- Coolant presence sensor

- Boiler priority relay

- Why is it needed?

- Device and principle of operation

- Classification of types of temperature sensors

- Types of sensors according to the method of determining temperature

- Types of sensors according to the method of interaction with the thermostat

- Functionality check

- The principle of operation of a gas double-circuit boiler

- Maximum pressure switch (gas)

- How does a draft sensor work in a gas boiler?

- Series from Siberia

- Setup and installation

- Installation

- How to disable

- How water pressure sensors for boilers work

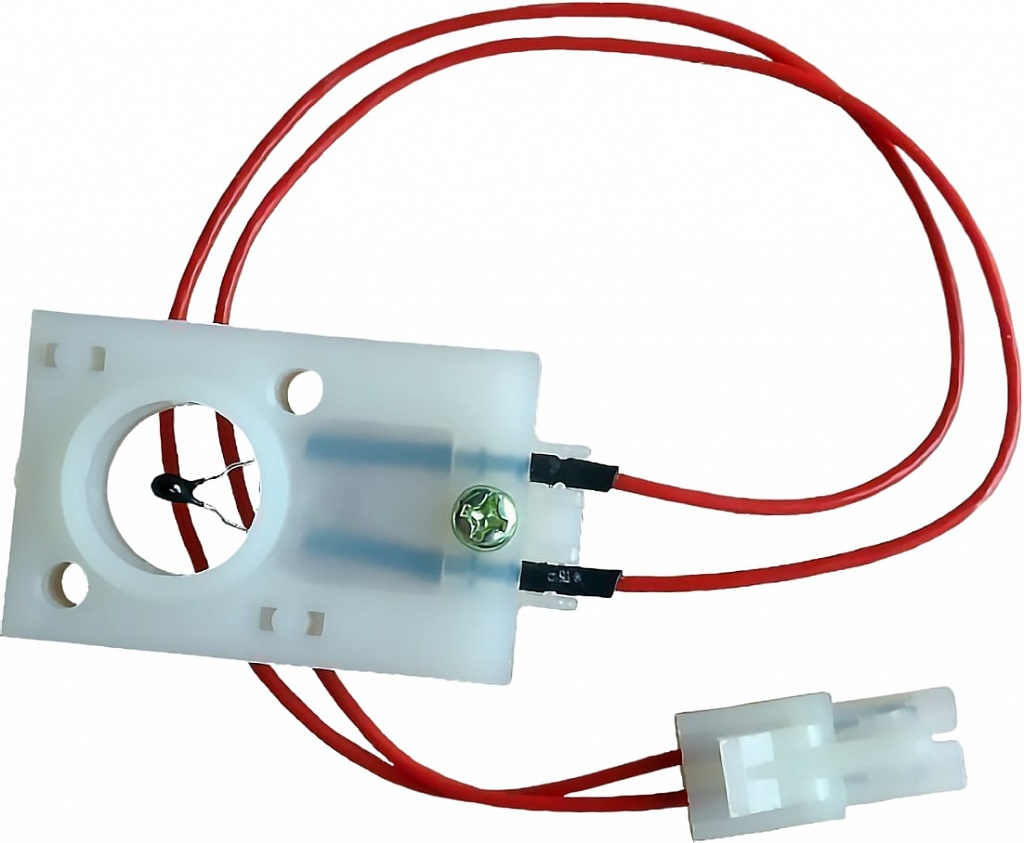

Coolant presence sensor

Other boilers can fail even during short-term operation in the absence of a coolant. To prevent such situations, a sensor for the presence (or absence) of a coolant is designed

This is especially important for electric boilers with heating elements. The sensor is installed either next to the boiler or inside

It is included in the control circuit of the device and closes the contacts only when the block is filled with coolant. The most common devices are reed switches and conductometric sensors.

In the first, the magnetic core is built directly into the float, which, when floating up, closes the contacts only in the presence of liquid.

The second type of sensors are special electrodes placed in the hydraulic circuit.When the boiler is filled with coolant, a current sometimes flows between the electrodes. A closed circuit is a sign of the normal situation of the coolant and a signal about the operation of the boiler.

Boiler priority relay

Domestic boilers for the most part have the ability to connect to the electrical circuit of the target that controls the storage tank. This involves, among other things, the connection of the power supply of the circulation pumps and their switching. For the correct implementation of the operation algorithms of the heating system pumps and the boiler (which is aimed at the priority of water heating), a special boiler priority relay is used. This is a device that switches the power circuit of the pumps according to the commands of the boiler control circuit. The relay is structurally a couple of groups of contacts controlled by a coil. The relay is used together with the base, which is built into the boiler. The entire load is attached to the base. When installing a base relay, the priority of the DHW system is ensured. Without such a relay, both heat loads function independently.

Why is it needed?

Today, gas-fired boilers are the most common, since today blue fuel remains the cheapest when compared with the cost of other energy sources. As a rule, gas heating equipment usually operates in automatic mode. In order for its operation to be safe, there are several sensors inside that monitor the health of the system.

As soon as some deviation occurs, the equipment immediately receives a shutdown command.

A draft sensor of this type works as follows - the controller simply analyzes the draft and turns off the device if the smoke intensity drops.

Device and principle of operation

The principle of operation of thermal sensors is based on measuring resistance, pressure, physical dimensions (thermal expansion), thermo-EMF, which have a strong dependence on temperature in a specific range. Data on the amount of heating can be obtained on the basis of the calibrations of the sensors when recalculating according to the corresponding formulas.

In automatic thermostats, these formulas are embedded in the control program, and in mechanical ones, special devices are installed that regulate the operating modes in some simple way, for example, mechanical or electrical relays that close or open the necessary contacts.

Thermal sensors have a relatively simple design - a small case with fasteners, inside which the sensor itself is located. They can be sealed or open, depending on the method of detection. To transmit measured data, they can be equipped with wireless sensors or connected via a wired connection.

Classification of types of temperature sensors

The choice of sensor depends on the medium in which the temperature is to be controlled: inside the boiler, in the room or in the heating system. The efficiency and safety of the heating equipment depends on the correctness of their choice.

The temperature sensor for a heating boiler is classified according to the following criteria:

- according to the method of determining the temperature,

- according to the type of interaction with the thermostat.

Types of sensors according to the method of determining temperature

According to the method of determining the temperature, the sensors are:

- Dilatometric, which are bimetallic plates or spirals, the principle of operation of which is based on the thermal expansion of metals or other types of solids.

- Resistive, having a strong dependence on temperature in a certain measured range, which manifests itself in the form of sharp changes in electrical resistance.

- Thermoelectric, which are thermocouples (alloys of two dissimilar conductors, for example, chromel-alumel), in which, at certain temperature intervals, thermo-emf begins to induce.

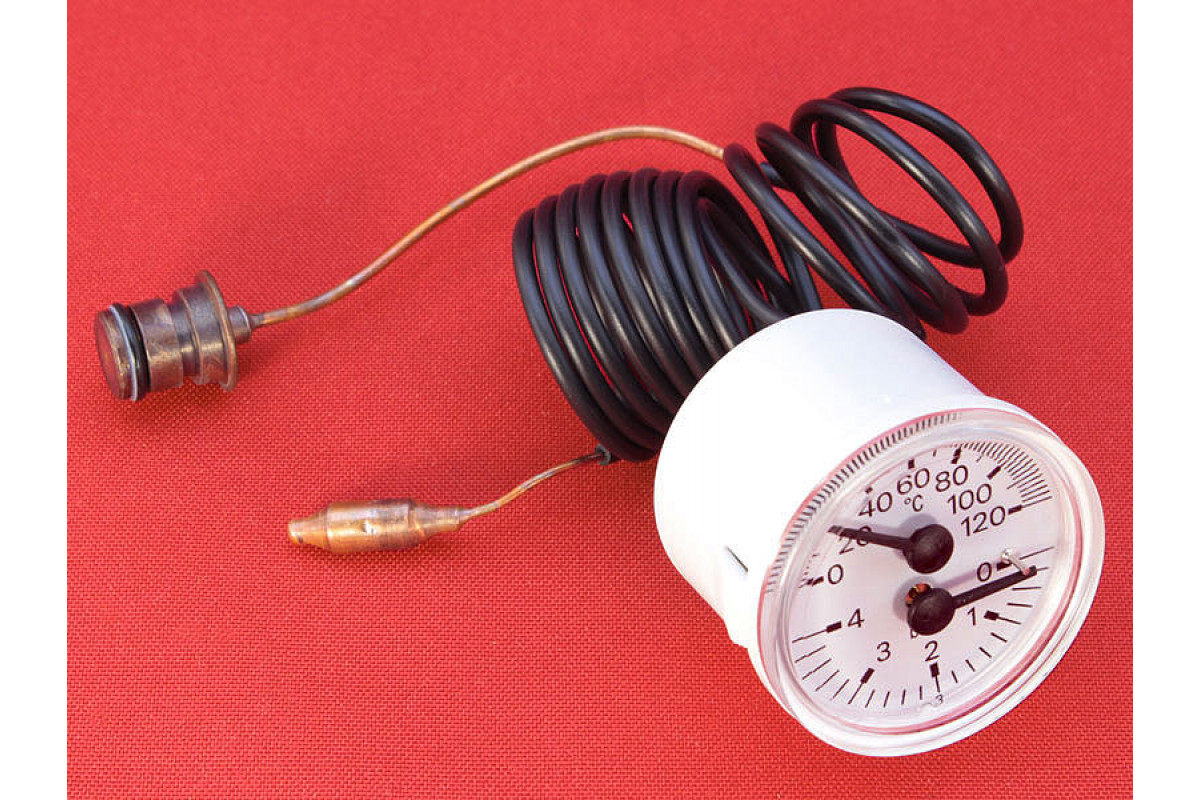

- Gauge, the principle of operation of which is based on a change in the pressure of a gas or liquid in a closed volume.

Dilatometric sensors are made from materials with a high coefficient of thermal expansion that respond to minimal temperature fluctuations. The principle of their operation is based on the closure or opening of electrical contacts. To increase their sensitivity and contact quality, magnets are used in the designs.

Resistive temperature sensors are made from special alloys of conductors or semiconductors. Structurally, they consist of a coil with a thin copper, platinum or nickel wire wound and a ceramic case or semiconductor wafers placed in a plastic or glass case.

Semiconductor resistors are of two types:

- thermistors having a non-linear temperature dependence, characterized by a decrease in resistance when heated,

- posistors, which also have a non-linear dependence on temperature, but differ from thermistors by an increase in resistance when heated.

Thermoelectric sensors are made of two specially selected dissimilar metals or alloys, at the contact point of which, when heated, a thermo-EMF is induced, the value of which is proportional to the temperature difference between the two junctions. In this case, the measured value does not depend on the temperature, length and cross-section of the wires.

Manometric sensors make it possible to determine the temperature in a non-magnetic way without the use of energy sources, which allows them to be used for remote measurements. However, their sensitivity is an order of magnitude worse than that of other thermal sensors, and there is also an effect of inertia.

Types of sensors according to the method of interaction with the thermostat

Temperature meters according to the type of interaction with the thermostat are divided into the following types:

- wired, transmitting data to the controller by wire,

- wireless - high-tech modern devices that transmit data at a certain radio frequency.

Wired temperature sensor for boiler

Wired temperature sensor for boiler

Functionality check

All of the above can be summarized into one: the sensor is necessary in order to shut off the fuel supply in the event of a danger - such as a gas leak or poor removal of combustion products. If this is not done, very sad consequences are possible.

About carbon monoxide poisoning has already been mentioned more than once above. It very often leads to death, and you definitely shouldn’t joke with it. And in the event that the burner suddenly goes out, but the gas continues to flow, sooner or later an explosion will occur. In general, it is clear that the sensor is vital.

But it can fully perform its functions only in good condition. Every piece of equipment is prone to failure from time to time.

The breakdown of this part will not affect the external state of the boiler, so it is very important to regularly check the performance of the element.Otherwise, you risk noticing a problem until it's too late. There are several methods for checking:

There are several methods for checking:

- attach a mirror to the area where the sensor is installed. During the operation of the gas column, it should not fog up. If it remains clean, then everything is in order;

- partially block the exhaust pipe with a damper. In the case of normal operation, the sensor should instantly react and turn off the boiler. For safety reasons, do not test for too long to avoid carbon monoxide poisoning.

If in both cases testing showed that everything is in order, then the element being tested is ready at any time to respond to an unforeseen situation and turn off the gas supply. But there is another type of problem - when the sensor works just like that.

If you carefully checked the draft level and other points, but the boiler still turns off, this means that the control element is not working correctly. You can further test this as follows.

Disconnect the element and ring it with an ohmmeter. The resistance of a good sensor should be equal to infinity. If this is not the case, then the part is out of order. There is only one option to correct the situation - it is necessary to replace the broken element.

Some homeowners, in situations where the sensor suddenly starts to constantly interrupt the fuel supply in the absence of visible problems with the chimney draft, decide to simply turn off this element. Of course, after that the column starts to work smoothly.

But such actions are a direct violation of safety regulations during the operation of gas equipment.By turning off the sensor, you cannot be sure that everything is in order with the draft, and that carbon monoxide does not begin to fill the room. Definitely not worth the risk. It is better to check the performance of the part in the ways described above. You can also get information on this issue from the video posted above. Good luck to you, as well as a safe and warm home!

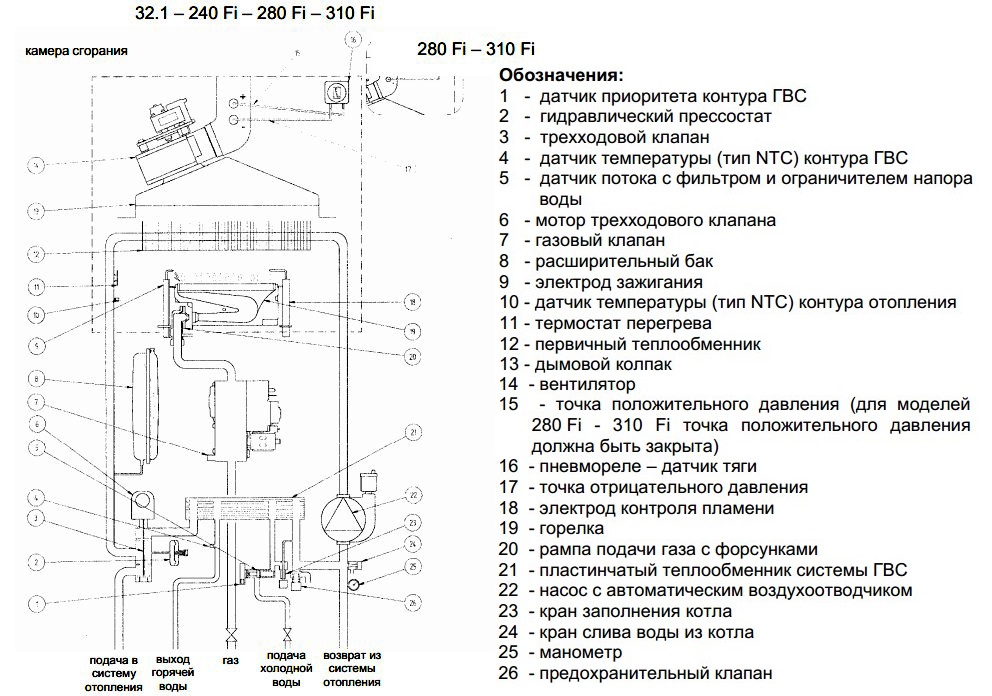

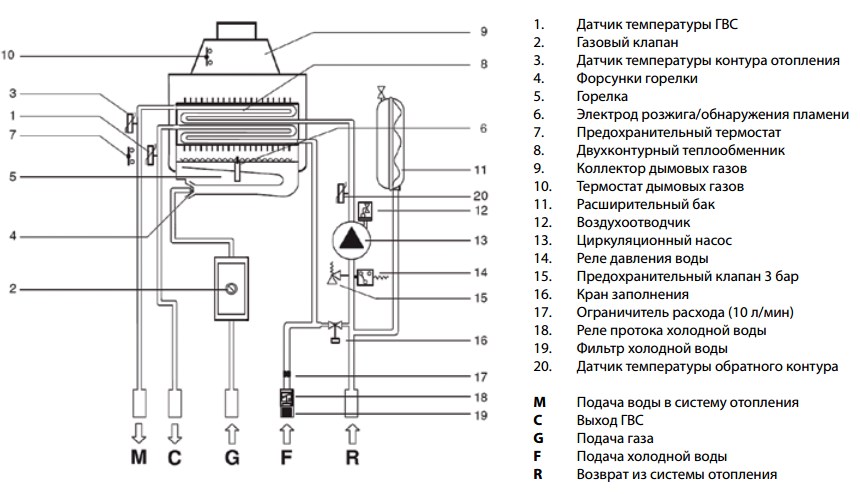

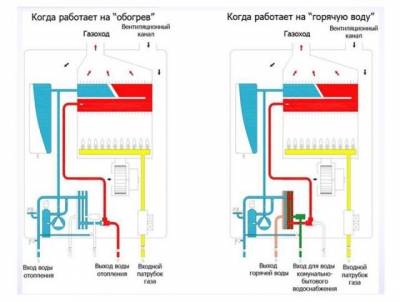

The principle of operation of a gas double-circuit boiler

A double-circuit gas boiler in its format resembles a gas instantaneous water heater, differing only in size. If you look into its filling, we will find equipment for the operation of two circuits - heating and hot water. In order to understand how this device works, you need to understand its internal structure. What will we find inside?

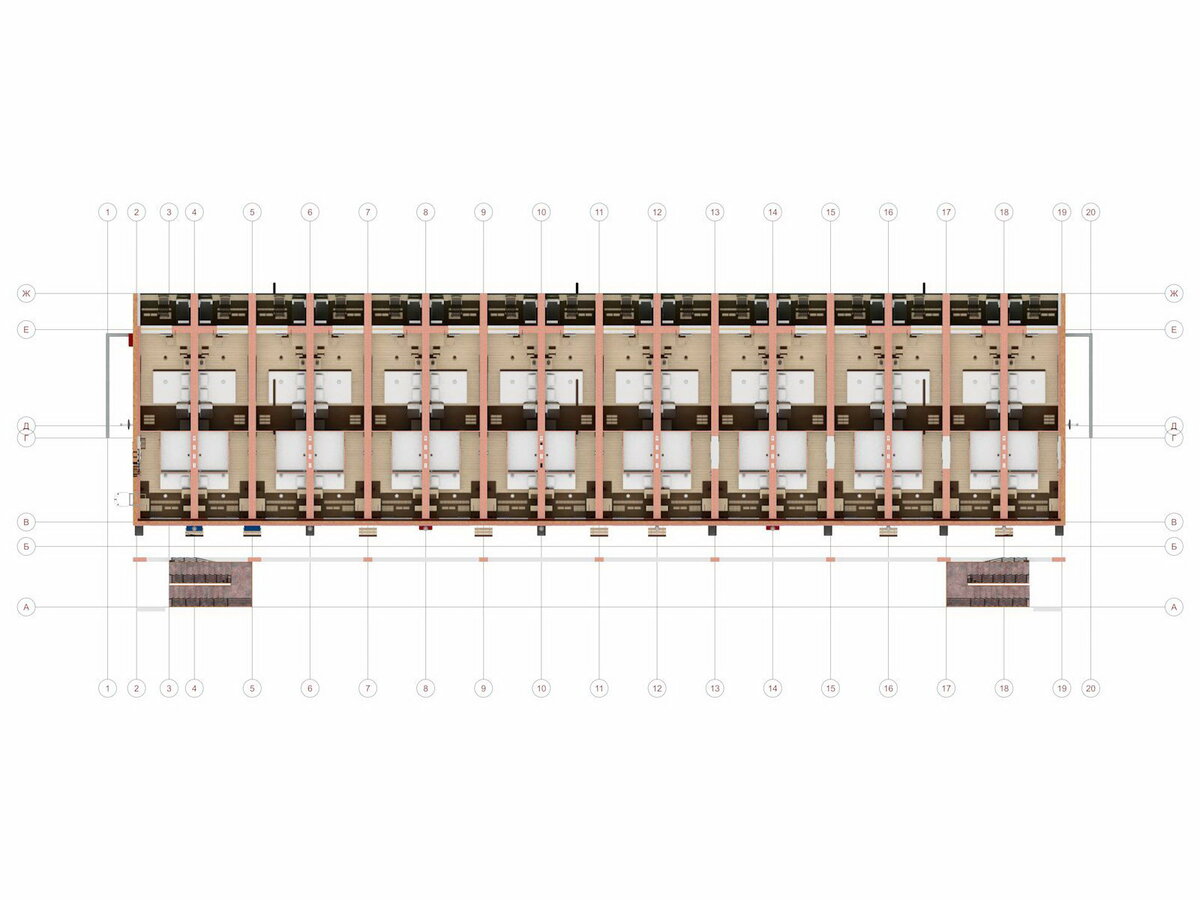

The device of a gas heating boiler with two circuits.

- The main (primary) heat exchanger - heats the coolant in the heating circuit;

- Secondary heat exchanger - responsible for hot water supply;

- Burner - a heat source (the burner here is one for two circuits);

- Combustion chamber - the primary heat exchanger is located in it and the burner burns in it);

- Three-way valve - responsible for switching between the heating mode and the DHW mode;

- Circulation pump - provides circulation of the coolant through the heating system or in a small circle of the DHW circuit;

- Automation (electronics) - ensures the operation of the above and many other nodes, controls the parameters and is responsible for safety by removing signals from sensors.

There are many other components in the design of double-circuit boilers. But in order to understand the principle of operation, it is enough to know the purpose of the above modules.

In some models, there is no secondary heat exchanger, and the preparation of hot water is carried out using dual combined heat exchangers.

Scheme of operation of the device in heating mode and in hot water supply mode.

Now we will understand the principles of work. We have already said that double-circuit gas boilers can operate in two modes - heating and hot water. When the boiler is started, the heating circuit starts to work - the circulation pump starts, the burner turns on, the three-way valve is in a position in which the coolant circulates freely through the heating system. The burner works until the control module gives a command to turn it off.

The operation of the burner is controlled by automation, which is able to evaluate the temperature of the coolant, the air temperature in the premises and on the street (support for room and internal sensors is available only in some models).

If you need hot water, turn on the tap. Automation will fix the current through the DHW circuit, and the three-way valve will turn off the heating system and start the circulation of part of the coolant in a small circle. This coolant will enter the secondary heat exchanger, through which the prepared water flows. As soon as we close the tap, the three-way valve will switch to heating mode.

Despite the complex device, the principle of operation is quite simple, and double-circuit gas heating boilers are becoming more common. They are chosen for their convenience, compactness and good performance.

You also need to pay attention to the fact that these boilers do not know how to work in two modes at once - either the heating or the DHW circuit is working.But given that we do not use hot water so often, then this disadvantage can be put up with (it is unlikely that you will consume water for so long that all the batteries will have time to cool down)

Maximum pressure switch (gas)

Relay devices for maximum gas pressure are designed to protect boilers from possible overheating or from the danger of destruction due to an uncontrolled increase in pressure on the burner. This can lead to an increase in the size of the torch itself and, as a result, to burnout of the combustion chamber, which is not intended for this. In addition, gas valves with increasing gas pressure may not close. The rise in pressure can also be provoked by a breakdown of the gas fittings on the supply line.

The relay is connected in series with the minimum pressure switch. This is done in such a way that the operation of any of them somehow turns off the boiler. Structurally similar relay is made similarly to the first one.

How does a draft sensor work in a gas boiler?

Traction sensors can have a different structure. It depends on what type of boiler they are installed in.

The function of the draft sensor is to generate a signal when the draft in the boiler deteriorates

At the moment there are two types of gas boilers. The first is a natural draft boiler, the second is forced draft.

Types of sensors in boilers of various types:

If you have a natural draft boiler, then you might notice that the combustion chamber is open there. The draft in such devices is equipped with the correct size of the chimney. Draft sensors in boilers with an open combustion chamber are made on the basis of a biometallic element

This device is a metal plate on which a contact is attached. It is installed in the gas path of the boiler and responds to temperature changes. With good draft, the temperature in the boiler remains quite low and the plate does not react in any way. If the draft becomes too low, the temperature inside the boiler will rise and the sensor metal will begin to expand. Upon reaching a certain temperature, the contact will lag behind and the gas valve will close. When the cause of the breakdown is eliminated, the gas valve will return to its normal position.

Those with forced draft boilers should have noticed that the combustion chamber in them is of a closed type. The thrust in such boilers is created by the operation of the fan. In such devices, a thrust sensor in the form of a pneumatic relay is installed. It monitors both the operation of the fan and the speed of the combustion products. Such a sensor is made in the form of a membrane that flexes under the influence of flue gases that occur during normal draft. If the flow becomes too weak, the diaphragm stops flexing, the contacts open and the gas valve closes.

The draft sensors in boilers with an open combustion chamber are made on the basis of a biometallic element. This device is a metal plate on which a contact is attached. It is installed in the gas path of the boiler and responds to temperature changes. With good draft, the temperature in the boiler remains quite low and the plate does not react in any way. If the draft becomes too low, the temperature inside the boiler will rise and the sensor metal will begin to expand. Upon reaching a certain temperature, the contact will lag behind and the gas valve will close.When the cause of the breakdown is eliminated, the gas valve will return to its normal position.

Those with forced draft boilers should have noticed that the combustion chamber in them is of a closed type. The thrust in such boilers is created by the operation of the fan. In such devices, a thrust sensor in the form of a pneumatic relay is installed. It monitors both the operation of the fan and the speed of the combustion products. Such a sensor is made in the form of a membrane that flexes under the influence of flue gases that occur during normal draft. If the flow becomes too weak, the diaphragm stops flexing, the contacts open and the gas valve closes.

Draft sensors ensure the normal operation of the boiler. In natural combustion boilers, with insufficient draft, symptoms of reverse draft may be observed. With such a problem, the products of combustion do not go out through the chimney, but return back to the apartment.

There are a number of reasons why the draft sensor may work. By eliminating them, you will ensure normal operation of the boiler.

Because of what the traction sensor may work:

- Due to clogging of the chimney;

- In case of incorrect calculation of the dimensions of the chimney or its incorrect installation.

- If the gas boiler itself was installed incorrectly;

- When a fan was installed in the forced draft boiler.

When the sensor is triggered, it is urgent to find and eliminate the cause of the breakdown. However, do not try to forcibly close the contacts, this can not only lead to the failure of the device, but is also dangerous for your life.

The gas sensor protects the boiler from damage. For better analysis, you can purchase an air gas analyzer, it will immediately report the problem, which will allow you to quickly fix it.

Overheating of the boiler threatens the entry of combustion products into the room. Which can have a negative impact on the health of you and your loved ones.

Series from Siberia

The manufacturer offers three series:

- Premium Topline-24. Premium models are designed for small buildings. Double-circuit - you can heat water for domestic needs. A feature of the series is electronic ignition. There is ionization control of fire and waste gas. There is an anti-scale function. Efficiency 90%.

- Comfort Siberia. Modifications 23, 29, 35, 40, 50 (heating capacity, kW). Any option is offered - single-circuit or double-circuit. Designed for large spaces.

- Econom Siberia. Issued since 2005. Four models differing in the number of circuits and power - 11.6 kW and 17.6 kW. The letter "K" in the marking means two circuits. It is possible to switch to liquefied gas - you can insure yourself in case of an accident in the gas pipeline. The cases are covered with enamel, which protects against mechanical damage.

Setup and installation

Before setting up the system, the sensor must be installed. Wiring diagram for water pressure switch:

In order to adjust the water level pressure switch to the water supply system with your own hands, you just need to change the boundaries of its operation. This process is called thoriation.

Step-by-step instructions on how to set up a water pressure switch:

- First, the cover of the device is removed. To do this, the screws on its surface are unscrewed;

- Visually, the springs can be distinguished due to the visible difference in size: the differential has a larger diameter, and the minimum pressure, respectively, is smaller;

- The upper one is pulled up to adjust the level of high (maximum) pressure in the system, and the lower one is to adjust the minimum one;

- After adjustment, the cover is installed in place. The nuts are tightened, but make sure they are not too tight.

It is worth noting that if the minimum trigger level is set incorrectly, a dry-running problem may occur. This is the main reason for the failure of the pump, boiler or other devices.

It occurs when a device with high efficiency (higher than necessary) is used to supply water. Also, experts say that another reason for dry running is the emptying of the storage tank. Such a problem is often found in a domestic hot water supply system (when pumping hot water through pipes, the pump completely empties the tank over time). At the same time, the water pressure in the system does not change, but then the pump and the relay operate “idle”.

To avoid this problem, you need to choose a special water pressure switch or supplement the existing one with certain devices:

- Buy a device that uses dry run protection. These devices are slightly more expensive than conventional ones, but they are more effective. Their main difference is the ability to respond to pressure drops below 0.4 bar (these are Danfoss models - Danfoss, XP600 Ariston 0.2-1.2 bar relay);

- Installing a special press control instead of a sensor. This is a special type of controller that not only controls the pressure, but also allows you to turn on the pump even if it falls below a predetermined minimum level. In the absence of water in the system, the pressure drops very quickly and many devices simply do not have time to respond to this.Even though the pump turns on after a short period of time, it still works in the set mode.

It should be noted that if repair or complete replacement of the sensor is required, then it is completely dismantled from the pipeline. "In place" to fix it will not work. For preventive maintenance, the device is disconnected from the water supply and electricity system.

Video: irrigation pump pressure switch

Installation

The kit comes with a passport and instructions. The latter is necessary to familiarize yourself with the device, the principle of operation and the rules for using the boiler. After reading the instructions, the user will be able to learn how to turn on the device. It is advisable to entrust the installation to specialists. Mounting Features:

• Issuance of a permit for the installation - from the gas workers.

• Installation is carried out by specialists with a license for the relevant work.

• The kit does not include an expansion tank and a circulation pump - they will have to be purchased separately.

• The device is placed against the wall, so be sure to leave a gap of at least three centimeters.

• For surface mounting, the machine needs a foundation. Usually it is made of brick. Wall models are firmly fixed.

• When connecting, there must not be the slightest leakage of gas. Connections must be carefully insulated.

• If you start the machine for the first time, condensation will collect on the heat exchanger, which will disappear when the system warms up.

How to disable

The instruction manual does not contain information on how to disable the draft sensor in a gas boiler. It does not recommend disabling this security system yourself.This can lead to negative consequences, both for the device and for human health, since the operation of the sensor is a clear sign of danger.

Disabling the draft sensor is a direct violation of the safety rules established by the heating equipment manufacturer!

Carbon monoxide poisoning has the following symptoms:

- mild degree - headache, dizziness, chest pain, pounding in the temples, cough, lacrimation, nausea, vomiting, hallucinations, redness of the skin and mucous surface, palpitations, hypertension are possible;

- medium - tinnitus, drowsiness, paralysis;

- severe - loss of consciousness, convulsions, involuntary defecation or urination, respiratory rhythm failure, blue skin color, death.

The consequences of carbon monoxide poisoning can adversely affect the further life of a person.

At the same time, the design of the boiler allows the possibility of shutting down this system. To do this, it is necessary to disconnect the thermocouple interrupter and the electrical wiring of the draft sensor from the solenoid valve, as well as from the electronic control unit of the boiler.

Thus, the control unit will continue to autonomously control the operation of the boiler, without taking into account the readings of the temperature of the burnt gas and the force of its removal into the atmosphere.

How water pressure sensors for boilers work

The water pressure switch for gas boilers is the first degree of their protection from working with a low-pressure coolant. It is a small device that is paired with an electronic control board. In boilers with automatic make-up, this device also controls the operation of the electric make-up valve.

In each boiler model, water pressure sensors are individual and may differ from other similar units:

- method of connection to the hydraulic group (threaded or clip-on);

- type of electrical connectors;

- the possibility of adjusting the minimum pressure of the coolant.

In the case of the water pressure sensor for the boiler, there are contacts and a membrane adjusted in such a way that at normal pressure of the coolant in the circuit, it closes the circuit, and the signal passes through it to the control board, informing about the normal pressure of the coolant. When the pressure drops below the minimum, the contacts open - and the electronic board blocks the boiler from turning on.

You can buy a water pressure sensor for a gas boiler of original origin or its high-quality analogue on our website at a bargain price with a guarantee and delivery in Russia. Call - and our experienced consultants will help you choose any spare part for your boiler model!

Now we will figure out what a water flow sensor is for (also called a “relay

duct") and look at the principle of its operation. You will also learn what types of these sensors are and how to install it yourself.

In everyday life, emergency switching on of the pump without water sometimes occurs, which can lead to equipment failure. Due to the so-called "dry running", the engine overheats and parts are deformed

In order for the pump to function at maximum efficiency, it is important to ensure the supply of water without interruption. To do this, you need to equip the heating and hot water supply system with a device such as a water flow sensor

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the stores in your city.Delivery across all territory of the Russian Federation and the CIS countries.

Water flow sensor