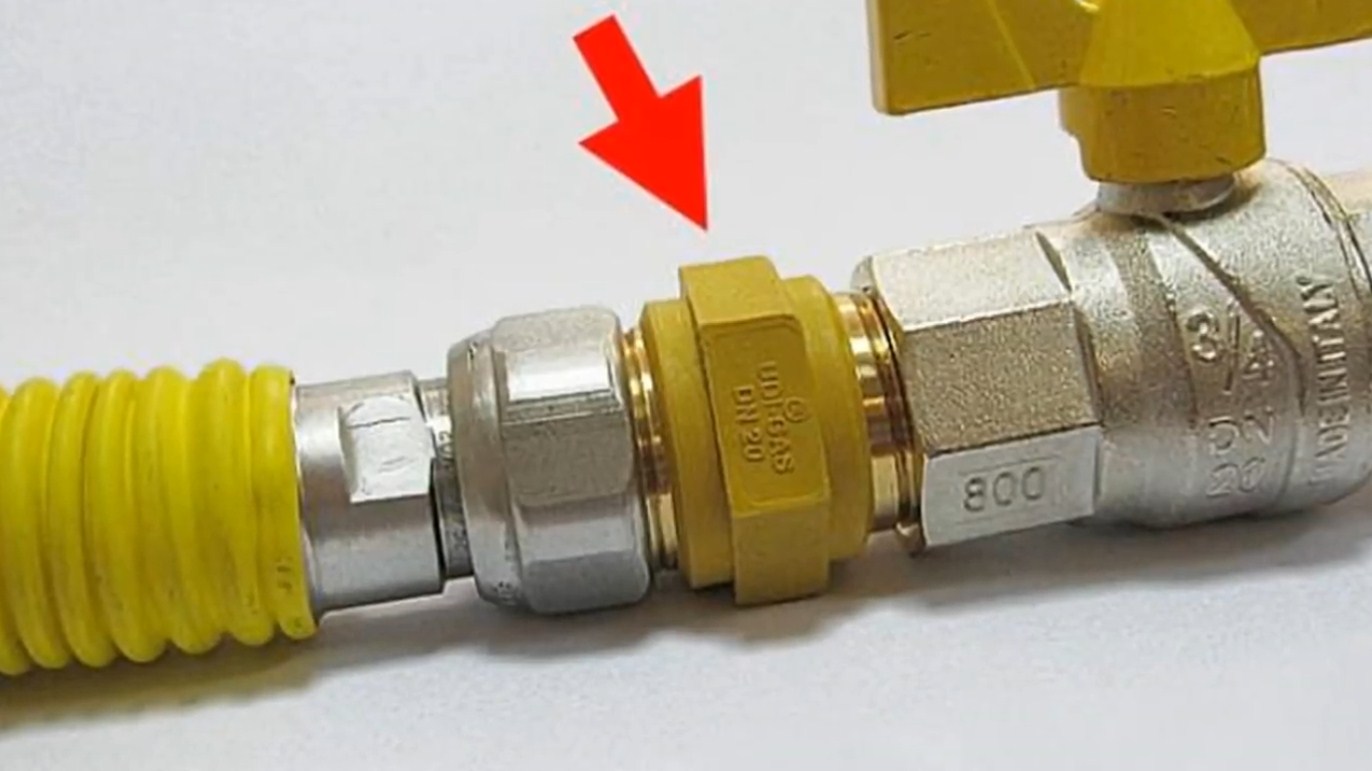

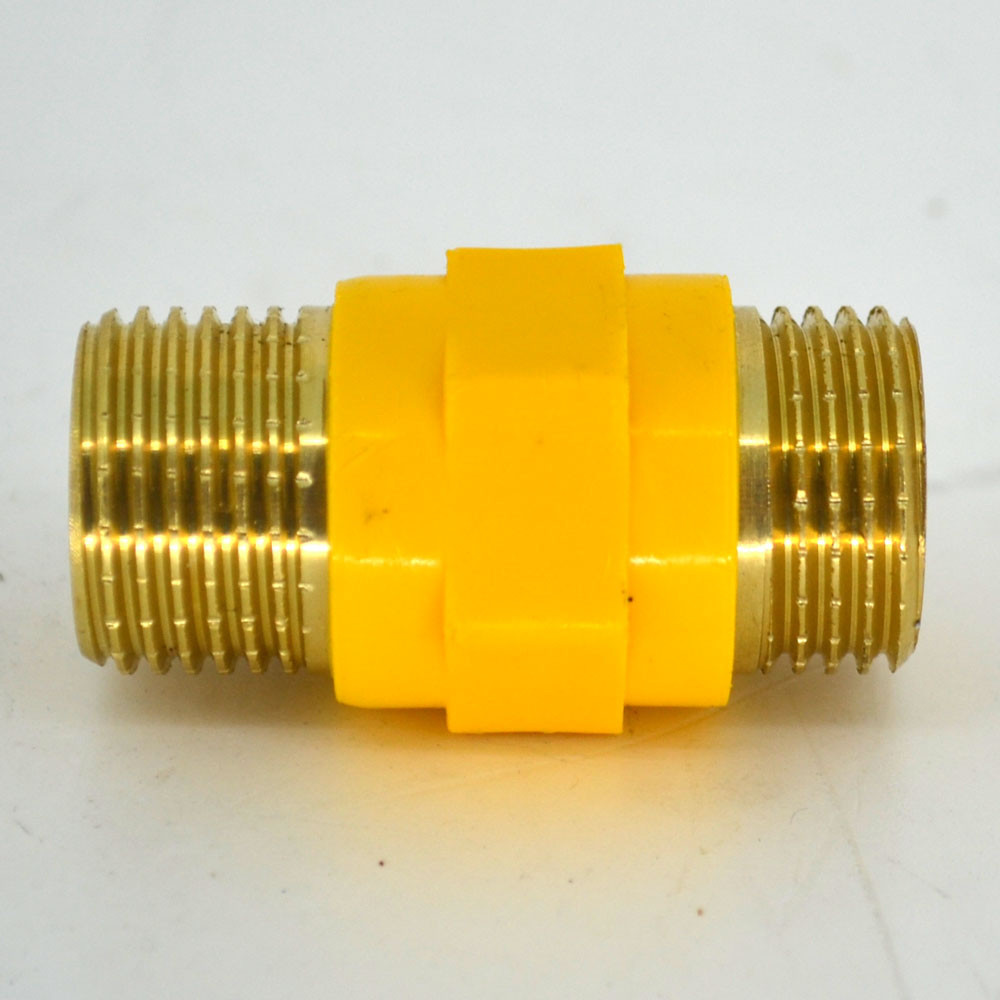

Option #2 - Couplings

Therefore, it is often called by installers that they are - couplings, universal insulating inserts for gas pipes are connected by the coupling method. They differ in the type of thread, diameter, material of manufacture, external design, but they perform the same function - they cut off the currents generated on the gas pipe from the equipment.

Inserts are manufactured in the factory in accordance with GOST or TU. They are produced in special molds in an automatic way, using screw extrusion of two materials: metal for threaded pipes, insulating polymer. The polymer material complies with the requirements of GOST 28157-89.

_

Material - any ingredients, raw materials, constituent elements, parts, etc. used to manufacture the product.

Products are designed for operation at a working pressure of 0.6 MPa, the critical indicator is 1.2 MPa. Working temperature on average - from -20 °С to +80 °С.

On sale you can find products with a black polyamide part, according to GOST 14202-69 inserts for gas belong to group 4 (combustible gases) and are marked in yellow.

It is better to purchase products of famous brands, rather than Chinese fakes, and choose products based on the following criteria:

- suitable specifications - resistance of at least 5 ohms with a sharp increase in voltage to 1000 V.

- fire safety - threaded metal elements do not burn, and plastic ones do not support combustion;

- wear resistance and durability - high-quality parts are made of brass and have a 20-year service life;

_

Combustion — an exothermic reaction proceeding under conditions of its progressive self-acceleration. (GOST 12.1.044-89)

Durability - a characteristic (parameter) of products that determines their ability to maintain performance for a given period, confirmed by the results of laboratory tests and expressed in conditional years of operation (service life). (GOST 23166-99); - housing and communal services - the property of equipment and heating networks to remain operational until the limit state occurs with the established system of maintenance and repair. (MDS 41-6.2000)

The best place to install the coupling is between the gas cock and the flexible piping.

The connection method is threaded, the device is screwed onto the pipe. Fittings can have both external and internal threads.

_

Device - a set of elements representing a single design (multi-contact relay, a set of transistors, a board, a block, a cabinet, a mechanism, a dividing panel, etc.). The device may not have a specific functional purpose in the product. (GOST 2.701-84)

Before buying a dielectric, you need to clarify the diameter of the gas pipe, as well as choose a flexible piping that is suitable in size. Therefore, do not forget to check the package contents, sometimes connection hoses are sold with the equipment.

It is constantly under the control of the gas service, which inspects the equipment annually, the insulator for gas installed for a long time and does not require maintenance.

The procedure for installing a dielectric on gas

Before any work on gas equipment or lines, it is necessary to turn off the valve to stop the flow of fuel and ensure safety. If a stove, column or boiler was used before, the burners must be left in working condition so that the remaining gas burns out.

Then we act in order:

If the flexible hose is already attached to the pipe, carefully twist the nut with a wrench

Long-established fasteners often “stick”, so you can use two keys to be sure.

We wrap a sealant on the freed end of the pipe - a fum-tape and carefully tighten the connection, first with a hand, and then with a key. We screw the coupling or “barrel” to the limit, trying not to knock off the thread and not deform the dielectric body.

In the same way, we screw the nut of the flexible liner onto the second end.

We diagnose the connection in a safe way.

Soap solution for checking the tightness of joints is used not only by users of gas equipment, but also by employees of Gorgaz. Diagnosis is simple: soap suds are applied with a brush or brush to the joints and observe what happens.

The appearance of bubbles, even small ones, indicates a lack of tightness - the coupling will have to be tightened. If there are no bubbles, the installation is done correctly and you can safely use the equipment.

Do not use open flames such as matches or lighters to check for gas leaks.

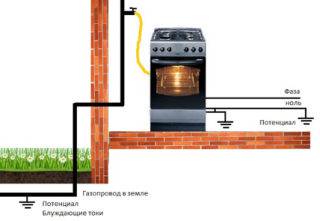

A dielectric coupling is a shut-off fitting that protects the “brains” of gas-consuming devices from the damaging effects of stray currents. That is, we have a very useful node, the effectiveness of which has been proven by the definition itself. However, many owners of gas stoves, columns and boilers, as well as employees of gas services, are not aware of the existence of such an insert. And in this material we will try to eliminate this knowledge gap by talking about the benefits of a dielectric fitting, its varieties and installation methods.

Such currents appear in the ground due to an accidental breakdown of a household or industrial power line. The source of stray voltage can be either a ground loop or an electrified railway or tram line. Such a current enters the gas pipeline due to the difference between the resistivity of the earth and the metal parts of the gas supply line. In fact, all the electricity discharged into the ground does not go into the ground (it has too much resistance), but into bare cables or metal structures. And since most of the main and household gas pipelines are made of metal, the appearance of a stray current in the system is only a matter of time.

Stray current protection

The main pipe can become a source of stray voltage in a household gas pipeline. To protect the gas supply pipeline from corrosion, the line is loaded with an electric potential of insignificant strength, which suppresses the natural process of electrochemical splitting in the structural material.And if in the common insulator separating the main from the household branch, a breakdown of the dielectric insert for gas occurs, then the useful protective potential will turn into an undesirable stray current.

In addition, stray voltage may appear in the internal gas supply line due to poor grounding of the circulation pump or other electrical appliances that come into contact with the heating system wiring or the home branch of the gas pipeline. Another reason for the appearance of such currents may be an error when installing a boiler, column or gas stove connected to the mains. As you can see, stray current is not a myth, but a real problem. And the metal structure that fell under its action turns into a serious threat to the safety of all residents of the house connected to the gas pipeline.

The purpose of the dielectric coupling for gas

Boilers and boilers are used to heat the water in the heating system. For cooking, stoves, ovens and hobs are placed in the kitchen. In the listed devices there is a system of control sensors, electric ignition, oven lighting. Therefore, the gas type of the device requires connection to the electrical network.

To prevent the current from flowing through the gas pipe indoors, polyamide insulators are used - couplings. For the dielectric coupling for gas, yellow polyamide is used due to the low content of conductive impurities.

Dielectric insulating inserts, when current enters the gas network, will maintain the performance of gas devices and gas meters.

Service life of gas hoses

The warranty period for the gas hose is indicated in the instructions for use. After its expiration, the product is replaced. Depending on the material of manufacture and the technical properties of the tubes, the following operating period is regulated:

- bellows hoses: 15-30 years, changes with gas equipment;

- rubber-fabric: 2-3 years, in the presence of the slightest defects, the product requires replacement;

- reinforced: up to 10 years, high-strength materials are used in their composition;

- oxygen: up to 5 years, more often used to connect liquefied gas cylinders;

- rubber with a metal braid: up to 10 years.

Various factors affect the service life: correct installation, correctly selected characteristics of hoses, quality of products.

Hose connections

To perform gas wiring, you can use not only pipes, but also rubber hoses. However these must be special two-layer hoses made of vulcanized rubber

. Between their layers there should be textile reinforcement. These hoses are used when connecting a torch or torch to gas cylinders.

As fittings connecting gas hoses, fittings of the required diameter are used. The hose must be pulled onto the fitting with force and secured with an aluminum clamp.

To facilitate the assembly of a gas supply made with a hose, grease must be applied to them before connecting the hoses. The same substance will seal the connection.

In the process of connecting the reducer to the gas cylinder, a connection consisting of a union nut and a gasket is used. As a rule, in this case, a gasket made of fluoroplastic is used.In case of loss of the latter or its destruction, vulcanized rubber can be used instead.

Metal-plastic for gas

Metal-plastic pipes can also be used for gas supply. From the inside, pipes of this type are polyethylene already familiar to us.

Due to the fact that metal-plastic pipes are supplied in coils, it becomes possible to lay a sufficiently long gas pipeline without using a large number of connections.

If the pipes still need to be connected, then only press fittings must be used. With their help, it is possible to ensure the tightness of the connection, which will retain its properties for a long time. However, a special device is required to make such a connection.

Installation rules

The assembly of protection units is carried out at the factory. When installing the unit on an existing gas pipeline, all safety requirements and technical rules of work with gas installations.

insulating insert

insulating insert

The finished unit is tested for resistance and tightness in the laboratory, which is recorded accordingly. Installation is carried out by welding, after which the quality of the electrical separation of the sections is checked. The evaluation criterion is the value of electrical resistance, which should be at least 5 ohms and provide a voltage drop of at least 5 mV when measured at different ends of the flanges.

The finished connection is isolated from possible contact with the ground or structural elements using aprons, boxes or similar means.

The acceptance of an insulating connection into operation is documented by a corresponding entry in the log and a certificate.

Gas hoses for gas stoves: which one is better, the main rules for choosing

The main rule when choosing a gas hose is to purchase a product in a certified store. If the seller cannot provide a quality certificate and does not give any guarantees, you should not buy a product in such a place. Typically, retail outlets provide a large selection of gas hose sizes for gas stoves.

It is important to pre-take all measurements and buy a product of the desired length, because it is not recommended to splice two products together

It is important to pre-take all measurements and buy a product of the desired length.

To reduce the risk of rupture of the eyeliner, it is not recommended to choose a length where the hose will be in constant tension after installation, as this may adversely affect the life of the product. The maximum length of the gas hose for a stove in an apartment should not exceed 2-2.5 meters, although there are various sizes, including 4 and 5 meters. Additionally, you need to make sure that the product not only does not stretch during installation, but it didn't sag too much.. Only the correct length of the hose guarantees safe connection and proper operation.

Another important indicator is the diameter of the hose section. Here you need to know that the minimum size that ensures the normal flow of gas to the device is 1 cm. At the same time, two nuts or one fitting and one nut must be present at the ends of the product. It must be taken into account that the nut is distinguished by the presence of an internal thread, while the fitting has an external thread. The cross-sectional diameter must be selected depending on the size of the outlet on the gas appliance.For ease of installation, there is a fitting-corner, which simplifies the connection process.

The most budgetary type of hose is a rubber-fabric product. It should be noted that by choosing this option, you need to constantly monitor its integrity - if necessary, you can use a soap solution, which makes it easy to detect a leak. If even the slightest violation of the integrity of the product occurs, the product must be replaced. The best options for combining price and quality include reinforced PVC hoseswhich also have a long service life.

In any case, the most reliable and safe is the bellows hose, which has received official approval from the state gas services for use in domestic conditions.

When choosing this type of product, it is imperative to pay attention to the type and quality of the connection.

The main rule when choosing gas hoses is to purchase products in certified stores

It is very important at the time of purchase to be able to distinguish the original product from the Chinese fake, which is why it is recommended to choose goods in specialized stores. In order not to purchase a fake, the hose should be carefully examined for defects, and also study the passport attached to the product.

You should also familiarize yourself with the price range so as not to buy a hose with a suspiciously low cost. The most important thing is to inspect the product for integrity.