- What is an expansion tank for?

- Expansion tank open

- Closed expansion mat

- What should be the normal pressure in a gas boiler

- Values in the expansion tank and heating system

- Pros and cons

- What pressure should be in the expansion tank of a gas boiler of a closed heating system

- How to check the pressure in the expansion tank

- Volume calculation

- What will cause the insufficient volume of the expansion tank

- The principle of operation of the expansion tank

- What is the purpose of an expansion tank?

- How to set the optimal pressure?

- Tests and parameters before the boiler

- Prevention

- Causes of rising pressure. Ways to solve the problem

- Expansion tank issue

- Why pressure rises in closed systems

- Other reasons

- Navien boiler error 03

What is an expansion tank for?

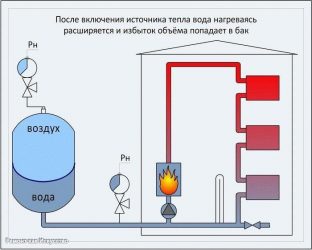

In the process of heating, water tends to expand - as the temperature rises, the volume of the liquid increases. Pressure begins to rise in the heating system circuit, which can have a devastating effect on gas equipment and pipe integrity.

The expansion tank (expansomat) performs the function of an additional reservoir into which it squeezes out the excess water formed as a result of heating.When the liquid cools and the pressure stabilizes, it returns through the pipes back to the system.

The expansion tank performs the function of a protective buffer, it dampens the water hammer that is constantly formed in the heating system due to the frequent turning on and off of the pump, and also eliminates the possibility of air locks.

To reduce the likelihood of air locks and prevent damage to the gas boiler by water hammer, the expansion tank should be mounted in front of the heat generator, on the return

There are two different versions of damper tanks: open and closed types. They differ not only in design, but also in the way, as well as in the place of installation. Consider the features of each of these types in more detail.

Expansion tank open

An open tank is mounted at the top of the heating system. The containers are made of steel. Most often they have a rectangular or cylindrical shape.

Typically, such expansion tanks are installed in the attic or attic. Can be installed under the roof

Be sure to pay attention to the thermal insulation of the structure

In the structure of the open-type tank there are several outlets: for water inlet, cooled liquid outlet, control pipe inlet, as well as an outlet pipe for coolant outlet to the sewer. We wrote more about the device and types of an open tank in our other article.

Functions of an open type tank:

- controls the level of the coolant in the heating circuit;

- if the temperature in the system has decreased, it compensates for the volume of the coolant;

- when the pressure in the system changes, the tank acts as a buffer zone;

- excess coolant is removed from the system into the sewer;

- removes air from the circuit.

Despite the functionality of open expansion tanks, they are practically not used anymore. Since they have many disadvantages, for example, a large container size, a tendency to corrosion. They are installed in heating systems that operate only with natural water circulation.

Closed expansion mat

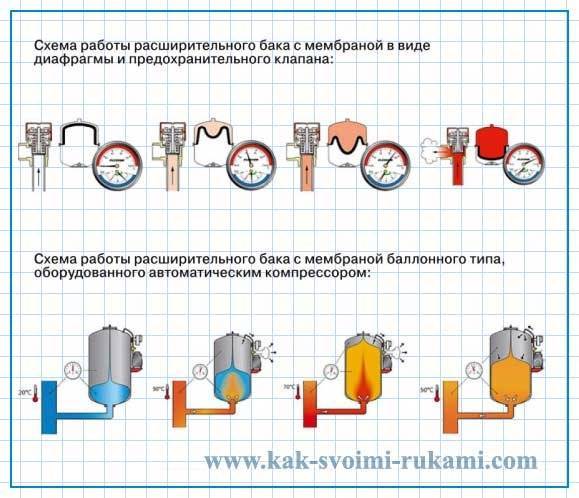

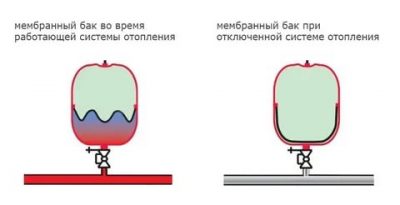

In closed circuit heating systems, a membrane-type expansion tank is usually mounted; it is optimally suited for any type of gas boiler and has many advantages.

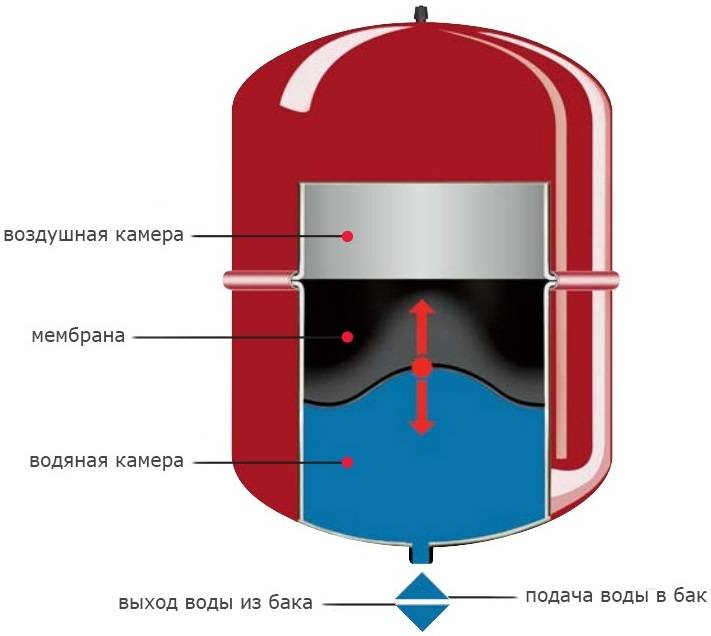

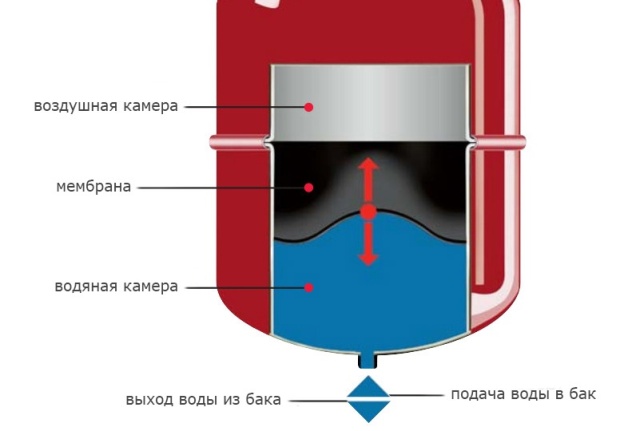

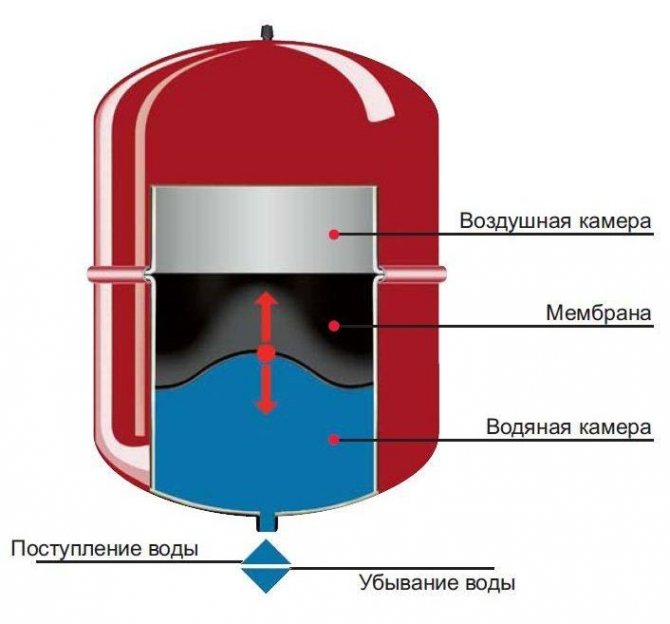

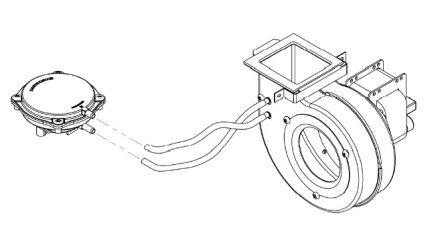

Expanzomat is a hermetic container, which is divided in the middle by an elastic membrane. The first half will contain excess water, and the second half will contain ordinary air or nitrogen.

Closed heating expansion tanks are usually painted red. Inside the tank is a membrane, it is made of rubber. A necessary element to maintain pressure in the expansion tank

Compensation tanks with a membrane can be produced in the form of a hemisphere or in the form of a cylinder. Which is quite suitable for use in a heating system with a gas boiler. We recommend that you familiarize yourself with the features of the installation of closed-type tanks in more detail.

Advantages of membrane types of tanks:

- ease of self-installation;

- resistance to corrosion;

- work without regular topping up of the coolant;

- lack of contact of water with air;

- performance under high load conditions;

- tightness.

Gas attachments are usually equipped with an expansion tank. But not always the additional tank from the factory is set up correctly and can immediately start heating.

What should be the normal pressure in a gas boiler

The value may differ for each brand and model of equipment. The exact figures can be found in the passport data. The average gas pressure depends on the design of the boiler:

| By installation type | Rated value (mbar) | Minimum (mbar) |

| wall | 13,0 | 4,5 |

| floor standing | 18,0 | Depends on the type of automation and settings |

| With atmospheric burners | 15,0 | 5,0 |

The “minimum” column indicates the indicator below which the boiler will not work. In this case, the protective automation will turn it off to avoid a serious breakdown or accident.

In a European type gas supply system, the nominal value is 20 mbar, while in our regions it is 12–18 mbar. Consumption depends on the type of fuel consumed: liquefied or main.

| Device brand | min. Pa LPG (mbar) | Max. Pa liquefied fuel | min. Pa natural gas (mbar) | Max. Pa natural gas |

| Wiesman | 5 | 23 | 25 | 31 |

| "Daewoo" | 4 | 25 | 28 | 33 |

| "Buderus" | 4 | 22 | 27 | 28 |

| "Ferolli" | 5 | 35 | 2,2 | 17,5 |

| "Proterm" | — | — | 13 | 13 |

In addition, there are other types of pressure - water and atmospheric. Water is indicated by the unit Pa. Until it is filled with water, the system maintains an atmospheric value of 1 bar.

Values in the expansion tank and heating system

The expansion tank is used to collect excess fluid. During heating, the liquid expands, which leads to an increase in values \u200b\u200b(norm 1.5 bar). To avoid breakdowns, the excess is taken into the tank, and after cooling it is returned to the system again.

A pressure gauge is installed to measure pressure. When changing, the pressure gauge pointer indicates the minimum or maximum allowable value. To change the situation, air is pumped using a nipple.

To properly install the tank, proceed as follows:

- Find out the rating for your model. The setting in the expansion tank must be 0.3 bar lower than in the heating circuit.

- Set these values before connecting the tank.

- After connecting, fill the circuit with liquid. Watch for changes on the gauge. As soon as they reach the norm, turn off the water supply.

- Start the pump.

- Set the thermostat to the highest temperature. This is done so that the liquid expands as much as possible and fills the expansion tank.

The higher the speed of the circulation pump, the faster the coolant moves through the system. Therefore, the thrust force is greater. There are no specific indications of the nominal pressure in the circuit. It is believed that the difference in the pressure force in the inlet and return pipes should not exceed 0.3–0.5 atm.

| Manufacturer brand | Working pressure in the heating system (bar) |

| "Arderia" | 1–2 |

| "Navien Ase" | Until 3 |

| "Ariston" 24 | Until 3 |

| Immergaz 24 | Up to 2 |

| "Cooper 09-K" | Up to 2 |

| "Baksi" wall | Until 3 |

| "Beretta" | Up to 4 |

- Leak in pipe connections, heat exchanger. Inspection, sealing and replacement of faulty components will help to fix the problem.

- Three-way valve problems. Clean it of debris.

- Deterioration of the expansion tank membrane. In case of deformation and damage, a replacement is carried out.

Reasons for the gas line:

- A sharp increase in the load on the highway. This happens in extreme cold. It remains to wait for the restoration of the supply.

- Clogged filter, hose, nozzles. Cleaning is in progress.

- Gas valve failure. Perhaps the mechanism is jammed or the valve needs to be replaced.

- Leakage in pipes. If you smell gas, turn off the supply valve and call the emergency service.

Monitor the operation of the boiler and its indicators. Then it will be possible to avoid breakdowns and accidents.

Pros and cons

Closed expansion tanks have a number of advantages over open ones:

- Closed analogues do not have to be installed in the attic, it can be installed near the boiler itself. And open ones must be installed at the highest point of the system.

- In closed tanks, water does not have access to contact with air, which means that oxygen will not dissolve in water and interfere with the movement of the coolant.

- Most people have converted the attics of their homes into living quarters, so using enclosed tanks is a space saver as they can be installed anywhere.

The disadvantages of closed tanks are as follows:

- High price.

- It is required to pump air into the device from time to time.

What pressure should be in the expansion tank of a gas boiler of a closed heating system

As a rule, the required value of the adjustable air pressure in the expansion tank is indicated in the passport for a gas or electric boiler, but this entry may not be. Then it is customary to use a pressure value of 0.2 - 0.3 atmospheres below the working one. It all depends on the size of the private house and the heating area. Typically, the pressure range in the membrane tank is from 1.5 to 2.5 atmospheres. For example, for a low-rise country house, the normal functioning of the heating system occurs at 1.5 - 1.8 atm, so the pressure in the expansion tank is adjusted within 1.2 - 1.6 atm.

How to check the pressure in the expansion tank

To measure the pressure in the expansion tank of a water supply or heating system for gas boilers of various types, it is necessary to connect an ordinary automobile pressure gauge to the nipple.

In order to get to the nipple, you need to remove the top plastic cover. There is also a spool with which you can bleed excess air pressure. To increase the pressure, you can use a car pump by connecting it to the nipple.

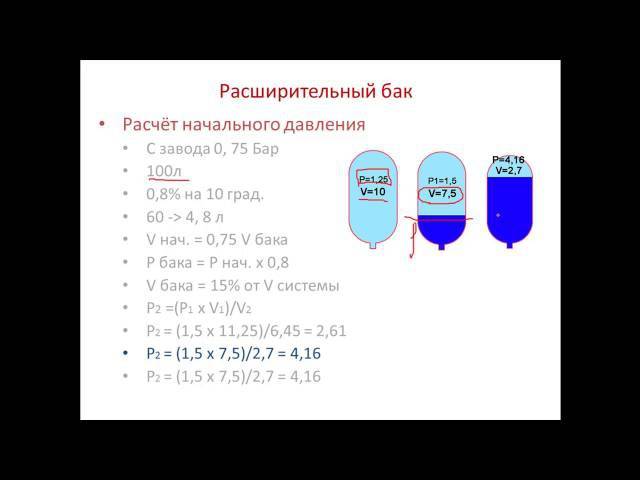

Volume calculation

In order for the heating system to function without interruptions and breakdowns, it is necessary to choose the right expansion tank of the required volume. For the calculation, indicators such as the volume of the coolant system Vt, coefficient of thermal expansion of the applied coolant Kt. It depends on the antifreeze used in the system. And the membrane efficiency index F. The formula is below:

Vb = Vt * Kt /F

the coefficient of thermal expansion is taken from a special table. It all depends on the percentage of the water-glycol mixture in the antifreeze.

Expansion coefficient of water and water-glycol mixture

Membrane performance index is calculated as follows:

F = (Pmax -Pb)/ (Pmax + 1),

where:

Pmax - maximum pressure in the heating system. This indicator can be found in the passport for the boiler; Pb – air pressure in the expansion tank.

This value can be taken from the expander's passport or determined independently by connecting an automobile pressure gauge to the tank nipple.

What will cause the insufficient volume of the expansion tank

When buying an expansion tank, you need to make sure that there is a relief valve. If it is not available, the valve must be purchased in addition.In the event that the relief valve begins to constantly discharge the coolant. This means that the selected expander volume is not enough.

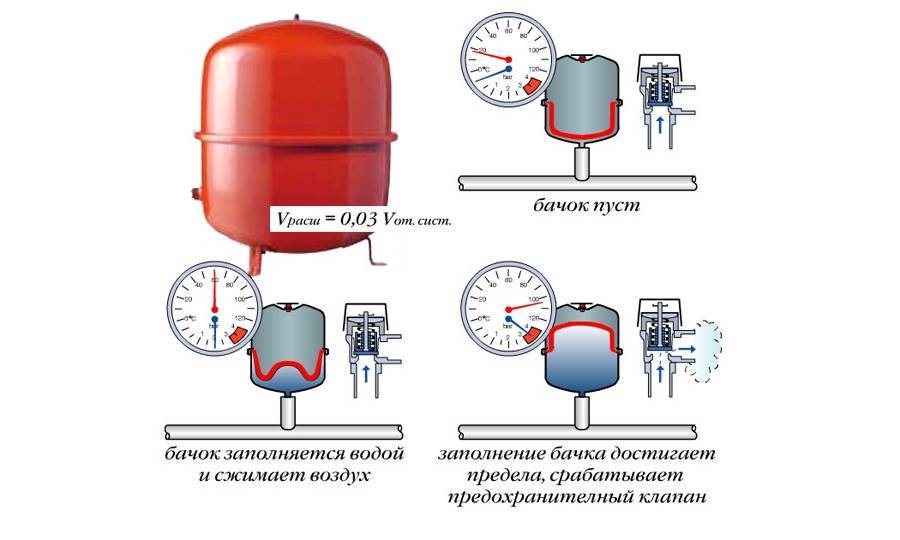

The principle of operation of the expansion tank

To organize effective heating, it is required that the system be filled with a coolant. When the liquid is heated to a high temperature, its volume increases, and its excess is discharged into the expansion tank. In different heating systems, the requirements for it are different. For example, with the natural movement of the coolant, it is enough to install a metal container of the desired size as an expansion tank.

The forced circulation system includes a sealed factory-made tank. It is a container divided into two parts by an elastic membrane. It is made of special rubber, which must be strong enough. One part of the tank is filled with air or water, the other is designed to receive excess liquid.

Note! If an expansion tank is not included in the heating system, then when heated, the water will increase and can simply break the pipeline or boiler. Expansion tanks differ in volume

When choosing this element, one should be guided by the fact that the tank must accept at least 10% of the mass of the coolant. It is advisable to buy a container with a small margin

Expansion tanks differ in volume. When choosing this element, one should be guided by the fact that the tank must accept at least 10% of the mass of the coolant. It is advisable to buy a container with a small margin.

What is the purpose of an expansion tank?

The expansion tank in a closed heating system performs two important functions:

- Compensates for thermal expansion of the coolant. For every 100°C increase in temperature, the volume of water increases by 4.5%. The fluid pressure in the system increases and presses on the walls of pipes and radiators. If the gas boiler is not equipped with an expansion tank or one tank is not enough, then this element is installed on the "return" of the device.

- It softens water hammer in the heating system, which may appear due to accumulated air masses or overlapping fittings.

From this it can be seen that without an expansion tank, the heating system simply cannot work correctly.

How to set the optimal pressure?

There are pressure gauges on the heating system, with the help of which the pressure in the circuit is controlled. On the expansion tank itself, there is no fitting for installing a measuring device. But there is a nipple or spool for releasing and pumping air or gas. The nipple is the same as on the wheels of cars. Therefore, you can check the pressure level and adjust it using a conventional car pump with a pressure gauge.

Even the simplest car hand pump with a pressure gauge or an automatic compressor is suitable for pumping air into the expansion tank.

Before releasing excess pressure or pumping air into the expansion tank of a domestic gas boiler, it is necessary to prepare the system. The car pressure gauge shows the value in MPa, the data obtained must be converted to atmospheres or bars: 1 Bar (1 atm) \u003d 0.1 MPa.

Pressure measurement algorithm:

- Turn off the gas boiler. Wait until the water stops circulating through the system.

- In the area with the hydraulic tank, close all shut-off valves and drain the coolant through the drain fitting. For boilers with a built-in tank, the return flow is blocked, as well as the water supply.

- Connect the pump to the tank nipple.

- Inflate air to 1.5 atm. Wait a little for the rest of the water to pour out, let the air in again.

- Shut off the stop valves and pump up the pressure with the compressor to the parameters indicated in the passport or to the level - the pressure in the system is minus 0.2 atm. In the case of pumping the tank, excess air is bled off.

- Remove the pump from the nipple, tighten the cap and close the drain fitting. Pour water into the system.

You can check the correct adjustment of the air pressure when the boiler reaches operating parameters.

If the tank is inflated correctly, then the arrow of the pressure gauge of the device during the measurement will show a smooth increase in pressure without any jumps and jerks

If the air pressure in the expansion tank is incorrectly set, the entire heating system may malfunction. If the expansion mat is pumped over, the compensating properties will not work. Since the air will push out excess heated water from the tank, increasing the pressure in the pipes of the heating system.

And with underestimated pressure readings of the compensating tank, water will simply push through the membrane and fill the entire tank. As a result, when the temperature of the coolant rises, the safety valve will operate.

Sometimes, in double-circuit gas boilers, fuses are triggered even when the pressure of the built-in expansion tank is set correctly. This indicates that the volume of the tank is too small for such a heating system. In this situation, it is recommended to install an additional hydraulic tank.

Tests and parameters before the boiler

The hydraulic accumulator is one of the key components of the Civil Code. Special tests are carried out to ensure its proper operation, and the operation of the boiler itself and the network. Usually they are arranged during the production of apparatuses and some pipeline units. The process comes after the installation and connection of the entire system. There is a check. The pressure is 1.5-3 times higher than the working one. It rises very slowly. The allowable indicator is calculated using a special formula. To control it, two unrelated pressure gauges are used. If the parameter is too high, it is necessary that air does not accumulate in volumes with water. During the test, the measured parameter is constantly monitored. Then it gradually decreases to normal.

The correct setting of this parameter is the key to the successful operation of the device. Each model has its own setting. The following table is provided as an example:

| Model | Min. parameter.(Pa). Type of gas - liquefied | Max. parameter.(Pa). (liquefied gas) | Min. Pa (natural gas) | Max Pa (natural gas) |

| Proterm LYNX Condens | 13 | 13 | ||

| Daewoo (Daewoo DGB | 4 | 25 | 28 | 33 |

| Mora W 65 | 2,5 | 20 | 6,2 | 13,2 |

| Buderus | 4 | 22 | 27 | 28 |

| Junkers K 144-8 | 18 | 24 |

The correct gas setting is important here:

- Loosen the bolt to change the pressure.

- Stringing a flexible hose.

Setting the maximum gas consumption:

- Any hot water faucet opens.

- Max. temperature.

Prevention

To keep the boiler in good condition and prevent excessive pressure, regularly:

Monitor the health of the hardware security group. It includes: pressure gauge, air vent and safety valve.

- Add coolant (antifreeze) to the coolant. Read the instructions carefully, because this is not allowed in all models of boilers.Thanks to this measure, the filter will become less clogged, the amount of scale on the air vents will decrease, and the components of the defensive valve will not stick.

- Do a heat exchanger flush. This is how its service life develops, and fistulas and scale will not appear on it.

Causes of rising pressure. Ways to solve the problem

To understand that there is too much pressure in the system, you can use the pressure gauges. Normal readings are 1-2.5 bar. If the pressure gauge needle reaches 3 bar, sound the alarm. If the increase is constant, it is urgent to find the cause and reduce the pressure.

Also pay attention to the safety valve: to relieve pressure, it will constantly emit water

Expansion tank issue

This tank can be located separately from the boiler or be part of the structure. Its function is to take excess water when heated. Hot liquid expands, it becomes 4% larger. This excess is sent to the expansion tank.

The size of the tank is affected by the power of the boiler. For gas equipment, its volume is 10% of the total amount of coolant. For solid fuel - 20%.

Membrane rupture. If the part is damaged, the coolant is not restrained by anything, therefore it completely fills the compensation tank. Then the pressure starts to drop. If you decide to open a tap to add water to the system, the pressure will rise above normal. The connections will leak.

The tank or diaphragm needs to be replaced to reduce the pressure.

The pressure is below or above normal. A machine pump will help to achieve normal values \u200b\u200b(nominal value) in a gas boiler.

- Drain all water from the system.

- Close the valves.

- Pump the circuit until you are sure there is no water.

- How to release air? Through the nipple on the other side of the supply.

- Download again until the indicators reach the norm indicated in the instructions "Ariston", "Beretta", "Navien" and other brands.

The location of the tank after the pump provokes water hammer. It's about how the pump works. When it starts, the pressure rises sharply, and then also drops. To avoid such problems, in a closed heating system, install a tank on the return pipe. The next to hit is the pump in front of the boiler.

Why pressure rises in closed systems

Air accumulates in a double-circuit boiler. Why does this happen:

- Wrong filling with water. The fence is from above, too fast.

- After repair work, excess air was not released.

- Mayevsky cranes for air release are broken.

The pump impeller is worn out. Adjust or replace part.

To relieve or reduce pressure, fill fluid correctly. The fence is carried out from below, slowly, while Mayevsky's taps are open to bleed excess air.

Open System Issues

Problems are the same as described above.

It is important to properly fill water and bleed air. If after that the pressure has not returned to normal, it is necessary to drain the system. Secondary heat exchanger

Secondary heat exchanger

The unit is used to heat domestic hot water. Its design consists of two insulated tubes. Cold water flows through one, hot water flows through the other. If the walls are damaged, a fistula appears, the liquids mix and enter the heating part. Then there is an increase in pressure.

If you do not want to repair and solder the heat exchanger, you can replace it.To do this, buy a repair kit and get to work:

- Shut off supply valves.

- Drain the water.

- Open the case, find the radiator.

The assembly is secured with two bolts. Unscrew them.

- Remove the defective part.

- Install new gaskets at the mounting points and connect the heat exchanger.

Other reasons

There are other reasons for such problems:

- Armature closed. During the intake, the pressure rises, protective sensors block the equipment. Inspect the taps and valves, unscrew them until they stop. Make sure the valves are working.

- Clogged mesh filter. It is clogged with debris, rust, dirt. Remove and clean the part. If you don't feel like cleaning regularly, install a magnetic or flush filter.

- The feed faucet is out of order. Perhaps its gaskets have worn out, then you can get by with a replacement. Otherwise, you will have to change the valve.

- Automation problems. Faulty thermostat or controller. The reason is wear, factory marriage, incorrect connection. Diagnostics and repairs are underway.

Check whether the boiler protection parts are in good condition: pressure gauge, valve, air vent. Clean radiators and other components from dust, soot, scale. Prevention helps prevent serious damage to gas equipment.

Navien boiler error 03

In gas boilers, the presence of a flame on the burner is checked by a special sensor - an ionization electrode. The logic of the unit is to continuously check for the presence of a flame after opening the gas valve. Symptoms of the appearance of error 03 on Navien boilers can be divided into two groups:

-

unsuccessful ignition attempts (flame does not appear)

-

ignition occurs, but the flame goes out

In the case when ignition does not occur, you need to check:

-

gas pressure at the inlet and outlet of the gas valve (can only be carried out by a qualified specialist using special equipment - a differential pressure gauge)

-

the condition of the ignition electrodes (gap compliance with the manufacturer's standard, contamination of the electrodes). The norm of the distance between the electrodes is 3.5-4.5 mm.

-

the integrity of the insulation of the electrode power wire (visually, you can make sure that the spark breakdown occurs precisely on the body of the gas burner, and not anywhere else)

-

correct setting of the boiler power on the DIP switch (valid if there is a problem during the first start-up of the boiler or after replacing the electronic board)

-

presence of voltage on the ignition transformer

Error 03 on the Navien boiler it will also appear in case of unstable combustion (intermittent flame) or if the control unit cannot determine the presence of a flame. In this case, it is necessary to make sure that the connection of the ionization electrode to the control board is reliable, check the boiler grounding and the absence of contamination on the electrode. Instability of combustion can be caused by an increase in the fan speed, so you need to make sure that the yellow hose from the turbine to the APS sensor is securely connected and not damaged.

If during the checks it was not possible to normalize the operation of the boiler, it is likely that the boiler board will need to be diagnosed, repaired or replaced. We recommend watching a video in which one of the users imitates error 03 on a Navien boiler: