- When to Disinfect

- What are the stocks

- Cleaning Safety

- Disinfection of mine wells

- How often should the quality of well water be checked?

- Do-it-yourself water purification in a well

- Mechanical cleaning method

- Biological water treatment

- Chemical cleaning

- Why is well water disinfected?

- Features of pollution by types of wells

- Cleaning the well by hand

- Cleaning the bottom - the most basic and difficult

- Sealing seams and gaps between the rings in the well shaft

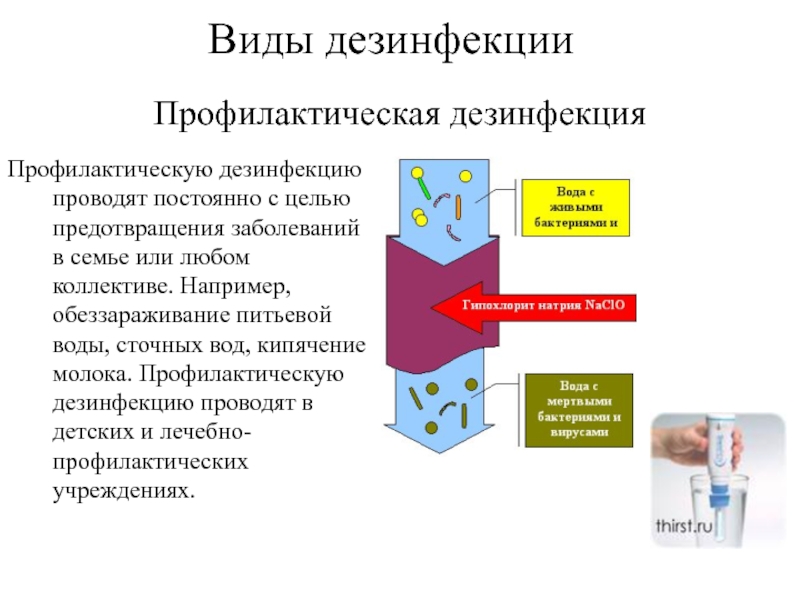

- Disinfection (disinfection)

- When to Disinfect

- Disinfectants

- Bleaching powder

- White

- Cartridges for purification of well water

- Potassium permanganate

- Iodine

- Special tablets

- Application of Aquatabs

- Other disinfection methods

- What may be required

- Combined methods of disinfection

- Conclusions and useful video on the topic

When to Disinfect

Wells are occasionally disinfected to produce high quality water, regardless of how often they are used.

The following factors may serve as the reason for such work:

- spring flood and mine flooding;

- ingress of ground or surface water;

- accidental ingestion of various chemicals, animal corpses;

- subsidence of the bottom, depressurization of the docking of the rings;

- the presence of foreign debris, mucus, dust inside.

It is recommended to disinfect the water in the well at least once every 12 months, but it is advisable to do this every 6 months. Otherwise, the extracted water may pose a direct threat to human and animal health.

What are the stocks

Stocks are:

- household - from houses, dachas, sanatoriums, food organizations, cultural buildings, shops;

- industrial and domestic - from various enterprises;

- from medical organizations, including infectious diseases hospitals;

- from livestock and poultry enterprises;

- runoff from mines, quarries;

- storm;

- drainage.

Household sewage is heavily polluted with microorganisms and organic particles. Before disinfection, they are cleaned mechanically and biologically. The composition of industrial effluents depends on the characteristics of the enterprise.

The most dangerous in terms of infection is wastewater from infectious diseases hospitals, livestock and poultry facilities. Drainage and storm drains are the least polluted.

To view the informative story:

Cleaning Safety

- Before cleaning, it is necessary to check the gas contamination of the bottom part. At the bottom of the well, harmful gases can accumulate - carbon dioxide, radon. To check, a burning candle is lowered into the mine, which, in the presence of gas contamination, will go out. However, during cleaning, there is always a chance that a radon bubble will be released from the bottom. Therefore, the worker must be carefully secured in belts, and an observer must stand at the mouth of the well, ready at any moment to lift him.

If the candle goes out, then it is necessary to pump out harmful gases, for example, using a powerful vacuum cleaner. Fresh air will enter the mine naturally. - If the cleaning work stretched over several days, then such a check should be done every time before going down. For people with problems in the cardiovascular system, it is better not to go down into the well, because. at depth there is a lack of oxygen.

- For work in shallow wells, an ordinary ladder is used, and for cleaning at a considerable depth it is better to take a rope ladder. The lifting of the load and the worker must be carried out with a winch or a shaft.

- It is also necessary to use protective equipment - overalls, goggles, gloves and a helmet, a respirator (gas mask) and observe safety measures when using cleaning caustic substances according to their instructions. Removal of stones and heavy objects should be done after lifting people.

- If there are "quicksands" in the area, it is not recommended to stand at the bottom of the well for a long time, especially for people with a large mass. The moving mass of quicksand can pull a person deep into.

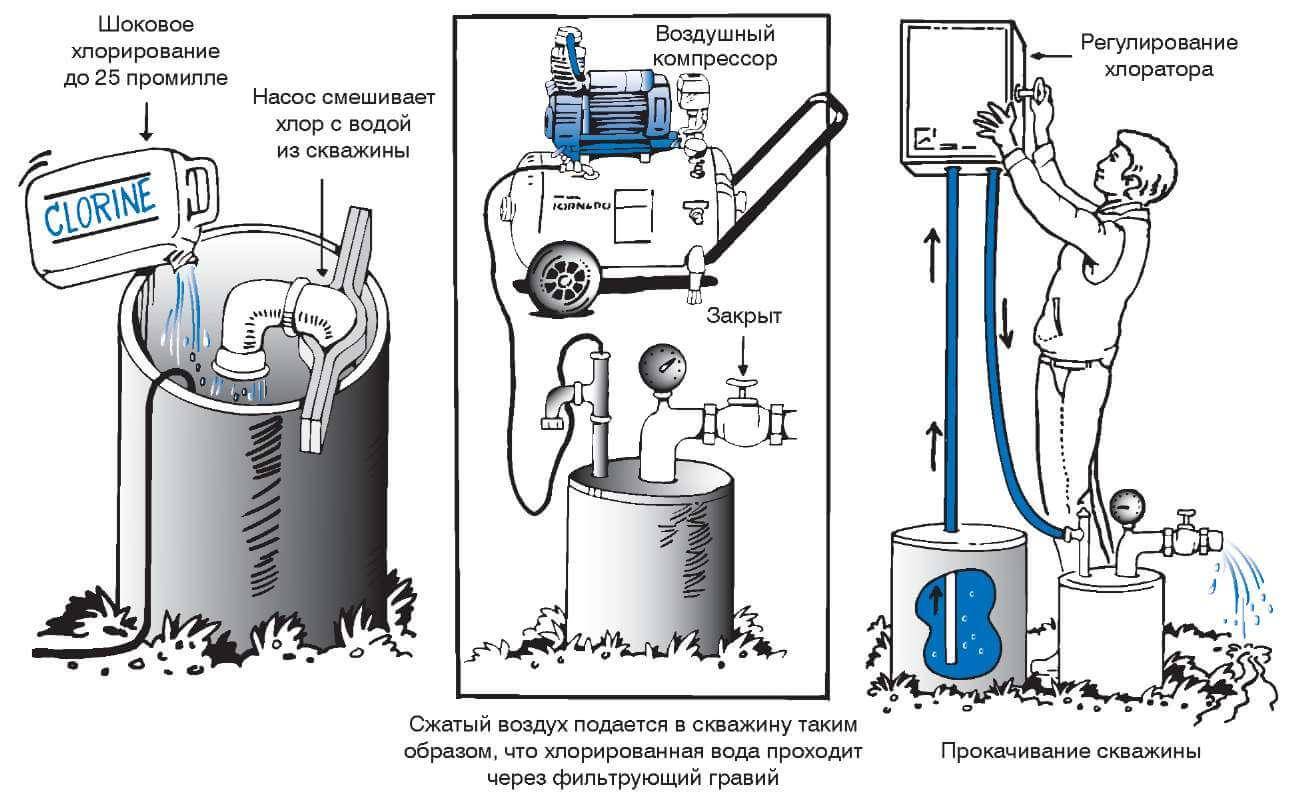

Disinfection of mine wells

Need

disinfection of wells is installed

centers of state sanitary

— epidemiological surveillance and

carried out:

- according to epidemiological

indications (with an outbreak of intestinal infections

in a populated area or when entering

sewage well water, faeces,

carcasses of animals, etc.);

- with preventive

purpose (on completion of construction of new

or after cleaning and repairing existing

wells).

For disinfection

wells can be used any

suitable disinfectants for this purpose

drugs approved for use

Ministry of Health of Russia. Most often for these

purposes use chlorine-containing

preparations - bleach or

two-thirds of the basic salt of hypochlorite

calcium (DTSGK).

1.1. Disinfection

wells according to epidemic indicators

Well disinfection

epidemiological indicators include:

— preliminary

well disinfection;

- cleaning the well;

- re-disinfection

well

1.1.1. preliminary

well disinfection.

Before

well disinfection by calculation method

determine the volume of water in it (in m3)

by multiplying the cross-sectional area of the well

(in m2)

to the height of the water column (in m).

1.1.1.1.

Irrigation with hydropump

outer and inner parts of the trunk

mines with a 5% bleach solution

or 3% solution of DTSGK based on

0.5 l per 1 m2

surfaces.

1.1.1.2.

Knowing the volume of water in the well, carry out

disinfection of the lower (water) part of it

by adding chlorine-containing preparations

at the rate of 100 - 150 mg (g) of active chlorine

per 1 l (m3)

water in the well.

water carefully

mix, close the well with a lid

and leave for 1.5 - 2 hours, avoiding

drawing water from it.

1.1.1.3.

Calculation of the amount of bleach or

DTSGK required to create in water

well of a given dose of active chlorine

(100 - 150 mg (g) per 1 liter (m3)),

carried out according to the formula:

,

,

where:

R

- the amount of bleach or DTSGK,

gr;

FROM

- a given dose of active chlorine in water

well, mg/l (g/m3);

E

- the volume of water in the well, m3;

H

- the content of active chlorine in the preparation,

%;

100 - numeric

coefficient.

1.1.2. Well cleaning

Cleaning is carried out

1.5 - 2 hours after the preliminary

well disinfection.

1.1.2.1. Well completely

free from water, cleanse from trapped

foreign objects in it and

accumulated sludge. The walls of the mine are cleaned

mechanically from fouling and

pollution.

1.1.2.2. Selected from

wells, dirt and silt are taken to a landfill

or immersed in a pre-dug on

a distance of at least 20 m from the well

depth of 0.5 m and bury, previously

filling the contents of the pit with a 10% solution

bleach or 5% solution

DTSGK.

1.1.2.3.

The walls of the cleaned well shaft at

repair as necessary, then

the outer and inner part of the mine

irrigate from a hydropanel with a 5% solution

bleach or 3% solution

DTSGK based on 0.5 l/m3

mines.

1.1.3. Repeated

well disinfection

After cleaning,

repair and disinfection of the walls of the mine

start re-disinfection

well.

1.1.3.1.

Maintain the time during which

the well is refilled with water

determine the volume of water in it (in m3)

and add the required amount of solution

bleach or DTSGK at the rate of

100 - 150 mg (g) of active chlorine per 1 liter (m3)

water in the well.

1.1.3.2. After making

disinfectant solution water in the well

stirred for 10 minutes, well

cover with a lid and leave for 6 hours,

not allowing water to be drawn from it.

1.1.3.3. After

the specified period the presence of residual

chlorine in water is determined qualitatively -

by smell or using an iodometric

method. In the absence of a residual

chlorine is added to water 0.25 - 0.3 of the initial

amount of disinfectant

and keep for another 3-4 hours.

1.1.3.4. After repeated

checks for residual chlorine

and positive results

checks carry out pumping of water to

the strong smell of chlorine disappears. And

only then can the water be used

for drinking and household

goals.

1.2. Disinfection

wells for preventive purposes

1.2.1. When disinfecting

wells for preventive purposes

pre-disinfection is not carried out.

1.2.2. Cleaning and repair

wells, as well as disinfection of the walls

the newly built well is being completed

volumetric disinfection of the well

(See paragraph 1.1.3 of the appendix).

How often should the quality of well water be checked?

The composition of well water is subject to seasonal changes. Therefore, a laboratory analysis of water from a well is recommended to be carried out periodically, which will allow timely detection of changes in its quality.

The service for checking the biochemical composition of water entering the well is provided on a paid basis by the authorities of Rospotrebnadzor at the request of the owner.

The analysis of water quality in the well must be carried out immediately after its construction, as well as during operation at least once a year

Companies selling equipment for cleaning and disinfecting well water can provide a similar service to their client for free. At the request of the owner, testing of water from the well can be performed by laboratory assistants:

- according to the standard scheme of analysis;

- study of the percentage of one or all of the components that make up the liquid being tested.

For the implementation of a comprehensive study of the water samples taken, laboratory assistants usually have two to three days. The duration of the procedure is specified in the contract concluded by an individual or legal entity with a company licensed to conduct biochemical analysis of drinking water.

Do-it-yourself water purification in a well

So, water purification requires the following procedure:

-

Preliminary inspection of the well and finding the causes of water pollution.

-

Fluid sampling for analysis and its implementation.

-

Elimination of visible defects and cleaning of the well.

-

Installation of bottom filters.

-

Disinfection and chlorination based on analysis data.

-

Selection and installation of a filtration complex.

Note that all manipulations can be reproduced independently (except for analysis). The most important thing is to understand what technological nuances each cleaning method has.

Mechanical cleaning method

The well and its cleansing is the first step in bringing water back to normal, since the mucus on its walls is a source of bacteria.

Cleaning should be done once every two years for frequent use and once a year for occasional use.

For this procedure, prepare the following materials and tools:

-

putty knife;

-

Master OK;

-

metal brush;

-

cement and sand mortar;

-

bucket;

-

belt for insurance;

-

ladder;

-

winch;

-

slings for holding;

-

water pump;

-

blocking and descent design.

Mechanical cleaning involves cleaning the entire surface of the well. The suggested course of action is as follows:

-

At the same time, after the gradual pumping out of the liquid, the walls are cleaned.

-

Surfaces are cleaned with a metal brush.

-

Then organic residues and debris are removed from the bottom.

-

The presence of cracks will require their sealing with cement.

-

To prevent displacement of the rings, reinforce the integrity of the structure with steel braces.

-

Wash the bottom filter or install a new one.

Biological water treatment

Biological treatment involves the arrangement of a filter layer at the bottom of the well. For such a filter, it is fashionable to use shungite, silicon gravel or natural sorbents.

Note that the substance of volcanic origin - zeolite, will provide a high degree of filtration.

To backfill the shungite layer, you must:

-

Lay out a layer of geotextile with high permeability on the bottom. In the future, it will greatly simplify the cleaning of the bottom filter.

-

First, fill in shungite with a fine fraction, and on top with a large one.

-

After waiting for the dust particles to shrink, go down into the well in a respirator and carefully distribute the shungite.

-

In order to remove excess dust, you can pre-wash the shungite.

After 3-4 weeks, the water quality will noticeably improve. Shungite thoroughly neutralizes sulfur bacteria, reduces iron content and has a positive effect on the formation of beneficial microflora. Purification of well water is necessary, especially in conditions of deterioration of the general environmental situation.

Chemical cleaning

If an unpleasant taste and smell is detected, it is necessary to disinfect the well. As a means for purifying water in a well, a solution of potassium permanganate or preparations with chlorine can be used.

It is necessary to follow a special sequence of actions.

-

Preparation of working solution:

-

300 grams of bleach is diluted in a small amount of water to a mushy state;

-

the mixture is poured into a ten-liter bucket of water;

-

mix thoroughly and let stand for 3-4 hours;

-

poured into an airtight container and put in a dark place.

Wall treatment with a brush or sprayer.

Preparation of a more concentrated solution and its settling.

Filling the well with water.

Moving the chlorine solution into the well and sequential mixing with a pole.

Closing the well for a day.

Repeat the procedure depending on the degree of contamination.

Then it is necessary to pump out all the water from the well and repeat filling / pumping out until the smell of chlorine disappears.

Do not forget that during the disinfection operation of the well is prohibited! Water purification in this way must be carried out in compliance with all prescribed measures.

A more gentle method of disinfection is the use of potassium permanganate. Here is the sequence:

-

a teaspoon of the powder is dissolved in a bucket of water.

-

The solution is poured into the well.

-

Leave for a day.

-

Pump out several times and add water.

-

Fill with clean water and lower a nylon bag with crumbs of silicon to the bottom.

-

The solution can also be applied to the walls.

After all the manipulations, it is recommended to re-analyze the water. If the situation has not improved, chlorine cartridges should be used. These are cylindrical containers with calcium hypochlorite. While under water, the cartridge continuously releases chlorine. It needs to be recharged every month. Installation of such products should be carried out by professionals who can accurately calculate the safe threshold for chlorine in water.

Read the material on the topic: Integrated water treatment

Why is well water disinfected?

Fluid cleaning in the well must be carried out regularly, otherwise pathogenic bacteria will appear, which will lead to health problems. It does not matter which water filter is in the house, the liquid in the well must be kept clean and cleaned periodically.

Standing water in a well has a beneficial effect on the reproduction of bacteria. Since this is an open source, branches, leaves from trees, debris and insects get into it. All this negatively affects the quality of the liquid.In addition, algae and fungi grow on the walls of the well, which only aggravate the situation. If well water is rarely used, then this increases the chances of water contamination with bacteria.

Well water can become contaminated for other reasons. If the tightness of the structure is broken, then microorganisms from the soil enter the water. And if there is a sewerage near the source, then the waste from it can get into the water, and then it becomes undrinkable.

Features of pollution by types of wells

There are such regularities:

- quality depends on the parameters of aquifers and terrain

- the shallower the depth (ordinary well, well "on the sand"), the higher the probability of exceeding the level of nitrates, pesticides, hydrogen sulfide compounds, iron, organic matter. Groundwater with these substances often enters such systems. Each increase in their level, precipitation causes pollution

- for deep (artesian) wells, the chances of getting usable water are higher. But depth does not guarantee purity: hydrogen sulfide appears in tightly sealed layers, salts penetrate inside, and it is necessary to rid the water of hardness. If the shaft passes through the layers with ores, then there is a risk of their getting inside

It should be noted that most wells are not made deep - up to 25 - 45 m, since artesian drilling is more laborious and a permit must be issued for it.

Cleaning the well by hand

For manual cleaning, you must either go down into the well yourself and pump out water, or use the help of a professional.

Of the main cleaning tools, you will need warm clothes, rubber boots, a safety rope, a flashlight, a bucket, rags, a sponge, and even a brush for cleaning concrete or surfaces of the mine to clean its walls in the process of descending to a depth while pumping out water. You will also need washed crushed stone of a fraction of 40 * 30, which will need to be added to the bottom of the well after cleaning its bottom.

Cleaning the bottom - the most basic and difficult

In the event that water does not enter the well from a perfectly clean spring, then a protective bottom filter is laid out on its bottom.

In many ways, the quality of well water depends on a well-made bottom filter.

The most valuable materials for the bottom filter are quartz sand, natural crushed stone, gravel, shungite, sauna stone (jadeite), geotextiles, which are stacked in several layers. At the very bottom there is also a bottom shield, which is designed to protect the bottom filter from destruction by groundwater.

One of the options for cleaning the bottom is to completely remove it, clean it and put all the bottom filter materials back in place.

The second way is even simpler and more realistic - this is to remove the bottom dirt from the top layer of rubble and add fresh washed gravel of the same standard fraction (40 * 30) by 15-20 cm.

Sealing seams and gaps between the rings in the well shaft

Experts recommend using a special solution based on sand, liquid glass and cement for these purposes. There is also a special composition - called hydroseal, which can be used if finances allow.

Disinfection (disinfection)

Disinfection includes the treatment of the walls with a solution of ten percent chlorinated lime, which is also poured onto the bottom of the well.Within two days, it is necessary to prevent the filling of the well with water and, if it is available, it must be immediately pumped out.

As a result, bleaching (chlorinated solution) and cleaning the shaft will allow the well water to regain its natural properties.

When to Disinfect

Wells are occasionally disinfected to produce high quality water, regardless of how often they are used.

The following factors may serve as the reason for such work:

- spring flood and mine flooding;

- ingress of ground or surface water;

- accidental ingestion of various chemicals, animal corpses;

- subsidence of the bottom, depressurization of the docking of the rings;

- the presence of foreign debris, mucus, dust inside.

It is recommended to disinfect the water in the well at least once every 12 months, but it is advisable to do this every 6 months. Otherwise, the extracted water may pose a direct threat to human and animal health.

Disinfectants

A variety of products can be used to disinfect well water. Consider the most effective of them.

Bleaching powder

- dilute 10g of 1% bleach in a liter of water from a well;

- then a few drops of the resulting liquid are added to a ten-liter bucket of water (we add drops until a slight smell of chlorine appears).

- we use this proportion to disinfect the well, having previously calculated the amount of liquid in the well (approximately 400 ml of solution is used per 1 cubic meter). This requires measuring the depth of the liquid and the diameter of the ring;

- then pour the solution into the well and mix;

- then carefully cover the shaft with polyethylene, and leave for 24 hours.

It is necessary to carry out this procedure for disinfecting wells so that the sun does not fall on the mine during this period. After a day, the liquid is pumped out, the walls are thoroughly washed out, then water should be downloaded again. Repeat this until until the chlorine smell will not go away.

White

To disinfect drinking water wells with this method, the same process is used as in the previous version. Most often use 1l. whiteness per ring.

For the best result, you need to spray whiteness on the walls of the well and cover the well well for 24 hours. Then the shaft is washed with pumping out the liquid, as many times as necessary until the smell disappears completely.

Cartridges for purification of well water

Disinfection of wells can be carried out using special cartridges. They include chlorine and calcium hypochlorite. 1 cartridge is immersed in water for 1 month. During this period, the liquid must not be used.

After we took out the cartridge and pumped out the water, we fill the mine with liquid and drain it again. We carry out the procedure until the smell disappears.

Potassium permanganate

Disinfection of water in a well with safe potassium permanganate is a gentle, but less effective option.

The process of this procedure:

- dissolve 1 tbsp. l. potassium permanganate in 10 liters. warm water;

- shake well and add to the well, close tightly for 1 hour;

- then the liquid is pumped out, and the mine is well washed out.

In order for the mine to remain cleared for a longer time, a medium-sized mesh with potassium permanganate (several grams) is installed on the bottom.

Iodine

Iodine solution for disinfection of wells is used in cases where it is not possible to perform a full cleaning.This is due to the fact that, despite the disinfecting characteristics of iodine, with a strong concentration, water cannot be used for consumption and irrigation.

In order to make a solution, you need 1 liter. add three iodine drops of water. The ring requires up to 5 liters. such a liquid. In this way, the complete cleansing of the well will not be carried out, but the quality of the water will improve for a certain period of time.

Special tablets

To disinfect the water in the well, there are tablet preparations containing chlorine. The exact dosage is indicated in the instructions for the preparations. Approximately use 4 tables. in a bucket of water at room temperature.

For cleaning, it is first necessary to pump out the liquid from the well. Next, the mine must be cleaned of debris and mud deposits. By means of a sprayer or a rag, the solution is applied to the walls. After 30 min. the surface is rinsed. Such cleaning agents include: Aquatabs, Ecobriz tablets, Septolit and others.

After that, the well is filled again. The solution is introduced into it and mixed. Then the liquid should stand in a tightly closed shaft for 3-12 hours. After that, the contents of the well should be pumped out until the smell disappears.

Application of Aquatabs

For the disinfection of individual water supplies, it is recommended to use tablets containing sodium salt of dichloroisocyanuric acid 3.5 mg, 8.5 mg, 12.5 mg and 17 mg in one tablet and the amount of active chlorine 2 mg, 5 mg, 7.3 mg and 10 mg, respectively, at the rate of one tablet per 1 liter of water.

For disinfection of polluted water (river, lake, pond, etc.), it is necessary to use tablets containing the active substance 8.5 mg, 12.5 mg and 17 mg, i.e. containing 5 mg, 7.3 mg and 10 mg of active chlorine, respectively. A mandatory requirement for the disinfection of natural turbid and high-colored waters is their preliminary filtration through a fine-cloth filter, and the amount of residual free chlorine should be 1.4-1.6 mg/l 30 minutes after the tablet disintegrates.

Determining the required dose of chlorine to obtain the required amount of residual chlorine is carried out by trial chlorination. To do this, take 3 containers, each filled with disinfected water with a volume of 1 liter, add 1, 2 and 3 tablets containing the same amount of active chlorine (2 mg for pure water or 5 mg for filtered muddy and colored water). The water is thoroughly mixed and after 30 minutes the presence of the smell of chlorine in the water is determined. A tablet is considered effective if, after 30 minutes, the smell of chlorine is detected in the water. If the smell is very strong, then it is necessary to repeat the test chlorination, reducing the number of tablets by 2 times or increasing the volume of water.

Disinfection of individual water supplies should be carried out only in a vessel with a screw cap (flask, etc.). After disintegration of the tablet, tightly screw the lid and shake the water, then unscrew the lid a little (by 1/2 turn) and turn the vessel over several times so that the dissolved drug, along with water, enters the threads of the lid and the vessel. Water is drinkable 30 minutes after dissolving the tablet.

To remove excess chlorine and possible by-product chlorine-containing hydrocarbons, it is recommended to filter disinfected water through activated carbon or boil it for 1 minute. For the disinfection of individual water supplies, it is recommended to use tablets containing sodium salt of dichloroisocyanuric acid 3.5 mg, 8.5 mg, 12.5 mg and 17 mg in one tablet and the amount of active chlorine 2 mg, 5 mg, 7.3 mg and 10 mg, respectively, at the rate of one tablet per 1 liter of water.

Other disinfection methods

You can also disinfect the water in the well with an iodine solution. Such a substance has excellent antibacterial properties that contribute to the destruction of pathogenic microorganisms and prevent their reproduction. But it is necessary to use this tool only in the case when it is not possible to carry out complete disinfection of the well.

To prepare the solution, you need to take 1 liter of water and add 3 drops of iodine, but it should be noted that 3-6 liters of such a product will be needed for 1 ring. This method of disinfection will slightly improve the quality of water.

In addition, you can purchase professional tools for disinfecting the well. Experts recommend buying tablets that contain chlorine: Septolite, Ecobreeze and Aquatabs. On average, 1 bucket of water will require 4 tablets. It should be noted that it is better to use a plastic or enamel container.

After pumping water from the well, you will need to clean it, pour in the solution and tightly close the drinking source with polyethylene. You need to withstand such a remedy for a minimum of 3 hours, a maximum of 12.

If you know the technology of well disinfection, then you can carry out such a procedure with your own hands.

What may be required

For preliminary work, the following tools and means may be required:

- Iron brush.

- Spatulas of various shapes.

- Bottom filling. As far as possible, it is necessary to remove the old bottom filling from the bottom and place a new one.

- Crushed stone of small fraction.

- Gravel.

- Sand.

Particular attention should be paid to the fact that it is absolutely impossible to use expanded clay as a bottom backfill due to the high level of its toxicity when in water. It is impossible to say in advance which remedy will help remove plaque from the walls of the well, because here the choice of remedy depends on the nature of the plaque. What can it be:

What can it be:

It is impossible to say in advance which remedy will help remove plaque from the walls of the well, because here the choice of remedy depends on the nature of the plaque. What can it be:

- Salt plaque requires the use of products with an acidic component. This may be a solution with a weak concentration of hydrochloric or acetic acid.

- Rust is removed without the use of chemicals using a grinder and a jackhammer. After cleaning, the surface of the well wall is treated with an anti-corrosion solution.

- To combat mold in wells, there is an old proven remedy - copper sulfate. Treating the walls with this substance will protect them for a long time from the reappearance of mold.

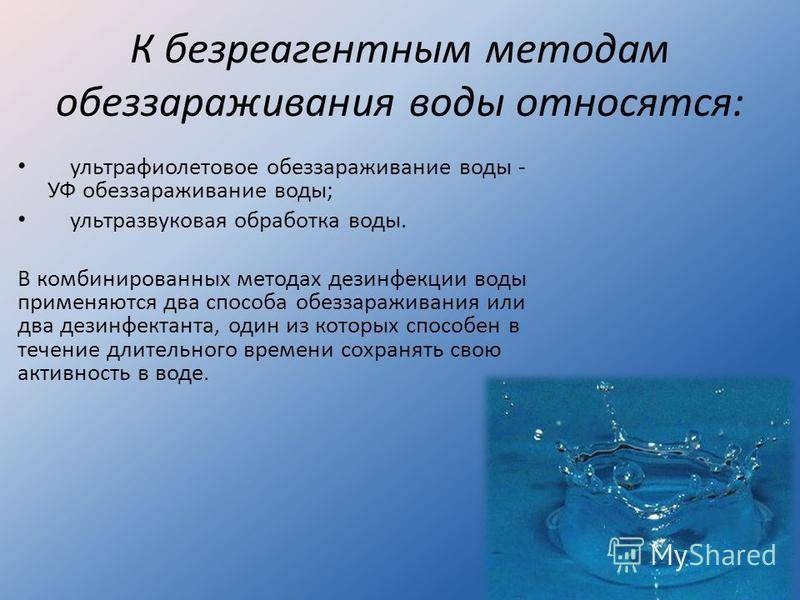

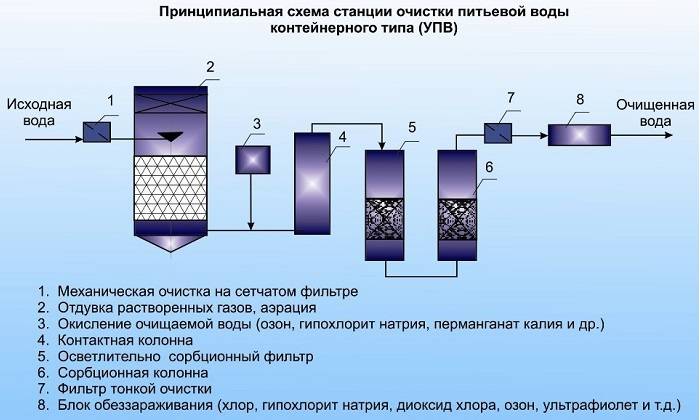

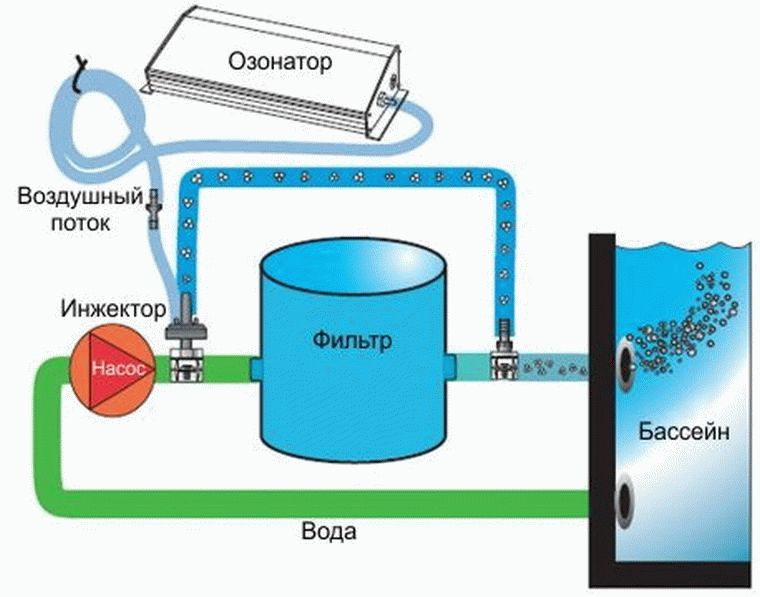

Combined methods of disinfection

Combined methods of water disinfection are considered more effective. They combine chemical and physical methods and are designed to improve processing efficiency.

At the moment, it is this approach that is considered the most progressive, but it is still practiced mainly in everyday life, and not in industry because of its high cost.

A striking example of a combined method is the use of a compact bactericidal unit designed to disinfect small volumes of water at home. But much more often they use an installation for disinfecting water with ultraviolet light in combination with chlorination or ozonation. Lamps destroy microorganisms, and chemical elements prevent their reappearance.

If you are interested in which method of water disinfection is best used at home or in nature, you should immediately clarify that for these purposes you need to use the simplest, but at the same time effective method. For example, at home, you can simply boil water intended for drinking. In nature, it is much more convenient to use special disinfecting tablets.

Effective methods for purifying drinking water at home are shown in the video.

Share

100

23.01.2019

5 992

Conclusions and useful video on the topic

Video review of the tableted disinfectant Aquabreeze:

Video presentation of the lamp for ultraviolet disinfection system:

Don't expect thunder from a clear sky. After all, water is what we use every day.

That is why it is so important to be sure that it does not contain harmful substances. To protect yourself and your loved ones, do not neglect the rules of operation and regularly check the composition of the water, even if it seems crystal clear

We are waiting for your stories about self-cleaning and disinfection of well water. Please write in the comment box. Here you can ask questions, share your impressions, useful information and thematic photos.