- Fan ON sensor

- Rules for competent installation

- Stage # 1 - tie-in ball valve

- Stage # 2 - installing the sensor

- Stage # 3 - controller installation

- Why are solenoid shut-off valves needed?

- Varieties

- What is a solenoid valve. Its types

- Peculiarities

- Gas leak sensor rating

- Hardware installation process

- Checking operation after installation

- The system of automatic control and protection against gas pollution and gas leakage in a house, apartment

- Dangerous properties of gas fuel:

- Gas alarm - gas leak sensor, is it necessary to install

- Gas detector for LPG

- Installation

- The choice of equipment for the apartment

- Varieties of solenoid shut-off valves

- Correlation of cutoff parameters with the system

Fan ON sensor

Expensive signaling devices can control additional equipment in the house, including a smoke exhaust system. To do this, they connect directly to the fan and, if triggered, send a start signal to the relay. Thus, even in the absence of a person in the room, the method of reducing the gas content of the room is instantly applied.

In addition, there are exhaust systems with an independent switch-on sensor on sale, but they react to temperature, therefore they are only effective for identifying fires. For reliability, they are combined with a gas sensor. Paired devices allow you to instantly activate the removal of carbon dioxide and carbon monoxide, which will increase the chances of survival.

There are two types:

- electromechanical (can be connected directly to the fan power circuit)

- electronic (installed only in the relay circuit).

The switch-on and switch-off temperatures are in the following ranges:

- 82-87 degrees Celsius,

- 87–92 degrees,

- 94-99 degrees.

Rules for competent installation

Before proceeding with the installation of the system, you should draw up a detailed layout of all its elements, on which you will need to mark the location of each device. In accordance with it, it is checked once again whether the length of the connecting wires included in the kit is sufficient for installation, if they are provided for by the design of the devices. The actual installation is carried out in the following sequence:

- We mark the areas for installing sensors, cranes and the controller.

- According to the connection diagram, we lay the installation wires.

- We cut ball valves.

- Installing sensors.

- We mount the controller.

- We connect the system.

Let's take a closer look at the most important stages.

Stage # 1 - tie-in ball valve

As already noted, the installation of an electric ball valve is best left to a specialist. The device is mounted after the manual valves at the inlet of the pipeline. It is strictly forbidden to install structures instead of cranes at the input.

Before the node, it is recommended to put filters on the pipeline that purify the water. So the devices will last longer.It is also necessary to provide them with uninterrupted power supply. In operating mode, the device consumes about 3 W, at the time of opening / closing the valve - about 12 W.

Stage # 2 - installing the sensor

The device can be installed in two ways:

- Floor installation. This method is recommended by the manufacturer. It involves inserting the device into a tile or floor covering in areas where water is likely to accumulate in case of a possible leak. In this case, the contact plates of the sensor are brought to the floor surface so that they are raised to a height of about 3-4 mm. This setting eliminates false positives. The wire to the device is supplied in a special corrugated pipe.

- Floor surface installation. In this case, the device is laid directly on the surface of the floor covering with the contact plates facing down.

Installing a water leak sensor with your own hands is quite simple, especially if the second method is used.

Manufacturers recommend installing water leakage sensor to the floor So that the panel with contacts is raised by 3-4 mm. This eliminates the possibility of false positives.

Stage # 3 - controller installation

Power to the controller must be supplied from the power cabinet. Zero and phase are connected to the device according to the connection diagram. To install the device, you need to perform the following operations:

We are preparing a hole in the wall for mounting the controller box.

We drill recesses for power wires from the installation site to the power cabinet, to each sensor and to the ball valve.

We install the mounting box on the prepared place in the wall.

We prepare the device for installation. We remove its front cover by alternately pressing on the latches on the front of the device with a thin slotted screwdriver.We remove the frame and connect all the wires in accordance with the diagram. We install the prepared controller in the mounting box and fix it with at least two screws.

We assemble the device

Carefully put the frame back in place. We impose the front cover and press on it until both latches work.

If the system is assembled correctly, after pressing the power button, it starts working. This is usually indicated by a glowing indicator on the controller. When a leak occurs, the indication color changes from green to red, a buzzer sounds and the tap blocks the water supply.

To eliminate the emergency, the manual valves of the pipeline are closed and the power to the controller is turned off. Then the cause of the accident is eliminated. The leakage sensors are wiped dry, the controller is powered on and the water supply is opened.

Properly installed leak protection system reliably protects against all sorts of troubles associated with water leakage

Why are solenoid shut-off valves needed?

These are devices that allow you to quickly shut off the gas supply in the event of a gas alarm. Valves are mounted at the inlet of the gas pipeline. Devices may differ in diameter, power, type of valve itself. The last criterion is especially important.

There are normally open and normally closed valves. Normally open, they are also called pulsed, because the electrical signal enters the coil of such a valve only at the moment the device is triggered. The coil of a normally closed valve is energized at the moment of opening, and the cutoff occurs when the voltage disappears.

Domestic models are easier to maintain and repair than foreign counterparts

In everyday life, it is most rational to use a normally open valve powered by a 220 V network. In the event of power outages, the device does not work, which allows you to use gas appliances that do not depend on electricity without restrictions. When open, the valve does not require electricity to operate.

Like all devices, the normally open valve has some limitations in use. It is undesirable to install it together with a gas sensor that checks its outputs automatically every time the power is turned on. The device will fire at these moments. Therefore, even before buying a valve, you should carefully familiarize yourself with the features of its operation. Basic information is indicated in the documentation for the device.

Do-it-yourself installation and connection of the shut-off valve is not allowed. This type of work should be carried out only by specialized organizations that have the appropriate permits.

Varieties

Today, there are a considerable number of different gas leak sensors. Most often they are divided into two large groups.

- wired;

- wireless;

There is another classification of such units. Depending on the method of determining the concentration of fuel, devices are distinguished:

- catalytic;

- infrared;

- semiconductor;

The first units are based on the principle of gas combustion, resulting in the formation of water and carbon dioxide. This happens during the passage of air through a special element of the device. Fuel leakage sensors from the second group work by absorbing the medium, which is within the infrared spectrum.The latter type of apparatus absorbs oxide gas heated to a high temperature.

Also, such devices are divided depending on the type of absorbed gas into:

- natural gas sensors;

- carbon monoxide detection devices;

- devices that detect carbon dioxide.

In addition, in specialized stores today you can find gas leakage sensors with a solenoid valve. They are made with a locking mechanism, which is designed to quickly close the electrical circuit in the event of a leak. After that, the valve closes. It has a fairly long service life.

A popular option today is a gas analyzer with a wireless GSM informing module. Often it is used together with a GSM alarm system. After the sensitive mechanism is triggered, a signal about a gas leak comes to the owners' phone.

Such a module is often used in conjunction with other elements that ensure the safety of owners of gas appliances. Fire alarms, a door opening and closing sensor can be connected to such devices.

What is a solenoid valve. Its types

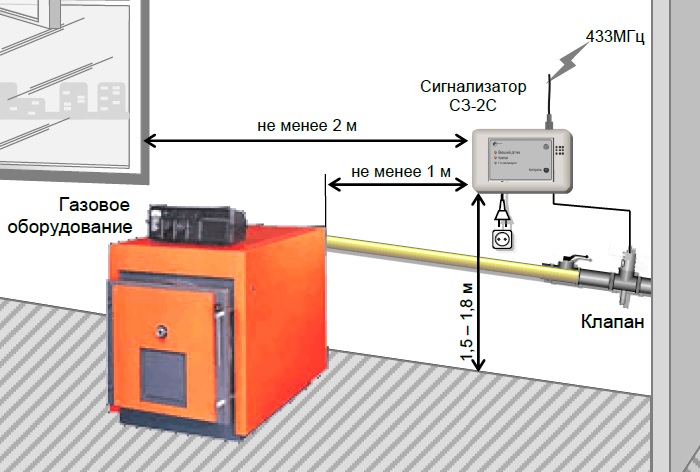

The solenoid shut-off valve is a device that is mounted at the gas pipeline inlet to the room and is a valve that, when an electrical signal is applied to its coil, must shut off the gas supply to gas appliances.

Shut-off valves differ in:

- nominal diameter. For domestic needs, valves Dn 15, 20, 25 are often used;

- nutrition. For domestic needs, optimally - 220 V;

- allowable pressure. For low pressure gas pipelines - up to 500 mbar;

- by valve type: normally open and normally closed.

The type of valve is the most significant characteristic for operation in combination with a gas detector.

A normally open (pulse) valve is a manually reset valve. During operation, no voltage is applied to its coil. When the gas alarm is triggered, a short-term electrical impulse comes to the valve coil from the sensor, causing the sensor to trigger and cut off the gas. The designation of this type of valve is N.A.

A normally closed valve is also a manually reset valve. However, in order to cock it (open), it is necessary to apply voltage to its coil. When the gas alarm is triggered, the voltage on the coil disappears and the valve cuts off. The designation of this type of valve is N.С.

For domestic use, a normally open valve with a 220 V supply is more suitable. This is due to the fact that a power outage will not cause it to operate. This makes it possible to use non-volatile gas appliances (stove, column). There is also no need to waste energy to keep the valve open.

The only inconvenience with such a valve may arise if it works in conjunction with a gas sensor, which automatically checks the health of its outputs when the power is turned on. After turning on the power, such a sensor will send a pulse to the valve, as a result of which it will work. When choosing a sensor, it is necessary to carefully study the sequence of its operation.

Information on the type of valve, supply, allowable pressure and conditional passage is indicated on its label.

Cost of solenoid shut-off valve: type N.A., 220 V, Pmax: 500 mbar:

| Nominal diameter | Cost, rub. |

| Madas Day 15 | 1490,00 |

| Madas Day 20 | 1515,00 |

| Gross Dn 20 | 1360,00 |

| Madas Day 25 | 1950,00 |

| Gross Dn 25 | 1470,00 |

Peculiarities

The gas leak sensor is made in the form of a small device consisting of a housing with gas analyzers located inside it. The latter are especially sensitive elements that determine the content of gas in the air, when its concentration is exceeded, they give a loud sound signal. A wide range of signaling devices is presented as simple models for the home, capable of recognizing natural methane, propane and their combustion products - carbon oxides, as well as powerful multifunctional devices designed for installation at large production facilities, warehouses of combustible materials and industrial workshops.

The main functions of gas sensors are the recognition of a substance, determining the level of its concentration in the air and giving a loud alarm in case of exceeding the norm. In many models, in addition to sound, there is also a light alarm that allows you to use the device in a house where there are hearing-impaired or elderly people. In addition, most modern models are equipped with a solenoid shut-off valve that instantly shuts off the gas supply at the slightest leak, and some of them are able to start a forced ventilation system.

Gas leak sensor rating

Compiling the rating of the best devices took a lot of time for the Expert's Choice team, since each of the many nominees had to go through a thorough check. The products were tested on several main aspects. First of all, we can highlight the opinion of users who bought the sensor and used it in practice.Thus, it was possible to determine how the product shows itself in real work conditions. The opinion of specialists in gas communications, who in the course of work encountered various devices, was also taken into account.

An equally important aspect of the analysis is the technical characteristics of devices. Through their analysis, it was possible to identify the options that are optimal for use in any conditions. In this case, several criteria were taken into account, among which:

- Functionality;

- The complexity of the installation;

- Ease of use;

- Quality of functional elements.

As a result of a comprehensive analysis of all the factors described, it was possible to select several of the best devices. Each of them provides safety by effectively warning the user of a gas leak in a timely manner.

Hardware installation process

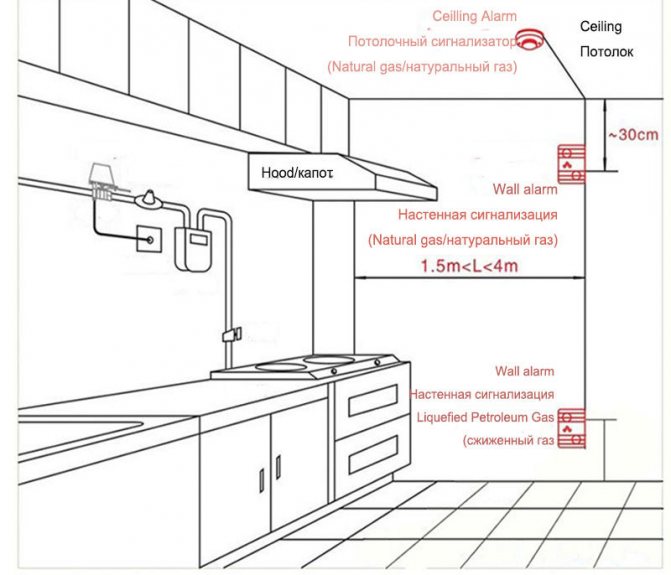

As standard, each carbon monoxide detector contains a special mounting element that serves to mount the fixture. The recommended installation location is on the wall closer to the ceiling. Domestic standards establish that the installation of the signaling device must be carried out at a distance of at least one and a half meters from the floor. Since the equipment detects a high concentration of carbon monoxide and natural gas, a number of installation considerations must be considered.

- The private house is connected to a pipeline with natural gas. In this case, the sensor is placed closer to the ceiling.

- A gas cylinder is installed in the house or in the country. The sensor is located closer to the floor.

Different requirements are explained by the different density of gaseous fuels: natural gas is lighter than the liquefied substance, which is filled with cylinders. In the event of a leak, natural gas rises, while a bottled alternative in a similar situation fills the lower level of the room. Depending entirely on an organized gas leak prevention system is not a completely right decision, since the device is used only to monitor a dangerous environment, unable to protect the health of people and animals. Before installation, the ventilation system is checked without fail and, if it is in good condition, the master proceeds with the installation of the equipment.

It is better to trust a competent specialist to connect the device to the electrical network, eliminating the creation of additional problems as a result of self-intervention. At least one of the sensors must be placed in the bedroom, since in most cases gas problems occur at night. In the case of a house with several floors, each level of the building should be equipped with an anti-collision system.

When installing the equipment in the same room with an open fire source, it is obligatory to observe the distance between the sensor and the stove. To obtain correct data on the composition of the air in the serviced room, it is necessary to withstand a minimum of 4-5 m. The device is placed in such a section of the room that no factor interferes with the air flow. The system will not show efficiency if any piece of furniture blocks the inlet of the device. This applies to placing the sensor behind a curtain, where the composition of the air may differ from that in the room.

Checking operation after installation

There are several ways to check the performance of the signaling device. The easiest and most appropriate way to control is to use a CO canister. It is enough to spray the contents of the can near the signaling device in order to make sure that it is connected correctly. A can of carbon dioxide is sold at any hardware store in the city of Moscow. When using a spray can, safety rules must be observed, since the contents are inside the container under high pressure.

Do not direct a jet of carbon monoxide directly in the direction of the sensor - the gas concentration is several times higher than the dangerous amount

All precautions are indicated in the instructions for use of the can. It will be better if you entrust the control of the device to a qualified employee (paid service)

In order to avoid damage to the equipment, timely cleaning of the device is mandatory. Accumulation of dust on the case may adversely affect the operation of the device.

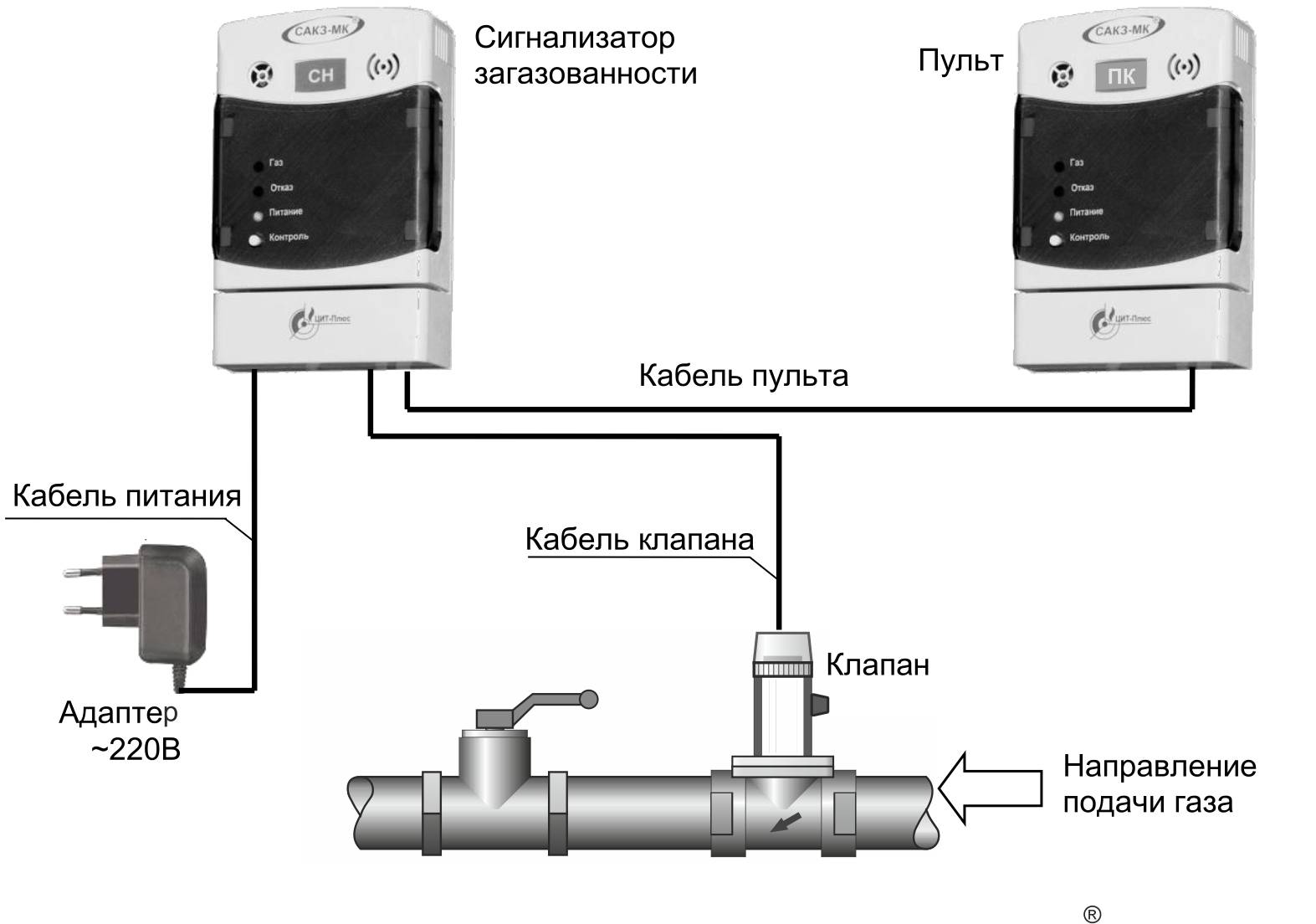

The system of automatic control and protection against gas pollution and gas leakage in a house, apartment

Dangerous properties of gas fuel:

- the ability of gas to form flammable and explosive mixtures with air;

- suffocating power of the gas.

The components of gas fuel do not have a strong toxicological effect on the human body, but at concentrations that reduce the volume fraction of oxygen in the inhaled air to less than 16%, they cause suffocation.

During the combustion of gas, reactions occur in which harmful substances are formed, as well as products of incomplete combustion.

Carbon monoxide (carbon monoxide, CO) - is formed as a result of incomplete combustion of fuel. A gas boiler or water heater can become a source of carbon monoxide if there is a malfunction in the combustion air supply and flue gas removal path (insufficient draft in the chimney).

Carbon monoxide has a highly directed mechanism of action on the human body up to death. In addition, the gas is colorless, tasteless and odorless, which increases the risk of poisoning. Signs of poisoning: headache and dizziness; there is tinnitus, shortness of breath, palpitations, flickering before the eyes, redness of the face, general weakness, nausea, sometimes vomiting; in severe cases, convulsions, loss of consciousness, coma. Air concentrations greater than 0.1% result in death within one hour. Experiments on young rats have shown that a concentration of CO in the air of 0.02% slows down their growth and reduces activity compared to the control group.

Gas alarm - gas leak sensor, is it necessary to install

Since 2016, building regulations (clause 6.5.7 of SP 60.13330.2016) require the installation of gas alarms for methane and carbon monoxide in the premises of new residential buildings and apartments in which gas boilers, water heaters, stoves and other gas equipment are located.

For buildings that have already been built, this requirement can be seen as a very useful recommendation.

The methane gas detector serves as a sensor domestic natural gas leaks from gas equipment. The carbon monoxide alarm is triggered in case of malfunctions in the chimney system and the ingress of flue gases into the room.

Gas sensors should be triggered when the gas concentration in the room reaches 10% of natural gas LEL and CO content in the air is more than 20 mg/m3.

Gas alarms must control a quick-acting shut-off (cut-off) valve installed at the gas inlet to the room and shutting off the gas supply by a signal from the gas contamination sensor.

The signaling device must be equipped with a built-in system for emitting a light and sound signal when triggered, and / or include an autonomous signaling unit - a detector.

The installation of signaling devices allows you to timely notice a gas leak and disturbances in the operation of the smoke exhaust path of the boiler, to prevent a fire, explosion, and poisoning of people in the house.

NKPRP and VKPRP - this is the lower (upper) concentration limit of flame propagation - the minimum (maximum) concentration of a combustible substance (gas, vapors of a combustible liquid) in a homogeneous mixture with an oxidizing agent (air, etc.) at which flame propagation through the mixture is possible at any distance from source of ignition (open external flame, spark discharge).

If the concentration fuel in the mixture less than the lower limit of flame propagation, such a mixture cannot burn and explode, since the heat released near the ignition source is not enough to heat the mixture to the ignition temperature.

If the concentration of a combustible substance in the mixture is between the lower and upper limits of flame propagation, the ignited mixture ignites and burns both near the ignition source and when it is removed. This mixture is explosive.

If the concentration of a combustible substance in the mixture exceeds the upper limit of flame propagation, then the amount of oxidizing agent in the mixture is insufficient for complete combustion of the combustible substance.

The range of concentration values between NKPRP and VKPRP in the "combustible gas - oxidizer" system, corresponding to the ability of the mixture to ignite, forms an ignitable region.

Gas detector for LPG

The building regulations do not contain mandatory requirements for the installation of gas alarms in rooms when using liquefied gas. But liquefied gas alarms are commercially available and installing them will undoubtedly reduce the risks for you and your loved ones.

Installation

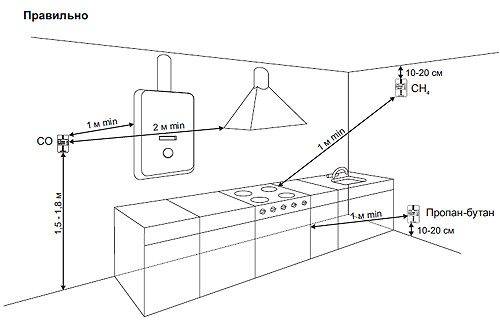

In apartments, houses and enterprises, the installation of natural gas leakage sensors should be carried out only by certified specialists. In this case, the following rules must be observed:

- The methane gas sensor should be located at a distance of 10-20 cm from the ceiling, since natural gas is lighter than air.

- The signaling device for propane, butane is fixed at a distance of 10–20 cm from the floor, since these substances are heavier than air.

- The minimum allowable distance between the device and the stove is 1 meter.

- The carbon monoxide detector is placed at an average height of about 1.5 meters from the floor, since CO has the same density as air. Since the substance in a heated state first rises to the ceiling and only then spreads throughout the volume of the room, it is allowed to install the device at the same height as for methane. You can find on sale combined devices for methane and CO.

- Do not place devices in corners and other areas without air circulation, as well as near hoods, air conditioners, batteries, stoves.

- It is forbidden to use analyzers in rooms where aerosols and ammonia are regularly sprayed.

The choice of equipment for the apartment

All elements of the system must be completed with permits, a Russian passport, a certificate and / or a declaration of conformity with the technical regulations of the Customs Union, which allow their use on the territory of the Russian Federation.

Purchasing a special kit is preferable to purchasing the instruments individually. In the first case, the elements of the kit are already coordinated among themselves in terms of parameters, adapted for work in domestic conditions, and provided with an instruction manual.

There are models of domestic and imported production on the market. Replacing and repairing the former is cheaper and easier to perform.

If you select equipment separately, please note that there are sensor models that are not designed to connect a solenoid valve. They signal a leak, they are able to inform the owner of the danger by sending SMS to the phone, but the gas is not blocked. Mounting a single sensor without a valve is inexpensive, you can install it yourself, but the reliability of protection against such a design is doubtful

Yes, and the current rules such a system will not comply

Mounting a single sensor without a valve is inexpensive, you can install it yourself, but the reliability of protection against such a design is doubtful. And such a system will not comply with the current rules.

Varieties of solenoid shut-off valves

Two types of cutoffs are connected to the sensor: open (NO) and closed (NC). The former block the fuel supply only after the alarm in the system is triggered. The latter also react when there is a power outage.

It is possible to return the initial position of the valve after actuation either manually or automatically.In an apartment, valves with manual cocking are mainly installed on the gas pipe, they are simpler and cheaper.

Normally open manual shut-offs allow the equipment to operate while there is no supply voltage to the coil. The de-energized state prolongs their service life.

But due to the lack of voltage, such a device will not shut off the gas during a power outage, which is unsafe.

A normally closed gas valve closes in a second if the alarm is triggered or the electricity in the apartment is turned off. In this position, it remains until the elimination of dangerous factors.

The disadvantage of the variety is the constant voltage on the coil and its strong heating (up to 70 degrees).

On sale there are cut-off devices with electric impulse control. They work differently. In the open position, the valve is held by a latch. If the coil receives a current pulse from the sensor, the latch is released.

If a closing impulse is received during a power outage (e/p) and when the signaling device is triggered, the device acts as normally closed. If the impulse is received only by the sensor signal, the valve operates on the normally open principle and does not interrupt the gas supply when the electricity is turned off. These algorithms can be changed using the alarm settings.

We have provided more information about the types of solenoid valve and the principle of operation of the device in our other article.

Correlation of cutoff parameters with the system

When choosing a device, the diameter of the pipe at the tie-in section of the valve matters. In most cases, a device with a Dn value of 15, 20 or 25 is suitable for domestic needs, which corresponds to 1/2 ″, 3/4 ″ and 1 ″ pipes.

If there is a boiler or column in the system that does not work when the mains voltage is turned off, a normally open valve is installed.

If the operation of the devices does not depend on the supply of electricity, a normally closed cutoff is mounted. It will not block the equipment in the absence of electricity and will not leave the room unprotected.