- Fire detection methods

- Fire flame smoke detector

- Types of fire detectors

- Smoke

- Thermal

- Flame sensors

- Gas fire detectors

- Manual

- Combined

- Reception and control devices

- Product models and manufacturers

- infrared sensors

- Characteristics of flame detectors

- Installation specifics

- Sensor device

- The principle of operation of sensors

- Conclusion

Fire detection methods

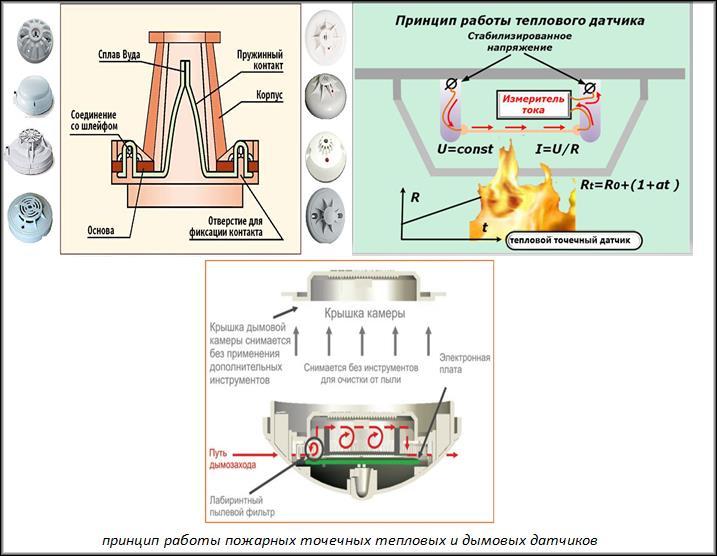

PI thermal and flame are based on the following principles:

- the first is the oldest, but fail-safe method - the sensor is activated when a critical level of t ° is reached, for example, under the ceiling. Threshold values are prescribed in the physical properties and mechanism of action. Principle of operation: the thermal relay is triggered, the fusible solder melts due to temperature, opening the contact (this is the maximum heat detector);

- the second method is fixing a sharp increase in temperature per unit. time. These are differential sensors.

Modern models of temperature and flame sensors usually combine the two indicated methods of action - these are maximum differential detectors. Such devices are the most sensitive and effective.

Smoke and gas sensors have a different principle of operation: they use materials and components that respond to ionization (opto-electronic), trap particles of smoke, soot, aerosols, and other combustion products (aspiration detectors).

Fire flame smoke detector

It is not uncommon for ignition to begin with a slight smoldering, due to which smoke is formed. Smoke detectors fix this. The installation of such devices is carried out in enclosed spaces with a ceiling height of up to thirteen meters. They can be located on columns, on the surface of walls at a distance of ten to forty centimeters from the ceiling and fifteen from the corners.

Smoke extractors are not suitable for kitchens, bathrooms or stairwells, as well as rooms where there is increased smoke.

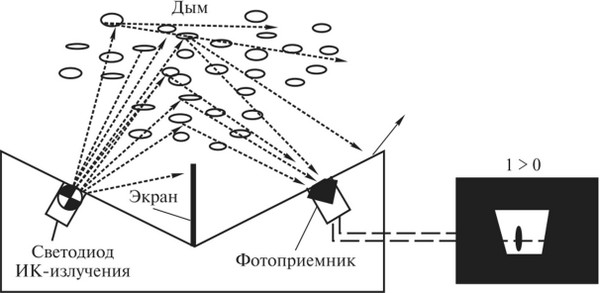

Optoelectronic smoke detectors consist of an LED and a photodetector located at different heights relative to each other in the smoke chamber. When smoke enters it, the refraction of light is fixed by a photocell, and a pulse is sent to the fire department console.

External light sources should not affect the photodetector, high dustiness of the room is unacceptable.

Inexpensive devices are able to fix the ignition at an early stage, but their effectiveness is modest - they can work falsely and do not respond to the black smoke that is released when burning rubber products.

Heat detector fire flame

Thermal devices - fire sensors - record a sharp temperature drop in a confined space. They are suitable for installation in smoking rooms, kitchens, toilets and other specific areas. Previously, such devices began to work at the moment when the transition of a certain temperature threshold was recorded, usually above seventy degrees. Modern technology has allowed the development of instruments, and now they take into account not only temperature fluctuations, but also the speed of how changes occur.

Modifications of devices of this type:

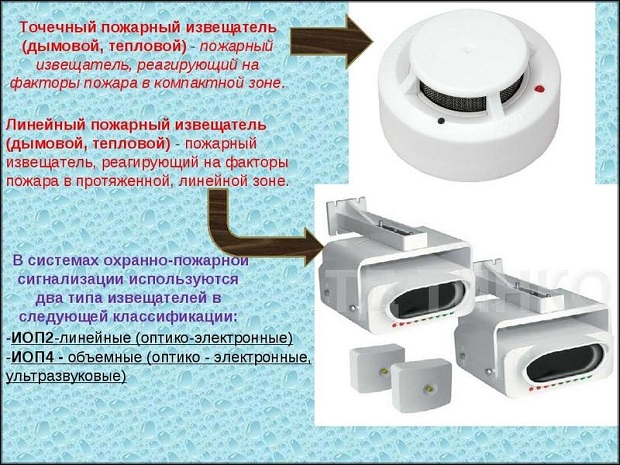

- point - designed to control small areas, automatically send a signal to the control panel, where the ignition source is localized;

- multipoint - installed on the same line with a given step. When an emergency occurs, the entire line of instruments is activated;

- linear - this is a thermal cable, which acts as a controlling element, triggered if the temperature changes along its entire length.

Where flame detectors are installed - on the ceiling, as this allows you to quickly respond to the rising temperature in a confined space.

Thermal IPPs are recommended to be installed in rooms with a low ceiling height, they are cost-effective, as they are inexpensive and easy to maintain. However, if a fire starts with the release of gases and toxic substances, and not with a sharp increase in temperature, then the effectiveness of the devices is reduced. There is a certain delay before the alarm is triggered, which endangers people's lives.

Types of fire detectors

Depending on the parameters to which the sensors of the detectors respond, they are divided into the following types.

Smoke

The vast majority of materials burn with the formation of smoke. Smoke is a substance of small particles formed from combustion products.

The principle of operation of the optoelectronic smoke detector is based on the dispersion of the light flux by these suspended small particles. The detector's sensor generates a light flux using an infrared LED. Depending on the concentration of smoke, a greater or lesser part passing through it is reflected by particles suspended in it.Information about the magnitude of the reflected light flux, which falls back on the sensitive element of the sensor, is analyzed by a special device. If the value of the reflected light flux exceeds a certain criterion, the detector's sensor gives a command to trigger an alarm.

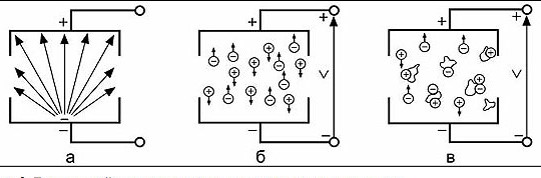

The action of a smoke radioisotope detector is based on a change in the ionization current due to the influence of combustion products on its value. In the standby mode, the ionization chamber, in which the anode and cathode are located, creates an electric current with ionized radioisotope elements in the capsule. Particles of smoke entering the chamber make it difficult to ionize, which helps to stop the electric current. Its zero value serves as a signal for transmitting information about the presence of a fire to the control panel.

The most complex and, accordingly, expensive smoke detector is aspiration. Air intake tubes and an electronic device for air analysis are placed inside the capital building. Before the laser beam of the electronic device begins to shine through and analyze the air, it passes through the filter system, being cleaned from dust particles. In the presence of combustion products in the air, the laser beam is scattered, which is recorded by an electronic device and reported to the control panel about the presence of ignition on the object.

Thermal

Some materials can burn without smoke, radiating large amounts of heat energy. The sensor, which will determine this type of fire, has a temperature-sensitive element in its design and just belongs to the type of heat detectors. It reacts to temperature increase in the controlled object.The heat emitter sensor sensor can work according to the following principles:

- fusible materials soldered together melt with increasing temperature and lose contact in the joint, giving a signal to the control point;

- the sensing element in the form of a thermistor, when the temperature changes, changes the electrical parameters of the circuit (voltage, current), which are configured to operate when a critical temperature is reached;

- the bimetallic plate, bending under the influence of temperature, touches the contact, which gives a signal about the development of undesirable thermal processes on the object;

- instead of a thermistor, an optical fiber can be used as a sensitive element. Its property to change the electrical conductivity with increasing temperature is used in the operation of the generator of electrical impulses to give an alarm signal.

Heat detector with thermistor. The LED lamp lights up when a critical parameter is reached.

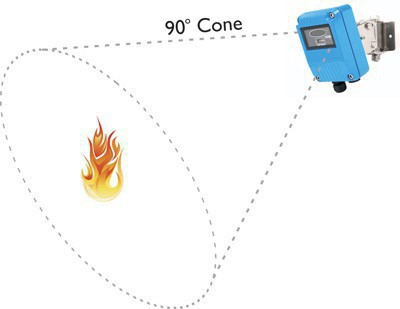

Flame sensors

The principle of operation of these devices is based on the fixation of flame radiation in the infrared and ultraviolet ranges. They are used in open production and storage areas, where, for example, there are difficulties in the formation of smoke accumulation zones and thermal sensors cannot always respond in a timely manner to a fire.

Gas fire detectors

The concentration of combustible (methane, hydrogen and others) and toxic (carbon monoxide, nitrogen, hydrogen sulfide and others) gases in the air determines the triggering of the alarm signal.A sensitive element in the form of a semiconductor plate, which changes its conductivity when in the atmosphere of the above gases, generates a signal after analyzing their concentration.

Manual

In any security and fire alarm system, their presence is mandatory. The ability to give a signal to the on-duty personnel, even earlier than the automation does, is the main advantage of manual call points.

Combined

Such fire detectors combine in their design several methods for detecting a fire. The most commonly used combined sensors combine smoke and heat methods for detecting a fire.

Reception and control devices

It is also important to correctly place the control units, if the sensors are not autonomous. The installation basics are:

- on non-combustible walls, partitions or combustible, but with a protective steel sheet of at least 1 mm thick or from other refractory material from 10 mm. The protrusion of the shield beyond the contour of the device is 0.1 m;

- to combustible floors - not less than 1 m;

- between devices - from 50 mm;

- APS loops and automation lines with 60 V cannot be placed together with cables with 110 V or more in 1 tray, bundle, except when the installation is carried out in different compartments of these structures with continuous non-combustible longitudinal jumpers with a fire limit. (REI) 0.25 h;

- when laying in parallel and openly, the distance from the wires of fire automatics from 60 V to power and lighting cables is from 0.5 m, less is allowed, but when there is protection against electromagnetic interference, it is also allowed to decrease to 0.25 m without protection, if the lighting devices and cables are single ;

- where the effects of electromagnetism, pickups are possible, there must be shielding and protection against these phenomena. Elements of these measures are grounded;

- it is desirable to place external electrical wiring in the ground, sewers, but it is also possible on the wall, under awnings, on cables and supports between buildings outside the streets, roads;

- the main and backup power lines - these should be different routes and cable structures, their failure at the same time is excluded. It can be laid along the walls in parallel, if the clearance between them in the light is from 1 m. And also together, if at least one line is in a non-combustible box with a pre. fire-resistant 0.75 hours;

- loops, if possible, are divided into sections by junction boxes. If there is no visual control, it is desirable to provide a control device with an indication on the IP.

Product models and manufacturers

Among them are the most popular, often used for installation:

Flame detectors “Spectron”

Flame detectors "Spectron". The developer and manufacturer is NPO Spektron with head offices in Yekaterinburg and Novosibirsk. The well-proven 200 series IPPs with IR sensors and 400 series with UV channels for detecting open flames are produced. High quality products at the best price on the market. Quite often, designers indicate products under the Spectron brand in the specifications of APS / AUPT projects, which characterizes them as time-tested products for fire safety systems.

Flame detector “Nabat”

The flame detector "Nabat" is manufactured by JSC "NII GIRIKOND" from St. Petersburg.The product line includes IR and multi-range IPPs, including addressable detectors, both in conventional and explosion-proof versions with a high degree of protection; as well as test devices for operation in normal/explosive environments. The power supply of the IPP is from 12 to 29 V, it is possible to use a spark protection unit of our own production.

Flame detector “Pulsar”

Flame detector "Pulsar" of the design and production enterprise "KB Pribor" from Yekaterinburg, which has been producing these products since 1993, which says a lot. IPP "Pulsar" are distinguished by small dimensions of the body of the product with a stationary or remote - up to 25 m IR sensor. It is characterized by long-range detection of a fire source - up to 30 m, a wide viewing angle - up to 120˚, a large area of \u200b\u200bprotection of a room / territory - up to 600 sq. m; which favorably distinguishes products from the Pulsar line from many IPPs from other manufacturers, both domestic and foreign. Since the beginning of production in Russia, hundreds of thousands of detectors of this brand have been installed.

Flame detector “Amethyst”

Fire flame detector "Amethyst", designed, manufactured by SPKB "Kvazar" from Obninsk, Kaluga region. Under this brand, 2 types of UV detectors are produced. IP 329-5M/5V standard/explosion-proof version, including two types of each type, differing mainly in the maximum possible open fire detection range: 80/50 m, depending on the modification; moreover, the response inertia at such distances is up to 15 s, and at 30 m - almost instantly.

Flame detector “Tulip”

Fire flame detector "Tulip" - produced by SPF "Poliservice" from St. Petersburg. There are more than 10 types of products in the commercial product line, including those with one IR sensor: "Tulip 1-1" for detecting radiation during the combustion of hydrocarbons, "T 1-1-0-1", which controls the increase in coal temperature on the fuel supply conveyor; with a UV sensor "T 2-18" - burning metals. There are models with 2 and 3 IR channels for detecting the flame of burning hydrocarbons, as well as a combined multi-range detector "Tulip 2-16", in the device of which one IR / UV radiation spectrum sensor is used.

NPF "Poliservice" also produces test lights to test the performance of flame detectors "Tulip TF-1" and "Tulip TF-2 Ex" for operation in normal / explosive conditions, respectively. The range of the devices is 5 m.

Unlike thermal, smoke sensors, when you can calculate their required number and installation locations, you can, in principle, without leaving your office / cabinet; the choice of equipment, mounting points for flame detectors for installation in protected premises, in open areas with technological apparatus / columns or on the territory of enterprises, is much more complicated, it requires a detailed inspection with access to the site, measurement of distances, a general assessment, often a difficult situation.

Theoretical knowledge alone is indispensable there, this requires specific experience, skills that only specialists of organizations that carry out design, installation and commissioning, service work of APS / AUPT systems that have the appropriate license from the Ministry of Emergency Situations, SRO admission to facilities under construction.

infrared sensors

Detectors of this type capture the radiation of thermal energy, which is well defined in the infrared range. This principle formed the basis of various devices, in particular binoculars equipped with thermal imagers, which help not only to look around, but also to find heat sources. The higher the temperature of an object, the more visible it becomes to the observer.

The characteristic on which the principle of operation of the detector is based is the wavelength, which directly depends on the increase in heat - the radiation intensity increases, the wavelength shortens. IR radiation is allocated eighty percent of the spectrum of electromagnetic waves.

The photocell of such a fire detector is capable of converting radiation in the infrared spectrum into an electrical impulse. Modern technology also takes into account the ultraviolet spectrum.

Optical filters are used to protect the detectors from false alarms due to illumination from the sun or lamps, welding and other sources:

- for infrared range 4.2…4.6 µm;

- for ultraviolet 150…300 nm.

This type of detectors is located not only indoors, but also in open spaces, for example, where explosive substances are concentrated. They help protect against fires:

- oil wells and platforms for oil production,

- sea terminals,

- oil storages and reservoirs,

- warehouses of fuels and lubricants,

- car filling stations.

False alarms for these devices in dusty rooms do not happen, which is also a significant advantage. Infrared sensors have a certain classification:

- responding to the pulsation of an open flame.Inexpensive and simple in design, however, they may not detect a fire arising from a flash due to a certain sensitivity threshold;

- registering the constant components of the flame. Suitable for installation in rooms where there are no flashes and sunlight;

- complex detectors detecting radiation in three IR ranges. They can separate flashes from the sun or a welding machine from actual ignition.

Multispectral infrared sensors are essential at oil and gas facilities, as they respond to both spectra and immediately notify of a fire. Such devices are able to withstand extreme conditions and operate over a wide temperature range. They have a high level of protection and a corresponding cost.

Some IPP models are multi-range and noise-resistant, they are equipped with a self-monitoring system that allows you to fix failures and report them to the console for timely repair.

Automatic systems designed for quick response are essential in hazardous industries. These most often include modern IR sensors that can work in a split second when a danger is detected.

Characteristics of flame detectors

The flame detector is used in modern fire alarm models, along with thermal, optical, smoke and gas sensors. The flame fire detector is designed to detect the source of fire at the initial stage. The sensitive device works before the traditional thermal sensor, until the temperature in the controlled area has reached a critical value. Flame detectors are used indoors and in large open areas.

Installation specifics

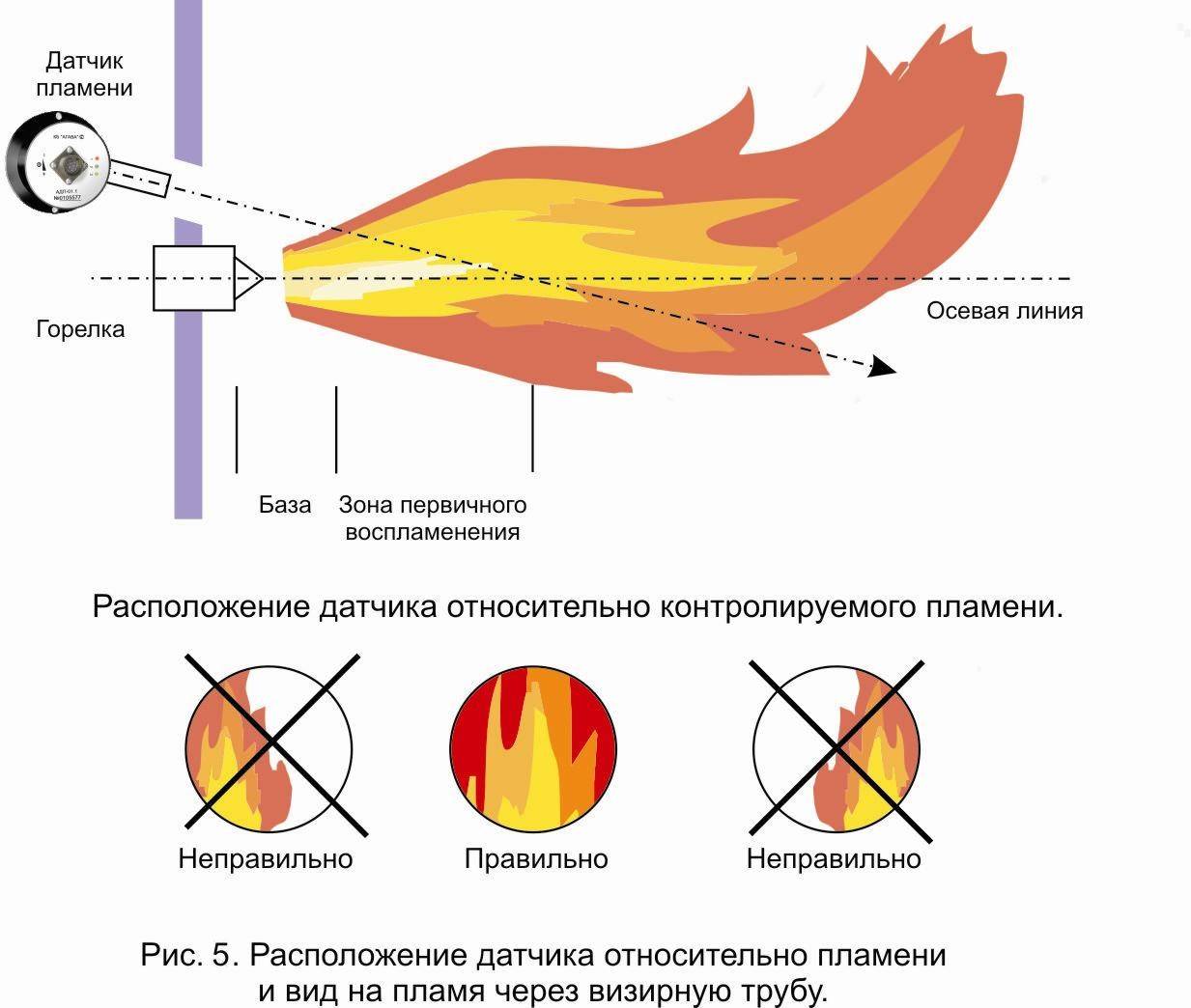

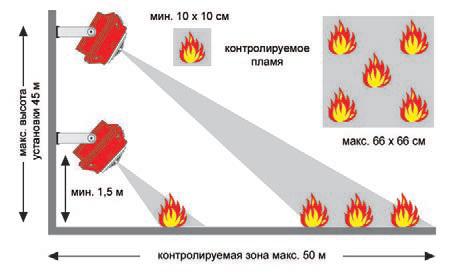

The infrared detector is mounted on the wall, ceiling, installed on production equipment. The number of fire detectors and the arrangement of devices should be determined in such a way as to exclude the possibility of optical interference, taking into account the purpose of the fire system and the conditions of a particular object. PIR detectors must not be mounted on vibrating structures.

To prevent false alarms of the IR detector sensors as a result of optical interference, the protection zone must be monitored by at least 2 flame detectors. Sensors establish control over the area from different directions. In case of failure of one of the devices, the second continues to function.

To start an automatic fire extinguishing installation, where the control signal is generated by at least two detectors, the protected area must be controlled by three devices. If one detector fails, the system will continue to work. The area controlled by the detector is determined by the value of the viewing angle and the sensitivity of the device's sensors to the flame in accordance with GOST R 53325-2012. Devices must be available for repair and maintenance work.

Each manufacturer develops its own unique algorithm for finding the source of ignition. This makes it possible to purchase high-quality devices with the required spectral sensitivity and the type of detection of an open fire source or a smoldering hearth.

By monitoring one zone, it is possible to combine detectors of various types, which significantly increases the effectiveness of the fire protection system.In the production/warehouses of alkali metals and metal powders, only fire detectors of the flame are used.

Fire protection systems must necessarily function in all industries and in rooms with a large crowd of people. Their installation in private houses and apartments is recommended.

Fire-fighting equipment is constantly being upgraded, using the latest electronics. The reliability of identifying the source of ignition increases. The flame detector becomes more resistant to non-fire interference. The Russian market offers a wide range of flame detectors from leading world and Russian manufacturers.

ratings: 2, 3.00 Loading…

Sensor device

Devices of this type are compact devices based on a temperature measurement system. To accomplish this task, special sensitive sensors are used. Their role can be performed by mechanical, thermally sensitive, optical or electromechanical devices that can change their electrical, mechanical or optical operating parameters depending on changes in the temperature of the environment. The main task of these elements is the continuous control of the temperature regime in a certain area of the room.

smoke

A fire alarm sensor device of this type includes an element that generates a light beam - a laser or LED and a photocell that receives a direct beam from the emitter or reflected from a smoke area. Depending on the design features of the device, it will fire when the generated beam hits or does not hit the photocell.

The presence of a flame

Sensors of this type are mainly used at production facilities, where the presence of smoke in the environment and elevated air temperature is typical. In this case, heat and smoke detectors are simply not suitable for such conditions.

The basis of flame sensors are detectors that are able to capture one or another region of the spectrum - IR, UV, electromagnetic.

Ultrasonic sensors

Detectors of this type are built on the basis of highly sensitive ultrasonic sensors that act similarly to security motion devices. Devices of this type allow you to capture the movement of air and issue an alarm in this case.

The principle of operation of sensors

Thermal

This type of device should transmit an alarm signal to the central alarm unit when a certain temperature or its rate of increase is reached. Depending on the operation algorithm, thermal devices can work:

- to increase the temperature of the controlled medium, above the selected setting;

- on the rate of temperature increase above the set value;

- in parallel, on the increase in temperature and on the rate of its increase.

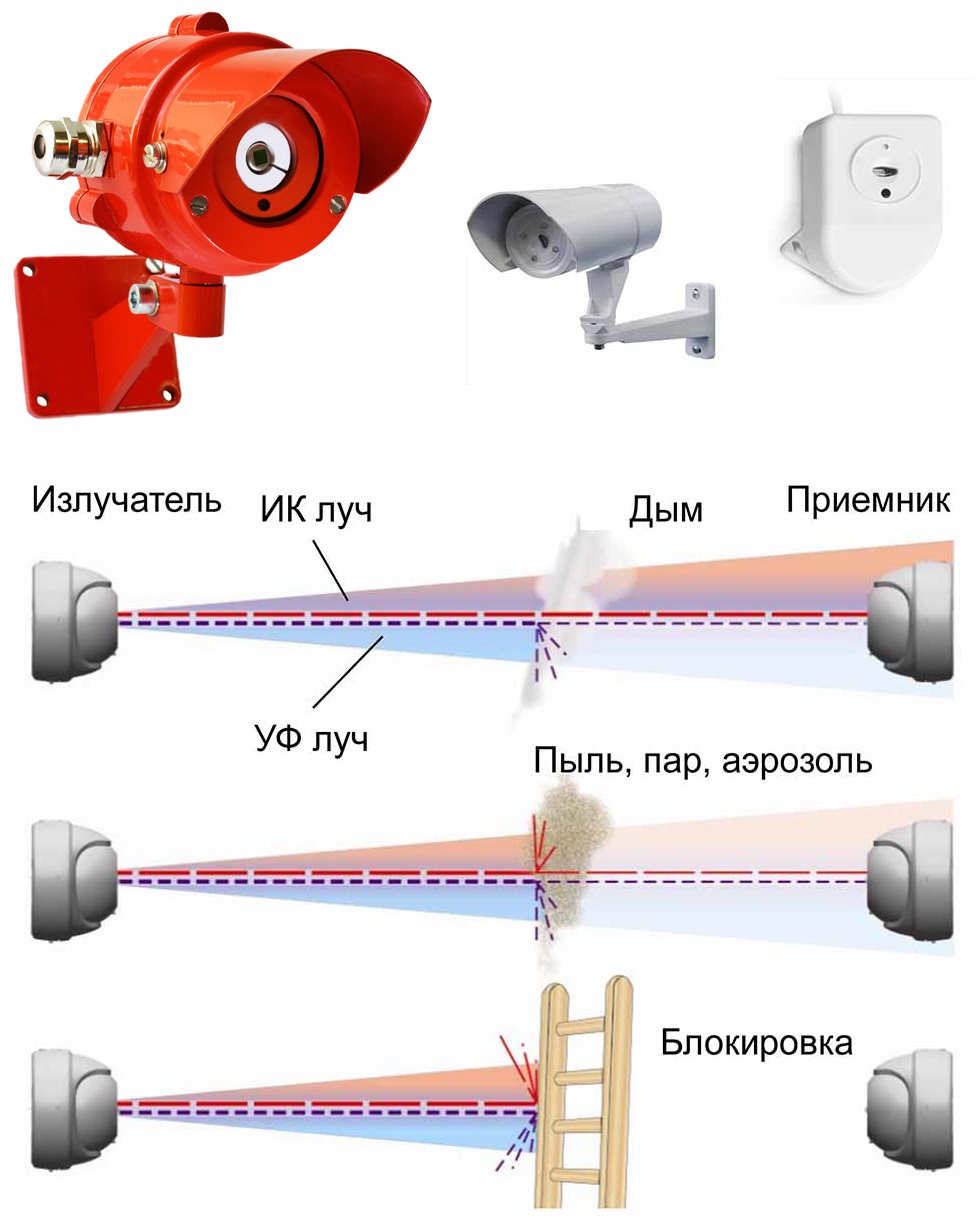

Smoke

The functioning of this type of detectors is based on continuous monitoring of the transparency of the air in the controlled area. In the case of a linear smoke detector, a directional UV or IR beam is generated, which, after passing a certain section of the path, must fall on the photocell. If there is smoke in the room, then it enters the active zone of the sensor, which leads to the scattering of the beam and not hitting the photocell. In this case, the device is triggered and an alarm signal is generated to the central unit.

Point smoke detectors do not function in the same way as line-type fire detectors. These devices send a low-intensity infrared beam into the air, which scatters in clean air.

The operation of flame sensors is based on capturing their sensitive radiation sensors in a particular region of the spectrum. This type of device can detect UV or IR radiation generated by an open flame. There are also sensor configurations that are multiband and provide response in both spectral bands. There are also devices that respond to the pulsing or flickering effect of IR radiation, which is typical for an open flame.

ultrasonic sensors

The functioning of such sensors is based on the different propagation of ultrasonic waves in still and moving air. When a fire occurs, heated air moves upward, causing air masses to move. It is this movement that triggers a sensor that detects the start of a fire.

Conclusion

When buying fire detectors, how their functional part works will be an important aspect of making the right choice. After all, an incorrectly selected detector will either give false alarms or will not work when factors indicating the onset of a fire appear. Correctly selected and correctly placed sensors will guarantee the effective operation of the fire alarm and a high level of safety at the facility.