- 1.3.1. Basic principles of pressure conversion by a strain gauge

- Step by step instructions how to connect

- Connection to frequency converter

- To the water supply system

- How to choose for a cottage?

- Membrane

- Piston

- labyrinthine

- The best models of gearboxes for the water supply system

- Honeywell Corporation (USA)

- Model RD-15

- FAR Rubinetterie S.p.A (Italy).

- Group of companies "VALTEC" (Italy-Russia).

- How to choose a pressure reducing valve

- Honeywell Water Regulator

- Pressure regulator RD-15

- Far water regulator

- Pressure regulator Valtec

- Material

- Installation

- Device adjustment

- Do I need a gearbox before the boiler?

- Direct Acting Flanged Valve Arrangement

- Threaded regulator device

- Conclusions and useful video on the topic

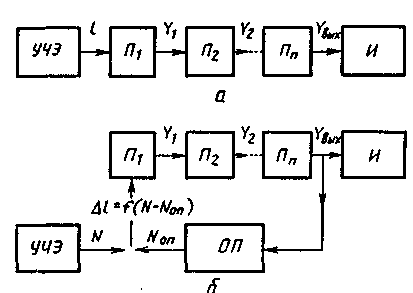

1.3.1. Basic principles of pressure conversion by a strain gauge

Fundamental

difference between strain gauges and

liquid and piston consists of

application of elastic sensitive

element (UCHE) as primary

pressure converter. sensitive

element that perceives the measured

pressure, is elastic

shell, which is usually executed

in the form of a body of revolution, and the thickness

shell walls are much smaller than it

external dimensions. Under the influence

measured pressure elastic shell

deformed so that at any point

shells are stressed,

balancing the effect on her

pressure.

concept

"strain gauge" in general

form can be formulated as follows.

way. deformational

manometer-

manometer, in which the measured

pressure acting on elastic

UCHE shell, balanced

stresses that occur in

elastic shell material. So

how the CEA converts the pressure,

which is the input variable, into the output

the value that carries the measurement

information about the pressure value. For UCHE

naturally choose as

output value depending on

operating principle of the deformation

pressure gauge: move set point

UCHE; stress in the material given

points and effort developed by the UCHE under

pressure action.

The choice of either

other output signal CCE determines

ways to further transform it

to get measurement results

pressure, and, consequently, the principle

strain gauge operation.

In the technique of measuring pressure found

application two main methods: method

direct conversion and method

balancing transformation

(Fig. 7).

By

direct conversion method (Fig. 7,

a) all transformations of information about

pressure values are carried out in the direction

from UCHE through intermediate

converters P1,

P2,

. . ., Pn

to device

AND,

representing

results of pressure measurements in

required form. At the same time, the total

conversion error

determined by the errors of all

converters included in

measuring channel.

Rice. 7. Methods

pressure measurements

Method

balancing transformation

(Fig. 7, b)

characterized

that two chains are used

converters:

chain

direct conversion, consisting of

intermediate converter circuits

P1,

P2,

. . ., Pn,day off

whose signal Atexit

goes to the result pointer

measurements And

and,

simultaneously on the reverse circuit

transformation, consisting of a converter

OP.

Method

balancing is that

an effort N,

developed

UCHE, balanced by effort Nop,

created by the inverse converter

OP

weekend

signal Iexit

direct conversion circuits. That's why

only

deviation of the specified point of the CEA from

equilibrium positions. Unlike

previous method total error

transformations in this case are almost

completely determined by the error

reverse converter. However

application of the balancing method

leads to design complexity.

strain gauge Depending on

from the purpose and principle of operation

separate links of measuring chains

strain gauges can

be constructed in the form

independent blocks. In many

cases, such as severe

operating conditions at the facility

measurements (increased or decreased

temperature, high vibration

inaccessibility of the connection point

etc.) it is advisable to minimize

the number of links that are

directly on the object

the totality of these measuring

elements with mandatory inclusion

in it, the CCE is called a sensor. At the same

time pointer measurement result

should be in a place with more

favorable conditions, convenient for

observer.The same goes for the rest

parts of the measuring circuit. Blocky

the principle of construction is also expedient

and from the point of view of the manufacture of manometers

at different enterprises with mass

production.

In this regard, it should

dwell on the commonly used

the concept of "measuring transducer

pressure "(IPD). Basically, the IPD is

part of the measuring circuit

many modern deformation

pressure gauges, including an intermediate

converter with unified

output signal. Therefore, selection

SDI in an independent section is inappropriate

due to the inevitability of repetitions when they

description. At the same time, SDI for functional

opportunities has a wider

application than pressure gauges.

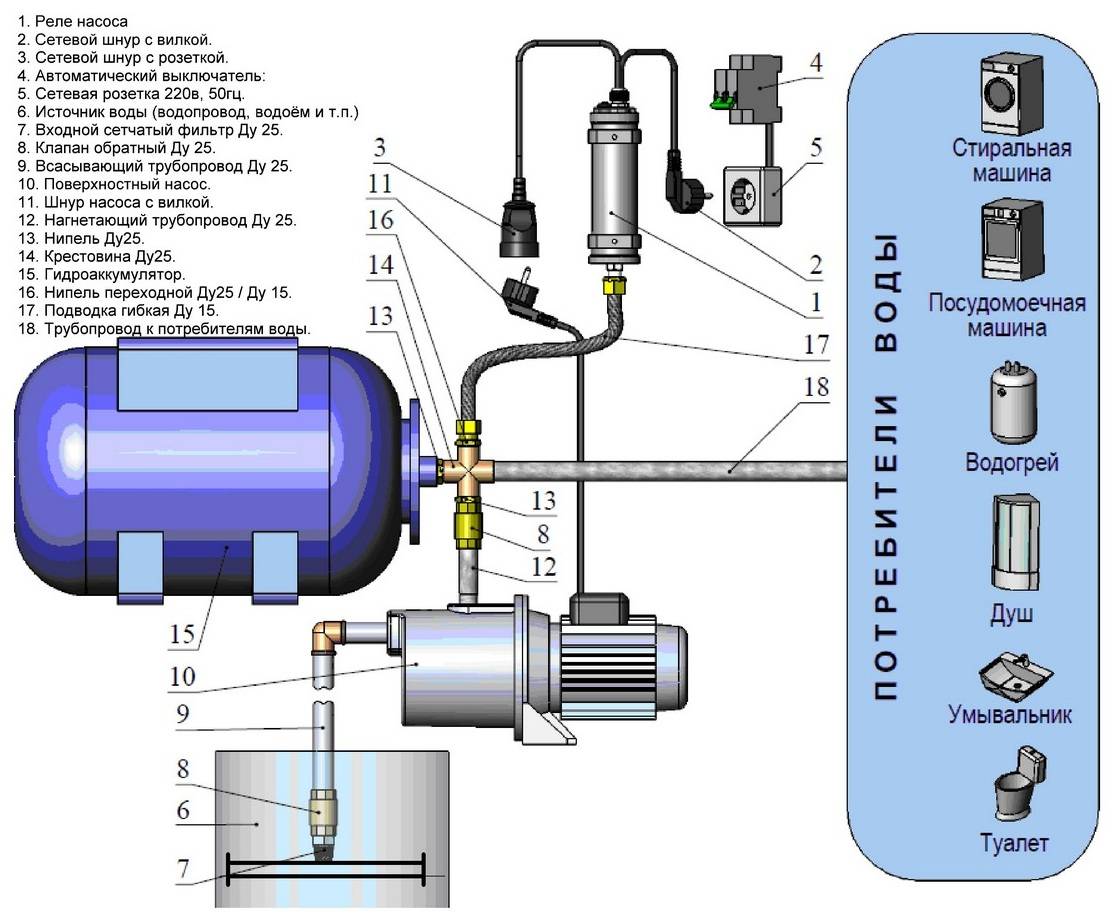

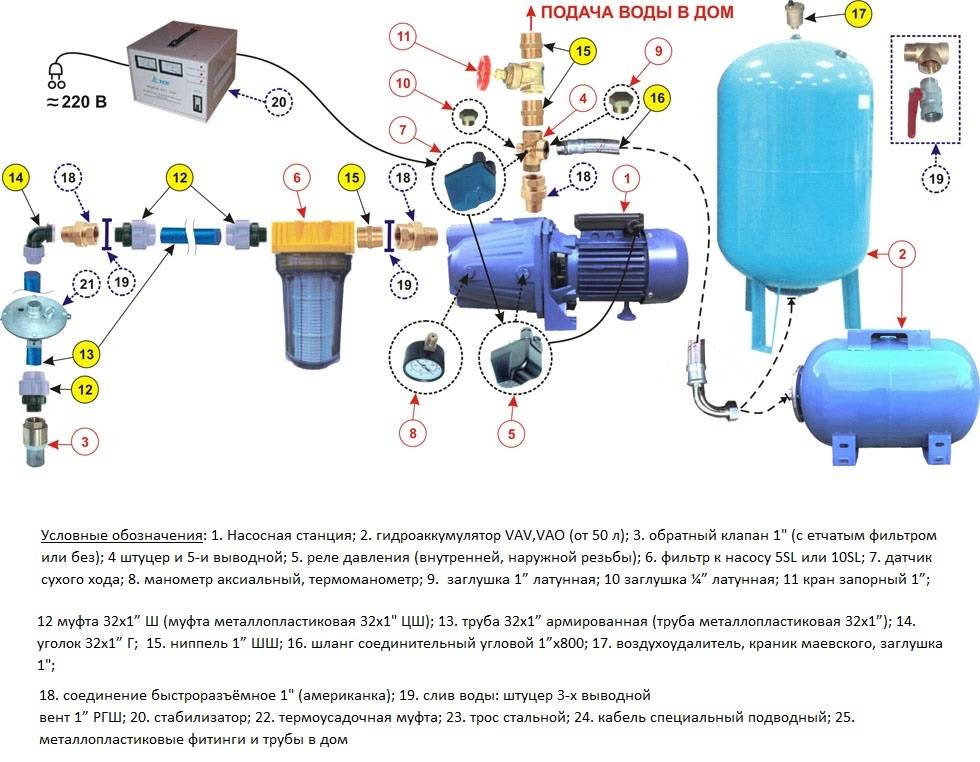

Step by step instructions how to connect

A detailed diagram of the installation of the pressure sensor is in the instructions with which the device is sold. In general, the sequence of steps is the same.

Connection to frequency converter

The sensor is connected to the inverter in the following order:

- mount the sensor on the pipeline, connect the device to the high-frequency converter with a signal cable;

- in accordance with the diagram given in the documentation, connect the wires to the appropriate terminals;

- configure the software part of the converter and check the operation of the bundle.

To prevent interference and correct operation of the inverter, a shielded signal cable is used for laying.

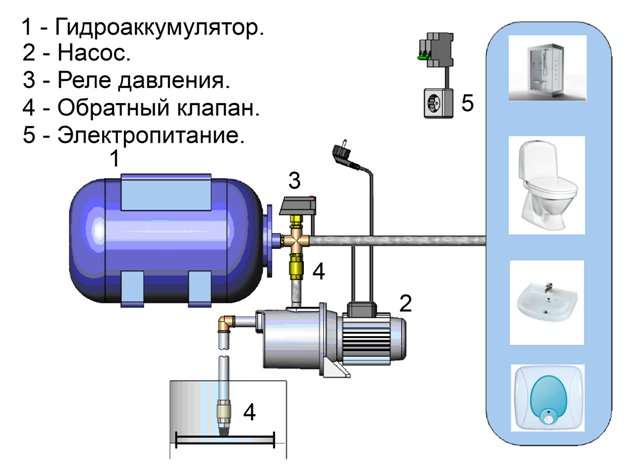

To the water supply system

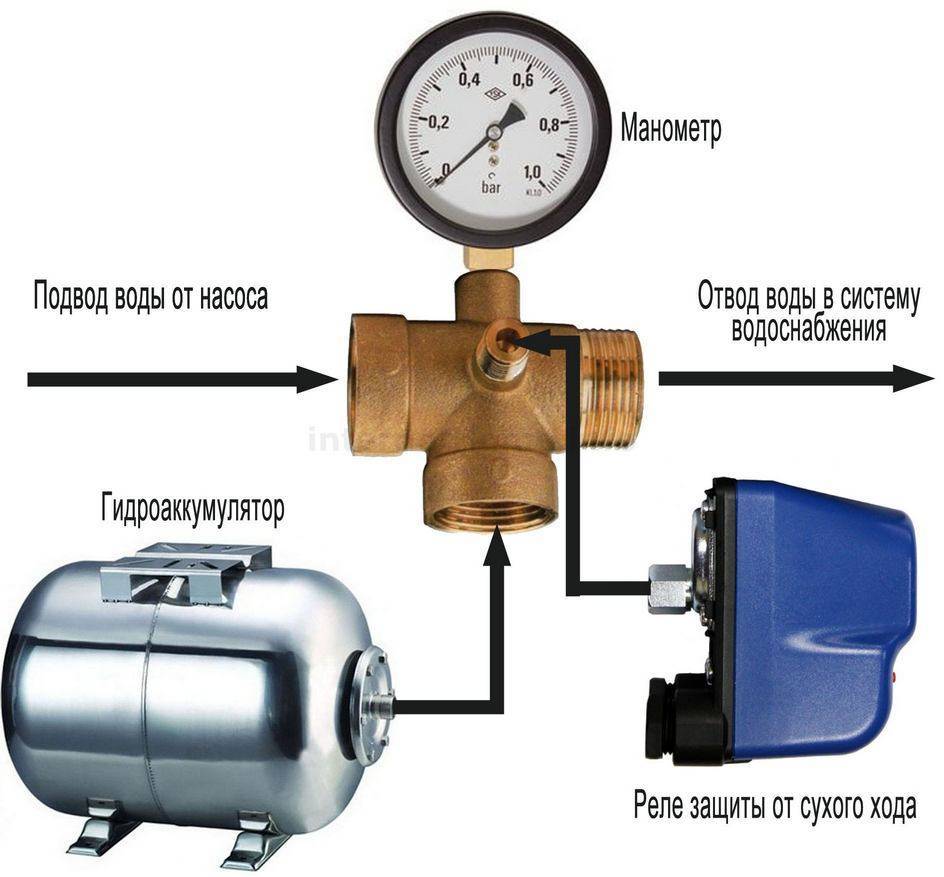

A typical pipeline mount transmitter requires a stub with five leads:

- water inlet and outlet;

- outlet to the expansion tank;

- under the pressure switch, as a rule, with an external thread;

- pressure gauge outlet.

A cord from the pump is connected to the sensor to control the on or off.The power supply is provided by a cable that is laid to the shield.

How to choose for a cottage?

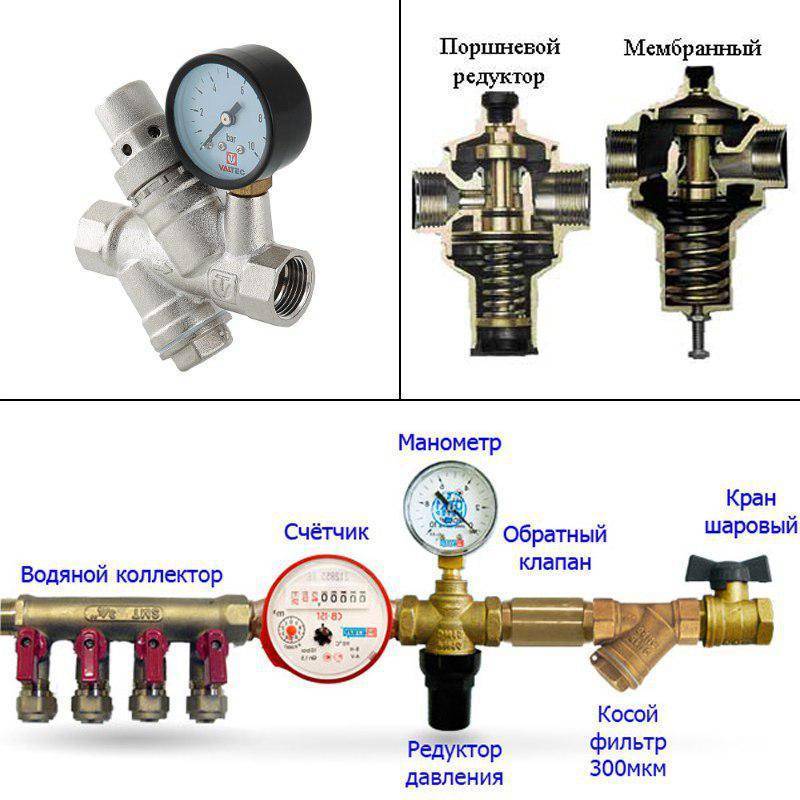

The choice depends on the technical parameters of the gearboxes: their throughput, reliability and price. Next, we give a comparative description of the advantages and disadvantages of devices that differ in the principle of operation.

Membrane

The maximum permeability of water through the device is up to 3 cubic meters per hour. The inner membrane supported by a spring, with an increase in the pressure at the inlet, bends.

The maximum permeability of water through the device is up to 3 cubic meters per hour. The inner membrane supported by a spring, with an increase in the pressure at the inlet, bends.

The displacement is transferred to the valve, which closes the inlet. There is a regulation of the pressure of running water by changing the bore diameter of the hole.

The gearbox is reliable and unpretentious in operation. For more precise adjustment and visual monitoring of the pressure, it is equipped with a pressure gauge. The disadvantages of the device include high cost, lower performance compared to analogues.

The membrane device of the reducer is placed in a hermetic chamber, is not subject to clogging and can be operated without preliminary water purification by a filter.

Piston

It has a great ability to pass water - up to 5 cubic meters per hour. The most simple in terms of design, refers to the budget options for devices. Stabilization of pressure in the water system occurs due to the movement of the piston.

When the water pressure increases, it acts on the spring. Moving, the piston closes part of the passage, and, accordingly, the watercourse. The outlet pressure returns to normal.

With a relatively low cost, the model has a serious drawback. The presence of solid fractions in the water system quickly disables the device, more often repair or replacement is required.

The piston gearbox is mounted in tandem with a coarse filter. This significantly extends the time of its work.

Details of the piston pressure regulator in the video:

labyrinthine

One of the simplest gearboxes in design and use. There is no internal moving mechanical part.

One of the simplest gearboxes in design and use. There is no internal moving mechanical part.

Hydraulic shocks (pressure surges) arising in the watercourse are extinguished due to the passage of water through systemically located small channels (mazes).

This type of regulator is mounted directly in front of the inlet of plumbing equipment.

The primitive design of the device does not guarantee complete safety in the operation of water equipment, which limits its use.

The best models of gearboxes for the water supply system

Currently, a large selection of devices is presented on the market for pressure regulators, differing in technical characteristics, cost and the company producing them (manufacturer's brand).

The models of the following companies are the most popular among users.

Honeywell Corporation (USA)

The product line from the pressure reducer group includes several series of similar devices, such as: the D04FM and D06F, D06FN, D06FH series.

The D04FM series are home use regulators. The body is made of brass with a threaded connection for inclusion in the water supply network, with a diameter of 1/2″ and 3/4″. The models have a pipe for installing a pressure gauge. The device can work in water supply networks, pipelines with compressed air and nitrogen. Main technical characteristics:

- working environment temperature – up to 70 °С;

- maximum pressure 16 bar;

- pressure adjustment - from 1.5 to 6.0 bar;

- number of cleaning steps - 1.

This is an economical device.

Series D06F - devices for domestic use. The body is made of brass with a threaded connection, the design includes a mesh filter and a fiber-reinforced diaphragm. Models are available in 1/4″, 1/2″, 3/4″, 1″ and 2″ diameters.

Main technical characteristics:

- working environment temperature – up to 40 °C;

- maximum pressure 16 bar;

- pressure adjustment - from 1.5 to 6.0 bar;

- number of cleaning steps - 1.

The D06FH and D06FN series can be used in domestic, industrial and commercial networks, in water networks and in networks with other non-aggressive liquids, as well as with compressed air and nitrogen. Models of this series are equipped with a pressure adjustment knob, as well as a built-in filter. The devices are available in 1/4″, 1/2″, 3/4″, 1″ and 2″ diameters.

Main technical characteristics:

- working environment temperature – up to 70 °С;

- maximum pressure 25 bar;

- pressure adjustment - from 1.5 to 12.0 bar, for the D06FH series and 0.5 - 2.0 - for the D06FN series;

- number of cleaning steps - 1.

Honeywell Corporation products are produced in different countries of the world and meet all the requirements for it. The Honeywell water pressure reducer is reliable and safe operation for the entire period of use.

Model RD-15

Produced by a number of manufacturers in Russia. This is a budget option for such products, which is widely used by users when installed in intra-apartment networks. The main technical characteristics of the model:

- diameter - 1/2 ";

- working pressure - 1.0 bar;

- pressure adjustment limit - 40.0%;

- maximum pressure - 4.0 bar.

Diaphragm model, body made of brass.Unpretentious in operation, one of the advantages is low cost.

FAR Rubinetterie S.p.A (Italy).

The line of products manufactured by the company includes a wide group of regulators for water supply systems made of brass and chrome steel. Models are available with internal and external threaded connection with a diameter of 1/4″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″ and 2″. Some models are equipped with a pressure gauge. Main technical characteristics:

- working environment temperature – up to 70 °С;

- maximum pressure 25 bar;

- pressure adjustment - from 1.0 to 6.0 bar.

FAR water pressure reducers are the best value for money.

Group of companies "VALTEC" (Italy-Russia).

Among the products of the "water pressure regulators" group, there are models of piston and membrane type, equipped with a pressure gauge and without it, as well as with a built-in filter.

Models are produced with various conditional passage and technical characteristics. VALTEC pressure regulators are widely used in Russia and the CIS countries due to their reliability and good performance.

How to choose a pressure reducing valve

Honeywell Water Regulator

When choosing a Honeywell water regulator (Honeywell), you should pay attention to the following parameters:

- water pressure regulator device;

- specifications;

-

device material.

The correct combination of all these factors will allow you to choose a device that will ensure the normal operation of engineering communications.

| Setting range (bar) | 1,5-6,0 |

| Static pressure PN | 16 |

| Production | Germany |

| Max. medium temperature | 70 |

| pressure reducer | Yes |

| Capacity m3 | 2.9 |

| Connection diameter (inch) | 3/4 |

Honeywell water regulators are considered very reliable, but the cost, respectively, starts from 1,500 rubles for the D04FM model.

Video:

Modern gearboxes are piston and diaphragm. The piston is highly resistant to wear. But, despite this, gearboxes of this type are characterized by low reliability in operation. This is due to the nature of water purification and the possibility of corrosion on the elements of the product. So, if small particles of dirt and sand may be present in the liquid, which will lead to jamming of the device. The only way out is a water pressure regulator with a filter.

Pressure regulator RD-15

The membrane water pressure regulator RD-15 has two working chambers, which are separated by a diaphragm. This makes the device unpretentious in maintenance and reliable in operation. One chamber is completely sealed to prevent water from entering it. It is here that the main part of the structural elements is located. This water pressure regulator circuit protects the device from corrosion and jamming. Proper use of the reducer and the integrity of the diaphragm ensures a long service life. And the cost is in the range from 300 to 500 rubles and has different versions. It is the most frequently used and has a certificate of conformity.

Pressure regulator RD-15

| Parameter name | Meaning |

|---|---|

| Nominal diameter DN | 15 |

| Nominal pressure (kgf/cm2) | 1,0 (10) |

| Regulation zone | 40 |

| Upper setting limit (kgf/cm2) | 0,4 (4) |

| Conditional throughput /h | 1,6 |

| Regulator weight | 0,35 |

Far water regulator

Choosing Far water regulator or another company, you should pay attention to its technical parameters. First of all, this concerns the value of inlet and outlet pressure.

Solving this problem is quite simple. You need to find out the requirements that apply to the device in a particular pipeline, as well as study the instructions for the water pressure regulator. It is in it that manufacturers indicate the nominal values \u200b\u200bof the working pressure.

Far water regulator

- Maximum inlet pressure: 16 bar.

- Adjustable pressure: 1 to 6 bar.

- Maximum temperature: 75°C.

- Set pressure: 3 bar.

The operating temperature is also important. So, some models are able to work in temperature conditions from 0 to 40 degrees. Such devices are used only in cold water supply systems. For a hot pipeline, models that operate in the range up to 130 degrees are suitable.

But the cost of a far water regulator already starts at 2,500 rubles.

Video:

Pressure regulator Valtec

Particularly popular are the Italian pressure reducing valves in the Valtec water supply, which are reliable and delight with their price (from 800 rubles). Perhaps this is the middle price segment for water pressure regulators for multi-storey buildings.

Valtec pressure reducer VT.087

Video:

Material

Such devices must be made of durable material. If we are talking about alloys, then they should contain ligatures that prevent the occurrence of a corrosion process.

Experts recommend paying attention to the best water pressure reducers from well-known manufacturers. Of course, such products will cost a lot, but a long service life is guaranteed.

There are also GOSTs for valves that lower water pressure.

Regulatory requirements for apartment pressure regulators

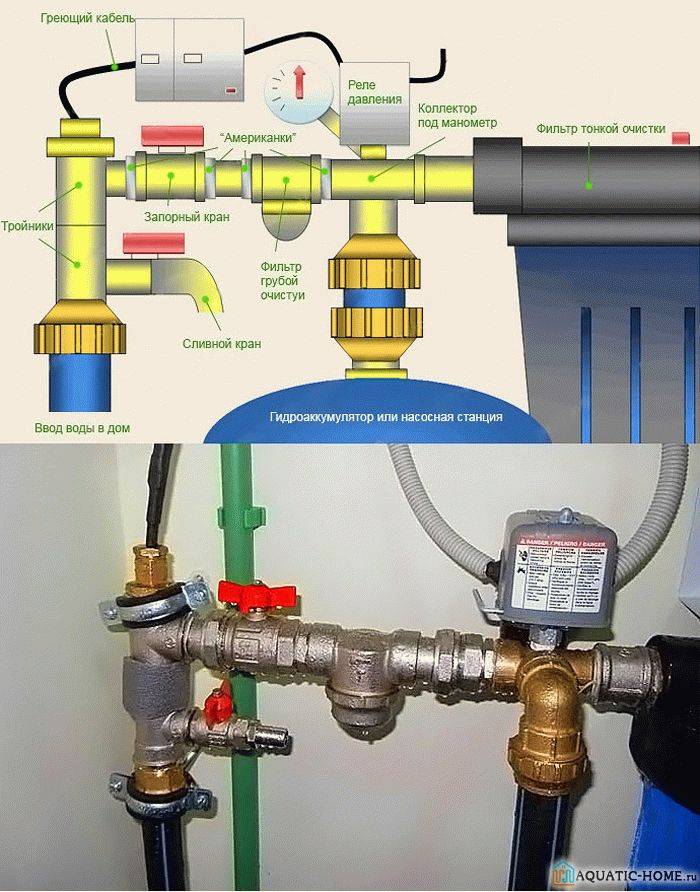

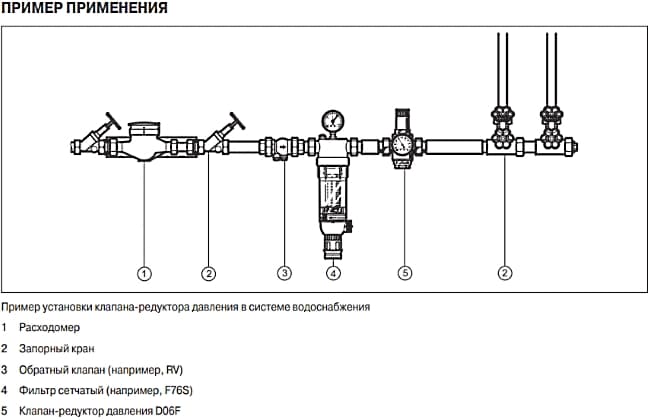

Installation

It is not recommended to install pressure regulators on your own, as it requires certain knowledge and skills. Consider the connection diagram of pressure reducers in the water supply system of the apartment.

Explanation:

- mechanical coarse filter;

- check valve;

- hot water and cold water meters;

- washing filter;

- Pressure reducer.

Installation of reducers is carried out in the main cold and hot water supply of the apartment. It is preferable to install pressure reducers on a horizontal section of the pipeline, but installation on a vertical one is also allowed. To ensure trouble-free operation of the gearbox, it is necessary to install a mechanical filter before it.

Usually the reducer is mounted behind the water meter. Behind the reducer, a pipeline of the same diameter with a length of 5xDn must be provided. To ensure the possibility of adjustment and maintenance of the gearbox, shut-off valves are installed behind it. If safety valves are provided in the system, the set outlet pressure of the reducer must be 20% lower than the opening pressure of the safety valves.

The set of rules for water supply and sewerage states that the installation of pressure regulators should be carried out immediately after the shut-off valves at the inlet, that is, before the metering devices.

This sounds sensible, because in this case the gearbox will protect all hydraulic devices, including the meter and the filtration unit.

But when installed up to the metering station, any possibility of water intake should be excluded, which means that the technical plugs for washing the filter and the stem will be sealed, and the gearbox itself will lose the possibility of maintenance.

This can be neglected, but even in this case it is very difficult to provide for different hydrodynamic resistance and achieve pressure equalization in the cold and hot water collectors. It is necessary either to install additional pressure gauges in them for more accurate adjustment, or to place pressure regulators immediately in front of the manifolds, as most experienced plumbers do.

Example of water distribution with a reducer

If it is not possible to install at the inlet of the system, but some components require protection against overpressure, local installation is also possible. There are quite a few primitive models of gearboxes for 20 mm pipe threads, and even without fine tuning, they do their job well with their protective function.

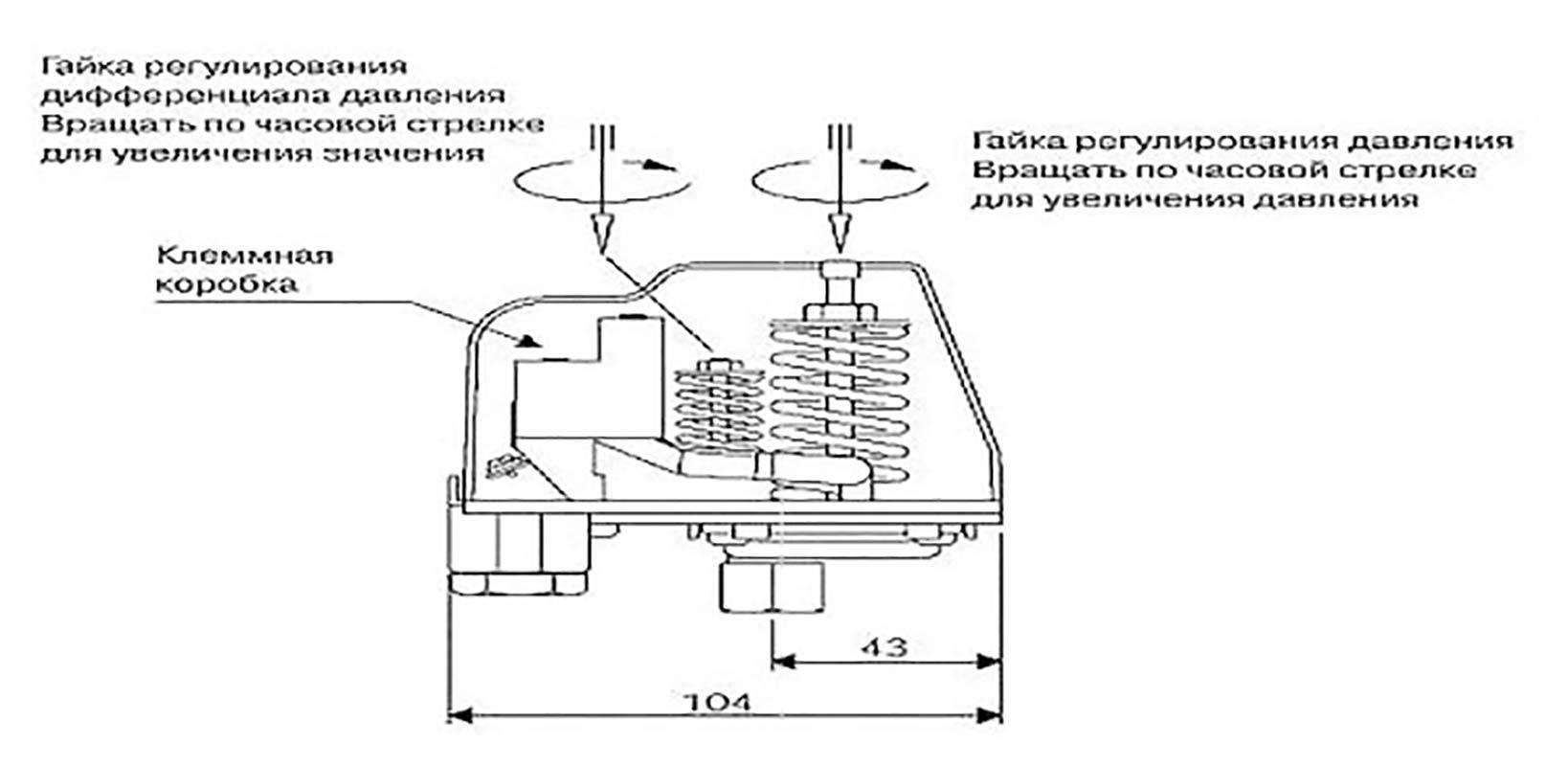

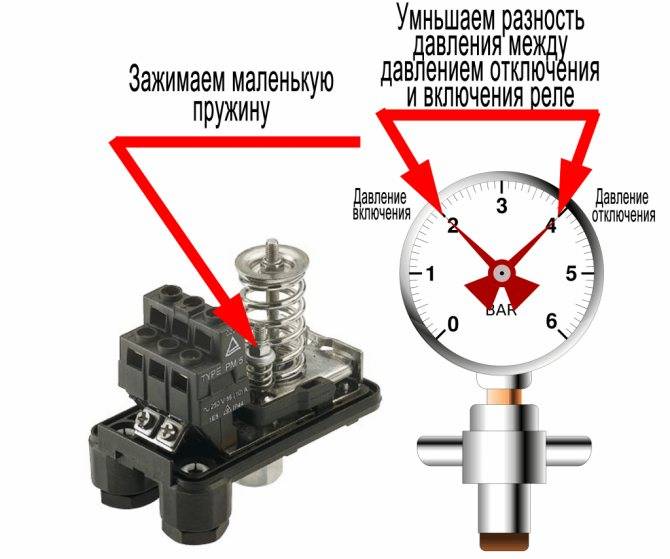

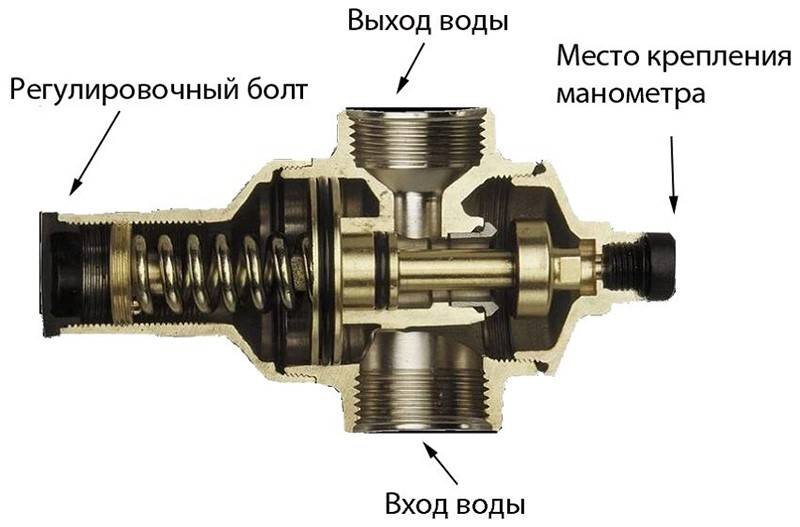

Device adjustment

Many owners are wondering how to adjust the water pressure regulator in the apartment. This task can be easily done by hand. Most devices come with a preset setting. According to this, the pressure in them is 3 bar. But, if necessary, you can reduce or increase this parameter yourself.

You may need a wrench or a wide screwdriver to make adjustments. The choice of tool depends on the gearbox model. Of course, in modern devices, configuration is done manually without using any additional tools.

First of all, you need to make sure that the water pressure reducer in the water supply is securely installed.After installation, the device opens the water supply. At this stage, you need to check the system for leaks. To prevent such problems, sealing material should be used when mounting the gearbox.

Adjustment of the water pressure reducer in the apartment is carried out with the taps closed. At the bottom of the device there is an adjusting head, which is responsible for adjusting the pressure of the liquid in the pipeline. If the pressure needs to be increased, the head rotates clockwise. Otherwise, the rotational movements are performed counterclockwise.

One full rotation of the head allows you to change the pressure by 0.5 bar. This will be noticeable by the movement of the arrow. Thus, the water pressure regulator in the apartment is adjusted. The work can be easily done by hand.

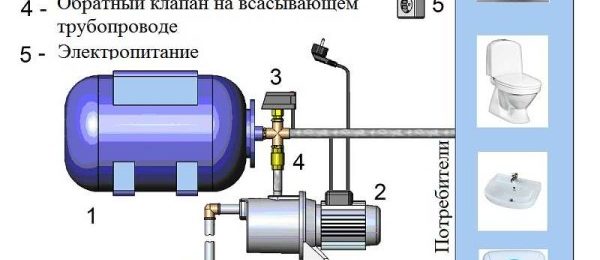

Do I need a gearbox before the boiler?

Water hammer, or water hammer, appears due to an instantaneous change in the movement of water inside the water supply. A common consequence of water hammer is ruptured high-pressure adapter hoses. Its manifestation is also characterized by the destruction of pipes weakened by rust and the failure of weak plugs.

When the boiler is running, a water hammer is likely to lead to a rupture of the tank.

A conventional boiler is designed for incoming water pressure up to 4 atmospheres - then its service life will be higher. When the pressure in the pipes is over 7-8 atmospheres, a safety check valve is turned on, which drains water from the boiler into the sewer.

One of the reasons for the constantly dripping boiler safety check valve can be excessive water pressure (more than 8 atmospheres) at the inlet.Increased pressure in the pipes can occur not only due to the failure of the temperature sensor, but also due to the fault of the water utility, because water can be supplied to the apartment with a pressure of more than 10 atmospheres.

Especially often this is observed in multi-storey buildings on the lower floors at night.

An analysis of boiler failure statistics showed that about 70% of all breakdowns were associated with a sharp pressure drop, water hammer and prolonged vibrations.

If the pressure reducer is not installed at the entrance to the apartment, it will be mandatory to install it in front of the boiler.

A pressure reducer connected at the inlet to the boiler will become a guarantor of protection against hydraulic shocks and a safety check valve leaking due to increased pressure.

For residential buildings, as a rule, direct-acting pressure regulators are used.

Direct Acting Flanged Valve Arrangement

They work on the principle of balancing the forces (Newton's third law) acting on the membrane: on the one hand, the spring tension force, and on the other hand, the pressure force after reduction.

In the event of a change in inlet pressure, the movable stem of the regulator will be in a new equilibrium position for a given pressure setting and the amount of water consumed (inlet pressure compensation).

Thus, even in the case of strong fluctuations in the inlet pressure, it is quickly extinguished, and the pressure at the outlet of the regulator is kept at a constant level.

In the event of a stop in the drawdown, the regulator closes completely. Inlet pressure compensation ensures that the opening and closing of the valve is independent of the instantaneous pressure at the inlet to the regulator. Thus fluctuations in inlet pressure do not affect the regulated outlet pressure.

Such regulators contain a "diaphragm-spring" system (1-2), which opens or closes the regulator depending on the pressure at the outlet from it. The other parts of the regulator are the fixed seat (3) and the moving diaphragm (4). The inlet pressure acts on chamber I, and the outlet pressure is applied to chamber II.

When water is withdrawn, the outlet pressure, and, consequently, the force developed by the membrane, drops, and an imbalance in the forces of the membrane and spring occurs, forcing the valve to open. After that, the pressure at the outlet (in chamber II) increases until the forces of the diaphragm and the spring are equal.

Flanged pressure regulators are usually installed on branch pipelines at the entrance to the building. They use a balancing piston (5) whose area is equal to the area of the valve diaphragm (4). The forces created by the initial pressure on the valve diaphragm and on the balancing piston are equal. However, they are directed in opposite directions to each other and therefore are balanced.

Threaded regulator device

A similar design is in threaded valves used for individual control and on the floors of buildings. The task of balancing the pressure in them is solved by fixing the valve membrane (4) and mobilizing the valve seat in the control sleeve (6). In this case, the inlet pressure is equally applied to the upper and lower annular surfaces of the sleeve.

The factory setting of the valves is usually 2.5-3 bar. The pressure value is set by the consumer by turning the adjusting knob or screw.

Conclusions and useful video on the topic

Video #1 Overview of sensor models that monitor pressure in the water supply system:

Video #2A detailed video clip about an electronic relay for controlling water pressure:

Video #3 Information in video format about the features of adjusting a domestic water pressure sensor:

Video #4 On the features of servicing a pressure sensor that has worked for 2 years. Initially, the task was to change the previous pump response range:

Having familiarized yourself with the specifics of the operation and adjustment of water pressure sensors in private water supply systems, you can configure the device yourself.

If there are doubts about your own abilities, then it is better to call a specialist who has a good reputation.

It is important that the sensor works correctly, then there will be no problems with the entire water supply system of the cottage / country house

We invite you to comment on the information provided by us for review. Please write comments in the block below, ask questions, share your personal experience and knowledge.