- The principle of operation of the thermostat

- Selection of temperature sensors

- Overview information

- How to properly regulate heating batteries

- How is the temperature controller set?

- Various operating modes and modifications

- Purpose of measuring instruments

- Types of thermostats

- Mechanical thermostats

- Electronic thermostats

- Liquid and gas-filled thermostats

- How to connect a thermostat: installation diagram

- Materials and tools

- Selecting an installation site

- Installation and connection

- Starting the system and checking it

- What are room thermostats for?

- The benefits of heating thermostats

- Manometric thermometers

- Peculiarities

- 6 Installation Guidelines

- Varieties of devices

- Mechanical

- Electronic

- Programmable

- Wired and wireless

- Post-purchase verification

- Conclusions and useful video on the topic

The principle of operation of the thermostat

The thermostat is designed to control the operation of the underfloor heating system (STP). It consists of an adjusting device and one or more sensors. Information from them is taken into account when turning on and off thermal mats.

Thanks to the operation of the device, an even temperature is maintained in the premises and energy consumption is minimized.

The rhythm of turning on the heating mats of the warm floor allows you to save half the electricity, which pays for the cost of the thermostat in a few months

Thermostats are easy to use, even teenagers can use them. In this case, the STP operating mode can be changed several times a day without fear of breakdown or premature equipment failure.

The minimum temperature can be set separately for each room. In addition, some models allow programming the operating mode of the device during the day.

Selection of temperature sensors

When choosing such devices, factors such as:

- temperature range in which measurements are taken;

- the need and possibility of immersing the sensor in an object or environment;

- measurement conditions: to take readings in an aggressive environment, it is better to prefer a non-contact version or a model placed in an anti-corrosion case;

- the service life of the device before calibration or replacement - some types of devices (for example, thermistors) fail quickly enough;

- technical data: resolution, voltage, signal feed rate, error;

- output signal value.

In some cases, the material of the housing of the device is also important, and when used indoors, the dimensions and design.

Overview information

Thermostatic heads of different companies with an operating temperature range from 0 to 40 degrees above zero, allow you to adjust the temperature in the room in the range from 6 to 28 degrees. Among them are the following devices:

- Danfoss living eco, electronic programming model.

- Danfoss RA 2994, mechanical type, equipped with gas bellows.

- Danfoss RAW-K mechanical, differs in that the bellows are filled not with gas, but with liquid and is designed for steel panel radiators.

- HERZ H 1 7260 98, mechanical type, bellows filled with liquid, the device of this company will cost a little less.

- Oventrop "Uni XH" and "Uni CH" with liquid bellows, mechanically adjusted.

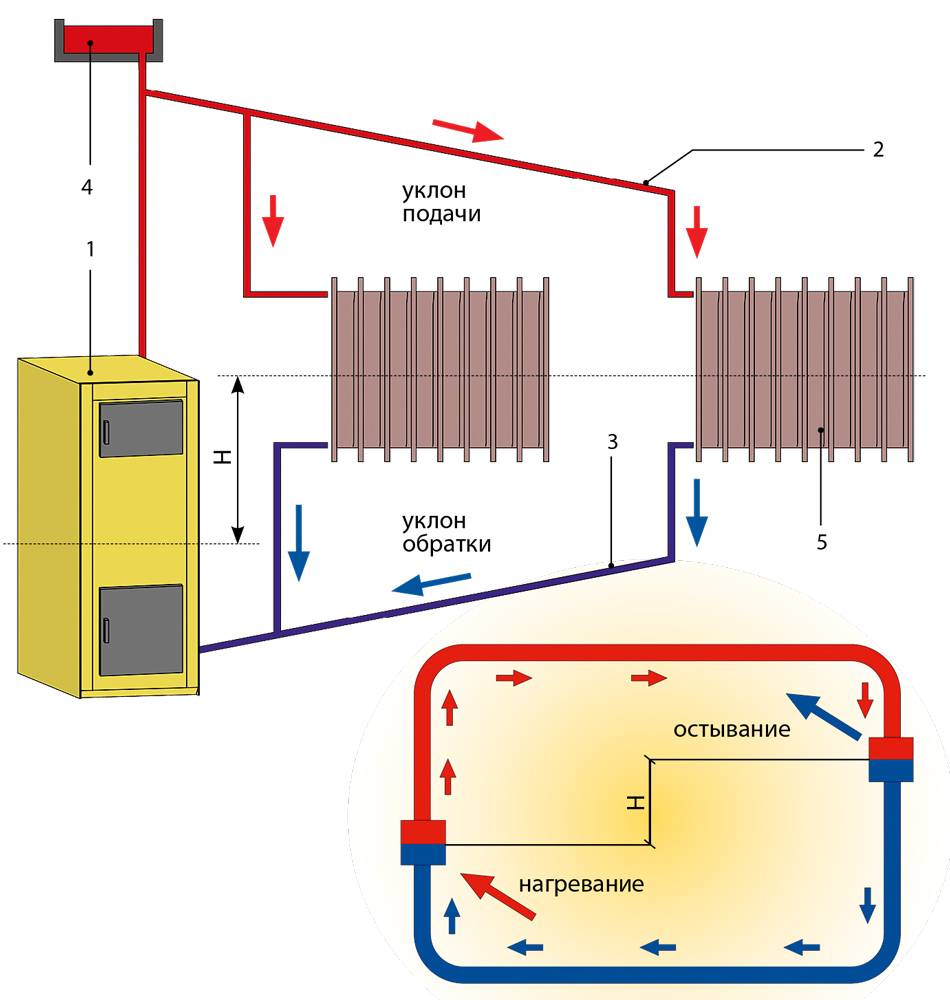

How to properly regulate heating batteries

Automatic thermostats are highly practical in residential heating systems and successfully replace shut-off valves. Despite the fact that conventional taps are a cheap option, heating control with the help of special elements is more safe and convenient. When using shut-off valves in the system, air locks or stoppages of water flows can form. The regulator works in such a way that the water flow is reduced, but not completely blocked, so emergency situations are excluded. With the use of taps, additional time is spent, and it is enough to set the required temperature on the automatic regulator.

So, the advantages of automatic valves have been established, and now we can talk about how to regulate radiators. Thermostats or thermostatic valves do an excellent job of providing heat transfer efficiency depending on the temperature conditions outside.

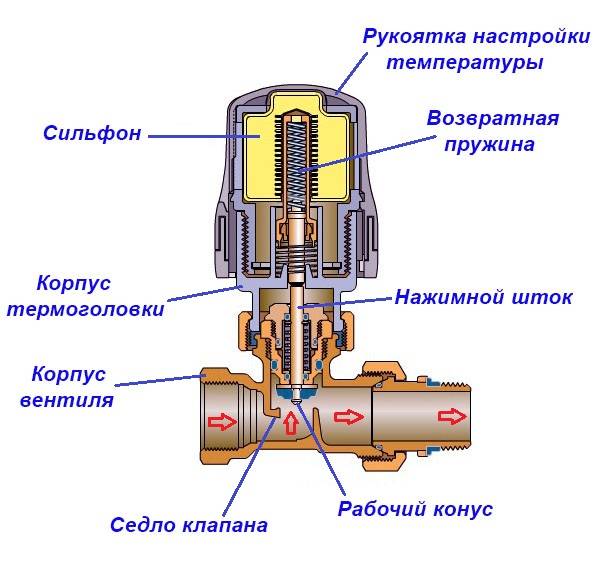

The standard automatic temperature controller is equipped with a thermal head that reacts even to a slight change in temperature. The regulator bellows contains a special compound that changes state and expands when heated.This provides an impact on the valve, after which the flow rate of the coolant decreases.

How is the temperature controller set?

Installation of equipment does not promise problems. Its primary adjustment takes place at the factory, but it is carried out according to the standard, and such average indicators cannot suit everyone. Reconfiguration depends on the type of device. If we talk about the simplest design, then in this case the sequence of actions is as follows:

- After installation, close the windows and all doors. If there is a hood, then turn it on. Then open the valve completely - move the thermostat head to the leftmost position.

- Install the thermometer in the place of the room where the most comfortable temperature is needed. After the temperature rises by about 6-8 °, the valve is closed to the stop, to the right.

- Then they begin to monitor the change in the readings of the thermometer. When the ideal temperature is reached, the thermostat is slowly opened until there is no noise, until the radiator starts to warm up. At this moment they stop.

The last action of the owners is to memorize the indicators on the device. For the convenience of setting different parameters in different rooms, you can make a table with two columns. One with divisions on the device, the other with the temperature corresponding to them. In order for the thermostat to last longer, it is recommended to periodically open it completely in the summer season.

The principle of operation of the temperature controller is not difficult to understand, it is quite simple. It is much more difficult to choose the optimal device, to find “your” variety.Since the assortment is quite wide, in this case the type of heating system decides a lot (autonomous or centralized, main or auxiliary). The willingness of the owners to exchange a certain (and considerable) amount for a device that can provide the most comfortable living conditions is also important.

You can get acquainted with one of the thermostats by watching this video:

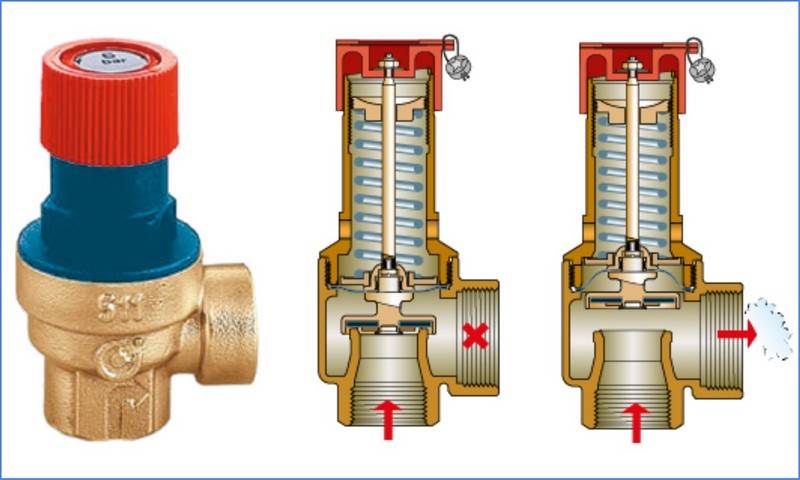

Various operating modes and modifications

DHW regulators are composed of two different modifications. The first of them makes it possible to use the device only as a temperature controller for hot water, while the second, in addition to the main function, makes it possible to protect the system from emptying. The first modification is correspondingly simpler and includes only a control valve, its drive and a control device. At a given temperature, all moving parts of the device are in a stationary state, and when it is exceeded, the volume of the cylinder of the regulating device changes and the shutter of the actuating device moves. In contrast to it, on the ‘protective’ modification, a universal direct-acting pressure regulator is additionally installed - URRD, which protects against pressure drops. With this scheme, the pressure in the return pipeline is less than in the local heating system. Due to this, during the pressure drop, the balance of the acting forces is disturbed, and the shutter closes. When the pressure normalizes, the automatic regulator will automatically switch to the state of maintaining the required temperature.

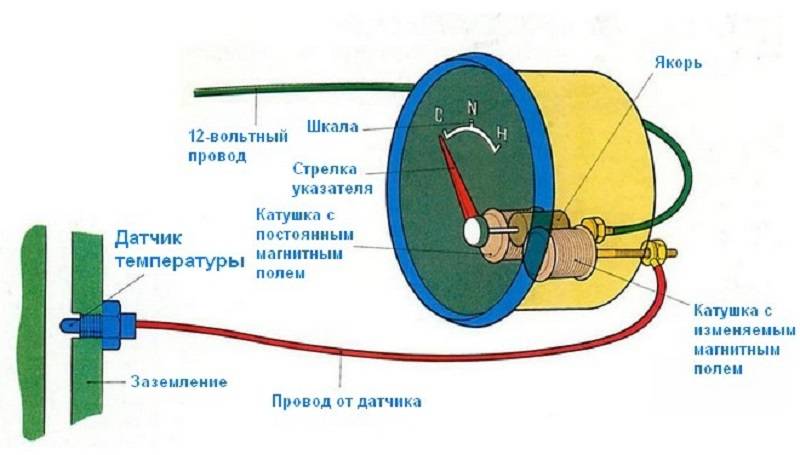

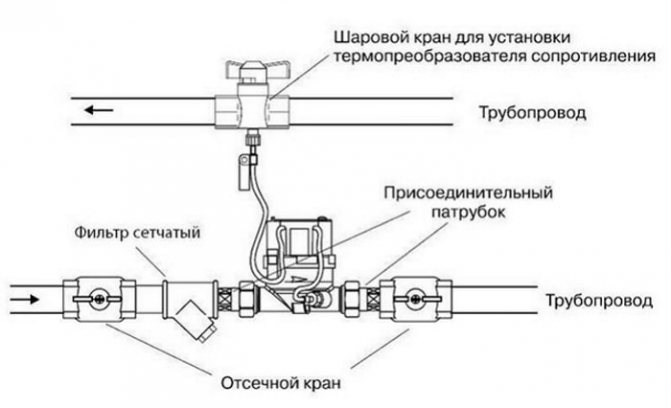

Purpose of measuring instruments

What does heating of any type have in common? This is a periodic change in the temperature of the coolant and, as a result, its pressure.To control the indicators of the degree of expansion of water, pressure sensors are needed in the heating system. With their help, you can observe the current data and, in case of deviation from the norm, take appropriate measures.

Sensors temperature for heating have a wider scope. In addition to visually displaying the degree of heating of the coolant in individual sections of the system, they can record data on the air temperature in the room or on the street. Together, the two types of devices should form an effective tool for tracking, and in some cases, automatic stabilization of the parameters of the heating system.

How to choose the best water pressure sensor in the heating system or a thermometer? The main criteria are the parameters of the system. Based on this, the following requirements are imposed on measuring instruments:

- Measuring range. Not only the accuracy, but also the relevance of the information depends on this. So, a temperature sensor in a heating system with an incorrectly selected upper limit will show biased data or fail;

- Connection method. If you need to know the level of heating of the coolant with high accuracy, you should choose submersible thermometer models. The classic pressure sensor for heating can only be mounted directly into the heat main of the house, boiler or radiators;

- Measurement method. The method of taking readings affects the inertia of the device - the delay in displaying the actual data. It also determines the appearance and visualization of the parameters - arrow or digital.

In an open system, the pressure parameter is not important, since it is almost always equal to atmospheric pressure. However, heating temperature sensors are installed in any scheme - gravity, with forced circulation or when connected to a central network.

Types of thermostats

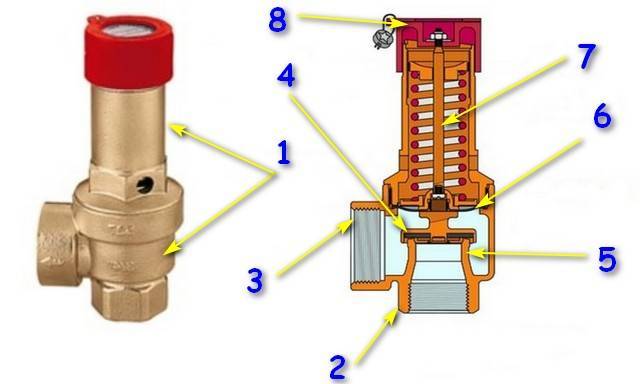

Mechanical thermostat

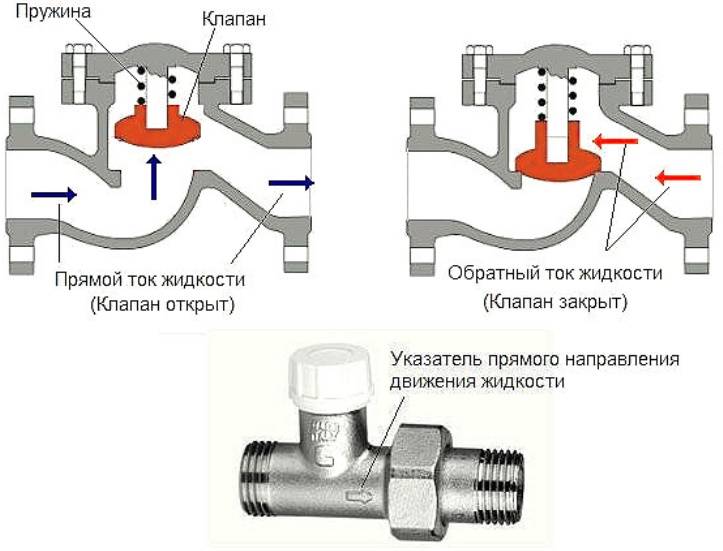

Thermostatic regulators have a common device principle and various actuators. The overall design consists of body, stem, seals, valve and connecting threads. The body is made of brass or stainless steel. The body is equipped with threads for the inlet and outlet of the working medium. The direction of movement is marked on the surface of the valve with an arrow. At the water outlet, usually, instead of a thread, for ease of installation and assembly, an “American” type drive is installed. On the upper part of the body there is a connecting outlet with a rod. The output has a thread or special clamps for installing a thermal head.

The rod is equipped with a spring and is in a raised position without applying the force of the control mechanism (thermal head or handle) to it. At the lower end of the stem there is an actuator - a valve with a rubber (or fluoroplastic) lining. Under the influence of the drive force, the stem falls and the valve closes (or opens) the channel for the movement of the coolant.

This device is called a thermostatic valve. According to the control mechanism acting on the stem, the following types of thermostats are distinguished:

- Mechanical;

- Electronic;

- Liquid and gas-filled;

- Thermostatic mixers.

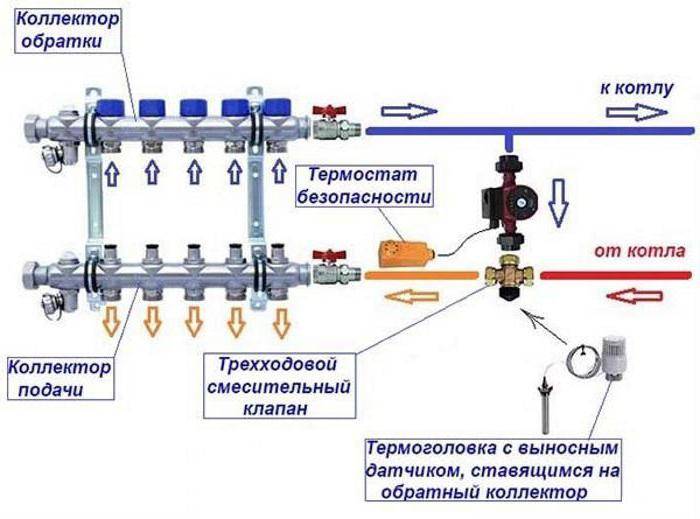

Thermostatic mixers are a special type of thermostatic fittings. They are the basis of the principle of operation of water heated floors.They set the temperature of the water in the heating circuits (as a rule, it does not exceed 50 degrees Celsius). The mixer for lowering the temperature of the heat carrier supplied from the boiler mixes cooled water from the return pipe of the underfloor heating circuits into the flow.

Mechanical thermostats

Mechanical thermostats are the basic model of thermostatic control valves. A detailed description of the thermostatic valve is given in the previous section. The main feature of a mechanical thermostat is manual control of the valve. It is carried out with a plastic handle that comes with the product. Manual adjustment does not allow to achieve the required accuracy in the control of the heater. In addition, the strength of the plastic cap leaves much to be desired. Connecting mechanical thermostats to a battery is the first step to good control.

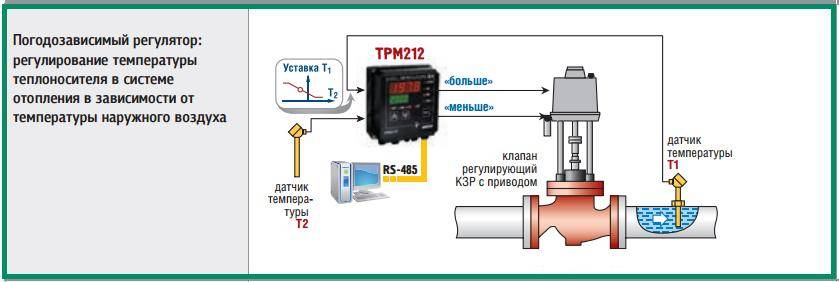

Electronic thermostats

An electronic thermostat is a thermostatic valve with a stem servo drive. The servomotor, according to the sensor data, drives the valve stem, regulates the flow rate. There are various layouts of electronic thermostats:

- Thermostat with built-in sensor, display and keypad control;

- Device with remote sensor;

- Thermostat with remote control.

The first model is installed directly on the thermostatic valve. The model with a remote sensor has an actuator mounted on the valve and a remote temperature sensor. The sensor is installed at a distance from the radiator in order to objectively assess the air temperature in the room.It can also be installed outside the building - the adjustment takes place depending on the ambient temperature.

The electronic thermostat with remote control has a common unit that integrates the control of a group of thermostats according to the remote principle.

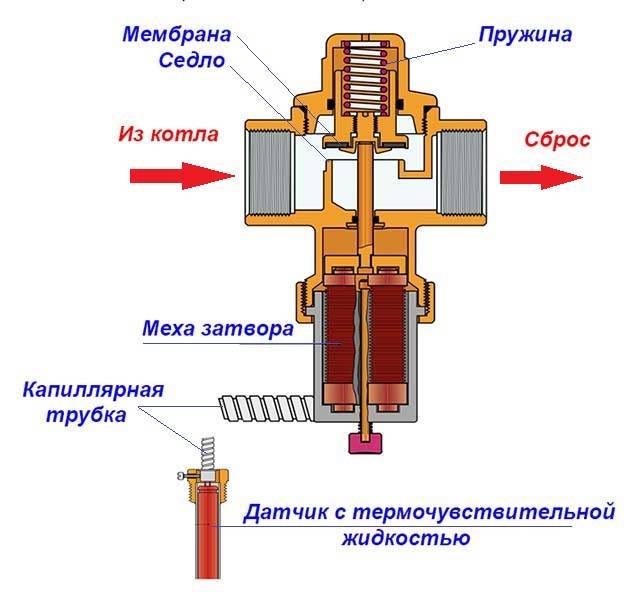

Liquid and gas-filled thermostats

This type of thermostat is the most popular. They are cheaper than electronic ones and are not inferior to them in terms of reliability. The principle of their operation is based on the use of thermophysical properties of certain liquids and gases.

A flexible vessel filled with a liquid or gas with certain properties is placed in the body. When the air is heated, the working medium of the reservoir expands and the vessel exerts pressure on the valve stem - the valve begins to close. When cooling, everything happens in the reverse order - the vessel narrows, the spring lifts the stem with the valve.

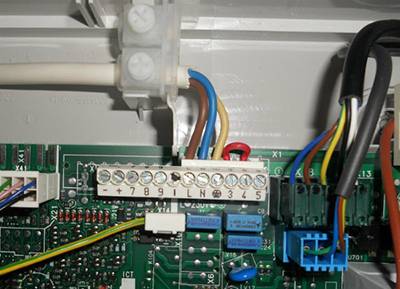

How to connect a thermostat: installation diagram

Before you install and connect the device, you need to prepare the necessary tools and determine the place for installation.

Materials and tools

It will be necessary to find the necessary section in the instructions for the boiler, and, according to the diagrams, connect an additional device to it.

In certain models of thermostats, the diagram is contained on the back of the decorative cover.

To date, almost all models of gas equipment have connection points for a thermostat that controls the operation of heating equipment. Often the device is fixed with a terminal on the boiler at the appropriate point. They also resort to using the thermostat cable, which is sold in the kit.

Selecting an installation site

Experts advise installing wireless room thermostats in residential areas away from household electrical equipment (computer, refrigerator, lamp, TV, etc.), as the heat radiated from them may cause the device to malfunction.

List of recommendations for installing a wireless thermostat:

In order for the temperature measurement in the room to work properly, it is important to provide sufficient air access to the thermostat. Do not clutter up the device with furniture

The device should preferably be located in cool rooms or residential areas.

It is important to limit access to direct sunlight

Do not clutter up the device with furniture

The device should preferably be located in cool rooms or residential areas.

It is important to limit access to direct sunlight

Do not install the device near a radiator or heater.

Do not install in a draft area

Installation and connection

It is important to connect the thermostat in accordance with the recommendations of the manufacturer of the heating unit. Usually all installation rules are in the technical documentation for the boiler. Since there are usually no special difficulties during the installation of this device, you can do the connection yourself

Since there are usually no special difficulties during the installation of this device, you can do the connection yourself.

Starting the system and checking it

After purchasing the thermostat for the boiler and connecting it to the heating equipment, you will need to configure it.Thanks to the instructions and the recommendations given in it, you can personally set the desired mode, which will correspond to the individual level of microclimate comfort.

Using the buttons and switches on the external panel of the device, the thermostat is configured. By means of toggle switches, you can control the heating and air conditioning of the air space.

Due to the delay of switching on, the boiler will not work if the temperature drops for a short time (due to drafts). If you set the fluctuation value to 1°C, then turning on or off will become available when the temperature rises or falls by 0.5 degrees.

Photo 3. By pressing the buttons and switches located on the external panel of the thermostat, you can control the temperature in the room.

The buttons will help in setting the optimal or economy mode. During the day, the required room temperature is set, and at night it drops to a level comfortable for sleeping. This type of mode allows you to significantly save on energy resources.

Different models of thermostats contain several set modes, therefore, everyone can choose the one that suits them.

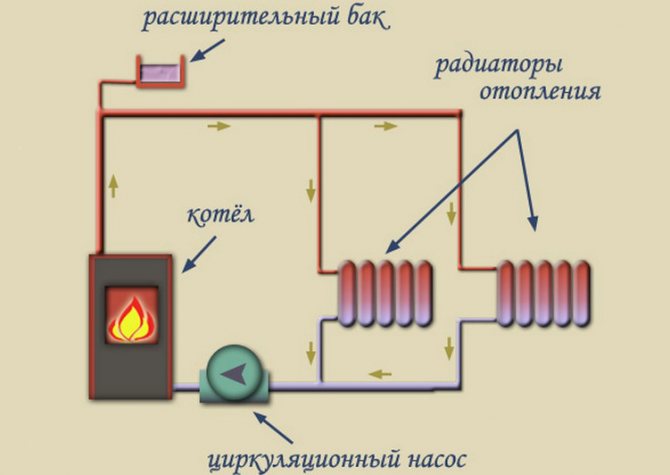

What are room thermostats for?

Owners of simple heating boilers do not have to think about the convenience of climate control in the house. Most often, all adjustments on such boilers come down to one simple knob for selecting the degree of heating of the coolant - a simple scale with numbers from 0 to 9 is used here. In the autumn cold, the equipment works on one or two, and in severe frosts, users set the knob to higher numbers.

Thus, the simplest thermostat is used here, focusing on the temperature of the coolant in the system. The required heating level is set manually, and then a simple thermoelement based on a bimetallic plate starts working in the boiler - it turns on the ignition, provides gas supply to the burner. This scheme is used in many simple models.

More advanced boilers regulate the temperature of the degree of heating of the premises as follows:

Models with a remote sensor will regulate the temperature of the exact place where the sensor itself is installed.

- By electronic sensor for monitoring the temperature of the coolant in the heating system;

- By remote air temperature sensor;

- By air temperature outside the premises;

- According to the sensor located in the remote room thermostat.

Weather-dependent sensors are used by consumers extremely rarely - people are used to relying on their own feelings. Therefore, they choose to control the temperature of the heating medium or control the temperature of the indoor air.

A remote thermostat for a boiler is an external control module installed at an arbitrary point in a household or apartment. It includes a room temperature sensor and controls. The main function of this miniature device is to monitor the set temperature based on the readings of the thermocouple. With a decrease in temperature, the controller sends a command to turn on the heating to the boiler, and after reaching the set value, turns off the burner.

Thermostats for heating boilers also have additional functionality:

- Adjusting the temperature in the hot water circuit is not the most necessary regulator, but some models have it;

- Setting the day and night temperature conditions - the equipment will automatically lower the night temperature to the set mark;

- Heating control according to a given program - the thermostat will turn the boiler burner on and off, focusing on pre-entered data. For example, we can program equipment for a week ahead;

- Management of external equipment - these are indirect heating boilers, solar collectors and much more.

Due to the remote design, thermostats provide the convenience of controlling the operation of a heating boiler, which can be located in any remote room - this is a kitchen, bathroom or basement.

The functionality of thermostats varies widely. The simplest modifications are a single adjustment knob with a mechanical scale. More complex devices are equipped with several regulators and electronic displays, which display various data. Accordingly, the prices for such devices are higher - they are more advanced, giving users many service functions.

This is interesting: Heat accumulators for heating boilers - we tell on the shelves

The benefits of heating thermostats

It is known that the temperature in different rooms of the house cannot be the same. It is also not necessary to constantly maintain one or another temperature regime.

For example, in the bedroom at night it is necessary to lower the temperature to 17-18 ° C. This has a positive effect on sleep, allows you to get rid of headaches.

The optimum temperature in the kitchen is 19°C. This is due to the fact that there is a lot of heating equipment in the room, which generates additional heat.If the temperature in the bathroom is below 24-26 ° C, then dampness will be felt in the room.

Therefore, it is important to ensure a high temperature here.

If the house has a children's room, then its temperature range may vary. For a child up to a year old, a temperature of 23-24 ° C will be required, for older children 21-22 ° C will be enough. In other rooms, the temperature can vary from 18 to 22°C.

A comfortable temperature background is selected depending on the purpose of the room and partly on the time of day

A comfortable temperature background is selected depending on the purpose of the room and partly on the time of day

At night, you can lower the air temperature in all rooms. It is not necessary to maintain a high temperature in the dwelling if the house is empty for some time, as well as during sunny warm days, when some electrical appliances that generate heat are operating, etc.

In these cases, the installation of a thermostat has a positive effect on the microclimate - the air does not overheat and does not dry out.

The table shows that in living rooms during the cold season, the temperature should be 18-23 ° C. On the landing, in the pantry, low temperatures are acceptable - 12-19 ° C

The thermostat solves the following problems:

- allows you to create a certain temperature regime in rooms for various purposes;

- saves the resource of the boiler, reduces the amount of consumables for system maintenance (up to 50%);

- it becomes possible to make an emergency shutdown of the battery without disconnecting the entire riser.

It should be remembered that with the help of a thermostat it is impossible to increase the efficiency of the battery, to increase its heat transfer. People with an individual heating system will be able to save on consumables. Residents of apartment buildings with the help of a thermostat will only be able to regulate the temperature in the room.

Let's figure out what types of thermostats exist, and how to make the right choice of equipment.

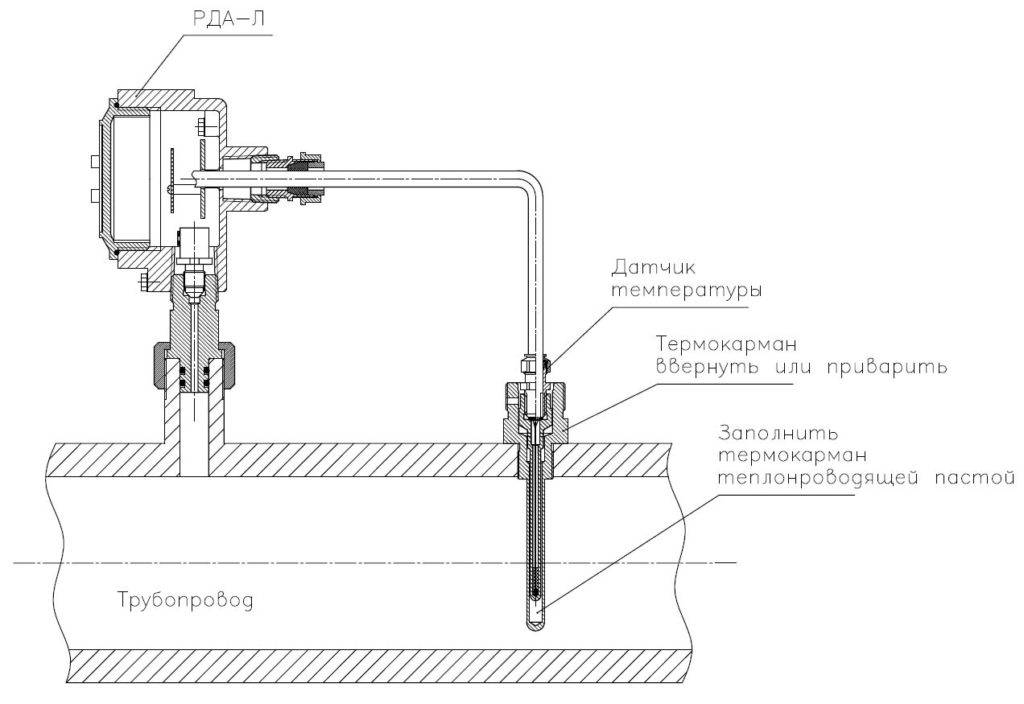

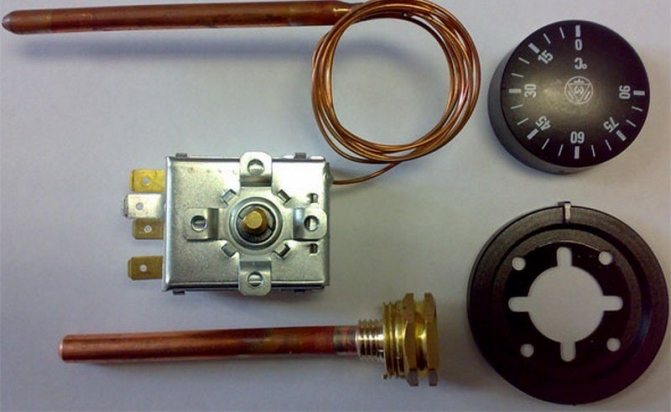

Manometric thermometers

A manometric thermometer has a more complex design than a simple glass one. The main elements are a cylinder placed at the temperature control point, a capillary in the form of a connecting tube, and a conventional spring pressure gauge.

Inside the cylinder there is a gas under pressure, the pressure change of which is transmitted through the capillary to the pressure gauge spring, where the arrow points to the corresponding value of the scale, graduated in Celsius.

The thermocouple, made of metal, is connected by means of a connecting tube to the pressure gauge spring, and the arrow indicates the temperature value. Manometric thermometers are divided according to the state of aggregation of the substance filling the balloon.

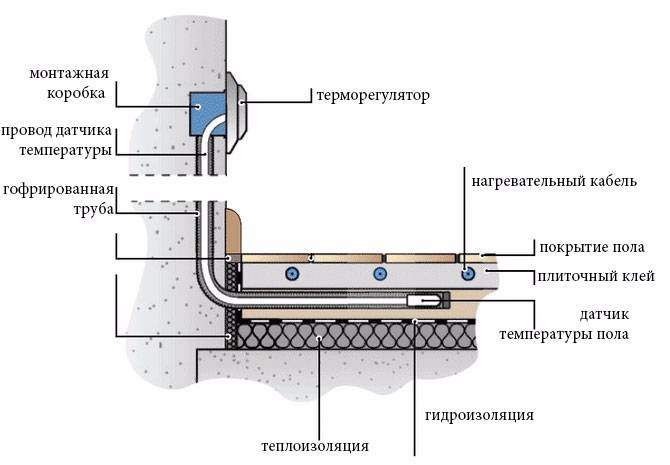

Peculiarities

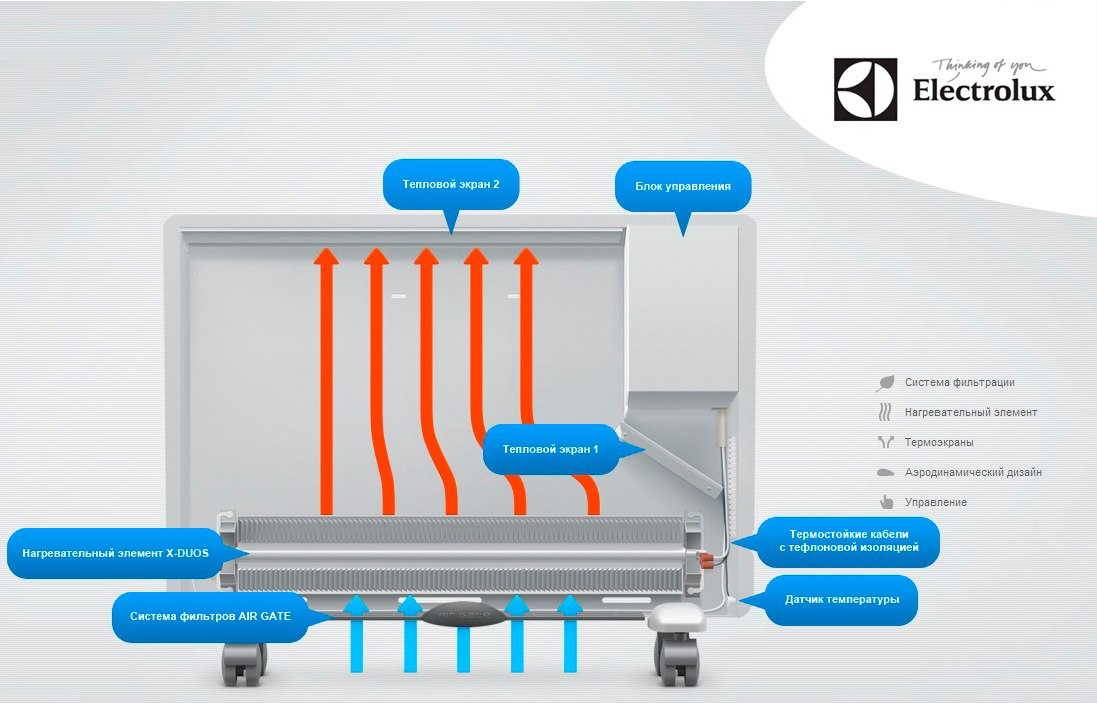

The basis for arranging a warm floor is the heating elements of the structure and the automation system, consisting of a temperature sensor and a regulator. The sensor is designed to measure the temperature of an object and transmit data to the control unit.

The sensor for the underfloor heating thermostat should be selected based on the features of the automation unit.

More often recommended for use are sensors with the measurement of ambient temperature. They are easier to install and subsequently replace, unlike sensors that measure the temperature in the design of a warm floor.

More complex systems of underfloor heating regulators have several sensors in their composition. An example of such a thermostat is one that measures the temperature at several points.These measuring points are usually the body of the floor heater, the ambient air in the room and the temperature outside the room. The principle of operation of such an automation unit is based on a comparison of the measured temperatures, as a result of which the specified floor mode is maintained.

Systems that have more advanced methods for heating a warm floor include electric heaters with a liquid coolant. Such systems are recognized as ideal for arranging a warm floor.

Electric heating systems with a liquid heat carrier have a uniform distribution of heat, a smooth change in temperature, and are flexibly configured and regulated. The composition of the thermostat with an electric heater and a liquid heat carrier must necessarily include a thermostat. Complete with a thermal head, the thermostat allows you to more precisely regulate the temperature of the floor.

6 Installation Guidelines

There are fragile parts in the design of heating regulators that can be damaged by careless handling, therefore, during installation, care should be taken, acting very carefully, not squeezing the plastic elements of the thermostat with gas wrenches and other clamps. It is necessary to install the valve in such a way that after fixing the thermostat has a horizontal position

Otherwise, warm air from the battery will enter the regulator, which may adversely affect its accuracy.

It is necessary to install the valve in such a way that after fixing the thermostat has a horizontal position. Otherwise, warm air from the battery will enter the regulator, which may adversely affect its accuracy.

When installing a thermostat on single-pipe radiators, it is possible to additionally install a bypass into the branch pipe, which greatly simplifies the subsequent operation of the heating system.

The use of temperature controllers in heating systems allows you to increase the efficiency of space heating, creates optimal conditions in each of the rooms, and reduces the cost of the homeowner to pay utility bills. Currently, mechanical, semi-automatic and automatic thermostats can be found on sale, differing in their principle of operation. The most widely used semi-automatic devices that combine functionality and ease of use. All installation work can be carried out independently, which will save on the services of professional plumbers.

Varieties of devices

The choice of a remote thermostat for a gas boiler is based on taking into account several characteristics, which include the type of connection. Uninterrupted operation is ensured by the contact of the remote module with the device that controls the operation of the gas boiler. From a constructive point of view, there are a couple of main options:

- cable models connected to the gas boiler through wires;

- wireless models with a remote maintenance method.

Mechanical

- durability;

- low cost;

- the possibility of repair;

- resistance to voltage drops.

The main disadvantages of mechanics include not too precise setting and the likelihood of errors within 2-3 ° C, as well as the need to periodically adjust the indicators in manual mode.

Electronic

In most cases, electronic thermostats for gas boilers are represented by a remote sensor with a display and a special control element responsible for the operation of the boiler. Currently, for this purpose, models with a timer are used that monitor the air temperature and change it according to the desired schedule, as well as electronic analogues. The main advantages of electronic devices:

- remote control;

- the smallest error;

- possibility of installation in any room;

- air temperature adjustment according to the schedule;

- the fastest response to temperature changes.

Almost instantaneous response to changes in indoor air temperature allows for significant energy savings. The disadvantages include only the rather high cost of such modern devices.

Programmable

The so-called "smart" technology has decent functionality, which includes temperature control, hourly adjustment and programming according to the days of the week. Especially popular are liquid crystal models that have a very convenient and intuitive interface, as well as built-in Wi-Fi.

Important advantages of programmable models:

- the presence of the function "day-night";

- significant energy savings;

- programming the mode for a long time;

- possibility of remote control of the entire system.

Gas heating boilers are equipped with devices with built-in SIM cards, which allows you to make adjustments using the most common smartphone. Users attribute the rather high cost of these devices to the disadvantages of any programmable models.

Wired and wireless

Wired thermostats are characterized by the presence of mechanical or electronic control. Such devices are fixed only by means of a wired system designed to be connected to gas heating equipment. The range of action, as a rule, does not exceed 45-50 meters. In recent years, programmable models of wire-type room thermostats have been increasingly installed.

Wireless devices include a working part for mounting directly next to the heating device, as well as a tracking element with a display. Sensors can be equipped with a display-sensor or push-button control. Functioning is provided by a radio channel. The simplest models are able to turn off or supply gas. In more complex devices, there is also a special program for settings in order to make changes to the specified parameters.

Post-purchase verification

If you purchased a submersible type device from one of the above companies, feel free to install it on the boiler or in the heating system. If not, then first check it for accuracy. What for? The low accuracy of readings, characteristic of cheap products, will lead to an inaccurate display of the real picture of the boiler, to a decrease in efficiency and reliability.

This verification process is shown in detail in the video:

How to check? Take the purchased thermometer and a sensor with an external spike for water. Bring the purchased thermometer to an open source of fire for 10 seconds, and then the control sensor. Given the large inertia of the readings, allow a little time for the thermometer to display the actual temperature readings. After that, compare the readings of the thermometer with the control sensor.The lower the difference, the more accurate the temperature measurement and display.

Conclusions and useful video on the topic

The video below explains in detail how to install thermal devices on a heating boiler:

Does the installation of sensors on the supply and return pipes differ:

Temperature sensors are widely used both in various industries and for domestic purposes. A wide range of such devices, which are based on different principles of operation, allows you to choose the best option for solving a particular problem. In houses and apartments, such devices are most often used to maintain a comfortable temperature in the premises, as well as adjust heating systems (batteries, underfloor heating).