- How to install?

- The best models of the middle price segment

- 5.Neptun Base Light½

- 4. Aquaguard Expert 1x15x2d

- 3. Aquaguard Classic ½

- 2. SpyHeat TRITON 20-002

- 1. Rubetek RK-3558

- Emergency protection means

- The main types according to the principle of action

- reed switches

- infrared

- Vibrating

- Acoustic (sound)

- Combined

- HBO gas level sensor device

- Gas analyzers based on physicochemical and physical methods

- Chromatographic gas analyzers

- Thermochemical gas analyzers

- Principle of operation

- Photocolorimetric gas analyzers

- Electrochemical gas analyzers

- Physical gas analyzers

- Magnetic gas analyzers

- Thermal conductometric gas analyzers

- Optical gas analyzers

- Choosing an Instrument for Gas Analysis

- Installation of a water leakage prevention system

- Ball valve tie-in

- Installation of water leakage sensors

- Controller Mounting Rules

- Checking system operation

- Principle of operation

- Household Gas Detector Valves

- Service

- Where are gas detectors installed?

- Carbon monoxide detectors for the home: installation

- Checking work

- Service

How to install?

The sensor should be mounted where leakage may occur. In modern devices, a bracket is provided for this.It is on it that you need to install the device boxes. It is better to mount it at a height just below the ceiling on the wall.

In a number of European countries, sensors must be located on the ceilings, otherwise it will be a violation of the rules. But in our country, such an autonomous sensor is usually mounted only on the wall. But the height of its placement may be different.

If your apartment has a gas pipeline, then the detector should be located higher. If there is a gas cylinder, then low, not far from the floor. In the event of a leak, natural gas goes up, and if it is liquefied, then down.

Before installing the device, you should also check the serviceability of the hood. If the ventilation is not working properly, you should fix it first. If the sensor is not autonomous, but powered by an electrical network, it is imperative to involve specialists.

If the appliance is installed in the kitchen, then you should remember the rules that are contained in the instructions. The device should be located 4-5 meters from the heat source. The reason for this is that a number of sensors respond to the overall air temperature. Usually the norm should not be higher than +50 degrees.

Also, do not place the device behind blinds or curtains, as this will interfere with the correct operation of the device. The carbon monoxide detector is a necessary electronic attribute in any room where there is a source of open fire.

For information on how to properly check and install carbon monoxide sensors, see the following video.

The best models of the middle price segment

Optimal in terms of cost and quality of performance are systems in the middle price category.

5.Neptun Base Light½

Model for placement on water supply systems of office premises, houses, shops, cottages.Includes control module, Neptun SW 005 2.0 sensor, Bugatti Pro motorized ball valve.

Price - 11223 rubles.

Neptun Base Light ½

Specifications:

- type of sensors - wired;

- tube diameter - ½;

- number of connected cranes - up to 6 pcs.;

- taps in the set - 1 pc.;

- number of connected sensors - up to 20 pcs.

pros

- good warranty service;

- quick blockage of water flow.

Minuses

- high price;

- low quality components.

Set Neptun Base Light ½

4. Aquaguard Expert 1x15x2d

A leak protection system with wired signal transmission reliably protects property in case of emergency. The faucets are made of high quality nickel plated brass. There is a self-cleaning function for the valves by turning them regularly.

Price - 12560 rubles.

Aquaguard Expert 1x15x2d

Specifications:

- type of sensors - wired;

- taps in the set - 1 pc.;

- sensors included - 2 pcs.;

- the maximum number of cranes for installation - 6 pcs.;

- independent food - yes.

pros

- a large number of sensors can be connected;

- valve closing time - 2.5 sec.;

- batteries included.

Minuses

short cable.

Set Aquaguard Expert 1x15x2d

3. Aquaguard Classic ½

Model with three sensors that instantly detect and block leaks. The indicators are placed on the main unit and notify the owner in a timely manner with light or sound. Crane shut-off time - 2.5 sec., output power is 40W.

Price - 12959 p.

Aquaguard Classic ½

Specifications:

- type of sensors - wired;

- wire length - 4 m;

- tube diameter - ½;

- cranes in the set - 2 pcs.

pros

- light or sound indication;

- brass taps;

- long cable;

- connection of several sensors.

Minuses

not found.

Set Aquaguard Classic ½

2. SpyHeat TRITON 20-002

The system detects and localizes leaks from refrigerators, washing machines, dishwashers, toilet bowls, water supply systems, heating systems, and sinks. The reaction time is 1 sec., it takes up to 5 seconds to turn off the taps. The device is equipped with two rechargeable batteries that provide operation without mains for up to 2 days.

Price - 11314 rubles.

SpyHeat TRITON 20-002

Specifications:

- tube diameter - ¾;

- maximum sensors for 1 controller - 8 pcs.;

- independent food - yes;

- taps included - 2 pcs.;

- type of sensors - wired.

pros

- uninterrupted work;

- the possibility of autonomous action;

- safe voltage at 5 V;

- automatic cranking.

Minuses

not identified.

SpyHeat kit TRITON 20-002

1. Rubetek RK-3558

The kit will protect the apartment from the flood, help save repairs and prevent flooding of the neighbor's apartment from below. The sensor reacts to the appearance of water under the device from the heating system or pipeline. The device sends leak notifications to the smartphone. The control unit allows you to connect many different devices - temperature, motion, smoke, gas, humidity sensors, etc.

Price - 12390 r.

Rubetek RK-3558

Specifications:

- type of sensors - wireless;

- tube diameter - ½;

- connection to a smartphone - yes;

- number of sensors in the set - 2 pcs.;

- limit number of sensors per 1 controller – 64 pcs.;

- ecosystem - Rubetek;

- taps in the set - 2 pcs.;

- connection to the "smart home" - yes;

- communication protocol - RF433, Wi-Fi.

pros

- fast and high-quality work;

- the ability to connect a large number of different sensors;

- wireless.

Minuses

complex connection.

Rubetek RK-3558 kit

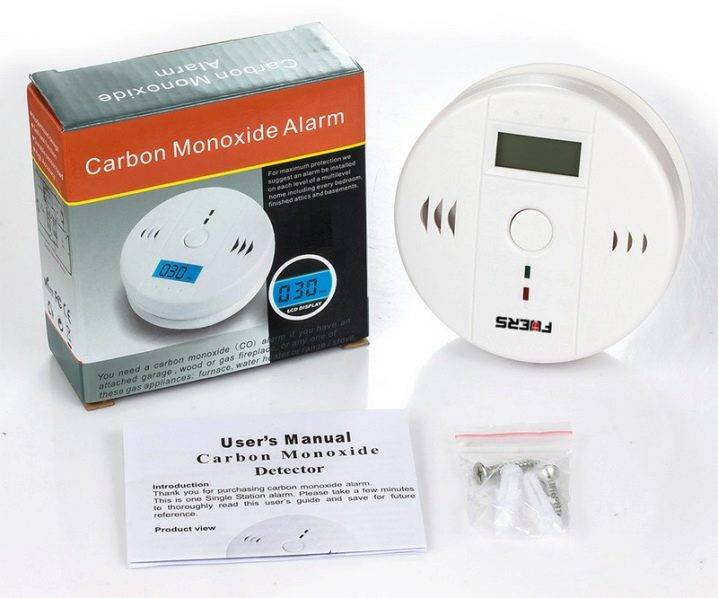

Emergency protection means

To eliminate false fears about a possible leak, it is worth installing a carbon monoxide identification system. The device will report on the state of the air in the room and notify residents in case of exceeding the norm of toxic fumes.

The detector does a good job of identifying not only CO, but will also inform residents of a household gas leak. If a fire has already started, the sensor does not recognize it, however, in terms of a preventive measure, it is indispensable.

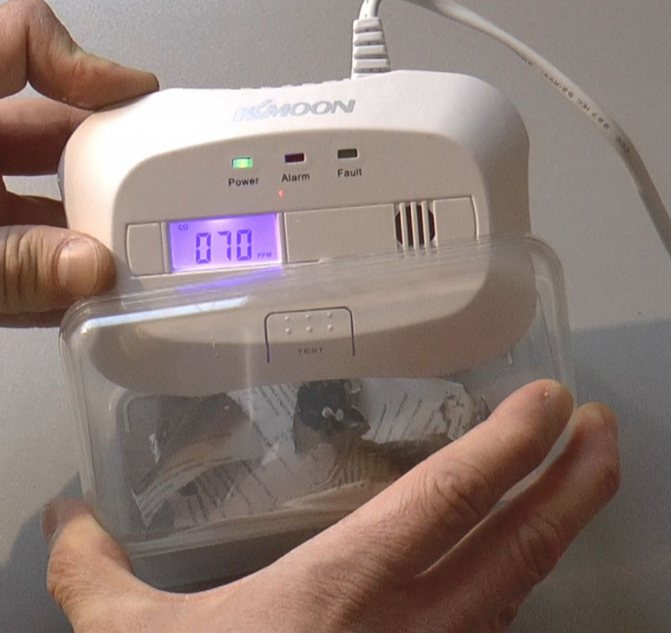

The detector can be placed on any vertical surface. Indication constantly informs about the status of the device and the level of toxic gases in the air

The device will instantly respond to changes in the chemical composition of the air. According to the installation rules, it is best not to install sensors in the immediate vicinity of open flame sources, but simply in the same room with heating equipment.

If the room is equipped with several heating units, it is necessary to organize a system of an equal number of detectors.

A wide range of manufacturers each year provides the consumer with different carbon monoxide detection devices. Despite the fact that the form factor of each device is determined individually, the design principle is almost always the same.

The photo introduces the principle of operation and the specifics of the sensor device:

A distinctive feature of the gas detection device is that the detector is not designed to identify smoke. This means that in addition to the CO sensor, it is recommended to separately install the fire safety system.

The reaction of the sensor to exceeding the permissible parameters in the air is an audible signal, which indicates a leak of toxic gas. Before operation, it is necessary to read the instructions and test the device in an accessible, non-hazardous way, because. Often people confuse the CO leak signal with the audible low battery indicator.

There are portable devices that have already become an integral attribute of fire safety in many countries, including Russia.

Also, almost all devices have the function of notification of their own malfunction. The tone and interval of each sound is different. If the detector signals a low battery, the sound in most cases has a clear jerky character and occurs 1 time per minute.

It is recommended to replace the battery in a timely manner, since the health and life of the household depends on the correct functioning of the device. Mostly replacement should be done no more than 2 times a year.

The constant squeak of the detector may indicate an increase in the level of toxins in the air, or a breakdown of the equipment. In any case, you must immediately call the emergency service.

If symptoms of poisoning are detected, it is necessary to immediately open all the windows and, after leaving the room, wait for the brigade on the street.

Specialists will check the oxygen level and identify leaks. If, nevertheless, it turns out that the signal is false, the detector will need to be replaced with a new one.

Some carbon monoxide and natural gas sensors for the home are able to recognize even fairly harmless substances that have a high degree of evaporation.First of all, this applies to alcohol and all alcohol-containing liquids.

When using alcohol-based cleaners, you need to better ventilate the room in order to avoid false alarms of the security system.

If the vapor concentration is high, the system may sound an alarm, but do not worry and immediately call the emergency service. Also, the detector may be triggered during the cooking of some products that have mainly undergone a fermentation process.

This is mainly characteristic when the device is close to the hob. If this happens quite often, you should install the sensor away from the hearth of cooking procedures.

The main types according to the principle of action

Existing types not only differ significantly in design, but also have a different operating principle. In order not to be mistaken, you need to know exactly what distinguishing features a certain variety has, in what cases it works and why. This will allow you to understand which model should be preferred in a particular situation.

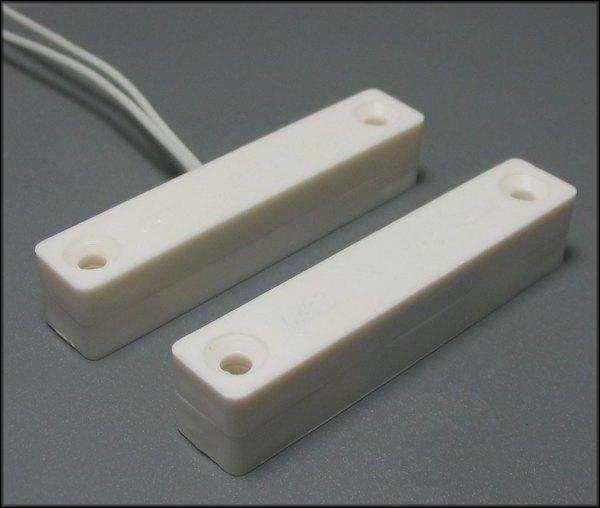

reed switches

Such devices are often called magnetocontact. They are mounted on window and door blocks in order to detect an open sash in a timely manner. They include:

- magnetically controlled contact, which is called a reed switch;

- magnet.

The operation of such devices requires that both parts must be in close proximity to each other. At the same time, they can be both closed and open. The second option is the most widely used. As soon as the distance between the magnet and the reed switch is about 10–20 mm, the position of the contacts changes.

During installation, a reed switch is installed on the fixed part of the window or door block, a magnet is fixed on the sash. According to the position of the latter, the user can track the position of the door leaf or window sash. As long as they are in the closed position, the contacts generally remain closed. When the leaf is opened, the contacts open and the user receives a corresponding signal.

infrared

The signals transmitted by devices of this type are in the infrared range. The sensors themselves are usually divided into:

- Active. In the process of work, such a variety is able to control the rays emitted by them. As soon as some object appears in the path of their propagation, the sensor will generate an alarm signal. The design of active IR models may differ. Manufacturers offer devices consisting of two blocks (emitter and receiver) and one block. During the operation of devices of the second type, the beam returns back, reflected from a special mirror;

- Passive. The composition of such a device includes a special lens that allows you to track the change in the IR background in different sectors. A similar phenomenon occurs if an object capable of absorbing or reflecting heat is in the controlled area.

Infrared detectors are also sometimes called motion sensors, as they are able to detect an object that has changed its position for one reason or another.

Vibrating

These alarm sensors can detect:

- Building structure damage. They work when breaking through or cutting out any fragment in a wall, grate, ceiling;

- Breaking glass.They are mounted on windows, showcases and other glass objects, the integrity of which is subject to increased requirements.

Most often, vibration devices are used to control the integrity of building structures. The safety of glazed elements is monitored using acoustic models.

Acoustic (sound)

Acoustic devices are often referred to as glass break detectors because they are triggered by a characteristic sound. The principle of operation of such devices is based on the sequential conversion of an acoustic signal into an electrical one. As soon as a characteristic sound appears, the system begins to analyze it and, if necessary, sends an alarm signal.

Combined

Such devices can be classified as hybrids, combining two types of devices in a housing. The most widespread are products that are capable of responding to sound and movement. However, other options are also possible. For example, manufacturers offer devices that combine infrared and radio waves.

HBO gas level sensor device

The use of gas instead of standard fuels allows you to save on purchases, reduce engine wear and increase the safety of exhaust gases for the environment. To do this, gas equipment is installed in the car, an important element of which is a gas level sensor.

The fact is that regular monometers are located directly on the cylinders, which makes checking the level long and cumbersome. The driver needs to stop moving, turn off the engine and get out of the car.

To solve the problem, additional sensors are used, which are displayed in the interior of the car, most often on the dashboard.Due to the fact that the readings are reproduced using LED, arrow or digital indicators, they can be combined with a conventional fuel gauge. In this case, between the types of indications are switched using the toggle switch.

In order for the advanced indication system to work, the sensing element of the sensor is installed in the multivalve of the cylinder.

Gas analyzers based on physicochemical and physical methods

Depending on the physics of the process used, devices of the 2nd group are divided into:

- Chromatographic

- Thermochemical

- Photocolorimetric

- Electrochemical

Chromatographic gas analyzers

This type of instrument is designed to measure the composition of a mixture of gases, solids or liquids. The principle of operation of the chromatographic analyzer is to indicate the qualitative and quantitative composition of the separated gas mixture.

There are 3 methods of chromatographic measurement:

- Displacement

- Frontal

- demonstrative

Thermochemical gas analyzers

Thermochemical gas analyzers are devices that determine the energy of heat released during a chemical reaction in a mixture of gases.

Principle of operation

The basic principle of operation is the process of oxidizing gas components using additional catalysts (manganese-copper catalyst, finely dispersed platinum).

The measurement of the resulting temperature is carried out using a thermistor, which, depending on the temperature, changes its resistance, thereby changing the passing current.

Photocolorimetric gas analyzers

A photocolorimetric gas analyzer is a device that uses an optical system (emitter-receiver), which determines it using the level of light flux absorbed by a substance.

There are 2 types of photocolorimetric gas analyzers:

- Liquid photocolorimetric gas analyzer (the reaction proceeds in solution, which makes it possible to determine the components of the mixture with an accuracy of 5%);

- Belt photocolorimetric gas analyzer (use solid carriers for the reaction).

Electrochemical gas analyzers

This type of device is designed to determine toxic gases in rooms or work areas. A distinctive feature of this device is the ability to use it in explosive areas. It is compact, energy-saving and practically insensitive to mechanical stress.

They are able to detect the following substances:

- Ammonia NH3;

- Hydrogen sulfide H2S;

- Carbon monoxide CO;

- Sulfur oxide SO2;

- Chlorine Cl2;

- Volume fractions of oxygen (O2).

According to the principle of action, they are divided into:

- Galvanic (react to changes in electrical conductivity);

- Electro-conductometric (react to changes in current or voltage);

- Potentiometric (measure the ratio of the field strength and active ions).

The operation of electrochemical gas analyzers is based on the phenomenon of electrochemical compensation, which consists in the release of a special reagent that reacts with a certain component of the mixture.

Physical gas analyzers

These devices work due to physical processes and are divided into the following types:

- Thermal conductometric;

- Magnetic;

- Optical;

- Densimetric.

Magnetic gas analyzers

Designed to determine the percentage of O2 in a mixture of gases.

Magnetic gas analyzers are divided into 2 groups:

- Thermomagnetic;

- Magneto-mechanical.

These devices measure the force that occurs in a non-uniform magnetic field and acts on the rotor of the device, and allows you to measure concentrations in the range of 10-2.

Thermal conductometric gas analyzers

These devices allow you to determine the composition of the gas mixture using such a physical quantity as thermal conductivity.

Principle of operation: when the qualitative and quantitative composition of the gas mixture changes, the thermal conductivity and, accordingly, the resistance in the thermistors change, as a result of which the data obtained are analyzed, and the composition of certain gas components is determined from the template.

Optical gas analyzers

Devices of this design operate on the principle of changing the optical properties of a gas mixture (optical density, spectral recovery, refractive index, etc.).

These gas analyzers can detect both organic (CH4 methane, C2H2 acetylene, C2H6 ethane, etc.) and inorganic (chlorine, ammonia, hydrogen sulfide, etc.) substances.

Optical gas analyzers are divided into:

- ultraviolet;

- infrared;

- Spectrophotometric;

- Interferometric.

Principle of operation: a certain gas absorbs infrared radiation from a certain wavelength, depending on which the device calculates.

Choosing an Instrument for Gas Analysis

Trying to make a choice of device, it is desirable to decide what task will be assigned to the device. Based on the intended tasks, it is easier to find the required equipment.In addition, the monetary issue with the exact selection of equipment will be decided in favor of the buyer. The fewer parts in the kit, the lower the cost.

The following performance criteria are usually taken into account when choosing:

- list of supported gases;

- boundary values for measuring concentrations;

- the possibility of analyzing volume and mass fractions;

- time of continuous work;

- Possibility of taking measurements at several points at once.

Of course, external design plays a certain role in the process of selecting equipment.

The presence of protective features, such as a waterproof housing, blocking the ingress of dust and soot - all this is also important if you count on the durability of the analyzer

A mobile model of a gas analyzer, attractive in addition to ease of use, also due to the fact that it is enclosed in a reliable moisture-proof housing. The tight design of the housing also protects against dust ingress

Given the saturation of the Russian market with foreign-made gas analyzers, one has to choose with an eye to adaptation to domestic conditions. It is clear that if the information part of the device is in a foreign language, it is more difficult to use such a device. True, you can get used to it with time.

Any gas analyzer is equipped with working sensors (sensors). As they are used, these elements lose their properties, lose their sensitivity and must be replaced.

How often replacements should be and how things are with the purchase of spare parts is also a matter of choice that requires a careful approach.

And the warranty period is not the last detail that you should pay attention to.

Installation of a water leakage prevention system

The protective circuit is a constructor, the elements of which are interconnected by special connectors. Ease of assembly ensures quick installation and integration with Smart Home systems. Before installation, they draw up a layout of individual parts and check that the length of the wires matches the distance that will be required to connect the meters and taps to the controller.

The order of work includes:

- marking mounting points;

- laying wires;

- tie-in cranes;

- installation of leak detectors;

- installation of the control module;

- connection and system check.

Ball valve tie-in

The most time-consuming stage is the fastening of the ball valve, which is explained by the need to use it on different types of pipes. The water supply is cut in the immediate vicinity of the previously closed water valve. Then the meter is removed and the shut-off valve is fixed on the tap, after which the water meter and pipeline sections are returned to their original position.

Metal-plastic elements are pressed with a lock nut, polypropylene structures are connected by soldering or using detachable couplings. A dedicated power line is used to connect ball valves to the power supply distributor.

Installation of water leakage sensors

Sensors are located in places of possible leakage, while special attention must be paid to the transition between the box where the pipes are placed. This is necessary so that in case of an accident, water gets on the sensor, and does not continue to flow past it. The scheme of their connection can be both floor and internal, in which the elements are cut into the coating material

In the first case, the plate is placed with the contacts down and fixed with double-sided tape or construction glue.This option is used in cases where the installation of the "anti-leakage" system is performed after the installation of plumbing equipment

The scheme of their connection can be both floor and internal, in which the elements are cut into the coating material. In the first case, the plate is placed with the contacts down and fixed with double-sided tape or construction glue. This option is used in cases where the installation of the "anti-leakage" system is performed after the installation of plumbing equipment.

Wiring diagrams water leakage sensor.

When the device is located internally, its contacts are placed 3-4 mm above the level of the coating, which makes it possible to exclude operation in case of accidental splashing of water or cleaning. The connecting wire is laid in a corrugated pipe impervious to water. Manufacturers guarantee the efficiency of the system even when the determinant is 100 m away from the control module.

Wireless devices are mounted on any surface thanks to the fastener system.

Controller Mounting Rules

The device is placed in a niche or on the wall next to the electrical wiring and shut-off valves. The power cabinet serves as the controller's power supply, so phase and zero are connected to the device. The wires are connected using special terminal connectors, which are numbered and signed for ease of installation. Then connect the water leakage detectors and proceed to the diagnosis.

Checking system operation

When the control module is turned on, a green indicator lights up on its panel, indicating that it is ready for operation. If at this moment the sensor plate is wetted with water, the light of the bulb will change to red, the sound pulse will turn on and the shut-off valves will block the water inlet.To unlock the detector, wipe it with a dry cloth and restart the device. After checking the status, the controller will be ready for operation.

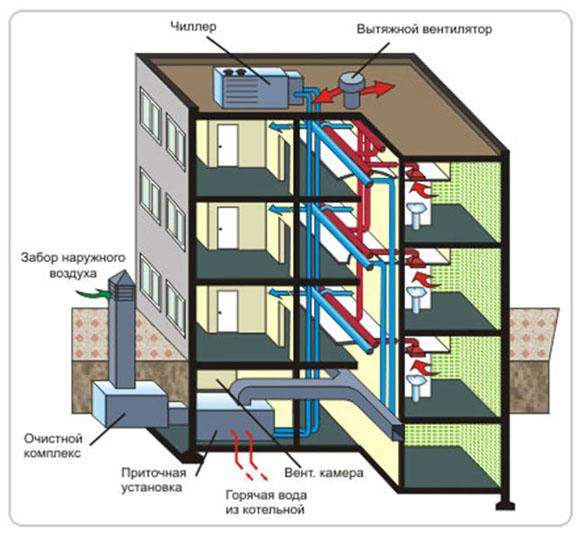

Principle of operation

Traditionally, the operation of the device is divided into two stages:

- Air sampling and analysis.

- Overshoot response.

Due to the fact that the carbon monoxide detector is placed in areas with natural convection, it regularly receives fresh air samples, passes through it and analyzes them. Therefore, installation in corners, behind cabinets and at other points of stagnation of air masses is prohibited. This can lead to an incorrect assessment of the threat level.

As soon as the analysis module reports an excess, the device activates an audible and visual alarm for people in the room. This is the most important step that helps save lives.

Then, if there are appropriate functions, it performs the following steps:

- Sends an SMS or PUSH message to the owner of the premises.

- Shuts off the gas supply to all devices that may be dangerous.

- Sends an alarm signal to the security console and the fire department.

- Includes smoke exhaust and ventilation system.

A carbon monoxide alarm sensor with an extended set of functions, as a rule, is purchased for a country house with a boiler room or industrial premises. Such models in Moscow can cost from 10,000 to 150,000 rubles. For a city apartment, a device with a minimum set of functions at an affordable price is enough.

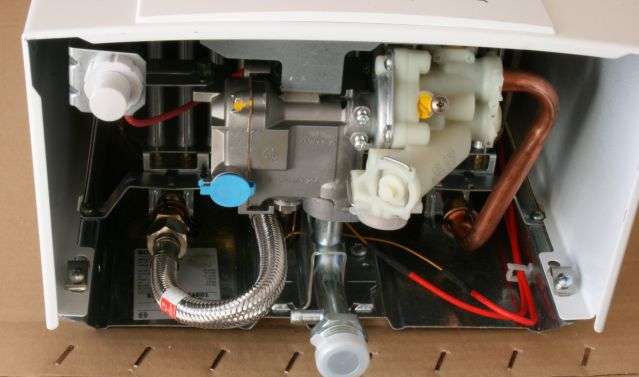

Household Gas Detector Valves

If the kitchen has a hood that turns on at the signal of the device, then the safety in the room is largely ensured by a shut-off valve.It works on the electromagnetic principle. It instantly stops the flow of fuel at the signal of the device.

There are such types of valves:

- The diameter of the pipe carrying the gas.

- Electrical.

- With acceptable pressure.

Their designs are as follows:

- Normally open. It is cocked manually. It does not require voltage to operate. When the detector is triggered, an electrical signal follows and the valve closes. The designation of the valve is "NA".

- Normally closed. His cocking is similar. But you need electricity. He always works under pressure. On impulse from the device, the voltage disappears, the valve closes.

For everyday tasks, it is optimal to use the first type. Indeed, in the event of a power failure, its functionality will not suffer in any way.

Service

From the manufacturer to the end user, the equipment comes calibrated, does not require additional configuration and preparatory work during commissioning. This is evidenced by the corresponding entry in his passport, the seal of the Quality Control Department and the date of the check.

But after installation, you can not leave it unattended:

- Once every 3-4 weeks, it is necessary to clean the location of the device from dust with a vacuum cleaner;

- With a slightly damp cloth, wipe the device, especially carefully in the area where the sensitive component is located;

- Periodically check the functionality of the sensor. To do this, for example, you can bring a lighter to the area of the sensitive element and apply gas for a few seconds. After triggering, you need to make sure that the sound alarm is clearly audible and the light alarm is working;

- After checking, the detector should return to normal operation on its own;

- If the performance test was carried out in conjunction with a shut-off valve, it is necessary to cock the stop valve stem by hand to supply gas to the equipment.

Where are gas detectors installed?

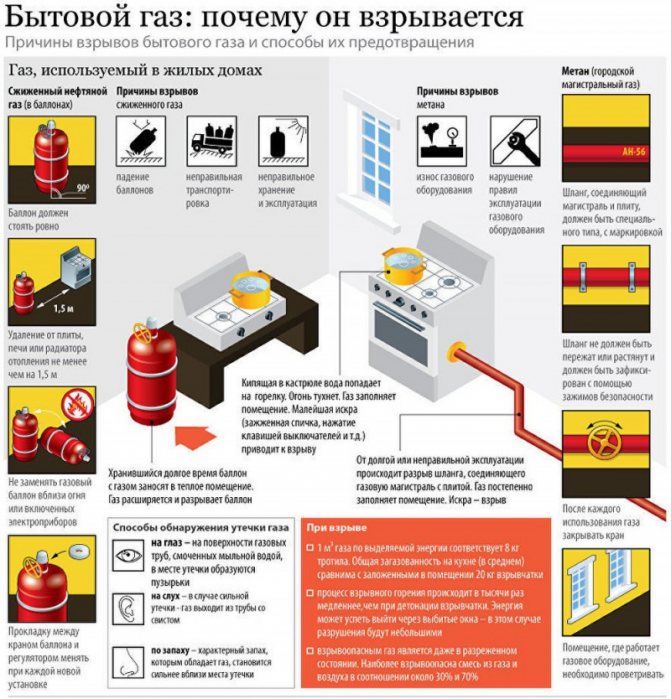

The main advantage of the gas sensor is the ability to detect a dangerous concentration of a toxic substance in the air and notify about it with a sound and light signal. As a rule, gas detectors as part of a fire safety system are installed in potentially dangerous places where gas equipment is operated: in boiler rooms, in the kitchen and other premises.

To avoid poisoning with toxic gases, you must:

- control the operation of the ventilation and air conditioning system,

- use gas equipment only for its intended purpose in accordance with the rules,

- regularly inspect and test gas equipment,

- use sensors to monitor indoor air quality.

Without devices for measuring the concentration of combustible gases, they cannot do at industrial facilities. Entire hazardous gas identification systems are installed at enterprises in premises that can become a source of poisoning. Obviously, a sensor capable of detecting a leak of poisonous gas is necessary not only in production, but also in everyday life. In a dangerous situation, the device will help protect residents of the house from accidents.

Carbon monoxide detectors for the home: installation

Modern devices have a special mounting bracket. It is on it that the instrument boxes should be installed. It must be mounted on a wall not far from the ceiling. Let's make a reservation right away, in some European countries, installing a detector on a wall is a gross violation. In such countries, devices are installed only on the ceiling.In turn, in Russia, as in other CIS countries, it is customary to mount devices on the wall.

Due to the fact that the detector is also aimed at recognizing natural gas, it is necessary to correctly calculate the installation location. Devices must be fixed at different heights. Let's take a closer look at how to do this.

If your apartment is equipped with a pipeline with gas, the detector should be installed high, not far from the ceiling. If a gas cylinder is used in the apartment - low, not far from the floor. This is due to the density of gas substances: in the event of a leak, natural gas tends to rise, while the gas from the cylinder descends.

note

Before installing the security system, we recommend checking the operation of the hood. If the ventilation is faulty, it is worthwhile to postpone the installation of the detector and deal with it first.

If your device is not powered by batteries, but by the mains, we strongly recommend that you use the services of a wizard. If the device is connected incorrectly, it may malfunction or not work at all.

Also, when choosing places for fastening carbon monoxide sensors, we recommend placing at least one in the bedroom. From year to year, many cases of poisoning are recorded in this particular room. If you live in a multi-storey apartment or a private house, the detector must be placed on each floor.

When installing the appliance in the kitchen, do not forget the rules prescribed in the instructions. Usually they say that the device must be placed at a distance of four to five meters from the source of fire. This is due to the fact that some brands of detectors react to the general air temperature. The average should not exceed fifty degrees Celsius.This is explained by the fact that in some fires, the fire may already begin to spread, and the level of toxic substances has not yet reached the mark set for the sensor.

Also, do not place the sensor behind a curtain or blinds. This will significantly interfere with its correct operation. After all, for the proper functioning of the device, it needs air circulation. If you install the device in a place that does not correspond to this parameter, the device will not work correctly.

Checking work

To test if your detector is working, you can purchase a small can of carbon monoxide from the store. Spray a small amount of the contents near the sensor. If it worked and the alarm turned on, the device is installed correctly.

Before checking, pay attention to the precautions. When spraying gas from a cylinder, do not direct pressure onto the device itself. The level of toxic substances that enter the sensor will exceed several times the device operation norms

This threatens to temporarily disable the detector, and in the worst case, break it.

The level of toxic substances that enter the sensor will exceed several times the device's response rate. This threatens to temporarily disable the detector, and in the worst case, break it.

Also, for further proper operation, it is necessary to monitor the cleanliness of the device and prevent dust from accumulating on the box.

Service

When buying a household gas leak sensor, it is already configured. Therefore, no preparatory work is required during installation. After installing it, you should watch it for a while.

In addition, it is necessary to clean the surrounding areas of the device from dust and other contaminants. In this case, you should not overdo it so as not to disable the sensitive element.

Another important point is the performance check. To do this, apply gas to the sensor. You can do this with a regular lighter.

After the sensor has worked, you need to pay attention to the alert signal. It must be loud enough for all staff to hear.

After the weathering of the gas, the device recovers itself. If the devices are equipped with shut-off valves, then the performance is checked manually.