- Features of internal wiring

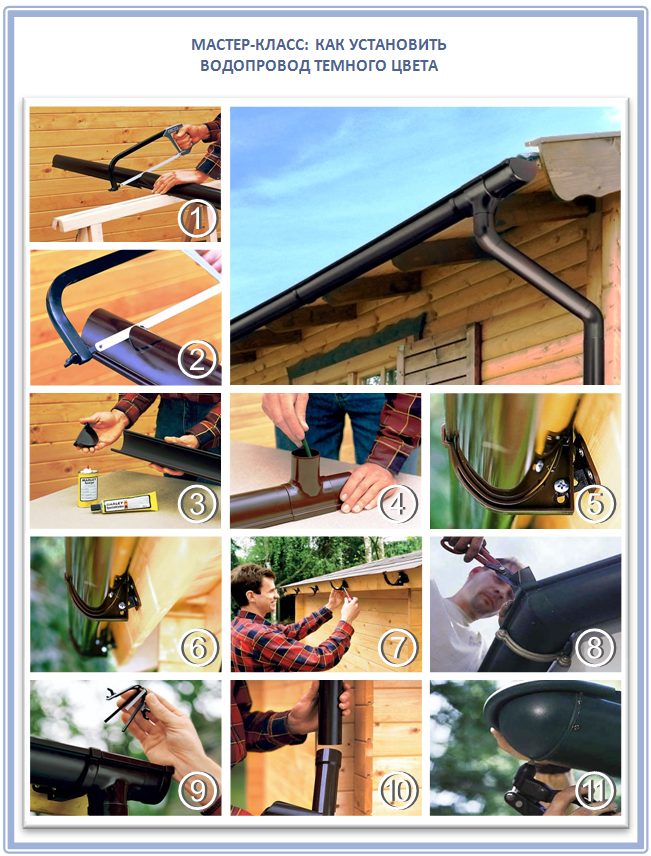

- Fitting workpieces to size

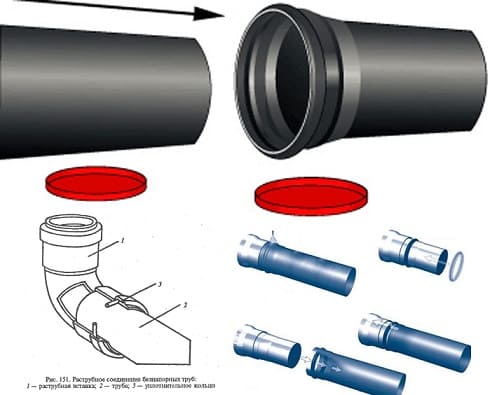

- bell joint

- Pipes used in sewers

- Types of sockets for sewerage

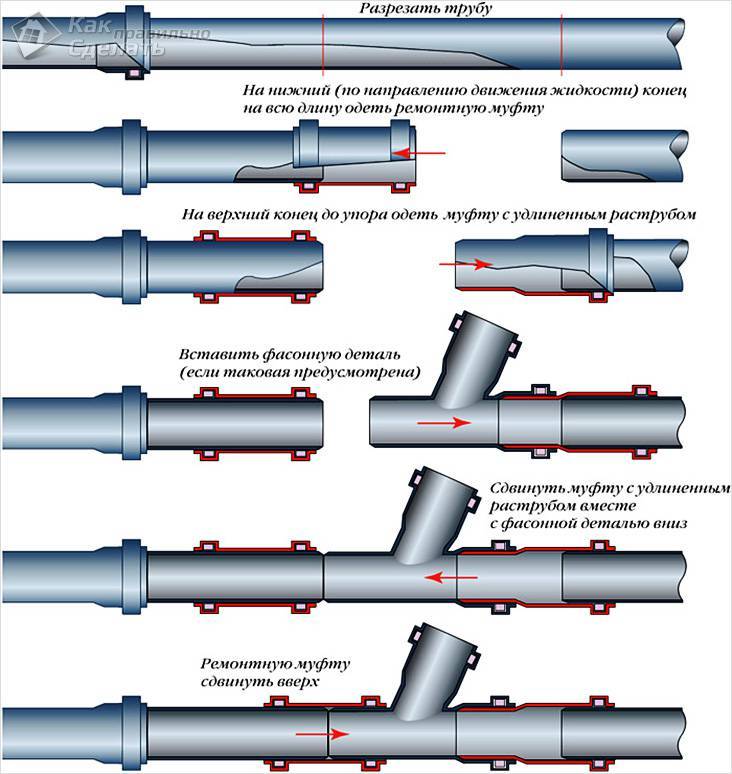

- How to join sewer pipes?

- With glue

- With fittings

- The main types of autonomous sewage for a country house

- Installation of a sewer system

- Chasing

- Preparatory work

- Connection step by step

- A set of tools and materials

- Work progress

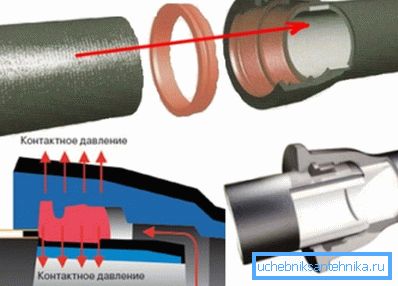

- Contact socket welding

- sewerage system

- External sewerage

- Installation of a drain well

- Installation of a septic tank

- Nomenclature of the components of the sewer system

- We connect plastic sewer pipes

- We connect plastic pipes on an adhesive basis

- We connect plastic pipes with a weld

- Video lesson - how to solder plastic pipes with your own hands

- Ceramic

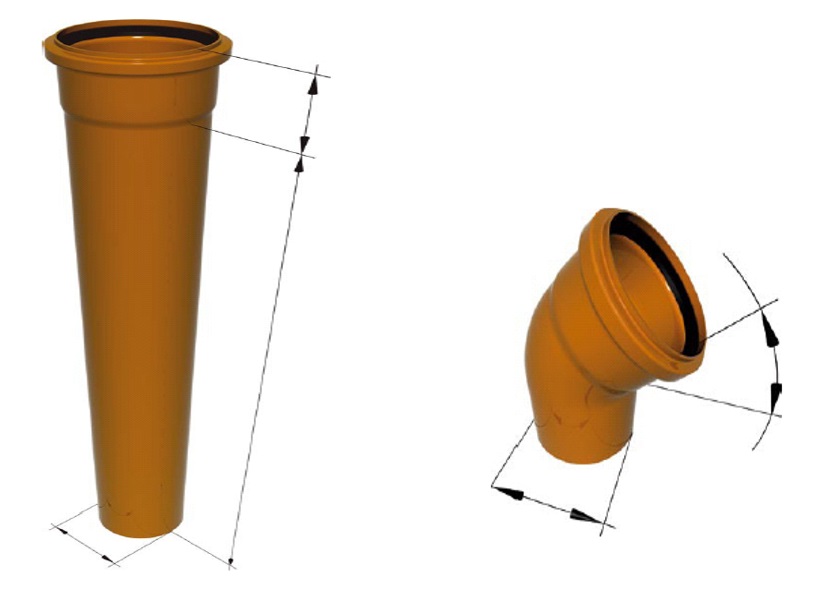

- Areas of use for pipes with a socket

- Installation with sealant and special adhesive

Features of internal wiring

Features of the arrangement of sewerage are that the basis for the functioning of home sewerage is gravity. Waste products move through the channels by gravity under the influence of gravity. In order for the drains from the water consumer to enter the riser, all lines must have a slope of 1-1.5%. So, with a line length of 200 cm, the height difference between the outlet and the pipe outlet to the common drain should be 2-3 cm.For each turn, another 1 cm is added. If you do not follow these rules, then the highway will be constantly clogged with waste.

The next nuance is the selection of the correct section size and line configuration.

You should choose plastic sewer pipes of this diameter:

- riser, tee, outlet and corrugation from the toilet - at least 100 mm;

- line from the bath, washbasin and kitchen sink - 50 mm;

- drain from the washing machine and dishwasher - 32 mm.

Since the largest waste products come from the toilet, the distance from it to the riser should be minimal. If you need to change the direction of the pipes to lay them, then it is better to do this with the help of bends at 45 °, as sharp turns can be clogged.

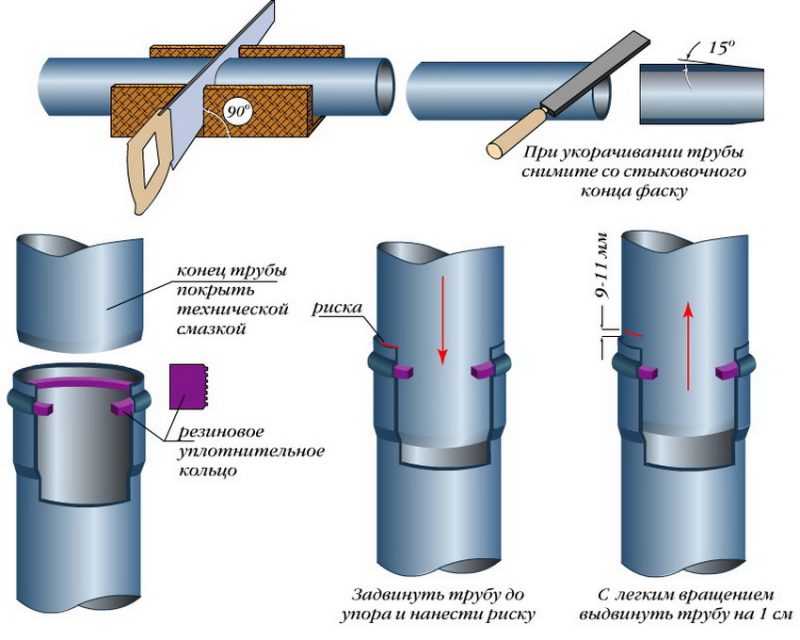

Fitting workpieces to size

A feature of products made of polymeric material is the change in their dimensions under the influence of temperature. Thus, with its increase by 1°, the length of the link increases by 0.5%. This must be taken into account when making calculations so as not to install turns close to the walls. You should always leave 1-2 cm of margin for the damper expansion of the links. A slight curvature does not affect the strength and tightness.

When cutting blanks, it is necessary to check that the diameter of the pipe corresponds to this indicator of the fittings used in laying communications. Technical indicators are printed on the products themselves, but it is better to check them in advance, even before the start of assembly. It should be remembered that the tightness of the connection and tightness are achieved through the use of gaskets. The difference between the inner and outer diameters of the connected links is 2 mm.A slight backlash allows you to compensate for minor errors made during design, marking and assembly.

bell joint

Consider the features of the connection of plastic pipes. They are performed using sockets, inside which rubber gaskets, rings and cuffs are installed. The best in terms of durability are double gaskets with a plastic ring. They are difficult to assemble, but the effort paid off by the reliability and durability of the joint. Before connecting the parts, you need to make sure that the elastic band is of the correct shape, tightly located in the groove of the bell and is not skewed. If the product is defective or was damaged during assembly, then it should be replaced with a serviceable part.

Attachment points are the weakest points of the pipeline. Over time, the lining material shrinks and decreases in volume. To slow down this process, it is necessary to use a high-quality lubricant with a preservative effect. Soap and car oils are not suitable for this. These substances corrode rubber. Professionals recommend using silicone grease.

The edges of the sawn pipe must be cleaned to get a chamfer. After the segment is inserted into the socket, it must be moved forward to the stop and fed back by 10-15 mm.

Pipes used in sewers

The following pipes are used for sewerage:

- from plastic;

- steel or cast iron.

There are plastic pipes made of polyvinyl chloride (PVC) and polypropylene (PP). The former are used for internal wiring as risers, for external sewerage - with insulation. Polypropylene pipes are durable, resistant to high temperatures.As for cast-iron pipes, it was they, and not steel ones, that proved to be better in use. After all, steel is a metal subject to corrosion. However, the negative side of cast iron pipes is a lot of weight. Thus, polymer pipes are better in all respects.

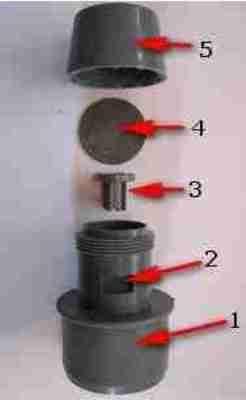

Types of sockets for sewerage

Pipes assembled from sockets are easy to lay, durable in use and cost-effective.

The most common type of socket is considered to be a concrete pipe. The larger the cross section of the pipe, the lower its cost. The concrete socket is very durable and practical to use. One end of the socket has an extension for attaching another part to it. Joints are sealed in the most appropriate way.

Pipes without sockets are also popular, durable and practical to use. The pipes are connected using special elements that can ensure the tightness of the structure.

We suggest that you familiarize yourself with How to protect the pipe in the bath from fire

In railway construction, a concrete flange is used to seal joints, and a clamp is used to connect cast iron pipes. In some situations, it is better to use socketless designs to simplify installation work and save time. Such pipes have found application in non-pressure sewer systems. If the joints are provided with sealing cuffs, then the pipes can be used in pressure systems, withstanding high inline pressure.

The area of wide application of the socketless design is drainage systems and sewage systems without the use of sockets.

Concrete sockets are used for the construction of houses and industrial facilities. Differ in a practicality, durability, the big term of application, profitability.

With the help of concrete structures, a sewerage system, stormwater systems, bypass pipeline systems are laid during the construction of roads.

Concrete sockets are used:

- 1.in a non-pressure system.

- 2.in the pressure system.

- 3.in all kinds of road construction.

For each type, GOST provides individual parameters for the manufacturing method, for the amount of load and the area of \u200b\u200buse.

Type T pipes are intended for laying non-pressure systems, they are laid in sewers, sewage disposal of waste water in a surface, underground way, as well as other liquids that the pipes can withstand. They provide great water permeability, inexpensive to manufacture and install.

Sockets type TB are used for sewers with increased load. The sockets can be initially equipped with rubber rings for sealing, reducing installation time and increasing the tightness of the product.

The most common sockets in operation are five meters long, the pipe section is one meter, and the wall thickness is seventy-five millimeters. They are practical for the installation of sewer collectors, withstand the optimal load when driving five cars on a special platform.

TV type sockets are used in the construction of roads. The sockets have increased strength, are sealed with rubber gaskets, withstand the increased pressure of the soil cover, and the load of the road surface.

A pipe with a socket made of concrete is designed for sewage, it is a rigid, durable structure. The term of use is over fifty years. The sockets are made using high technology from durable material with surface reinforcement.For sockets made of concrete, the quality and price of products correspond to each other, therefore, when laying sewers, many organizations choose these products.

Cast iron products well protect cables laid underground. The sockets resist fire, protect from excessive moisture, mechanical damage. From freezing, the pipes are covered with a layer of geofabric. The disadvantage of the design can be considered that cast iron lends itself to corrosive changes. In order for the pipes to serve for a long time, the pipeline is subjected to anti-corrosion insulation.

Plastic sockets take out cast-iron products from everyday life. Plastic sewer elements are almost weightless, practical to use, have the characteristics of cast iron pipes, but are inferior to them in strength. Plastic structures are made of polyvinyl chloride, polypropylene, polyethylene of different pressure.

They are also used for laying sewers and drainage, but the material limits the scope of pipes. Socket joints are laid with a rubber seal to ensure sealing. Sometimes a welded connection of elements is used. Pipes are made in different colors, which carries information about the purpose in the pipeline system, and also increases the aesthetic appearance of the structure.

How to join sewer pipes?

All communication installation methods available today are conditionally divided into two groups:

- detachable;

- one-piece.

In the first case, the dismantling of the pipeline is possible. To connect sections of communications, use couplings and flanges. Additional elements must match the pipes in size. The outer diameter must be taken into account.The sleeve is put on the parts of the products, the edges of which are cut at an angle of 90°. The center of this element must coincide with the junction line of communications. In the flange mounting method, bolt fastening is used.

It is possible to connect sewer pipes in an integral way. In this case, the following options for mounting pipeline sections are used:

- socket connection;

- welding, use special equipment (soldering iron for working with plastic);

- adhesive connection;

- installation of fittings.

The first of the options does not require the use of additional elements. When installing plastic products using this technology, only a rubber gasket is used. Additionally, the joint can be treated with silicone sealant.

If a welding method has been chosen, in this case, with the help of special equipment, the heated ends are pressed against each other. This option can be implemented by butt-joining products and by means of an electrofusion coupling. When heated to extreme temperatures, polyvinyl chloride loses its properties, softens, and becomes plastic.

If at this moment a connection is made, the end sections of the communications will be securely fixed, since they are soldered. When the pipeline cools down, it will become solid. It will not be possible to dismantle it without damaging the pipe.

With glue

The method is based on the mutual penetration of the polymer at the molecular level. Adhesive bonding of plastic sewer pipes requires the use of a special adhesive. When applied, it changes the structure of polyvinyl chloride, which allows you to securely connect the elements of the pipeline. Dismantling in this area will not work, you will have to cut communications.Installation instructions:

- The end sections are cleaned: burrs are removed, polished. In this case, the rule applies: the smoother the edges, the better the pipes fit together, which means that a sufficiently strong joint will be obtained.

- To increase the reliability of the connection, the pipes are cleaned of contaminants. If dust or larger fractions remain on the surface, the quality of adhesion will deteriorate. As a result, leaks may occur after a certain period of operation.

- Prepared communications need to be degreased. In this case, the areas on which the adhesive will be applied are treated with a solvent.

- At the last stage, the connection of products is performed. After applying the glue, the ends are pressed tightly against each other. After some time, the composition dries out, a silicone sealant is applied to the seam joint.

This technology is often used when installing a sewer pipe using the socket method. It must be remembered that the adhesive used to install PVC communications contains volatile substances. After being applied to the surface of the pipes, it rapidly loses its properties, so it is necessary to install the pipeline sections as quickly as possible. This takes 1.5 minutes.

With fittings

It is not always advisable to purchase special equipment (a soldering iron for connecting PVC products), especially if the pipeline is being installed internally in an apartment or a private house. The number of seams is small, which means that you can use a simpler method - sewer fittings. Connecting elements are presented in two types:

- cast;

- compression.

There are a large number of versions that differ in configuration: cross, tee, branch, straight and adapter sleeve, revision. For connection with fittings, only a rubber seal is used. It is laid inside the bell. When the pipes are connected, PVC is treated with a sealant along the seam.

The main types of autonomous sewage for a country house

Despite the fact that cesspools are considered by many to be the “last century”, this type of autonomous sewerage is the easiest to build with your own hands.

An equally important argument in defense of cesspools is the fact that their internal arrangement has now changed.

Before you make a sewer in your house like a cesspool, you need to find out the engineering and geological features of your site.

The easiest way to build cesspool walls is with masonry, with ceramic red brick being the most viable option.

If it is possible to use additional equipment, then it is possible to build a cesspool from reinforced concrete rings. Experts recommend concreted the bottom of the cesspool, cover the pit with a slab with equipped ventilation and a special inspection hatch.

You still have not decided how to make a sewer in a private house yourself?

We recommend installing a local autonomous sewage system, for example, a septic tank.

This type of sewerage is especially relevant in those houses where people constantly live, and has gained particular popularity among Russians.

The septic tank is quite simple and reliable in operation, it is easy to install it on your own, following step by step installation guide (it is attached when buying a septic tank, for example, their polypropylene).

In addition, septic tanks do not require frequent cleaning, so you will spend less money on calling a vacuum truck.

Modern septic tanks are even three-chamber, they have a very high degree of purification of wastewater and domestic water due to the elements of the aeration system and biofilters.

To decide which type of autonomous sewerage is most suitable for your home and site, sewerage in a private house video will help.

The sequence of actions in the construction of an individual sewer system

Before you make a sewer in the house, you need to decide on a pan of initial actions:

Determine on the ground where the sewer well (cesspool or septic tank) will be located

Important: the drain well must be located below the level of the house.

Determine the exit point of the sewer from the house.

Carefully inspect the exit point of the collector pipe. Keep in mind that at this point all drains and used water from all plumbing fixtures in your house (sinks in the kitchen, toilet, bath, boiler) will accumulate. to make sure that the collector is mounted correctly (there should be no distortions and deviations).

Only after a preliminary inspection has been made, it is possible to draw up a preliminary sewerage project for a private house. Please note: the external sewer system is usually straight, the internal sewer system usually has many bends and corners. Therefore, it is very important when drawing up its project to calculate all pipe sizes, their bends, and so on.

Only after everything is thought out and calculated, you can start buying the necessary materials.

We proceed to the installation of external and internal sewerage systems.

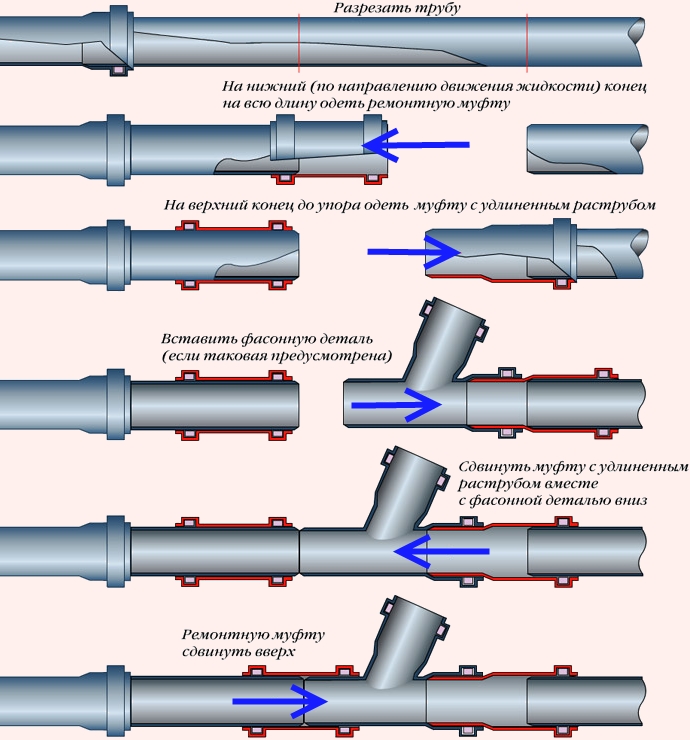

Installation of a sewer system

First, the axes of the pipelines are marked. Then fasteners are mounted, assemblies are assembled from fittings, pipes and pipes. The correctness in horizontal and vertical arrangements is checked. Mounting is being done.

Cutting the pipe "to size" is carried out immediately before installation, so that there is the possibility of "fitting".

Cutting into pieces of a given length, while installing water and sewer pipes, is done with an ordinary hacksaw. The end face is cleaned with a needle file, a chamfer is removed at an angle of 15o.

It is unacceptable to place socket connections between floors, to change the angle of inclination from the calculated one in horizontal sections.

Methods for laying sewer pipes

Installation of a new system begins with sealing the socket of the first element on the riser tee, taking into account the angle of the pipeline. Fixation is made with fixing clamps to the wall or to the floor.

The parts to be joined must be clean and without visible damage and deformations in diameter. Rejection should be made at the acquisition stage.

The installation of plastic sewer pipes is carried out so that the smooth end does not enter the socket all the way. Temperature fluctuations and, as a result, a change in the length of the pipe should be taken into account. A compensation gap of 10 mm will provide the system with tightness in case of temperature changes. With a pipe length of 3-10 m, compensation couplings are used.

Reliability of docking will give silicone sealant. Sealant lubricates the outer part of the pipe (you can not use grease inside).

During installation, it is important to comply with the requirements for the slope of sewer pipes. The use of sound-absorbing pipes (longitudinal stripes of green and red) will reduce the complexity of installing the sewerage system. But one should take into account the high cost of such products.

But one should take into account the high cost of such products.

The use of sound-absorbing pipes (longitudinal stripes of green and red) will reduce the complexity of installing the sewerage system. But you should take into account the high cost of such products.

Noise control: sound-absorbing pipes and sewer pipe soundproofing

Therefore, to reduce sound from sewage drains, the pipe can be insulated. Risers located close to the bedrooms, kitchen or living room need soundproofing. If the riser passes in a place remote from the constant presence of people, then the need for protection against sound vibrations is eliminated.

The assembled system must be checked for leaks. Having collected water in buckets in advance, you need to sharply pour it into the tested device: washbasin, sink, bathtub. The leak should be dismantled and sealed again.

Instructions for assembling sewer pipelines (in text or video formats) will allow you to avoid further operation of the cleaning system, noise from the movement of drains, repair of deformed elements and other unpleasant moments.

Chasing

This method of transferring plastic and cast iron pipes refers more to the installation of cast iron pipes, and chasing implies the performance of sealing works using flax, other materials for winding, followed by pouring with sealant or cement mortar.The pipes are connected, as in the previous case, by introducing a pipe of a smaller diameter (made of PVC) into a pipe or socket of a larger diameter (made of cast iron).

The connection technology is carried out in several stages. First, a layer of glue and sealant is applied to the PVC pipe, then a layer of flax is wound and the pipes are connected, additionally embossing is carried out, flax is stuffed in diameter for better sealing. After that, the junction is filled with sealant, sanitary silicone or other composition. The difference from chasing cast iron pipes is that hot bituminous mastics are not used for this method, which can damage the PVC pipe.

The connection technology is carried out in several stages. First, a layer of glue and sealant is applied to the PVC pipe, then a layer of flax is wound and the pipes are connected, additionally embossing is carried out, flax is stuffed in diameter for better sealing. After that, the junction is filled with sealant, sanitary silicone or other composition. The difference from chasing cast iron pipes is that hot bituminous mastics are not used for this method, which can damage the PVC pipe.

Preparatory work

To lay a pipeline for draining wastewater, you will need special equipment for laying a channel of the desired configuration in floors, walls and furniture.

It is necessary to use the following tools and devices:

- oil or diamond level;

- perforator with a set of drills, impact nozzles and a diamond crown;

- roulette;

- a hammer;

- chisel

- marker;

- Silicone Grease.

Preparation for the installation of the sewer begins with the drawing of a horizontal line from the entrance of the tee to the riser to all water consumers. After that, every 50 cm, marks are made corresponding to the required slope. In order not to be mistaken, during assembly, supports are placed on which pipes will be laid. Holes are drilled in the walls, into which clamps with the corresponding pipe diameter are installed. At the end, drilling of holes, clearing the bed and removing construction debris is carried out.

Connection step by step

Let us consider in more detail the work on the flange connection with our own hands.First of all, it is necessary to prepare for the operation: determine the dimensions and types of flanges, materials, and select a tool.

A set of tools and materials

To dismantle the cast-iron pipeline element, you will need:

- a mallet with a rubber nozzle (you can easily split brittle cast iron with an ordinary hammer);

- grinder for cutting cast-iron parts of the pipe.

For the installation of the structure you need:

- welding machine;

- pipe cutter for plastic;

- plastic pipes;

- flange;

- appropriate seal;

- crimp sleeve for polymer pipes;

- to clean the end of a cast-iron pipe - a file or a cleaning disc for a grinder;

- screwdriver with sockets for bolts or socket wrenches of a suitable size.

Work progress

- Bulgarian cut off the desired size of the end of the pipe.

- They clean it from notches with a file or a special disk using a grinder.

- A flange is welded to the end of the cast-iron pipeline.

- The compression sleeve is put on the plastic part of the structure, and its flange part is bolted to the flange of the cast-iron pipe. A sealing gasket (ring) is placed between them.

Contact socket welding

The connection of sewer steel pipes by resistance socket welding involves preheating the products in a bath or electric furnace and forming a socket using a specially designed mandrel.

In this situation, the inner diameter of the completed socket should be less than the outer one.

Socket welding is carried out by means of a heating element consisting of a mandrel that serves to melt the inner surface of the socket, and a sleeve that contributes to the melting of the outer area of the end face of pipeline fittings.For pipes and parts of each diameter, a separate special element or a set of mandrels and sleeves is required.

The working surface of the heating element is necessarily covered with a fluoroplastic film or other composition that can prevent the sticking of molten materials.

sewerage system

Sewer systems often become clogged. Often this is not due to violations during the installation of the sewer system, but due to the fact that it is often used for other purposes, throwing various garbage into it.

But it is also impossible to write off the errors of installing sewer pipes in the house. Since some "masters" use pipes with a rough surface for the sewerage system, which become clogged an order of magnitude more often than smoothly coated ones. Another mistake is an incorrectly drawn up CS plan, and the assembly is done, right, then the result will be a well-assembled non-working CS, which will become clogged in places of large bending and turning angles.

All this must be foreseen before starting the installation of the sewer system with your own hands.

External sewerage

Scheme of the sewerage system

The external elements of the sewerage include sedimentation tanks, wells and supply pipes. The term of creation and features of operation directly depend on the type of system you have chosen.

The following factors influence the placement of any of the selected options:

- how deep is the sewage

- relief of the local area

- how hard does the soil freeze in winter

- availability of wells in the area

- soil structure

- passage of other communications on the site

Installation of a drain well

sewer well

Installation of a drain well

The easiest option for external sewage is a drain well.How to make it with your own hands?

- Decide where to dig the hole for the well. The well should be located slightly lower than the house

- Dig a supply channel from the house to the pit and the pit itself

Choose the material for lining the walls of the tank - Collect a well, bring a pipe from the house

- Fill in the moat and mount the cover for the tank

The most common tank wall materials are:

- ready-made concrete rings or blocks. For the installation of such structures, lifting equipment is required.

- monolithic structures. In this case, the prepared pit is poured with concrete using metal fittings. There are monolithic septic compartments.

The drain well can be airtight and screening. If you choose airtight, then the bottom of the pit will also need to be laid. At the bottom of screening wells, as a rule, crushed stone or pebbles are poured so that they pass part of the runoff into the soil.

Installation of a septic tank

Installation of a septic tank

Installation of a septic tank

Before starting the construction of a septic tank, you need to prepare its project. The project must take into account the volume of the future structure, take into account construction and sanitary standards. Those who are faced with a similar problem for the first time are advised to seek help in drafting a project from specialists. But you can try to make a project yourself

The most important part of the preparation is the calculation of the volume of the septic tank compartments. In order for wastewater treatment to be carried out as efficiently as possible, wastewater must be in the drain chamber for 3 days. You need to calculate the volume of drained liquid according to the number of people living in the house

Preparation of pits, ditches.Roem a pit for cameras and a ditch from the house for a pipe

We determine the material for septic chambers

Camera assembly. We mount cameras in the pit

Pay special attention to the tightness of the compartments, the joints must be sealed, well sealed

Connection. At the final stage, we connect the pipes to the septic tank and conduct a test

It is necessary to take into account the norms for the placement of waste structures on a personal plot

The most common materials for septic chambers:

- ready-made concrete rings or blocks. For the installation of such structures, lifting equipment is required.

- monolithic structures. In this case, the prepared pit is poured with concrete using metal fittings. Monolithic septic compartments exit

Water filter for the country house: flow, main and other filters (Photo & Video) + Reviews

Nomenclature of the components of the sewer system

The wastewater disposal system is a complex engineering piece of equipment. In addition to the actual sewer pipes, it includes the sanitary devices themselves, such as sinks, toilets, bathrooms, and so on, and connecting devices that bear the common name - fittings.

The installation of the sewer system begins with the preparation of a project, during the development of which it is determined how many sewer connecting nodes you will have at home.

We connect plastic sewer pipes

The most popular and affordable material for the construction of a sewer system are plastic pipes. The material of their manufacture is polypropylene or polyvinyl chloride. They are very light and easy to assemble.The only drawback is the increased noise, so the sewer riser from such pipes must be closed with a box, otherwise you will be aware of everything that happens with the neighbors upstairs.

Scheme of connection of sewer pipes (plastic)

Connection method "in the bell"

Plastic sewer pipes come in several sizes, both in cross section and in length. Of these, it is easy, as from a children's designer, to assemble any equipment of any complexity. The connection process "in the bell" is as follows:

- The pipe joints (smooth end and socket) are carefully cleaned of debris.

- There must be rubber insulation at the junction. If not, you need to choose the right size.

- Apply an even layer of silicone grease or ordinary liquid soap to the smooth end of the pipe. Then the pipes are connected so that there is no play between them, until it stops. On the introduced pipe we make a mark that will show us the depth of the connection.

- Then the pipes are undocked 1 centimeter from the deepest penetration.

Connecting pipes through a socket

The same method can be applied when connecting drainage pipes.

Connection of plastic sewer pipes scheme

We connect plastic pipes on an adhesive basis

Polyvinyl chloride sewer pipes are very often interconnected with special glue. To do this, you must perform the following operations:

- Clean and degrease the surfaces that will be in contact with each other during gluing.

- Apply glue to the surfaces to be glued with a brush.

-

Insert the pvc sewer pipes one into the other and fix them in a fixed position for about a minute. During this time, the glue will set.The joints must be sealed with another adhesive layer. The adhesive layer should be applied to the joints in the form of a small roller. This will give additional strength to the structure and serve as a guarantee against sewage leaks.

We connect plastic pipes with a weld

Some types of plastic sewer pipes can be welded together. To carry out such an operation, specialized equipment is needed - a plastic welding machine. With its help, the ends of the pipes are heated, their ends begin to melt. The ends of the pipes melting from high temperature are pressed against each other and fixed for a while, until the plastic cools and sets. As a result, a monolithic connection appears between the ends of the plastic pipes, which is completely identical in terms of strength qualities to a conventional section of the pipe.

Video lesson - how to solder plastic pipes with your own hands

We connect plastic pipes with fittings

Purchasing or leasing a welding machine makes sense if you do a lot of installation work. In the event that the entire sewerage system has several articulated connections, it is easier to install using fittings or couplings. This connection method is also recommended for fixing pipes and corrugated hoses. In any case, when using a coupling-fitting to connect pipes, it is necessary to use rubber or silicone gaskets to ensure the tightness of the joint.

And one more thing - plastic pipes do not have very high bending resistance. Therefore, in order for them not to sag, it is better to mount them along the walls on special brackets.

Plastic Pipe Welding Machine

Ceramic

Ceramic pipes used in a free-flow sewerage device are connected into a socket or by means of a coupling. Product parameters:

- length - up to 1,500 mm;

- wall thickness - 20–40 mm;

- diameter - 100–600 mm;

- resistance to loads - 240–350 MPa;

- moisture absorption - 7.5–8%;

- resistance to aggressive environments - 90-95%.

Standards: GOST 286-82. The inner surface of the products is coated with a special glaze that provides resistance to chemicals. 5 notches are made on the inner surface of the socket, the same notches are made on the smooth end of the pipe.

Ceramic

Low water absorption, high resistance to corrosion, chemically active substances, mechanical stress provide the possibility of using products in adverse conditions:

- in sewer networks laid in places with a high level of occurrence of aggressive groundwater;

- in production networks transporting chemically active effluents;

- in the device of sewer networks laid near highways.

Flaws:

- short length - complicates and increases the cost of installation;

- large weight - complicates and increases the cost of installation (requires a cushion device and the use of equipment) and transportation;

- fragility;

- high cost;

- low frost resistance - requires additional work on thermal insulation.

Ceramics are very difficult to cut, which, again, complicates installation. The length of the elements must be calculated at the design stage to avoid cutting.

Arrangement of joints of ceramic pipes

The use of ceramic pipes in the sewerage system of a private house is in the vast majority of cases impractical.

Areas of use for pipes with a socket

Transportation of liquids, sewerage, storm system is impossible without the use of a special type of pipe. The socket design is reliable and easy to use, relatively inexpensive to manufacture and practical to operate. Its application is ubiquitous:

- industrial and civil construction;

- hydraulic works of various directions;

- road construction;

- construction of railway facilities and tracks;

- Agriculture.

Pipe structures are made from various materials. The main ones that have firmly entered the practice of application are concrete, cast iron and plastic. Each type has its own merits and demerits. The technical characteristics of these products predetermine the scope of their application.

Installation with sealant and special adhesive

Installation with sealant and glue occurs in a certain order:

- The outer smooth end of the socket pipe should be rubbed with coarse sandpaper. The rough surface that will be obtained after the procedure will provide the best adhesion to the walls inside the funnel-shaped expansion.

- Approximately at a distance of two centimeters from the edge of the pipe, apply a strip of glue or sealant, and its width should be such that the glue, after placing the pipe in the socket, does not flow out of the pipe, but is evenly distributed over its surface.

- Allow the sealant to dry a little - about half a minute.

- Then insert the end of the element with glue into the socket and press for a couple of seconds.

- After that, give the product a certain time to solidify. More accurate figures are indicated on the container with the drug used.

- Having endured all conditions, test the system.