- 5 Do-it-yourself ventilation deflector

- Popular product types

- How to make a do-it-yourself chimney deflector

- How to calculate a static deflector

- Self-assembly of the deflector

- Why you need a chimney deflector and how it works

- How to make a TsAGI deflector on a chimney pipe with your own hands

- Required Tools

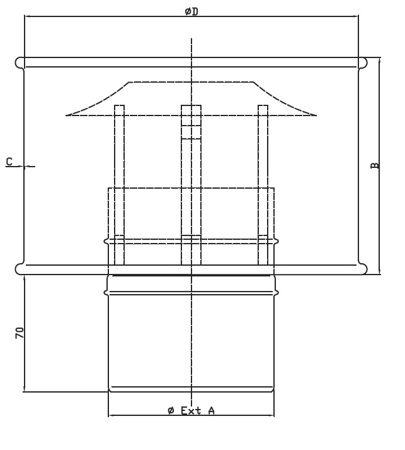

- Development of a drawing of the TsAGI deflector model

- Step-by-step instruction

- Classification of deflectors for chimneys

- Options for gas ducts for a country house

- Selection Guide

- Chimney of solid fuel boiler

- The device of the smoke channel deflector and the principle of its operation

- Main types

- Varieties

- Installation of a ventilation deflector

5 Do-it-yourself ventilation deflector

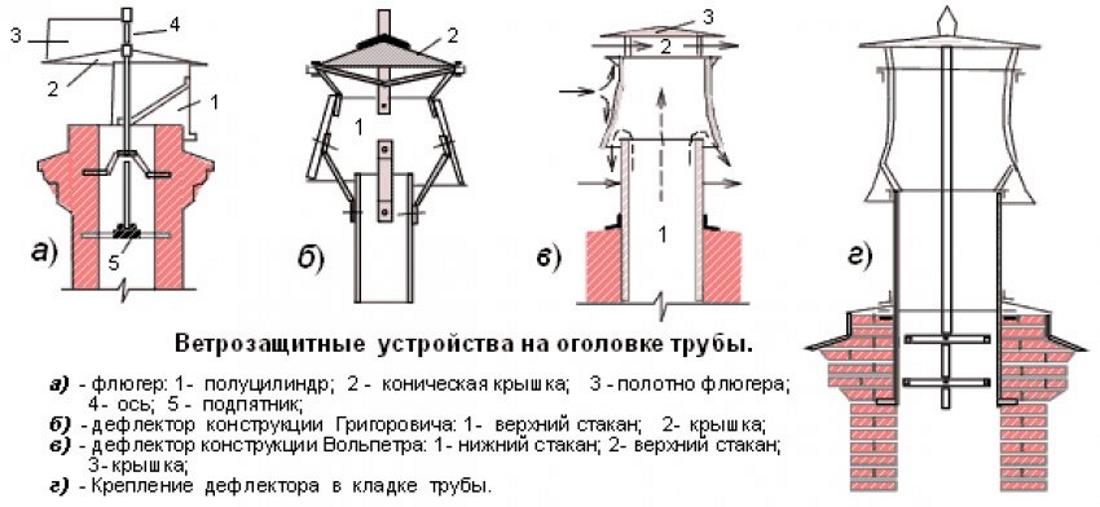

Knowing about the device and the principle of operation of the device, many owners decide to make a ventilation deflector with their own hands. From the point of view of his own implementation, the version of Grigorovich's product is unrivaled, so we will consider the implementation of this particular version. The main advantage is that such ventilation works without electricity, all year round.

You should first prepare:

- stainless steel sheet type, can be replaced with galvanized;

- electric drill;

- fixing clamps, bolts, rivets and nuts;

- drawing tool for metal surfaces;

- compass;

- sheet cardboard;

- ruler;

- scissors for metal and paper.

Popular product types

You probably noticed that they come in different shapes. Modern devices may have different tops:

- flat

- Semicircle

- with lid

- With gable roof

semicircular cap

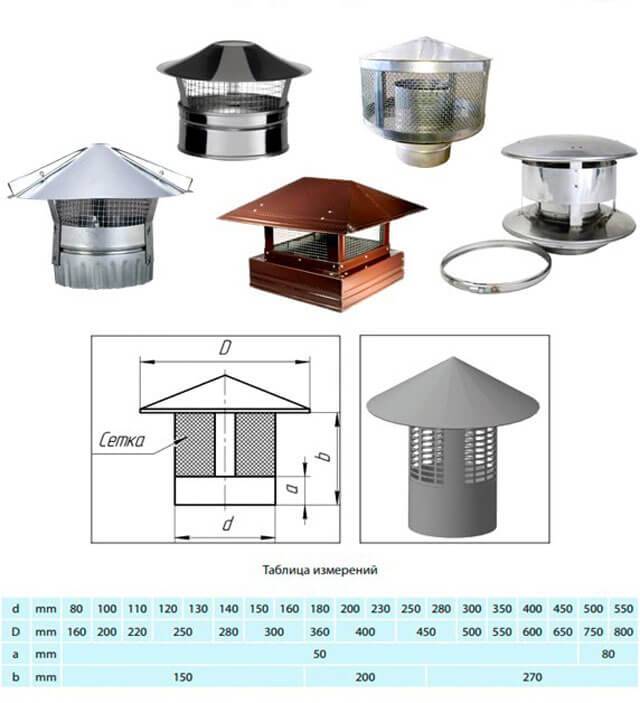

The first type is most often installed on houses made in the Art Nouveau style. For ordinary modern buildings, a semicircular cap is mainly used. A deflector gable roof does the best job of protecting the chimney from snow.

Chimneys are mainly made of galvanized iron, less often of copper. But today products covered with enamel or heat-resistant polymer are coming into fashion. If the device is used on ventilation ducts where there is no direct contact with heated air, then a plastic cap can be used.

The designs of the deflectors are also different.

In the domestic market, the most popular are:

- TsAGI deflector, spherical with rotation, open "Astato"

- Grigorovich's device

- "Smoke Tooth"

- Round chimney "Voller"

- Star Shenard

Various types of chimney caps

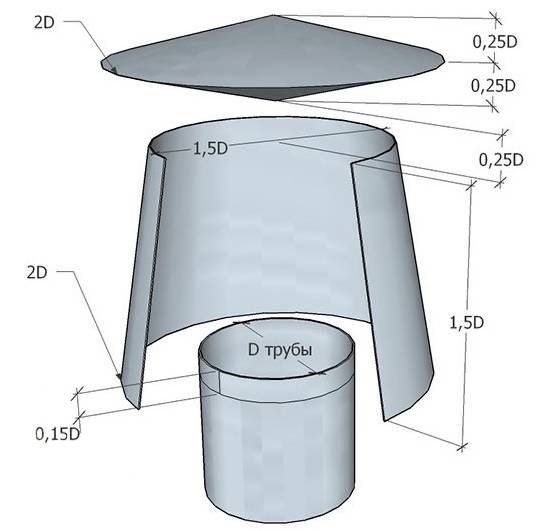

The TsAGI deflector has become the most popular in the Russian open spaces. Its package includes:

- Branch pipe (inlet)

- frame

- Diffuser

- Umbrella

- brackets

You can buy a factory deflector and install it on the chimney, but some people prefer to make it themselves from scrap materials. To do this, follow a few simple rules.

This is a mechanism that has a rotating body and is connected to a bearing assembly, specially curved parts are fixed on it. The weather vane itself is located on top, it allows the entire device, as it were, to constantly keep in the wind.

The ring with a bearing assembly built into it is attached to the chimney cut with strong bolts. The air flow passing between the visors is accelerated, which leads to the creation of a rarefied zone. Thrust, respectively, increases and increases the efficiency of the output of combustion products.

How to make a do-it-yourself chimney deflector

First you need to decide what material it will be created from. It can be galvanized iron or stainless steel. Copper is also suitable, although it is an expensive material. The use of these metals is due to the fact that the deflector must be as resistant to temperature extremes and atmospheric influences as possible.

The device has its own specific parameters that must be adhered to. For example, the height of the chimney should be 1.6-1.7 parts of the inner diameter of the pipe, and the width should be 1.9.

The device has its own specific parameters that must be adhered to. For example, the height of the chimney should be 1.6-1.7 parts of the inner diameter of the pipe, and the width should be 1.9.

The sequence of work on the independent creation of the deflector is as follows:

- On cardboard we draw a scan of the main details.

- We transfer the patterns to the metal and cut out individual parts.

- We connect all the elements to one another, using fasteners or welding for this.

- We make steel brackets needed for fastening the cap on the surface of the chimney.

- We collect the cap.

A self-made deflector is first assembled and only then mounted on a pipe. The cylinder is installed first, which is fixed with fasteners. Using clamps, a diffuser is fixed on it, as well as a cap, in the form of an inverse cone. This simple element allows the device to function in any wind.

Watch the video, do it yourself and step by step:

To make a cap yourself, you will need the following items and tools:

- Rubber or wooden mallet

- A hammer

- Bar

- clamps

- Scissors for working with metal

- Steel corner.

To simplify the process of assembling the device, corners are specially cut off on all parts on both sides.

The installation of a deflector is mandatory and is most effective in the presence of an indirect chimney.

When making the device yourself, you must strictly adhere to the proportions indicated above. If the deflector installed on the chimney does not meet these parameters, then it will not be able to properly perform its main function of creating good draft.

We make the cap ourselves, video review:

When making metal blanks on your own, it is best to do this using cardboard patterns cut to the required dimensions. By attaching them to a sheet of metal, it will be enough to circle the details along the contour and you can safely cut them out without fear of making a mistake.

If the pipe has the maximum allowable diameter, then installation will require the use of an extension made of wire.

How to calculate a static deflector

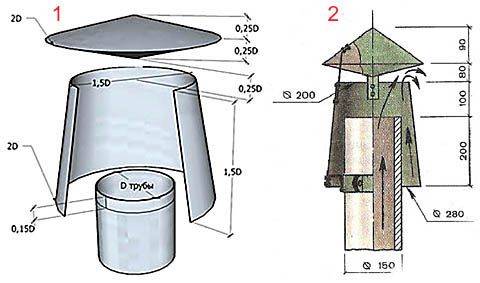

When making the deflector yourself, you need to perform calculations and sketch out a sketch of the future product. You need to proceed from the inner diameter of the chimney pipe.

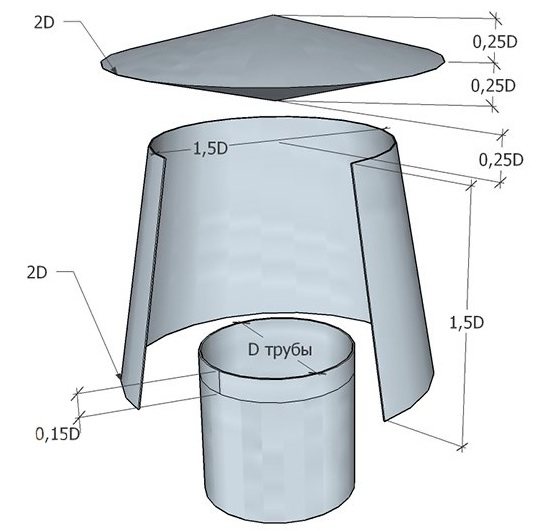

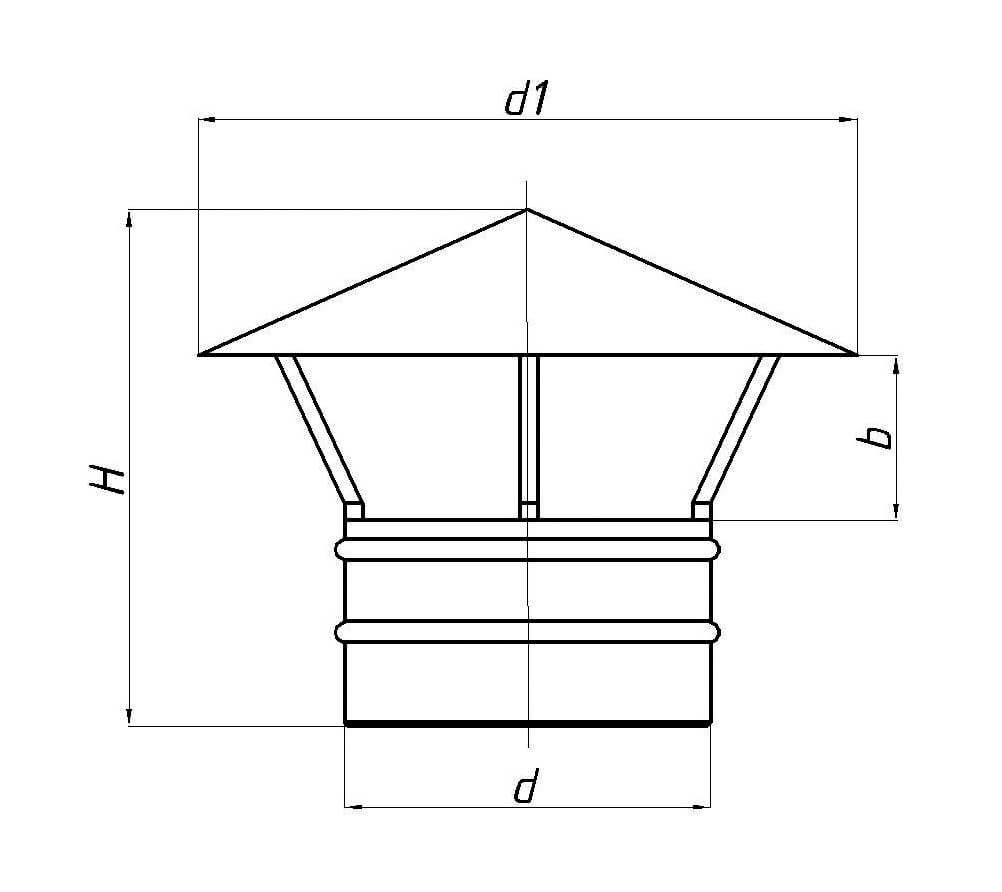

The photo shows the dependence of the size of the deflector on the diameter of the chimney. To determine the lower diameter of the diffuser, the base parameter is multiplied by 2, the upper one by 1.5, the height of the diffuser by 1.5, the height of the cone, including the reverse one, the height of the umbrella itself by 0.25, the pipe entering the diffuser by by 0.15

For a standard device, the parameters can be selected from the table:

The table will allow you to choose the dimensions of the deflector without performing calculations.But if there are no suitable sizes in it, you still have to arm yourself with a calculator or find the appropriate program on the Internet.

In the manufacture of a deflector with individual parameters, these special formulas are also used to determine the dimensions: • Diffuser = 1.2 x din. pipes; • H = 1.6 x din. pipes; • Cover width = 1.7 x din. pipes.

Having learned all the dimensions, you can calculate the sweep of the cone of the umbrella. If the diameter and height are known, then the diameter of the round billet can be easily calculated using the Pythagorean theorem:

R = √(D/2)² + H²

Now we have to determine the parameters of the sector, which will subsequently be cut from the workpiece.

The length of a full circle in 360⁰ L is equal to 2π R. The length of the circle underlying the finished cone Lm will be less than L. The length of the segment arc (X) is determined from the difference of these lengths. To do this, make up the proportion:

L/360⁰ = Lm/X

The desired size is calculated from it: X \u003d 360 x Lm / L. The resulting value of X is subtracted from 360⁰ - this will be the size of the cut sector.

So, if the height of the deflector should be 168 mm and the diameter 280 mm, then the radius of the workpiece is 219 mm, and its circumferential length Lm = 218.7 x 2 x 3.14 = 1373 mm. The desired cone will have a circumference of 280 x 3.14 = 879 mm. Hence 879/1373 x 360⁰ = 230⁰. The cut sector should have an angle of 360 - 230 = 130⁰.

When you need to cut a workpiece in the form of a truncated cone, you have to solve a more difficult task, because. the known value will be the height of the truncated part, and not the entire cone. Regardless of this, the calculation is performed on the basis of the same Pythagorean theorem. The total height is found from the proportion:

(D – Dm)/ 2H = D/2Hp

Whence it follows that Hp = D x H / (D-Dm).Having learned this value, calculate the parameters of the workpiece for a full cone and subtract the upper part from it.

With known parameters: the height of the cone - full or truncated and the radius of the base, by simple calculations, simply determine the radius of the outer and inner (in the case of a truncated cone) and then the initial angle and length of the generatrix of the curve

Suppose a truncated cone is required, in which H \u003d 240 mm, the diameter at the base is 400 mm, and the upper circle should have a diameter of 300 mm.

- Total height Hp = 400 x 240 / (400 - 300) = 960 mm.

- Workpiece outer radius Rz = √(400/2)² + 960² = 980.6 mm.

- Smaller hole radius Rm = √(960 - 240)² + (300|2)² = 239 mm.

- Sector angle: 360/2 x 400/980.6 = 73.4⁰.

It remains to draw one arc with a radius of 980.6 mm and the second one with a radius of 239 mm from the same point and draw the radii at an angle of 73.4⁰. If it is planned to overlap the edges, then allowances are added.

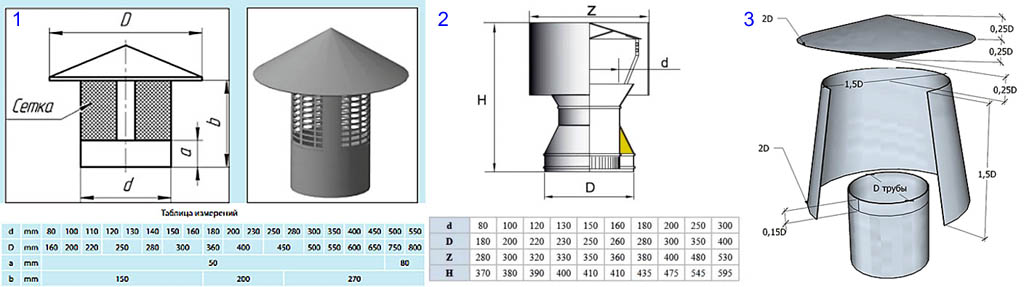

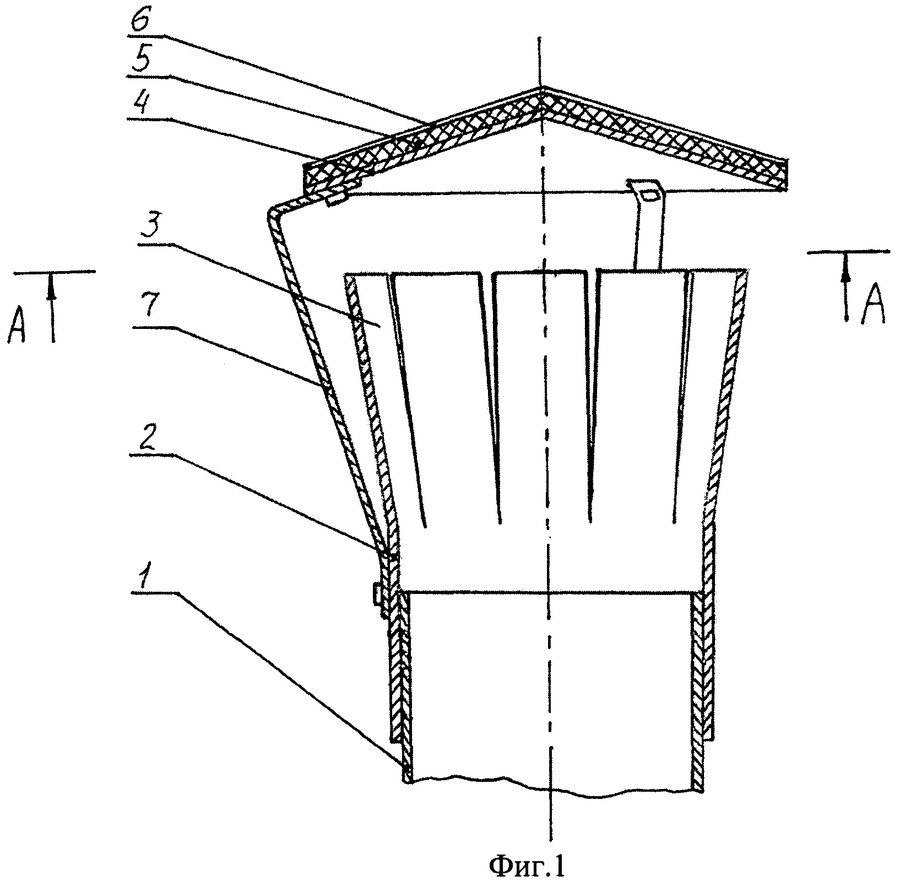

Self-assembly of the deflector

First, patterns are prepared, then they are laid out on a sheet of metal and the parts are cut out using special scissors. The body is folded, the edges are fastened with rivets. Next, the upper and lower cones are attached to each other, using the edge of the first one for this. it is larger and special fixing cuts about 1.5 cm wide can be cut in it in several places, and then bent.

It is not difficult to assemble a simple deflector, but if a rotational type device is to be installed, you will have to deal with many parts

Before assembly, 3 racks are installed in the lower cone, evenly distributing them around the perimeter and using threaded studs for this.To connect the umbrella to the diffuser, loops of metal strips are riveted on the latter. The racks are screwed into the hinges and, for greater reliability, they are fixed with nuts.

Further, they carry out work on the installation of a deflector made by hand on the chimney of a gas or other type of boiler. The assembled device is placed on the pipe and fixed using clamps, avoiding gaps. Sometimes the joint is treated with a heat-resistant sealant.

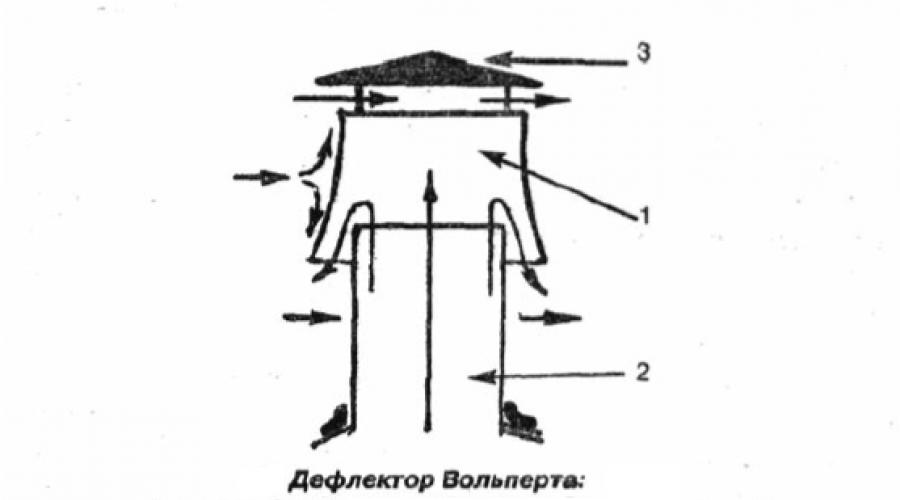

Why you need a chimney deflector and how it works

Even the best stove will not be able to show good results if its chimney does not create the necessary draft. It is this factor that affects the efficiency of air supply and the timely removal of exhaust gases.

and a decrease in efficiency is facilitated by strong winds and sudden changes in atmospheric pressure. These weather factors cause flue gas turbulence and can cause reverse thrust, in which the direction of movement of the combustion products is reversed. In addition, precipitation and debris easily enter the open chimney, which significantly reduces the cross section of the smoke channel. It is clear that there can be no question of any normal operation of the furnace under such conditions.

Being a reflector of air flows, the deflector, in fact, serves as an ordinary barrier to the wind.

Bumping into an obstacle, the air flow bypasses it from two sides, so immediately behind the reflector there is a low pressure area. This phenomenon has been known since the school course of physics as the Bernoulli effect. It is this that contributes to the enhanced removal of gases from the combustion zone and allows you to supply the furnace with the necessary amount of air.

The principle of operation of the deflector is based on the appearance of a low pressure zone on the leeward side

More recently, engineers have been closely involved in this topic. During numerous experiments, they found that with just the right choice of deflector, the thermal efficiency of the furnace can be increased by 20%

It is also important that the reflective device improves the aerodynamic properties of the chimney, regardless of the strength and direction of the wind, the presence of precipitation and other weather factors.

How to make a TsAGI deflector on a chimney pipe with your own hands

The process of developing and assembling a deflector on an exhaust pipe consists of four stages: drawing, creating blanks, assembling, installing the structure and fixing it directly on the chimney.

Required Tools

You will definitely need:

- a sheet of thick paper for drawing and layout;

- marker for marking;

- riveter for connecting structural elements;

- scissors for metal for cutting parts;

- drill;

- a hammer.

Do not forget about the right tool before installing the deflector

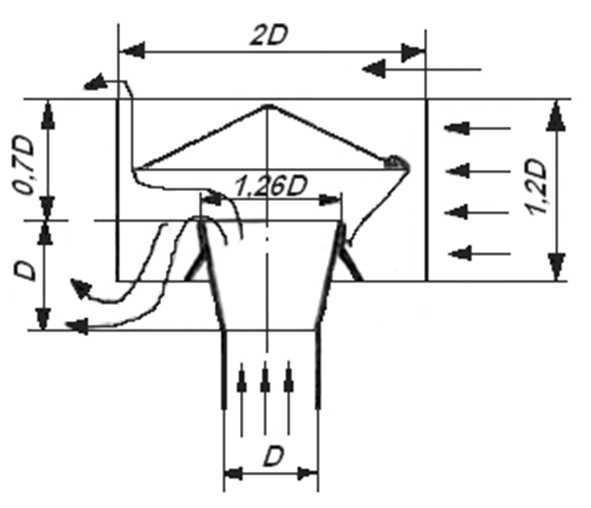

Development of a drawing of the TsAGI deflector model

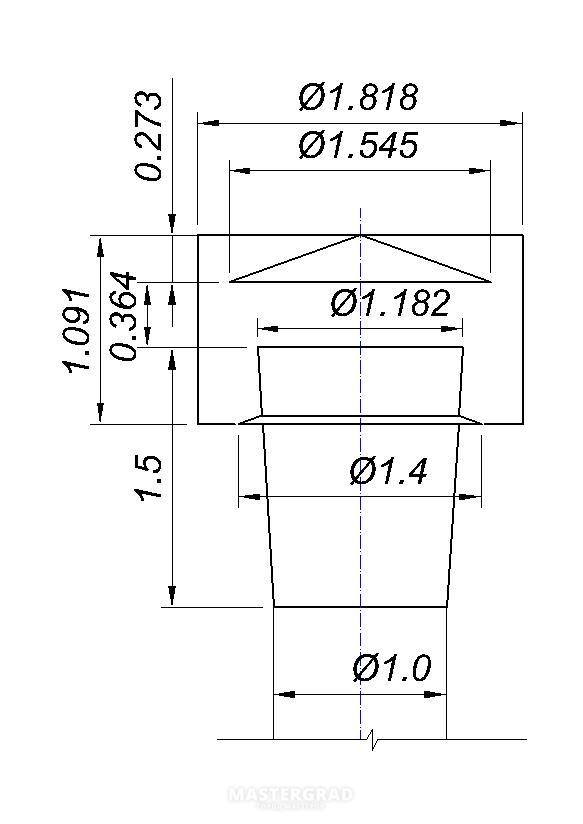

There is an algorithm for how to make a deflector on a chimney pipe with your own hands. The first step is recommended to be done on paper. First you need to calculate the dimensions of the diameter of the nozzle and the upper cap of the structure, as well as calculate the height of the reflector.

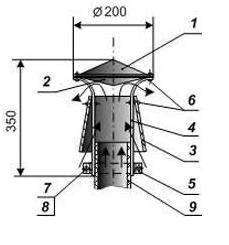

For this, special formulas are used:

- diameter of the upper part of the deflector - 1.25d;

- diameter of the outer ring - 2d;

- construction height - 2d + d / 2;

- ring height - 1.2d;

- cap diameter - 1.7d;

- the distance from the base to the edge of the outer casing is d/2.

Where d is the diameter of the chimney.

A table will help to facilitate the task, which contains ready-made calculations for standard sizes of metal pipes.

| Chimney diameter, cm | Outer casing diameter, cm | Height of the outer casing, cm | Diffuser outlet diameter, cm | Cap diameter, cm | Installation height of the outer casing, cm |

| 100 | 20.0 | 12.0 | 12.5 | 17.0…19.0 | 5.0 |

| 125 | 25.0 | 15.0 | 15.7 | 21.2…23.8 | 6.3 |

| 160 | 32.0 | 19.2 | 20.0 | 27.2…30.4 | 8.0 |

| 20.0 | 40.0 | 24.0 | 25.0 | 34.0…38.0 | 10.0 |

| 25.0 | 50.0 | 30.0 | 31.3 | 42.5…47.5 | 12.5 |

| 31.5 | 63.0 | 37.8 | 39.4 | 53.6–59.9 | 15.8 |

If the chimney has a non-standard width, then all calculations will have to be done independently. But, knowing the formulas, it is easy to measure the diameter of the pipe and determine all the necessary indicators to use them when drawing up drawings.

When the patterns are made, it is recommended to first assemble a paper prototype of the future reflector. Even if you are an experienced craftsman and are sure that you will construct a deflector for a stove chimney with your own hands without problems, you should not skip this step, since it will help you identify possible errors and flaws, and correct calculations or a drawing. Only after creating the correct paper layout, which confirms that the deflector scheme is accurate, you can proceed to the next step.

Step-by-step instruction

There is a work order that must be followed, otherwise you will not be able to connect the individual parts of the chimney deflector yourself with your own hands.

The procedure is as follows:

- Using paper blanks, transfer the template to the surface of the metal from which you plan to make a reflector. Carefully trace the outlines of the paper details. You can use a permanent marker, special chalk and even a simple pencil for this purpose.

- Using scissors for metal, cut out the blanks of the necessary structural details.

- Along the entire contour on the sections, the metal must be bent by 5 mm and carefully walked with a hammer.

- Roll the workpiece into a cylinder shape, drill holes for fasteners so that you can connect the structure with rivets. Welding is allowed, but not arc welding. Care must be taken not to burn through the metal. The distance between the main attachment points, choose from 2 to 6 cm, it varies according to the size of the finished structure. The outer cylinder is folded and fastened in the same way.

- Bending and connecting the edges, make the rest of the details: an umbrella and a protective cap in the form of a cone.

- Fasteners must be cut out of the galvanized sheet - 3-4 strips: width 6 cm, length - up to 20 cm. Bend around the entire perimeter on both sides and walk along them with a hammer. From the inside of the umbrella, it is necessary to drill mounting holes, departing from the edge by 5 cm. 3 points will be enough. After that, fasten the metal strips to the cap with rivets. Then they need to be bent at an angle of 90 degrees.

- Connect the diffuser and cone using rivets to the inlet pipe. Having made a deflector for a round pipe with your own hands, you can proceed with its installation.

A Volper chimney deflector can also be created using a similar method. Its design is very similar to the TsAGI model, but there are some differences in the upper part. They are also made of stainless steel, galvanized or copper.

Classification of deflectors for chimneys

All devices are divided into three large groups according to several criteria.

Before making a final decision, it is recommended that you familiarize yourself with the most famous deflector designs.

The comparative table will list only those models that are popular with private developers.

Table.Types of deflectors for the chimney

| Grigorovich's cap | A classic and very common option, the speed of movement of combustion products increases by about 20–25%. The device consists of two almost identical umbrellas connected into one structure at a small distance between them. Can be installed on both round and square chimneys. Due to the design features, there is a double acceleration of the movement of air flows: in the direction of the constriction of the diffuser and towards the upper return hood. |

| TsAGI nozzle | The model was developed by employees of the Central Aerohydrodynamic Institute, in the recent past the most famous specialized scientific institution. Thrust is enhanced by attracting wind pressure and pressure difference in height. The nozzle inside has an additional screen, inside of which a traditional deflector is installed. The TsAGI nozzle eliminates the effect of reverse thrust. The disadvantage is that under certain climatic conditions in the winter period, frost may appear on the walls, which worsens the parameters of the chimney draft. |

| Cap Astato | The product was developed by specialists of the French company Astato. It consists of a static and dynamic part, it is rarely used on chimneys. The reason is that the extremely difficult operating conditions of the fan put forward strict requirements for reliability and security. Such fans significantly increase the overall cost of installing chimney pipes. |

| Turbo deflectors | Quite complex devices, consisting of a rotating turbine head and a fixed body. Due to the rotation of the blades under the hood of the device, the pressure decreases, the smoke from the chimney is sucked out more efficiently.Modern bearings allow the turbine to rotate at a wind speed of only 0.5 m/s, which significantly improves the performance of the chimneys. Turbo deflectors are 2–4 times more efficient than static models and have an attractive appearance. |

| Rotatable hoods | The protective visors are connected to the chimney pipe by a small bearing closed on both sides. The canopy has a curved geometry and in terms of projection completely covers the cross section of the chimney. A weather vane is installed on top of the hood, which rotates the structure depending on the direction of the wind. Air flows pass through special slots and go up. Such movement causes a decrease in pressure and an increase in the natural draft of the exhaust gases from the chimney. |

| H-shaped module | It is most often mounted on industrial chimneys. The main feature is the ability to work with strong gusts of wind. In addition, the possibility of reverse thrust is completely eliminated. |

The master should choose a suitable deflector after a careful analysis of all factors. But it must be borne in mind that very strong traction has not only positive, but also negative sides. What exactly?

- The air movement is so fast that the wick is extinguished. This problem often occurs on gas heating boilers. Modern models have automatic ignition with an electric spark. It constantly works, which causes inconvenience to users. Boilers of an outdated design are not equipped with such devices; they have to be started manually.

If the draft is too strong, the flame in the boiler will constantly blow out

- Strong draft reduces the efficiency of the heating boiler.Hot combustion products for a short period of contact with the heat exchanger do not have time to give it the maximum amount of thermal energy. A significant part of it is removed through the chimney, which increases the cost of financial resources for the maintenance of the building in the winter.

Strong draft significantly reduces the efficiency of the boiler, as a result of which heating costs increase

- The strong draft of the chimney causes an increased influx of cold outside air. As a result, the comfort of staying in the premises worsens, the temperature drops, it is necessary to increase the power of the boilers. And this, taking into account the current cost of energy carriers, is reflected in the financial situation of users.

Method for checking the presence and strength of draft in the chimney

Options for gas ducts for a country house

To discharge combustion products with a relatively low temperature (up to 120 ° C) emitted by gas boilers, the following types of chimneys are suitable:

- three-layer modular stainless steel sandwich with non-combustible insulation - basalt wool;

- a channel made of iron or asbestos-cement pipes, protected by thermal insulation;

- ceramic insulated systems such as Schiedel;

- brick block with a stainless steel pipe insert, covered from the outside with heat-insulating material;

- the same, with an internal polymer sleeve of the FuranFlex type.

Three-layer sandwich device for smoke removal

Let us explain why it is impossible to build a traditional brick chimney or put an ordinary steel pipe connected to a gas boiler. The exhaust gases contain water vapor, which is a product of the combustion of hydrocarbons. From contact with cold walls, moisture condenses out, then events develop as follows:

- Thanks to numerous pores, water penetrates into the building material. In metal chimneys, condensate flows down the walls.

- Since gas and other high-efficiency boilers (on diesel fuel and liquefied propane) operate periodically, frost has time to grab moisture, turning it into ice.

- Ice granules, increasing in size, peel the brick from the inside and out, gradually destroying the chimney.

- For the same reason, the walls of an uninsulated steel flue closer to the head are covered with ice. The passage diameter of the channel decreases.

Ordinary iron pipe insulated with non-combustible kaolin wool

Selection Guide

Since we initially undertook to install an inexpensive version of the chimney in a private house, suitable for do-it-yourself installation, we recommend using a stainless steel pipe sandwich. Installation of other types of pipes is associated with the following difficulties:

- Asbestos and thick-walled steel pipes are heavy, which complicates the work. In addition, the outer part will have to be sheathed with insulation and sheet metal. The cost and duration of construction will definitely exceed the assembly of a sandwich.

- Ceramic chimneys for gas boilers are the best choice if the developer has the means. Systems such as Schiedel UNI are reliable and durable, but too expensive and out of reach for the average homeowner.

- Stainless and polymer inserts are used for the reconstruction - lining of existing brick channels, previously built according to old projects. Specially fencing such a structure is unprofitable and pointless.

Flue variant with ceramic insert

A turbocharged gas boiler can also be connected to a conventional vertical chimney by organizing the supply of outside air through a separate pipe.The technical solution should be implemented when a gas duct has already been made in a private house, brought to the roof. In other cases, a coaxial pipe is mounted (shown in the photo) - this is the most economical and correct option.

Noteworthy is the last, cheapest way to build a chimney: make a sandwich for a gas boiler with your own hands. A stainless pipe is taken, wrapped in basalt wool of the required thickness and sheathed with galvanized roofing. The practical implementation of this solution is shown in the video:

Chimney of solid fuel boiler

The mode of operation of wood and coal heating units involves the release of hotter gases. The temperature of the combustion products reaches 200 ° C or more, the smoke channel warms up completely and the condensate practically does not freeze. But it is replaced by another hidden enemy - soot deposited on the inner walls. Periodically, it ignites, causing the pipe to heat up to 400-600 degrees.

Solid fuel boilers are suitable for the following types of chimneys:

- three-layer stainless steel (sandwich);

- single-wall pipe made of stainless or thick-walled (3 mm) black steel;

- ceramics.

Brick gas duct of rectangular section 270 x 140 mm is lined with an oval stainless pipe

It is contraindicated to put asbestos pipes on TT-boilers, stoves and fireplaces - they crack from high temperatures. A simple brick channel will work, but due to roughness it will become clogged with soot, so it is better to sleeve it with a stainless insert. Polymer sleeve FuranFlex will not work - the maximum operating temperature is only 250 ° C.

The device of the smoke channel deflector and the principle of its operation

All chimney deflectors have the same design and consist of four elements:

- cylinder;

- diffuser;

- ring breaks;

- protective cap.

Devices may differ in design, dimensions and the number of additional elements, but they all work on the same principle.

Since the design does not create resistance to the internal air flow, the smoke does not get back into the room and is effectively removed outside the building. In addition, the device protects the channel from dirt and debris and looks aesthetically pleasing.

Studies show that installing a deflector on a chimney increases the efficiency of heating appliances by 15–20%. However, this value depends not only on the deflector, but also on the location and diameter of the chimney section.

Main types

Specialized stores offer many design options. Which deflector is better to choose for the chimney will depend on the type of boiler. Very often, simple models are made by hand in order to save money. The most popular reflectors include the following devices:

- TsAGI is considered the most popular device. It has a cylindrical shape. Such a reflector is made of stainless steel or galvanized. According to the type of connection, it can be nipple and flange. The main advantage is a convenient location for the removal of air masses through the ventilation ducts, which improves traction. Through this design, smoke quickly exits the chimney. Among the disadvantages is the difficulty in manufacturing.

- Round Volper is very similar to TsAGI, but it has differences in the upper part. A protective visor is installed there from various contaminants and precipitation.The most relevant model for baths, made of stainless steel, galvanized and copper.

- The Grigorovich reflector is the most affordable option, so it is often made by hand. A simple design consists of an upper and lower cylinder, a cone, nozzles and brackets for fixing. The simplicity of the device is its main advantage, and the high position of the umbrella is considered a minus, which contributes to the side blowing of smoke.

- The H-shaped reflector is suitable for installation with pipe segments, which allows it to withstand maximum wind loads. The main parts of the device are mounted in the form of the letter H. This feature prevents dirt and precipitation from entering the pipe due to the horizontal location of the pipe. The vertically arranged side elements improve internal draft, resulting in smoke being discharged simultaneously in different directions.

- A weather vane is a device with a rotating housing fixed at the top of the chimney. It is made from stainless steel or carbon steel. Peaks that cut through the air currents of the wind are designed to improve draft in the chimney. They also serve to protect boilers and furnaces from contamination from outside. The disadvantage of the device is the fragility of the bearings that contribute to the movement of the visors.

- The plate reflector can also be attributed to the simplest and most affordable deflectors. It protects the chimney system well and provides strong draft. To prevent dirt and precipitation from entering the pipe, the device is equipped with a special visor. In its lower part there is a cap directed towards the pipe. Internal thrust is improved twice due to the narrow and rarefied channel, where air masses enter.

Some of the models can be made independently. To do this, you must have working drawings with the specified dimensions. The required values can be obtained after measuring the inner diameter of the chimney. If there are inaccuracies in the parameters, then difficulties will arise during the installation of the device and during its further operation.

Installation of products is carried out in two ways - on a piece of pipe or on a chimney. The first option is the most convenient, since preliminary work can be done below, and not on the roof, which is safer. Factory products are most often equipped with a lower nozzle, which makes the task easier. It is simply put on the pipe and fixed with metal clamps.

Varieties

Many users are constantly wondering: which deflector is better for the chimney? To answer this question, you need to study the existing models and, based on their characteristics, choose the best option.

Today, there are several varieties of deflectors that have gained popularity due to their practicality and reliability.

Poppet Astato. This deflector is open, but it is very effective. Its main distinguishing feature is that it is able to provide good traction, regardless of which direction the wind is blowing. Production material — galvanized/stainless steel.

Chimney deflector plate Astato

TsAGI deflector. This model is recognized as one of the most popular and in demand. It is made in the form of a cylinder. The material of manufacture is stainless or galvanized steel. Connection type - flange.

Round Volper. In terms of design features, this model resembles the previous one.The main distinguishing feature is the top of the device. Usually such deflectors are made of stainless steel or copper. Most often they are purchased for installation on the chimney of the bath.

Grigorovich deflector. This type is a more modern and improved version of TsAGI. It is installed in places where the winds are generally not very strong.

H-shaped. This model is highly durable and reliable, regardless of the direction of the wind - effective. An H-shaped deflector is made of stainless steel. The connection is made by means of a tie-in on the nozzle of the device.

Weather vane deflector. It is a rotating body, on top of which there is a weather vane. Made from stainless steel or carbon steel.

Types of deflectors for the chimney

Basically, chimney deflectors differ in shape and constituent elements. As can be seen from the examples, products are usually made of stainless steel and galvanized steel. Models are round, square, in the form of an open and closed cylinder. The “top” of the device is also different. In some it has the shape of an umbrella, in others the lid can be gable or hip, and in others it is completely flat or with decorative figured elements.

The diameter of the deflector on the chimney pipe can be 100-500 mm, the width of the diffuser varies from 240 to 1000 mm, the height of the device is 140-600 mm.

The deflector is connected to the chimney using brackets, bolts and sealing tape. It is made of steel, the thickness of which is 0.5-1 mm. You can also install a spark arrester. Typically, equipment is equipped with such a part, in case of a risk of a possible fire of the roof.

Installation of a ventilation deflector

To increase the draft in the supply air ducts, it is best to use Tsaga deflectors. They are characterized by a simple design. Therefore, they can be quickly made by hand.

The cap in question may have a different cross section. It is equipped with a special cylinder. To achieve uninterrupted operation of the device, it must be installed at a distance of one hundred to one hundred and sixty centimeters above the roof.

The design of this device consists of:

- umbrella;

- corps;

- a set of brackets;

- special diffuser;

- inlet pipe.

Installing the device does not require much effort. It's easy enough to deal with.

It is important to mount the device in a free airflow area. It is strictly forbidden to mount the deflector in the aerodynamic shadow created by nearby buildings

The device is placed on the top of the channel. The lower cylinder is fixed with bolts. The diffuser is attached with brackets. The cap is arranged on clamps

It is important to secure every part of the device securely. Be sure to check the operation of the valve, which will allow you to adjust the draft in strong winds

Proper implementation of all recommendations will allow you to create an efficiently working ventilation duct. Note that Tsaga deflectors can also be used to equip chimney pipes.