- Filling methods built-in mechanism and pumps

- Filling the heating with antifreeze

- Automatic filling system

- Automatic make-up of the system

- Installation of the membrane device

- Correct container position

- Features of choosing an installation site

- Setting up the instrument before use

- Tank as additional capacity

- Operating pressure in the heating system of an apartment building

- Types and their meanings

- Working pressure in the heating system of an apartment building: how to control?

- Pressure drops and its regulation

- Norm in an autonomous heating system

- Outdoor leaks

- Optimal Performance

- In an open system

- Closed

- Setup and Troubleshooting

- Recommendations when choosing radiators

- Drops and their causes

- How to increase the pressure in the heating system?

- Why does the pressure in the heating system increase?

- How to eliminate gaps?

- 4 The pressure in the heating system is growing - how to find out the cause

- Ginseng tincture

- Conclusions and useful video on the topic

Filling methods built-in mechanism and pumps

Heating filling pump

How to fill the heating system in a private house - using the built-in connection to the water supply using a pump? This directly depends on the composition of the coolant - water or antifreeze.For the first option, it is enough to pre-flush the pipes. Instructions for filling the heating system consists of the following items:

- It is necessary to make sure that all shut-off valves are in the right position - the drain valve is closed in the same way as the safety valves;

- The Mayevsky crane at the top of the system must be open. This is necessary to remove air;

- Water is filled until water flows from the Mayevsky tap, which was opened earlier. After that, it overlaps;

- Then it is necessary to remove excess air from all heating devices. They must have an air valve installed. To do this, you need to leave the system filling valve open, make sure that air comes out of a particular device. As soon as water flows out of the valve, it must be closed. This procedure must be done for all heating devices.

After filling the water in a closed heating system, you need to check the pressure parameters. It should be 1.5 bar. In the future, to prevent leakage, pressing is performed. It will be discussed separately.

Filling the heating with antifreeze

Before proceeding with the procedure for adding antifreeze to the system, you need to prepare it. Usually 35% or 40% solutions are used, but to save money, it is recommended to purchase a concentrate. It should be diluted strictly according to the instructions, and only using distilled water. In addition, it is necessary to prepare a hand pump to fill the heating system. It is connected to the lowest point of the system and, using a manual piston, the coolant is injected into the pipes. During this, the following parameters must be observed.

- Air outlet from the system (Mayevsky crane);

- Pressure in pipes.It must not exceed 2 bar.

The whole further procedure is completely similar to the one described above. However, you should take into account the features of the operation of antifreeze - its density is much higher than that of water.

Therefore, special attention should be paid to the calculation of the pump power. Some formulations based on glycerin may increase the viscosity index with increasing temperature. Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite

This will greatly reduce the chance of leaks.

Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite ones. This will greatly reduce the chance of leaks.

Automatic filling system

For double-circuit boilers, it is recommended to use an automatic filling device for the heating system. It is an electronic control unit for adding water to pipes. It is installed on the inlet pipe and operates fully automatically.

The main advantage of this device is the automatic maintenance of pressure by the timely addition of water to the system. The principle of operation of the device is as follows: a pressure gauge connected to the control unit signals a critical pressure drop. The automatic water supply valve opens and remains in this state until the pressure stabilizes. However, almost all devices for automatically filling the heating system with water are expensive.

A budget option is to install a check valve. Its functions are completely similar to the device for automatic filling of the heating system. It is also installed on the inlet pipe.However, the principle of its operation is to stabilize the pressure in pipes with a water make-up system. When the pressure drops in the line, the pressure of tap water will act on the valve. Due to the difference, it will automatically open until the pressure stabilizes.

In this way, it is possible not only to feed the heating, but also to fully fill the system. Despite the apparent reliability, it is recommended to visually control the coolant supply. When filling the heating with water, the valves on the devices must be opened to release excess air.

Automatic make-up of the system

The second node that ensures the maintenance of excess pressure in the system is an automatic make-up device. Of course, you can pump water into the system manually, but this is inconvenient to do with large amounts of leakage. For example, if there are many fittings in the system or there are gaps through which microscopic doses of coolant regularly leak. Also, automatic make-up is practically indispensable for closed systems with a special coolant - without a pressure pump, it will simply not be possible to provide a sufficiently high pressure.

The first type of automatic make-up devices works on the principle of a compressor automation group. The high and low pressure switches turn on and off the make-up if the pressure in the system is below or, respectively, above the set threshold. Such devices are the simplest and cheapest, but they have the main drawback - they do not take into account the temperature of the liquid and the degree of its expansion.

Let's say, during the operation of the system, the pressure drops by 20–30% below the operating pressure, but at the same time does not reach the minimum threshold that the relay is set to.This is not surprising, because the calibration of the relay occurs in the cold state of the system. Another special case: when the relay is activated, the make-up is turned on, adding a portion of cold, that is, not yet expanded liquid, to the system. If the expansion tank has insufficient capacity, as a result, the expansion of the coolant will trigger the safety valve, part of the coolant will be released, the pressure will drop again, the make-up will turn on again and then in a circle.

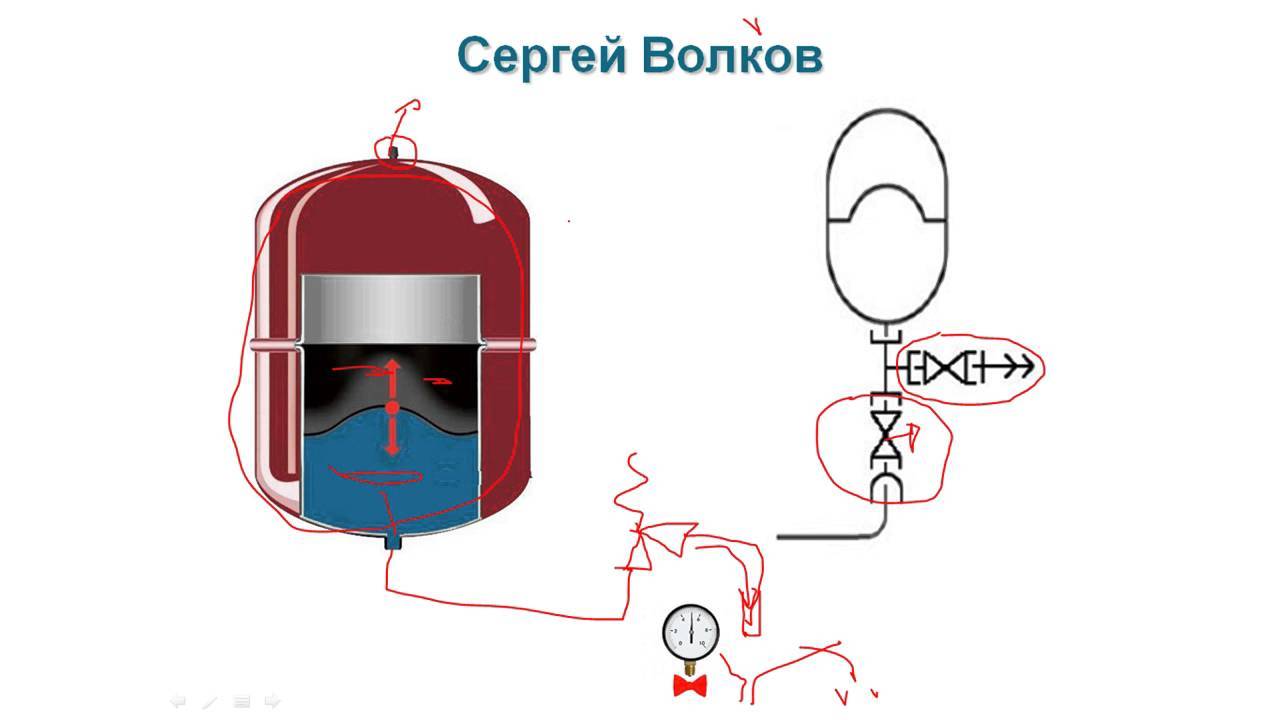

The described nuance is important for heating systems that contain over 300 liters of water. It is optimal in such cases to use digital make-up dispensers, which are equipped with most advanced boiler equipment. The controller will make the necessary corrections and add a strictly defined amount of coolant to the system, taking into account its temperature and ability to expand. Like conventional mechanical make-up valves, it is better to connect the electronic dispenser to the supply line immediately after inserting the bypass tube into it in order to avoid temperature shock of the heat exchanger. It is recommended to install a mud or cartridge filter on the coolant inlet pipe, the injection unit is connected through a ball valve.

Installation of the membrane device

A hydraulic accumulator of this type is installed where there is a minimum probability of coolant turbulence, since a pump is used for the normal circulation of the water flow along the circuit.

Correct container position

When connecting an expansion tank to a closed heating system, it is imperative to take into account the location of the air chamber of the device.

The rubber membrane periodically stretches and then contracts.Due to this impact, microcracks appear on it over time, which gradually increase. After that, the membrane has to be replaced with a new one.

If the air chamber of such a tank remains at the bottom during installation, then the pressure on the membrane will increase due to gravitational influence. Cracks will appear faster, repairs will be needed sooner.

It makes more sense to install the expansion tank so that the compartment filled with air remains on top. This will extend the life of the device.

Features of choosing an installation site

There are a number of requirements to consider when installing a membrane expansion tank:

- It cannot be placed close to the wall.

- Ensure free access to the device for its regular maintenance and necessary repairs.

- The tank hung on the wall should not be too high.

- A stopcock should be placed between the tank and the heating pipes, which will allow the device to be removed without completely draining the coolant from the system.

- The pipes connected to the expansion tank, when wall-mounted, must also be attached to the wall in order to remove possible additional load from the tank nozzle.

For a membrane device, the return section of the line between the circulation pump and the boiler is considered the most suitable connection point. Theoretically, you can put an expansion tank on the supply pipe, but the high temperature of the water will adversely affect the integrity of the membrane and its service life.

When using solid fuel equipment, such placement is also dangerous because steam can enter the container due to overheating.This will seriously disrupt the operation of the membrane and may even damage it.

In addition to the stopcock and the “American”, it is recommended to install an additional tee and a tap when connecting, which will allow you to empty the expansion tank before turning it off.

Setting up the instrument before use

Before installation or immediately after it, it is necessary to correctly adjust the expansion tank, otherwise called the expansion tank. This is not difficult to do, but first you need to find out what pressure should be in the heating system. Let's say an acceptable indicator is 1.5 bar.

Now you need to measure the pressure inside the air part of the membrane tank. It should be less than about 0.2-0.3 bar. Measurements are carried out with a manometer with a suitable graduation through a nipple connection, which is located on the tank body. If necessary, air is pumped into the compartment or its excess is bled off.

The technical documentation usually indicates the working pressure, which is set by the manufacturer at the factory. But practice shows that this is not always true. During storage and transportation, part of the air could escape from the compartment. Be sure to take your own measurements.

If the pressure in the tank is set incorrectly, this can lead to air leakage through the device for removing it. This phenomenon causes a gradual cooling of the coolant in the tank. It is not necessary to pre-fill the membrane tank with coolant, just fill the system.

Tank as additional capacity

Modern models of heating boilers are often already equipped with a built-in expansion tank. However, its characteristics do not always correspond to the requirements of a particular heating system.If the built-in tank is too small, an additional tank must be installed.

It will ensure the normal pressure of the coolant in the system. Such an addition will also be relevant in case of a change in the configuration of the heating circuit. For example, when a gravity system is converted into a circulation pump and old pipes are left.

This is true for any systems with a significant amount of coolant, for example, in a two-three-story cottage or where, in addition to radiators, there is a warm floor. If a boiler with a small built-in membrane tank is used, the installation of another tank is almost inevitable.

An expansion tank will also be appropriate when using an indirect heating boiler. A relief valve, similar to that installed on electric boilers, will not be effective here, an expansion valve is an adequate way out.

Operating pressure in the heating system of an apartment building

The page contains information about the operating pressure in the heating system of an apartment building: how to control the drop in pipes and batteries, as well as the maximum rate in an autonomous heating system.

For efficient operation of the heating system of a high-rise building, several parameters must comply with the norm at the same time.

The water pressure in the heating system of an apartment building is the main criterion by which they are equal, and on which all other nodes of this rather complex mechanism depend.

Types and their meanings

The working pressure in the heating system of an apartment building combines 3 types:

- Static pressure in the heating of apartment buildings shows how strongly or weakly the coolant presses from the inside on pipes and radiators.It depends on how high the equipment is.

- Dynamic is the pressure with which water moves through the system.

- The maximum pressure in the heating system of an apartment building (also called “permissible”) indicates what pressure is considered safe for the structure.

Since almost all multi-storey buildings use closed-type heating systems, there are not so many indicators.

- for buildings up to 5 floors - 3-5 atmospheres;

- in nine-story houses - this is 5-7 atm;

- in skyscrapers from 10 floors - 7-10 atm;

For the heating main, which stretches from the boiler house to the heat consumption systems, the normal pressure is 12 atm.

To equalize the pressure and ensure stable operation of the entire mechanism, a pressure regulator is used in the heating system of an apartment building. This balancing manual valve regulates the amount of heating medium with simple turns of the handle, each of which corresponds to a certain water flow. These data are indicated in the instructions attached to the regulator.

Working pressure in the heating system of an apartment building: how to control?

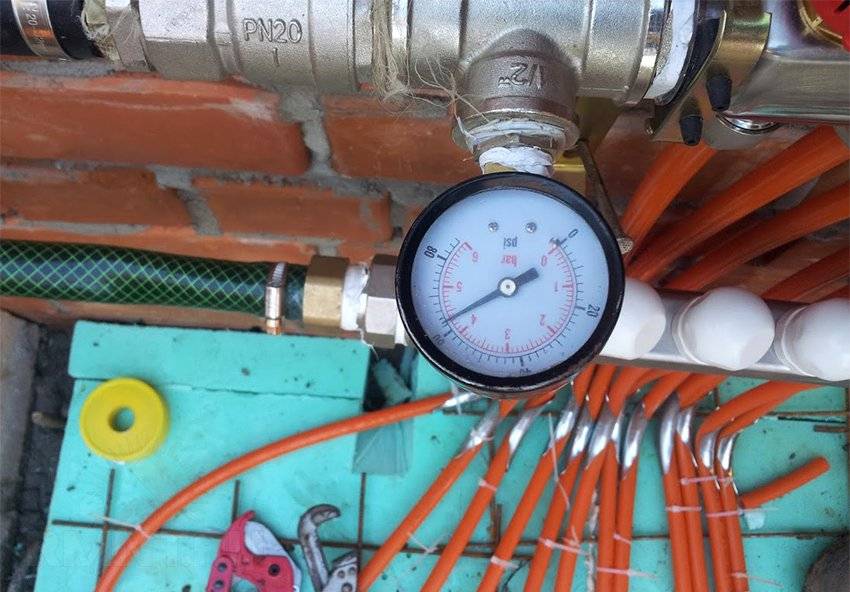

To know if the pressure in the heating pipes in an apartment building is normal, there are special pressure gauges that can not only indicate deviations, even the smallest ones, but also block the operation of the system.

Since the pressure is different in different sections of the heating main, several such devices need to be installed.

Usually they are mounted:

- at the outlet and at the inlet of the heating boiler;

- on both sides of the circulation pump;

- on both sides of the filters;

- at points of the system located at different heights (maximum and minimum);

- close to collectors and system branches.

Pressure drops and its regulation

Jumps in the pressure of the coolant in the system are most often indicated with an increase in:

- for severe overheating of water;

- the cross section of the pipes does not correspond to the norm (less than required);

- clogging of pipes and deposits in heating appliances;

- presence of air pockets;

- pump performance is higher than required;

- any of its nodes are blocked in the system.

On downgrade:

- about the violation of the integrity of the system and the leakage of the coolant;

- breakdown or malfunction of the pump;

- may be caused by malfunctions in the operation of the safety unit or a rupture of the membrane in the expansion tank;

- coolant outflow from the heating medium to the carrier circuit;

- clogging of filters and pipes of the system.

Norm in an autonomous heating system

In the case when autonomous heating is installed in the apartment, the coolant is heated using a boiler, usually of low power. Since the pipeline in a separate apartment is small, it does not require numerous measuring instruments, and 1.5-2 atmospheres is considered normal pressure.

During start-up and testing of an autonomous system, it is filled with cold water, which, at a minimum pressure, gradually warms up, expands and reaches the norm. If suddenly in such a design the pressure in the batteries drops, then there is no need to panic, since the reason for this is most often their airiness. It is enough to free the circuit from excess air, fill it with coolant and the pressure itself will reach the norm.

To avoid emergency situations when the pressure in the heating batteries of an apartment building rises sharply by at least 3 atmospheres, you need to install either an expansion tank or a safety valve.If this is not done, the system may be depressurized and then it will have to be changed.

- carry out diagnostics;

- clean its elements;

- check the performance of measuring instruments.

2 thousand

1.4 thousand

6 min.

Outdoor leaks

To begin with, consider external leaks, that is, leaks through pipes. Basically, cheap types of pipes are used in heating systems, such as metal-plastic and plastic pipes. Copper pipes are rarely used. All of them can cause leaks.

The first step is to check the entire system for leaks. To do this, the boiler is turned on to the maximum (for example, 80 degrees), the entire system heats up completely, and after warming up the entire system, we bring the pressure in the system to the maximum, which will be approximately 2-2.5 bar. On some boilers, this value can be around 3 bar. That is, the pressure is brought to such a maximum possible value, above which the explosive valve will operate.

After pumping up pressure, you should wait until the system starts to cool down. While the system is cooling, take out regular tissues, toilet paper, newspapers, or any other material that will show water leaks. With the help of this material, all pipes, all valves and other elements are crimped, passing through all points.

Particular attention should be paid to those places in which there are oxides. They usually form around the places where fittings enter the battery. Such oxides can accumulate in large quantities

Why is it necessary to heat the heating system?

Such oxides can accumulate in large quantities. Why is it necessary to heat the heating system?

When the heating system is heated (read about the selection and comparison of heating systems here), the maximum expansion of water occurs, and if there is a leak somewhere, the crack will expand, and water will start to run from there, to come out. When the heating system is heated to 80 degrees, the leak cannot be detected. Leakage can be determined only at the moment when the heating system cools down to 20-30 degrees. At high temperatures, the water will simply evaporate, and the leak will not be noticeable.

If a section of the heating system is immured into the walls or into the floor, then it will be almost impossible to determine the leak in this place. For example, if the warm floor is made of low-quality pipes, then in this case it will not be possible to find a leak.

Optimal Performance

There are generally accepted averages:

- For a small private house or apartment with individual heating, pressure ranging from 0.7 to 1.5 atmospheres is sufficient.

- For private households in 2-3 floors - from 1.5 to 2 atmospheres.

- For a building of 4 floors and above, from 2.5 to 4 atmospheres are recommended with the installation of additional pressure gauges on the floors for control.

Attention! To carry out calculations, it is important to understand which of the two types of systems is being installed. Open - heating system in which the expansion tank for excess fluid interacts with the atmosphere

Open - a heating system in which the expansion tank for excess fluid interacts with the atmosphere.

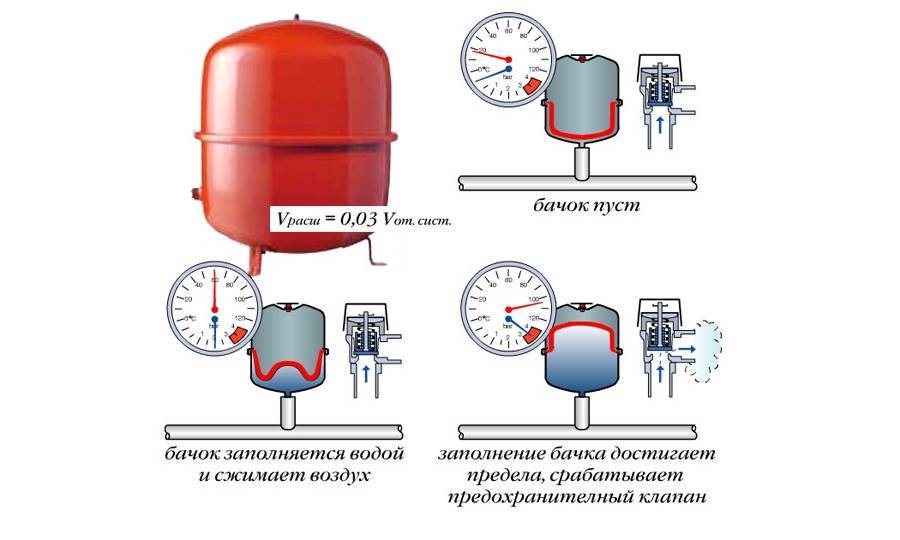

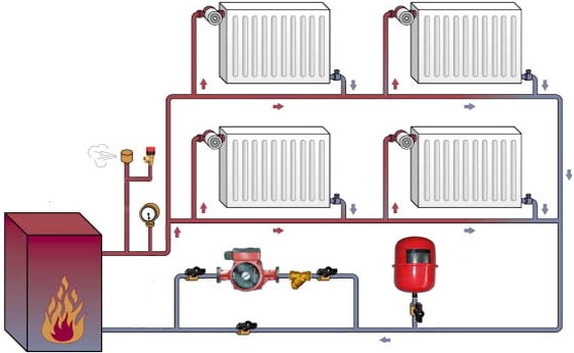

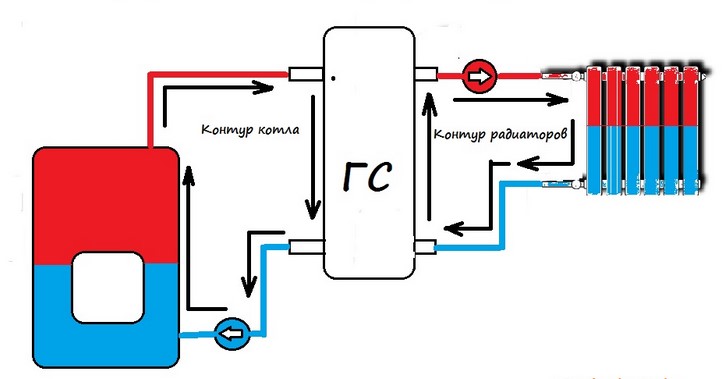

Closed - hermetic heating system. It contains a closed expansion vessel of a special shape with a membrane inside, which divides it into 2 parts. One of them is filled with air, and the second is connected to the circuit.

Photo 1.Scheme of a closed heating system with a membrane expansion tank and a circulation pump.

The expansion vessel takes in excess water as it expands when heated. When the water gets cold and decreases in volume - the vessel makes up for the deficiency in the system, preventing its rupture when the energy carrier is heated.

In an open system, the expansion tank must be installed in the highest part of the circuit and connected, on the one hand, to the riser pipe, and on the other, to the drain pipe. The drain pipe insures the expansion tank from overfilling.

In a closed system, the expansion vessel can be installed in any part of the circuit. When heated, water enters the vessel, and the air in its second half is compressed. In the process of cooling the water, the pressure decreases, and the water, under the pressure of compressed air or other gas, returns back to the network.

In an open system

In order for the excess pressure on the open system to be only 1 atmosphere, it is necessary to install the tank at a height of 10 meters from the lowest point of the circuit.

And in order to destroy a boiler that can withstand a power of 3 atmospheres (the power of an average boiler), you need to install an open tank at a height of more than 30 meters.

Therefore, an open system is more often used in one-story houses.

And the pressure in it rarely exceeds the usual hydrostatic, even when the water is heated.

Therefore, additional safety devices, in addition to the described drain pipe, are not needed.

Important! For normal operation of an open system, the boiler is installed at the lowest point, and the expansion tank is at the highest point. The diameter of the pipe at the inlet to the boiler must be narrower, and at the outlet - wider

Closed

Since the pressure is much higher and changes when heated, it must be equipped with a safety valve, which is usually set to 2.5 atmospheres for a 2-story building. In small houses, the pressure can remain in the range of 1.5-2 atmospheres. If the number of storeys is from 3 and above, the boundary indicators are up to 4-5 atmospheres, but then the installation of an appropriate boiler, additional pumps and pressure gauges is required.

The presence of a pump provides the following advantages:

- The length of the pipeline can be arbitrarily large.

- Connection of any number of radiators.

- Use both serial and parallel circuits for connecting radiators.

- The system operates at minimum temperatures, which is economical in the off-season.

- The boiler operates in a sparing mode, since the forced circulation quickly moves the water through the pipes, and it does not have time to cool down, reaching the extreme points.

Photo 2. Measurement of pressure in a closed-type heating system using a pressure gauge. The device is installed next to the pump.

Setup and Troubleshooting

It is impossible to maintain pressure in the heating system without observing the rules for filling it. This should be done at a minimum pressure and with open valves to bleed air in the radiator network. The underfloor heating loops are filled alternately, otherwise, due to the difference in length, air will certainly be displaced into longer coils. After the system is filled, it is pressurized with double working pressure and the pressure gauge readings are monitored for a certain time. Usually, the pressure of the water supply system is sufficient for pressure testing, otherwise you have to use a manual plunger hydraulic pump.After checking, the pressure is reduced to the minimum, the system is heated to the maximum operating temperature, after the heating of the entire volume of the coolant, the pressure is measured: it should be less than the limit by 20–30%.

Decreasing pressure over time is a common thing for systems filled with fresh water. Dissolved oxygen is released from it, respectively, over time, the total volume of the coolant decreases. You just need to periodically feed the system until the effect disappears on its own. An increase in pressure is a clear sign of an incorrect calculation of the expansion tank, its volume must be increased. Small drops within 10-15% of the working pressure are considered quite normal, this is due to the linear expansion of the pipes. If the pressure surges during heating and cooling of the system go beyond 30% of the nominal value, this indicates either damage to the membrane in the tank, or the presence of air plugs in the system.

Recommendations when choosing radiators

One of the main problems with heating is the leakage of heating radiators. There are several components to highlight here:

- Steel radiators and convectors are most often not intended for installation in a working environment of more than 8-10 atm. Check with the seller or look in the passport for the parameters of the maximum allowable pressure and operating conditions in which the manufacturer recommends installing their heaters. Even if your pressure gauge in the basement of your apartment building shows a pressure of 5 atm. this does not mean that during the season the pressure will not be raised to 12-13 atm.Unfortunately, the deterioration of main pipelines can reach more than 100%, and the only way to check the integrity of the pipes and guarantee the trouble-free operation of the heating system is to carry out pressure tests. In these cases, the heating plant can supply peak pressures of both 13 and 15 atm. which will lead to the destruction of steel batteries. Measurements are made every hour, and the pressure drop should not exceed 0.06 atm. All the while, your radiators will be under dangerously high pressure.

- Long battery life can lead to corrosion, and if in a private house, at a pressure of 1.5-3 atm. the radiator can be quickly blocked, then in an apartment building as a result of such an accident, you can flood your neighbors while you wait for the arrival of a plumber or an emergency team. In this regard, in apartment buildings, it is mandatory to install shut-off valves, shut-off valves or taps.

If you want to control the pressure parameters, you can install special thermomanometers that allow you to evaluate the operating parameters of the heating in real time.

In case of a drop in temperature, pressure, detection of leaks or damage to the heating system, you must immediately contact the operator serving your heating network. Otherwise, you run the risk of aggravating the situation, which will lead to more serious consequences than a drop in temperature of the batteries by a few degrees.

Drops and their causes

Pressure surges indicate that the system is not working properly.The calculation of pressure losses in the heating system is determined by summing the losses at individual intervals that make up the entire cycle. Timely identification of the cause and its elimination can prevent more serious problems that lead to costly repairs.

If the pressure in the heating system drops, this may be due to such reasons:

- the appearance of a leak;

- failure of the expansion tank settings;

- failure of pumps;

- the appearance of microcracks in the boiler heat exchanger;

- power outage.

How to increase the pressure in the heating system?

Expansion tank regulates pressure drops

In the event of a leak, check all connections. If the cause is not visually identified, it is necessary to examine each area separately. To do this, the valves of the cranes alternately overlap. The pressure gauges will show the change in pressure after cutting off one or another section. Having found a problematic connection, it must be tightened, previously additionally compacted. If necessary, the assembly or part of the pipe is replaced.

The expansion tank regulates the differences due to heating and cooling of the liquid. A sign of a tank malfunction or insufficient volume is an increase in pressure and a further decline.

To the result obtained, a gap of 1.25% should be added. The heated liquid, expanding, will force the air out of the tank through the valve in the air compartment. After the water cools, it will decrease in volume and the pressure in the system will be less than necessary. If the expansion tank is smaller than required, it must be replaced.

An increase in pressure can be caused by a damaged membrane or an incorrect setting of the pressure regulator of the heating system.If the diaphragm is damaged, the nipple must be replaced. It's fast and easy. To set up the tank, it must be disconnected from the system. Then pump the required amount of atmospheres into the air chamber with a pump and install it back.

You can determine the malfunction of the pump by turning it off. If nothing happens after shutdown, then the pump is not working. The reason may be a malfunction of its mechanisms or lack of power. You need to make sure that it is connected to the network.

If there are problems with the heat exchanger, then it must be replaced. During operation, microcracks may appear in the metal structure. It can't be fixed, only replaced.

Why does the pressure in the heating system increase?

The reasons for this phenomenon may be improper circulation of the fluid or its complete stop due to:

- the formation of an air lock;

- clogging of the pipeline or filters;

- operation of the heating pressure regulator;

- incessant feeding;

- blocking valves.

How to eliminate gaps?

An airlock in the system does not allow fluid to pass through. Air can only be bled. To do this, during installation, it is necessary to provide for the installation of a pressure regulator for the heating system - a spring air vent. It works in automatic mode. Radiators of the new sample are equipped with similar elements. They are located at the top of the battery and work in manual mode.

Why does the pressure in the heating system increase when dirt and scale accumulate in the filters and on the pipe walls? Because the fluid flow is obstructed. The water filter can be cleaned by removing the filter element. Getting rid of scale and clogging in pipes is more difficult. In some cases, washing with special means helps.Sometimes the only way to fix the problem is to replace the pipe section.

The heating pressure regulator, in the event of an increase in temperature, closes the valves through which liquid enters the system. If this is unreasonable from a technical point of view, then the problem can be corrected by adjustment. If this procedure is not possible, replace the assembly. In the event of failure of the electronic control system of the make-up, it should be adjusted or replaced.

The notorious human factor has not yet been canceled. Therefore, in practice, shut-off valves overlap, which leads to increased pressure in the heating system. To normalize this indicator, you just need to open the valves.

4 The pressure in the heating system is growing - how to find out the cause

By checking the pressure gauges from time to time, you may notice that the pressure inside the system is increasing. This can happen for several reasons:

- you raised the temperature of the coolant, and it expanded,

- the movement of the coolant has stopped for some reason,

- on any section of the circuit, the valve (valve) is closed,

- mechanical clogging of the system or air lock,

- additional water constantly enters the boiler due to a loosely closed tap,

- during installation, the requirements for pipe diameters were not met (larger at the outlet and smaller at the inlet to the heat exchanger),

- excessive power or flaws in the operation of the pump. Its failure is fraught with a water hammer that is detrimental to the circuit.

Accordingly, it is necessary to find out which of the listed reasons led to the violation of the working norm and eliminate it. But it happens that the system worked successfully for months and suddenly there was a sharp jump, and the pressure gauge needle went into the red, emergency zone.This situation can be provoked by the boiling of the coolant in the boiler tank, so you need to reduce the fuel supply as quickly as possible.

Modern devices for individual heating are equipped with a mandatory expansion tank. It is a hermetic block of two compartments with a rubber partition inside. A heated coolant enters one chamber, air remains in the second. In cases where the water overheats and the pressure begins to rise, the partition of the expansion tank moves, increasing the volume of the water chamber, and compensates for the difference.

In the event of boiling or a critical surge in the boiler, mandatory safety relief valves are provided. They can be located in the expansion tank or on the pipeline immediately at the outlet of the boiler. In an emergency, part of the coolant from the system is poured out through this valve, saving the circuit from destruction.

In well-designed systems, there are also bypass valves, which, in the event of a blockage or other mechanical blockage of the main circuit, open and let the coolant into the small circuit. This safety system protects the equipment from overheating and damage.

Do I need to explain how important it is to monitor the health of these elements of the system. With a small volume or violation of pressure inside the expansion tank, as well as coolant leaks through microcracks, even significant pressure drops in the system are possible

Ginseng tincture

Ginseng root has a good effect on the whole body. However, it is worth remembering that this tincture should be taken under the supervision of a doctor.

Although this tincture has a large number of positive qualities, it can also affect your body badly, so you need to know when not to take this tincture.

For example, hypertensive people are forbidden to take this remedy, since ginseng itself is a tonic plant, but in another language, with the help of vasodilation, many times more oxygen enters the blood than under normal conditions.

Signs for which you need to take ginseng tincture:

- Rapid fatigue.

- Lethargy.

- Slow response.

- Headache.

- Little appetite.

- Vertigo.

The first effect of the use of this medicine occurs after 14 days, so do not be upset if you do not see results in the first few days.

Conclusions and useful video on the topic

Pressure surges in a heating system with a double-circuit boiler:

Why does the pressure in the heating system drop:

Reasons for the increase in pressure in the heating circuit:

Pressure instability in the heating system occurs due to its incorrect connection, non-compliance with operating rules, and the use of faulty devices.

Understanding the reasons for the drop and increase in pressure in a gas boiler helps to properly maintain the system, but this is not a reason to intervene in the operation of the equipment on your own. For help, it is better to contact a master from the gas service that supplies blue fuel.

And what problems with a drop or increase in pressure arose during the operation of your gas boiler? Share the methods you used to bring the head up to standard values.Please leave comments in the block form below, here you can also ask questions and post a photo on the topic of the article.