- Classification of leakage protection systems

- Model types by notification method

- Wired and wireless sensors

- Top Professional Models

- 2. Neptun Bugatti Base ½

- 1. Gidrolock apartment 1 Winner Tiemme

- Homemade alarms

- Some features of popular systems

- Features of one block

- Additional functions

- On the issue of reliability: power and other points

- Do-it-yourself leak protection

- The easiest way is based on the use of a transistor

- Do-it-yourself water watchman

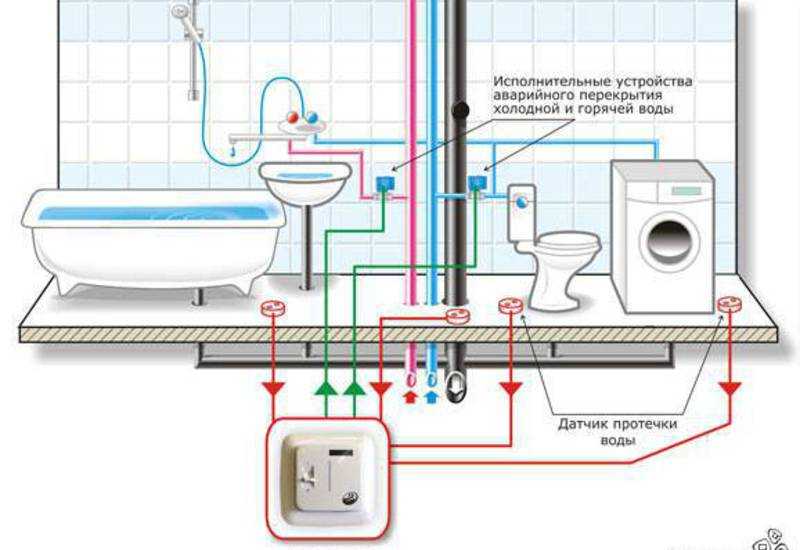

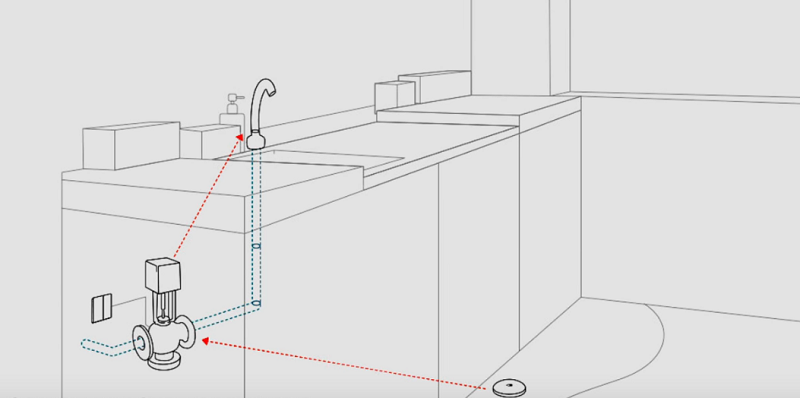

- Installation of a water leakage prevention system

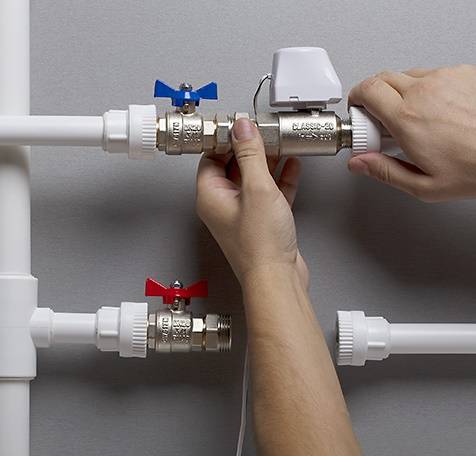

- Ball valve tie-in

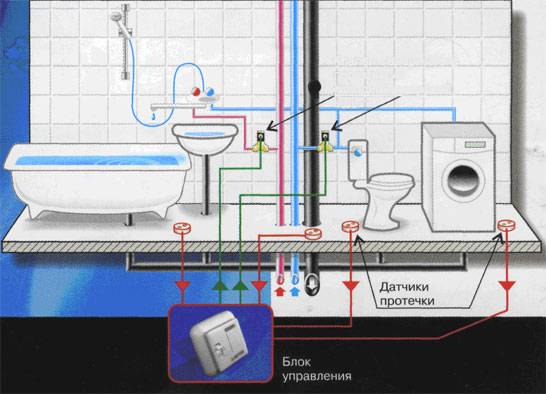

- Installation of water leakage sensors

- Controller Mounting Rules

- Checking system operation

- How and from what to make a case for a signaling device

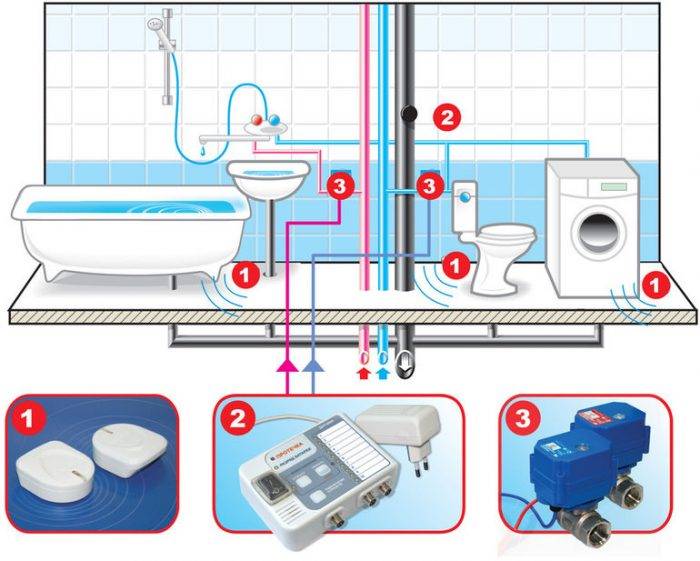

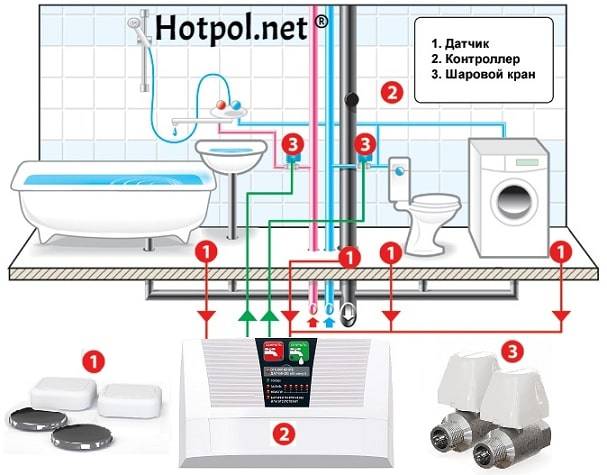

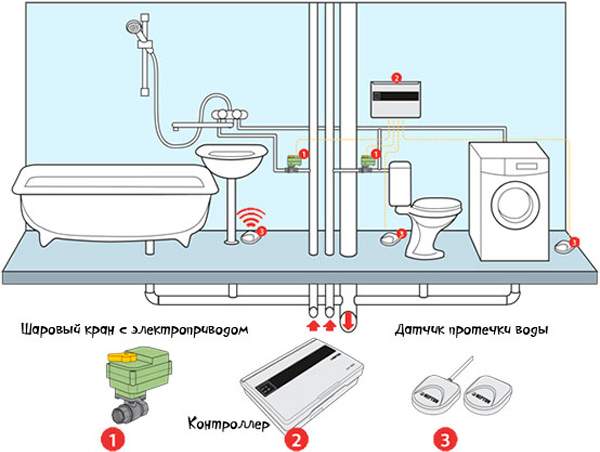

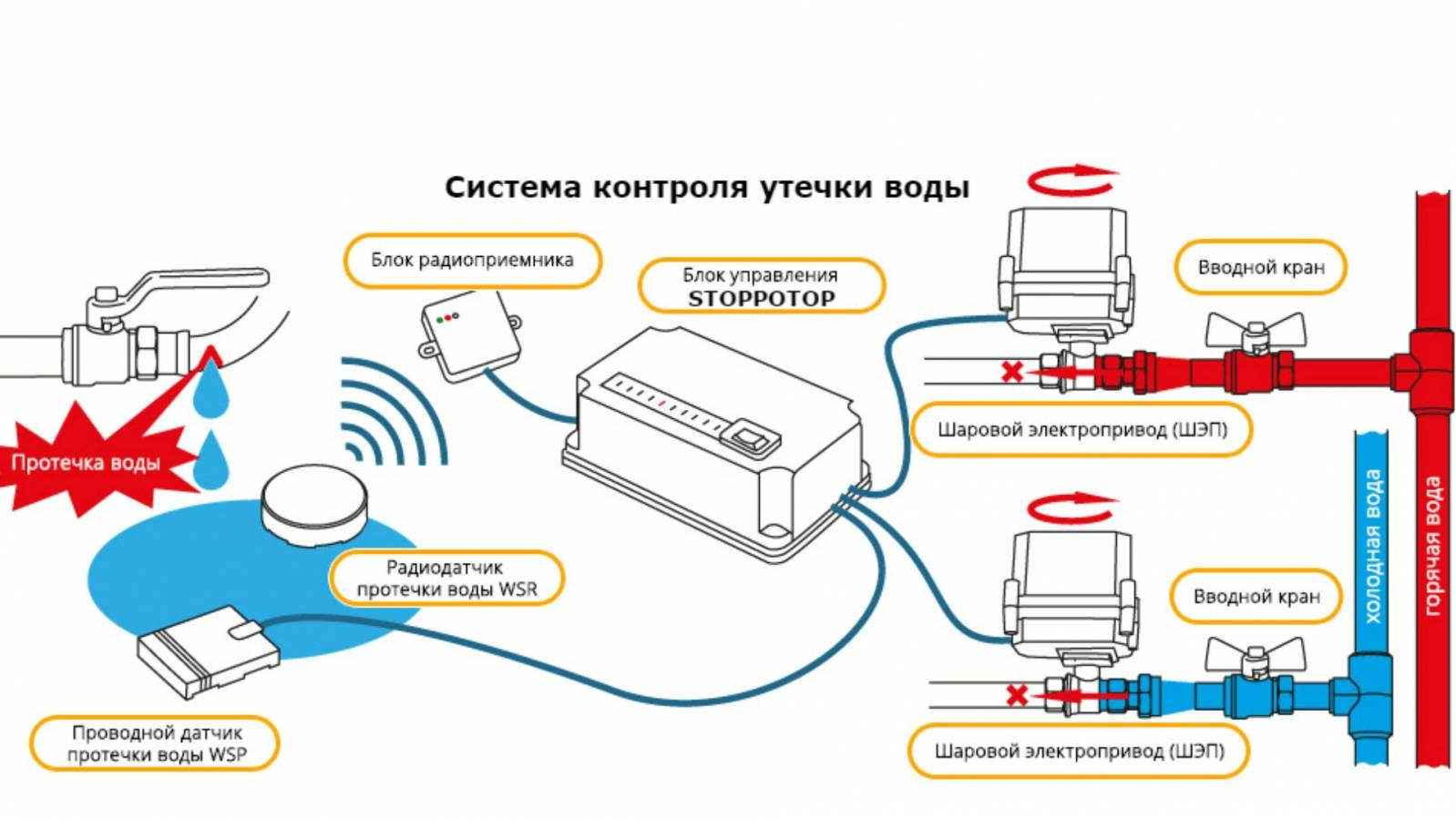

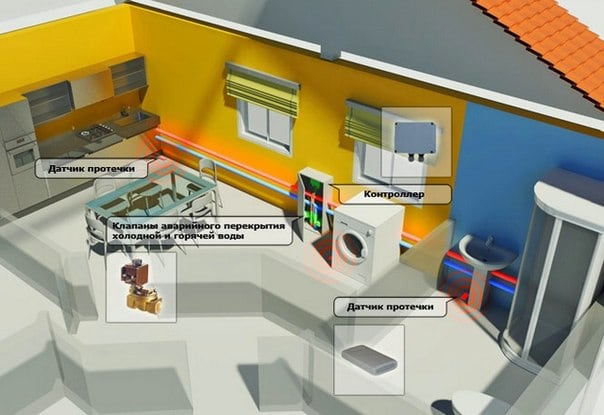

- What are SPPV

- Neptune system

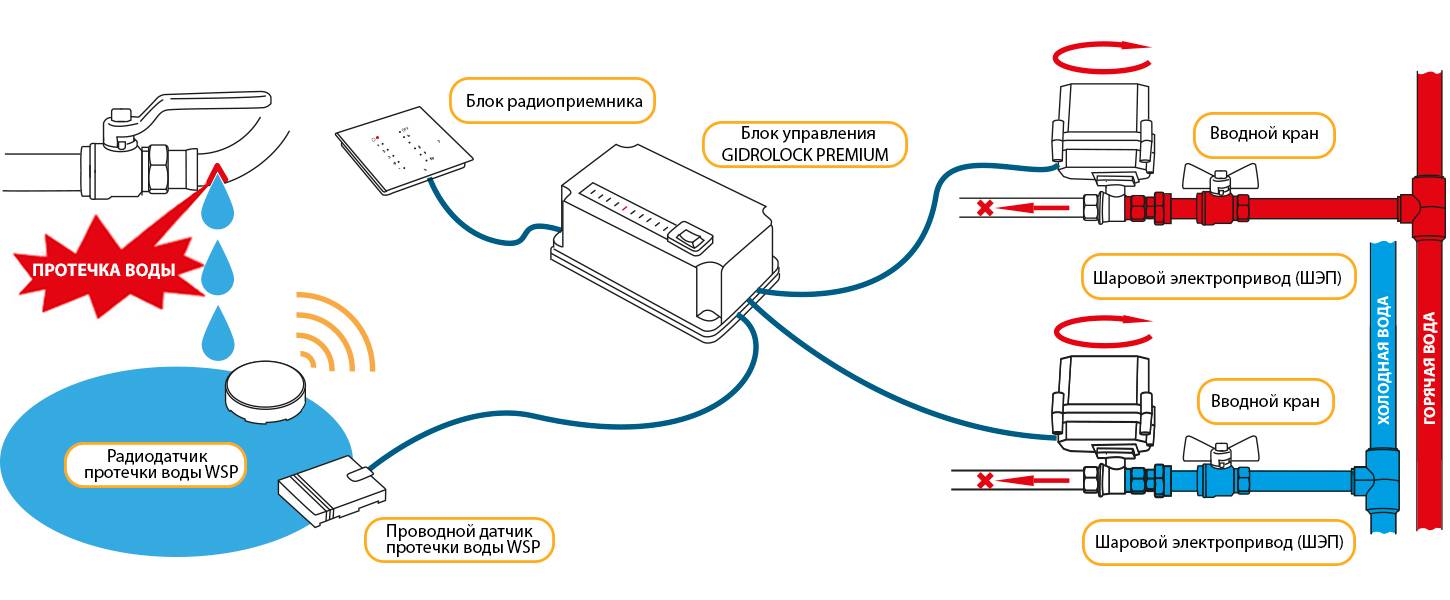

- GIDROLOCK systems

- Aquaguard system

- Advantages of using water leakage sensors

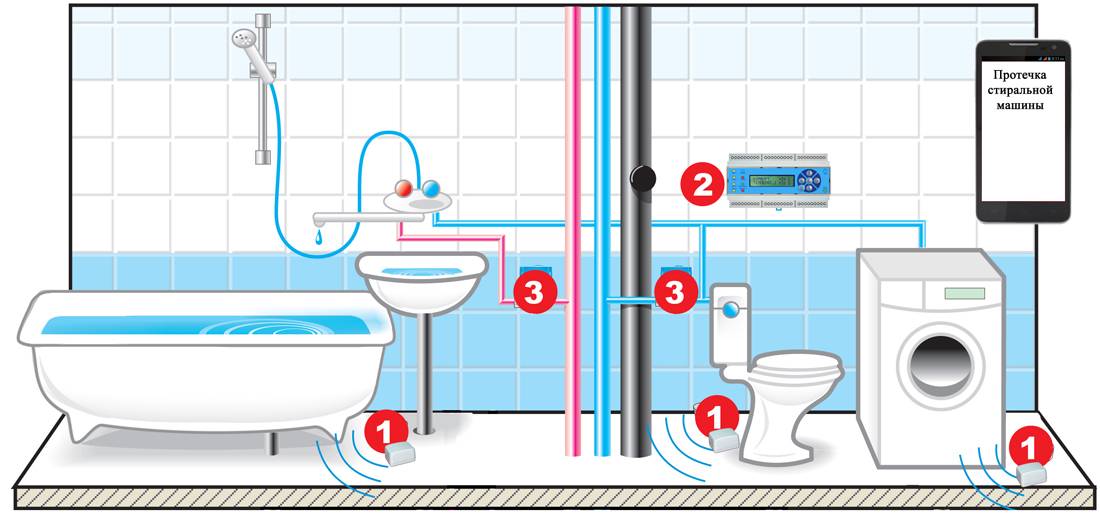

- Rules for competent installation

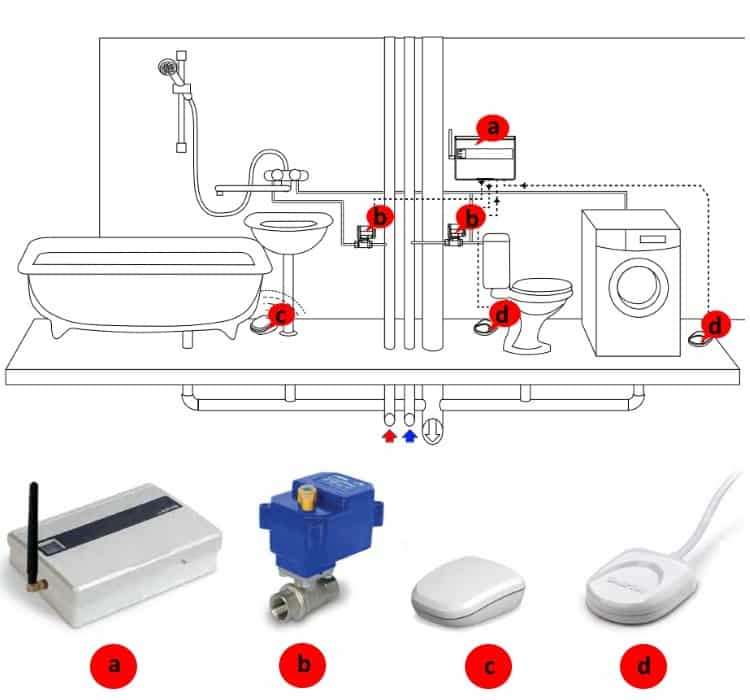

- Stage # 1 - tie-in ball valve

- Stage # 2 - installing the sensor

- Stage # 3 - controller installation

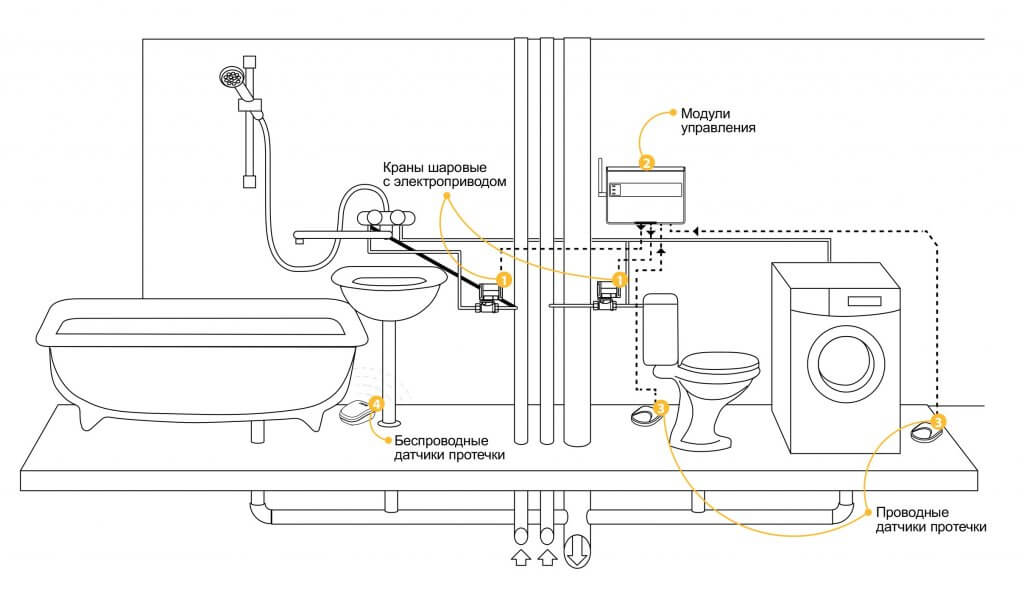

- The principle of operation of the devices that make up the system

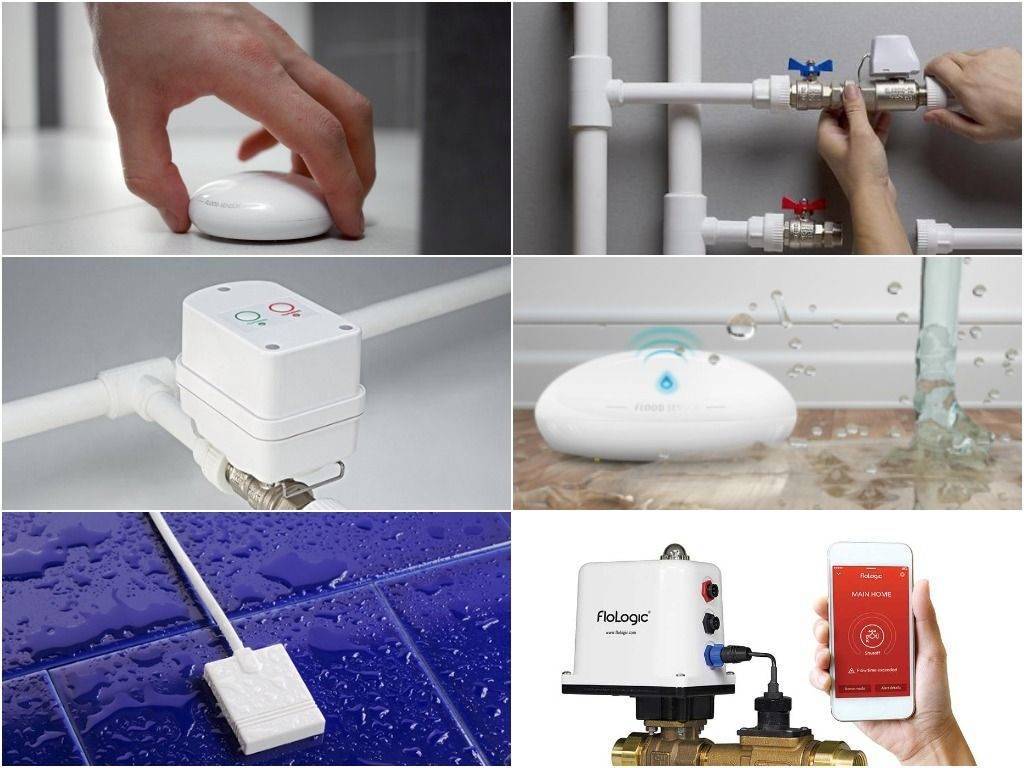

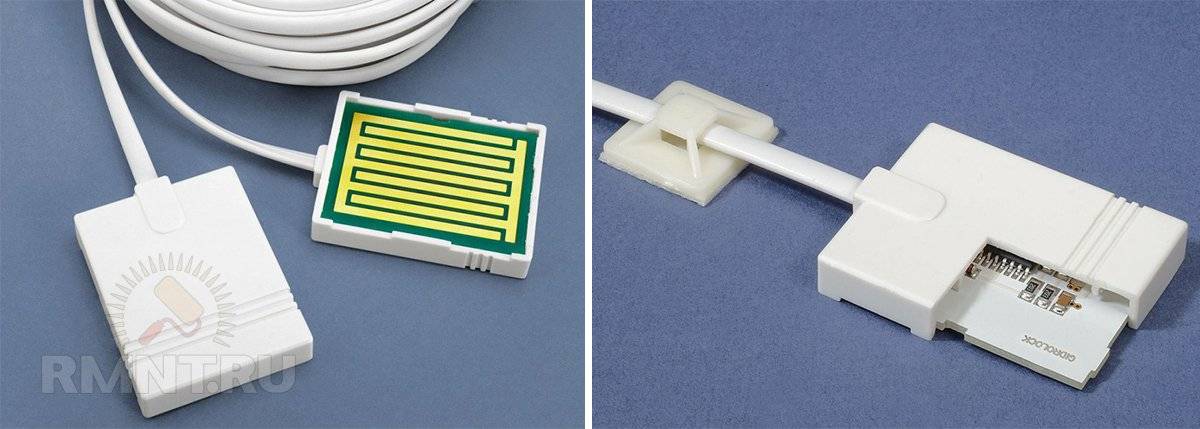

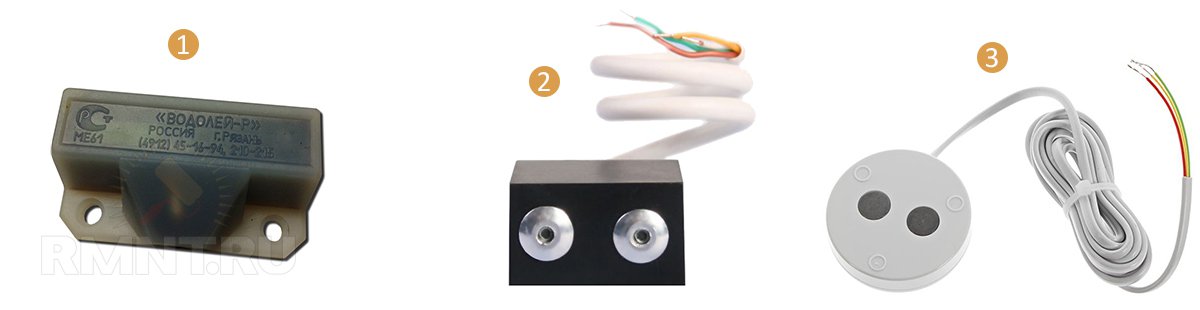

- Sensors

- Controller

- Executive (locking) devices

Classification of leakage protection systems

Anti-leakage systems are classified according to the following main features:

- According to the number of electric cranes included.

- According to the method of informing about the leak.

- According to the method of information exchange between the sensors and the control unit.

As a rule, the number of electric cranes in a set should be at least two. This is due to the fact that the taps must be installed on the risers of cold and hot water. The number of taps, depending on the selected system, can be increased.

Model types by notification method

There are the following ways to report a leak:

- indication on the controller display;

- indication on the display, accompanied by noise signals;

- noise alarm, indication and message sending.

Message transmission is possible if the system is equipped with a GSM transmitter. In this case, an SMS message is sent to a phone number stored in the device's memory.

The phone number is entered from the control panel. When the system is connected to the Internet, it is possible to send messages via a GPRS connection.

The magnetic contact sensor is equipped with a GSM notification function for 6 phone numbers. Thanks to this, all residents of a house or apartment will be notified almost simultaneously about a leak.

The magnetic contact sensor is equipped with a GSM notification function for 6 phone numbers. Thanks to this, all residents of a house or apartment will be notified almost simultaneously about a leak.

The information displayed on the control panel varies by model. Most often, information is displayed on the presence of leaks, the status of sensors, the level of charge of batteries and batteries.

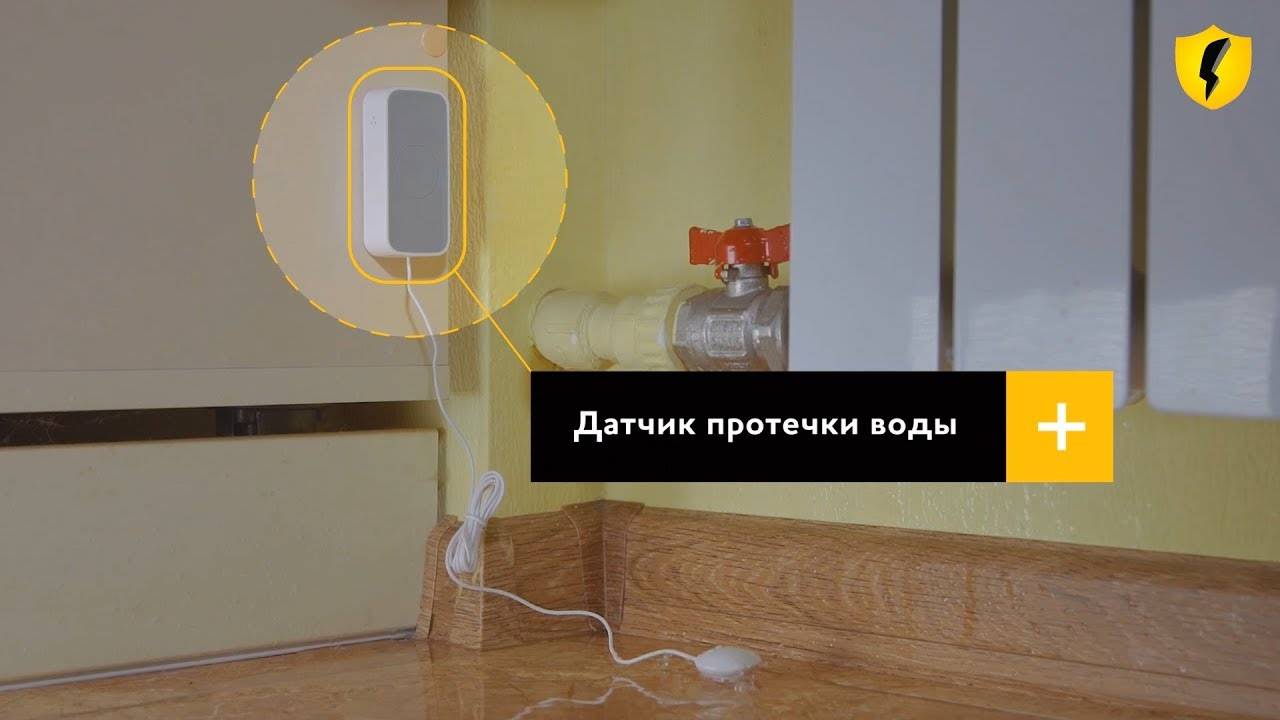

Wired and wireless sensors

Signals from water leakage sensors can be transmitted to the controller both via wires and radio channels. In this regard, it is customary to distinguish between wired and wireless systems focused on flood prevention.

In wired information transmission systems, voltage up to 5 V is applied to the sensor. In the case of a dry surface, there is no current due to the high resistance between the contacts.As a result of exposure to moisture, the resistance decreases and the current increases.

A small voltage is applied through the wires to the sensor electrodes, however, due to the high resistance between the contacts, there is no current. When exposed to moisture, the resistance drops and the circuit closes.

To avoid false positives, you need to set the minimum current threshold at which the controller closes the solenoid valves.

This is due to the fact that the resistance between the contacts decreases with the formation of steam or splashing of water, but its value remains quite high and does not reach the minimum values, as a result of leakage.

Inside each wireless sensor there is a current comparison circuit that is triggered when the set value is reached. A special transmitter constantly measures the resistance of the contact and, in the event of flooding, immediately sends a radio alarm signal to the receiver. The receiver and transmitter are tuned to the same frequency.

A special transmitter detects the increase in resistance on the sensor contacts and gives a radio alarm signal, which is received by the radio receiver of the control unit

The transmitter signal is modulated to avoid false alarms due to electromagnetic interference.

Each manufacturer applies its own modulation principles. In this regard, wireless water leakage sensors cannot be used in other leakage control systems.

Top Professional Models

Expensive device options are distinguished by a wide range of functions, high-quality parts and significant performance.

2. Neptun Bugatti Base ½

Assembly of Russian sensors and module, Italian cranes.In the event of a leak, it gives alerts with sound and light indicators. It consists of three Neptun SW 005 sensors and a Neptun Base control module, two Bugatti Pro model ball valves.

Price - 18018 rubles.

Neptun Bugatti Base ½

Specifications:

- type of sensors - wired;

- number of taps per 1 controller - up to 6 pcs.;

- tube diameter - ½;

- number of sensors per 1 controller - up to 20 pcs.;

- taps in the set - 2 pcs.

pros

- good balance of price and quality;

- branded cranes Bugatti;

- aesthetic appearance;

- effective work.

Minuses

- short wires;

- complex connection;

- inconvenient power connection.

Set Neptun Bugatti Base ½

1. Gidrolock apartment 1 Winner Tiemme

A set of two electric cranes and a pair of WSP sensors, optionally supplemented with a power supply. The autonomous system is completely ready for use. The sensors are directly connected to the taps, which are synchronized by a patch cable.

Price - 17510 rubles.

Gidrolock apartment 1 Winner Tiemme

Specifications:

- type of sensors - wired;

- wire length - 3 m;

- independent food - yes;

- tube diameter - ½;

- taps in the set - 2 pcs.

pros

- reliable drives;

- quality cranes Bonomi, Enolgas and Bugatti;

- lithium batteries type FR6;

- service life with wireless power over 10 years.

Minuses

not found.

Gidrolock set flat 1 Winner Tiemme

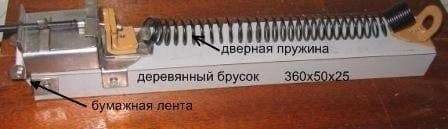

Homemade alarms

Assemble with your own hands a simple household electrical sensor that gives a signal when a leak is detected water, almost anyone who has ever held a soldering iron in their hands can, in any case, it will be cheaper than buying a finished product.

A spring was used as the main mechanism, and an ordinary piece of a sheet from a school notebook was used as a leakage sensor. That is, when it gets wet, it releases the spring, which closes the damper. Below is shown such a mechanism in the cocked state and after operation.

Cocked mechanism

mechanism

We cited such a device as an example, it makes no sense to assemble it due to low reliability, bulkiness and, in fact, archaism, and installing such a mechanism in a modern apartment will cause a lot of difficulties.

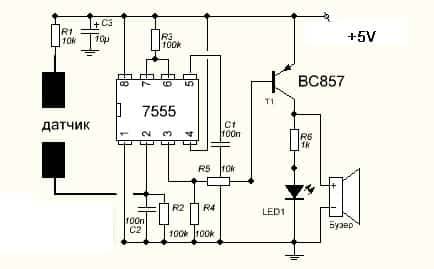

Now there are a lot of simple, more elegant solutions, below is a diagram of one of them.

Wiring diagram: stand-alone leak detector

The principle by which this sound autonomous protection signaling device works is quite simple: as soon as the water closes the contact (sensor), the buzzer (boomer) is activated, and the LED turns on. The cost of the element base will be significantly cheaper than the price of a finished sensor with similar functionality.

Advantages of this scheme:

- low cost of the element base;

- The size of the assembled sensor is quite tiny, so there are no restrictions on the place of its installation. In particular, such a sensor can be installed under a bathtub or a pipe on which a clamp is installed to make sure that the leak is completely eliminated;

- a properly assembled sensor does not need to be adjusted.

Some features of popular systems

To somehow highlight your defense from water leaks, manufacturers are trying to improve reliability or come up with other moves. It is impossible to systematize these features, but it is better to know about them when choosing.

Features of one block

For different manufacturers, one control unit can control a different number of devices. So it doesn't hurt to know.

- One Hydrolock controller can serve a large number of wired or wireless sensors (200 and 100, respectively) and up to 20 ball valves. This is great - at any time you can install additional sensors or put a few more cranes, but not always such a reserve of capacity is in demand.

- One Akastorgo controller can serve up to 12 wired sensors. To connect wireless, you need to install an additional unit (designed for 8 pieces of "Aquaguard Radio"). To increase the number of wired - put another module. This modular extension is more pragmatic.

- Neptune has control units of different power. The most inexpensive and simple are designed for 2 or 4 cranes, for 5 or 10 wired sensors. But they lack a crane health check and no backup power source.

As you can see, everyone's approach is different. And these are just the leaders. There are even smaller campaigns and Chinese firms (where to be without them), which either repeat one of the above plans, or combine several.

Additional functions

Additional - not always unnecessary. For example, for those who are often on the road, the ability to control cranes from a distance is far from superfluous.

- Hydrolock and Aquatorozh have the ability to turn off water remotely. For this, a special button is placed at the front door. Come out for a long time - press, turn off the water. Aquawatch has two versions of this button: radio and wired.Hydrolock has only wired. The Aquastorge radio button can be used to determine the “visibility” of the wireless sensor installation location.

- Hydrolock, Aquaguard and some variants of Neptune can send signals to the dispatching service, security and fire alarms, and can be built into the "smart home" system.

- Hydrolock and Aquaguard check the integrity of the wiring to the taps and their position (some systems, not all). In Hydrolock, the position of the locking ball is controlled by an optical sensor. That is, when checking in the tap there is no voltage. Aquaguard has a contact pair, that is, at the time of checking, there is voltage. Protection against water leaks Neptune also monitors the position of taps using a contact pair.

The hydrolock can be controlled using a GSM module - via SMS (commands for switching on and off). Also, in the form of text messages, signals can be sent to the phone about accidents and “disappearances” of sensors, about cable breaks to electric cranes and from a malfunction.

Being always aware of the state of your home is a useful option

On the issue of reliability: power and other points

Reliable operation is not only about the reliability of cranes and controllers. Much depends on the power supply, on how long each of the blocks can work offline.

- Aquawatch and Hydrolock have redundant power supplies. Both systems shut off the water before the standby power supply is completely discharged. Neptune has batteries only for the last two models of controllers, and then the taps do not close when discharged. The rest - earlier and less expensive models - are powered by 220 V and have no protection.

- Neptune's wireless sensors operate at a frequency of 433 kHz.It happens that the control unit “does not see” them through the partitions.

- If the batteries in the Hydroloc's wireless sensor run out, an alarm lights up on the controller, but the taps do not close. The signal is formed a few weeks before the battery is completely discharged, so there is time to change it. In a similar situation, Aquaguard shuts off the water. By the way, the Hydrolock battery is soldered. So changing it is not easy.

- Aquawatch has a lifetime warranty on any sensors.

- Neptune has wired sensors installed "flush" with the finishing material.

We have considered all the features of the three most popular manufacturers of water leakage protection systems. In short, the worst thing about Aquastorage is a plastic gearbox on the drive, while Hydrolock has a large system power and, accordingly, the price. Neptune - Inexpensive systems are powered by 220 V, do not have a backup power source and do not check the performance of cranes.

Naturally, there are Chinese leak protection systems, but they should be chosen with care.

Do-it-yourself leak protection

Any person who is familiar with a soldering iron and has minimal skills as an amateur radio electronics can assemble an electrical circuit that works on the appearance of an electric current in it if there is water between the contacts. There are many options, both simple and more complex. Let's give some examples.

The easiest way is based on the use of a transistor

The circuit uses a fairly large range of composite transistors (for details about which models we are talking about - see the image). In addition to it, the following elements are used in the scheme:

- power supply - a battery with a voltage of up to 3 V, for example, CR1632;

- a resistor ranging from 1000 kOhm to 2000 kOhm, which controls the sensitivity of the device to respond to the appearance of water;

- sound generator or signal LED light.

A semiconductor device is in a closed state in a circuit where the power supply is not allowed to make it work with the installed power. If there is an additional source of current caused by leakage, the transistor opens and power is supplied to the sound or light element. The device works as a signaling device for water leakage.

The housing for the sensor can be made from the neck of a plastic bottle.

Of course, the above version of the simplest circuit can only be used to understand the principles of operation, the practical value of such a sensor is minimal.

Do-it-yourself water watchman

Unlike the previous method, where the presence of a person is required to eliminate the leak, here the signal is sent to an emergency device that automatically shuts off the water supply. To generate such a signal, it is required to assemble a more complex electrical circuit, in which the LM7555 chip plays the main role.

The presence of a microcircuit allows you to stabilize the signal parameters due to the comparative analog device contained in it. It works on those signal parameters that are necessary to activate the emergency device that shuts off the water.

As such a mechanism, a solenoid valve or a ball valve with an electric drive is used. They are built into the plumbing system immediately after the inlet water supply valves.

This circuit can also be used as a sensor to provide light or sound signals.

In conclusion, we can add that the leakage sensor is not a particularly complex device that will be inaccessible to the average man in the street, if you want, you can assemble it yourself at home. The functions that this small nondescript box performs should be implemented in every home, and the benefits from it are simply invaluable.

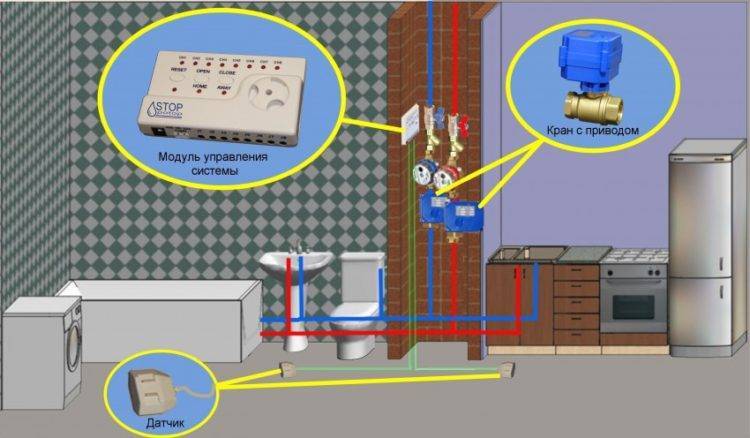

Installation of a water leakage prevention system

The protective circuit is a constructor, the elements of which are interconnected by special connectors. Ease of assembly ensures quick installation and integration with Smart Home systems. Before installation, they draw up a layout of individual parts and check that the length of the wires matches the distance that will be required to connect the meters and taps to the controller.

The order of work includes:

- marking mounting points;

- laying wires;

- tie-in cranes;

- installation of leak detectors;

- installation of the control module;

- connection and system check.

Ball valve tie-in

The most time-consuming stage is the fastening of the ball valve, which is explained by the need to use it on different types of pipes. The water supply is cut in the immediate vicinity of the previously closed water valve. Then the meter is removed and the shut-off valve is fixed on the tap, after which the water meter and pipeline sections are returned to their original position.

Metal-plastic elements are pressed with a lock nut, polypropylene structures are connected by soldering or using detachable couplings. A dedicated power line is used to connect ball valves to the power supply distributor.

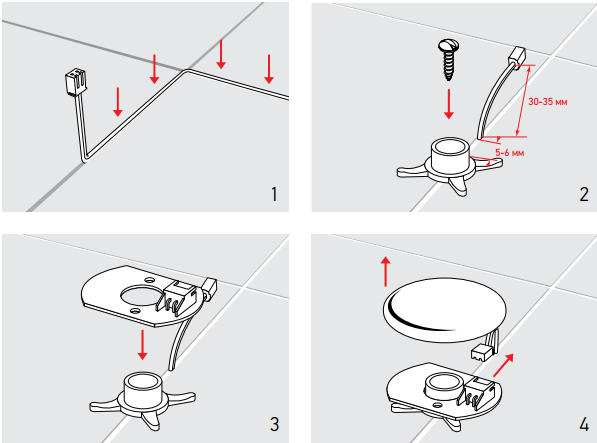

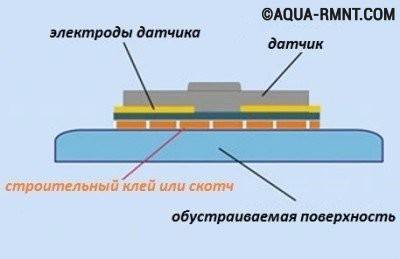

Installation of water leakage sensors

Sensors are located in places of possible leakage, while special attention must be paid to the transition between the box where the pipes are placed. This is necessary so that in case of an accident, water gets on the sensor, and does not continue to flow past it. The scheme of their connection can be both floor and internal, in which the elements are cut into the coating material

In the first case, the plate is placed with the contacts down and fixed with double-sided tape or construction glue. This option is used in cases where the installation of the "anti-leakage" system is performed after the installation of plumbing equipment

The scheme of their connection can be both floor and internal, in which the elements are cut into the coating material. In the first case, the plate is placed with the contacts down and fixed with double-sided tape or construction glue. This option is used in cases where the installation of the "anti-leakage" system is performed after the installation of plumbing equipment.

Water leakage sensor connection diagrams.

When the device is located internally, its contacts are placed 3-4 mm above the level of the coating, which makes it possible to exclude operation in case of accidental splashing of water or cleaning. The connecting wire is laid in a corrugated pipe impervious to water. Manufacturers guarantee the efficiency of the system even when the determinant is 100 m away from the control module.

Wireless devices are mounted on any surface thanks to the fastener system.

Controller Mounting Rules

The device is placed in a niche or on the wall next to the electrical wiring and shut-off valves.The power cabinet serves as the controller's power supply, so phase and zero are connected to the device. The wires are connected using special terminal connectors, which are numbered and signed for ease of installation. Then connect the water leakage detectors and proceed to the diagnosis.

Checking system operation

When the control module is turned on, a green indicator lights up on its panel, indicating that it is ready for operation. If at this moment the sensor plate is wetted with water, the light of the bulb will change to red, the sound pulse will turn on and the shut-off valves will block the water inlet. To unlock the detector, wipe it with a dry cloth and restart the device. After checking the status, the controller will be ready for operation.

How and from what to make a case for a signaling device

The housing for the signaling device should be the same miniature. The most suitable size option is a lid from a liter can of milk or from a package with soap bubbles.

To make the body of the signaling device, you need not only a cap, but also a screw part, which must be cut off from the bottle. The screw part must be soldered on one side with a piece of plastic. Use a glue gun for this, and a plastic blister may come in handy for the wall. Make holes in it with a hot knitting needle in order to thread the contact wires. The cover of the signaling device will be the cover from the package. It is necessary to make several holes in it with a hot needle so that the sound of the signaling device is clearly audible. It remains only to connect the cover to the screw part, the whole circuit will be hidden inside

You will get a very tiny sensor that can be hidden under the sink or bath. When in contact with water, the squeaker will work and attract your attention.You will be able to react in time and eliminate the leak

Watch this video on YouTube

Previous STORIESIngenuity of the master: life hacks in working with simple tools

Next STORIESConstructor for adults: how to assemble a chair from plastic pipes

What are SPPV

Systems vary in:

- power supply - from batteries, accumulator or mains;

- installation methods - some are installed during repairs, others can be installed after it is completed;

- type of valves - ball, ceramic, etc.;

- type and power of electric drives;

- type of sensors - wired and wireless;

- a set of additional functions - monitoring the status of batteries and taps, notification of events on the phone, remote control, etc.

Neptune

hydrolock

Aquaguard

They offer options for an apartment, country house, office and other premises. The basic set can be expanded with additional equipment.

Neptune system

It is produced in 4 versions. The prices of ready-made kits range from 9670 rubles. up to 25900 rub.

Wired system Neptune Aquacontrol

for an apartment, it has two 1/2 inch taps (or two 3/4 inch taps), two sensors connected by wires 0.5 m long to the basic control module. This module closes and opens the taps once a month, even if there is no leakage, to prevent them from souring. The system is powered by 220 V (there is no backup power source), the taps are closed 18 seconds after water hits the sensor. It is recommended to install it during repairs, as it is necessary to lay electrical wiring. 6 cranes and 20 sensors can be connected to the control module. The warranty period is 4 years.

Wired Neptune Base System

has 3 sensors with 2 m power cords, two Italian Bugatti cranes for 1/2 or 3/4 inches, a basic control module. Crane motors are activated no later than 21 seconds later, they are powered by 220 V (there is also no backup power source). Recommended for an apartment. Installation during renovation. The warranty period is 6 years.

Neptune Pro Wired System

differs from previous models in the control unit, which allows it to be integrated into third-party warning systems (dispatching, smart home, security systems), and the presence of a backup power source. Suitable not only for an apartment, but also for a cottage. Warranty 6 years.

Wireless system Neptune Bugatti Pro+

- the latest development of the designers of the manufacturer. The system is equipped with two radio sensors, but it can be connected to 31 radio sensors or 375 wired sensors, as well as 4 cranes. Radio sensors operate at a distance of up to 50 m from the control module. When connected through a router, the signal reception range increases. Installed both during and after repair. Suitable for large cottages with many places of possible water leaks. Warranty 6 years.

GIDROLOCK systems

Operates on AA batteries. Options for use in apartments, country houses and cottages have been developed. More than 30 modifications are presented, taking into account the type of water supply - hot or cold individual or centralized, pipe diameter - 1/2, 3/4, 1, 1 1/4, 2 inches, floor space and so on. The control unit monitors the performance of the sensors.

200 wire sensors, 20 ball valves, 100 radio sensors and a GSM alarm are connected to the control unit of the GIDROLOCK PREMIUM system, notifying about an accident by sms-message to the phone.The electric drive closes the valve within 12 seconds from the moment the leakage signal is received.

There is a manual control of the position of the ball valve. It will be needed when there is no time to wait for the sensor to dry in order to turn on the water, or if you need to turn off the water when no accident has occurred. For example, when replacing a valve in the kitchen. To do this, remove the metal retainer and close the valve by turning the housing of the electric drive. Open in reverse.

The manufacturer offers kits for apartments and country houses with autonomous and centralized water supply. The body of the electric drive is detached from the ball valve, which simplifies the installation of the ball valve on the pipe.

Aquaguard system

It is positioned as the world's first flood protection system with triple power supply: from batteries, a network universal mini-USB adapter and a built-in uninterruptible power supply. It accumulates energy and ensures the operability of the system when the batteries are dead and / or when the electricity in the apartment is turned off. The system detects a damaged or lost sensor and gives a signal to turn off the taps.

The Avtostor-Expert model implements the ability to integrate into the Smart Home system and connect a GSM module for SMS notifications.

Advantages of using water leakage sensors

The main advantage of using water leakage sensors is the ability to receive information about an accident in time. A flood caused by a leaky water pipe or a clogged sewer can cause a lot of trouble not only to the owner of the apartment, but also to the neighbors below. With timely notification of a leak, residents have the opportunity to minimize its consequences.

Modern water leakage sensors with Wi-Fi, in addition to sound and light signals, are able to transmit messages to homeowners on remote mobile devices. Thanks to this, residents will be promptly notified of the accident, even when they are away from home.

Even more convenient to use are detectors connected to automatic shut-off valves. Thus, a whole security system is being created, capable of independently, without human help, blocking the emergency section of the pipeline. For this, special valve valves equipped with servo drives are used. Their management in the system is entrusted to the electronic control unit. In the event of an alarm from the leakage sensor, the controller instantly shuts off the water supply, minimizing the possible negative consequences of an accident.

Thus, the use of water leakage control sensors can save a lot of money, which otherwise would have to be spent on cosmetic repairs and compensation for damage to downstairs neighbors. Even the most expensive security systems, equipped with emergency cranes and Wi-Fi connection, in the event of an accident will more than pay back the money, effort and time spent on acquiring and connecting them.

Rules for competent installation

Before proceeding with the installation of the system, you should draw up a detailed layout of all its elements, on which you will need to mark the location of each device. In accordance with it, it is checked once again whether the length of the connecting wires included in the kit is sufficient for installation, if they are provided for by the design of the devices.The actual installation is carried out in the following sequence:

- We mark the areas for installing sensors, cranes and the controller.

- According to the connection diagram, we lay the installation wires.

- We cut ball valves.

- Installing sensors.

- We mount the controller.

- We connect the system.

Let's take a closer look at the most important stages.

Stage # 1 - tie-in ball valve

As already noted, the installation of an electric ball valve is best left to a specialist. The device is mounted after the manual valves at the inlet of the pipeline. It is strictly forbidden to install structures instead of cranes at the input.

Before the node, it is recommended to put filters on the pipeline that purify the water. So the devices will last longer. It is also necessary to provide them with uninterrupted power supply. In operating mode, the device consumes about 3 W, at the time of opening / closing the valve - about 12 W.

Stage # 2 - installing the sensor

The device can be installed in two ways:

- Floor installation. This method is recommended by the manufacturer. It involves inserting the device into a tile or floor covering in areas where water is likely to accumulate in case of a possible leak. In this case, the contact plates of the sensor are brought to the floor surface so that they are raised to a height of about 3-4 mm. This setting eliminates false positives. The wire to the device is supplied in a special corrugated pipe.

- Floor surface installation. In this case, the device is laid directly on the surface of the floor covering with the contact plates facing down.

Installing a water leak sensor with your own hands is quite simple, especially if the second method is used.

Manufacturers recommend installing a water leakage sensor in the floor.So that the panel with contacts is raised by 3-4 mm. This eliminates the possibility of false positives.

Stage # 3 - controller installation

Power to the controller must be supplied from the power cabinet. Zero and phase are connected to the device according to the connection diagram. To install the device, you need to perform the following operations:

We are preparing a hole in the wall for mounting the controller box.

We drill recesses for power wires from the installation site to the power cabinet, to each sensor and to the ball valve.

We install the mounting box on the prepared place in the wall.

We prepare the device for installation. We remove its front cover by alternately pressing on the latches on the front of the device with a thin slotted screwdriver. We remove the frame and connect all the wires in accordance with the diagram. We install the prepared controller in the mounting box and fix it with at least two screws.

We assemble the device

Carefully put the frame back in place. We impose the front cover and press on it until both latches work.

If the system is assembled correctly, after pressing the power button, it starts working. This is usually indicated by a glowing indicator on the controller. When a leak occurs, the indication color changes from green to red, a buzzer sounds and the tap blocks the water supply.

To eliminate the emergency, the manual valves of the pipeline are closed and the power to the controller is turned off. Then the cause of the accident is eliminated. The leakage sensors are wiped dry, the controller is powered on and the water supply is opened.

Properly installed leak protection system reliably protects against all sorts of troubles associated with water leakage

The principle of operation of the devices that make up the system

To understand how all the components of the system function, you need to consider each separately.

Sensors

These elements are available in two types: wired and wireless. The former take power from the controller, the latter need batteries.

The advantage of a wired sensor is the efficiency of energy consumption, however, such devices cannot be installed everywhere. For example, the installation location is too far from the controller, or it is not possible to run a wire to it. Most often, the installation of both types of sensors is combined. The main characteristics are:

- The number of possible water leakage sensors that can be connected to the complex. Most often, four is enough, but there are individual situations when additional devices may be required: then chains of sensors are created.

- Ease of connection to the control device. It is convenient if the cables are equipped with connectors and the corresponding inscriptions are present. This all saves time when installing equipment.

- The number of devices included. Some manufacturers complete their water leakage monitoring systems with a minimum set of sensors. In this case, you will have to buy additional elements.

- Functionality. This may be the length of the cable, the ability to hide its wiring, protection from environmental influences, simple replacement of damaged sections.

- The operating distance of the wireless sensor. This moment is important, since the remoteness of the device from the controller can be significant, or there are additional obstacles in the form of walls, ceilings, and so on. In this case, you should consult with the seller of the goods.

Controller

The controller is the main control center of the system.There are a number of features of its operation:

The autonomy of the device in the event of a power outage. In case of severe flooding, a short circuit of the electrical wiring may occur, which means that the controller will fail and the electric cranes will not work.

Therefore, it is so important that the main control center has an autonomous power supply.

Providing backup power for the device is very important, because even with a standalone version, the batteries can be discharged.

An important condition is the ability of the control device to work with radio sensors. This is important because in some rooms it is not possible to run cables.

Minimum response time to leak

In this case, we mean the time during which the sensors react, the controller itself, and the electric crane closes.

Monitoring of protection against breakage in the sensor circuit. This is an important parameter, since during operation the wiring can be cut off by children, pets or rodents. In this case, the sensor will cease to function and the room will remain unprotected.

The number of taps and sensors connected to the controller at the same time. Most often, these are four sensors and two electric cranes. But there are options when this is not enough, so the function of additional devices that the stop flood system may have is important.

Operating comfort is an indicator of the level of charge, an indication in the event of a leak, self-cleaning of taps, the ability to temporarily turn off sensors, for example, to clean the room, a range of batteries for power supply that are easy to purchase.

Executive (locking) devices

Another important element in the system is the electric crane.

It is important that the leakage faucets used meet certain characteristics:

Valve closing speed. The amount of water that will flow in an emergency depends on this. The sooner the closure occurs, the less damage the premises will receive.

Compactness, overall dimensions of taps - this affects their location in the plumbing system.

Easy to install and dismantle

Since the work with taps is carried out in a cramped sanitary cabinet, it is very important to provide easy access to them.

Material of manufacture: affects the duration of operation and reliability of the device. The best options are brass or stainless steel.

Electric wire length

This indicator is affected by the remoteness of the crane from the controller.

The thickness of the cable is important when installing anti-leakage and the desire to hide it from view.