- Preparation for disinfection treatment

- Well cleaning

- How to dilute bleach for disinfection

- What to do after the end of disinfection?

- How to clean and disinfect blooming water

- Boiling

- Potassium permanganate (potassium permanganate, KMnO4)

- Iodine

- Hydrogen peroxide

- Salt

- How to disinfect the source

- Preparing the well for disinfection

- Disinfection of the well with chlorine-containing products

- Water disinfection with chlorine-free preparations

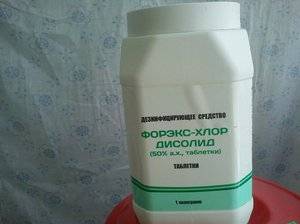

- The use of tablet preparations

- Prevention

- Septic tanks with soil aftertreatment

- The frequency of disinfection and the use of water after this event

- Cleaning systems for private houses and cottages

- Rough cleaning

- Non-pressure scheme

- Fine cleaning

- pressure system

- Reverse osmosis

- How to clean from lime

- Physical methods of disinfection

- Areas of application of bleach

- household needs

- Water and wastewater treatment

- public places

- Hypochlorites in medical practice

- Disinfectant qualities of chlorine

- Well disinfection

- Measures to prevent source pollution

Preparation for disinfection treatment

Preparatory work is recommended to be carried out without fail immediately before the disinfection procedure. The speed and quality of disinfection treatment largely depends on the correct preparation.

First of all, it is necessary to pump out the water.If there is not enough water in the well, then it will be enough to use a surface pump.

If the water level is significant, then a powerful submersible pump will be required. Before starting the pump, floating debris must be removed from the well; a long-handled net with a fine mesh is best suited for this purpose.

After pumping out the water, a descent into the well is carried out and its bottom and walls are inspected for cracks, leaks, deposits.

If there are cracks, they must be repaired with a special waterproofing solution. It also removes debris, algae, silt from the walls of the well.

Image gallery

Photo from

The quality of water extracted from a well can decrease not only in old structures

A well with a silty bottom, in which algae has appeared, must be cleaned before disinfection and a new bottom filter should be laid

If the decrease in water quality is associated with a violation of the tightness of the walls, it is necessary to carry out repairs before disinfecting the source.

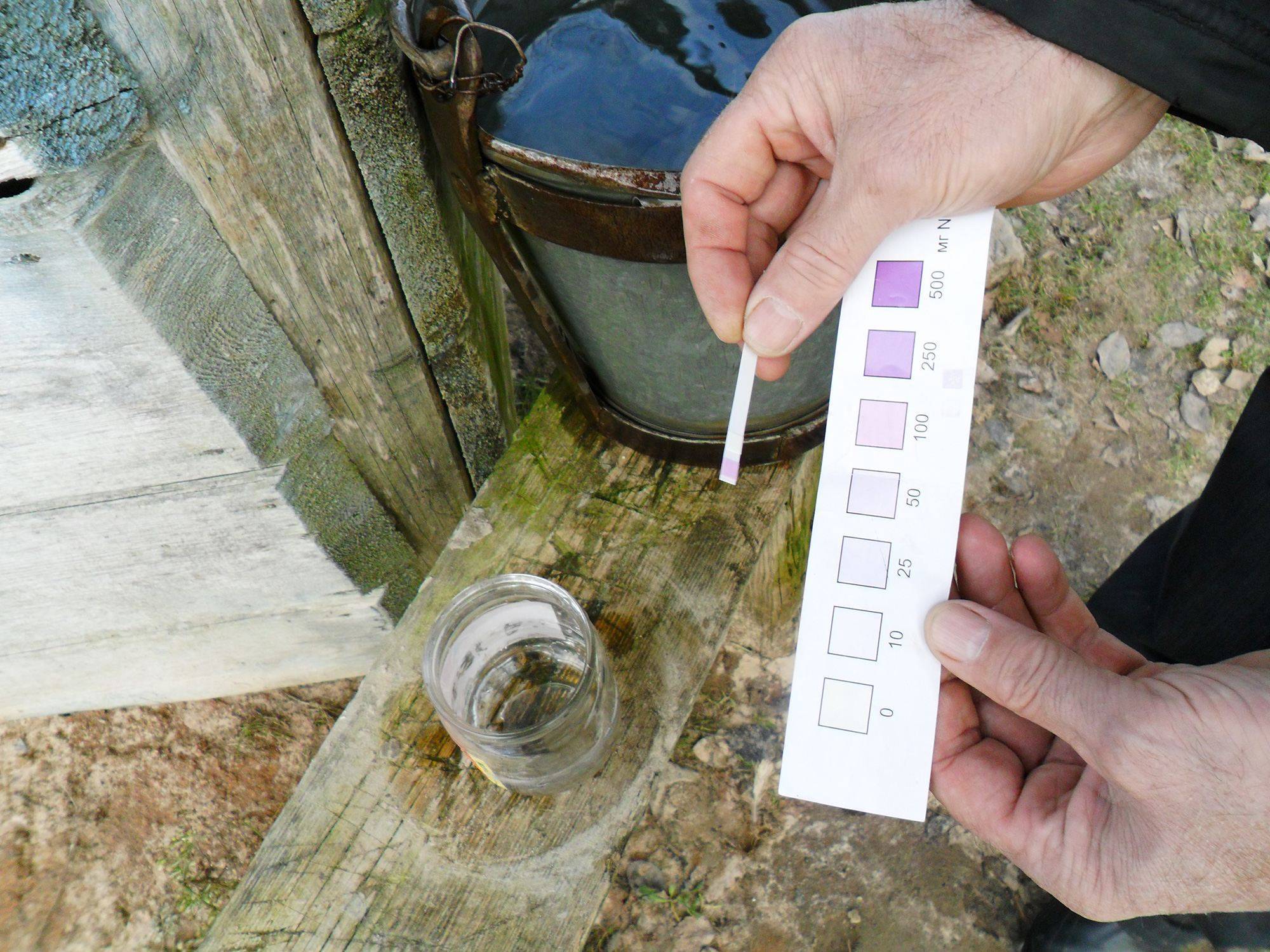

After the disinfection and emptying of the shaft, the water should be checked for the content of chemicals in it 2-3 times. If there are excesses, pumping is carried out several more times, then the sample is carried for analysis to the SES

Poor quality of water from the well

Do-it-yourself well cleaning

Wall repair before disinfection

Checking the composition of water for acidity

The tools used are hard brushes, spatulas. The bottom of the well is cleared of sediment, as far as possible, the old bottom backfill is removed and a new one is filled up.

Fine crushed stone, gravel, sand can be used as bottom backfill. Expanded clay cannot be used because of its too low specific gravity and high toxicity.

If there is plaque on the concrete rings, it should also be removed. For this, various substances are used, the composition of which depends on the nature of the deposits.

Salt deposits are removed with acidic solutions, such as a weak solution of hydrochloric acid or vinegar.

It is recommended to carefully remove corrosion spots with a jackhammer or grinder, and treat the surface with a waterproof anti-corrosion compound. In the presence of moldy deposits, treatment with copper sulphate is required.

Before the disinfection procedure, it is necessary to thoroughly clean the shaft and the bottom of the well from debris and various deposits using special tools.

Well cleaning

So, let's take a closer look at how to get rid of the smell of water in the well. At least once a year it is necessary to carry out preventive cleaning of water. Thanks to this, it will be possible to avoid many problems with water supply, and therefore with health. If this is not done, then mucus may appear quite quickly. It is she who is the expanse for the rapid reproduction of harmful bacteria. In addition, debris and silt can settle at the bottom of the well. As a result, the quality of well water deteriorates.

The procedure consists of several stages:

- Disinfection with special preparations. It is used strictly with the instructions in the attached instructions.

- The water is pumped out with a pump.

- The well is cleaned from various deposits using a mechanical method, that is, with your own hands.

How to dilute bleach for disinfection

First you need to prepare a mother solution, which is then used for disinfection, but not in its pure form, but diluted.

To prepare a solution of 10% concentration, you must:

- Mix 1 kilogram of bleach powder with water, in the amount of 2 liters.

- Stir with a wooden spatula.

- Bring the volume up to 10 liters.

- Seal tightly and place in a dark place.

- Stir occasionally for 4 hours.

- Leave for one day (24 hours).

- After the time has passed, strain through cheesecloth, folding it into several layers.

- Do not use the formed precipitate.

- Pour into a dark glass bowl.

Store the stock solution in a well-ventilated area in a tightly closed container. This is due to the fact that bleach tends to weather and lose its property. The shelf life of the mother liquor is up to 10 days.

To enhance the properties of chlorine for disinfection, you can use ammonia, which is added to the bleach solution. This mixture has the best bactericidal properties and is most effective.

What to do after the end of disinfection?

After the end of the disinfection procedure, which was carried out using chlorine-containing products, it is recommended to follow the following recommendations:

- Do not use well water for the first 24 hours after disinfection is complete.

- For 5-10 days it is necessary to boil and / or pass water from the well through the filter before use.

- If there is a smell of chlorine in the water, then a complete pumping of the well is required.

- It is advisable to conduct a chemical analysis of well water to assess the quality of treatment and confirm its safety.

For a more thorough analysis of water from a well, visual inspection is not enough; it is necessary to conduct a study of the chemical composition in the laboratory

How to clean and disinfect blooming water

"Water bloom" is caused by blue-green algae.This water is the hardest to clean. Some of these algae are capable of producing toxins that are dangerous to human health.

The method of water purification from toxins is the same as for other “chemical” contaminants: activated carbon filters, followed by disinfection from bacteria and other microorganisms.

Boiling

In this case, boiling water is simply necessary! At a temperature of 70C, most microorganisms die within 30 minutes, at temperatures above 85C - within a few minutes.

Boiling is a very reliable method, but in extreme conditions it may not be very convenient.

Potassium permanganate (potassium permanganate, KMnO4)

To purify water with potassium permanganate, you need to add a couple of crystals of the substance to 3-4 liters of water. Water should acquire a light pink hue (a bright color is unacceptable, such a solution can be harmful to health).

The advantages of this method of water disinfection are: high efficiency, low cost, compactness and low weight. KMnO4 is a strong oxidizing agent, therefore, it not only destroys bacteria, but also neutralizes a number of toxins (waste products) secreted by these same bacteria. However, today, potassium permanganate is extremely difficult to find in pharmacies.

Iodine

The method is emergency, but in a critical situation it can help, since iodine can be found in almost any first aid kit.

The method of disinfection is simple: 10-20 drops of a 10% alcohol solution of iodine are added to 1 liter of water (less is possible, but this dosage may not be effective enough). The amount of iodine must be determined visually, based on the degree of water pollution.

Iodized water should be allowed to stand for 20-30 minutes in summer, an hour or more - in the cold season. For guaranteed destruction of especially tenacious and dangerous bacteria, a longer time is required (up to 4 hours).

Such water is not very healthy and tastes unpleasant. To get rid of the taste of iodine, it is recommended to pass water through a carbon filter or add activated carbon to it (the latter is less effective). You can also crumble ascorbic acid into water (iodine easily oxidizes it).

Hydrogen peroxide

Another popular way to disinfect water is to use hydrogen peroxide for this purpose. It is also an "emergency" disinfection method. Hydrogen peroxide is able to disinfect water from protozoa (giardia and cryptosporidium), bacteria, viruses.

Method of application: it is necessary to add one tablespoon (in case of severe pollution - 2 tablespoons) per liter of water, let stand for 1 hour. To purify water from peroxide residues, as well as to accelerate its decay, add a couple of tablets of activated charcoal to the water.

The advantages and disadvantages of this method are the same as for other medicines - you have to dose "by eye". Despite the breakdown of hydrogen peroxide, the water may have a slight "medical" taste.

Salt

It can be used if no other reagents are available. It is enough to dissolve a tablespoon of salt in 2 liters of water. The solution is left to stand for 30 minutes.

Enjoy your trips and bright, positive impressions!

How to disinfect the source

Preparing the well for disinfection

Perform the following operations:

- Clear the spring of large floating debris. For these purposes, use a net with a long handle.

- Pump out all the water.

- Inspect the bottom of the barrel for cracks and gaps. If found, seal them with waterproofing solutions. Do not use cement mortars to seal cracks, they will quickly be washed away with water.

- Using a stiff brush and spatula, clean the walls of algae and silt.

- Clean the walls of deposits. Salt remove with hydrochloric acid or vinegar. Corrosive cut off with a grinder or knock down with a perforator.

- Remove the mold mechanically, and then cover the damaged area with a solution of copper sulfate.

- Remove dirt and deposits from the bottom.

- If there is a bottom filter, dismantle it and fill in a new one.

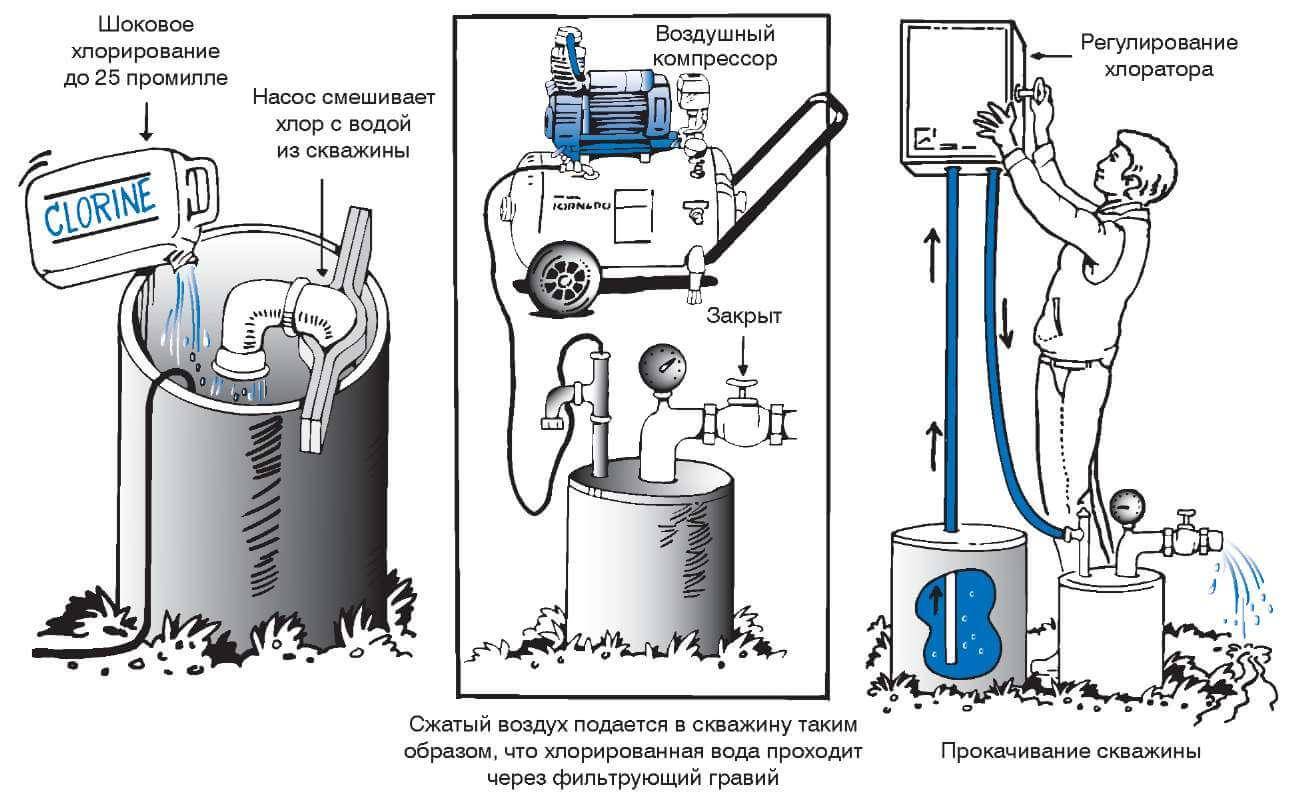

Disinfection of the well with chlorine-containing products

First you need to disinfect the walls:

- Pump the water out of the well.

- Remove dirt from the walls mechanically.

- Make a wall treatment mixture - a 3% bleach solution. Prepare the solution at the rate of 0.5 l per 1 m2 of the mine surface. Wait for the thick particles to settle. Pour the upper clear liquid into another bowl, and use the thick one for work.

- Scrub the surface with a brush or mop that has a cloth wrapped around it.

- Rinse the walls several times with clean liquid.

The second stage of source disinfection is water purification:

- Dilute 20 g of 1% lime powder in 1 liter of clean cold water. Do not use hot Chlorine evaporates quickly and becomes very toxic. During the operation, follow the safety rules, make sure that the liquid does not get on the naked body, eyes.

- Prepare 3 containers of 200 ml. Fill them up with water. Add 2 drops of lime mortar to one jar, 4 to the second, 6 to the third. Stir the contents of the jars and do not touch them for half an hour.

- Check the level of chlorine smell in each jar. For further use, choose a substance with a barely audible odor. If this is the first container, calculate the amount of lime to disinfect 1 m3 of water: 10 drops are required per liter of liquid, 10,000 per cubic meter. Considering that 1 ml consists of 25 drops, then 400 milliliters will be needed to treat 1 m3 of water.

- Calculate the volume of liquid in the well and the amount of lime needed to clean it.

- Pour the calculated amount of lime into a container and fill with water. Stir the contents until the lime is completely dissolved.

- Pour the substance into the well. Shake the water for 10 minutes using a long pole.

- Cover the head of the well with plastic wrap and tie a cord around the trunk.

- Place an opaque sheet on top to keep sunlight out of the shaft. Natural light destroys chlorine and reduces the effectiveness of the procedure. Leave the spring in this state for 6-10 hours in summer and 12-24 hours in winter.

- Remove the film and try to smell the chlorine. If it is completely absent, then the substance disintegrated during the preparation of the solution and it was not possible to purify the water. In this case, the procedure will have to be repeated.

- Pump out all the liquid from the well several times until the specific smell disappears.

Water disinfection with chlorine-free preparations

Cleaning with potassium permanganate is performed in this way:

- Pour out 1 tbsp. a spoonful of potassium permanganate in a bucket of warm water and shake the contents until the product is completely dissolved. Do not immediately pour the powder into the source. This can lead to unwanted chemical reactions and toxic heavy compounds.

- Pour the mixture into the well, stir and leave for 1 hour.

- Also wipe the walls with a brush dipped in the solution.

- Completely pump out the water from the spring several times.

- After the last pumping, leave a metal sieve with 3-5 grams of potassium permanganate at the bottom. The substance should be there constantly as a disinfectant and antibacterial agent.

The use of tablet preparations

Walls are processed as follows:

- Prepare the source for cleaning as described above.

- Prepare a plastic or enameled bucket of at least 10 liters. Water for cooking should be at room temperature.

- The dosage of the wall disinfectant depends on the type of product. When using Septolit-DHC, you will need 4 piglets per 10 liters of water. To create a solution based on Ecobreeze-Oxy, add 50 milliliters of the product to 10 liters of liquid.

- Using a brush or spray, wash the walls of the well with the resulting solution.

- Rinse the shaft with clean water after 30 minutes.

3

Prevention

In order to carry out disinfection measures as rarely as possible, but at the same time use high-quality water, it is necessary to observe a number of measures aimed at preventing contamination of the well.

Such measures include the following:

- you can not leave the well open;

- keep a distance from the well to the sewerage and drainage system of at least 20 meters;

- securely seal the walls of the well, preventing the penetration of groundwater;

- use submersible pumps with remote injectors, this significantly reduces the number of leaks;

- comply with sanitary standards, do not drain waste into the well.

By following these simple steps, clogging and silting of the well, which are the most likely causes of water quality deterioration, will be avoided.

Septic tanks with soil aftertreatment

A cheap, simple and advanced analogue of concrete wells are plastic septic tanks with soil aftertreatment. They usually look like barrel-shaped tanks with lids. When choosing a factory septic tank, the number of tanks, the volume and the number of chambers in them should be taken into account. So, at a flow rate of 1 cubic meter of water per day, a single-chamber tank is enough, at a flow rate of 5 cubic meters per day - a two-chamber tank, and at a flow rate above 8 cubic meters per day - a three-chamber tank. The more compartments, the better the wastewater treatment.

Multi-chamber installations provide wastewater treatment for their subsequent discharge into ditches

How it works? In the three-chamber model, wastewater first enters the first chamber, and the heavy fractions sink to the bottom. After some time, they turn into silt. Light particles, together with water, enter the second chamber, where they are processed by bacteria. The purified composition is pumped into the third chamber. There, a filter and a special antiseptic mesh with colonies of bacteria are waiting for him.

Further, purified by 60-70% water enters the filtration field, which is a trench with crushed stone, in which perforated pipes or an infiltrator are laid. Here, wastewater is additionally treated with aerobic bacteria, after which the liquid is drained into a drainage ditch. An integral part of such a treatment system is ventilation pipes (they are needed to provide air access and maintain the vital activity of aerobic bacteria).

It looks like a septic tank with soil aftertreatment in the form of a multi-chamber installation and a filtration field with perforated pipes

How good are these septic tanks? The fact that the water obtained at the end of cleaning can be drained into drainage ditches (but it cannot be used for irrigation and drinking!), For the full operation of the system, energy sources are not needed, and the container needs to be cleaned no more than once every 1-3 years.

For a family of 2-3 people, a single-chamber septic tank with a production volume of several cubic meters is enough.

The disadvantages of septic tanks with soil aftertreatment are:

- inability to use purified water for drinking and irrigation;

- within a radius of 3 m from the filtration field, you cannot grow vegetables and plant fruit trees and shrubs (for a small area, this can play a fatal role).

It should also be remembered that in areas with heavy soil or a high level of groundwater, such a septic tank will not “work”. In order for the system to function, you will have to install an additional container with a drainage pump and build a special dome for additional water treatment on the soil surface. It will be very expensive and ineffective.

Thus, wastewater is still a serious "headache" for owners of private houses. There are not so many purification methods, after which recycled water can be drunk, and they are not cheap. Still, it is easier to dispose of wastewater in small doses using modern environmentally friendly technologies.

The frequency of disinfection and the use of water after this event

Experts recommend decontaminating the well shaft at least once every one and a half to two years, or as needed. If the water acquires a bad smell and taste, cleaning should be carried out immediately. When the well has not been used for a long time, its use must be preceded by disinfection.

The main advantage of using potassium permanganate is that the water from the well after cleaning can be drunk after 24 hours. When there is no other alternative source, the liquid is boiled for the first day before use. If bleach or whiteness is used, boiling will take 5-10 days, but with this method of disinfection, complete confidence in the purity of water can only be obtained by chemical analysis.

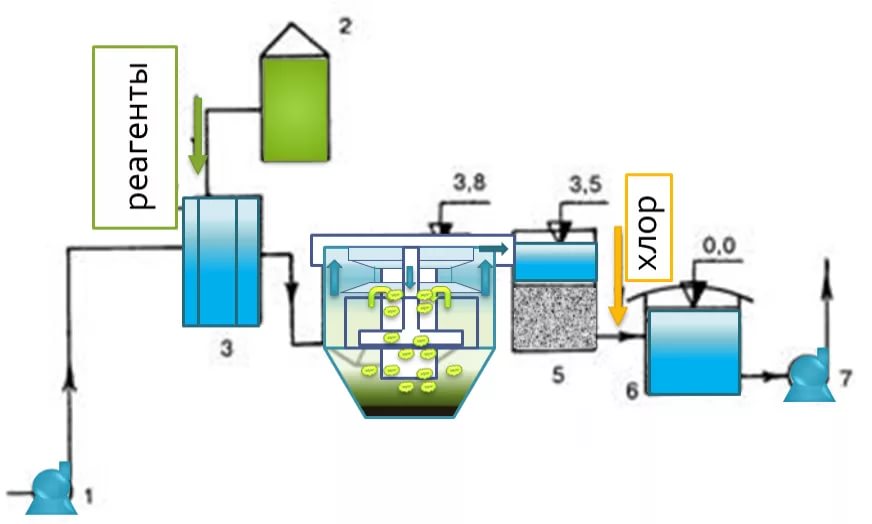

Cleaning systems for private houses and cottages

Rarely are sources that require one type of filtering. For water treatment, complex solutions are used.

Rough cleaning

Liquid enters the water purification systems from the well after mechanical filters made of fine mesh.

Non-pressure scheme

Fluid purified by inlet filters is supplied from the well to the system.

Overflow prevention float switch for the pump. For the same purpose, a drainage hole is equipped in the upper part with a drain into the sewer.

The volume of the container is chosen depending on the number of people living in the house. According to sanitary standards, each person consumes (spends) 200 liters per day. After filtration, up to 30% of the tank capacity goes into the drainage.

Calculation example. A family of three requires 600 liters per day. 300 l after sludge will go to the drain. In total, for uninterrupted water supply of the family, a capacity of 1 m3 is installed.

System operation. The tank is filled with liquid from the well.

Installing a compressor speeds up oxidation. The non-compressor method increases the oxidation time, but it is also effective.

The pumping station supports the installed pressure in water pipes.

Liquid is withdrawn through tap 1 installed in the lower third of the tank.

Through the tap 2 remove water containing a precipitate of metals, precipitated in the form of flakes.

By combining the positions of the taps, they regulate the direction of the flows: clean water goes to the house, dirty water goes to the drainage.

Fine cleaning

The task of the equipment is to saturate the liquid with oxygen, which turns ferrous iron to ferric. It is subsequently removed by filtration.

Similarly, the removal of salts of manganese and aluminum.

Aeration systems are non-pressure and pressure.

pressure system

The pressure device includes a column and a compressor that pumps air into a special mixer when a water flow passes through it. Turning on controls the fluid flow sensor.

A valve is installed in the upper part to bleed excess air. Enhanced mixing of the mixture throws water into the valve, so the outlet pipe is connected to the sewer.

The pressure cleaning system justifies its purpose when the iron content is exceeded by 20-30 times. The equipment pays for the cost of buying and paying for the electricity consumed by the compressor by reducing the cost of new filters.

After pressure and non-pressure systems, additional equipment is installed.

Reverse osmosis

The resource of membranes is no more than 5000 liters. Therefore, for the daily complete purification of water in a country house, the possibilities of such a device are limited.

The washing machine consumes from 40 to 60 liters per wash cycle. The dishwasher will require up to 20 liters. Taking a shower by one person will cost 40-50 liters. Thus, a consumption of 200 liters per person is accumulated per day.

A family of three will use up a reverse osmosis membrane in 10-15 days. In addition to the cost of the membrane itself (from 900 to 2500 rubles), labor costs for replacement are taken into account.You can do the procedure with your own hands if you have the skills and experience. Errors lead to a violation of the tightness of the connections, the breakdown of the thread and the need to replace the kit.

Purification of bacteria and viruses is carried out with ultraviolet light.

How to clean from lime

If the laboratory analysis showed an increased content of calcium in the water, this problem will have to be addressed.

When the permissible norms are inflated several times, ion-exchange filters are used. The equipment consists of a tank filled with ion-exchange resins of natural or synthetic origin. Additionally, you will have to put a regeneration tank with a salt solution for periodic washing of equipment and resin.

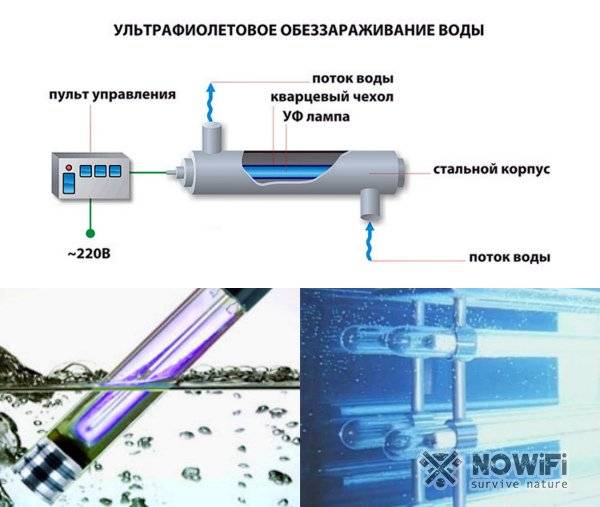

Physical methods of disinfection

These methods include cleaning with ultrasound and ultraviolet light. These methods are efficient and environmentally friendly. The main disadvantage is the need to purchase expensive devices. It is rational to use such equipment if the well is connected to an autonomous water supply system and is used year-round.

The cleaning device is equipped with an automatic system that regulates the water supply through a special unit. This emits ultraviolet radiation, which is harmful to bacteria. At the same time, the smell and color do not change. However, such a device is not used in the absence of a cover at the well. Almost similarly, the equipment that affects the mold with ultrasonic waves operates.

Areas of application of bleach

Due to its wide spectrum of activity, bleach can be used in almost any industry.

The main properties of this multifunctional substance include:

- Antiviral

- Whitening

- bactericidal

- antiseptic

- insecticidal

- Anthelmintic

With such a set, hypochlorite has gained popularity in widespread use, and the only negative can be called only a pungent unpleasant smell of all chlorine-containing substances.

household needs

At home, bleach replaces a large number of all kinds of cleaning products. With its help, the apartment is disinfected after illness or suspicion of the presence of a virus. Bleach also stops the spread of the fungus and completely destroys it. In private homes, mold treatment of the basement, greenhouses and other utility rooms is especially relevant.

INFORMATION:

Water and wastewater treatment

Chlorine has long been used to disinfect tap water and clean swimming pools. Wells are also treated with it, which avoids the spread of various infections. Of course, other methods are also used to purify water, but only in parallel with chlorination. Chlorine is also indispensable for cleaning filters and piping systems. For this, solutions of sodium or potassium hypochlorite, bleach, chloramine, as well as the gaseous form of chlorine are used.

Chlorine has long been used to disinfect tap water and clean swimming pools. Wells are also treated with it, which avoids the spread of various infections. Of course, other methods are also used to purify water, but only in parallel with chlorination. Chlorine is also indispensable for cleaning filters and piping systems. For this, solutions of sodium or potassium hypochlorite, bleach, chloramine, as well as the gaseous form of chlorine are used.

Given the toxicity of the substance and its unpleasant odor, it is important to accurately observe the dosage. It depends on the variant of the active substance - they have different concentrations of chlorine

Therefore, you need to follow the attached instructions. So, for chlorination of private pools, whiteness can be used (at the rate of 1 liter for every 10 cubic meters of water). But there are other parameters that should not be ignored:

- The environment should be slightly acidic (ph = 7.2-7.6), otherwise a strong odor cannot be avoided.

- Dilute preferably in cool water.

- The recommended interval between chlorination and the start of using the liquid is at least 20 hours.

public places

Disinfection is most often carried out in order to reduce the possibility of the spread of infection or prevent the occurrence of a viral disease. However, in high traffic areas, disinfection is a mandatory and regularly performed action; in these cases, disinfection can be considered a preventive measure.

The main objects that are processed daily with bleach are:

- Educational institutions: kindergartens, schools, technical schools, universities

- Crowded places: train stations, cafes, shopping centers, cinemas, theaters

- Medical organizations: polyclinics, hospitals, medical centers

- Sphere of cosmetology: beauty salons, hairdressers

Hypochlorites in medical practice

Sodium hypochlorite exhibits pronounced antiseptic properties, therefore, in the form of a solution, it is used in medicine for the treatment of skin, mucous and wound surfaces. Sometimes the solution is injected. It is also used to combat most bacterial and viral microorganisms, parasitic fungi, as well as some types of protozoa. It effectively eliminates the most dangerous pathogens, such as the pathogens of herpes, tuberculosis, hepatitis, typhoid, anthrax and even AIDS. Let's apply solution in various directions of medicine.

Sodium hypochlorite exhibits pronounced antiseptic properties, therefore, in the form of a solution, it is used in medicine for the treatment of skin, mucous and wound surfaces. Sometimes the solution is injected. It is also used to combat most bacterial and viral microorganisms, parasitic fungi, as well as some types of protozoa. It effectively eliminates the most dangerous pathogens, such as the pathogens of herpes, tuberculosis, hepatitis, typhoid, anthrax and even AIDS. Let's apply solution in various directions of medicine.

It is noteworthy that sodium hypochlorite eliminates not only active pathogenic organisms, but also their spores. Therefore, both sodium and potassium salts of hypochlorous acid (hypochlorites) are used to treat medical products, dishes, furniture, linens, floors and walls, bathrooms, etc.These products have strong corrosive characteristics, which must be taken into account when disinfecting tools and metal equipment.

Disinfectant qualities of chlorine

Restaurants and meat and poultry processing plants use chlorine bleach and other chlorine-based products to kill harmful levels of bacteria, such as salmonella and E. coli, on food preparation surfaces and during food handling.

Chlorine is so important in poultry processing that the USDA requires a near-constant chlorine flush for most cutting equipment. In fact, there is no proven economic alternative to chlorine disinfection for use in meat and poultry processing plants.

Well disinfection

If the well water began to exhaust unpleasant odors, this indicates the active reproduction of bacteria. The cause of unpleasant odors is hydrogen sulfide, which is released as a result of the vital activity of pathogenic microflora. This liquid is not suitable for use.

Disinfection of the well can be carried out in several ways:

- Well cleaning with chlorine.

- UV treatment.

The disadvantage of the latter method is the high cost. However, there are also advantages - the implementation of the method does not require preparatory work, the taste of spring water does not change.

The source of ultraviolet radiation is special devices that need to be mounted in places close to the place where the liquid is taken. This method is more often used as prevention than cleansing.

As for disinfection with chlorine, unlike ultraviolet radiation, it can adversely affect a person’s well-being and health.

When using a chemical, it is important to strictly follow all prescriptions and recommended dosage.

You need to work in personal protective equipment: special gloves to the elbow and a respirator. Conventionally, the entire disinfection process is divided into three stages:

- Preparatory work.

- Well cleaning.

- Final disinfection.

It is necessary to completely free the source from water and begin to clean the walls, remove mucus and dirt from the concrete rings, and from the bottom - silt and debris accumulation. All waste is brought to the surface and disposed of.

It is also important to assess the condition of the concrete rings: is there any damage on their surface, what is the condition of the seams. Defects are eliminated, the seams are treated with a special solution. After completing these works, it is necessary that the source is completely filled with clean water.

After completing these works, it is necessary that the source is completely filled with clean water.

The disinfectant solution is re-prepared at the rate of 200 grams of bleach per 1,000 ml of water. The contents of the container are poured into the shaft and left for at least 24 hours. After this time, using a pump, you need to completely pump out the water, process the walls and pour plenty of clean water. Several times water is collected and pumped out.

Measures to prevent source pollution

In order to carry out disinfection measures as rarely as possible, but at the same time use high-quality water, it is necessary to observe a number of measures aimed at preventing contamination of the well. These measures include:

- you can not leave the well open;

- keep a distance from the well to the sewerage and drainage system of at least 20 meters;

- securely seal the walls of the well, preventing the penetration of groundwater;

- use submersible pumps with remote injectors, this significantly reduces the number of leaks;

- comply with sanitary standards, do not drain waste into the well.

By following these simple steps, clogging and silting of the well, which are the most likely causes of water quality deterioration, will be avoided.

Timely preventive disinfection will allow you to keep the well in the required sanitary condition, will make it possible to safely use water from it for various household needs.