- How does a draft sensor work in a gas boiler?

- How to check the thermocouple of the AOGV boiler

- Diagnosis of errors in the smoke exhaust system of traditional gas boilers

- Correct installation

- Why is it needed?

- Functionality check

- How to check this indicator?

- Conclusion

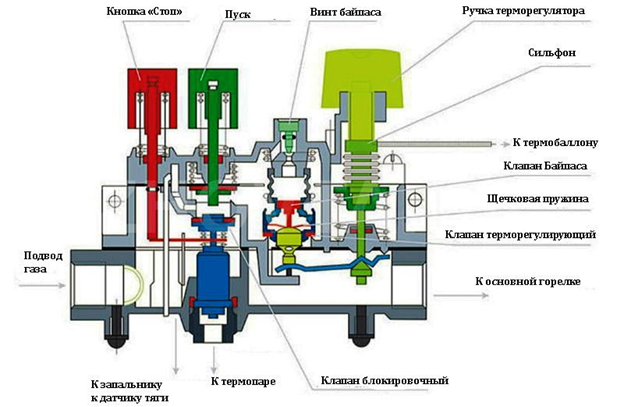

- Automation of a gas heating boiler

- Why is there a back draft in the chimney

- The principle of operation of the sensor

- Diagnosis of problems and ways to solve them

- Reasons for lack of traction

- How water pressure sensors for boilers work

- Signs of need for replacement

- Health check

- How does a draft regulator work?

How does a draft sensor work in a gas boiler?

Traction sensors can have a different structure. It depends on what type of boiler they are installed in.

The function of the draft sensor is to generate a signal when the draft in the boiler deteriorates

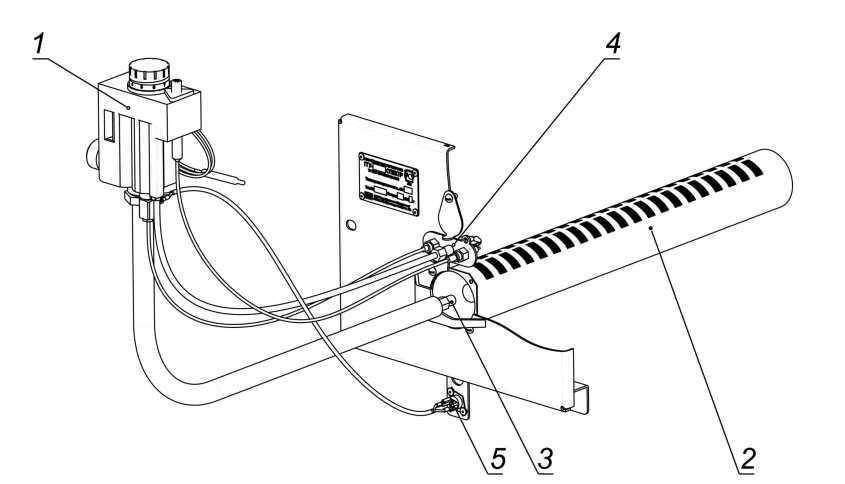

At the moment there are two types of gas boilers. The first is a natural draft boiler, the second is forced draft.

Types of sensors in boilers of various types:

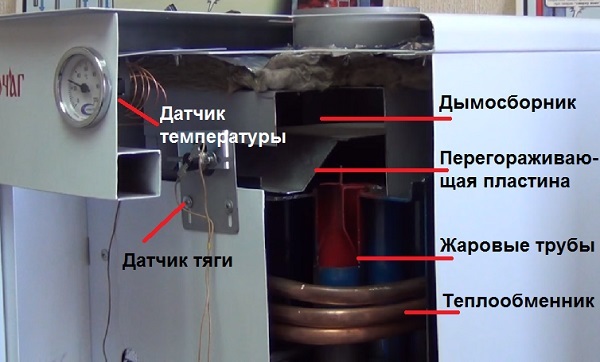

If you have a natural draft boiler, then you might notice that the combustion chamber is open there. The draft in such devices is equipped with the correct size of the chimney. Draft sensors in boilers with an open combustion chamber are made on the basis of a biometallic element

This device is a metal plate on which a contact is attached. It is installed in the gas path of the boiler and responds to temperature changes. With good draft, the temperature in the boiler remains quite low and the plate does not react in any way. If the draft becomes too low, the temperature inside the boiler will rise and the sensor metal will begin to expand. Upon reaching a certain temperature, the contact will lag behind and the gas valve will close. When the cause of the breakdown is eliminated, the gas valve will return to its normal position.

Those with forced draft boilers should have noticed that the combustion chamber in them is of a closed type. The thrust in such boilers is created by the operation of the fan. In such devices, a thrust sensor in the form of a pneumatic relay is installed. It monitors both the operation of the fan and the speed of the combustion products. Such a sensor is made in the form of a membrane that flexes under the influence of flue gases that occur during normal draft. If the flow becomes too weak, the diaphragm stops flexing, the contacts open and the gas valve closes.

The draft sensors in boilers with an open combustion chamber are made on the basis of a biometallic element. This device is a metal plate on which a contact is attached. It is installed in the gas path of the boiler and responds to temperature changes. With good draft, the temperature in the boiler remains quite low and the plate does not react in any way. If the draft becomes too low, the temperature inside the boiler will rise and the sensor metal will begin to expand. Upon reaching a certain temperature, the contact will lag behind and the gas valve will close.When the cause of the breakdown is eliminated, the gas valve will return to its normal position.

Those with forced draft boilers should have noticed that the combustion chamber in them is of a closed type. The thrust in such boilers is created by the operation of the fan. In such devices, a thrust sensor in the form of a pneumatic relay is installed. It monitors both the operation of the fan and the speed of the combustion products. Such a sensor is made in the form of a membrane that flexes under the influence of flue gases that occur during normal draft. If the flow becomes too weak, the diaphragm stops flexing, the contacts open and the gas valve closes.

Draft sensors ensure the normal operation of the boiler. In natural combustion boilers, with insufficient draft, symptoms of reverse draft may be observed. With such a problem, the products of combustion do not go out through the chimney, but return back to the apartment.

There are a number of reasons why the draft sensor may work. By eliminating them, you will ensure normal operation of the boiler.

Because of what the traction sensor may work:

- Due to clogging of the chimney;

- In case of incorrect calculation of the dimensions of the chimney or its incorrect installation.

- If the gas boiler itself was installed incorrectly;

- When a fan was installed in the forced draft boiler.

When the sensor is triggered, it is urgent to find and eliminate the cause of the breakdown. However, do not try to forcibly close the contacts, this can not only lead to the failure of the device, but is also dangerous for your life.

The gas sensor protects the boiler from damage. For better analysis, you can purchase an air gas analyzer, it will immediately report the problem, which will allow you to quickly fix it.

Overheating of the boiler threatens the entry of combustion products into the room. Which can have a negative impact on the health of you and your loved ones.

How to check the thermocouple of the AOGV boiler

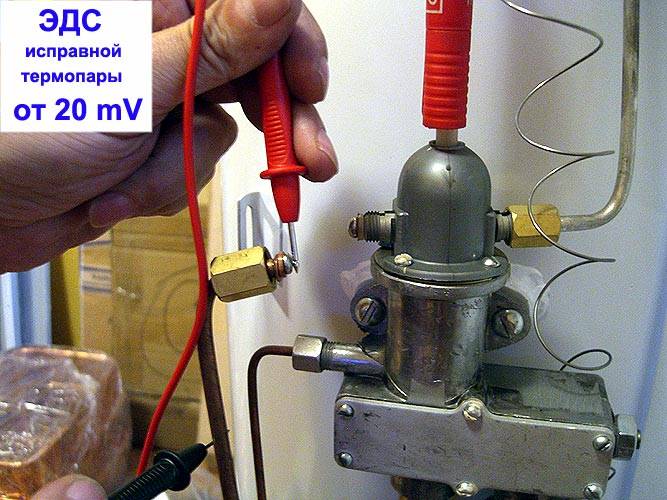

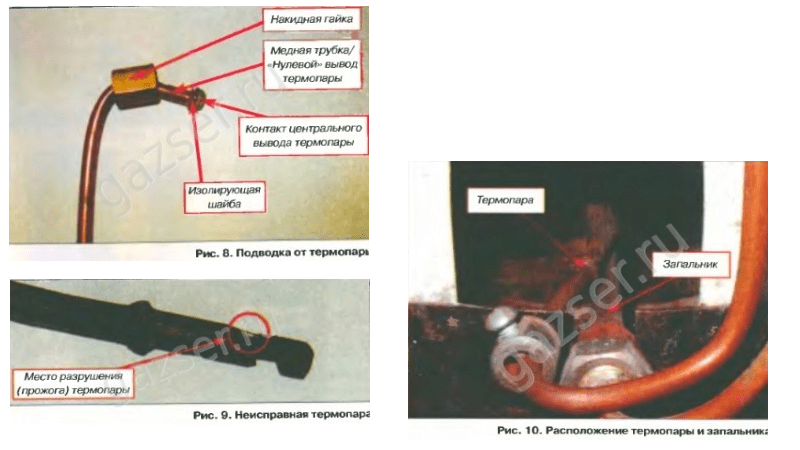

To check the thermocouple, unscrew the union nut (Fig. 7)

located on the left side of the electromagnet. Then turn on the igniter and measure the constant voltage (thermo-EMF) at the thermocouple contacts with a voltmeter. (rice.

. A heated serviceable thermocouple generates an EMF of about 25 ... 30 mV. If this value is less, the thermocouple is faulty. For its final check, the tube is undocked from the casing of the electromagnet and the resistance of the thermocouple is measured. The resistance of the heated thermocouple is less than 1 ohm. If the resistance of the thermocouple is hundreds of ohms or more, it must be replaced. The appearance of a thermocouple that failed as a result of burnout is shown in rice. 9

. The price of a new thermocouple (complete with tube and nut) is about 300 rubles. It is better to purchase them in a store at the manufacturer or use the services of an authorized service center. The fact is that the manufacturer is constantly improving its products. This is reflected in the parameters of self-made parts. For example, in the boiler AOGV-17.4-3 of the Zhukovsky plant, since 1996, the length of the thermocouple connection has been increased by about 5 cm (that is, similar parts manufactured before or after 1996 are not interchangeable). This kind of information can only be obtained from a shop (authorized service center).

The low value of thermo-EMF generated by a thermocouple can be caused by the following reasons:

- clogging of the igniter nozzle (as a result, the heating temperature of the thermocouple may be lower than the nominal one).A similar defect is “treated” by cleaning the igniter hole with any soft wire of a suitable diameter;

- shifting the position of the thermocouple (naturally, it can also not heat up enough). Eliminate the defect in the following way - loosen the screw securing the eyeliner near the igniter and adjust the position of the thermocouple (Fig. 10);

- low gas pressure at the boiler inlet.

If the EMF at the thermocouple leads is normal (while maintaining the symptoms of the malfunction indicated above), then the following elements are checked:

- the integrity of the contacts at the connection points of the thermocouple and the draft sensor.

Oxidized contacts must be cleaned. Union nuts are tightened, as they say, "by hand". In this case, it is undesirable to use a wrench, since it is easy to break the wires suitable for the contacts;

- the integrity of the electromagnet winding and, if necessary, solder its conclusions.

The performance of the electromagnet can be checked as follows. Disconnect the thermocouple lead. Press and hold the start button, then ignite the igniter. From a separate source of direct voltage to the released contact of the electromagnet (from the thermocouple), a voltage of about 1 V is applied relative to the housing (at a current of up to 2 A). To do this, you can use a regular battery (1.5 V), as long as it provides the necessary operating current. Now the button can be released. If the igniter does not go out, the electromagnet and draft sensor are working;

—

thrust sensor

First, the force of pressing the contact to the bimetallic plate is checked (with the indicated signs of a malfunction, it is often insufficient). To increase the clamping force, loosen the lock nut and move the contact closer to the plate, then tighten the nut.In this case, no additional adjustments are required - the pressure force does not affect the temperature of the sensor response. The sensor has a large margin for the angle of deflection of the plate, ensuring reliable breaking of the electrical circuit in the event of an accident.

Unable to ignite the igniter - the flame flares up and immediately goes out.

There may be the following possible reasons for such a defect:

- the gas valve at the boiler inlet is closed or faulty; - the hole in the igniter nozzle is clogged; in this case, it is enough to clean the nozzle hole with soft wire; - the igniter flame is blown out due to strong air draft

The gas supply is turned off during boiler operation:

Diagnosis of errors in the smoke exhaust system of traditional gas boilers

There are a number of basic reasons why a diesel engine can give a signal to cut off the gas. They appear regardless of the type of combustion chamber installed in the gas boiler. Users should not rely on the operability of the sensor in everything and it would be more correct to understand the reasons for the emergency operation of the boiler and control these parameters. Thus, the owner of the boiler will be able to prevent the possible development of negative events in advance, eliminating their root cause.

The main reasons for the emergency operation of the boiler:

- The draft or resolution does not correspond to the allowable parameters set by the boiler regime card. This is the main reason for triggering the traction sensor. This problem can appear due to erroneously mounted blast air supply systems and gas ducts.The problem can also be associated with a violation of the integrity of the smoke ducts, in the case when the individual parts of the pipes are poorly connected to each other. After the compaction work is completed, the thrust or rarefaction is restored.

- Reverse thrust is a dangerous form of low-quality vacuum. This situation also occurs if an air lock forms in the smoke ventilation system, which prevents the exhaust gases from being released into the atmosphere. This problem is quite common as a result of poor-quality thermal insulation of the chimney system.

- Chimney blockage. Such a failure occurs when its outlet is not fenced and protected from external blockages. In this case, various atmospheric and natural debris, for example, foliage, can get into it. Protection against this shortcoming is the mandatory annual cleaning of the smoke ventilation ducts, before the start of the heating period.

- Strong wind pressure. If the draft controller does not work in such a case, then the gas will flow uncontrollably into the boiler, but combustion will not occur, which means that an explosive gas mixture may form in the room. In order to prevent such a development of an accident, it is necessary to buy a stabilizer and install it in the system at the point where the pipe exits to the atmosphere.

- If any of the above draft sensors in the gas boiler did not work, it needs to be replaced.

Indicators of the need to change diesel fuel:

- The controller switches off continuously in the absence of breakdowns in the gas exhaust system of the boiler.

- The gas boiler operates for no more than 30 minutes, after which it switches off on its own and can restart only after the heating surfaces and the combustion chamber have completely cooled down.

In the event that one of these signs is detected, it is better to invite a service master, especially if the boiler is under warranty service.

Thus, it can be summed up that the principle of operation of the draft sensor of a gas boiler operating on gaseous fuel is to send a signal when the parameters in the smoke exhaust system, set by the manufacturer of the equipment, are overestimated. The signal will be sent to the gas shut-off valve of the electromagnetic type, which will instantly shut off the gas supply and the boiler will stop. In cases where the unit is under warranty service or the user cannot repair the draft sensor on his own, it is better to contact a service center.

Correct installation

It is important to know that, depending on the type of heater being installed, the installation standards and connection rules will also change. Only with the right calculation can you get the efficient operation of the heating system without the occurrence of rarefied air

This is largely affected by the combustion temperature of the fuel. The higher it is, the stronger the thrust, but at the same time, the need to obtain a volume of air sufficient for combustion will also increase proportionally. If ventilation does not provide it, then the stove or boiler will begin to take it out of the room, thereby provoking the occurrence of reverse thrust.

To avoid this phenomenon, when operating the stove, it is necessary to use a chimney tooth in its design. The device is a small ledge between the firebox itself and the smoke box.The reverse draft in the chimney of the gas column is eliminated by installing an inlet valve, but its operation does not always help to really solve the problem.

Why is it needed?

Today, gas-fired boilers are the most common, since today blue fuel remains the cheapest when compared with the cost of other energy sources. As a rule, gas heating equipment usually operates in automatic mode. In order for its operation to be safe, there are several sensors inside that monitor the health of the system.

As soon as some deviation occurs, the equipment immediately receives a shutdown command. A draft sensor of this type works as follows - the controller simply analyzes the draft and turns off the device if the smoke intensity drops.

Functionality check

All of the above can be summarized into one: the sensor is necessary in order to shut off the fuel supply in the event of a danger - such as a gas leak or poor removal of combustion products. If this is not done, very sad consequences are possible.

About carbon monoxide poisoning has already been mentioned more than once above. It very often leads to death, and you definitely shouldn’t joke with it. And in the event that the burner suddenly goes out, but the gas continues to flow, sooner or later an explosion will occur. In general, it is clear that the sensor is vital.

But it can fully perform its functions only in good condition. Every piece of equipment is prone to failure from time to time.

The breakdown of this part will not affect the external state of the boiler, so it is very important to regularly check the performance of the element. Otherwise, you risk noticing a problem until it's too late. There are several methods for checking:

There are several methods for checking:

- attach a mirror to the area where the sensor is installed. During the operation of the gas column, it should not fog up. If it remains clean, then everything is in order;

- partially block the exhaust pipe with a damper. In the case of normal operation, the sensor should instantly react and turn off the boiler. For safety reasons, do not test for too long to avoid carbon monoxide poisoning.

If in both cases testing showed that everything is in order, then the element being tested is ready at any time to respond to an unforeseen situation and turn off the gas supply. But there is another type of problem - when the sensor works just like that.

If you carefully checked the draft level and other points, but the boiler still turns off, this means that the control element is not working correctly. You can further test this as follows.

Disconnect the element and ring it with an ohmmeter. The resistance of a good sensor should be equal to infinity. If this is not the case, then the part is out of order. There is only one option to correct the situation - it is necessary to replace the broken element.

Some homeowners, in situations where the sensor suddenly starts to constantly interrupt the fuel supply in the absence of visible problems with the chimney draft, decide to simply turn off this element. Of course, after that the column starts to work smoothly.

But such actions are a direct violation of safety regulations during the operation of gas equipment. By turning off the sensor, you cannot be sure that everything is in order with the draft, and that carbon monoxide does not begin to fill the room. Definitely not worth the risk. It is better to check the performance of the part in the ways described above. You can also get information on this issue from the video posted above. Good luck to you, as well as a safe and warm home!

How to check this indicator?

To avoid these risks, before using the boiler, it is necessary to check the presence of draft. The verification methods are:

- Anemometer readings. This is a special device used to determine the speed of movement of gases (often called a "vetrometer"). Modern anemometers allow you to accurately determine the value of thrust and come to a reasonable conclusion about the feasibility of starting the equipment. Unfortunately, a quality measuring device will not be cheap.

- Visual "grandfather" methods. A sheet of light paper (for example, toilet paper) held up to the chimney will show the presence of draft and its intensity. The more the leaf deflects under the wind current, the better the traction. Similar information will give us smoke from a cigarette placed in the chimney.

- Check for mechanical blockages. A common cause of smoke removal problems is clogging in pipes. You can check for blockage using a metal ball that descends on a rope from the top of the chimney to the bottom. If the ball reaches the end without problems, then the chimney is clean.The presence of problems with the removal of smoke in this case means that there are problems in another area (short or insufficiently wide channel).

Check for blockage, possibly by visual inspection, if the design of the chimney allows it.

Conclusion

If there is any suspicion regarding a violation of draft, it is necessary to stop the boiler until the situation is sorted out. The best way to check the indicator is to use an anemometer, but a piece of paper is enough to estimate the presence of thrust.

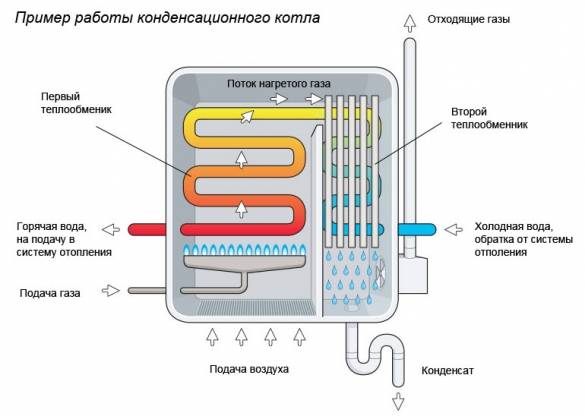

Draft (also vacuum) is a decrease in pressure in the combustion chamber of the boiler due to temperature differences, which contributes to the influx of new air masses into it. Accordingly, the heated air is forced out and discharged through the chimney. With sufficient draft, the boiler receives the air necessary for gas combustion in full, and the combustion products are immediately removed to the street.

Read in the article

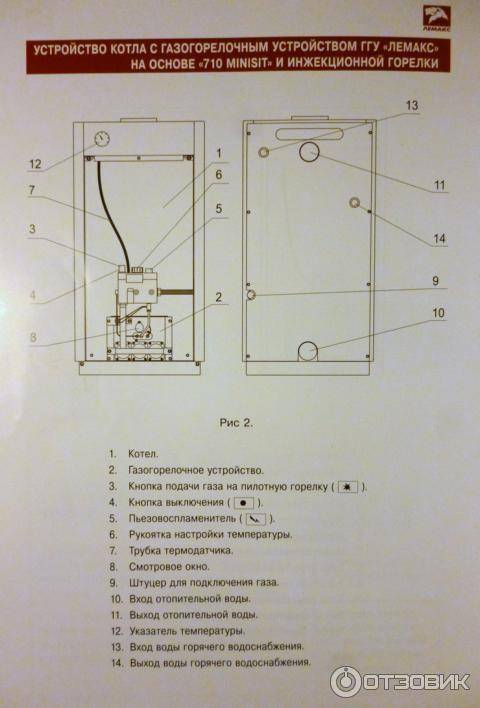

Automation of a gas heating boiler

The main thing that owners need to do when using explosive equipment, which includes a gas-fired boiler, is the rules for safe operation. In accordance with the requirements of PB 12.368.00, all gas units are necessarily equipped with safety automatics, the list of regulatory control parameters includes a draft sensor.

Modern automatic systems warn the owners of boilers about the separation of the flame in the piezo igniter, the accumulation of gas in the boiler and the room, in order to protect the room from a possible accumulation of explosive gas. Automation performs such work with the help of primary devices - thrust sensors for heating gas boilers.The basic principle of their operation is the generation of an emergency signal, with its supply to the actuator to disconnect the boiler from the gas main, and prompt notification to users about the reasons for the shutdown through sound and light alarms.

The main sensors responsible for the safe operation of the gas boiler:

- By discharge or draft, for boilers with natural circulation: 20-30 PA or 2-3 mm of water. Art.;

- by ambient temperature external/internal, С;

- by the temperature of the supply coolant, C;

- by the presence of a torch in the furnace;

- according to the minimum / maximum allowable coolant pressure, atm.

Why is there a back draft in the chimney

This process is influenced by a large number of factors. The main one is the incorrect design of the chimney at the construction stage. In order not to face the problem of insufficient or incorrect traction in the future, it is necessary to correctly calculate in advance:

- chimney section size;

- its location;

- material of manufacture;

- form;

- pipe height;

- the presence of additional devices that increase traction.

The number of people or devices consuming oxygen in the room also affects the quality of air movement. The latter include heaters, irons, stoves and so on.

It is important for proper operation and regular ventilation of the room

A person can control all this on his own, therefore, the presence of reverse draft in the chimney depends only on him. What to do if the weather influences traction? It is impossible to control them, but it is quite possible to resist them.

The principle of operation of the sensor

The gas boiler works by burning blue fuel. Naturally, in this case, combustion products are released.If they get into the room, then this is fraught with severe poisoning of all residents of the house, up to and including death. Therefore, the design of the column provides for connection to the chimney, through which all harmful substances are removed to the street.

Naturally, for high-quality removal, the ventilation shaft must have impeccable draft. But it happens that some kind of violation occurs - for example, the chimney can become clogged with debris or soot. If in such a situation the boiler stubbornly continues to burn fuel, then the combustion products will inevitably go into the house.

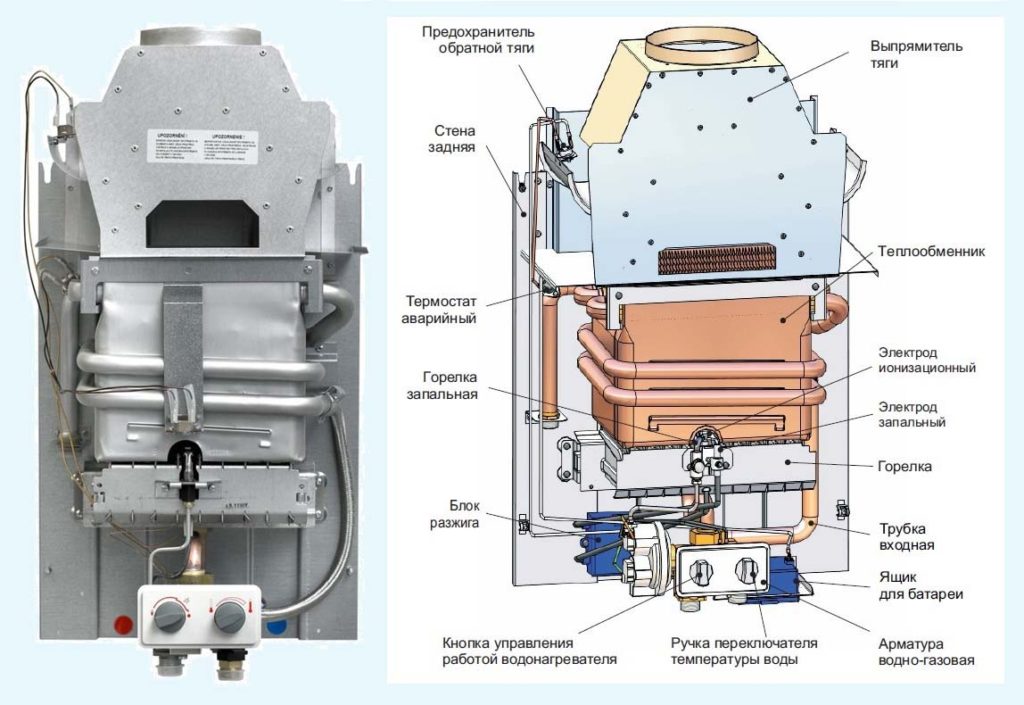

To prevent this, an element such as a chimney draft sensor is included in the design of the gas boiler. It is located in the place that is located between the ventilation duct and the equipment case. The type of sensor depends on the type of boiler:

- in a boiler with an open combustion chamber, the protective sensor is a metal plate to which a contact is connected. This plate is the indicator that monitors the temperature increase. The fact is that normally escaping gases are usually heated to 120-140 degrees. If the outflow is disturbed, and they begin to accumulate, then this value increases. The metal from which the plate is made reacts to such a situation and expands. The contact attached to the element is displaced and closes the valve responsible for the gas supply. Thus, the combustion process stops, and at the same time, the entry of a new portion of harmful substances is prevented;

- in a boiler with a closed combustion chamber, the products are removed through a coaxial channel, while a fan is used. The sensor in this case is a pneumatic relay with a membrane.It reacts not to temperature, but to the flow rate. While it is within the acceptable range, the membrane is bent, and the contacts are in the closed position. When the flow rate becomes weaker than necessary, the membrane straightens, the contacts open, and this leads to the blocking of the gas supply valve.

As you can see, if the draft sensor is triggered, turning off the gas column, this means some kind of malfunction in the equipment. For example, it could be:

- initially poor quality traction. This is the first and main reason why the sensor can work. As a rule, this phenomenon is associated with improper installation of the exhaust structure. If the products of combustion are poorly drawn out, then this is a danger to all living things in the house;

- reverse thrust. This phenomenon occurs when an air lock forms in the chimney. Gases, which normally should move to the very top of the pipe and then go outside, cannot overcome this obstacle and return back, filling the room with themselves. The effect of reverse draft can occur if the thermal insulation of the chimney is made very poorly. The temperature difference leads to the formation of air congestion;

- chimney blockage. It may seem to inexperienced owners that the pipe leading to the roof simply cannot be clogged with anything. In fact, there are many factors that lead to clogging. The first one is birds. They can make nests on the pipe, which then fall down. Yes, and the birds themselves often manage to get stuck in the chimney, and then die there. In addition to birds, one should also take into account the possibility of getting, for example, leaves, as well as the deposition of soot on the inner walls of the pipe.If the chimney is clogged, the draft intensity becomes too low, and there is only one way out - cleaning;

- strong wind. If the pipe is not properly positioned, gusts can enter it and blow out the burner. Naturally, in such cases, the sensor shuts off the fuel supply. To avoid such a danger, it is necessary to purchase and install a stabilizer.

Diagnosis of problems and ways to solve them

If your geyser, equipped with an automatic security system, does not work, you need to make sure that the problem lies in the operation of one of the sensors:

- If your draft sensor works, then in the room, most likely, at this moment you will feel the smell of burning or gas. To make sure that it is really the wrong draft, bring your palm or a piece of paper to the chimney. If the draft is broken and the air goes from the chimney into the room, then the solution to the problem often lies in calling a stove-maker who will clean the chimney from soot and combustion products that have settled in it.

- The overheat sensor will work in your geyser if the cause of the excessive temperature rise is the contamination of the heat exchanger. You need to act as follows: open windows and doors, wait until the room is cleaned with fresh air and the boiler cools down, then contact a qualified specialist.

- If you have an ionization sensor installed, it may cause the igniter to fail to ignite due to the igniter nozzles being clogged with soot, and the safe ignition time programmed in the flame detector will expire. The way out in this situation is to clean the nozzles at the igniter and try again to ignite.If it is not successful, you should contact a qualified master.

Reasons for lack of traction

You can identify the source of the malfunction by visually inspecting the column for errors made during its installation.

There are several typical violations:

- The diameter of the air duct is less than the cross section of the outlet pipe of the water heater.

- Use of more than three repeated corners and adapters when installing the pipe.

- The length of the chimney is less than 2.5 meters.

- Chimney connections are loose, there are leaks.

- The distance from the water heater to the chimney is less than 30-50 cm.

- The length of the corrugation exceeds 2 meters.

It is also important to assess the compliance of the premises with technical operational conditions. In one room it is forbidden to install a geyser and forced exhaust

When installing metal-plastic windows, supply valves should be used.

How water pressure sensors for boilers work

The water pressure switch for gas boilers is the first degree of their protection from working with a low-pressure coolant. It is a small device that is paired with an electronic control board. In boilers with automatic make-up, this device also controls the operation of the electric make-up valve.

In each boiler model, water pressure sensors are individual and may differ from other similar units:

- method of connection to the hydraulic group (threaded or clip-on);

- type of electrical connectors;

- the possibility of adjusting the minimum pressure of the coolant.

In the case of the water pressure sensor for the boiler, there are contacts and a membrane adjusted in such a way that at normal pressure of the coolant in the circuit, it closes the circuit, and the signal passes through it to the control board, informing about the normal pressure of the coolant. When the pressure drops below the minimum, the contacts open - and the electronic board blocks the boiler from turning on.

You can buy a water pressure sensor for a gas boiler of original origin or its high-quality analogue on our website at a bargain price with a guarantee and delivery in Russia. Call - and our experienced consultants will help you choose any spare part for your boiler model!

A gas boiler is a complex household appliance, which also works with an energy source of increased danger. Therefore, the safety of its operation, along with reliability, is an indispensable attribute of the design. The automatic control of the wall-mounted unit is directly related to the stability of its operation with possible fluctuations in the gas supply. The gas boiler pressure switch or pressure sensor is precisely the diagnostic unit that ensures reliable operation.

Signs of need for replacement

The sensor is an integral part of the gas system. It, despite its high reliability, after a long time of use may become unusable. It will need to be replaced sooner or later. What will happen if this is not done is described above.

The following symptoms may indicate the need to replace the controller:

- The unit is permanently switched off in the absence of a malfunction in the output system.

- The heat generator operates at intervals of 20-30 minutes, after which it is deactivated, and re-enabled only after complete cooling.

If one of these signs appears, you should either call a repair service or check the sensor for serviceability yourself.

The operation of the gas boiler sensor in the heating system can be checked in one of the following ways:

- it is necessary to install a mirror near the sensor mounting point. And if the boiler is in an active state, and the glass surface fogs up, then the sensor is faulty;

- if you close the damper of the outlet system halfway, then the boiler in the operating mode should immediately turn off, since the traction force will be insufficient. If this does not happen, the sensor is not working correctly and needs to be replaced.

There is another, less accurate, but still quite effective way to check the health of the sensor. It is necessary to transfer the boiler to the hot water supply mode and open the water at full capacity. If in this case the heat generator turns off, then with a high degree of probability the sensor does not work. The accuracy of the verification method is 95%.

The boiler may turn off even if the controller is working properly. The case may be a malfunction of other devices inside the boiler.

To solve any problem that has arisen, it is imperative to contact the gas service specialists and in no case try to fix the breakdown yourself.

Health check

If problems are observed in the operation of the boiler, then the sensor may need to be replaced. For example, if the burner is switched off regularly, but there are no problems in the combustion gas exhaust system. You also need to check the operation of the device when it periodically turns off after 20-30 minutes.

To check the health of the boiler sensor, you need to consider 3 ways:

- Attach a regular mirror near the device.If the sensor is working properly, then the surface of the mirror should not be covered with condensate.

- An easy way to check by partially closing the chimney. A working sensor will promptly give a signal, and the equipment will turn off.

- If a double-circuit boiler is used as heating equipment, then to check the device, you can switch it to the DHW mode, without heat supply. Then open the tap on a powerful jet of water. Here the situation is reversed - turning off the sensor will be a sign of its problematic operation.

There are many manufacturers of thrust sensors. Among them are such market leaders as Junkers, KAPE, Sitgroup, Eurosit. Some boiler manufacturers (Baxi, Danko) produce appliances for their heating equipment. It is necessary to choose the right sensors for the equipment that is used (gas water heaters, wall-mounted or floor-standing boilers)

It is important to periodically check the health of the boiler draft sensor

How does a draft regulator work?

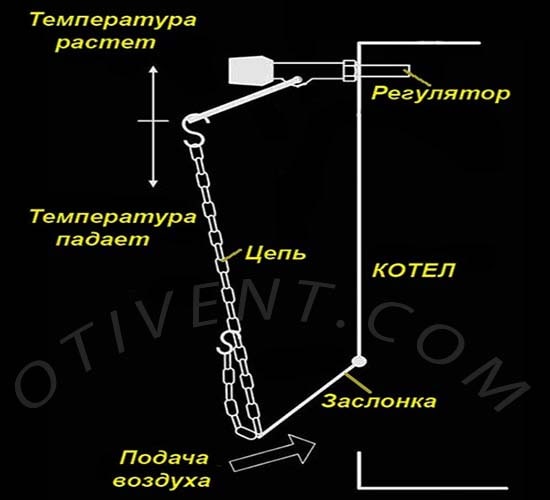

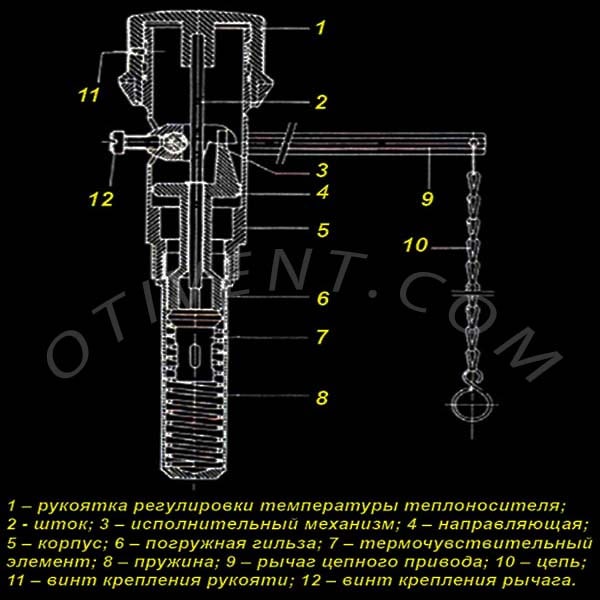

The main part of the air regulator is a mechanical thermoelement placed in a cylindrical body. Through a lever and a chain, he regulates the rise of the air damper on the ash pan door.

The device is a sealed flask filled with a thermosensitive liquid that expands greatly when heated. The flask is inside the housing, which is screwed into the sleeve of the boiler water jacket and is in contact with the coolant. How a chain-driven thermostat is arranged is shown in the diagram:

The principle of operation of the automatic draft regulator is based on controlling the flow of air going into the firebox under the influence of the chimney draft. The algorithm looks like this:

- When solid fuel is burned and the coolant is heated, the liquid inside the element expands and acts on the actuator and lever, overcoming the spring force.

- The lever loosens the chain, the damper begins to close and reduce the flow area. Less air enters the furnace, the combustion process slows down.

- The temperature of the water in the boiler tank decreases, the liquid is compressed and the return spring forces the lever to open the damper again by means of a chain.

- The cycle is repeated until the firewood in the firebox burns out completely, then the spring opens the door as wide as possible.